Circuit board of LED lamp, LED lamp board and processing technology of circuit board

A production process and circuit board technology, which is applied in the direction of printed circuits, circuits, printed circuits, etc., where non-printed electrical components are connected, can solve the problems of poor welding performance, poor weldability, and long durability, and achieve good welding effect. High soldering temperature and high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

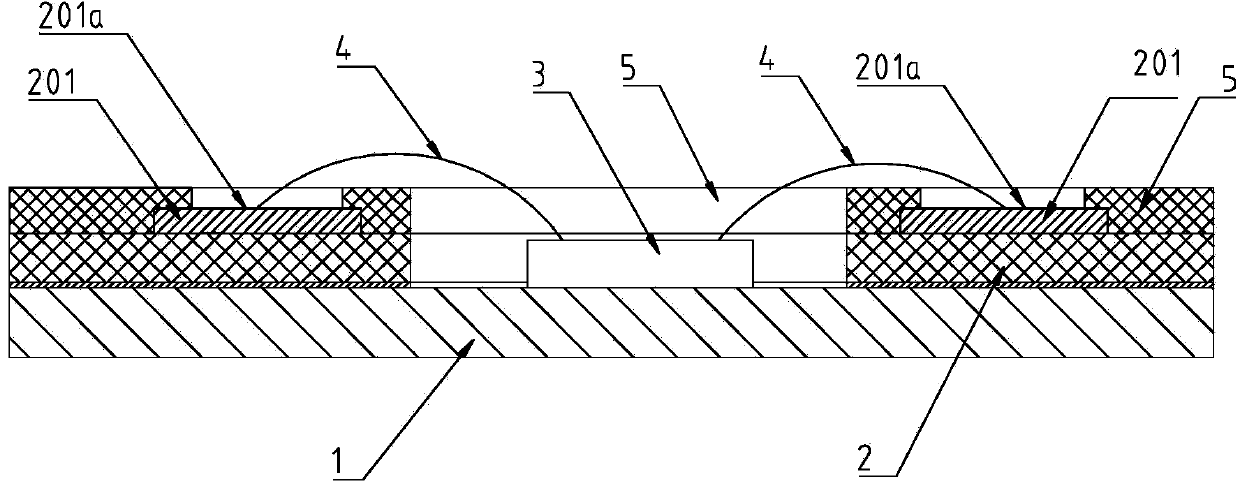

[0074] Conductive lines are formed on the surface of the board. After sandblasting, a solder mask is applied, and holes for welding wafers are drilled. The steps are as follows:

[0075] 1) Select an aluminum-silicon alloy foil plate with a thickness of 0.1mm (aluminum 40μm / insulation layer 50μm / glue 10μm) and cut it to the required size;

[0076] 2) After the board surface is cleaned, directly print the conductive circuit pattern of acid-resistant ink, and bake in an oven at 70°C for 30 minutes;

[0077] 3) After etching and removing the film, the conductive lines required for the circuit design are formed;

[0078] 4) Make an on-off test, there is no open and short circuit phenomenon, which meets the circuit design requirements;

[0079] 5) On the surface of the aluminum-silicon alloy foil plate forming the conductive circuit, do a sandblasting treatment; the sandblasting parameters are:

[0080] Sand blasting machine: JYN1121 (Shenzhen Juyongneng Technology Co., Ltd.)

...

Embodiment 2

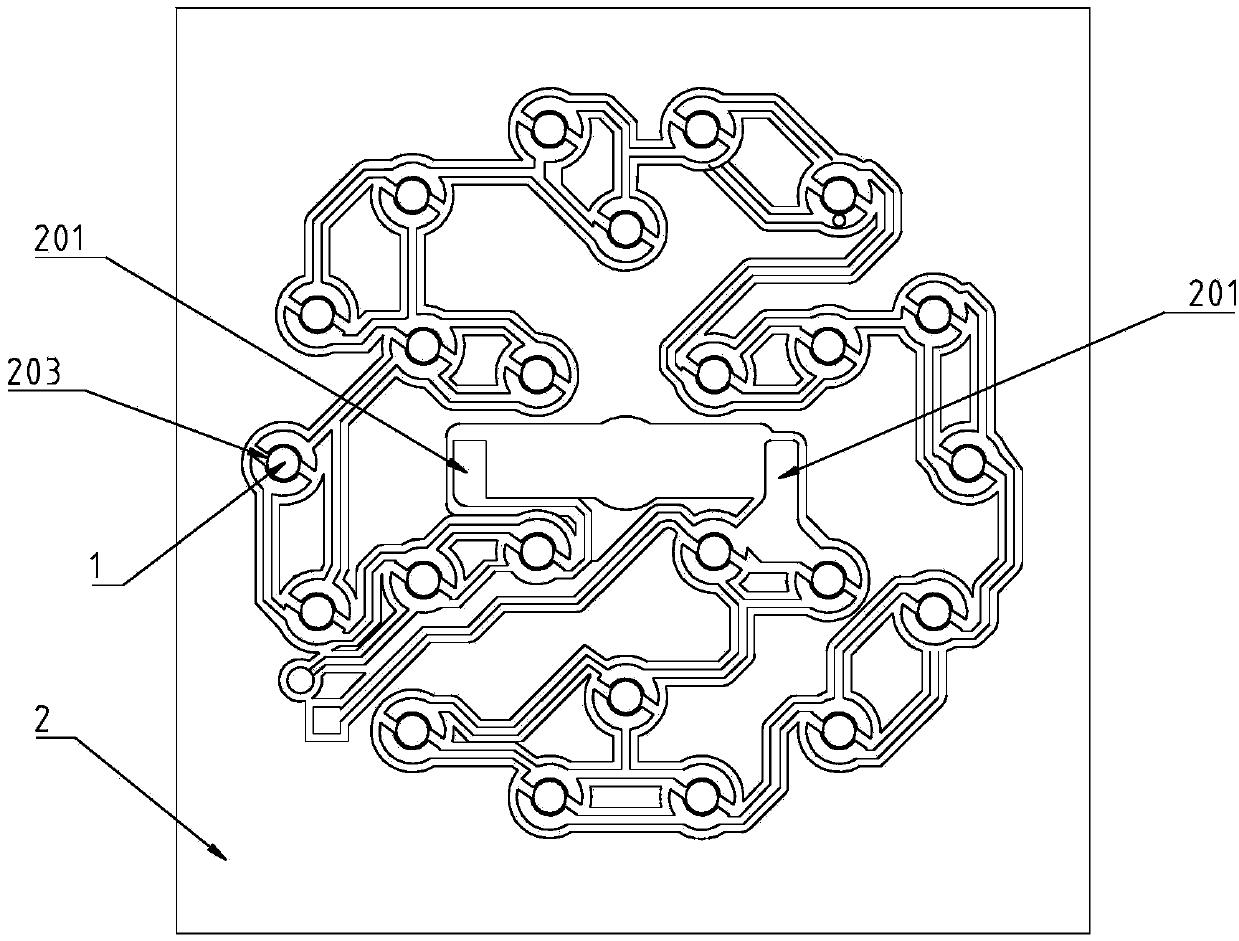

[0099] The production process of aluminum-silicon alloy foil board adopts the method of first transferring the conductive circuit pattern on the board surface image, then drilling the hole for welding the wafer, then etching, removing the film, and finally attaching the gold-plated pad, and the reflective white film, pressing and then drilling Screw holes and wire holes, the steps are as follows:

[0100] 1) Select an aluminum-silicon alloy foil plate with a thickness of 0.1mm (aluminum 40μm / insulation layer 50μm / glue 10μm) and a reflective white film with a thickness of 0.1mm, and cut it into the required size;

[0101] 2) After the board surface is cleaned, directly print the conductive circuit pattern of acid-resistant ink, and bake in an oven at 70°C for 30 minutes;

[0102] 3) According to the circuit design, drill holes at the position where the wafer needs to be welded; at the same time, drill the cut reflective white film according to the position of the soldered wafer...

Embodiment 3

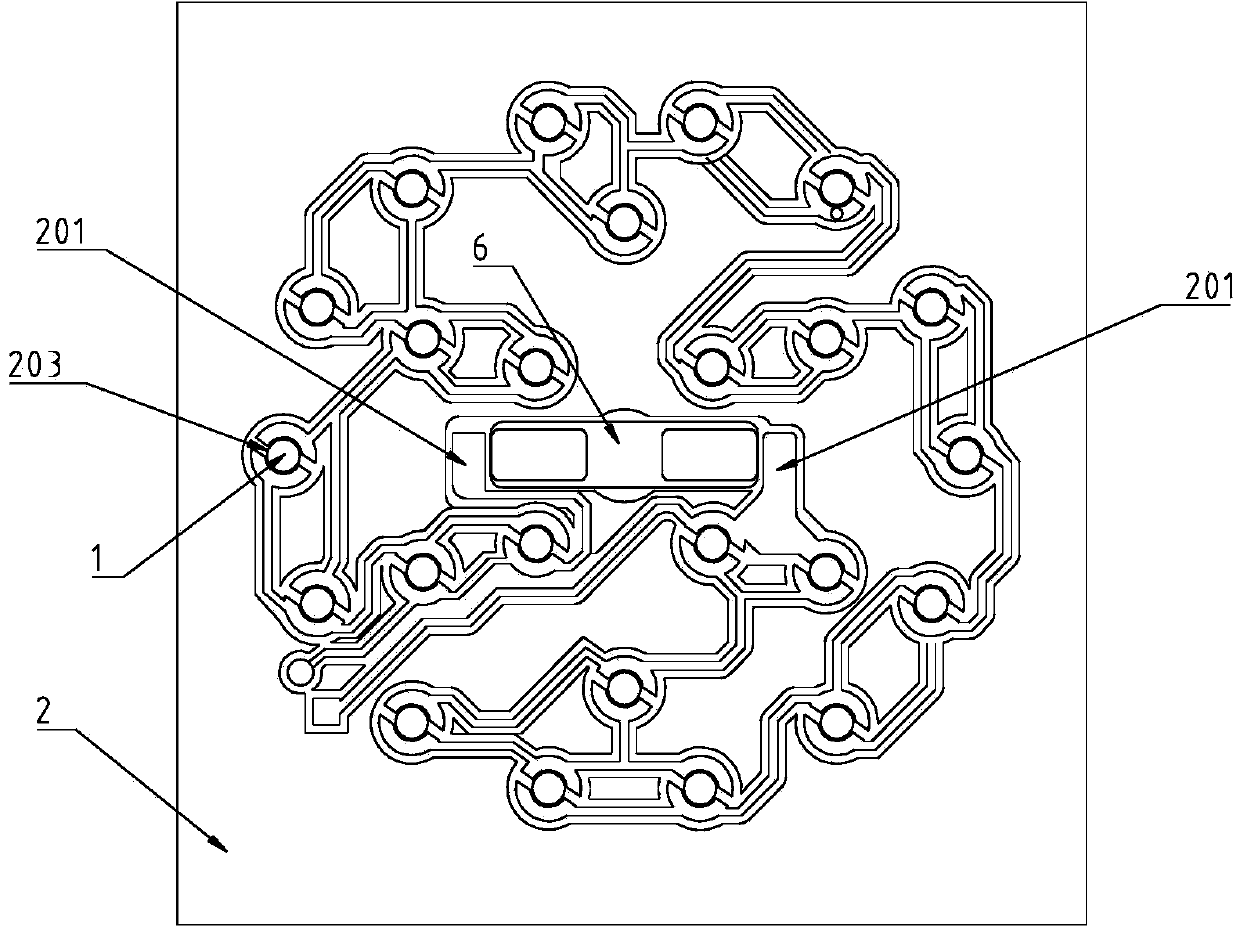

[0122] The production process of aluminum-silicon alloy foil board adopts the method of first transferring the conductive circuit pattern on the board surface, then drilling the holes for soldering wafers, then etching, removing the film, and finally pasting the copper pad, and the reflective white film, and then laminating it. Drill screw holes and cable holes, the steps are as follows:

[0123] 1) Select an aluminum-silicon alloy foil plate with a thickness of 0.1mm (aluminum 40μm / insulating layer 50μm / glue 10μm) and a reflective white film of 0.1mm, and cut it into the required size;

[0124] 2) After the board surface is cleaned, directly print the conductive circuit pattern of acid-resistant ink, and bake in an oven at 70°C for 30 minutes;

[0125] 3) According to the circuit design, drill holes at the position where the wafer needs to be welded; at the same time, drill the cut reflective white film according to the position of the soldered wafer and the positive and nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com