Methyltin composite heat stabilizer and preparation method thereof

A compound heat stabilizer, methyl tin technology, applied in the field of methyl tin compound heat stabilizer for PVC resin and its preparation, can solve the problems of insufficient market competitiveness, imperfect lubrication system, environmental pollution, etc., and achieve excellent Initial and long-term thermal stability, good lubrication system, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

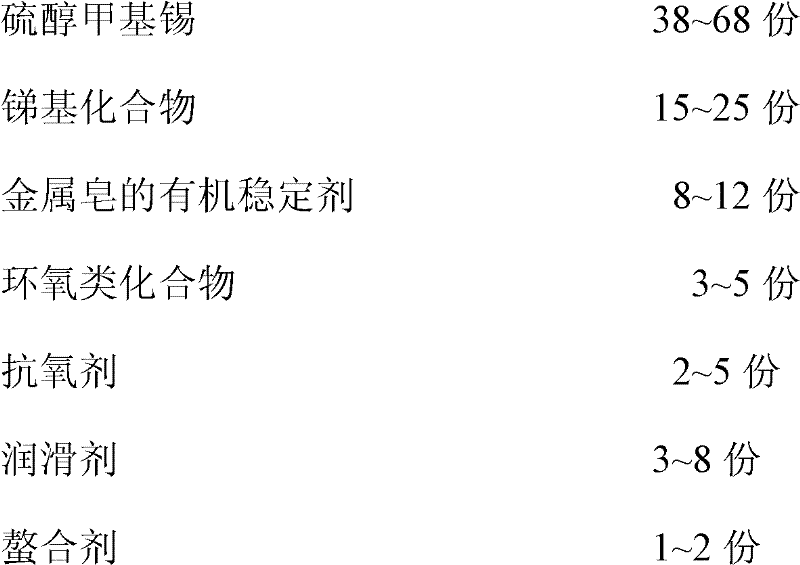

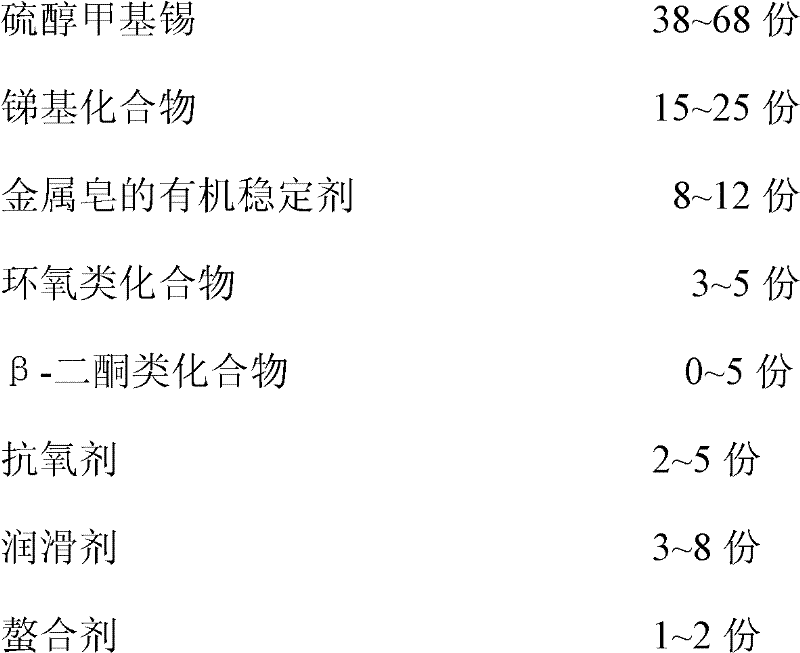

Embodiment 1

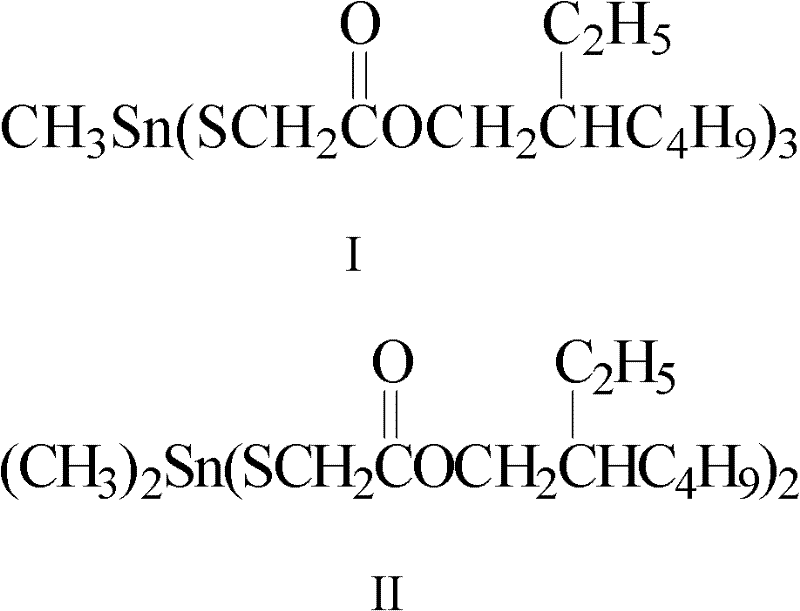

[0069] S, S', S''-tris(isooctyl thioglycolate)monomethyltin and S,S'-di(isooctyl mercaptoacetate)dimethyltin compositions with a mass ratio of 20:80 were respectively taken 68kg, isooctyl antimony trimercaptoacetate 15kg, calcium oleate, zinc isooctanoate mass ratio 3:1 mixture 8kg, epoxy soybean oil 3kg, triphenyl phosphite 2kg, pentaerythritol oleate 3kg and dimer aspart Mix 1kg of amino acid and put it into the reaction kettle, control the stirring speed at 80r / min, control the temperature at 65°C, mix and hold for 0.5h, then cool and filter to obtain 100kg of colorless and transparent liquid methyl tin composite heat stabilizer .

Embodiment 2

[0071] S, S', S''-tris(isooctyl thioglycolate)monomethyltin and S,S'-di(isooctyl mercaptoacetate)dimethyltin compositions with a mass ratio of 20:80 were respectively taken 62kg, isooctyl antimony pentamercaptoacetate 19kg, calcium isooctanoate, lanthanum isooctanoate mass ratio 2:1 mixture 9kg, epoxy linseed oil 3kg, stearyl benzoyl methane 1 kg, triphenyl phosphite 2kg, 3 kg of butyl stearate and 1 kg of catechol aminocarboxylic acid are mixed and put into a reactor, the stirring speed is controlled at 110 r / min, the temperature is controlled at 75 ° C, the mixing and holding time are 1.5 h, then cooled and filtered to obtain Color transparent liquid methyl tin compound heat stabilizer 100kg.

Embodiment 3

[0073] S, S', S''-tris(isooctyl thioglycolate)monomethyltin and S,S'-di(isooctyl mercaptoacetate)dimethyltin compositions with a mass ratio of 20:80 were respectively taken 56 kg, antimony oleate 19 kg, lanthanum isooctanoate 10 kg, epoxy castor oil 4 kg, dibenzoylmethane 2 kg, thiodipropionate 3 kg, trimethylolpropane oleate 4 kg and dimer Mix 2 kg of aspartic acid and put it into the reaction kettle, control the stirring speed at 120r / min, control the temperature at 85°C, mix and hold for 3 hours, then cool and filter to obtain a colorless and transparent liquid methyl tin composite heat stabilizer 100kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com