A preparation method and device for a stable arsenic trioxide standard gas

A technology of arsenic trioxide and a flow control device, which is applied in the field of flue gas purification, can solve the problems of low efficiency of arsenic hydrogen, etc., and achieve the effects of improved generation and oxidation efficiency and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

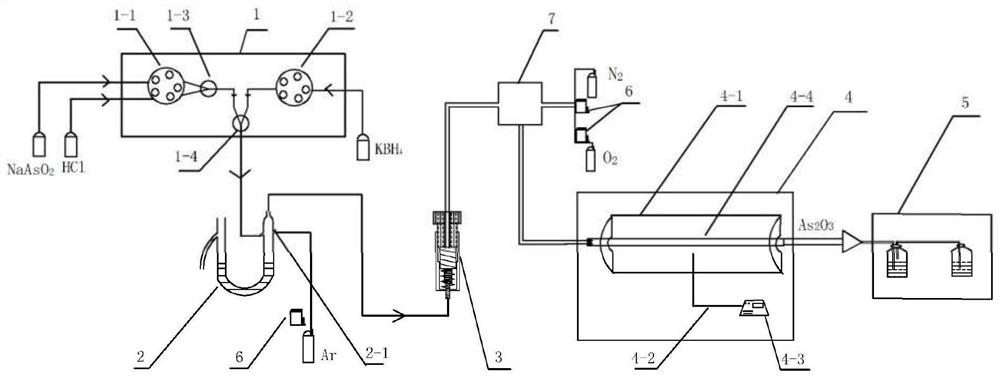

Image

Examples

Embodiment 1

[0029] When sodium arsenite with a concentration of 30 ppm is mixed with 10% (V / V) hydrochloric acid in the three-way reaction block I, it is further reacted with 0.3% (V / V) potassium borohydride in the three-way reaction block II , the generated arsine and hydrogen gas are mixed with 200 mL / min argon gas through the gas-liquid separator, and then brought into the atomization reactor (400 ℃) for atomization, and the generated atomic arsenic is mixed with 400 mL / min nitrogen and oxygen mixed gas (oxygen is 60 mL / min) for mixed oxidation, and finally arsenic trioxide gas is generated. The determination of the arsenic content in the separated mother liquor showed that the content was less than 1.5 ppm (<5%), which proved that the arsenic in the sodium arsenite device basically formed arsenic hydride and participated in the subsequent reaction. After cleaning the arsenic in the reaction tube, tail gas absorption liquid and connecting tube, it was found that the recovery rate of to...

Embodiment 2

[0031] When sodium arsenite with a concentration of 60 ppm is mixed with 10% (V / V) hydrochloric acid in the three-way reaction block I, it is further reacted with 0.5% (V / V) potassium borohydride in the three-way reaction block II, The generated arsine and hydrogen gas are mixed with 300mL / min argon gas through the gas-liquid separator, and then brought into the atomization reactor (500°C) for atomization, and the generated atomic arsenic is mixed with 500mL / min min nitrogen and oxygen mixed gas (oxygen is 100 mL / min) for mixed oxidation, and finally arsenic trioxide gas is generated. Determination of the arsenic content in the separated mother liquor showed that the content was less than 2.4 ppm (<5%). The recovery rate of total gaseous arsenic was higher than 95%, the concentration of formed arsenic was 0.047 mL / min, and the standard deviation of multiple determinations was less than 9%.

Embodiment 3

[0033] When sodium arsenite with a concentration of 120 ppm is mixed with 15% (V / V) hydrochloric acid in the three-way reaction block I, it is further reacted with 0.8% (V / V) potassium borohydride in the three-way reaction block II, The generated arsine and hydrogen gas are mixed with 600mL / min argon through the gas-liquid separator, and then brought into the atomization reactor (600°C) for atomization, and the generated atomic arsenic is mixed with 600mL / min at 750°C min nitrogen and oxygen mixed gas (oxygen is 200 mL / min) for mixed oxidation, and finally arsenic trioxide gas is generated. Determination of the arsenic content in the separated mother liquor showed that the content was less than 3.6 ppm (<5%). The recovery rate of total gaseous arsenic was higher than 94%, the concentration of formed arsenic was 0.088 mL / min, and the standard deviation of multiple determinations was less than 7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com