A method for harmless recovery of waste circuit board smelting soot

A technology of discarded circuit boards and recycling methods, applied in the direction of improving process efficiency, etc., can solve problems such as circuit board waste, achieve the effects of improving the properties of slag, reducing metal loss, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

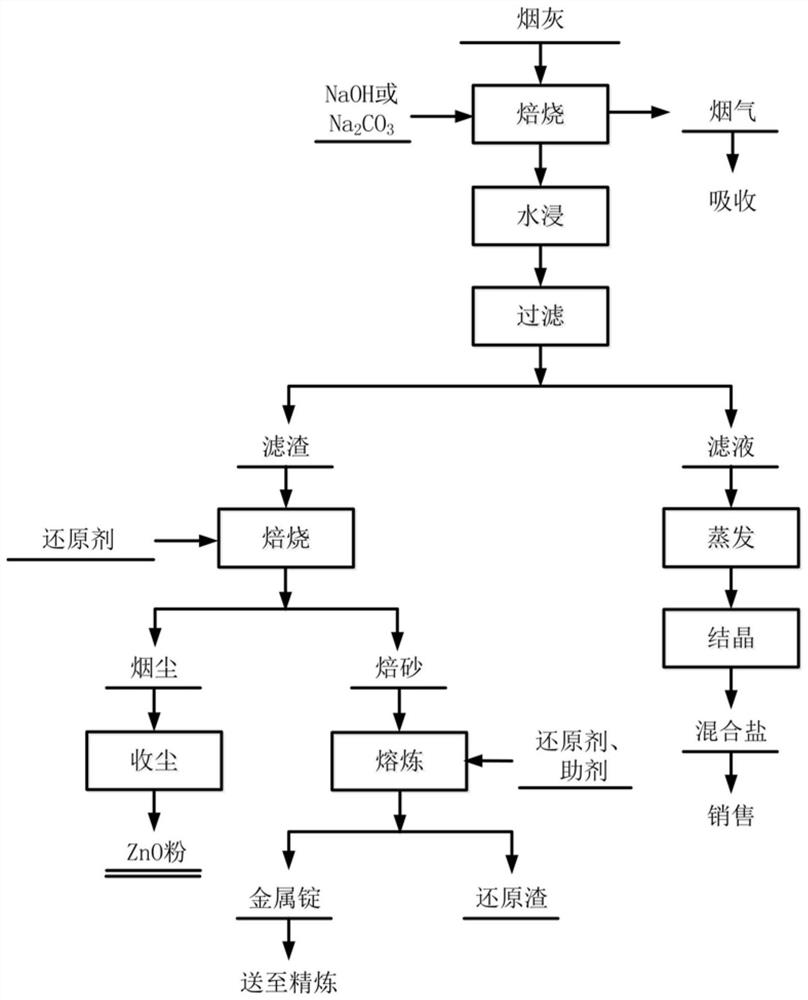

[0022] use figure 1 The shown harmless recovery method of waste circuit board smelting soot is to process the waste circuit board smelting soot, including the following steps:

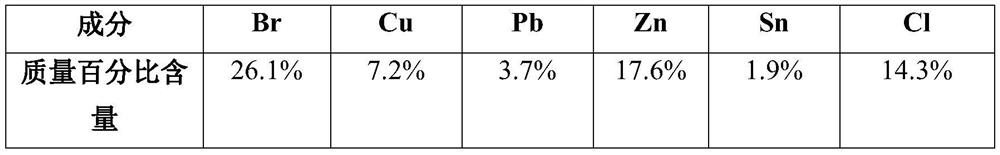

[0023] Take 500g of smelting soot, and its composition analysis is shown in Table 1.

[0024] Table 1

[0025]

[0026] The smelted soot is roasted with alkali, the alkali used is NaOH, 100g of NaOH is added to the soot, mixed evenly, and put into a corundum crucible. The crucible was placed in a muffle furnace and calcined at 500°C for 3 hours. After calcining, the material was taken out, totaling 467.3g.

[0027] Weigh 200g of roasted soot and add it to a stirring tank, add 600mL of water to the tank, adjust the rotation speed to 300rpm, react at room temperature for 2h, and filter to obtain 587.2mL of filtrate and 120.8g of filter residue after the reaction.

[0028] Take 200mL of the filtrate, evaporate and crystallize at an evaporation temperature of 95-100°C, and evaporate to dryness to obt...

Embodiment 2

[0033] use figure 1 The shown harmless recovery method of waste circuit board smelting soot is to process the waste circuit board smelting soot, including the following steps:

[0034] Take 500g of smelting soot, and its composition analysis is shown in Table 1.

[0035] The smelting soot is roasted with alkali, and the alkali used is Na 2 CO 3 , add 130g of Na to the soot 2 CO 3 , and put it into a corundum crucible after mixing evenly. The crucible was placed in a muffle furnace and calcined at 800°C for 2 hours. After calcining, the material was taken out, totaling 483.6g.

[0036] Weigh 200g of roasted soot, put it into the stirring tank, add 400mL of water into the tank, adjust the rotation speed to 300rpm, react at room temperature for 3h, filter after the reaction to obtain 387.4mL of filtrate and 127.2g of filter residue.

[0037] Take 200mL of filtrate, evaporate and crystallize at 105-110°C, and evaporate to dryness to obtain 33.8g of NaCl and NaBr mixed salt. ...

Embodiment 3

[0042] use figure 1 The shown harmless recovery method of waste circuit board smelting soot is to process the waste circuit board smelting soot, including the following steps:

[0043] Take 500g of smelting soot, and its composition analysis is shown in Table 1.

[0044] The smelting soot is roasted with alkali, the alkali used is NaOH, 120g of NaOH is added to the soot, mixed evenly, and put into a corundum crucible. The crucible was placed in a muffle furnace and calcined at 600°C for 4 hours. After calcining, the material was taken out, totaling 487.1g.

[0045] Weigh 200g of roasted soot and add it to a stirring tank, add 800mL of water to the tank, adjust the rotation speed to 300rpm, react at room temperature for 2h, and filter to obtain 784.2mL of filtrate and 109.8g of filter residue after the reaction.

[0046] Take 200mL of filtrate, evaporate and crystallize at 115-120°C, and evaporate to dryness to obtain 32.9g of NaCl and NaBr mixed salt.

[0047] Take 100g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com