A kind of comprehensive recovery method of waste circuit board smelting soot

A technology of waste circuit boards and recycling methods, applied in the direction of improving process efficiency, etc., can solve problems such as ecological environmental pollution and waste of precious resources, and achieve the effects of improving purity, improving slag properties, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

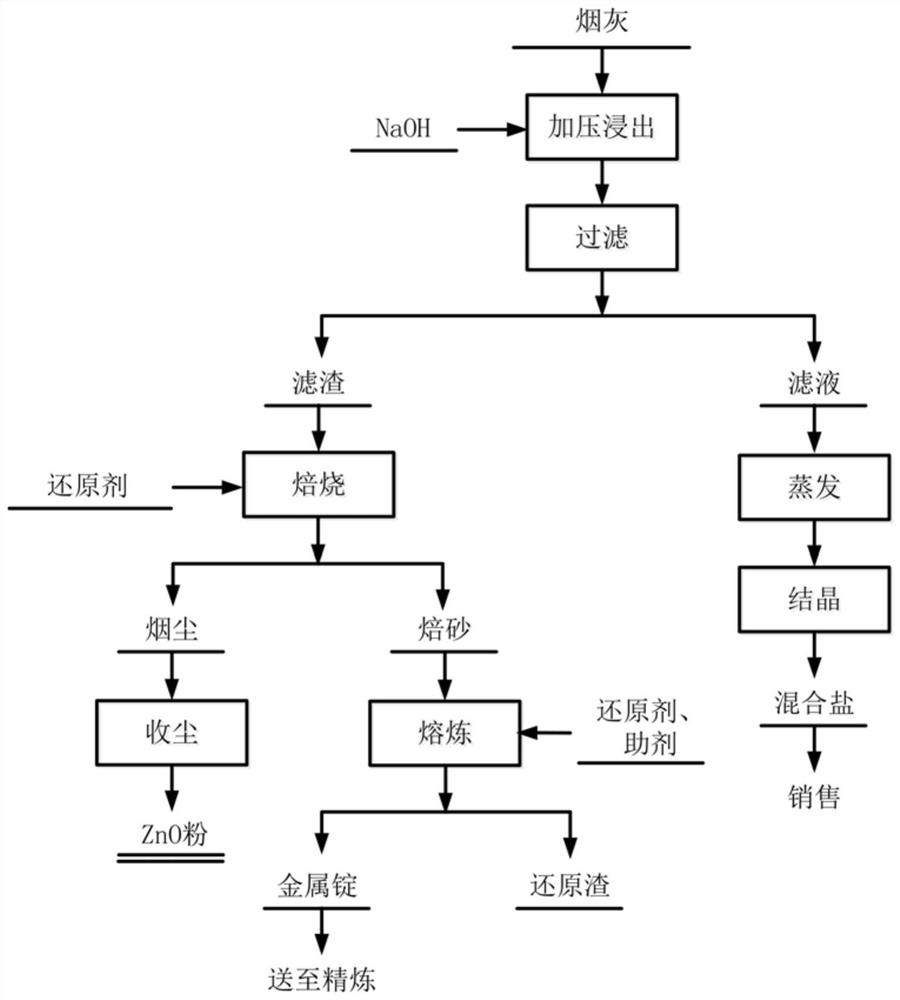

[0021] use figure 1 The method for comprehensively recovering waste circuit board smelting soot as shown includes the following steps:

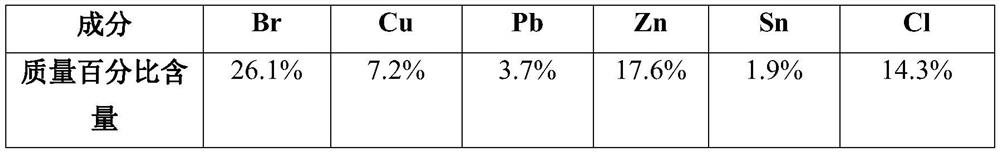

[0022] Take 500g of smelting soot, and its composition analysis is shown in Table 1.

[0023] Table 1

[0024]

[0025] Mix smelting soot with 100g of NaOH, then add water to adjust the liquid-solid ratio of the reaction system to 2:1, then add the reaction mixture into the autoclave, set the rotation speed at 300rpm, and react at 150°C for 2h. After the reaction, the slurry was filtered to obtain 254.9 g of filter residue and 933.4 mL of filtrate.

[0026] Take 200mL of filtrate, evaporate and crystallize at 100-105°C, and evaporate to dryness to obtain 51.3g of NaCl and NaBr mixed salt.

[0027] Take 100g of filter residue, add 5g of coke, and reduce and roast at 1100°C until no obvious smoke is produced. The produced smoke is collected to obtain 44.1g of crude zinc oxide, which is roasted to obtain calcined sand.

[0028] The calcin...

Embodiment 2

[0031] use figure 1 The method for comprehensively recovering waste circuit board smelting soot as shown includes the following steps:

[0032] Take 500g of smelting soot, and its composition analysis is shown in Table 1.

[0033] Mix smelting soot with 150g of NaOH, then add water to adjust the liquid-solid ratio of the reaction system to 3:1, then add the reaction mixture into the autoclave, set the rotation speed at 300rpm, and react at 180°C for 2h. After the reaction, the slurry was filtered to obtain 248.4 g of filter residue and 1443.2 mL of filtrate.

[0034] Take 200mL of filtrate, evaporate and crystallize at 115-120°C, and evaporate to dryness to obtain 36.6g of NaCl and NaBr mixed salt.

[0035] Take 100g of filter residue, add 8g of coke, and reduce and roast at 1200°C until no obvious smoke is produced. The produced smoke is collected to obtain 44.9g of crude zinc oxide, which is roasted to obtain calcined sand.

[0036] The calcined sand is then reduced and s...

Embodiment 3

[0039] use figure 1 The method for comprehensively recovering waste circuit board smelting soot as shown includes the following steps:

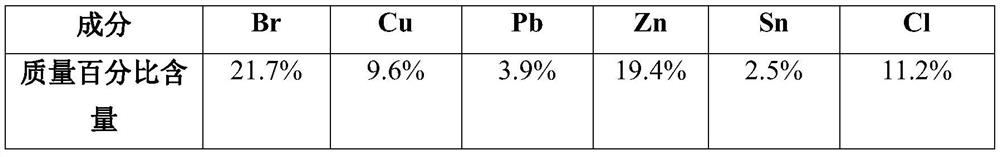

[0040] Take 500g of smelting soot, and its composition analysis is shown in Table 2.

[0041] Table 2

[0042]

[0043] Mix smelting soot with 120g of NaOH, then add water to adjust the liquid-solid ratio of the reaction system to 2.5:1, then add the reaction mixture into the autoclave, set the rotation speed at 300rpm, and react at 200°C for 2h. After the reaction, the slurry was filtered to obtain 278.3 g of filter residue and 1213.4 mL of filtrate.

[0044] Take 200mL of filtrate, evaporate and crystallize at 95-100°C, and evaporate to dryness to obtain 30.8g of NaCl and NaBr mixed salt.

[0045] Take 100g of filter residue, add 10g of coke, and reduce and roast at 1000°C until no obvious smoke is produced. The produced smoke is collected to obtain 47.0g of crude zinc oxide, which is roasted to obtain calcined sand.

[0046] The cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com