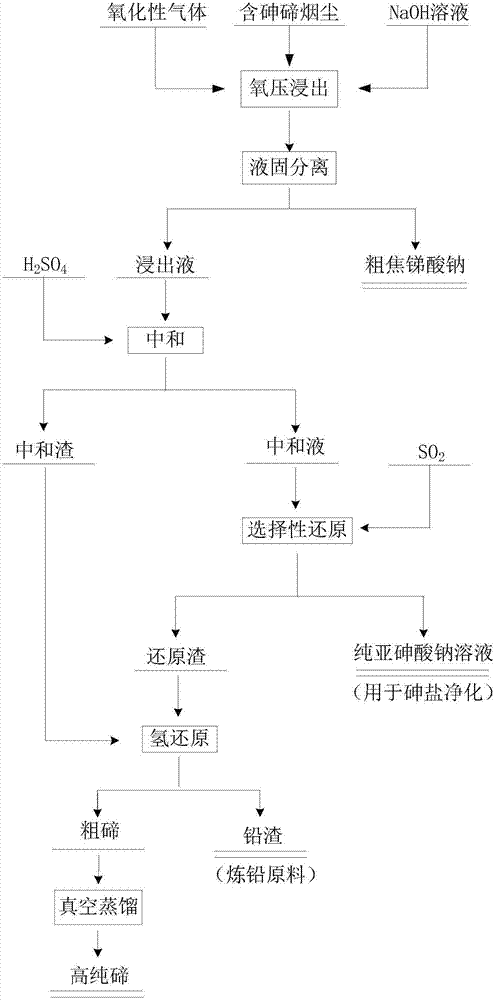

A method for recovering and preparing high-purity tellurium from arsenic-containing tellurium fumes

A high-purity tellurium and soot technology, which is applied in the field of hydrometallurgy, can solve the problems of low recovery rate of arsenic-containing tellurium soot and complex process flow, etc., and achieve the effects of a wide range of raw materials, pollution problems, and high comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Taking arsenic-containing soot from a lead-zinc smelter in China as an example, the main components of the raw materials are Pb 1.57%, As48.56%, Sn0.51%, Sb 21.24%, Zn 0.73%, Te 0.35%, Se 0.25%, and the following steps are adopted To process:

[0043] (1) Oxygen pressure leaching: Weigh a certain quality of high-arsenic and antimony fumes in the reaction kettle, according to the liquid-solid volume mass ratio of 10:1, the NaOH concentration of 3mol / L, the stirring speed of 300r / min, the leaching temperature of 160°C, and the oxygen content Pressure 2Mpa, leaching time 2h, after leaching, remove the slurry, filter and separate to obtain crude sodium antimonate and leaching solution;

[0044] After testing: the arsenic leaching rate is 41.53%, and the concentration of each element in the leach solution is Pb 709.60ppm, Se31.02ppm, Sb8.2ppm, Te 123.28ppm, As 20.17g / L.

[0045] (2) Neutralization: Add H 2 SO 4 Adjusting the pH of the leaching solution obtained in step (1...

Embodiment 2

[0050] Taking arsenic-containing soot from a lead-zinc smelter in China as an example, the main components of the raw material are Pb 6.88%, As36.51%, Sn1.11%, Sb 29.77%, Zn 0.54%, Te 0.24%, Se 0.05%, and the following steps are adopted To process:

[0051] (1) Oxygen pressure leaching: Weigh a certain quality of high arsenic and antimony fume in the reaction kettle, according to the liquid-solid volume mass ratio 5:1, NaOH concentration 5mol / L, stirring speed 300r / min, leaching temperature 200℃, oxygen content Pressure 1.5Mpa, leaching time 2.5h, after leaching, remove the slurry, filter and separate to obtain crude sodium pyroantimonate and leaching solution;

[0052] After testing: the arsenic leaching rate is 41.29%. The concentration of each element in the leachate is 515.20ppm Pb, 31.56ppm Se, 9.40ppm Sb, 122.26ppm Te, and 15.07g / L As.

[0053] (2) Neutralization: adding H to the leaching solution at a temperature of 80°C and a stirring speed of 150r / min 2 SO 4 Adjus...

Embodiment 3

[0058] Taking arsenic-containing soot from a lead-zinc smelter in China as an example, the main components of the raw material are Pb 5.46%, As 30.29%, Sn 0.98%, Sb 29.58%, Zn 0.68%, Te 0.26%, Se 0.07%, and the following steps are used deal with:

[0059] (1) Oxygen pressure leaching: Weigh a certain quality of high-arsenic and antimony fumes in the reaction kettle, according to the liquid-solid volume mass ratio of 15:1, NaOH concentration of 1mol / L, stirring speed of 400r / min, leaching temperature of 180°C, oxygen content Pressure 2Mpa, leaching time 1.5h, after leaching, remove the slurry, filter and separate to obtain crude sodium pyroantimonate and leaching solution;

[0060] After testing: the arsenic leaching rate is 86.95%, and the concentration of each element in the leach solution is Pb 956.35ppm, Se 18.91ppm, Sb9.63ppm, Te 144.92ppm, As 17.56g / L.

[0061] (2) Neutralization: under the condition that the temperature of the leachate is 40°C and the stirring speed is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com