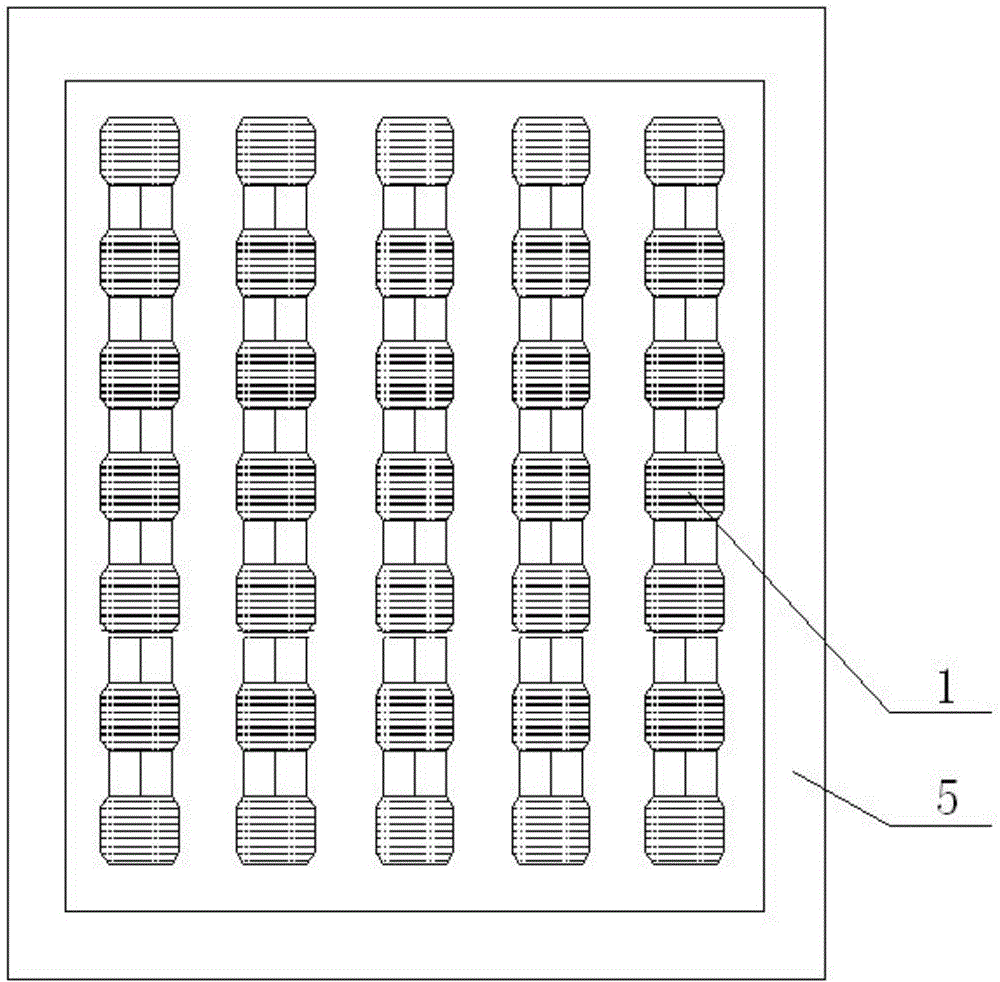

Solar cell module for sunlight room and preparation method thereof

A solar cell and sun room technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of high heat, easy water leakage, and poor sealing performance in the house, and achieve high conversion efficiency, high light transmittance, soft light and sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

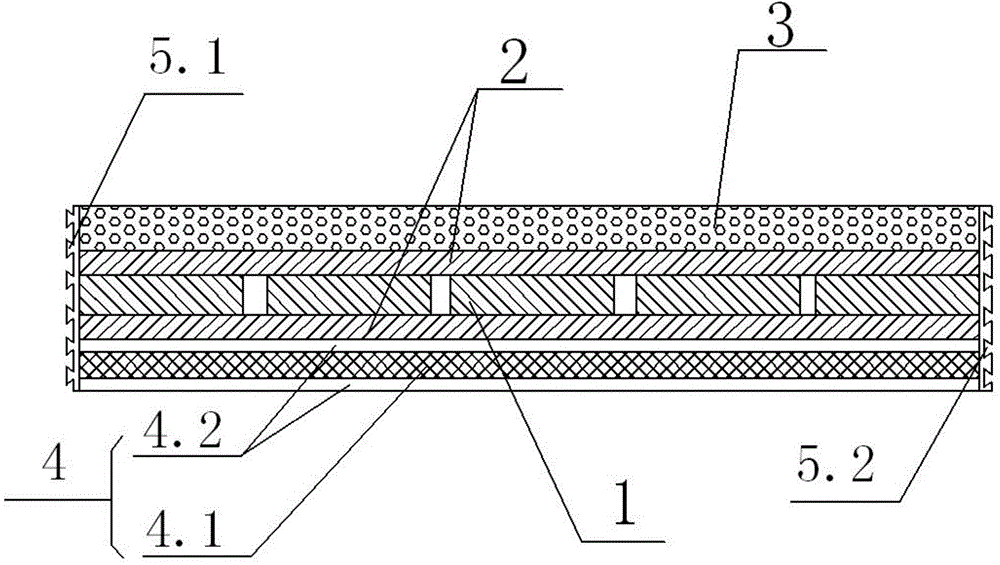

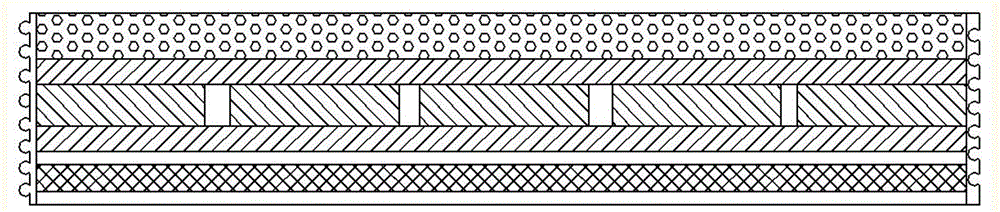

[0037] (1) Battery test: Check the current and voltage of the battery to be consistent with the manufacturer's calibration; to ensure that the conversion efficiency of the module is 24% and above, the peak power reaches 220W, the maximum working voltage reaches 30v, and the light transmittance reaches 40%. Size 650×998×40mm;

[0038] (2) Welding: Weld the bus strip on the front (negative) busbar of the cell. The busbar is a tinned copper strip, which is spot welded on the busbar in the form of multiple points; The length of the strip is 1.5-2.5 times the side length of the cell, and the excess bus strip is connected to the back electrode of the subsequent cell when the back is welded; the welding temperature is 310-330 °C for monocrystalline silicon wafers, and 230-230 °C for polycrystalline silicon wafers 340℃, welding time is 2-5s;

[0039] (3) Backside series connection: connect the cells in series, the operator uses electric soldering iron and solder wire to weld the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com