High-tin-content copper-tin brazing filler metal grid-shaped composite strip and preparation method thereof

A composite strip and content technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to process and form, tin is easily extruded, and the amount of tin added is reduced. The effect of increased melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

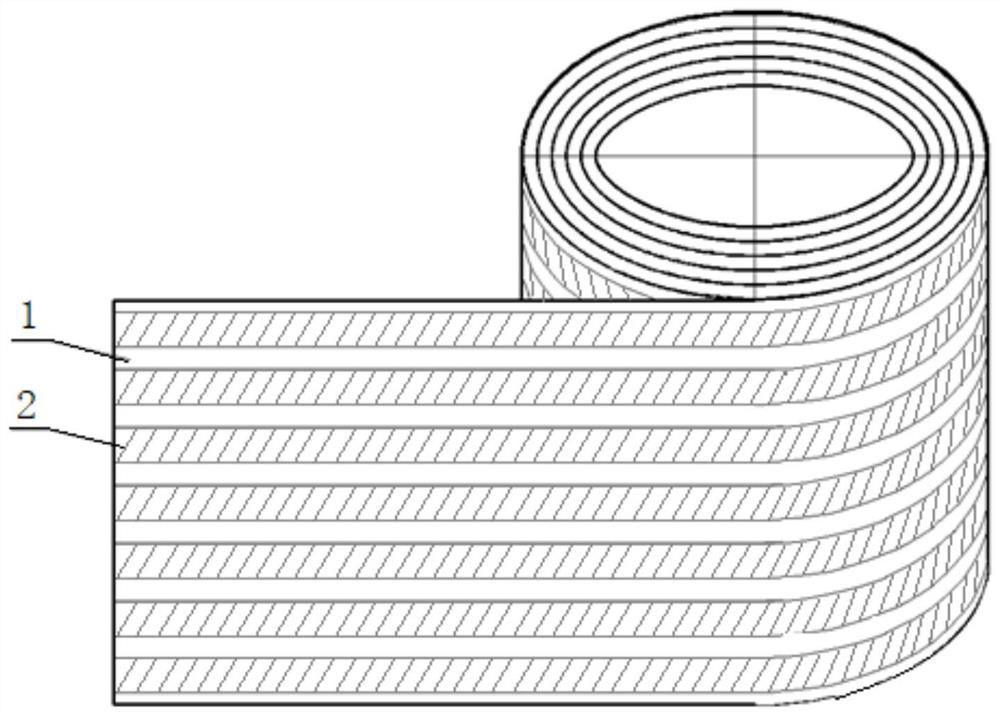

[0025] refer to figure 1 , a high tin content copper-tin solder grid-shaped composite strip, the tin content of which is 10-60wt%, comprising: a strip-shaped copper substrate, wherein one side of the strip-shaped copper substrate has a plurality of grooves arranged in parallel and at intervals, The groove is filled with tin to form a tin strip, and the tin strip is integrated with the copper around the groove; at least one end of the tin strip is flush with one end of the strip-shaped copper substrate; the groove is arranged along the long side of the strip-shaped copper substrate ; The number of grooves is at least two.

Embodiment 2

[0027] A method for preparing a grid-shaped composite strip of copper-tin solder with high tin content, comprising the steps of:

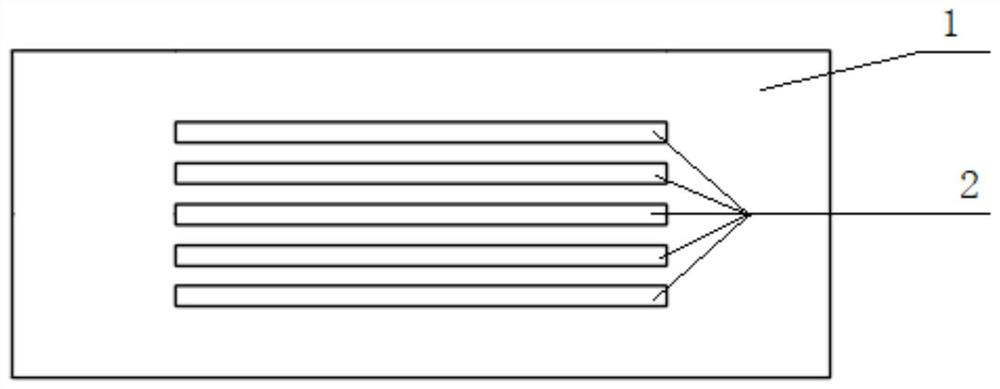

[0028] refer to figure 2 , take a piece of pure copper plate 80mm wide x 600mm long x 10mm thick, along the direction parallel to the long side of the pure copper plate, open 5 grooves arranged in parallel at intervals in the center of the pure copper plate, and keep any end of the groove in line with any end of the copper plate There is a certain distance at one end, the size of each groove is 5mm wide x 400mm long, 5mm deep, and the distance between two adjacent grooves is 5mm;

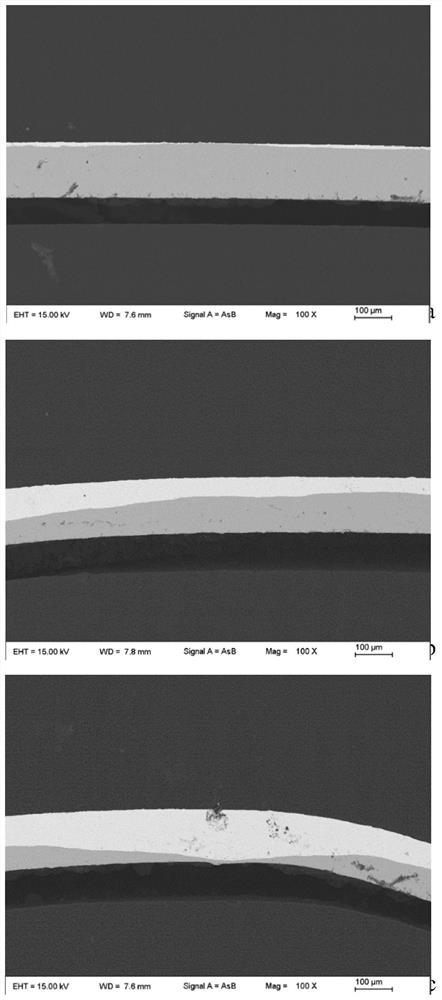

[0029] Place 5 strips of pure tin in the groove, then melt the tin strips by flame brazing method, cool and solidify, connect with the copper plate to form a whole, and completely fill the groove (this can prevent other impurities from entering the groove), Make the tin content 20wt%, then use two-high rolling mill and four-high rolling mill for rolling, then use edge ...

Embodiment 3

[0033] refer to figure 2 , take a piece of pure copper plate 80mm wide x 600mm long x 10mm thick, along the direction parallel to the long side of the pure copper plate, open 5 grooves arranged in parallel at intervals in the center of the pure copper plate, and keep any end of the groove in line with any end of the copper plate There is a certain distance at one end, the size of each groove is 5mm wide x 400mm long, 2.5mm deep, and the distance between two adjacent grooves is 5mm;

[0034] Place 5 strips of pure tin in the groove, then melt the tin strips by flame brazing, connect with the copper plate after cooling and solidification to form a whole, and completely fill the groove so that the tin content is 10wt%, and then use a two-roll mill Rolling with a four-roll mill, and then using an edge trimmer to remove the pure copper matrix at both sides and both ends and trim the strip to finally obtain a copper-tin brazing grid-shaped composite strip with a width of 50mm and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com