Lead-free solder

A lead-free solder and instrument technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of easy oxidation, decreased stretchability of lead-free solder, poor processability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

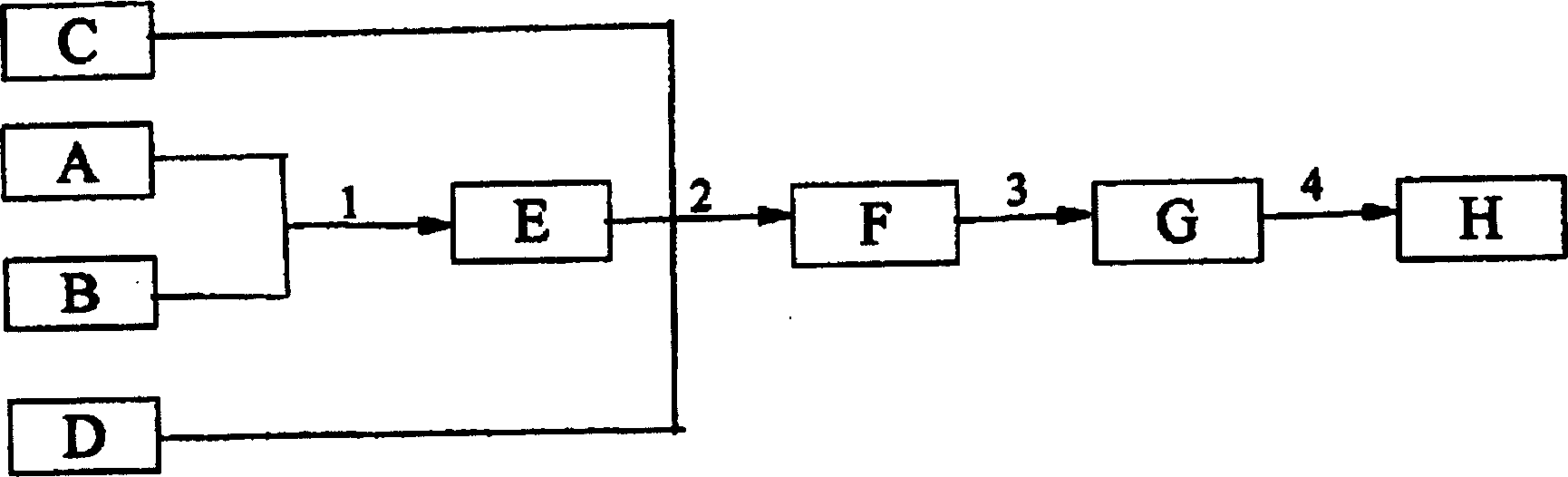

Method used

Image

Examples

Embodiment 1

[0033] Example 1: B is 2.5-3% Cu, C is 0.5-1.0% antimony, 0.8-1.2% In, and 1.8-2.0% Ag.

Embodiment 2

[0034] Example 2: B is 1.0-2.5% Cu, C is 0.2-0.8% antimony, 0.6-1.0% In, and 1.6-2.2% Ag.

Embodiment 3

[0035] Example 3: B is 0.5-1.0% Cu, C is 0.5-2.0% antimony, 1.0-2.0% In, 2-4% Ag.

[0036] Composition

[0037] Test items

[0038] All test data are in line with the standard data.

[0039] Test items

[0040] * The comparison product is an imported product, and it can be seen from the table that the indicators of the lead-free solder of the present invention are equivalent to the comparison product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com