Patents

Literature

43 results about "Sodium arsenite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

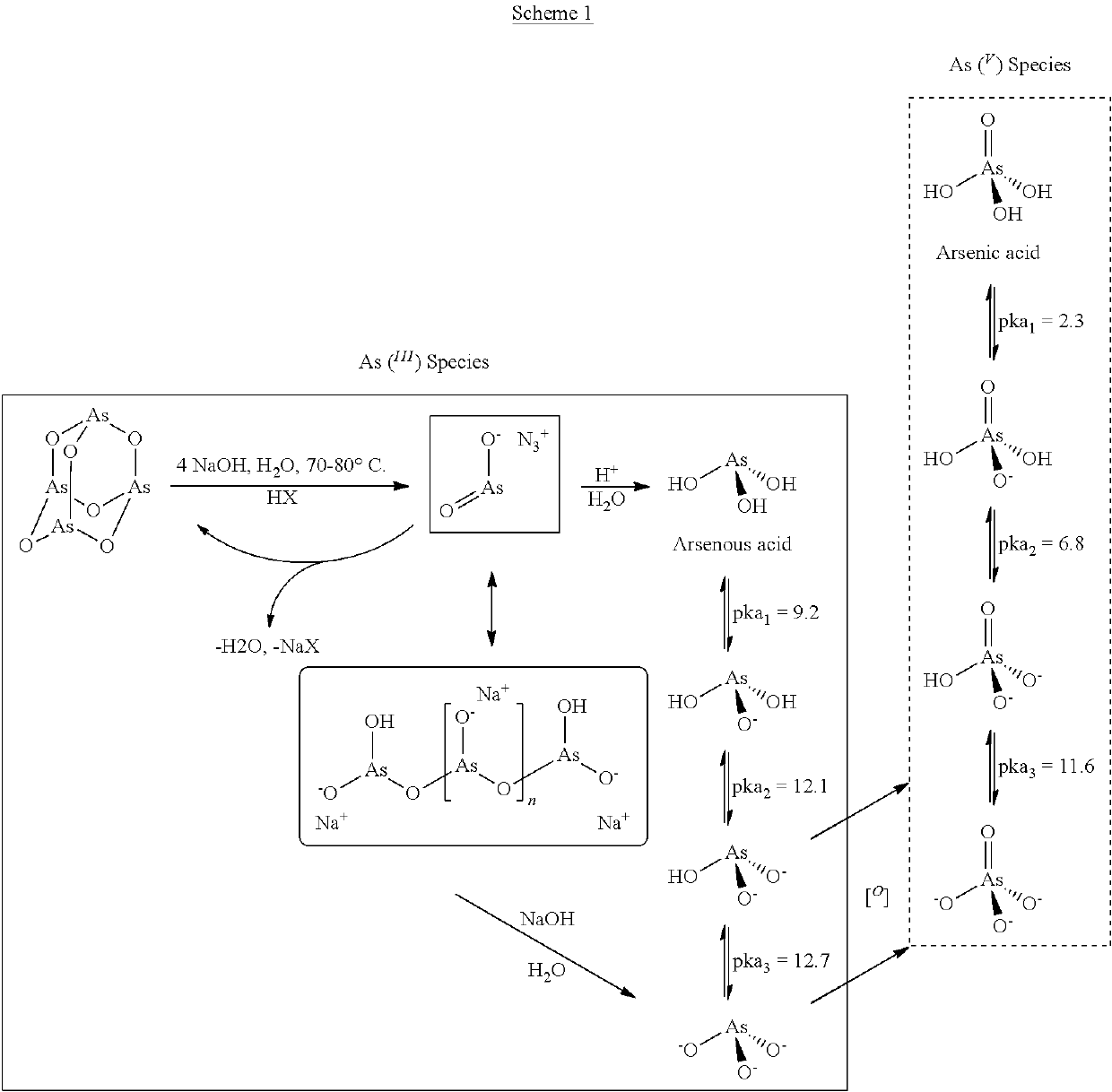

Sodium arsenite usually refers to the inorganic compound with the formula NaAsO₂. Also called sodium meta-arsenite, it is the sodium salt of arsenous acid. Sodium ortho-arsenite is Na₃AsO₃. The compounds are colourless solids.

Use of arsenic compounds for treatment of pain and inflammation

ActiveUS20080193560A1Reduce inflammationReducing chronicBiocideNervous disorderAutoimmune diseaseDisease

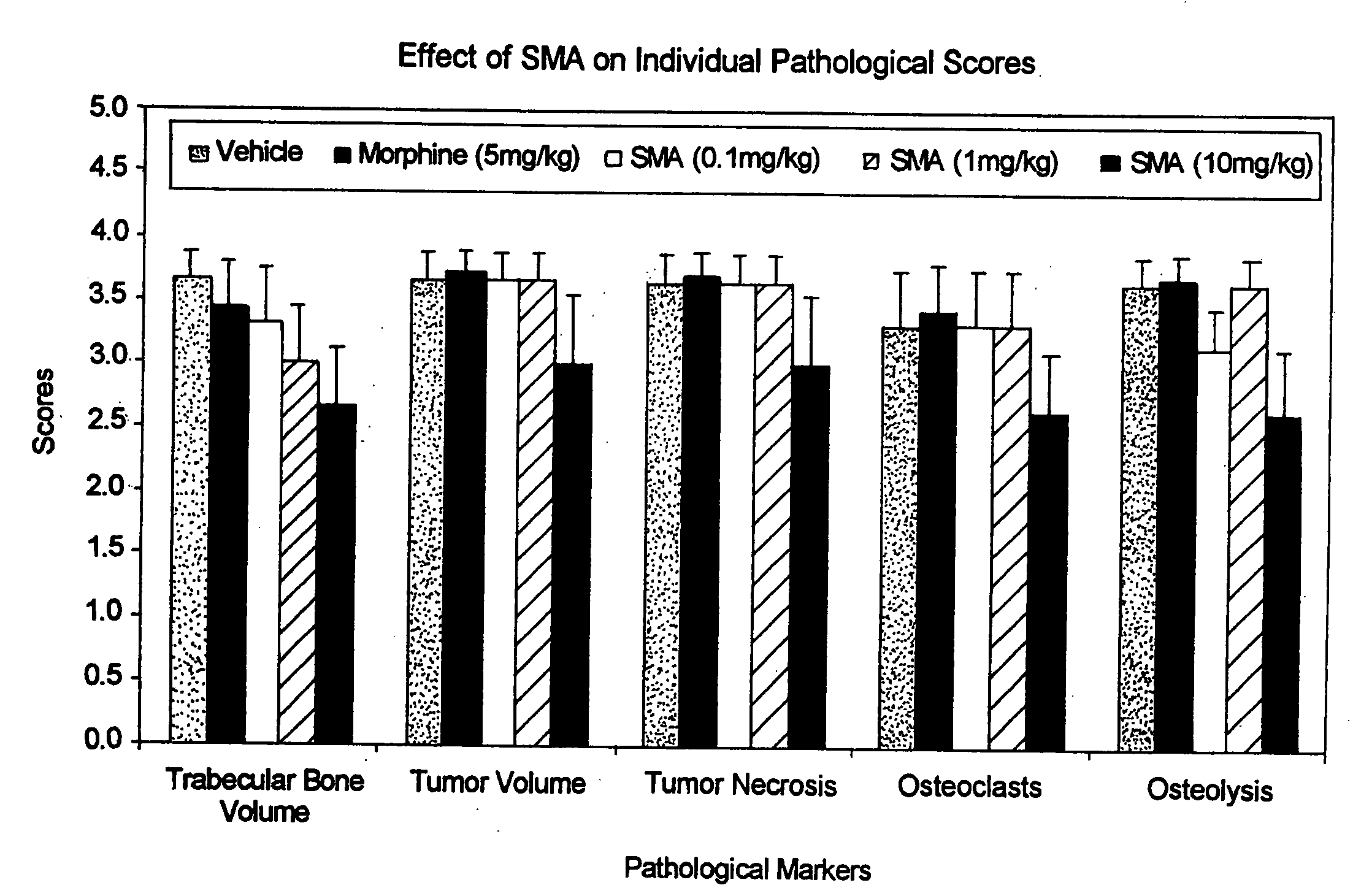

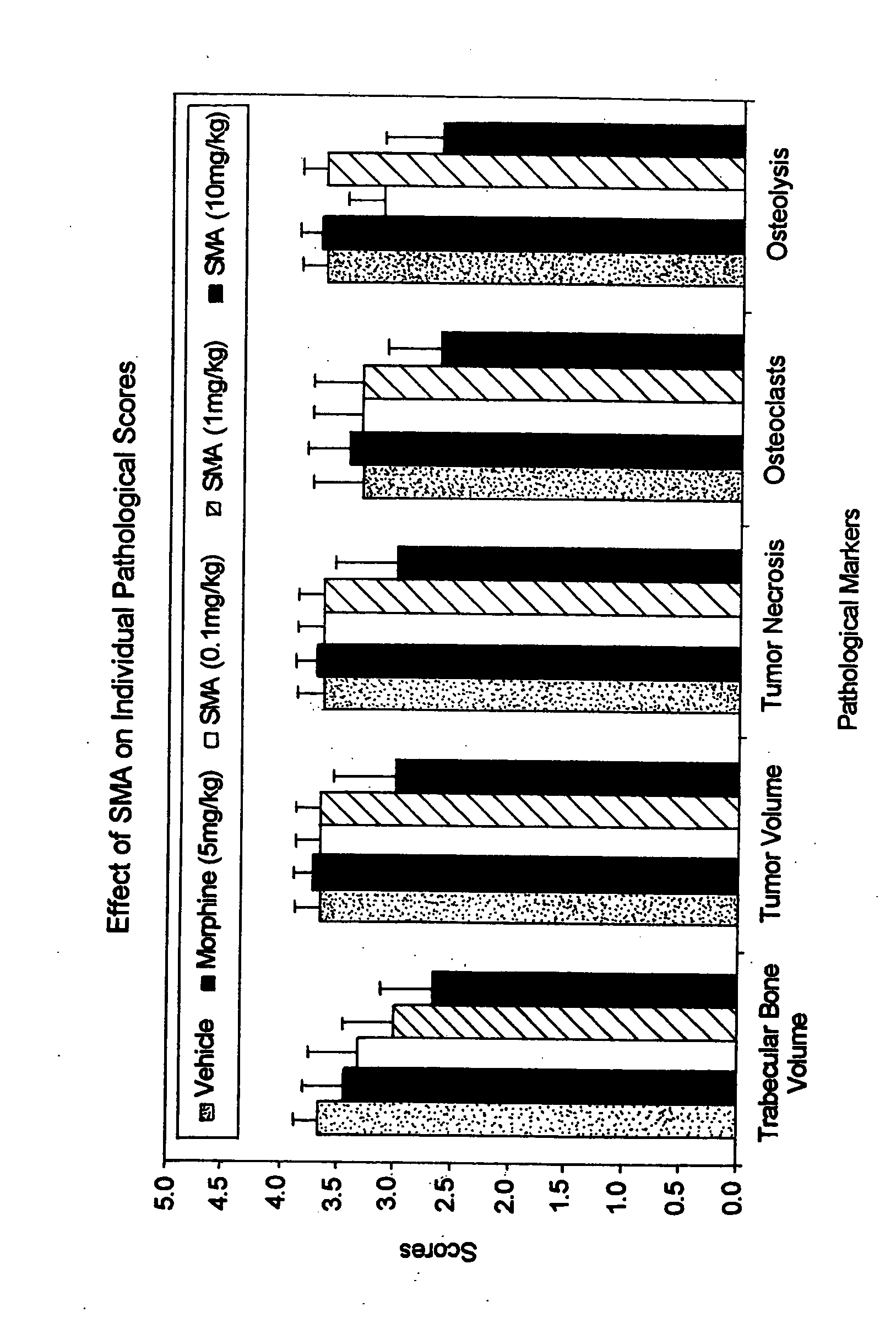

The present invention relates to the use of arsenic compounds such as sodium meta arsenite (NaAsO2), arsenic trioxide (As2O3), and arsenic hexoxide (As4O6) or combinations thereof, for the treatment of painful, hyperalgesic and / or inflammatory conditions. The present invention also relates to compositions containing the above arsenic compounds for use in the treatment of pain, inflammation and immunological and autoimmune diseases and disorders.

Owner:PANAPHIX INC

Treatment method of arsenic-containing waste

ActiveCN106180138AReduce leaching toxicityConvenient and harmless disposalSolid waste disposalWater contaminantsHigh concentrationSodium arsenite

The invention discloses a recycling treatment method of hazardous arsenic-containing waste. The recycling treatment method comprises the steps of carrying out alkaline leaching on a high-arsenic material to obtain a high-concentration sodium arsenite solution or a high-concentration sodium arsenate solution, and completely converting the high-concentration sodium arsenite solution or the high-concentration sodium arsenate solution into sodium arsenate through oxidation; adding a small amount of seed crystal-lepidocrocite (gamma-FeOOH) slurry into a reaction kettle; slowly adding an arsenic-containing solution; adding a slightly excessive high-concentration malysite solution; maintaining the reaction pH to be 3.5 to 5.5 through adding a neutralizer; and controlling the temperature in the reaction process to enable arsenic in the solution to completely react and totally deposit, wherein an obtained deposit is easy to filter, harmless and stable treatment of the arsenic-containing solution can be achieved, when the method is utilized to deposit arsenic, the concentration of arsenic in filtrate after reaction can directly reach the standard, and secondary arsenic deposition is avoided. The treatment method is simple in technological process, low in cost and applicable to industrial application.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

Serum-free culture medium and stem cell culture method

InactiveCN105087481AMaintain propertiesExtended GI periodSkeletal/connective tissue cellsFood additiveStem cell culture

The invention relates to a serum-free culture medium which comprises a basal culture medium, insulin, iron-containing food additive, sodium arsenite, fibronectin, glucagon, hepatocyte growth factor and myllicin. In addition, the invention further discloses a stem cell culture method. The stem cell culture method includes the following steps: acquiring stem cells; adopting the serum-free culture medium for in vitro culture. By the serum-free culture medium, the problem of difficulty in cell purifying due to pollution of pathogens carried by a serum culture medium can be avoided, stability of cell production can be improved, cell proliferation amount can be increased, and cell activity can be enhanced.

Owner:SHEN ZHEN ISTEM REGENERATIVE MEDICINE SCI TECH CO LTD

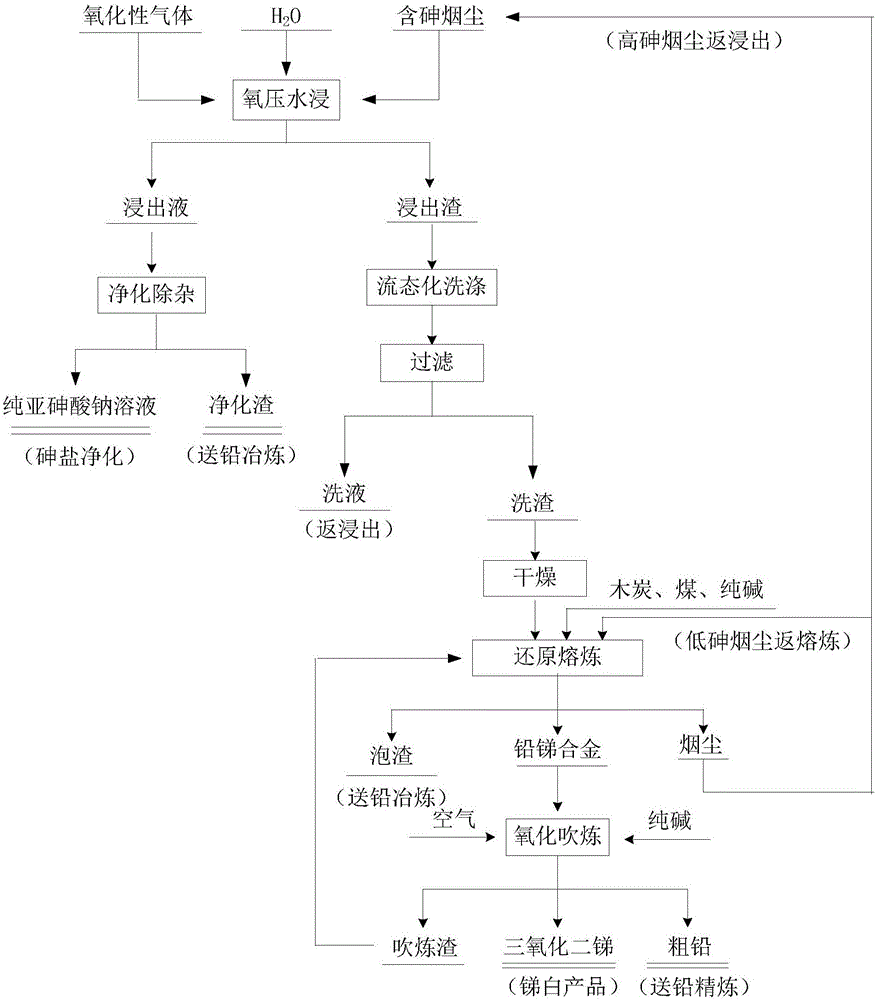

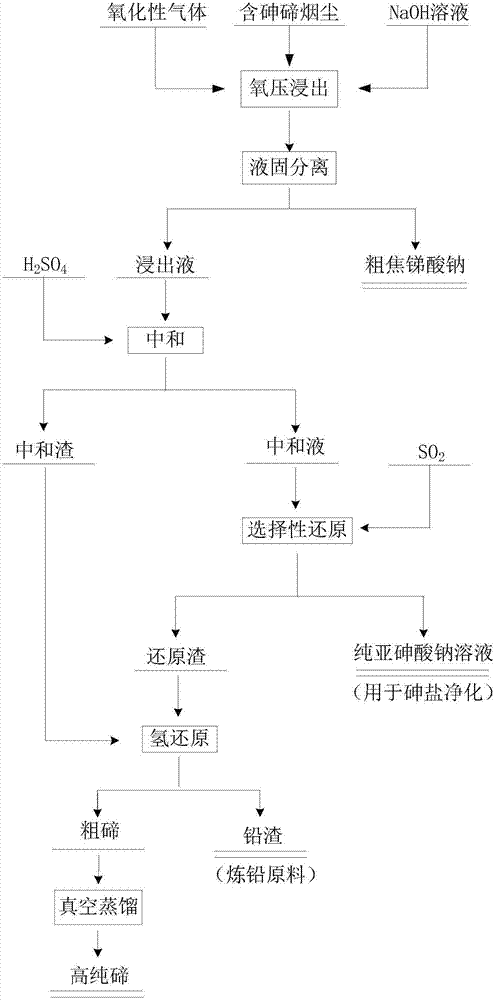

Method for arsenic containing material comprehensive recovering and arsenic resource utilization

ActiveCN106834707ASeparation and detoxificationImprove resource utilizationProcess efficiency improvementResource utilizationSodium arsenite

The invention belongs to the technical field of metallurgy, and particularly relates to a method for arsenic containing material comprehensive recovering and arsenic resource utilization. The method sequentially comprises the four steps including oxygen pressure water leaching, leaching liquid selective reduction purification, leaching slag washing and slag washing for valuable metal recovering. Through the processes that oxygen pressure water leaching, soluble arsenic in smoke is desorbed, leaching liquid is subject to selective reduction purification, purified liquid is a pure sodium arsenite solution, and the leaching slag is subject to washing, reduction smelting, oxidation blowing and the like, all valuable elements are recycled to the greatest extent. According to the method, the arsenic is desorbed from the smoke, the stable arsenic fixing ore is synthesized, stibium, lead, bismuth and the like are left in arsenic removal slag as many as possible, and separation and harmless treatment of the arsenic and the valuable metal are achieved. The method is high in resource comprehensive utilization rate and wide in raw material application scope, and the problem of pollution in the traditional handicraft extraction process is solved. The beneficial effects of the method are more obvious for the smoke generated in the lead and zinc smelting process particularly.

Owner:CENT SOUTH UNIV

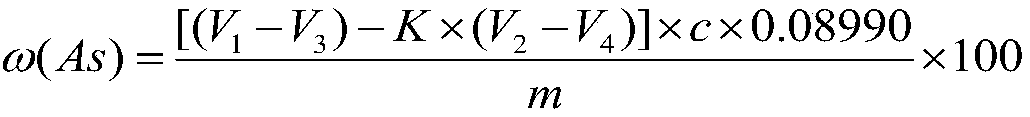

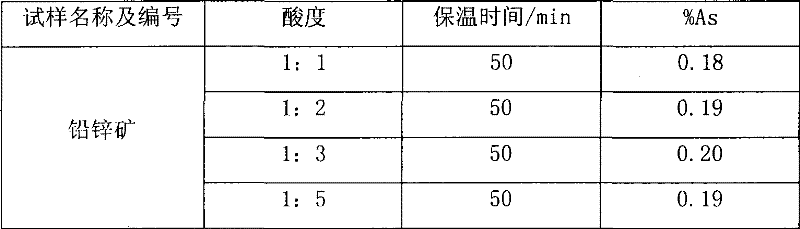

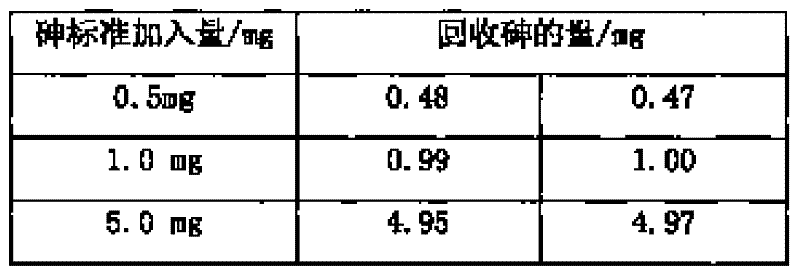

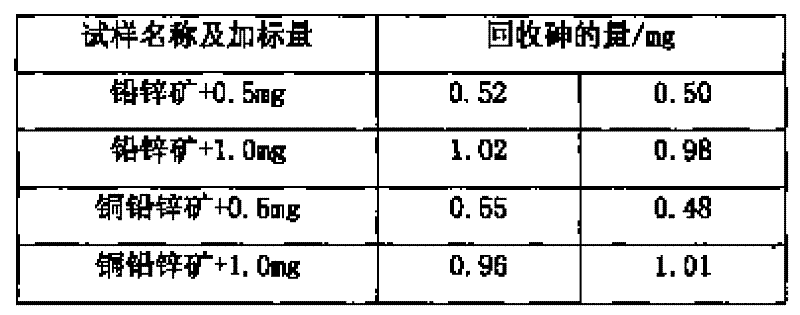

Method for analyzing arsenic in ore sample

InactiveCN101726487AReduce usageReduce reducing acidityMaterial analysis by observing effect on chemical indicatorSodium arseniteCopper sulfate

The invention relates to a method for analyzing arsenic in an ore sample, comprising the following steps of: adding nitric acid and potassium chlorate in a certain amount of sample; adding sulphuric acid heating, dissolving and evaporating until sulfur trioxide smother smokes for a few minutes, cooling and adding water and blowing and washing; heating and dissolving; adding copper sulfate and hydrochloric acid; then adding sodium hypophosphite until the yellow of Fe3<+> completely fades; excessively adding and boiling under the reducing acidity and keeping for a certain micro boiling time to enable the arsenic to settle and agglomerate; settling and filtering the arsenic; washing a beaker and the sedimentation by using a hydrochloric acid solution containing sodium hypophosphite; washing the beaker and the sedimentation by using an ammonium chloride solution until the pH value is 5; transferring a degreasing cotton wool to an original beaker; adding a buffer solution and a starch solution into the beaker; accurately adding an iodine standard liquid; and dropping a sodium thiosulfate standard liquid to blue until the blue color disappears, i.e. an end point is achieved. The method avoids the use of a rank poison of sodium arsenite, reduces the reducing acidity and improves the operation conditions. The invention can be directly used for titrating an excessive iodine solution with sodium thiosulfate without repeatedly titrating the standard liquid for multiple times, can obtain accurate and reliable result and is more applicable for analysis and measurement of a flow sample.

Owner:有研资源环境技术研究院(北京)有限公司

Oyster polypeptide-nano selenium granule compound having hangover-relieving and liver-protecting effects and preparation method and application thereof

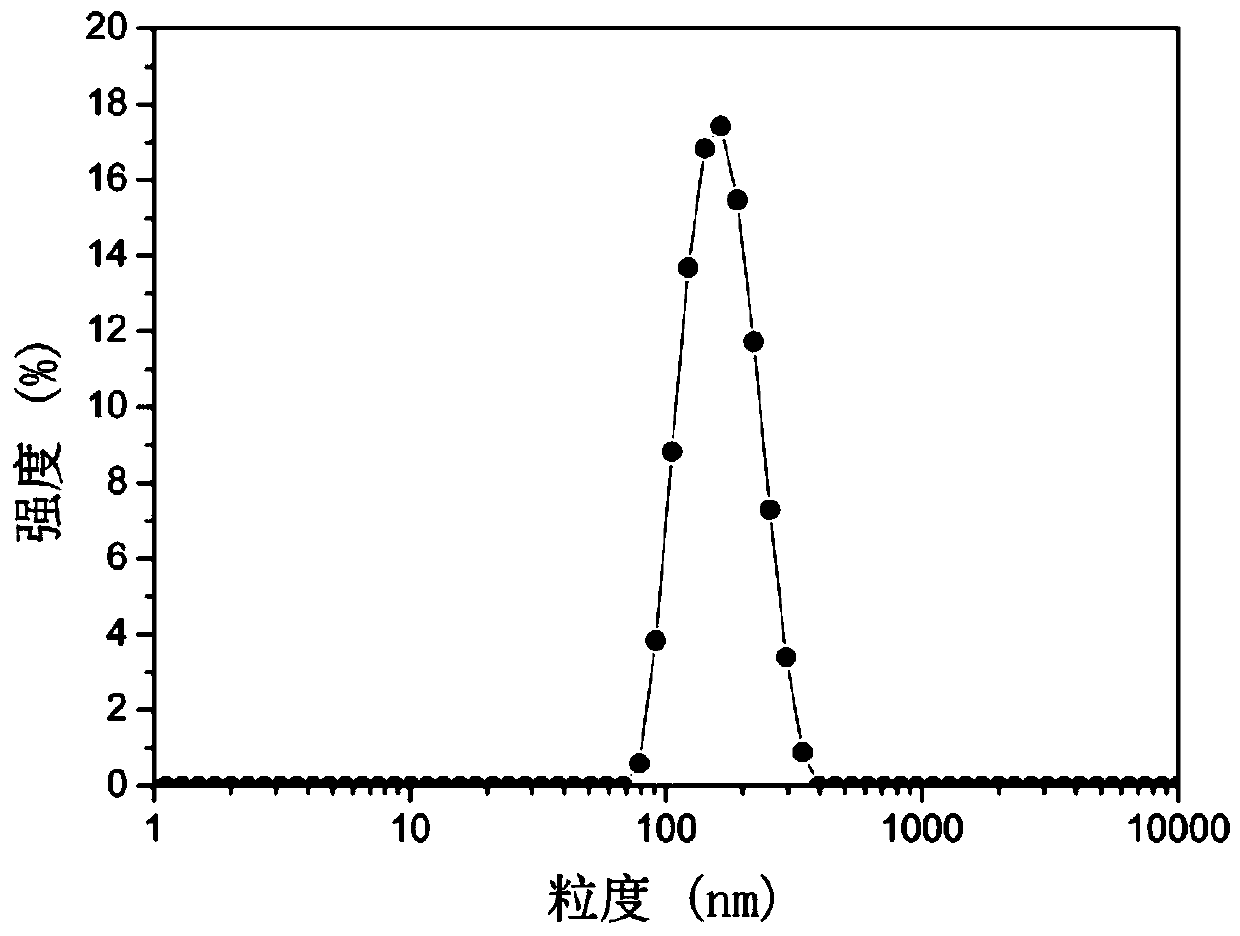

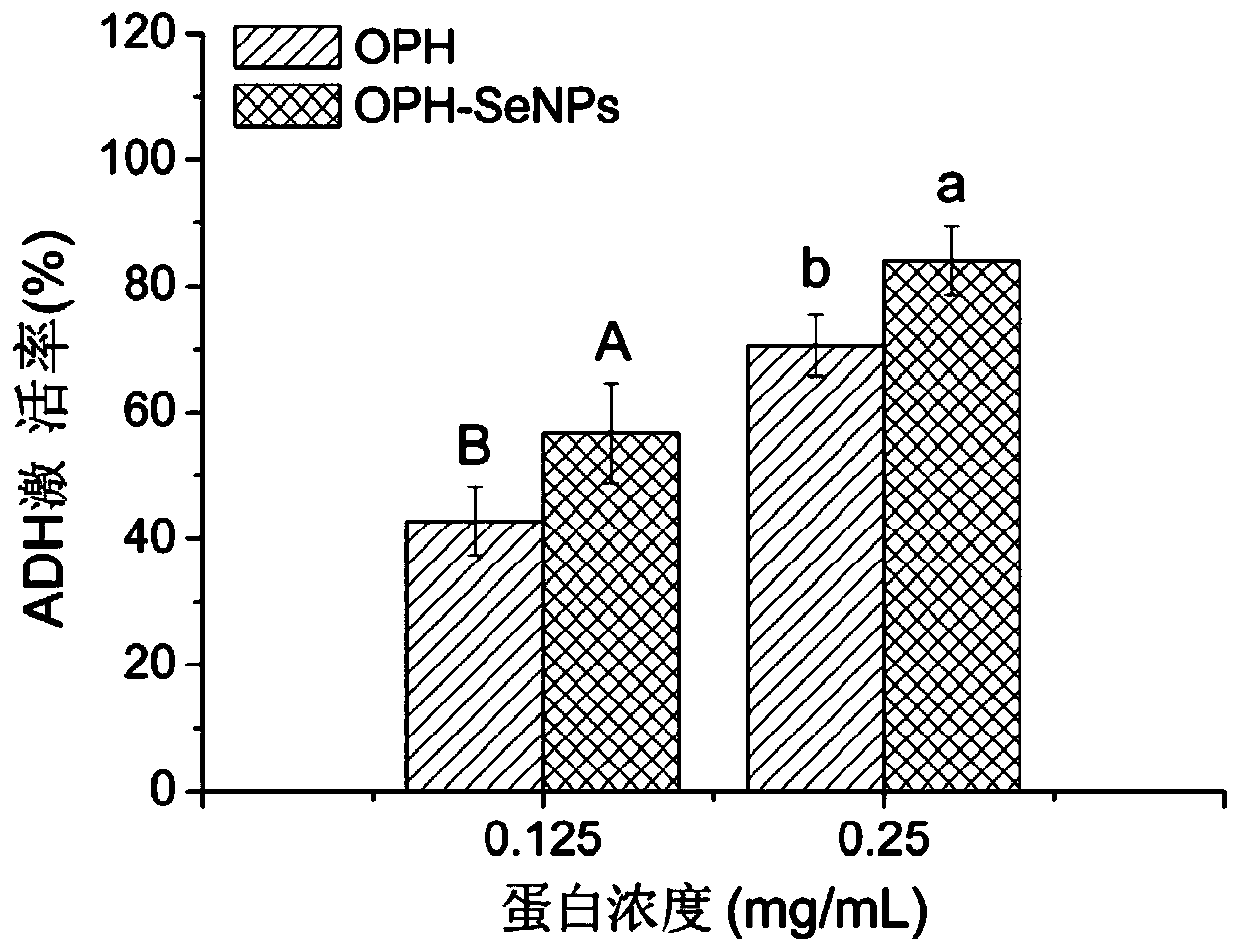

ActiveCN110200287AGood effectEasy to prepareFood ingredient functionsFood ultrasonic treatmentWater bathsActive enzyme

The invention discloses an oyster polypeptide-nano selenium granule compound having hangover-relieving and liver-protecting effects and a preparation method and application thereof. The method includes: homogenizing oyster meat, adding water and active enzyme, enzymolyzing, allowing boiling water bath, centrifuging to take supernate, cold-drying the supernate to obtain oyster polypeptide powder, adding the oyster polypeptide powder into water, well mixing to obtain a solution, adding a sodium arsenite solution into the oyster polysaccharide solution, well mixing, adding an ascorbic acid solution while stirring, allowing water bath reaction, dialyzing to obtain functionalized nano selenium sol, ultrasonically treating, and freeze-drying to obtain the oyster polypeptide-nano selenium granulecompound. Oyster polypeptide is used to stabilize nano selenium, so that stability of nano selenium is remarkably improved, and nano selenium can be stably stored at 4 DEG C for one month; through MTT method detection, nano granules can relieve damage effect of alcohol or hydrogen peroxide on liver. If the compound is converted into healthcare products having a liver protecting function and capable of supplementing selenium element, great social and economic benefit can be generated.

Owner:SOUTH CHINA UNIV OF TECH +1

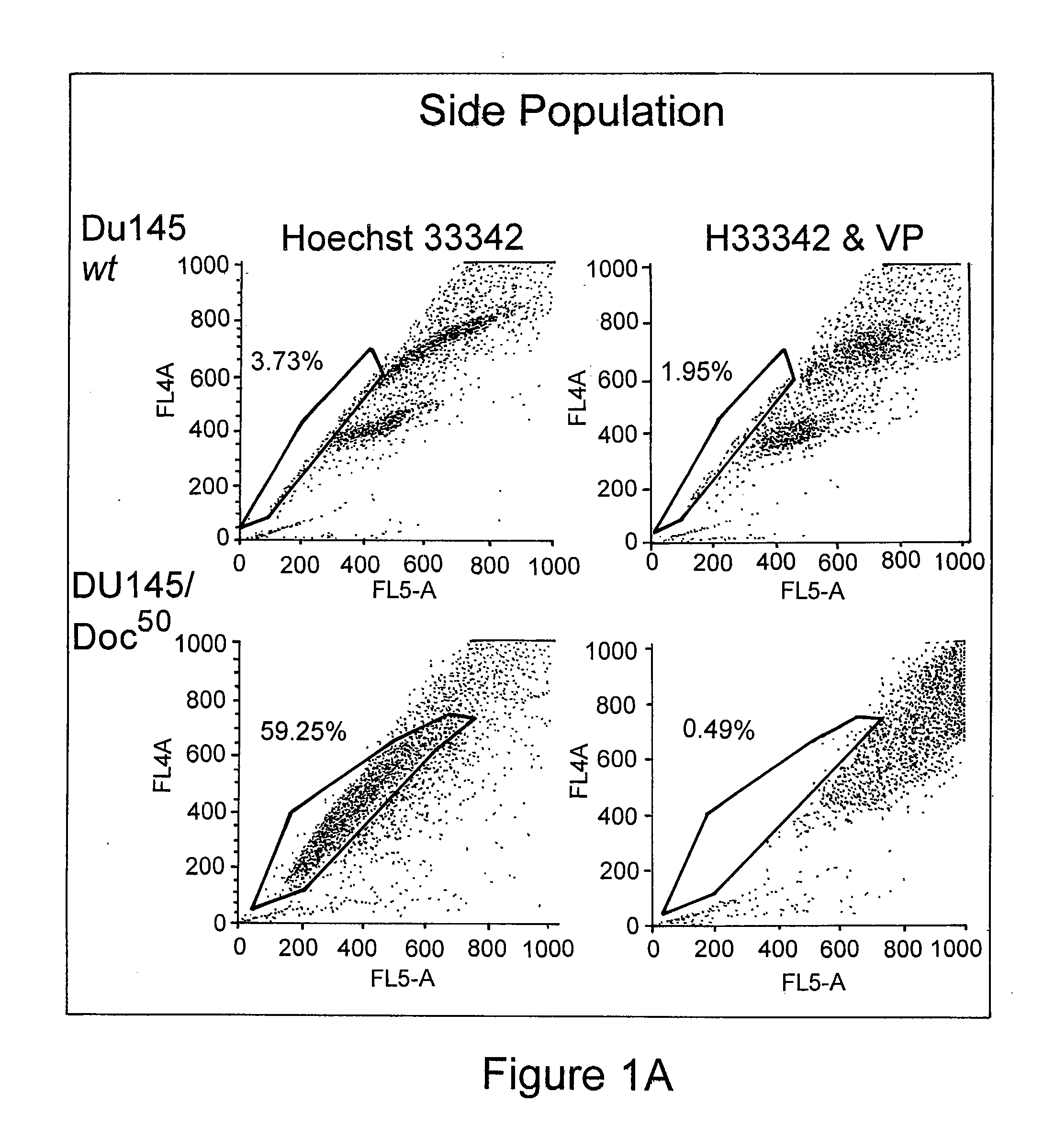

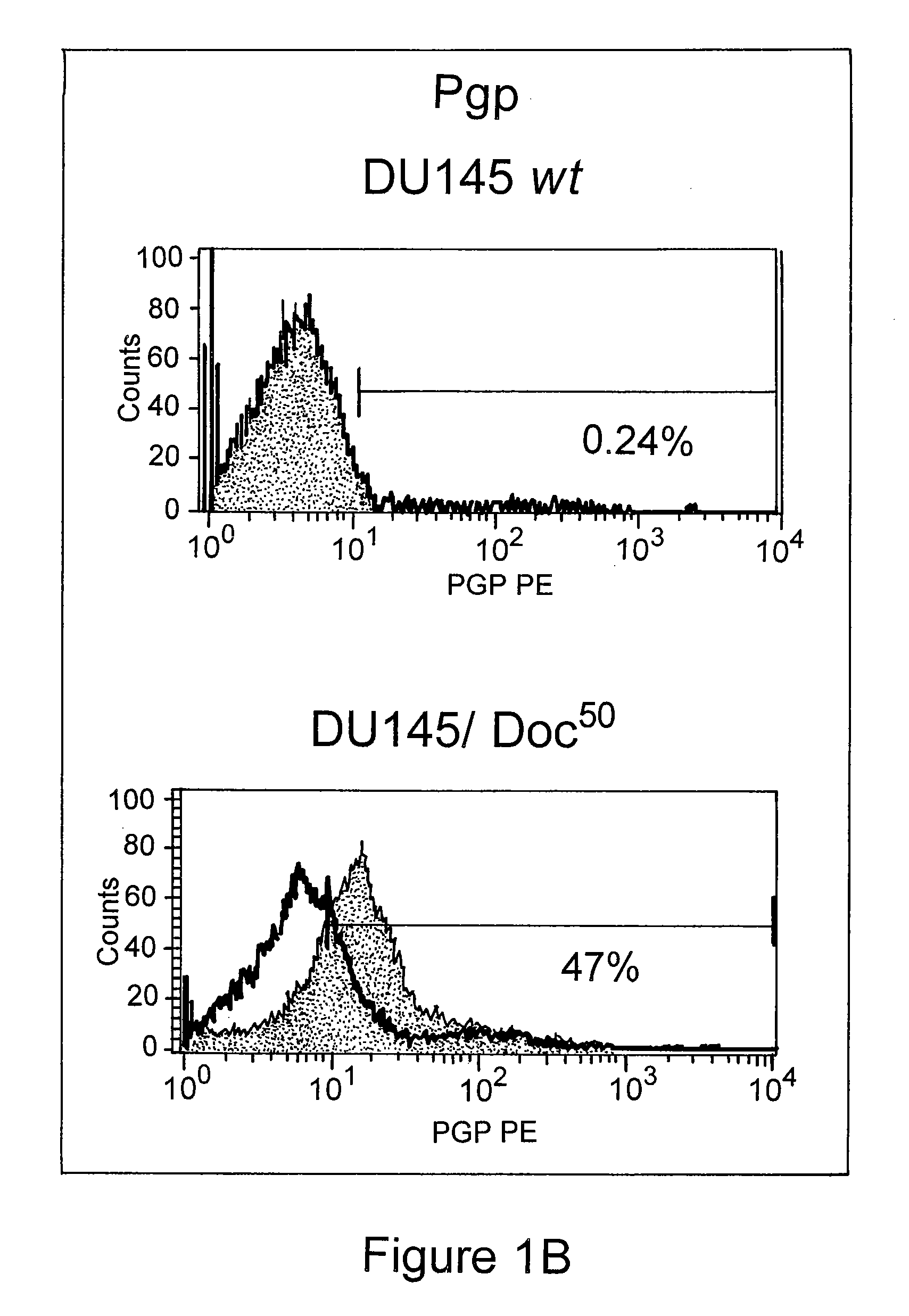

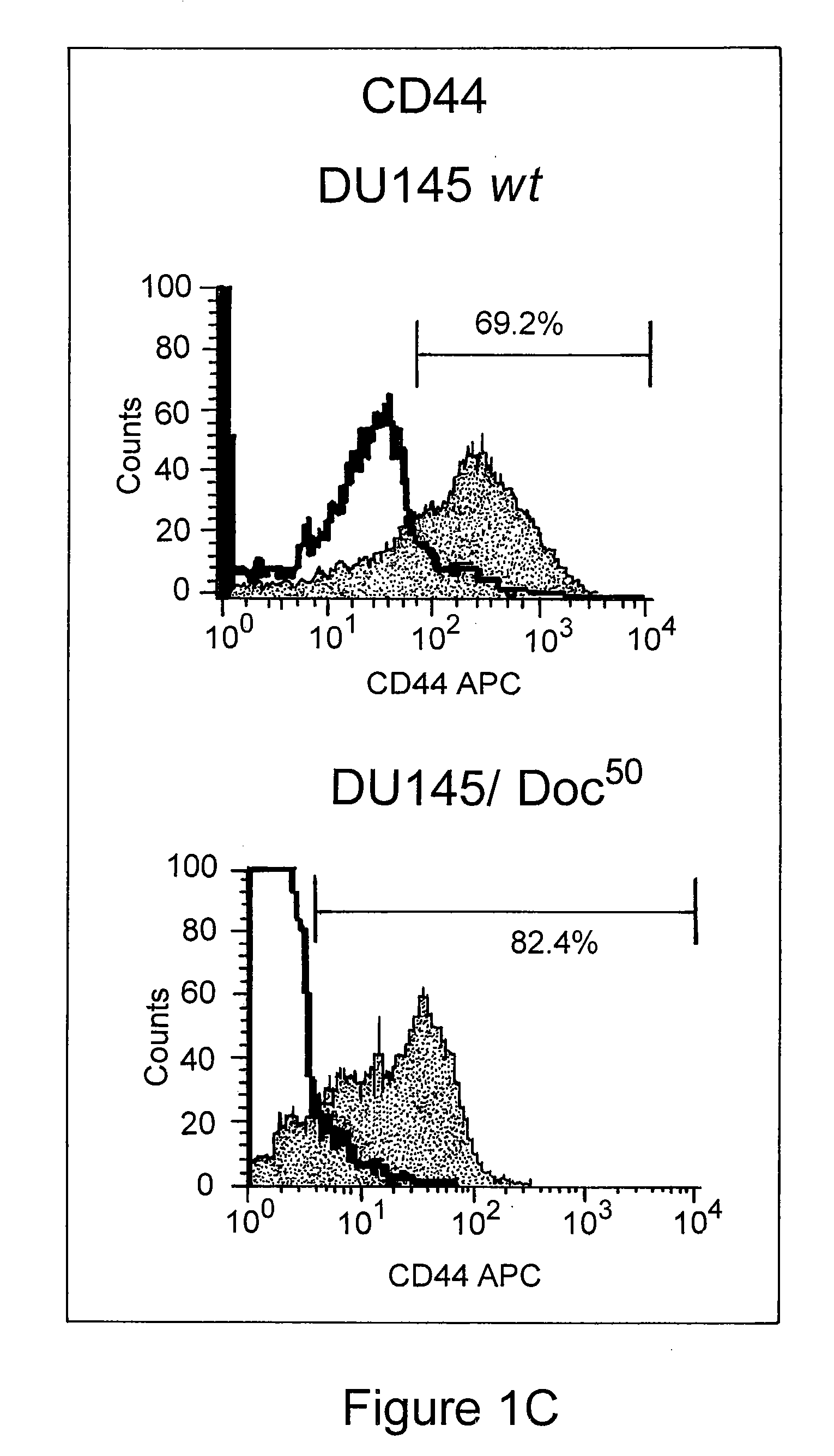

Cancer stem cell-targeted and drug resistant cancer therapy

InactiveUS20110059186A1Reduces and eliminates cell populationReduces and eliminates growth of tumorHeavy metal active ingredientsOrganic active ingredientsDrug resistanceResistant cancer

The present invention provides methods for preventing, treating, and / or managing cancer, the method comprising administering to a subject in need thereof therapeutically effective amount of sodium meta arsenite that reduces or eliminates drug resistant cancer stem cell populations as well as drug resistant mature cancer cells.

Owner:KOMINOX

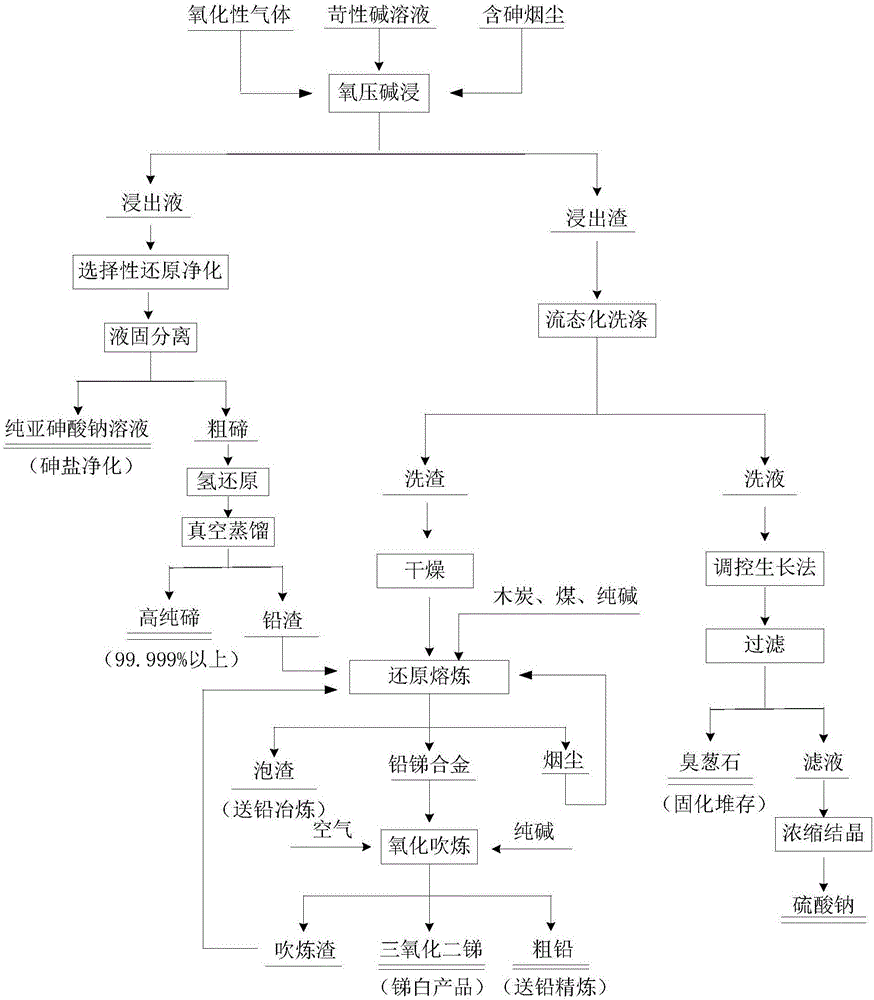

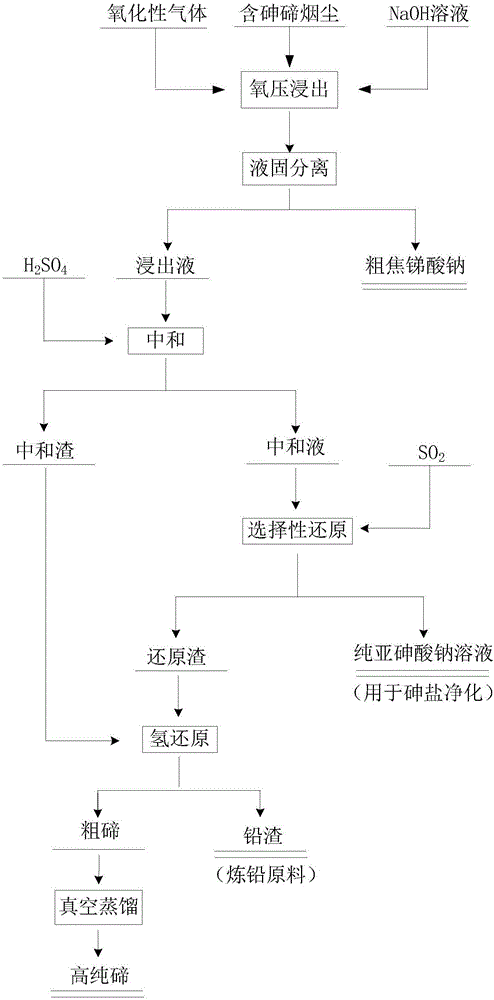

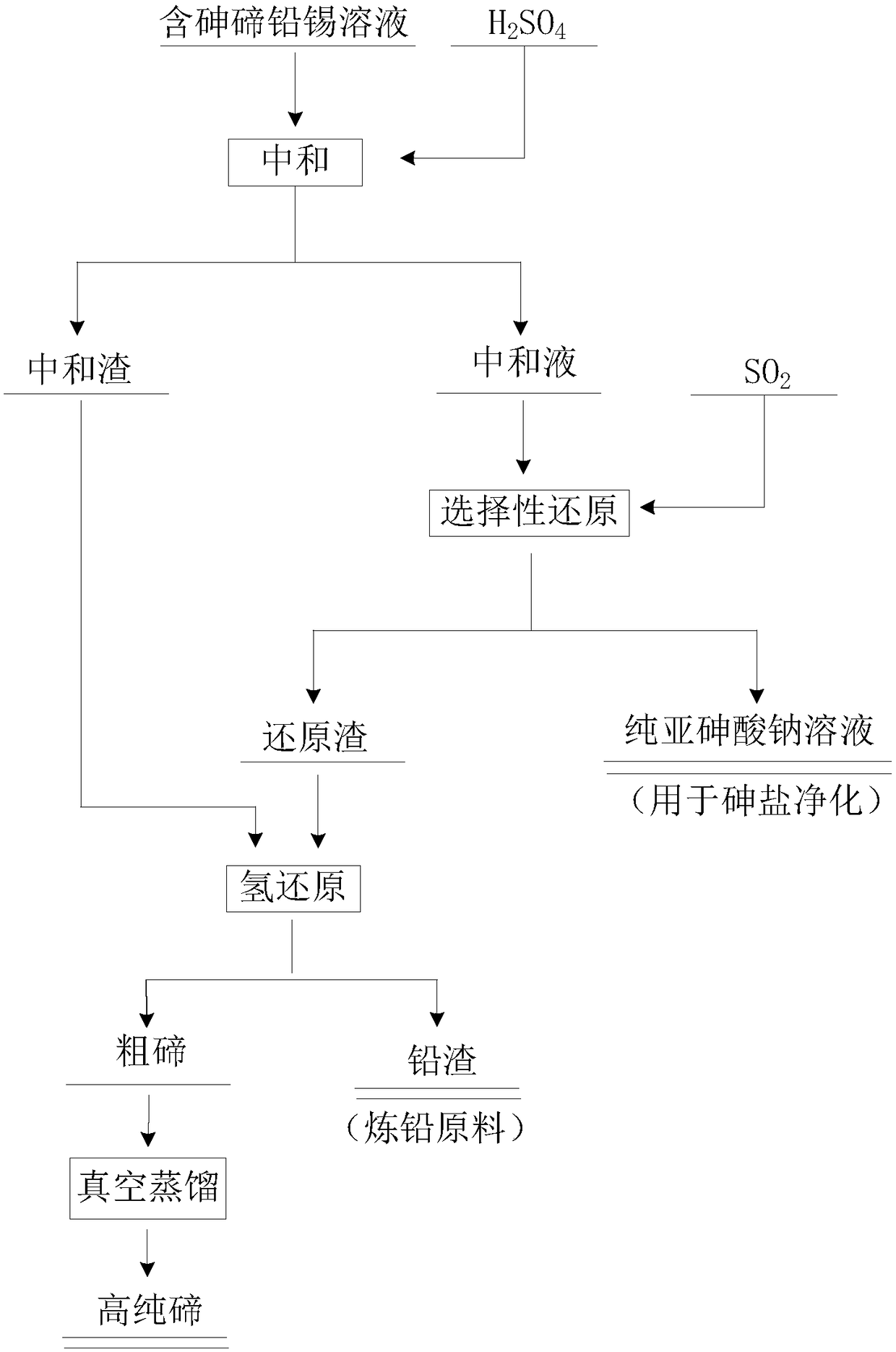

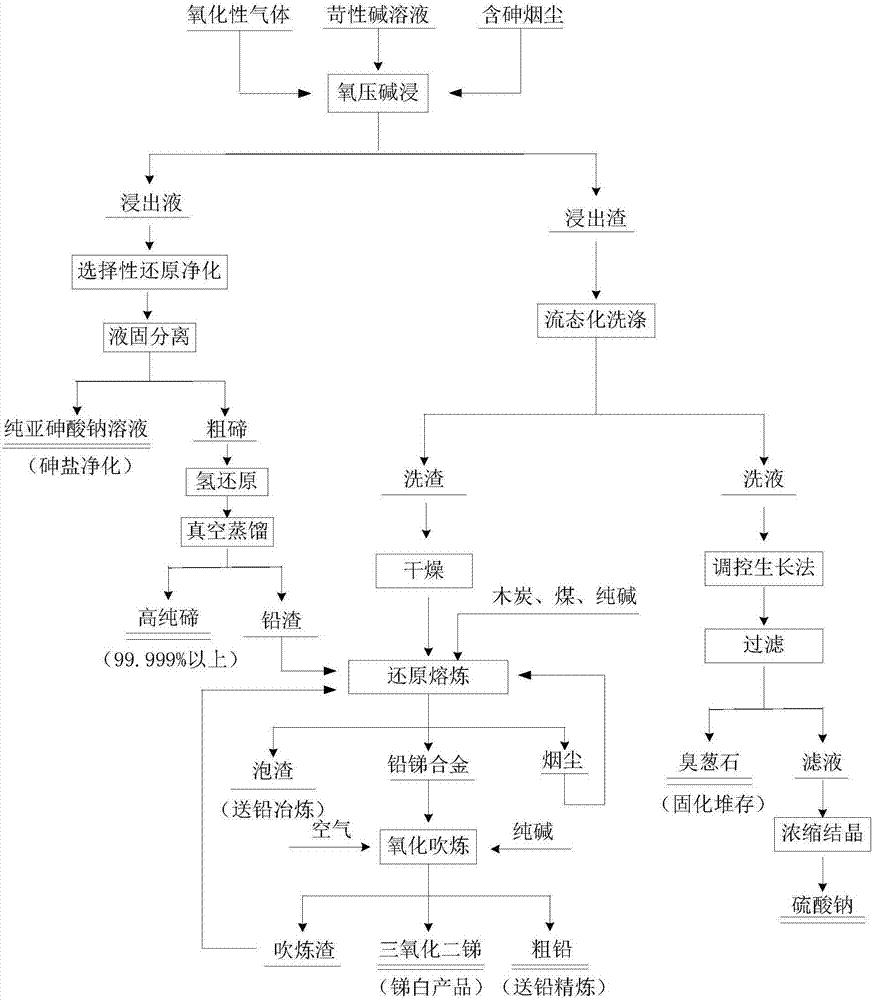

Harmless treatment method for recycling valuable metal and arsenic resources from arsenic-containing smoke

The invention provides a harmless treatment method for recycling valuable metal and arsenic resources from arsenic-containing smoke. All valuable elements are recycled and utilized through the procedures of carrying out oxygen pressure leaching via caustic alkali; carrying out selective reduction purification on leachate; during purification, carrying out hydrogen reduction and vacuum distillation on obtained crude tellurium so as to obtain high-purity tellurium; after purification, obtaining a pure sodium arsenite solution, and using the solution for the arsenic salt purification of a zinc sulfate solution so as to remove cobalt and nickel; carrying out fluidization washing on leaching residues; after washing, solidifying arsenic in the solution, and carrying out reduction smelting on the residues; and carrying out oxidization blowing and the like. The arsenic is removed from the smoke, stibium, lead, bismuth, stannum and the like are kept in the residues from which the arsenic is removed as much as possible, and the deep separation of the arsenic and the stibium is realized. The obtained pure sodium arsenite solution is used for the arsenic salt purification of the zinc sulfate solution used for wet-process zinc smelting so as to remove the cobalt and nickel raw materials, part of sodium arsenate with high impurity content is solidified, the arsenic is precipitated, the harmless recycling of the arsenic resource is realized, and the valuable elements, such as the tellurium, the stibium, the lead and the bismuth are recycled. The comprehensive utilizing rate of the resources is high, the application range of the raw materials is wide, and a pollution problem in the extracting process of a traditional technology is solved.

Owner:CENT SOUTH UNIV

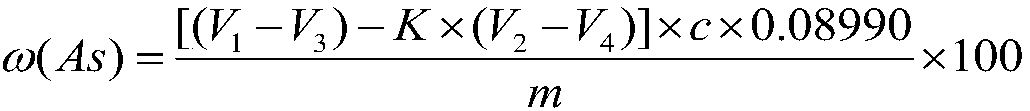

Method for determining arsenic content in ore

InactiveCN108152441ASolve the problem of being unable to conduct test analysis under controlSolve problems that cannot be tested and analyzedChemical analysis using titrationAmmonium ferrous sulfateChemical control

The invention belongs to the technical field of analytical chemistry, and particularly relates to a method for determining arsenic content in ore. Potassium dichromate is adopted to replace iodine inthe conventional hypophosphite titration method, and ammonium ferrous sulfate is adopted to replace poisonous sodium arsenite reagent in the conventional hypophosphite titration method. Compared withdetermination by conventional hypophosphite titration, the method avoids the usage of sodium arsenite medicine, achieving the a poison-less and environment-friendly effect, and also avoids the problemof poisonous chemical control and environmental pollution caused by the usage of arsenic trioxide. The method adopts potassium dichromate and ammonium ferrous sulfate for joint titration, avoiding the usage of poisonous and harmful reagents, so the method is not only safe but also environmentally friendly; moreover, the method is easy to operate, the range of determination is wide, determinationresults are accurate, and the method is suitable for the testing and analysis of samples in large batch, and can be widely applied in the field of testing and analysis of arsenic content in ore. The method is suitable for the analysis of ore with arsenic content of 0.15 to 10 percent.

Owner:CHANGCHUN GOLD RES INST

Selenium-enriched microbial fertilizer and preparation method thereof

InactiveCN108558484AGrowth-promotingIncrease contentBio-organic fraction processingBacteriaDipotassium phosphateSodium arsenite

The invention discloses selenium-enriched microbial fertilizer and a preparation method thereof. The method includes the steps of adjusting the COD concentration of red date processing wastewater to 30-60 g / L, adding ammonium sulfate, dipotassium phosphate and sodium arsenite, adjusting the pH value to 7.2-8.0 after heating, and then obtaining a plant growth-promoting bacteria liquid culture medium; inoculating bacillus amyloliquefaciens into the liquid culture medium, and obtaining bacillus amyloliquefaciens liquid seeds after cultivation; inoculating the bacillus amyloliquefaciens liquid seeds into a new liquid culture medium, introducing sterile air for cultivation, and then obtaining a bacillus amyloliquefaciens liquid; adopting excrement of livestock and poultry, mushroom shreds and smashed straw as raw materials of a solid culture medium, adding the bacillus amyloliquefaciens liquid into the raw materials of the solid culture medium, conducting standing and stacking, introducingair for cultivation, and then obtaining a solid fermented product; drying the solid fermented product to obtain the selenium-enriched microbial fertilizer. The production cost is reduced from two aspects including the production raw materials and the production process, and meanwhile, the selenium-enriched microbial fertilizer has the reinforced functions of promoting growth of plants and preventing and treating plant diseases.

Owner:河北丰禾绿光农业科技有限公司 +1

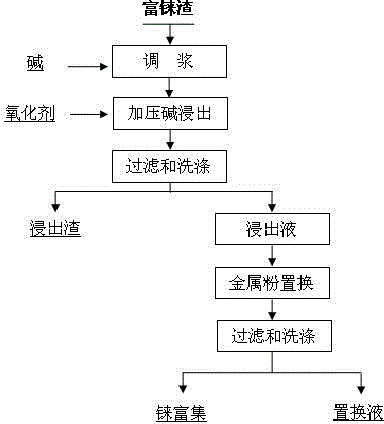

Efficient method for enriching rhenium from high-arsenic copper sulfide material containing rhenium

InactiveCN105861843ASimple processImprove leaching rateProcess efficiency improvementPregnant leach solutionSlag

The present invention discloses an efficient method for enriching rhenium from high-arsenic copper sulfide material containing rhenium. The process is as below: mixing rhenium-enriched slag with a certain amount of alkali into a slurry; pressurizing, heating and leaching alkali; filtering and washing; and sending ammonium rhenium in the form of ammonium rhenate and arsenic in the form of sodium arsenite into a leaching solution. The method uses reactive metal powder heating for replacement of rhenium in the leaching solution; and filtering and washing are carried out to obtain the enrich rhenium oxide and achieve separation of rhenium and arsenic. The raw material is rhenium-enriched slag obtained by sulfide precipitation of waste acid in produced the production of copper smelting enterprises, wherein the slag contains large amount of copper and arsenic. By the process, rhenium can be completely leached, while the metal powder substituties the leaching solution to obtain rhenium-enriched material. The method simplifies subsequent rhenium extraction procedure and reduces the cost of rhenium extraction. The invention has the advantages of simple and short process, high enrichment rate, strong adaptability of raw materials, low cost, easiness to industrialization and good application value, and can increase value and profits copper smelting enterprises.

Owner:KUNMING METALLURGY COLLEGE

Comprehensive utilization method of arsenious waste hydrochloric acid

InactiveCN108250243ASimple processReduce manufacturing costGroup 5/15 element organic compoundsDesalinationEconomic benefits

The invention relates to a comprehensive utilization method of arsenious waste hydrochloric acid. The method comprises the following steps of slowly adding the arsenious waste hydrochloric acid into an alkaline benzyl arsonic acid sodium mother solution to perform acid-base neutralization reaction to precipitate benzyl arsonic acid; enabling the precipitated benzyl arsonic acid to be subjected todehydration to obtain a benzyl arsonic acid product; preparing a sub-arsonic acid sodium solution by reusing a dehydrated arsenious waste solution through crystal desalination. The alkaline benzyl arsonic acid sodium mother solution is prepared through the following steps of enabling arsenic trioxide to react with an excessive sodium hydroxide solution to obtain sodium arsenite and then reacting with benzyl chloride to obtain the benzyl arsonic acid sodium mother solution. The invention creatively provides comprehensive utilization of the arsenious waste hydrochloric acid to produce the benzylarsonic acid, the arsenious waste hydrochloric acid is effectively treated, turning waste into wealth is achieved, comprehensive recycle is realized, not only can the environmental protection problembe solved, but also the economic benefit can be improved.

Owner:红河砷业有限责任公司

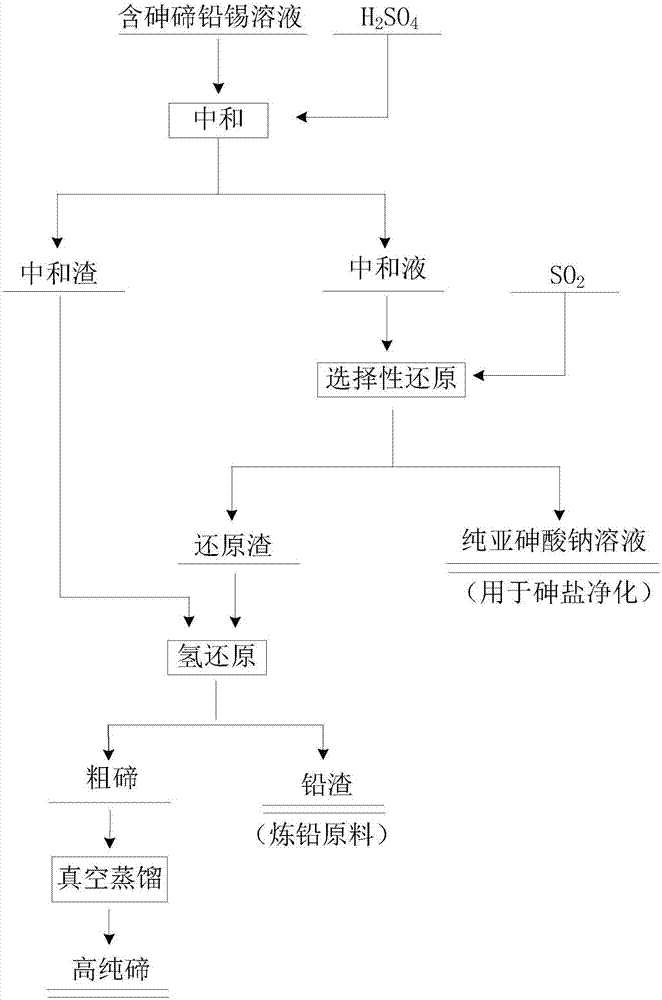

Method for obtaining high-purity tellurium from arsenic-containing alkaline leaching liquid

ActiveCN106868319AAchieve separationSolve pollutionProcess efficiency improvementElemental selenium/telluriumSlagHydrometallurgy

The invention relates to alkaline leaching liquid containing arsenic, tellurium, lead and tin, in particular to a method for obtaining high-purity tellurium from arsenic-containing alkaline leaching liquid. The alkaline leaching liquid is leaching liquid obtained after oxygen pressure alkaline leaching treatment of high arsenic and antimony smoke. The alkaline leaching liquid is neutralized through sulfuric acid, neutralization solution selective reducing is conducted, and the liquid obtained after reducing is a pure sodium arsenite solution and is used as a raw material for purification and removal of cobalt and nickel through zinc sulfate solution arsenic salt; and reducing slag and neutralizing slag are subjected to hydrogen reducing and vacuum distillation, and high-purity tellurium with the purity being 99.999% or above is obtained. According to the method, the tellurium is recycled from the high-tellurium solution, and the pure sodium arsenite solution is obtained and used as the raw material for purification and removal of cobalt and nickel through the zinc hydrometallurgy zinc sulfate solution arsenic salt. According to the method, the technology process is short, the recycling rate is high, and the problem of pollution in the extraction process in the traditional technology is solved.

Owner:CENT SOUTH UNIV

Serum-free stem cell culture medium and application thereof

InactiveCN105087480AAvoid toxicityGuaranteed stabilitySkeletal/connective tissue cellsTransferrinSodium arsenite

The invention provides a serum-free stem cell culture medium which comprises a basal culture medium and supplement factors. The recruitment factors include sodium arsenite, transferrin, bovine serum albumin, insulin, fibronectin and hydrocortisone. Compared with serum culture mediums of the prior art, the serum-free stem cell culture medium has the advantages that quality difference among serum batches can be avoided, and repeatability of cell culture and experiment results is improved; exogenous pollution caused by serum and cytotoxic effect of serum components are avoided. The serum-free stem cell culture medium has relatively clear own ingredients, uniform quality, low protein content and is conducive to improving stability of cell product production and easy to purify. In addition, after stem cell proliferation and property degrees are maintained through several specific matching modes, high-density cell culture can be maintained for a long time by prolonging GI period of cells or forcing the cells to be in G0 period, and stem cell characteristics can be retained better.

Owner:SHEN ZHEN ISTEM REGENERATIVE MEDICINE SCI TECH CO LTD

Method for recycling high-purity tellurium from arsenium-containing and tellurium-containing smoke and preparing high-purity tellurium

ActiveCN106834711AImplement resourcesHarmlessProcess efficiency improvementElemental selenium/telluriumResource utilizationHydrometallurgy

The invention provides a method for recycling high-purity tellurium from arsenium-containing and tellurium-containing smoke and preparing high-purity tellurium, and relates to production for comprehensively recycling valuable elements, such as arsenium, tellurium and lead, from the arsenium-containing and tellurium-containing smoke and harmless recycling processing of the arsenium. Oxygen pressure leaching is conducted on caustic alkali, leaching residues are rough sodium pyroantimonate, leachate is neutralized through sulfuric acid, the neutralized liquid is selectively reduced, the reduced liquid is a pure sodium arsenite solution and is used as a raw material of zinc sulfate solution arsenic salt purification and cobalt and nickel removal, reduction residues and neutralization residues are subjected to hydrogen reduction and vacuum distillation, and the high-purity tellurium with the purity being 99.999% or above is obtained. The arsenium and the tellurium are leached out from the smoke, while stibium, lead, bismuth, tin and the like are reserved in dearsenification residues as much as possible, the pure sodium arsenite solution is obtained through leachate purification and is used as the raw material of zinc sulfate solution arsenic salt purification and cobalt and nickel removal in zinc hydrometallurgy, harmless recycling of the arsennium is achieved, and valuable elements such as the stibium, the lead, the bismuth and the tin are recycled. The method is high in resource utilization rate and wide in raw material application range and solves the problem of pollution in the extraction process of the traditional process.

Owner:CENT SOUTH UNIV

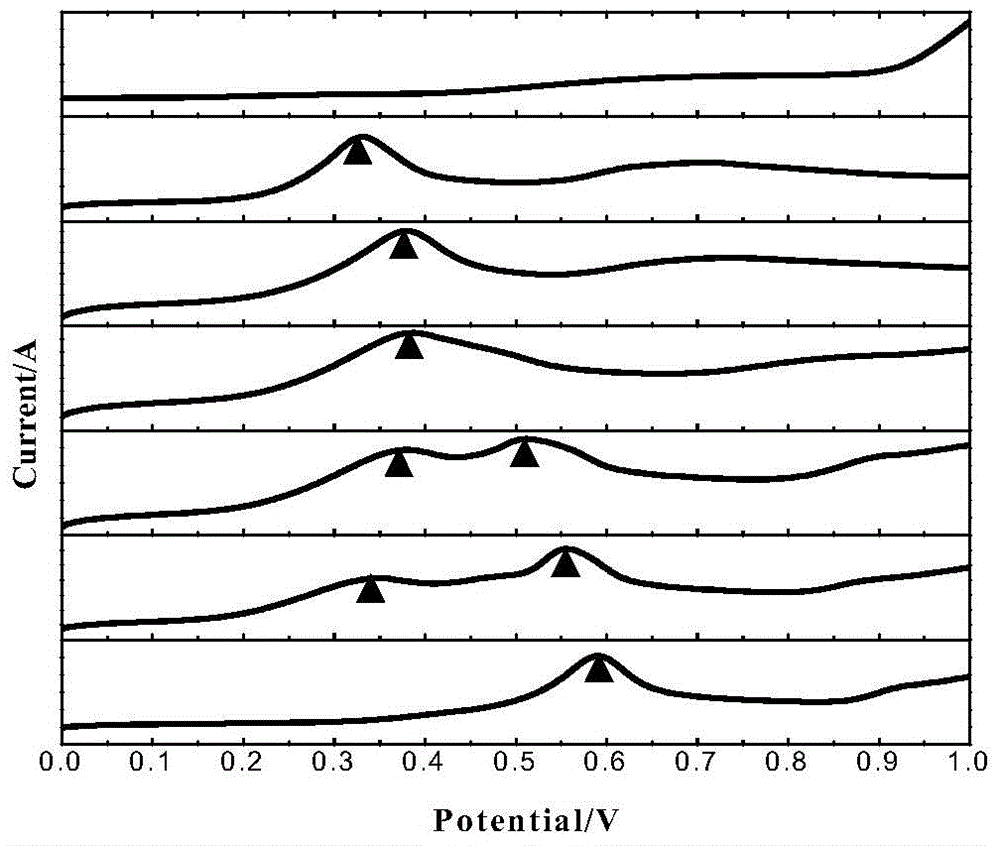

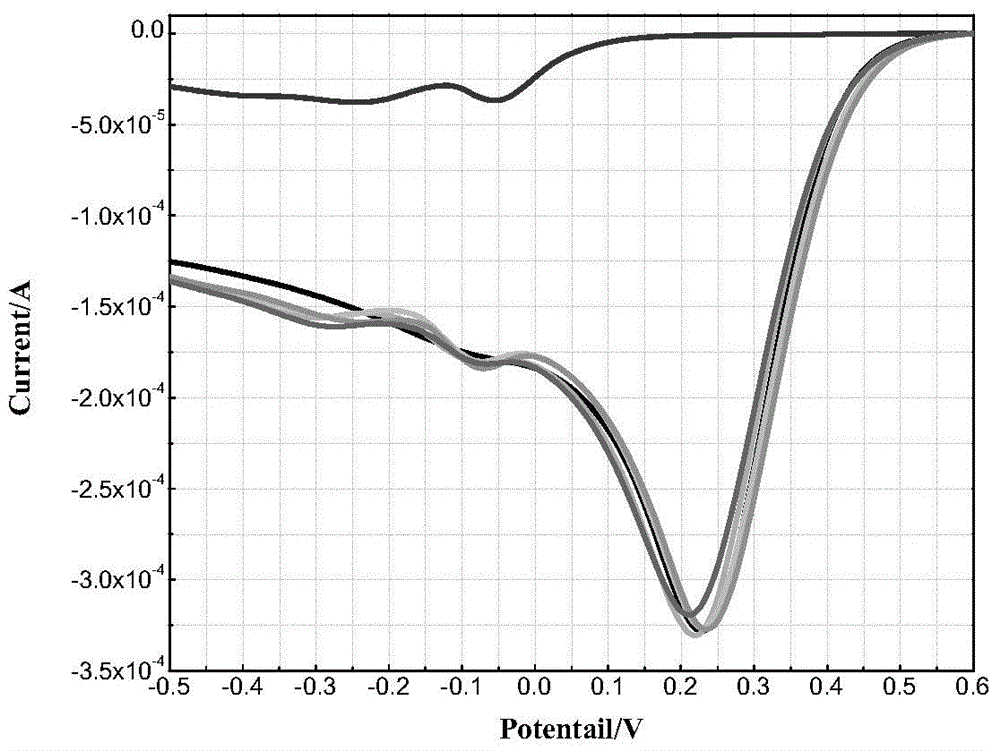

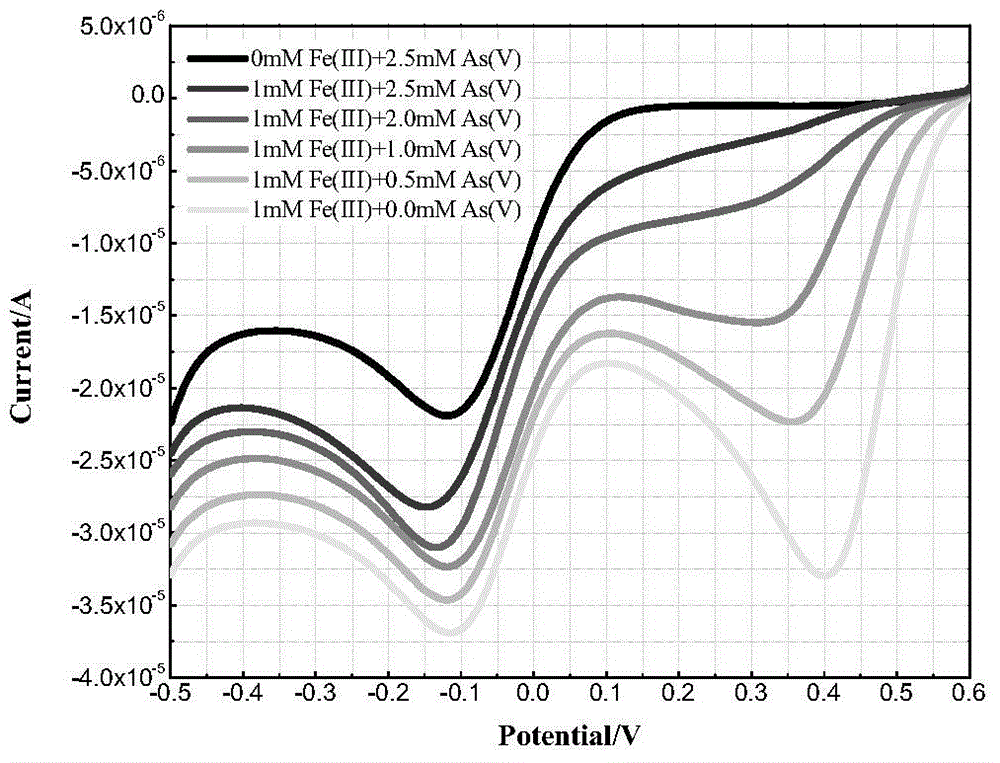

Method for assisted determination for unknown arsenic form in wastewater based on electrochemistry system

ActiveCN104407038ARealize in-situ real-time detectionSimple and fast operationMaterial electrochemical variablesSupporting electrolyteSodium arsenite

The invention discloses a method for assisted determination for an unknown arsenic form in wastewater based on an electrochemistry system. The method comprises the following steps: (1) establishing a three-electrode system: taking a gold electrode or a platinum electrode as a working electrode, taking a glassy carbon electrode as a counter electrode, and taking a saturated calomel electrode as a reference electrode; (2) preparing an experiment solution : using a sodium sulphate solution or a sulfuric acid solution as a supporting electrolyte to prepare the experiment solution, and using sodium arsenite, sodium arsenate, sodium carbonate and ferric sulfate to prepare an As (III)-CO32-(HCO3-) solution, an As (III)-Fe (III) solution and an As (V)-Fe (III) solution; (3) carrying out linear scanning detection. Based on the oxidation-reduction reaction and electrochemical principle of arsenic, the method adopts the linear scanning voltammetry of the three-electrode system to capture the change of a corresponding oxidation reduction potential when the arsenic form is changed, thereby predicting the unknown arsenic form in the wastewater containing arsenic. The method implements regulation and controlling for grasping the existing form of arsenic in the wastewater and provides methodology support for realization of deep purification.

Owner:CENT SOUTH UNIV

Pharmaceutical compositions comprising sodium meta arsenite for treatment of multiple myeloma

The present application relates to pharmaceutical compositions and methods for treatment of urogenital diseases and bone metastasis in a human, which pharmaceutical composition contains an effective amount of arsenous acid alkaline or earth alkaline metal salt and / or a pharmaceutically acceptable adjuvant. According to the present invention, the alkaline arsenous acid metal salt is sodium meta-arsenita (AsO2Na) or potassium meta-arsenite (AsO2K). The effective amount of arsenous acid alkaline or earth alkaline metal salt is 0.0001-1500 mg / kg, preferably 1-1000 mg / kg, more preferably 1-150 mg / kg, and most preferably 50-100 mg / kg of body weight / day. The administration form of the pharmaceutical compositions of the invention is preferably oral, such as a tablet, capsule, powder and / or solution with a pharmaceutically acceptable carrier, diluent or excipient.

Owner:KOMINOX

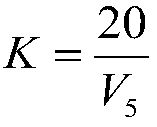

A method for analyzing arsenic in ore samples

InactiveCN101726487BReduce usageReduce reducing acidityMaterial analysis by observing effect on chemical indicatorSodium arseniteCopper sulfate

The invention relates to a method for analyzing arsenic in ore samples. The steps include: adding nitric acid and potassium chlorate to a certain amount of sample, adding sulfuric acid to continue heating and dissolving and evaporating until thick smoke of sulfur trioxide is emitted for several minutes, cooling, adding water to blow Wash, heat to dissolve, add copper sulfate, add hydrochloric acid, then add sodium hypophosphite until the Fe3+ yellow color completely fades, and then overdose, boil at this reducing acidity, and keep a certain slight boiling time to make the arsenic precipitate and condense; Filter the precipitate, wash the beaker and the precipitate with hydrochloric acid solution containing sodium hypophosphite, and then wash the beaker and the precipitate with ammonium chloride solution until the pH is 5; transfer the absorbent cotton ball to the original beaker, add buffer, starch solution, accurately add iodine standard solution, and drop sodium thiosulfate standard solution until the blue color disappears, which is the end point. The method avoids the use of highly toxic reagent sodium arsenite, reduces reducing acidity, and improves operating conditions. Direct titration of excess iodine solution with sodium thiosulfate does not require repeated titration of standard solution, the result is accurate and reliable, and is more suitable for the analysis and determination of process samples.

Owner:有研资源环境技术研究院(北京)有限公司

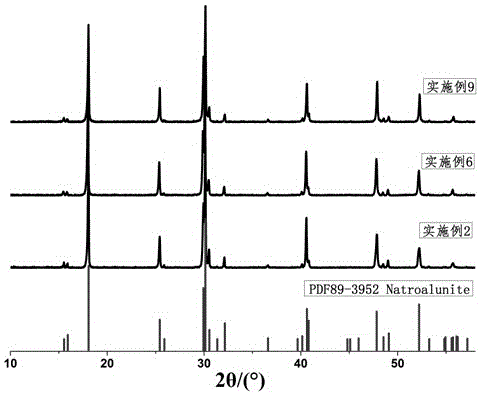

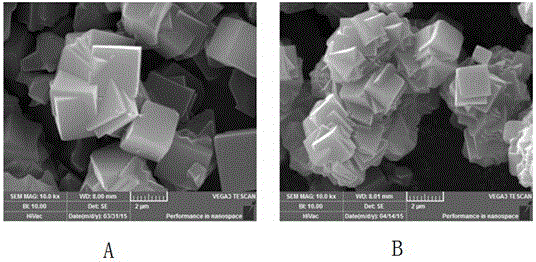

Low-temperature solid-phase method for synthesis of arsenic natroalunite

The present invention discloses a preparation method and application of a sulfate mineral containing arsenic, and particularly relates to a low-temperature solid-phase method for synthesis of an arsenic natroalunite solid solution and application thereof. The method uses aluminum sulfate or aluminum nitrate as an Al source, sodium sulfate as a Na source, arsenic, sodium arsenite or arsenic waste residue as an As source, and conducts a solid phase reaction at 100-220 DEG C for 2.5-72 h, so as to synthesize the arsenic natroalunite solid solution with high crystallinity and good stability. The method is mainly used in the transformation of solid phase soluble arsenic substances into poorly soluble arsenic natroalunite solid solution, solves the disadvantages of required high pressure, high requirements on the reactor, huge energy consumption and high economic cost in the conventional hydrothermal synthesis of arsenic natroalunite, as well as environmental pollution caused by poor stability of conventional arsenic compound. Compared to prior art, the obtained arsenic natroalunite solid solution has advantages of good long-term stability, safe and reliable storage, low economical cost, and reaction conditions close to the industrialization.

Owner:KUNMING UNIV OF SCI & TECH

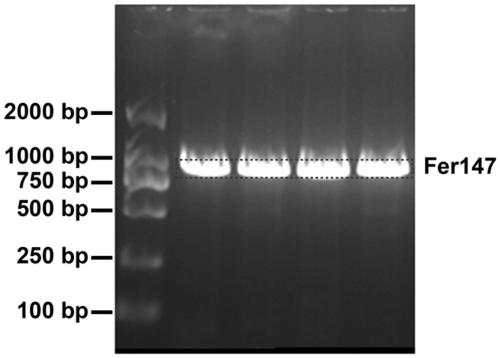

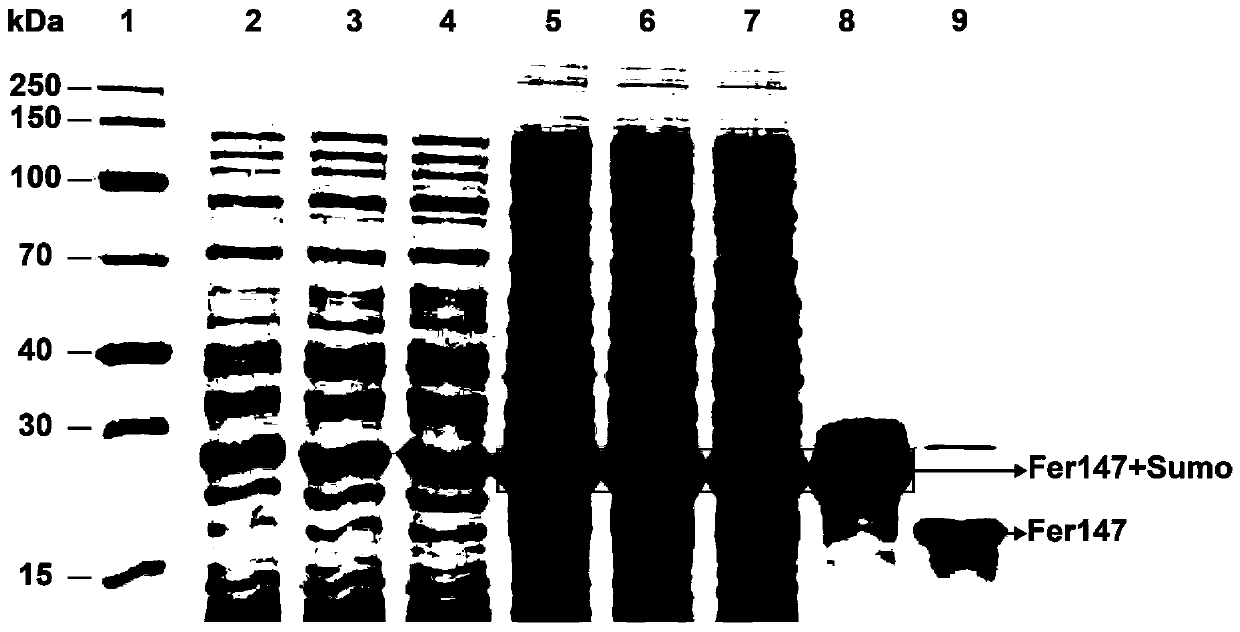

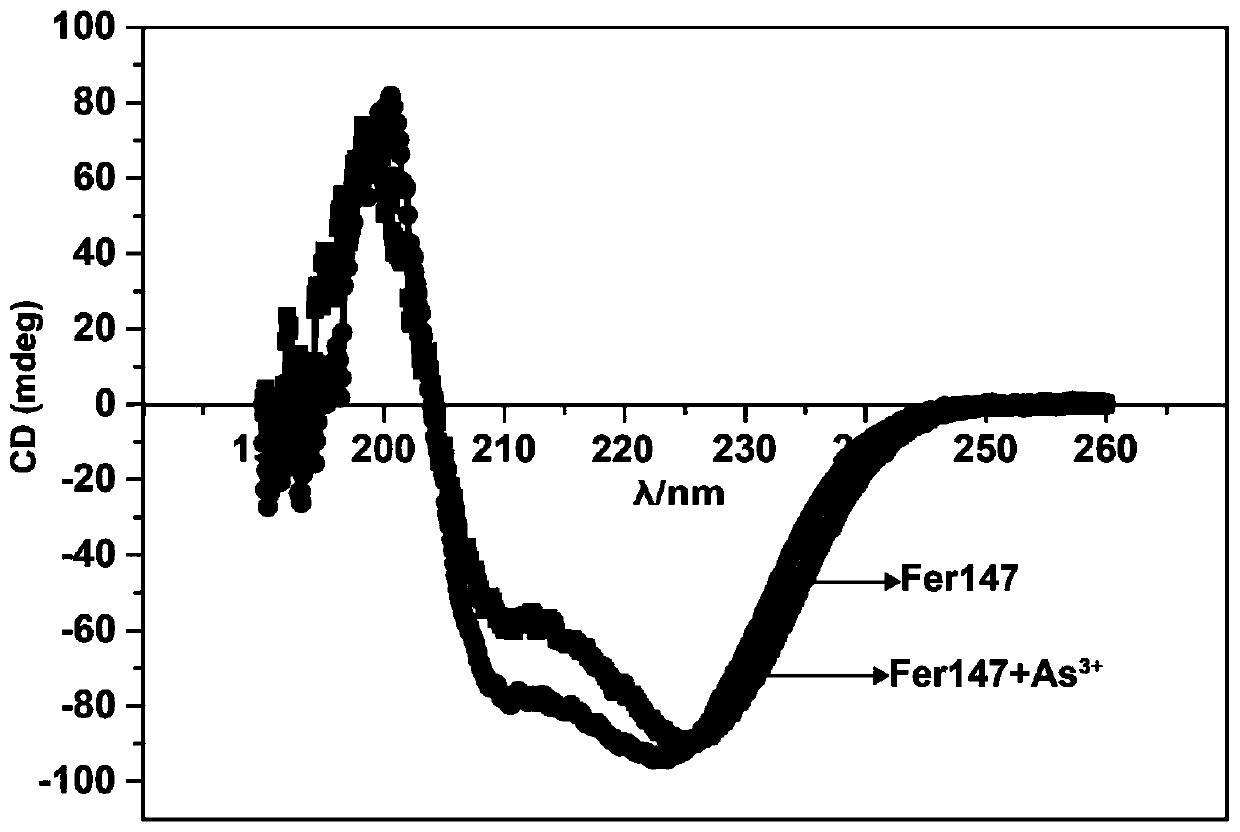

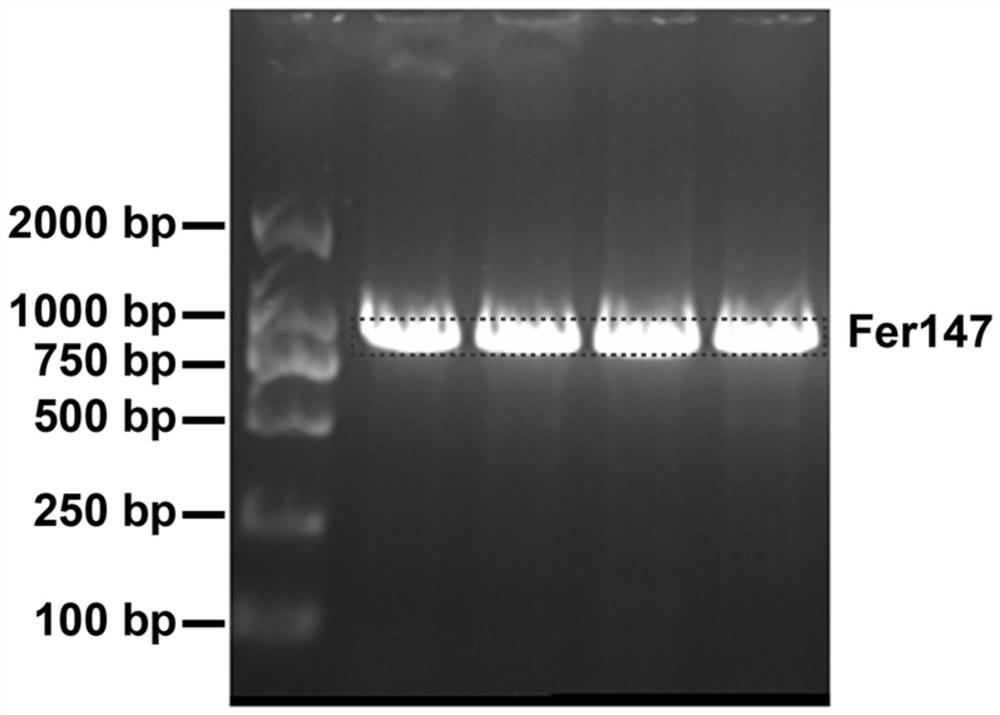

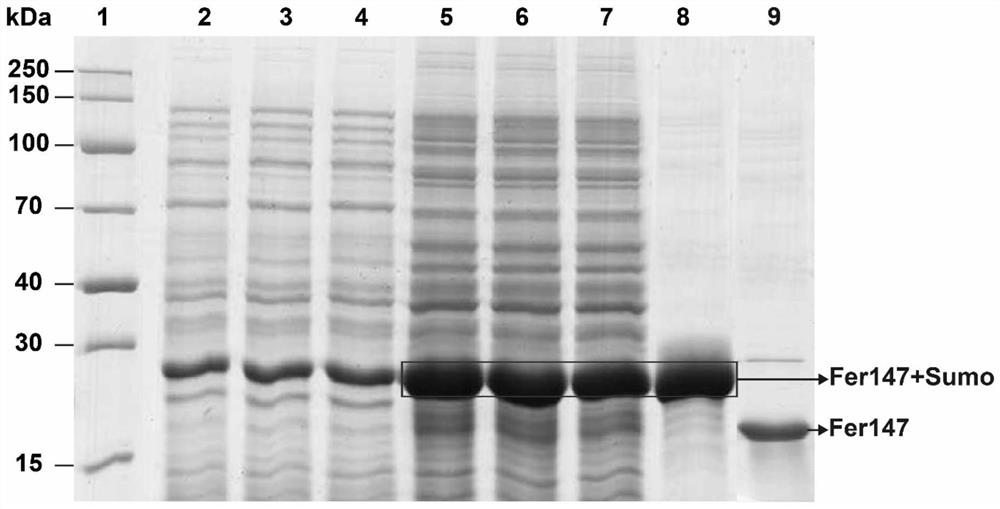

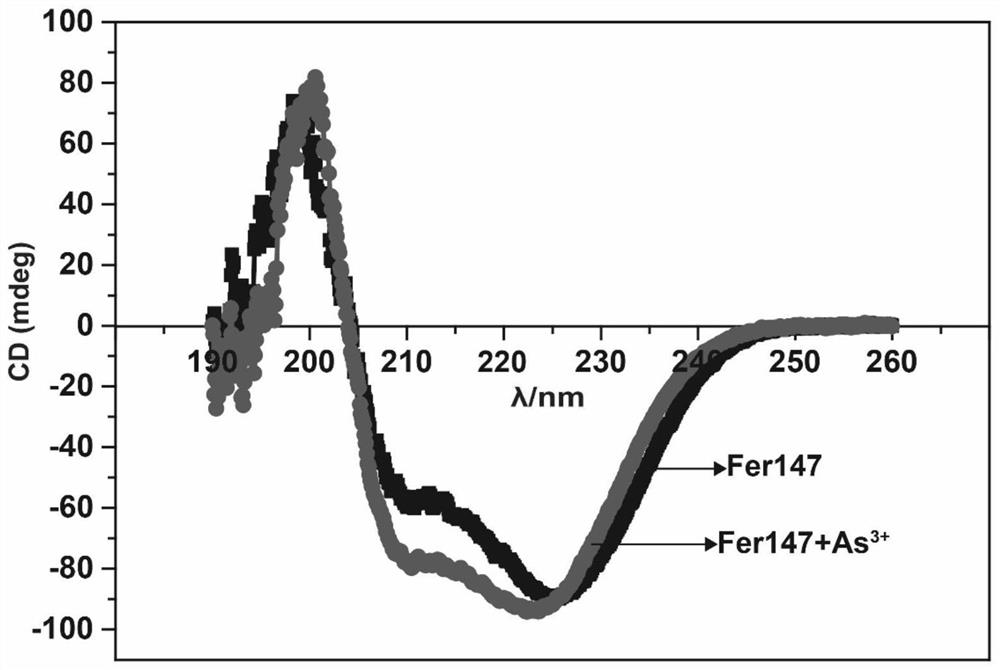

Preparation method and application for invertebrate recombinant ferritin based anti-tumor nano arsenic sphere

ActiveCN110200995AGood inhibitory effectEnhanced inhibitory effectInorganic active ingredientsMicroorganism based processesProtein solutionWhite blood cell

The invention discloses a preparation method and application for an invertebrate recombinant ferritin based anti-tumor nano arsenic sphere. The preparation method is characterized in that the method includes the following steps: (1) obtaining invertebrate recombinant ferritin successively through gene amplification, the construction and prokaryotic expression of prokaryotic expression vectors andprotein purification; and (2) placing the invertebrate recombinant ferritin into a dialysis bag, performing dialysis in a 5 mM sodium arsenite solution, using a magnetic stirrer to simulate flowing liquid during a whole enrichment process, placing the dialysis bag into a protein buffer solution to perform dialysis for 12 h after 12 h of the dialysis, replacing the protein buffer solution every 4 h, taking the protein solution in the dialysis bag, and obtaining invertebrate recombinant ferritin based anti-tumor nano arsenic spheres after concentration. The preparation method has significant inhibition effects on the propagation of chronic granulocyte white blood cell K562 cells.

Owner:NINGBO UNIV

A method for recovering and preparing high-purity tellurium from arsenic-containing tellurium fumes

ActiveCN106834711BReduce labor intensityShort processing timeProcess efficiency improvementElemental selenium/telluriumResource utilizationHydrometallurgy

Owner:CENT SOUTH UNIV

Pharmaceutical composition comprising meta arsenite and method of manufacture

PendingUS20210000746A1Minimize the possibilityLow moisture levelSenses disorderNervous disorderArsenous acidSodium arsenite

The present application relates to pharmaceutical compositions comprising a salt of arsenous acid, such as sodium meta arsenite or potassium meta arsenite, and methods of manufacturing the pharmaceutical compositions.

Owner:KOMIPHARM INT AUSTRALIA PTY LTD +1

A method for obtaining high-purity tellurium from arsenic-containing alkali immersion solution

ActiveCN106868319BHigh in arsenicReduce labor intensityProcess efficiency improvementElemental selenium/telluriumSlagHydrometallurgy

The invention relates to alkaline leaching liquid containing arsenic, tellurium, lead and tin, in particular to a method for obtaining high-purity tellurium from arsenic-containing alkaline leaching liquid. The alkaline leaching liquid is leaching liquid obtained after oxygen pressure alkaline leaching treatment of high arsenic and antimony smoke. The alkaline leaching liquid is neutralized through sulfuric acid, neutralization solution selective reducing is conducted, and the liquid obtained after reducing is a pure sodium arsenite solution and is used as a raw material for purification and removal of cobalt and nickel through zinc sulfate solution arsenic salt; and reducing slag and neutralizing slag are subjected to hydrogen reducing and vacuum distillation, and high-purity tellurium with the purity being 99.999% or above is obtained. According to the method, the tellurium is recycled from the high-tellurium solution, and the pure sodium arsenite solution is obtained and used as the raw material for purification and removal of cobalt and nickel through the zinc hydrometallurgy zinc sulfate solution arsenic salt. According to the method, the technology process is short, the recycling rate is high, and the problem of pollution in the extraction process in the traditional technology is solved.

Owner:CENT SOUTH UNIV

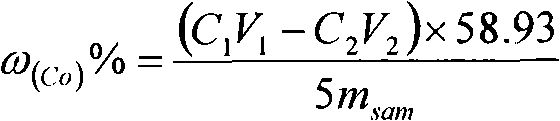

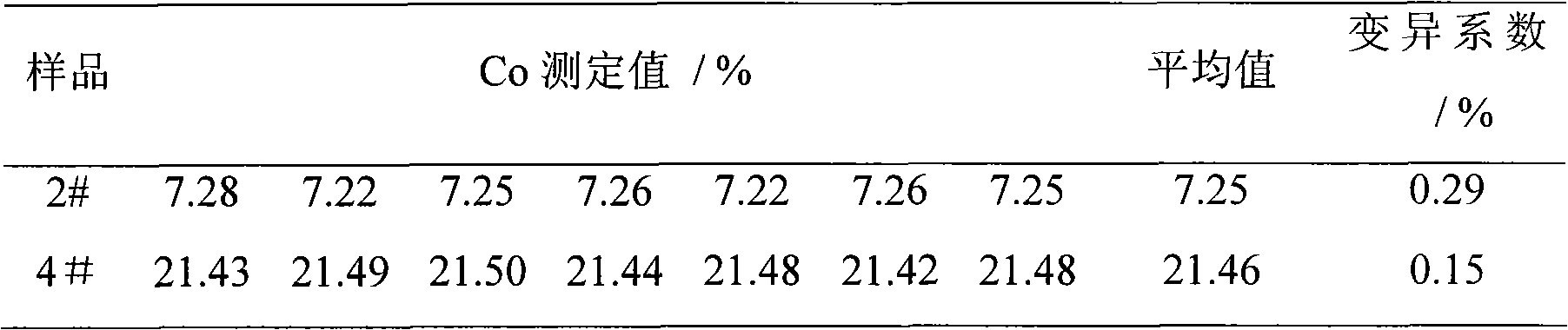

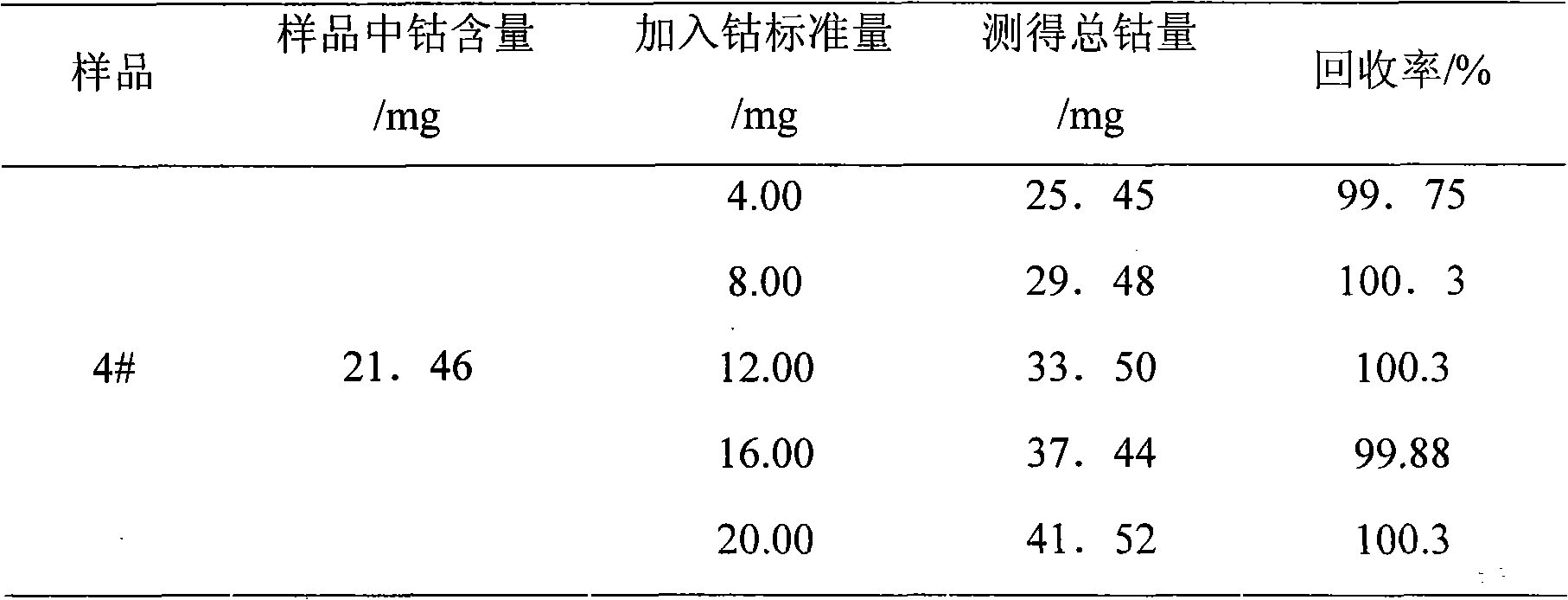

Chemical assay method for cobalt in lithium ion battery anode material LiCoxMnyNi1-x-yO2

InactiveCN101504400BDiscoloration sharpHigh measurement accuracyChemical analysis using titrationChemical analysis using precipitationManganeseStrong acids

The invention provides a chemical detection method for cobalt. The method is characterized in that: a sample containing manganese-nickel-cobalt is heated and dissolved under the action of strong acid, the interfering ion manganese is oxidized into manganese dioxide which undergoes filtering separation, the cobalt-nickel is precipitated by a precipitator and then filtered, and the obtained precipitate is separated from other trace elements; a mixture of Co(OH)2 and Ni(OH)2 is dissolved by acid; under ammonia condition, the cobalt is reacted with excessive and quantitative iodine standard solution to generate [CO(NH3)5I](NO3)2(S), and the excessive iodine undergoes back titration by sodium arsenite standard solution ; and the content of the cobalt is worked out according to the stoichiometric relationship.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

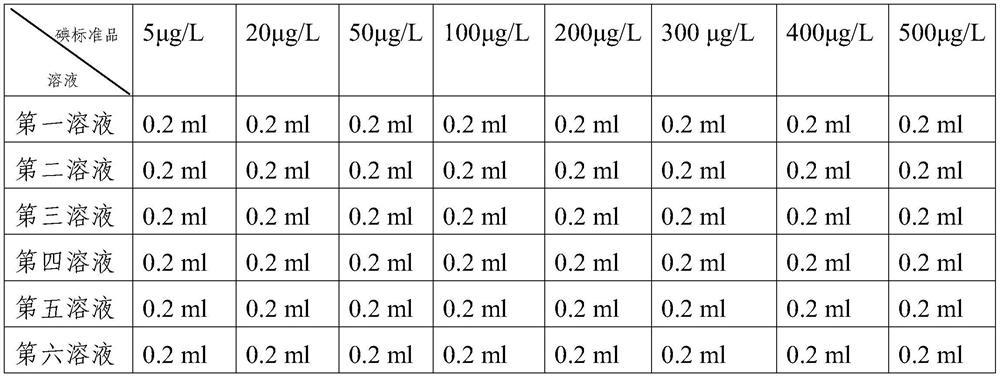

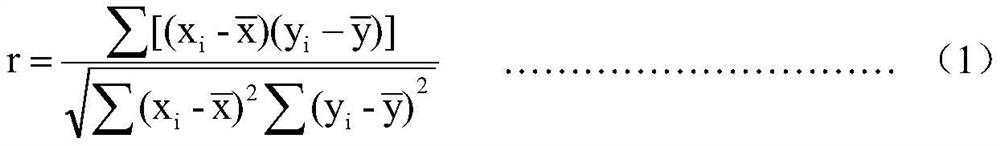

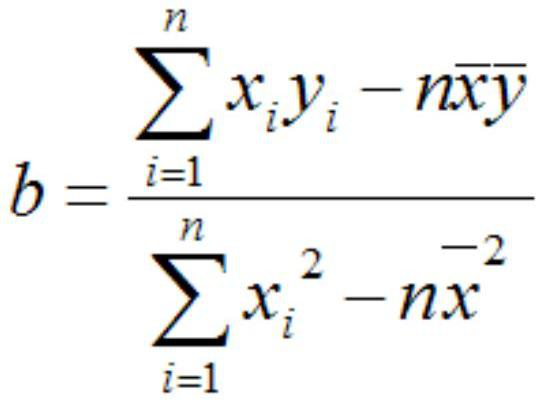

Reagent, kit and detection method for quantitative detection of blood iodine

PendingCN113340888AReduce acidityNot easily affected by manual errorsMaterial analysis by observing effect on chemical indicatorAgainst vector-borne diseasesPhenanthrolineEthyl acetate

The invention discloses a reagent, a kit and a detection method for quantitative detection of blood iodine. The reagent comprises a first composition, wherein the first composition is a combination of acetonitrile and ethyl acetate or a combination of ammonium sulfate and isopropanol; a second composition which is a combination of sodium hypochlorite and sodium chloride; a third composition which is a combination of sulfuric acid and hydrochloric acid; a fourth composition which is a combination of sodium chloride and sodium arsenite; a fifth composition which is a composition of ferrous sulfate, phenanthroline and sulfuric acid; and a sixth composition which is a combination of ceric ammonium sulfate, cerous sulfate and sulfuric acid. According to the reagent and the method for rapidly detecting iodine in serum, the digestion solution is low in acidity, the operation is simple, convenient and rapid, and the method can be synchronously used in combination with detection equipment and is not easily influenced by manual errors of experimenters, so that the experimental result is accurate and stable.

Owner:长沙塞克陆德医疗科技有限公司

A method for recovering valuable metals from arsenic-containing fumes and harmless disposal of arsenic resources

ActiveCN106834676BEasy to separateReduce tin contentProcess efficiency improvementSodium arseniteCobalt

Owner:CENT SOUTH UNIV

Preparation method and application of anti-tumor nano arsenic spheres based on invertebrate recombinant ferritin

ActiveCN110200995BEnhanced inhibitory effectInorganic active ingredientsMicroorganism based processesProtein solutionVertebrate Animals

The invention discloses a preparation method and application of an anti-tumor nano arsenic sphere based on invertebrate recombinant ferritin, which is characterized by the following steps: (1) successively through gene amplification, construction of prokaryotic expression vector and prokaryotic expression and Protein purification to obtain recombinant ferritin based on invertebrates; (2) Place recombinant ferritin based on invertebrates in a dialysis bag, dialyze in 5 mM sodium arsenite solution, and use a magnetic stirrer to simulate the entire enrichment process After dialysis for 12 hours, put the dialysis bag in the protein buffer for 12 hours of dialysis, during which the protein buffer was replaced every 4 hours, and the protein solution in the dialysis bag was taken out and concentrated to obtain recombinant iron based on invertebrates. The protein anti-tumor nano arsenic ball has the advantage of significantly inhibiting the proliferation of chronic myeloid leukocyte K562 cells.

Owner:山东北游生物科技有限公司

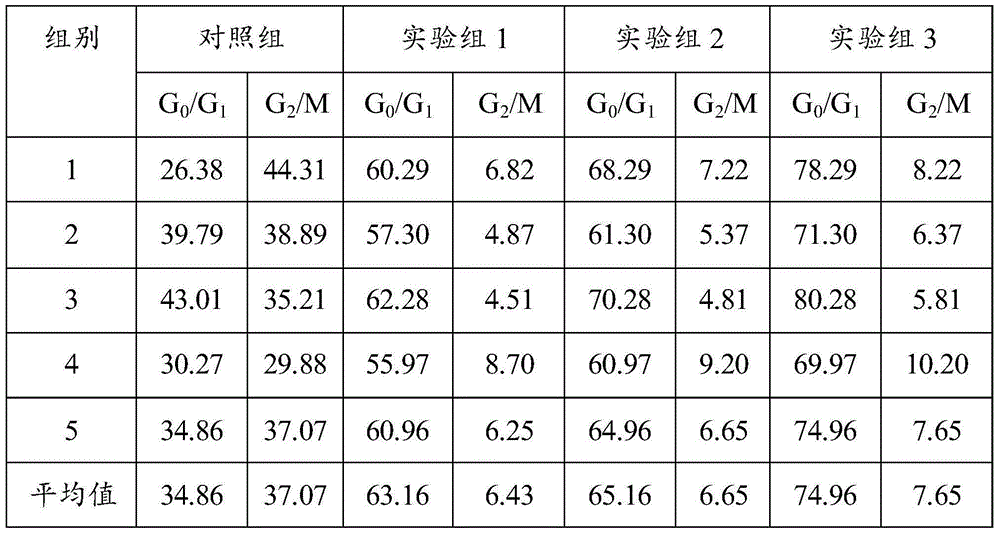

Optimized dosage of sodium arsenite for promoting synthesis and secretion of insulin in pancreatic beta cells

On the basis of studies on influence the sodium arsenite on the synthesis and secretion of insulin in pancreatic beta cells, the invention provides an optimized dosage of the sodium arsenite for promoting the synthesis and the secretion of the insulin in the pancreatic beta cells. The optimized dosage of the sodium arsenite for promoting the synthesis and the secretion of the insulin in the pancreatic beta cells is obtained from various experiments, so that the unhelpful influence of arsenic in conventional dosages on human body is changed; the proliferation of insulin cells is promoted by controlling the amount of the sodium arsenite, and the number of the insulin cells is directly linked to the treatment of such diseases as diabetics; therefore, the invention has a relatively important value on the study.

Owner:陈慧

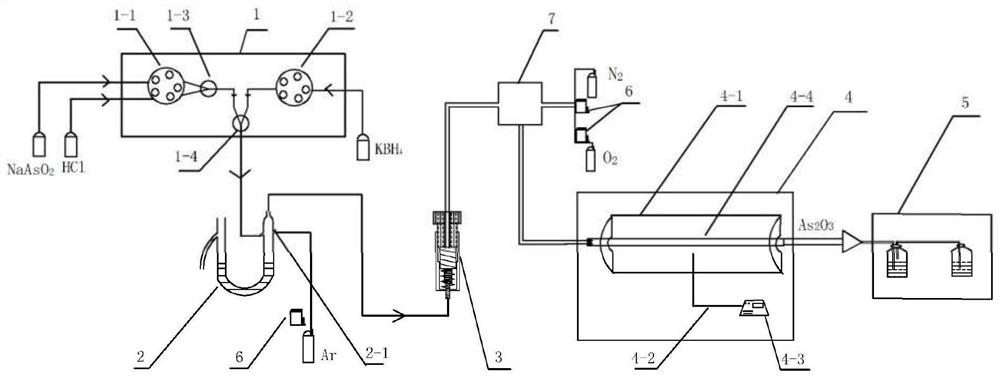

A preparation method and device for a stable arsenic trioxide standard gas

ActiveCN110398403BImprove production efficiencyImprove oxidation efficiencyArsenic oxides/hydroxides/oxyacidsPreparing sample for investigationPotassium borohydrideSodium arsenite

A stable method for preparing arsenic trioxide standard gas, comprising the following steps: generation of arsenic hydride: sodium arsenite reacts with hydrochloric acid and potassium borohydride to generate arsine gas and hydrogen gas, which are then separated by a gas-liquid separator; arsenic Atomization: The separated arsine gas and hydrogen gas enter the atomization reactor through the carrier gas, preheat at a certain temperature, and atomize the arsine gas into arsenic atoms through the flame at the furnace mouth of the atomizer ;Arsenic atomic oxidation: atomic arsenic is mixed with nitrogen and oxygen gas in the gas mixing chamber and brought into a high-temperature electric heating furnace, and fully combined with oxygen at a certain temperature to form arsenic trioxide; tail gas absorption. The present invention solves the problem of low generation efficiency of arsine by adjusting the ratio parameter of solution supply; an atomization unit is arranged after the arsenic hydride generation unit, so that arsine is pyrolyzed into atomic arsenic, and atomic arsenic is then combined with oxygen Combined with the generation of arsenic trioxide gas, the oxidation efficiency of arsenic hydrogen is greatly improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

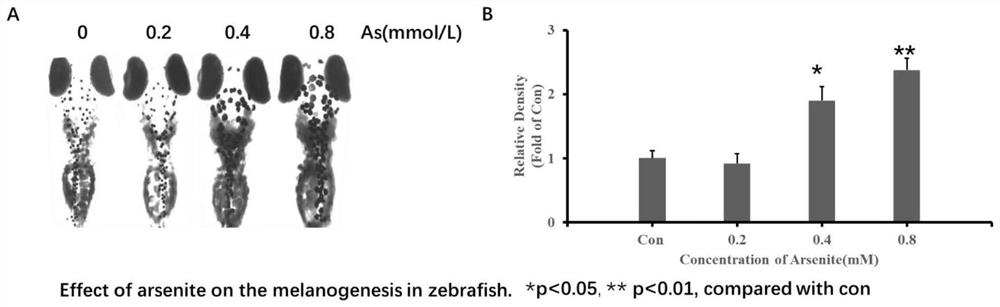

Method for constructing zebra-fish melanin deposition model

InactiveCN112920990AShorten the growth cycleBreeding is easyCulture processEmbryonic cellsAnimal scienceMicroscopic observation

The invention discloses a method for constructing a zebra-fish melanin deposition model. The method comprises the following steps: putting sexually mature zebra-fish into a mating fish tank according to male and female, and separating the male and female zebra-fish by inserting a separator; turning on a lamp to change water overnight, taking out the separator, and collecting roes after 30-60 minutes; placing the roes in a culture dish containing methylene blue, selecting fertilized fish eggs to a separated dish and adding embryo culture solution into the fertilized fish eggs for constant-temperature incubation; selecting well-developed fertilized eggs, randomly dividing the fertilized eggs into a control group and a sodium arsenite solution group, and carrying out constant-temperature culture; and performing microscopic observation on the cultured zebra-fish, and obtaining the zebra-fish melanin deposition model if the melanin generation of the sodium arsenite solution group is increased in comparison with the control group. According to the method, the zebra-fish melanin generation increasing model can be quickly established in a short time after treatment of the sodium arsenite solution. The zebra-fish is short in growth cycle, easy to reproduce, large in egg laying amount, small in size and easy to breed, so that the experimental requirements can be greatly reduced, and a simple, efficient and low-cost biological model is provided for the mechanism research of arsenic-induced skin pigmentation.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com