Recovery process of ITO waste target material

A target and process technology, applied in the field of recycling technology, can solve the problems of high cost and heavy pollution, and achieve the effects of low cost, reduced energy consumption, and low requirements for electrolytic current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

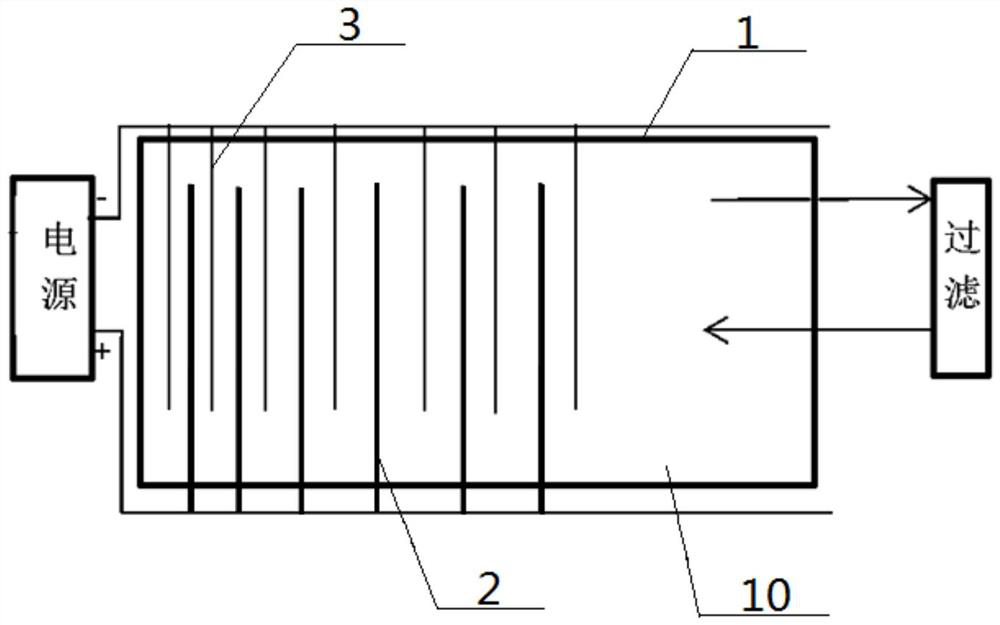

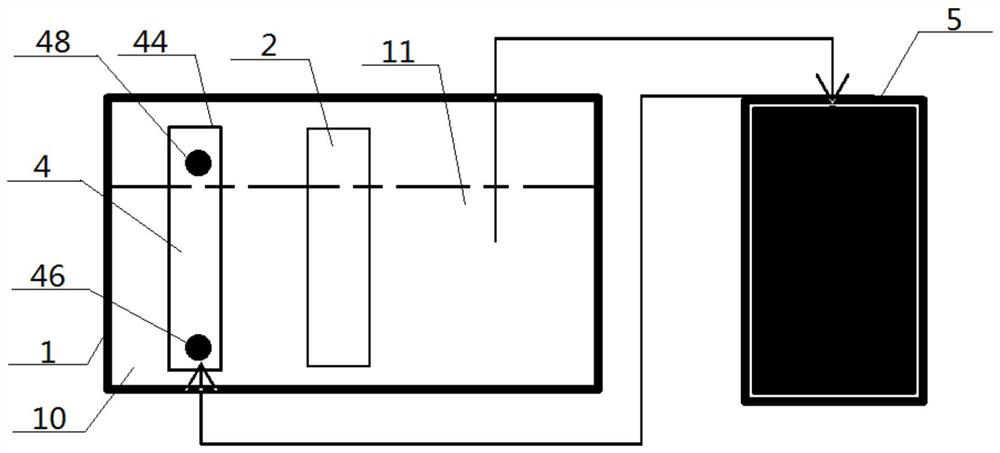

[0056] see figure 1 — Figure 8 , a recovery process for ITO waste target material, the recovery process comprises the following steps:

[0057] Liquid-making step: prepare an electrolyte solution 10 in the electrolytic cell 1, the pH value of the electrolyte solution 10 is between 0.5-2; the solute in the electrolyte solution 10 is 0.01-5 mol / l of organic acid radicals and 0.01-5 mol of inorganic acid radicals / l, the solvent in the electrolytic solution 10 is ultrapure water;

[0058] Feeding steps: first put the waste ITO target into the anode basket 2, then put the cathode plate 3 and the anode basket 2 into the electrolyte 10, the inside of the anode basket 2 communicates with the electrolyte 10, and then put the anode basket 2 on The anode lug 22 on the cathode plate 3 is connected to the circuit;

[0059] Electrolysis step: start the circuit where the anode lug 22 and the cathode lug are located, start electrolysis, the electrolysis temperature is 10-50°C, the electr...

Embodiment 2

[0061] Basic content is the same as embodiment 1, the difference is:

[0062] The organic acid group is any one or any mixture of sulfonate, citrate, formate and sulfinate.

[0063] The inorganic acid group is any one of sulfate group and nitrate group or mixed arbitrarily.

Embodiment 3

[0065] Basic content is the same as embodiment 1, the difference is:

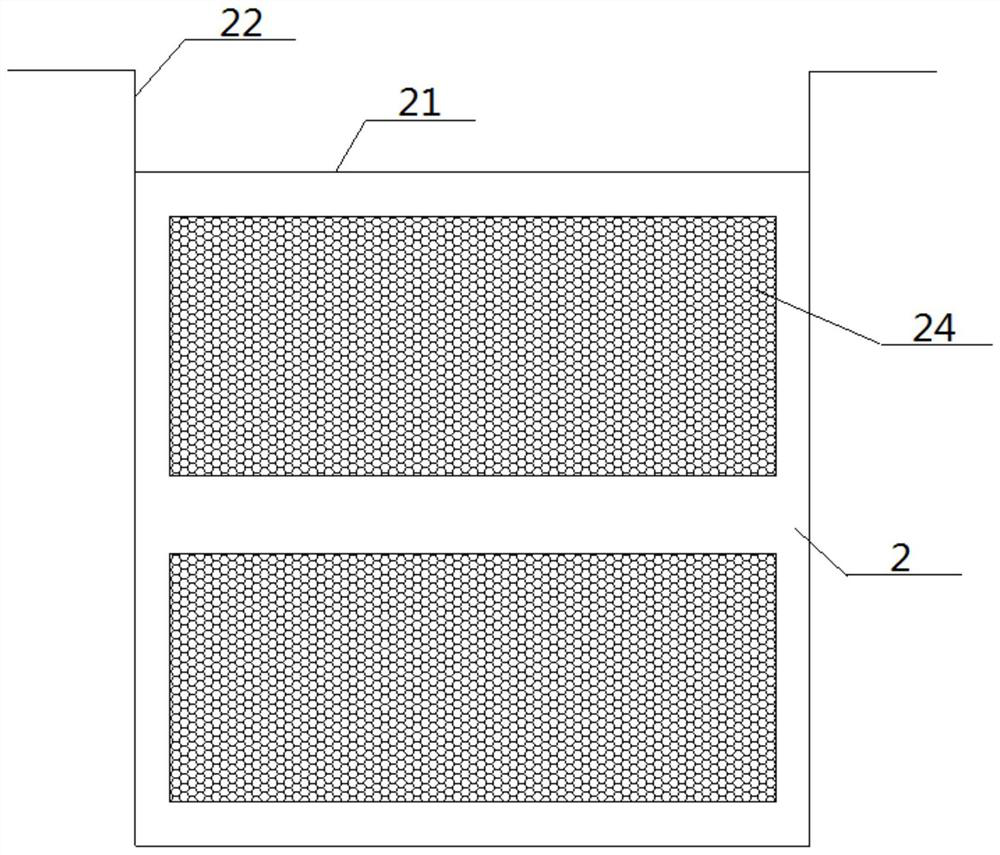

[0066] The top of the anode basket 2 is provided with an anode lug 22 at a position close to the anode basket opening 21, and the anode basket 2 is provided with an anode basket cavity 23 for setting waste ITO targets, and the side of the anode basket 2 is provided with A plurality of male through holes 24 communicate with the electrolyte solution 10 in the electrolytic cell 1 . Preferably, the anode basket 2 and the anode lug 22 are made of titanium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com