Patents

Literature

110results about "Arsenic oxides/hydroxides/oxyacids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for innocent treatment of low-concentration arsenic-containing waste residue and recovery of arsenic

ActiveCN106011475AEfficient leachingReduce arsenic levelsArsenic oxides/hydroxides/oxyacidsIron compoundsResource utilizationMaterials science

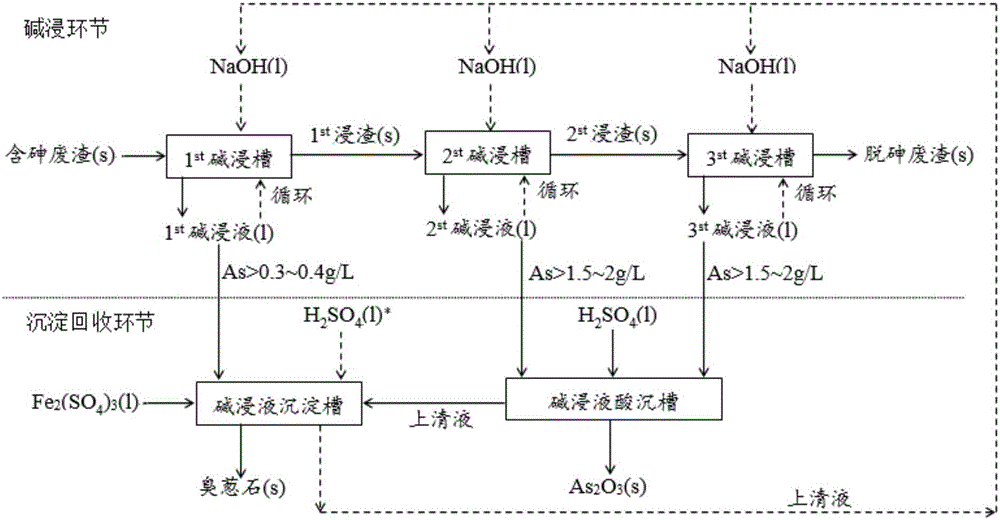

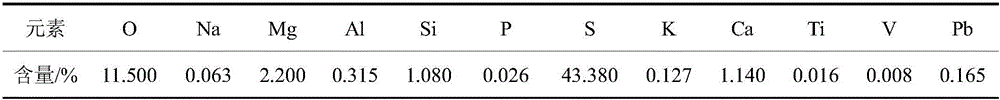

The invention relates to a method for innocent treatment of low-concentration arsenic-containing waste residue and recovery of arsenic. Aiming at low-concentration arsenic-containing waste residue, according to the invention, a multistage alkaline leaching method is adopted, wherein mechanical stirring is performed for 10-12h in the environment of 60-80 DEG C, three-stage successive leaching is adopted, the arsenic leaching rate reaches more than 80%, the arsenic content of waste residue after treatment is less than 0.05%, which is lower than the hazardous waste identification limiting value, and therefore, the waste residue can be used as making material of building materials. As2O3 in an arsenic-containing alkaline leaching solution can be recovered by acid neutralization and sedimentation, and ferric sulfate is added to a leaching solution after filtering and sedimentation so as to produce FeAsO4.2H2O sedimentation, the comprehensive arsenic removing rate of the arsenic-containing alkaline leaching solution can reach 99%, and filter liquor can be recycled. Compared with the prior art, according to the invention, no wastewater discharge is caused in the whole process, the technology is simple, and the material is easily available, and the method can be widely popularized and applied to treatment and resource utilization of low-concentration arsenic-containing solid waste.

Owner:TONGJI UNIV

Polymer-Metal Compound Composite Ink, and Preparation Method and Application Thereof

ActiveUS20180016456A1Readily availableEasy to prepareArsenic oxides/hydroxides/oxyacidsElectrical apparatusComposite filmSolvent

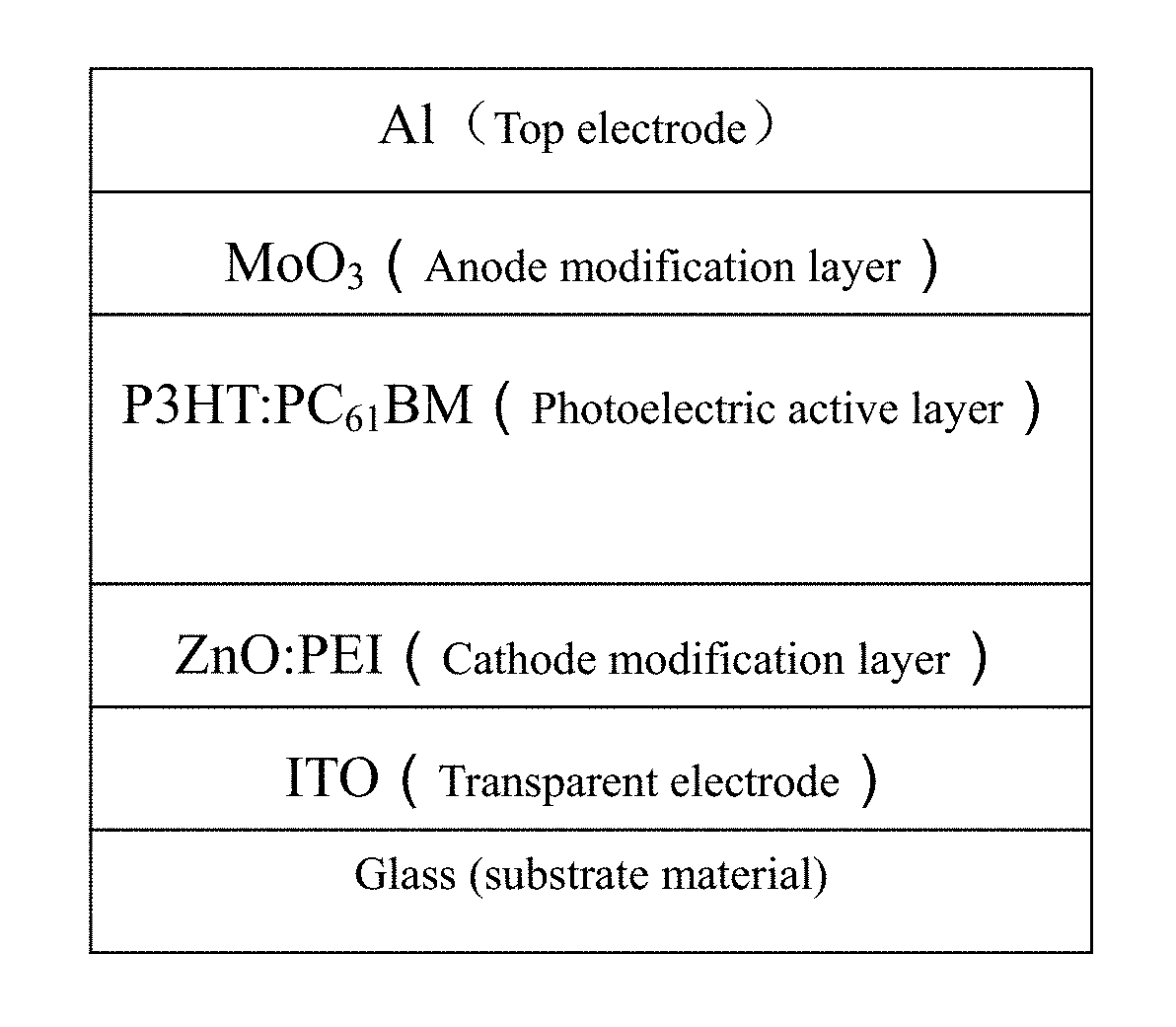

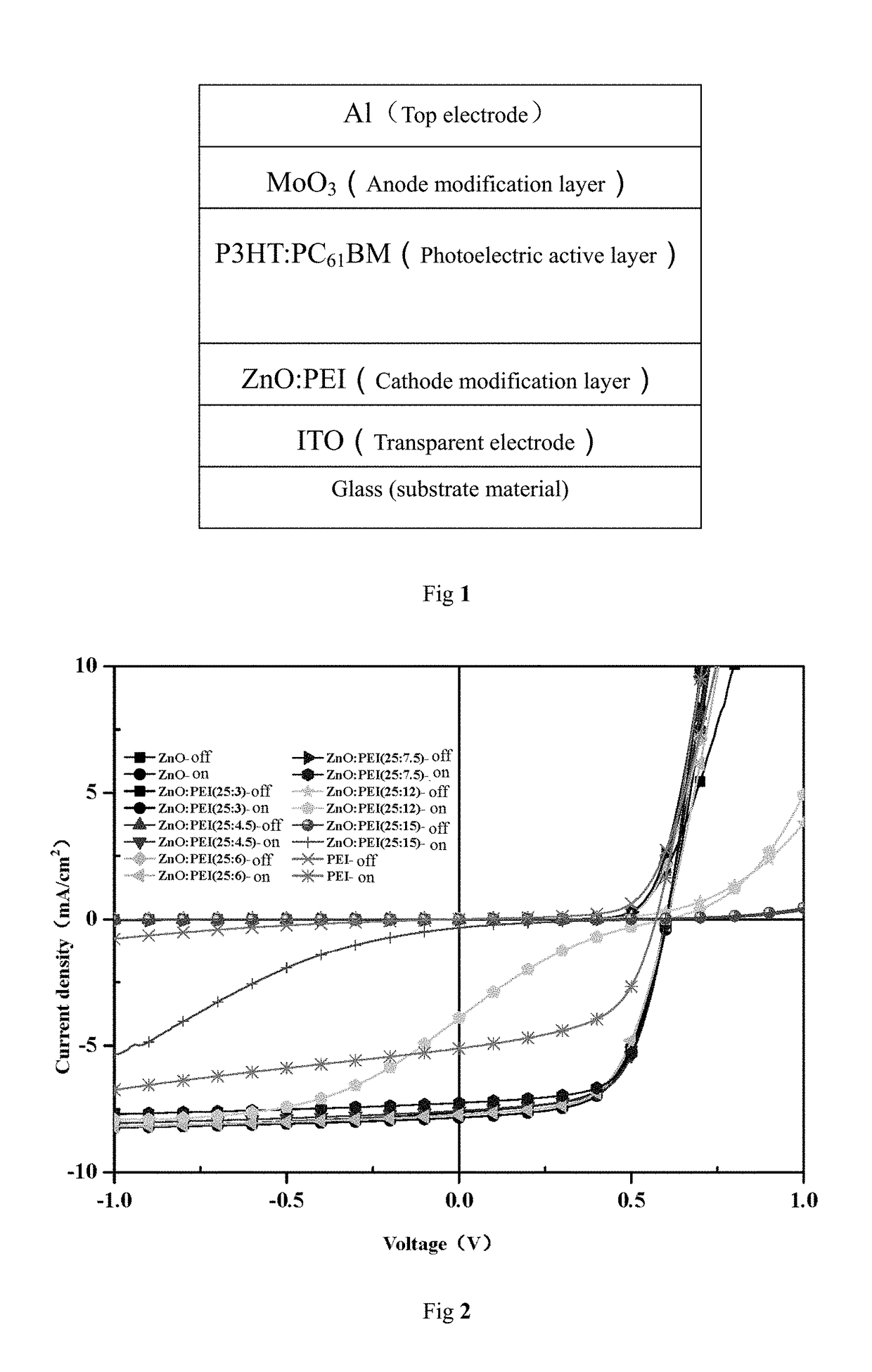

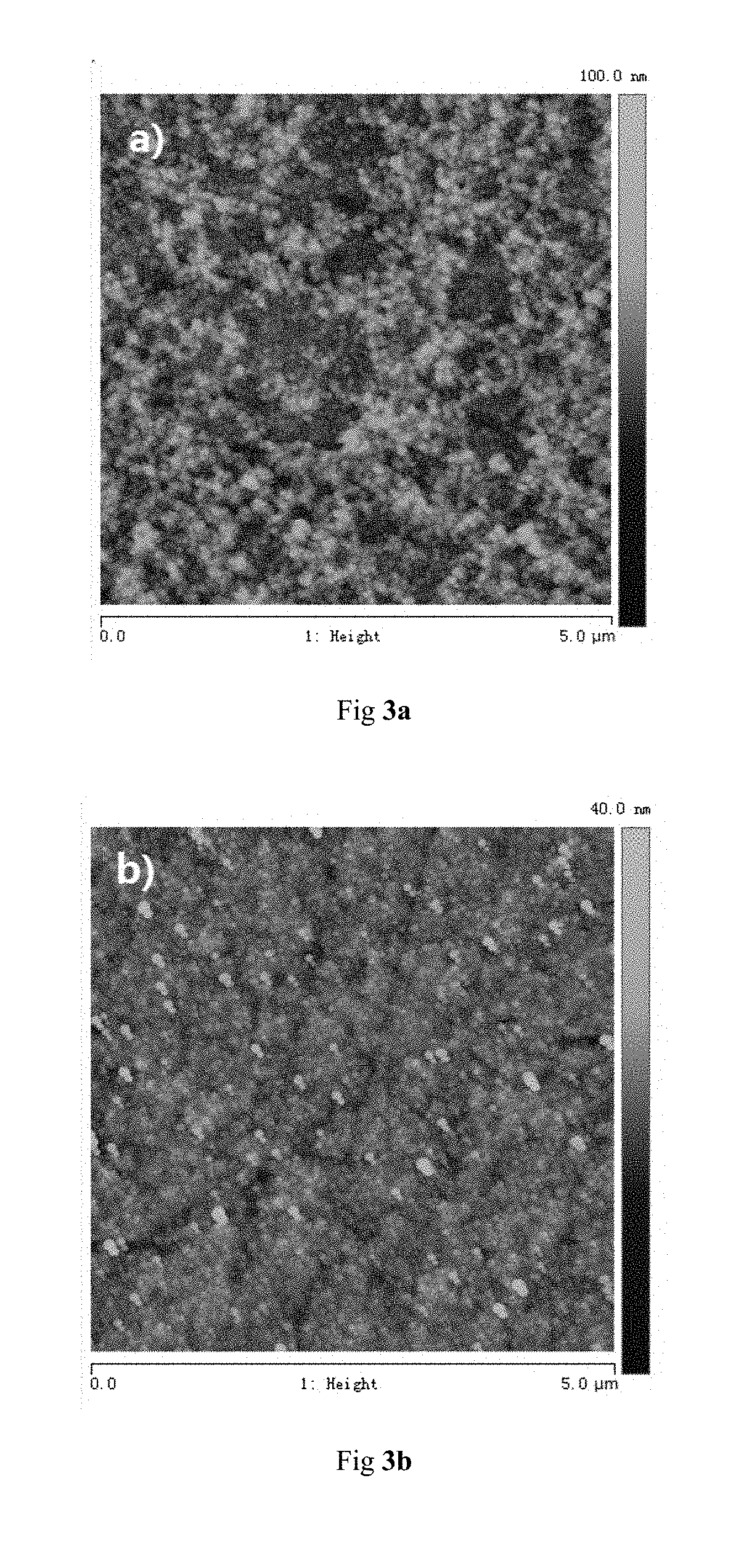

The present invention discloses a polymer-metal compound composite ink, a preparation method and application thereof. The composite ink comprises: at least one polymer; at least one metal compound material, the metal compound material being selected from polyoxometalate compounds and nanocrystalline metal oxides; at least one solvent which is used for forming a disperse system in the form of a uniform fluid together with the remaining components in the composite ink. The present invention also discloses a method for preparing the composite ink. The composite ink of the present invention is easily available in raw material, easy to prepare and low in cost, and can be manufactured into a composite thin film by spin-coating, printing or in other ways. The composite thin film, as an electrode modification layer, can be applied to photoelectric devices such as solar cells or light-emitting diodes, so as to improve the contact performance between an electrode and an organic active layer and thus enhance the performance and yield of photoelectric devices.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

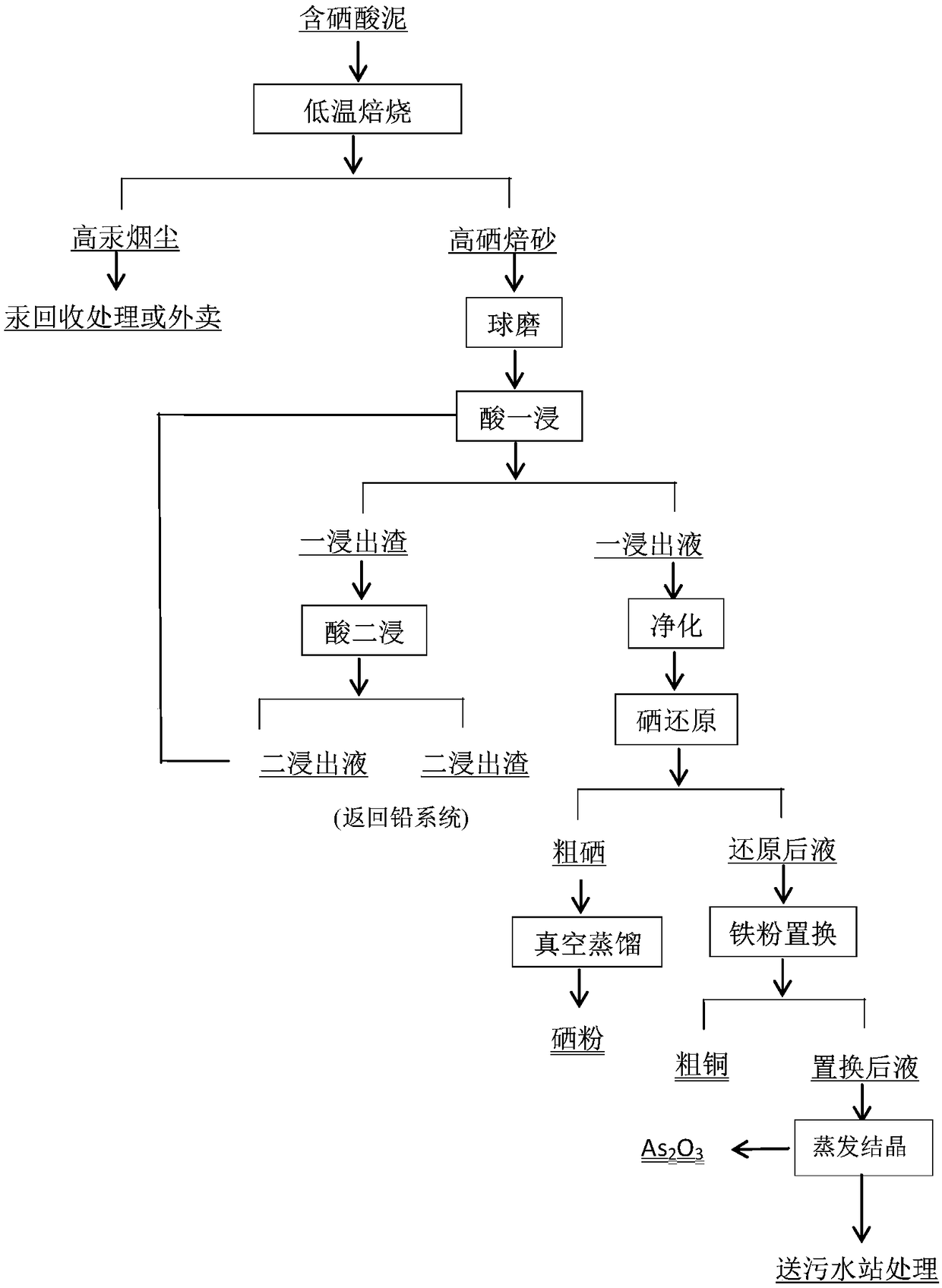

Method of recovering valuable metal from selenium-containing acid mud

InactiveCN109055719AAvoid environmental problemsAvoid pollutionArsenic oxides/hydroxides/oxyacidsProcess efficiency improvementMaterials scienceReducing agent

The invention belongs to the field of comprehensive recovery and utilization of metallurgical waste slags, and discloses a method of recovering valuable metal from selenium-containing acid mud. The method comprises the following steps that A, low-temperature roasting is carried out, the low-temperature roasting is carried out on the selenium-containing acid mud, a mercury removal rate of the roasted selenium-containing acid mud is roasted to 99% or above, and high-mercury smoke dust and high-selenium roasted sand slag is obtained; B, first acid leaching is carried out on the roasted slag; C, second acid leaching is carried out on the roasted slag, the first acid leaching is conducted on second acid leaching solution, and the slag is recycled to a lead system; D, selenium reduction is carried out, a reducing agent is added into the first leaching solution obtained in the step C to carry out reduction on selenium to prepare crude selenium; E, copper replacement is carried out, iron powder is added into the reduced post-liquid obtained in the step D to carried out displacement and reduction on copper, and high-grade copper slag is obtained; and F, the post-liquid obtained in the stepE is reduced, evaporated, concentrated, cooled, crystallized to recycle arsenic, and the wastewater is sent to a wastewater station for treatment. The method of recovering valuable metal from the selenium-containing acid mud has the remarkable characteristics of simple process operation, no environmental pollution, high recovery value, low operation cost and high economic benefit.

Owner:CHENZHOU FENGYUE ENVIRONMENTAL PROTECTION TECH

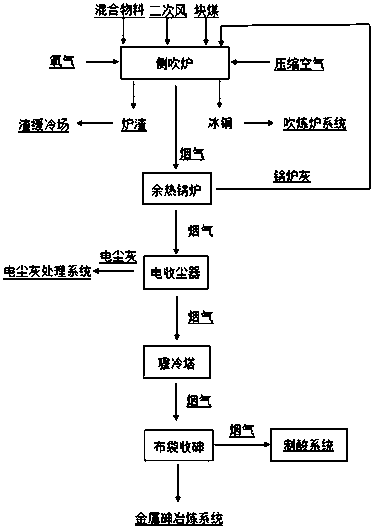

Method, with a side blowing furnace, of treating high-arsenic ore

InactiveCN110438346AAdaptableIncrease relative volatilityArsenic oxides/hydroxides/oxyacidsEnergy inputSulfurAlloy

The invention discloses a method, with a side blowing furnace, of treating high-arsenic ore. The method comprises the following steps that the high arsenic ore is mixed with lead matte, quartz, coal and the like; and after the steps of oxidation, matte making, reduction and oxidation, copper is transformed into the matte, sulfur is transformed into sulfur dioxide and arsenic is transformed into arsenic trioxide for recycling, and precious metal alloys containing gold, silver and copper are obtained, and lead-containing smoke dust is obtained by the reduction - oxidation of lead. The method adopts side blowing furnace to treat high arsenic ore and comprehensively recover valuable elements such as copper, lead and arsenic, so that the method has the characteristics of strong adaptability ofraw materials, concentrated distribution of valuable elements, remarkable economic and environmental benefits.

Owner:SHANDONG HUMON SMELTING

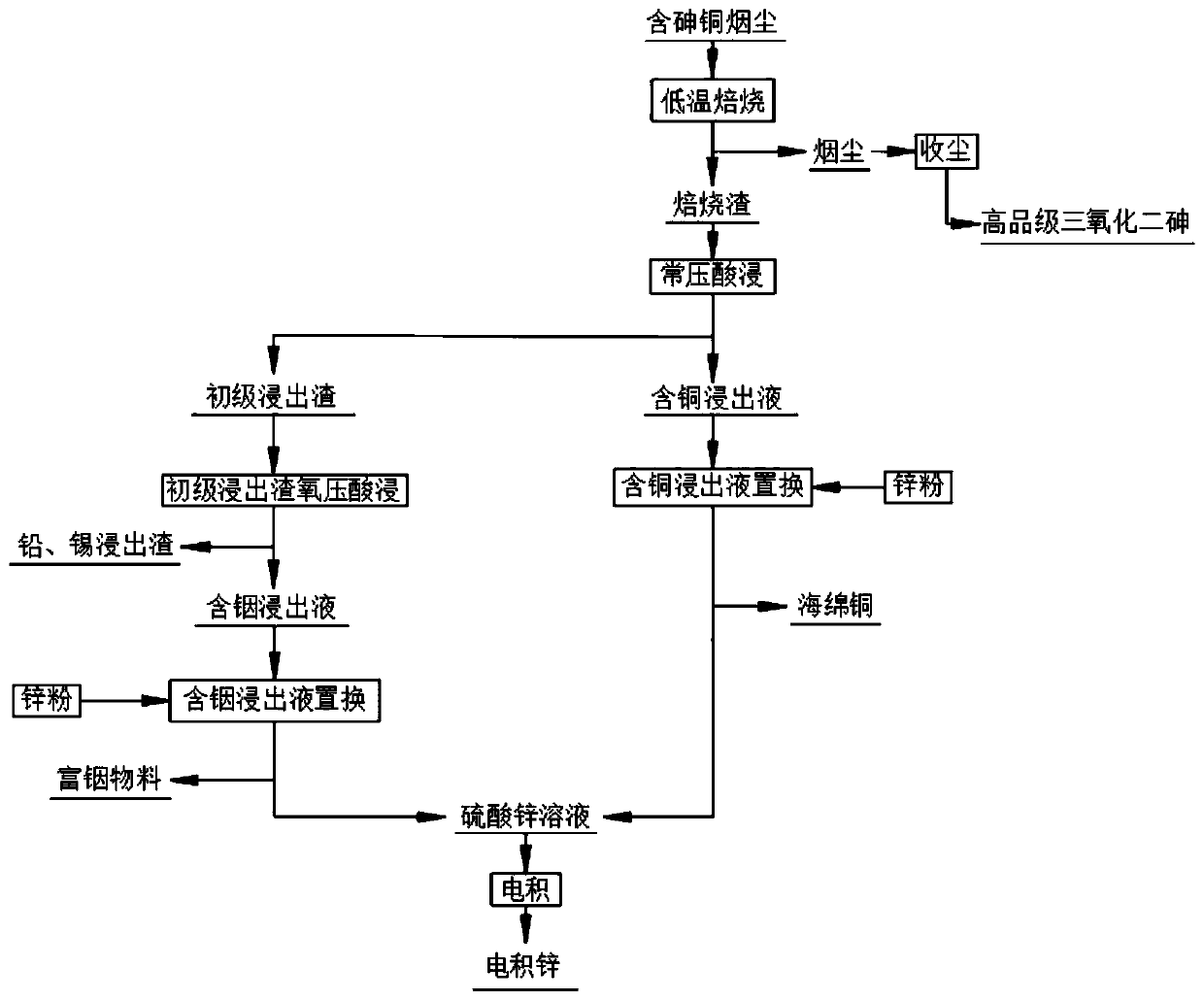

Method for comprehensively recovering valuable metals from arsenic-containing copper smoke dust

InactiveCN110093510AImprove direct yieldQuality improvementPhotography auxillary processesArsenic oxides/hydroxides/oxyacidsPregnant leach solutionIndium

The invention discloses a method for comprehensively recovering valuable metals from arsenic-containing copper smoke dust. The method comprises the following steps that low-temperature roasting is carried out, wherein low-temperature roasting is carried out on the arsenic-containing copper smoke dust in a rotary kiln, smoke dust and roasting slag are obtained during roasting, wherein the smoke dust is arsenic trioxide, and then dust collecting treatment is further carried out on the smoke dust to obtain the high-grade arsenic trioxide; normal pressure acid leaching is carried out, specially leaching is carried out on the obtained roasting slag by adopting sulfuric acid with the concentration of 150-200 g / L, and a copper-containing leaching solution and primary leaching slag are obtained atthe moment; replacement is carried out on the copper-containing leaching solution; oxygen-pressure acid leaching is carried out on the primary leaching slag, and specifically the primary leaching slag is treated by adopting an oxygen-pressure acid leaching method to obtain an indium-containing leaching solution and lead-and-tin-containing slag; replacement is carried out on the indium-containingleaching solution; electrodeposition treatment is carried out on a zinc sulfate solution; and electrodeposition treatment is carried out on the obtained zinc sulfate solution to obtain electrodeposition zinc. In the application process, the method has the advantages that the direct yield of the valuable metal is high, the process is short, arsenic-calcium slag is not generated, and the applicationis facilitated.

Owner:TONGREN UNIV

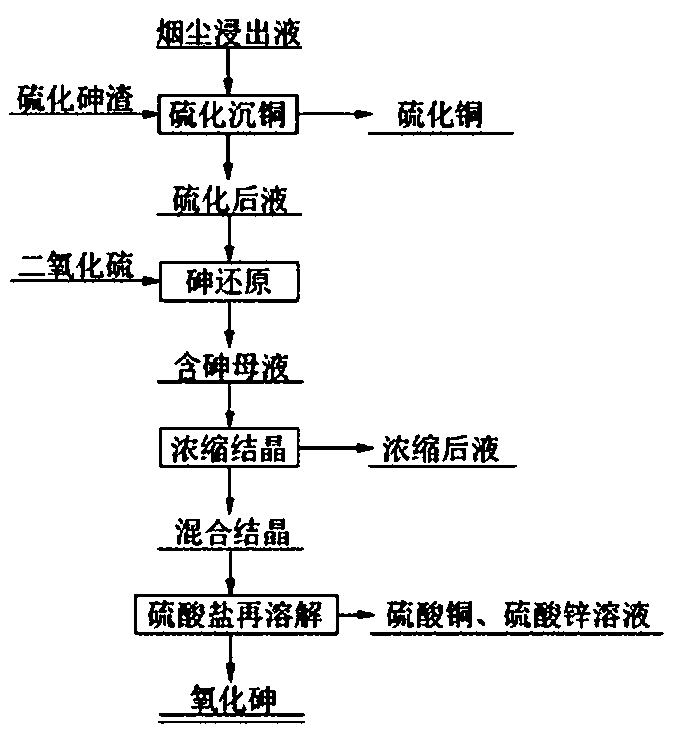

Comprehensive recovery method for arsenic in arsenic sulfide residues and smoke leaching liquid in copper smelting

InactiveCN108249480AHarmless maximizationMaximize resourcesZinc sulatesArsenic oxides/hydroxides/oxyacidsRecovery methodVulcanization

The invention provides a comprehensive recovery method for arsenic in arsenic sulfide residues and a smoke leaching liquid in copper smelting. The smoke leaching liquid and the arsenic sulfide residues are subjected to normal-pressure vulcanization copper precipitation treatment to obtain solid state copper sulphide and a vulcanized liquid; the vulcanized liquid is discharged into a reaction tankII, and sulfur dioxide is introduced into the reaction tank II to make the vulcanized liquid converted into an arsenic-containing mother liquid; the arsenic-containing mother liquid is discharged intoa reaction tank III, the arsenic-containing mother liquid is subjected to concentration and crystallization, and filtration is performed to obtain a sulfate mixed crystal and a concentrated liquid; the sulfate mixed crystal is added into a reaction tank IV, copper sulfate and zinc sulfate in the sulfate mixed crystal are dissolved into water, and filtration is performed to obtain arsenic oxide and a solution of the copper sulfate and the zinc sulfate. The method provided by the invention has the advantages that the process collocation is reasonable, parameters in each process are strictly controlled, the arsenic can be safely disposed, and valuable elements such as copper, lead and zinc are recycled and effectively utilized, the purposes of environmental protection, economy, energy conservation and a high resource utilization rate are achieved, and harmlessness and resource utilization maximization of the arsenic are realized.

Owner:DONGYING FANGYUAN NONFERROUS METALS +2

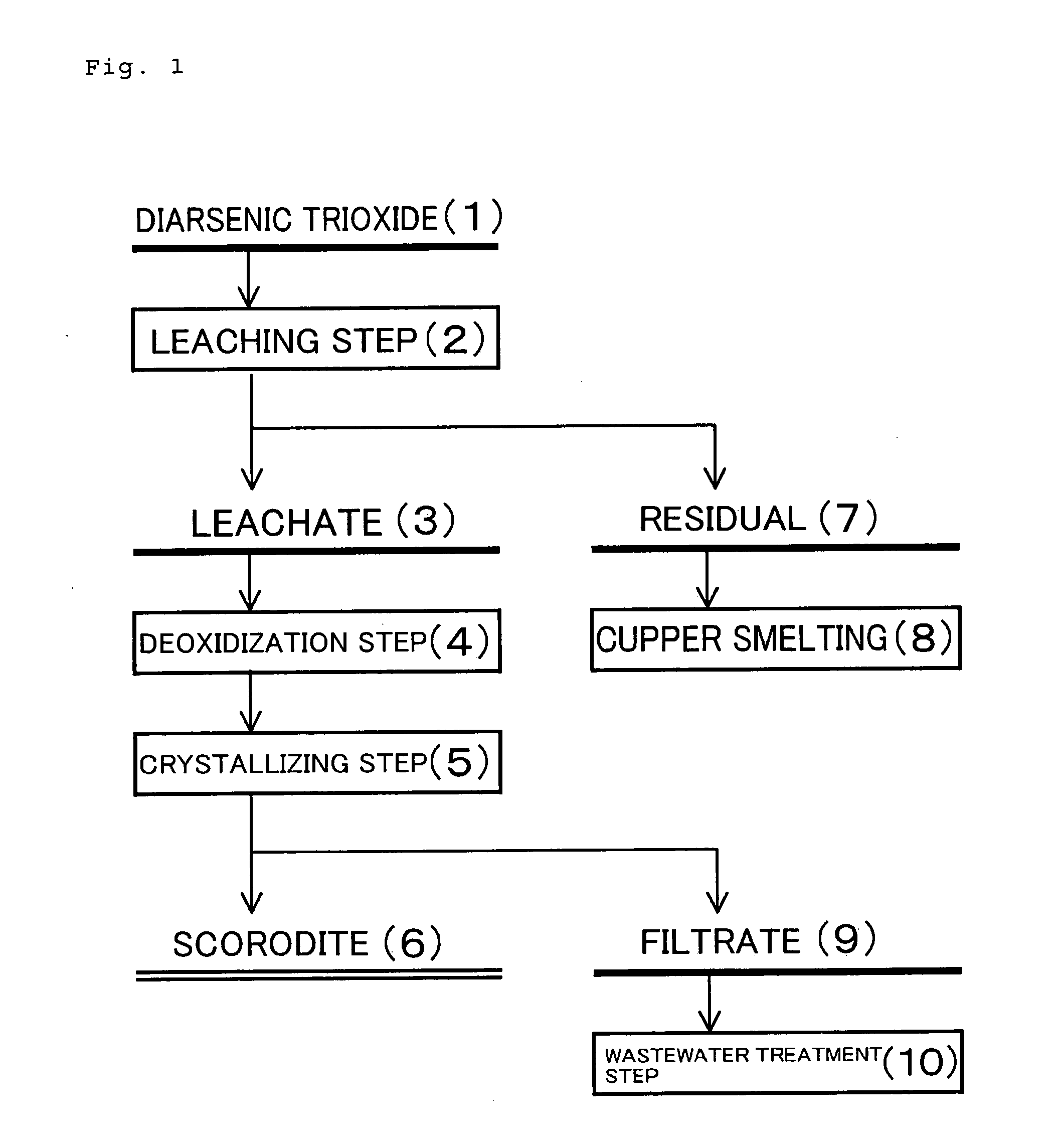

Method of processing diarsenic trioxide

ActiveUS20100266484A1Good filterbilityImprove stabilityArsenic oxides/hydroxides/oxyacidsAntimony compoundsElutionSlurry

To provide a method of generating, with good reproducibility and ease and without complicated operations, scorodite which satisfies the elution standard (in accordance with Notification of No. 13 of Japanese Environment Agency) and which has good filterbility and stability for processing arsenic contained in a diarsenic trioxide form. A method of processing diarsenic trioxide, including: a leaching step of adding water to diarsenic trioxide to produce slurry, heating the slurry, and leaching arsenic while adding an oxidant to obtain leachate; a deoxidization step of removing the oxidant so as to obtain an adjusted solution; and a crystallizing step of converting arsenic in the adjusted solution to scorodite crystal.

Owner:DOWA METALS & MINING CO LTD

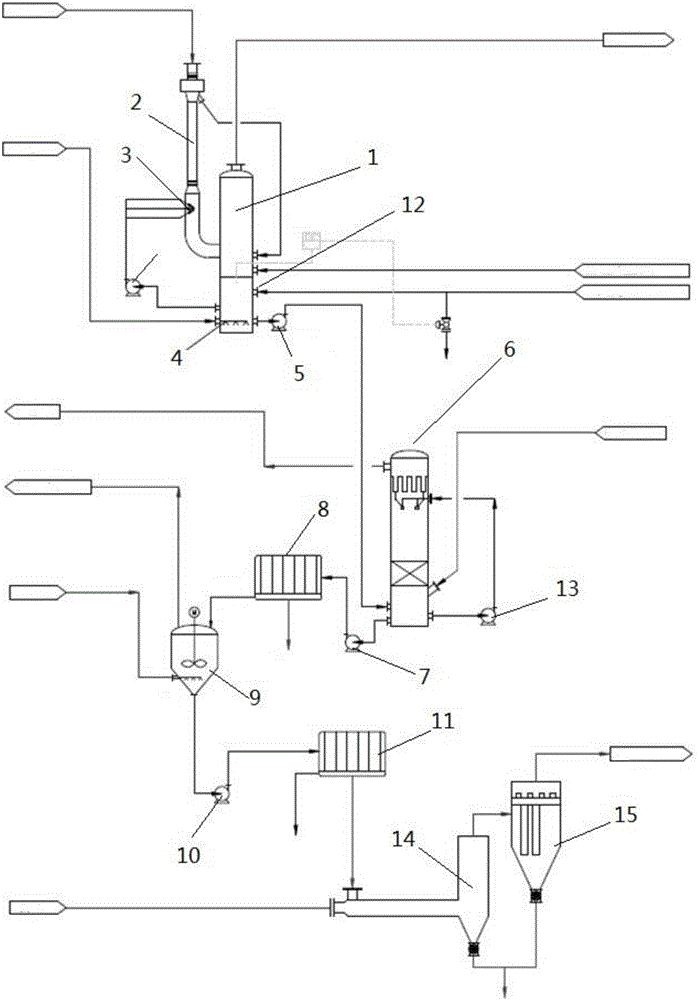

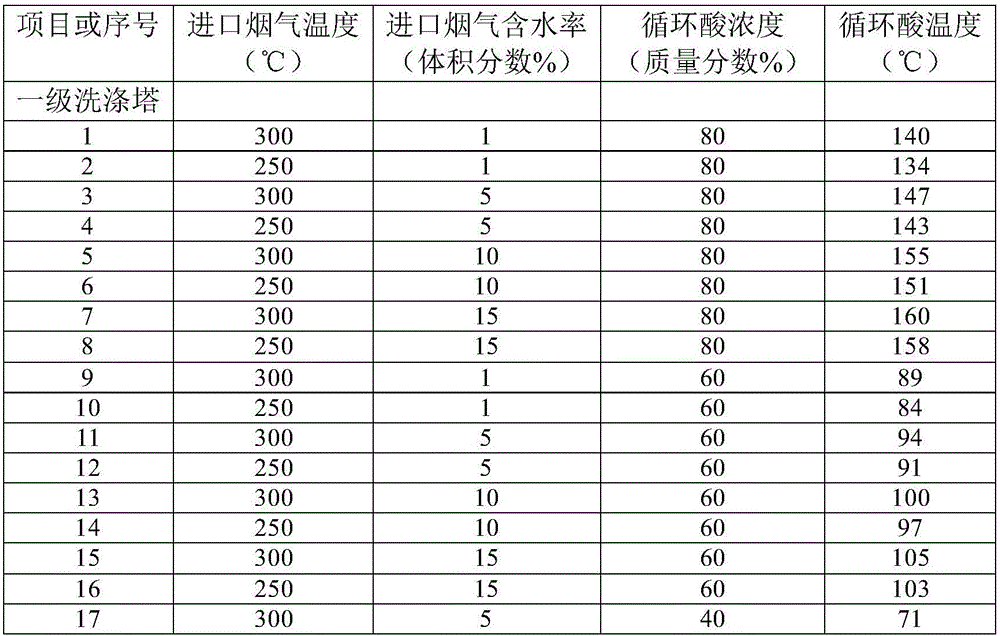

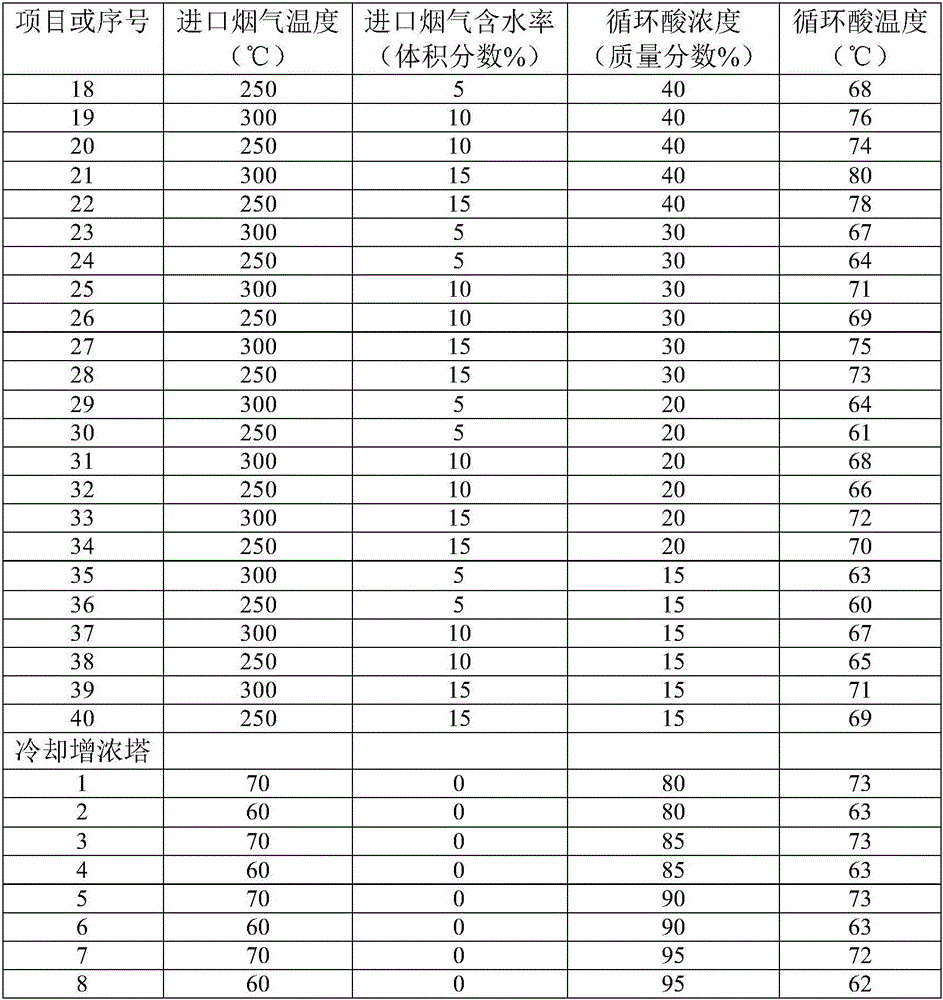

Energy saving process and system for comprehensively recycling waste acid of sulfuric acid purification

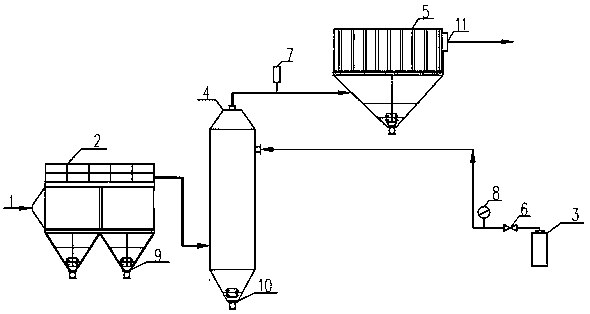

ActiveCN106268179ALow running costReduce solubilityGas treatmentArsenic oxides/hydroxides/oxyacidsHigh concentrationSlag

The invention discloses an energy saving process for comprehensively recycling waste acid of sulfuric acid purification. The energy saving process comprises the following steps: high-temperature flue gas is fed into a first-stage washing tower; acidic liquor at the bottom of a tower is pumped to an acid discharging spraying head in a gas inlet pipeline of the first-stage washing tower, and the acidic liquor is in contact with the high-temperature flue gas reversely to absorb SO3 in the flue gas; the flue gas washed by the acidic liquor is cooled and then enters a subsequent conventional purification process for continuous cooling, and condensed diluted acid generated in the subsequent cooling process is returned into the first-stage washing tower to keep the SO3 and water in the tower balanced; heavy metal dust and arsenic elements in the flue gas form sulfate and arsenious acid after being washed by the acidic liquor; a compressed air aeration device oxidizes the arsenious acid in the acidic liquor into arsenic acid; the acidic liquor containing the arsenic acid and the heavy metal acid salt is conveyed into a cooling and thickening tower; concentrated acid from the cooling and thickening tower is filtered by a slag filter to filter out heavy metal sulfate slag; filtrate enters an SO2 reducing tank, and high-concentration SO2 gas is fed into the tank, so that the arsenic acid is reduced into arsenious acid precipitates which can be slightly dissolved in the sulfuric acid; the acidic liquor containing the arsenious acid precipitates is subjected to solid-liquid separation to obtain an arsenious acid filter cake.

Owner:中铝环保节能集团有限公司

Method for recycling gold and silver from high-arsenic gold concentrate

InactiveCN111057865AEfficient recyclingReduce energy consumptionArsenic oxides/hydroxides/oxyacidsProcess efficiency improvementPregnant leach solutionSlag

The invention relates to a method for recycling gold and silver from high-arsenic gold concentrate and relates to the field of gold concentrate smelting. The method comprises the following steps: feeding high-arsenic gold concentrate in a two-section fluidized bed roaster for desulfuration and dearsenification; adding certain amount of sulfuric acid in roasted slag to remove copper, and opening part of ferric oxide parcels; enabling acid leaching slag to enter a following leaching system after solid-liquid separation, and adding lime in acid leaching solution, controlling pH value to produce multi-metal arsenious slag and iron-containing gypsum slag, returning to the acid leaching procedure; in the leaching procedure, adopting the normal temperature and normal pressure chlorination processgold extracting technology to rapidly extract gold and silver; after being adsorbed by active silica, enabling the leaching solution to enter a smelting workshop to generate finished product of silver and gold; after extracting gold and silver, adopting the chemical method to remove impurities from the leaching solution, recovering activity through diaphragm electrodeposition, and returning to leach. According to the method, the gold and silver recovery rate is high, the output quantity of hazardous wastes is small, the method takes the wet process as the principal thing, and energy consumption is less.

Owner:烟台市金奥环保科技有限公司

Method for separating lead, arsenium and copper in high-lead high-arsenium copper slag

ActiveCN111154984AReduce consumptionRealize separation and recoveryArsenic sulfidesArsenic oxides/hydroxides/oxyacidsSmelting processSulfidation

The invention discloses a method for separating lead, arsenium and copper in high-lead high-arsenium copper slag. The method includes the steps that the high-lead high-arsenium copper slag and accessories are added into a smelting furnace to be smelted at the temperature of 1,000-1,100 DEG C; arsenic trioxide and arsenic sulfide generated in the smelting process volatilize into smoke dust; the copper and the lead are vulcanized into sulfide, and the sulfide is precipitated at the bottom of the furnace to form lead copper matte; the arsenium is separated; lead sulfide in the obtained lead copper matte is oxidized into lead oxide to form high-lead slag to be recovered; low-lead copper matte left at the bottom of the furnace is blown to form crude copper; and the lead and the copper are separated. The method is short in process and high in treatment efficiency, harmful matter does not directly make contact with people in the whole treatment process, and therefore the perniciousness of theharmful matter is greatly reduced. The consumption of additional reagents is avoided, the copper, the lead and the arsenium can be well separated, and the high recovery rate is achieved. All elementsin the high-lead high-arsenium copper slag are efficiently separated under the conditions of being low in cost, low in consumption, short in process and free of pollution, and good social and economic benefits are achieved.

Owner:HENAN YUGUANG GOLD & LEAD

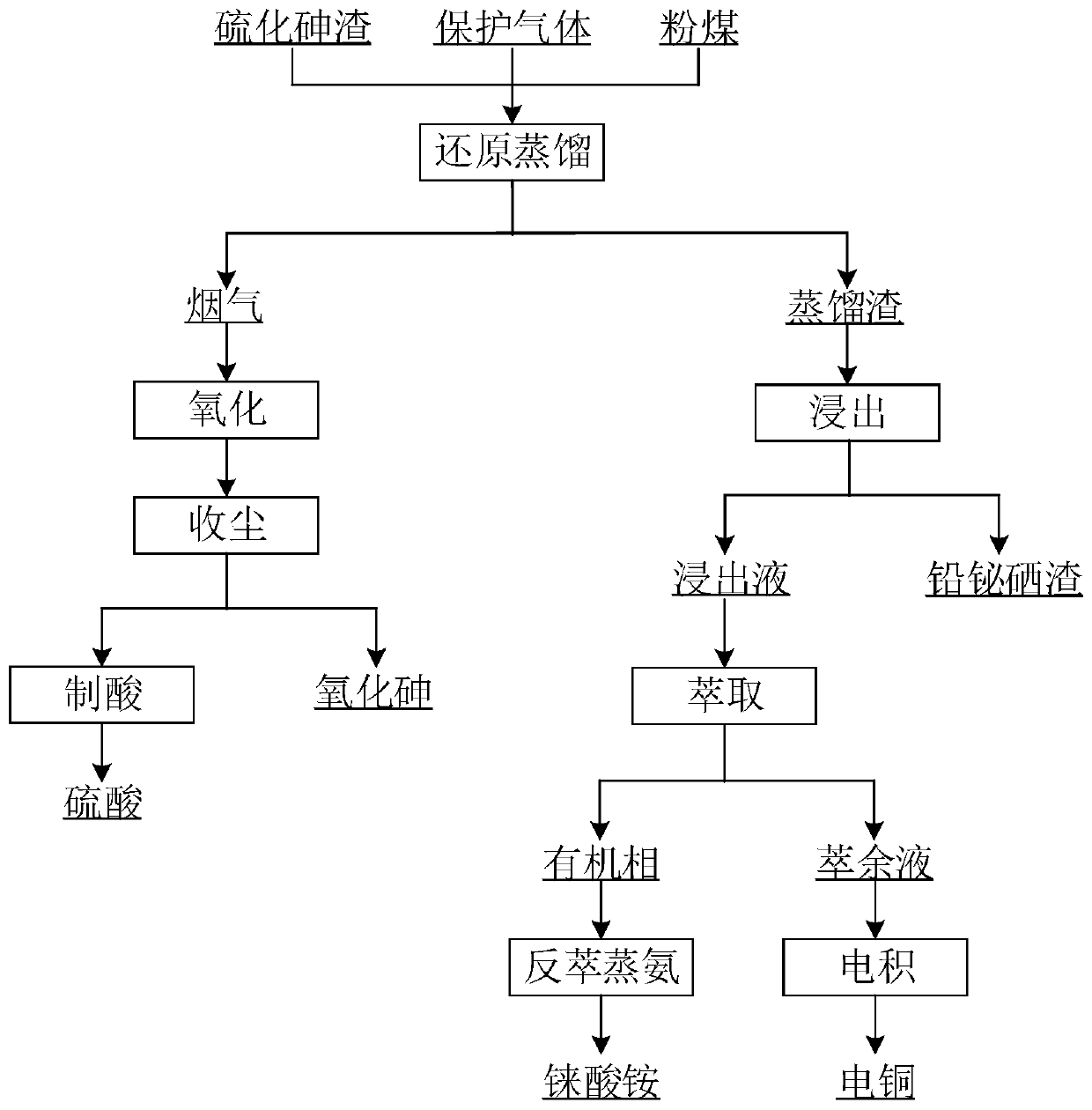

Arsenic sulfide slag comprehensive recovering process

InactiveCN111004917AAchieve separationRealize comprehensive utilizationArsenic oxides/hydroxides/oxyacidsSulfur-trioxide/sulfuric-acidRheniumSlag

The invention discloses an arsenic sulfide slag comprehensive recovering process. The recovering process comprises the following steps: (1) reductive distillation: arsenic sulfide slag and a reducingagent are mixed in protective gas for selective distillation to obtain mixed gas, the mixed gas is oxidized by air to generate arsenic oxide and sulfur dioxide, arsenic oxide is obtained by condensation, and sulfur dioxide is made into acid to obtain sulfuric acid products; (2) oxygen pressure leaching: distillation residues are subjected to oxygen pressure leaching, valuable metals such as copperand rhenium are selectively leached, rhenium is extracted and recovered from a leach solution, raffinate is subjected to electrowinning or evaporation, electric copper or copper sulfate is produced,leach residues contain lead, bismuth and selenium, and lead residues after alkaline leaching and selenium recovery are used as a lead recovery raw material. The process has the beneficial effects thatarsenic sulfide is directly distilled out in a reducing atmosphere in the arsenic sulfide distillation stage, volatilization waste of valuable metals due to oxidation roasting is avoided, arsenic andsulfur are effectively recovered, and valuable metals such as lead, copper, rhenium, bismuth and selenium are enriched.

Owner:湖南腾驰环保科技有限公司

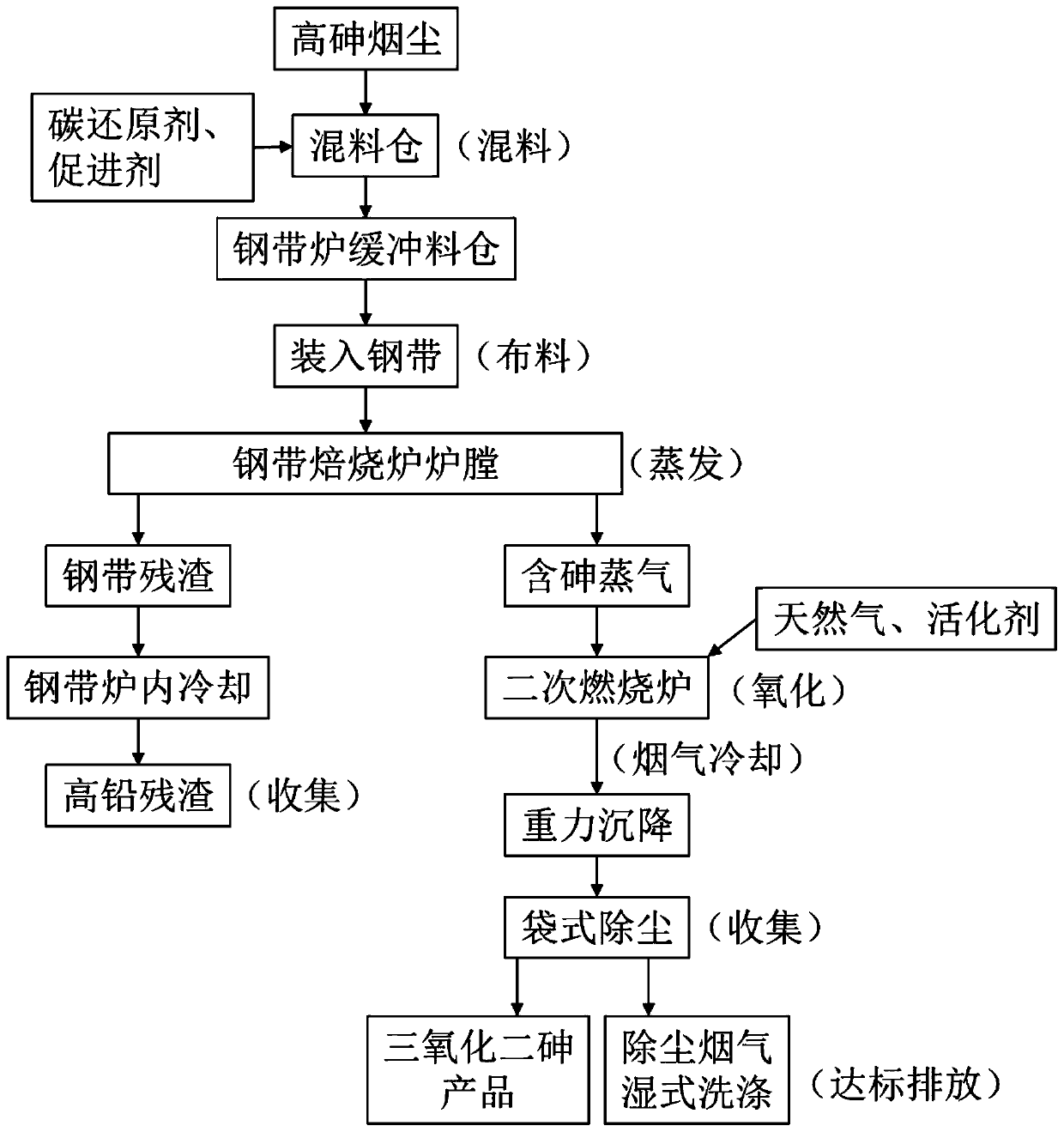

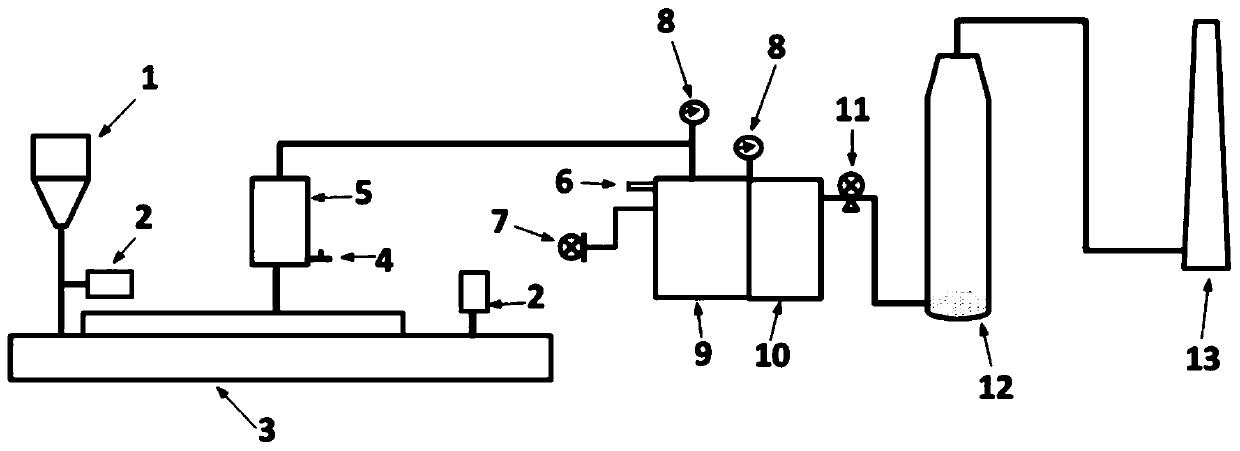

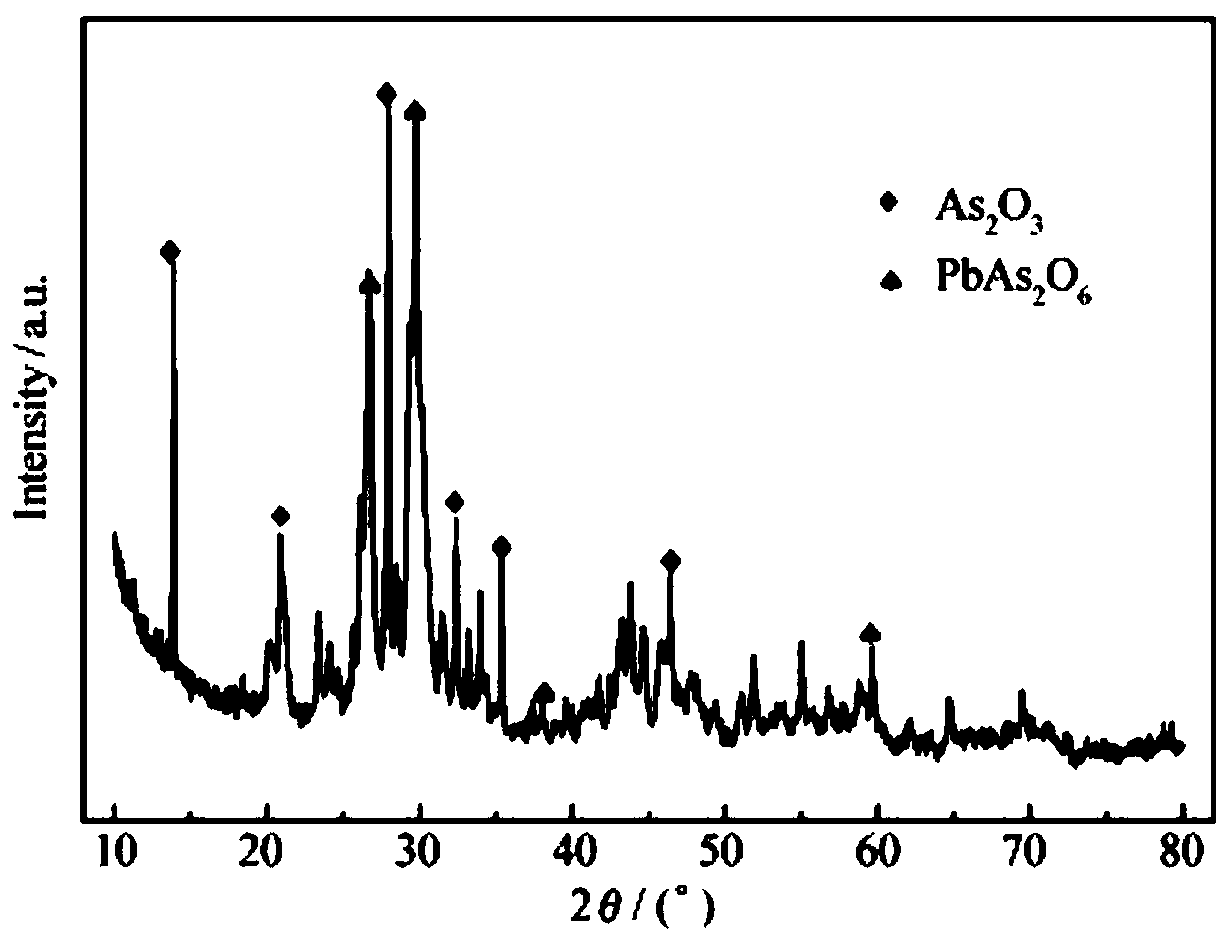

Method and device for recycling arsenic from high arsenic smoke

PendingCN111440954ARealize resourcesAchieve reductionCombination devicesArsenic oxides/hydroxides/oxyacidsReducing agentArsenide

The invention discloses a method for recycling arsenic from high arsenic smoke. The method comprises the steps that the high arsenic smoke and a carbon reducing agent are mixed to obtain a high arsenic smoke mixed material, and the high arsenic smoke mixed material is roasted in an inert atmosphere or a reducing atmosphere to obtain arsenious tail gas and high-lead ash residue; the arsenious tailgas is introduced into a combustion furnace, an activating agent is injected into the combustion furnace through a pulse powder injection valve for combustion, and high-temperature flue gas is obtained; and the high-temperature flue gas is condensed to obtain arsenic trioxide. A device for recycling arsenic from high arsenic smoke comprises a roasting furnace, the combustion furnace, a settling chamber, a dust remover, a spray tower and an externally-discharging chimney which sequentially communicate with one other; and the roasting furnace comprises a hearth and a continuous feeding device for guiding the high arsenic smoke into the hearth for roasting, and a material mixing cabin is arranged above the continuous feeding device. According to an arsenic removal technology, the arsenic removal selectivity and stability are good, the arsenic removal efficiency reaches up to 96.0% and above, and arsenic compounds obtained by purification reach 98.0% and above.

Owner:河南昌宜有色金属有限公司

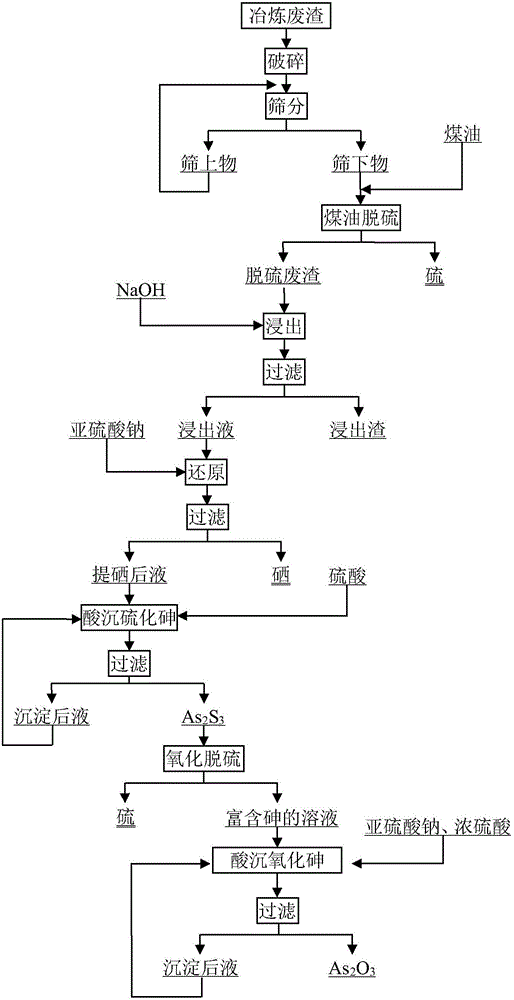

Method for recycling valuable elements in high-sulfur nickel-molybdenum ore smelting waste

ActiveCN106145054AEliminate the effects ofRealize comprehensive utilizationArsenic oxides/hydroxides/oxyacidsSulfur compoundsArsenic sulfideMaterials science

The invention discloses a method for recycling valuable elements in high-sulfur nickel-molybdenum ore smelting waste. The method includes the first step of pretreatment and desulfurization of smelting waste, the second step of leaching of arsenic and selenium, the third step of extraction of selenium, the fourth step of preparation of arsenic sulfide, the fifth step of oxidative desulfurization of arsenic sulfide, and the sixth step of preparation of arsenic trioxide. The method solves the key technical problems that in a traditional process, the recycling rate of target elements is low, the energy consumption is high, poisonous gas such as SO2, SeO2 and As2O3 is likely to be generated and leak, dust flies, and environmental pollution is caused; the metallurgical purposes of low carbon and environmental friendliness are achieved; selenium is recycled, arsenic and sulfur in smelting waste are also recycled, the influence of arsenic on the environment is fundamentally eliminated, elemental sulfur, selenium powder and arsenic trioxide products meeting national standard requirements are synthesized, waste is turned into wealth, comprehensive utilization of secondary waste resources is achieved, and thus the method has good economic benefits, environmental protection benefits and social benefits.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

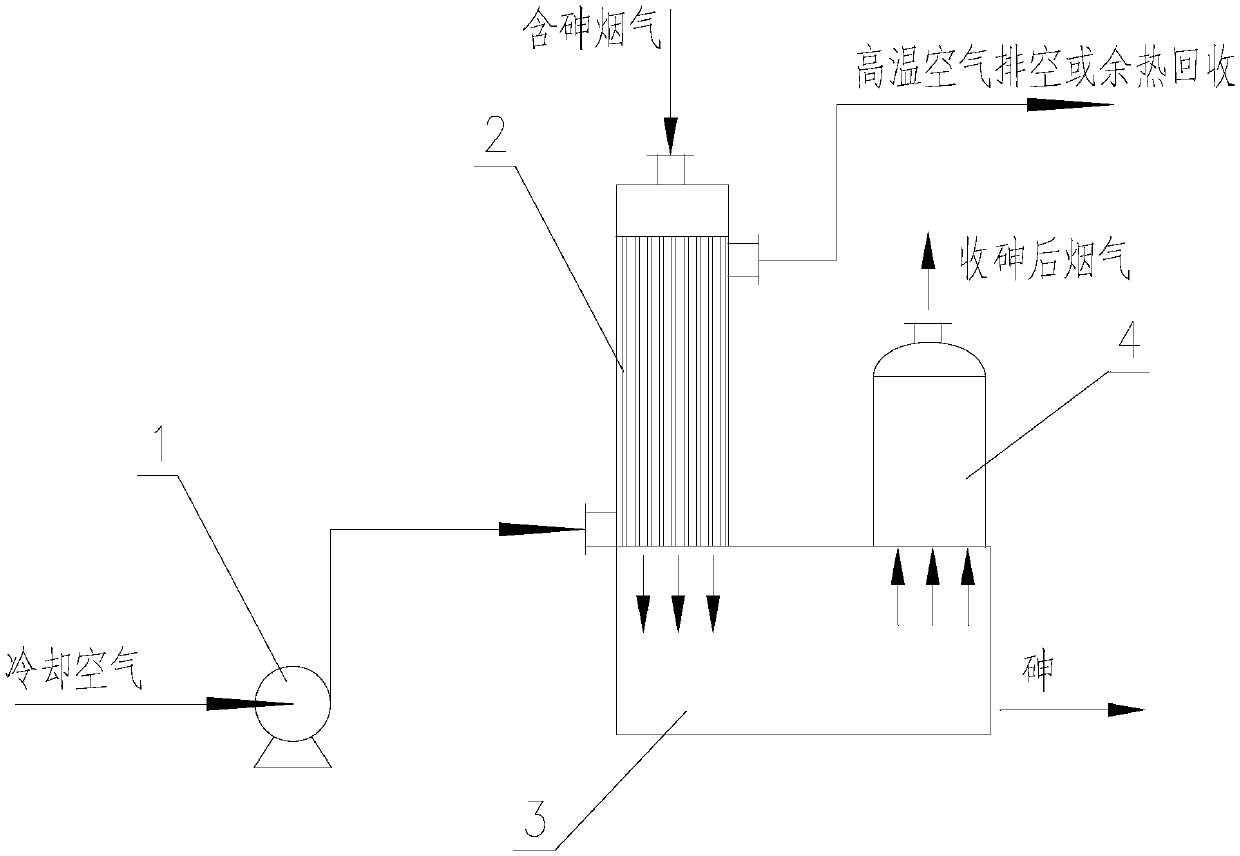

Treatment method and device for incineration arsenic-containing flue gas

PendingCN108339361ANo secondary pollutionNo heat pollutionCombination devicesArsenic oxides/hydroxides/oxyacidsTechnical gradeMaterials science

The invention discloses a treatment method and device for incineration arsenic-containing flue gas. The treatment method comprises the following steps: the incineration arsenic-containing flue gas ofwhich the temperature is higher than 313 DEG C is introduced in a ceramic tube dust collector for dust collection, the flue gas after dust collection enters a mixing chamber, liquid nitrogen is introduced in the mixing chamber, and is in reverse contact with the flue gas to reduce the temperature of the flue gas to 30 DEG C, part of arsenic trioxide particles separated out through temperature reduction are sedimentated to the bottom of the mixing chamber to be discharged, the rest of arsenic trioxide particles enter an electric dust collector along with the flue gas to complete collecting, andthe flue gas after arsenic removal is directly discharged. A large amount of heat is absorbed through vaporization of liquid nitrogen, and the solidification range of amorphous arsenic trioxide is quickly crossed, so that crystal form arsenic trioxide is obtained to the maximum limit; liquid nitrogen entering the flue gas does not react with a gas component, and the chemical property of the gas component is not changed; arsenic is collected with electricity and is only removed; and no water is used in the whole process, so that water consumption and the subsequent water treatment cost are reduced greatly, an industrial arsenic trioxide product is produced, and environmental benefits and social benefits are improved.

Owner:KUNMING UNIV OF SCI & TECH

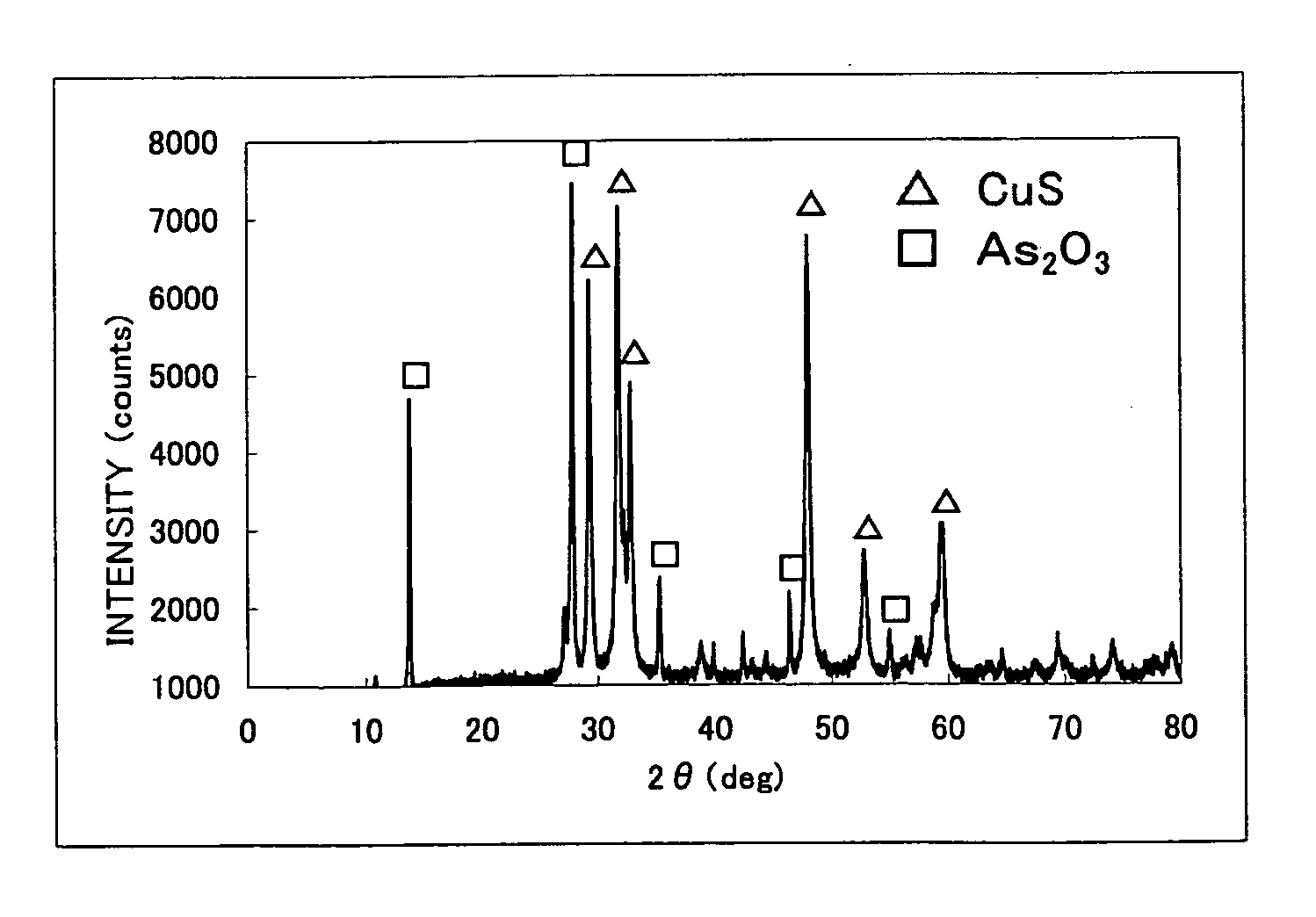

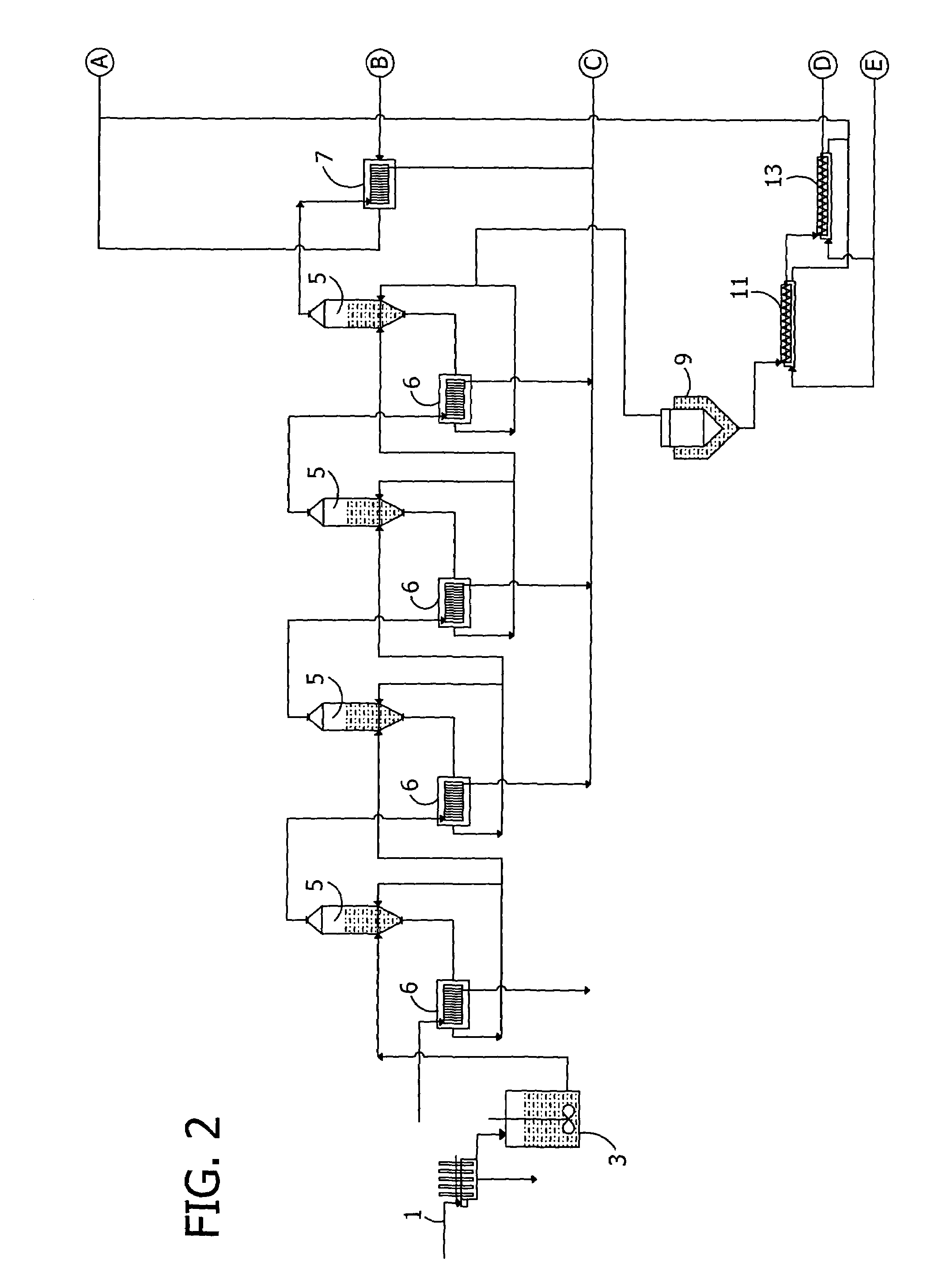

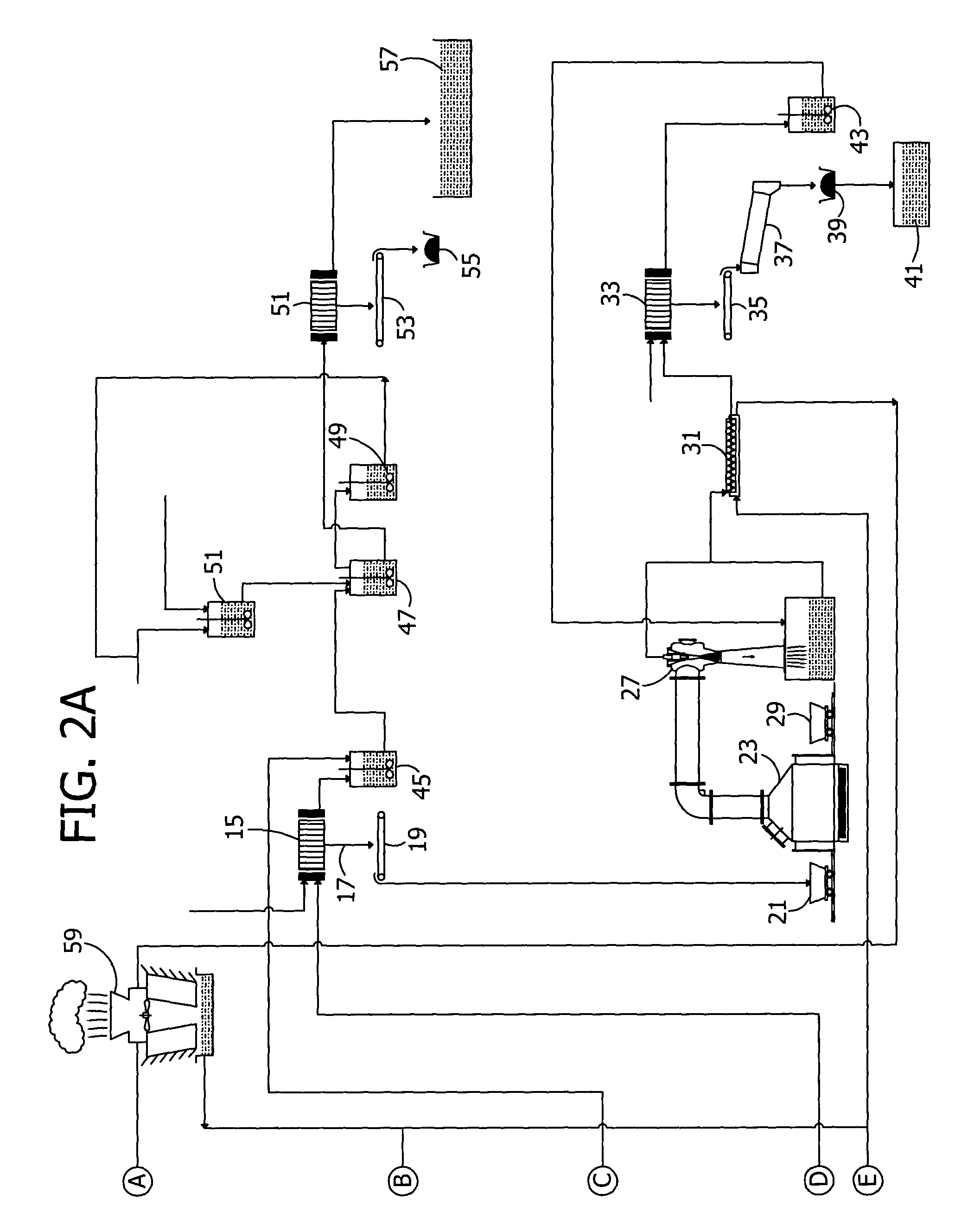

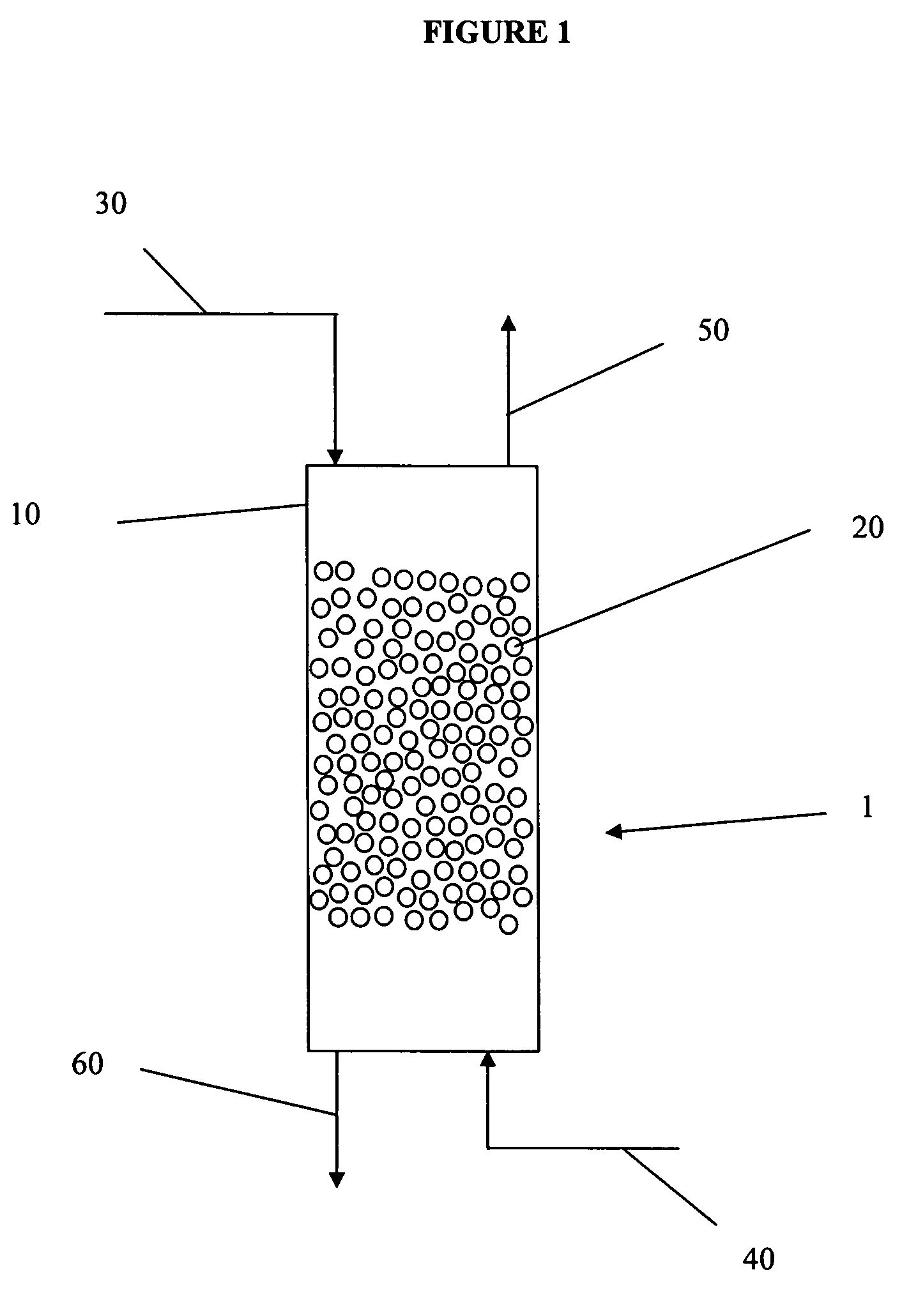

Process for recovering arsenic from acidic aqueous solution

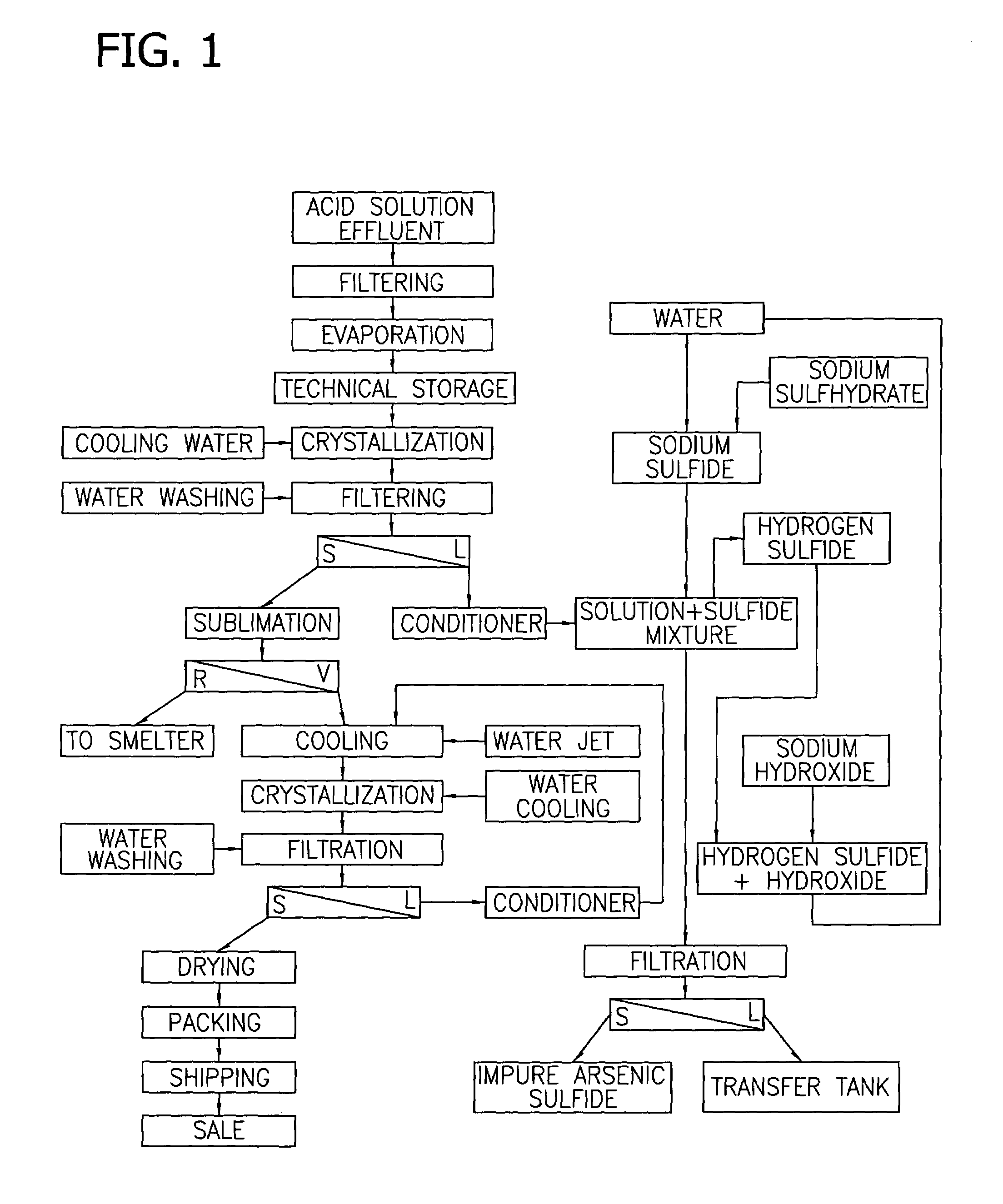

InactiveUS7232554B2Minimizing their potentially negative effects on the environmentArsenic oxides/hydroxides/oxyacidsSedimentation separationProduct gasCopper sulfide

A process for the recovery of arsenic trioxide from acid solutions, particularly the aqueous acid effluent produced by a gas-washing process in the pyrometallurgy of copper sulfide ores is provided. Generally, the process comprises concentrating the acid solution in one or more evaporators in series; crystallizing arsenic contained in the concentrated solution as arsenic trioxide crystals; filtering the crystallized solution to obtain a solid phase comprising impure arsenic trioxide crystals; and purifying the solid phase to obtain a purified crystal product comprising arsenic trioxide. The process produces a commercially salable arsenic trioxide product without producing any solid or liquid residues subject to special handling or treatment regulations.

Owner:BARRICK GOLD

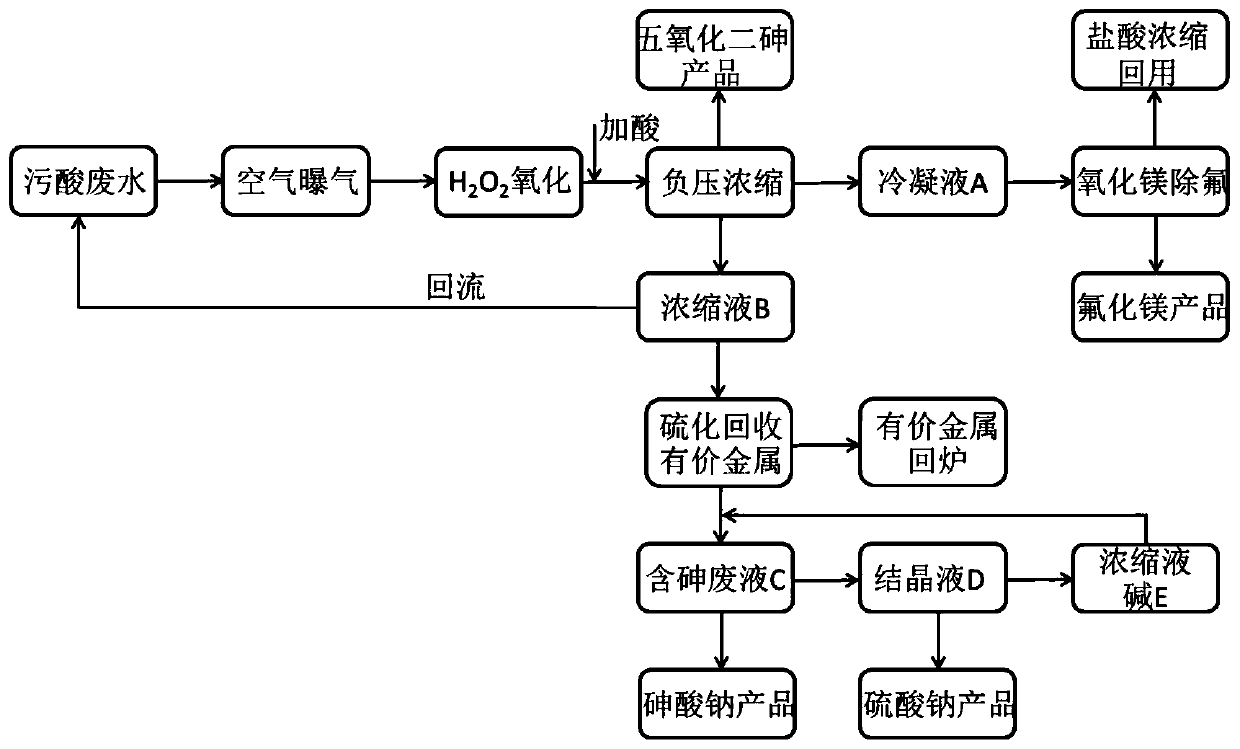

Method for resource utilization of waste sulfuric acid wastewater produced in copper smelting and acquisition of arsenic-containing products

ActiveCN111018229ANothing producedIncrease the areaMagnesium fluoridesChlorine/hydrogen-chloride purificationArsenic oxideArsenic pentoxide

The invention belongs to the technical field of industrial sewage treatment, and particularly discloses a method for resource utilization of waste sulfuric acid wastewater produced in copper smeltingand acquisition of arsenic-containing products. The method comprises the following steps: 1, oxidization of trivalent arsenic: oxidizing the waste sulfuric acid wastewater by air and hydrogen peroxidein sequence; 2, separation of arsenic from fluorine and chlorine: carrying out negative pressure evaporation after oxidation to obtain a condensate A containing fluorine and chlorine, a concentratedsolution B and arsenic pentoxide crystals; 3, separation of fluorine and chlorine: absorbing the condensate A with magnesium oxide to obtain a magnesium fluoride product and diluted hydrochloric acid;4, recovery of valuable metal: adding a sodium sulfide solution into the concentrated solution B to obtain a valuable metal precipitate and arsenic-containing waste liquid C, and returning the valuable metal precipitate to a furnace for refining; and 5, crystallization: adding caustic soda flakes or recycled concentrated alkali liquor E into the arsenic-containing waste liquor C, adjusting a pH value to 13.5-14.0 to obtain a sodium arsenate product and a crystallized filtrate D, filtering the crystallized filtrate D, and conducting concentrating to obtain a sodium sulfate product and the concentrated alkali liquor E. According to the method, waste sulfuric acid wastewater is subjected to resource recycling, and arsenic pentoxide and sodium arsenate products are obtained.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES +1

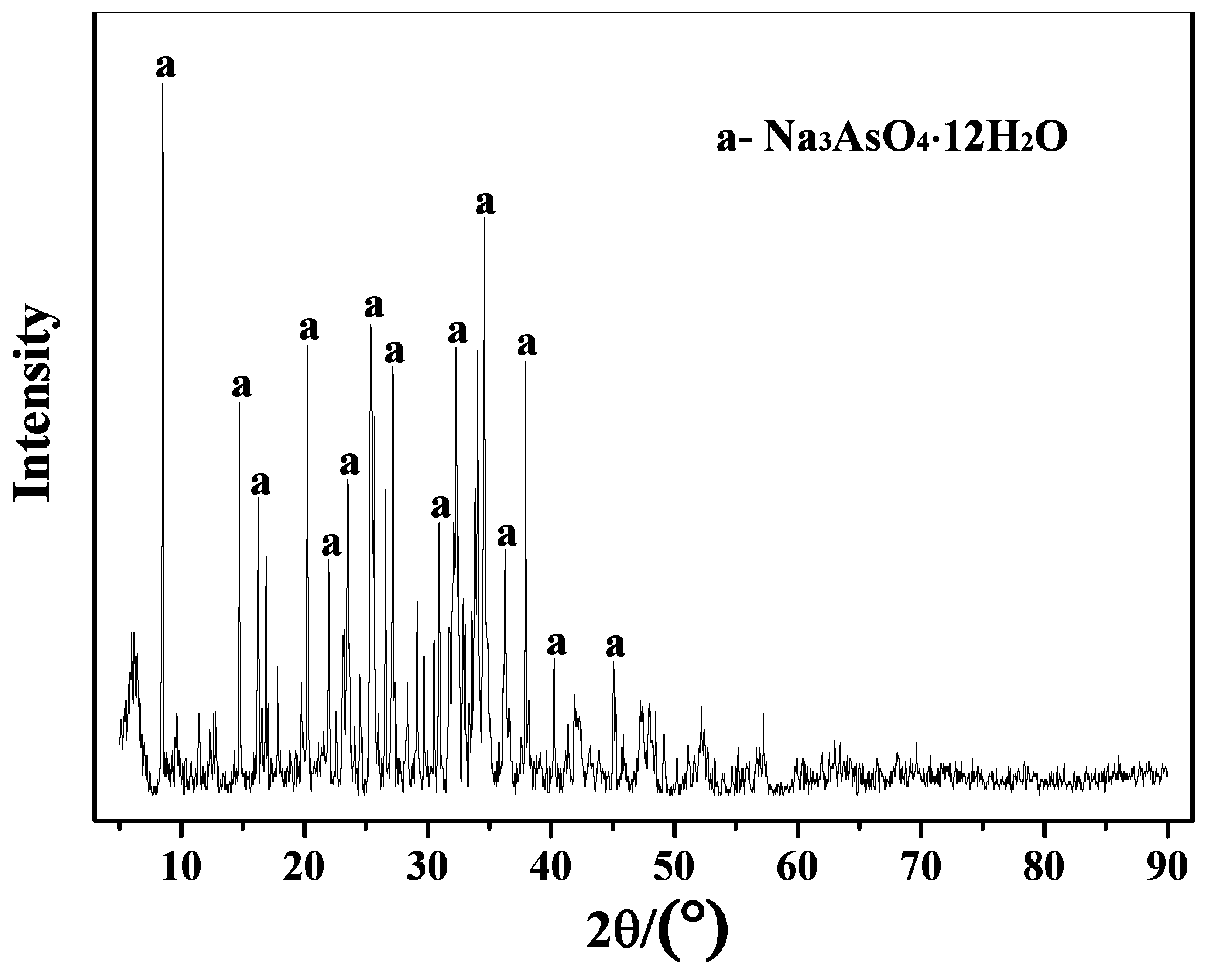

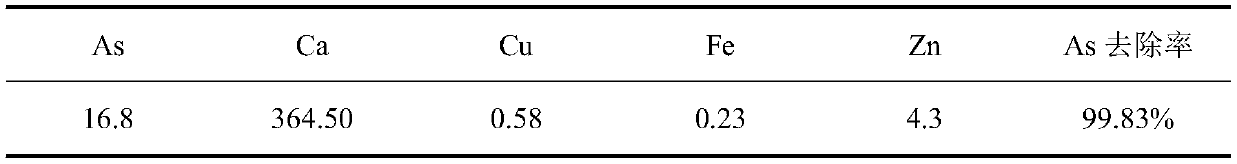

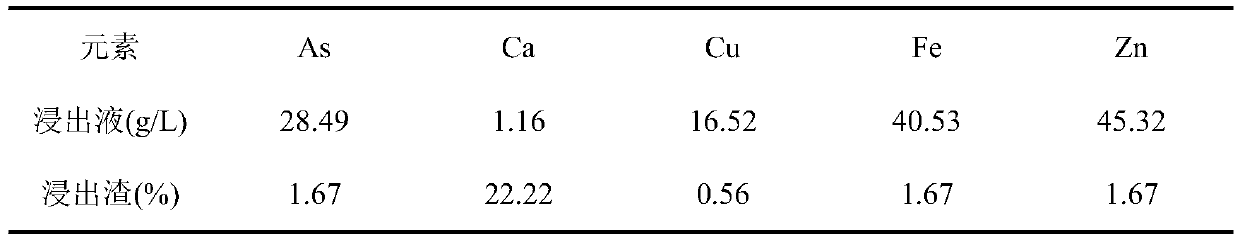

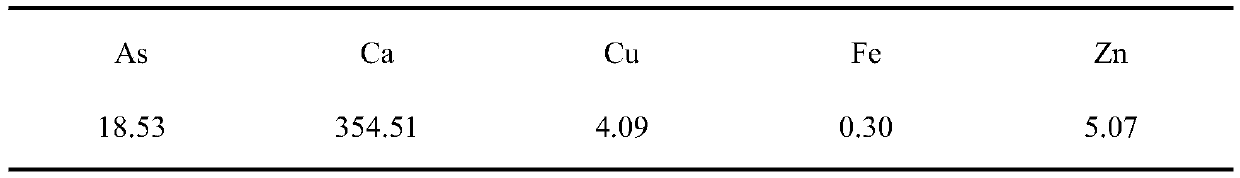

Method for treating arsenic-containing wastewater with recyclable composite salt precipitation agent

ActiveCN110627179AEasy to settleImprove adsorption capacityArsenic oxides/hydroxides/oxyacidsWater contaminantsPregnant leach solutionWastewater

The invention discloses a method for treating arsenic-containing wastewater with a recyclable composite salt precipitation agent. The method comprises the following steps of (1) adding composite saltinto the arsenic-containing wastewater to be precipitated, adjusting the pH value to be 7.5-9.0 by alkali for reaction, and performing filtering to obtain arsenic-containing residues and post-arsenic-precipitation liquid, wherein the composite salt is a mixture of soluble salts of Ca, Cu, Fe and Zn; (2) leaching the arsenic-containing residues with sulfuric acid, and performing filtering to obtainleaching liquid and leaching residues; (3) introducing SO2 into the leaching liquid for reduction, and performing evaporation concentration, cooling crystallization and filtering to obtain arsenic trioxide and arsenic removal mother liquid; and (4) supplementing the soluble salts to the arsenic removal mother liquid according to the concentration of the composite salt in the step (1), and returning to the step (1) for cycle use. According to the method, the arsenic-containing wastewater can be directly treated, oxidation is not needed, arsenic in the arsenic-containing residues can be efficiently recovered with the low energy consumption, the complex salt can be recycled, and the concentration range of the treated wastewater is wide.

Owner:深圳准诺检测有限公司

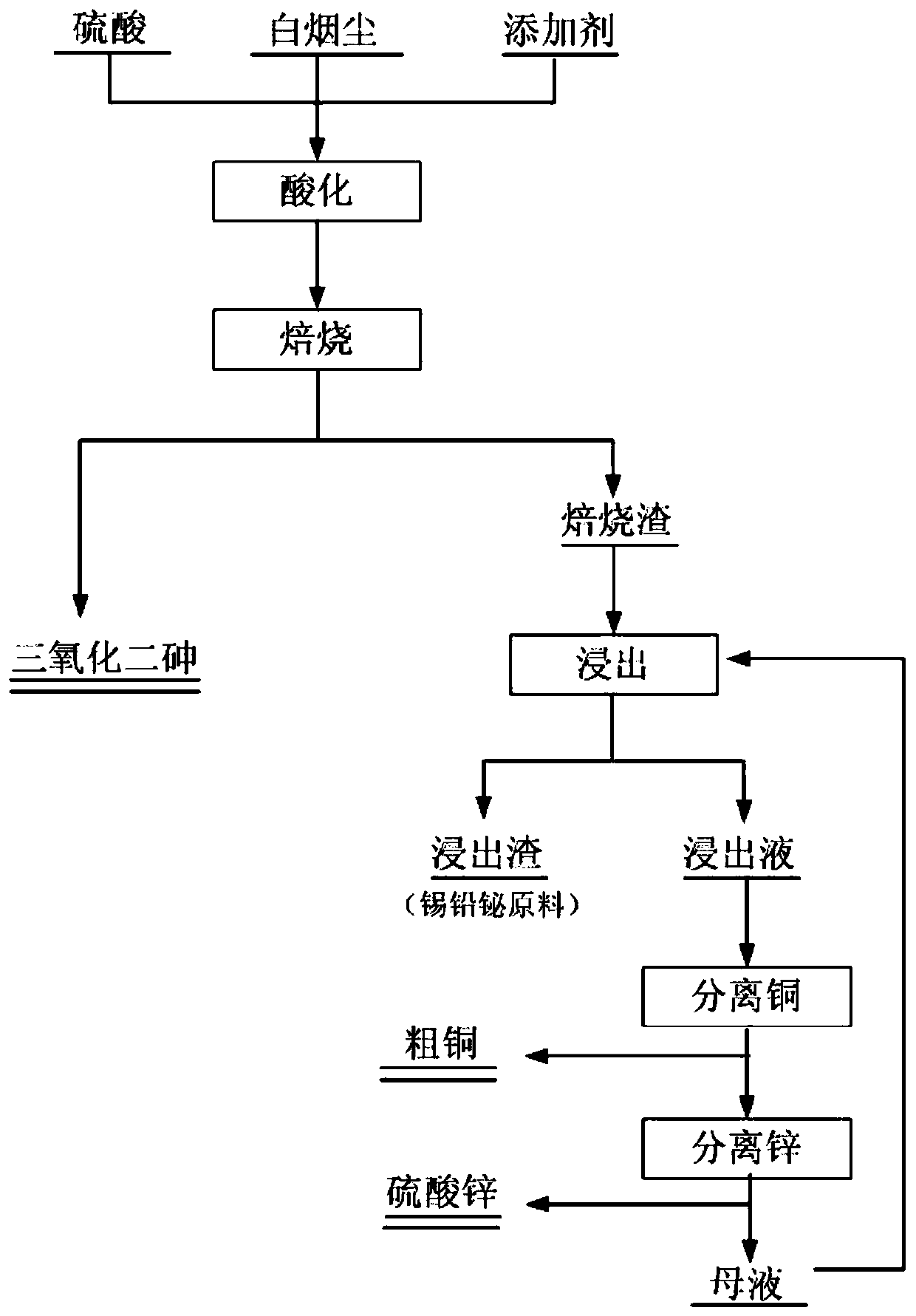

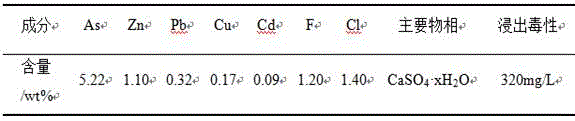

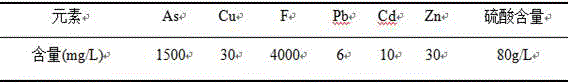

Method for selectively removing arsenic and recycling valuable metals from white smoke dust

InactiveCN110669941AInhibition formationEasy to separateZinc sulatesArsenic oxides/hydroxides/oxyacidsSlagSulfide

The invention discloses a method for selectively removing arsenic and recycling valuable metals from white smoke dust. The method comprises the following steps: mixing and acidifying arsenic-containing white smoke dust generated by copper smelting, sulfuric acid and an additive in a ratio of white smoke dust to sulfuric acid to the additive being 1 to (0.1-1) to (0.01-0.5); roasting the mixed acidified materials for 1-6 hours at a temperature of 250-600 DEG C, violating and introducing arsenic in the white smoke dust into smoke dust in the form of arsenic trioxide, roasting and transforming valuable metals into sulfate or metal oxides or sulfide for slagging, and realizing separation of arsenic and valuable metals, thereby accomplishing arsenic removal; adding water into roasted slag for leaching in a solid-to-liquid ratio being 1 to (2-7), controlling the pH value of leach liquor to be smaller than or equal to 7 at a leaching temperature being 80-95 DEG C, stirring and leaching for 2-4 hours, and filtering; and recycling copper and zinc from filtrate, and recycling other metals from filter slags. The method disclosed by the invention is good in universality, is wide in raw material adaption, is good in value metal and arsenic separation effect, and is simple in value metal recycling process.

Owner:云南锡业研究院有限公司 +1

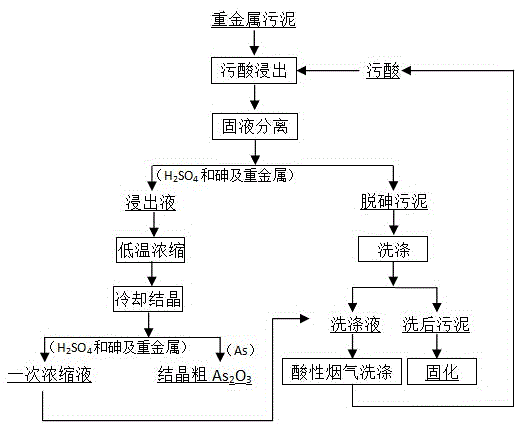

Combined treatment method for heavy metal sludge and waste acid

ActiveCN105541064ALow toxicityRealize comprehensive utilizationSludge treatmentArsenic oxides/hydroxides/oxyacidsPregnant leach solutionSludge

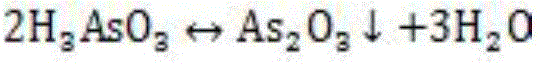

The invention relates to a combined treatment method for heavy metal sludge and waste acid, and belongs to the technical field of heavy metal sludge resource comprehensive utilization. The combined treatment method comprises the following steps: first, naturally drying the heavy metal sludge; then, crushing the naturally dried heavy metal sludge to the particle size of 1 to 10 mm; next, adding the crushed heavy metal sludge into the waste acid, stirring for 5 to 15 hours at normal temperature to make the mixture emulsible, and performing solid-liquid separation to obtain leaching liquid and arsenic removal sludge; later on, concentrating the leaching liquid at a low temperature, cooling and crystallizing the concentrated leaching liquid to obtain primary concentrate and crystallized coarse As2O3; finally, washing the obtained arsenic removal sludge with clean water to obtain a washing solution and washed sludge, solidifying the washed sludge by a conventional method to obtain a solidified product, washing the washing solution and the obtained primary concentrate with acidic gas, and returning the washed washing solution and the primary concentrate as the waste acid. According to the method, wastewater is not generated and secondary pollution is not caused in the treatment process; the finally obtained arsenic trioxide also has an economic value.

Owner:KUNMING UNIV OF SCI & TECH +2

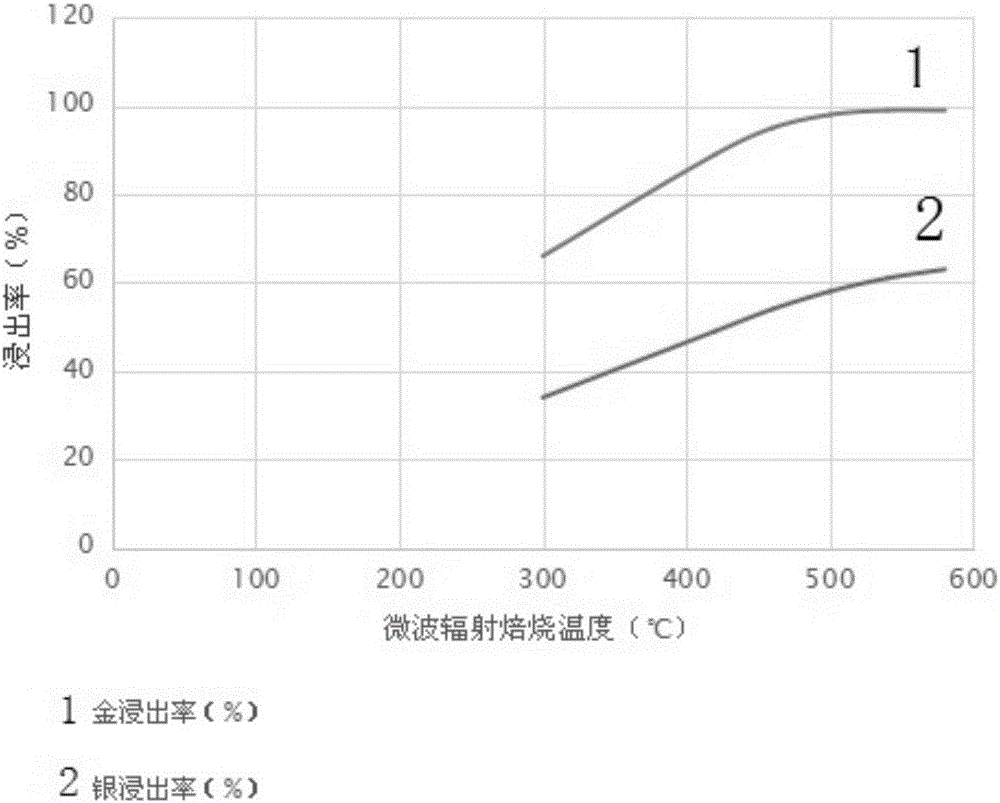

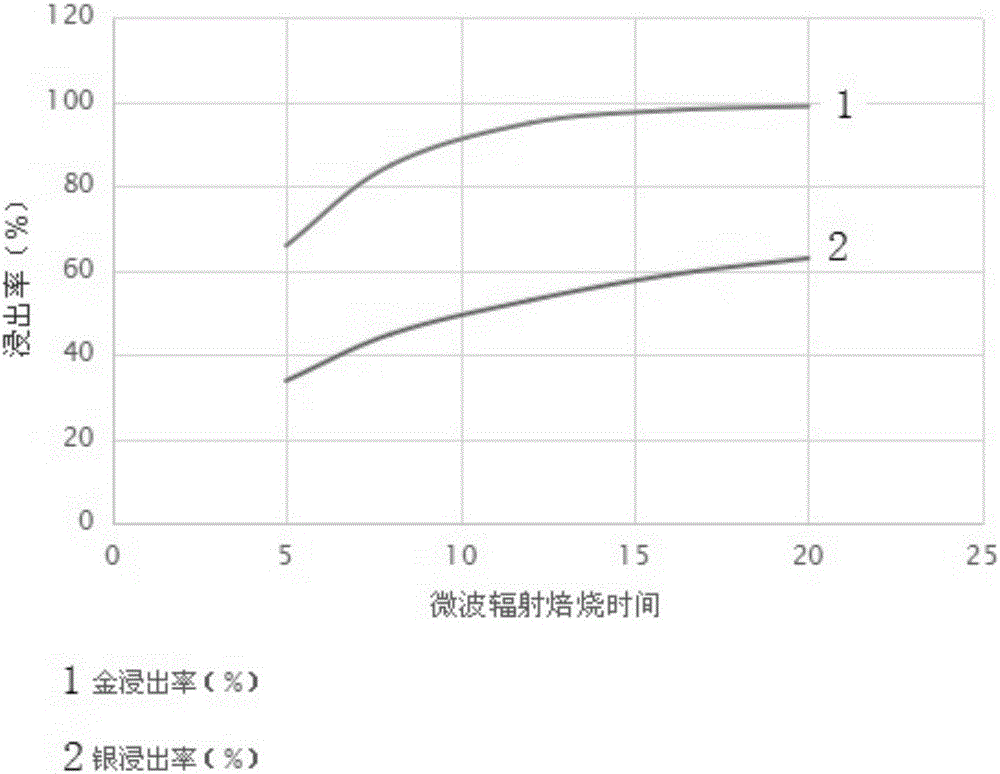

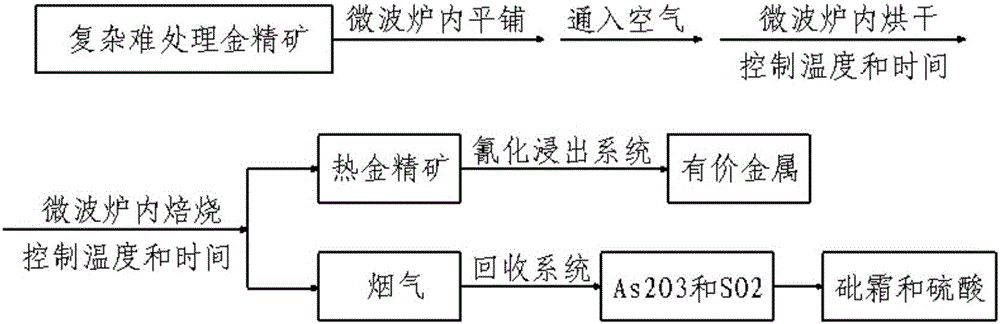

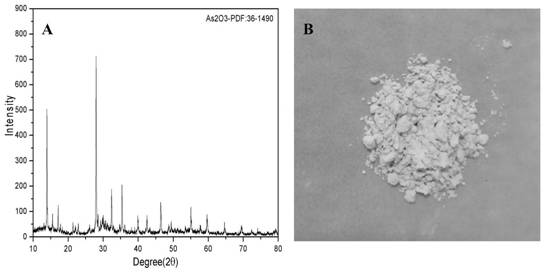

Technology for pretreating complex and difficult-to-treat gold concentrate through utilizing industrial microware

InactiveCN105936976APromote monomer dissociationIncrease the effective reaction areaArsenic oxides/hydroxides/oxyacidsSulfur compoundsMicrowave ovenCyanide

The invention relates to a technology for pretreating complex and difficult-to-treat gold concentrate through utilizing industrial microware. The technology comprises the steps of putting the complex and difficult-to-treat gold concentrate in an industrial microwave oven, and paving the complex and difficult-to-treat gold concentrate; starting a microwave oven fan, and introducing air; starting a microwave heating device to sequentially dry and bake the complex and difficult-to-treat gold concentrate; sending obtained flue gas into a recycling system to recycle As2O3 and SO2, so as to prepare arsenic and arsenic; and sending obtained hot gold concentrate to a cyanide leaching system to recycle valuable metals such as gold and silver. According to the technology, the leaching rate of gold can be greatly increased, the operation is easy, the technological process is short, the reaction temperature is decreased, the reaction time is shortened, and the production efficiency is improved.

Owner:托里县招金北疆矿业有限公司

Method of separating arsenic from copper slag through cooperation of high-arsenic material

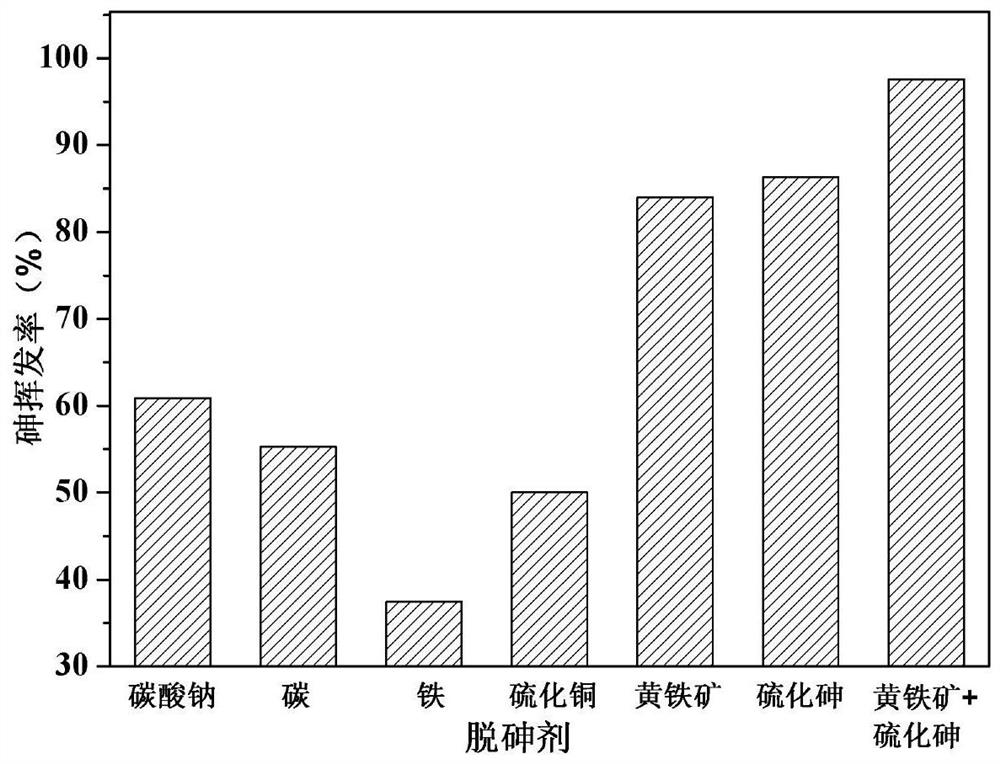

ActiveCN111996383AReduce arsenic levelsEasy to changeArsenic oxides/hydroxides/oxyacidsProcess efficiency improvementPyriteArsenic oxide

The invention discloses a method of separating arsenic from copper slag through cooperation of a high-arsenic material. The method comprises the steps of taking a mixed material of pyrite and arsenicsulfide slag as an arsenic remover, mixing the arsenic remover and copper slag evenly, and heating the mixture under an inert atmosphere at the temperature rising rate of 1-5 DEG C / min to 1100-1300 DEG C to be subjected to roasting to obtain mixed gas containing arsenic oxide and arsenic sulfide; introducing the air into the mixed gas to have a reaction at 800-900 DEG C to be oxidized to generatearsenic trioxide and sulfur dioxide; and finally conducting condensing to obtain an arsenic trioxide product. According to the method, the mixed material of pyrite and arsenic sulfide sliding groove serves as the arsenic remover and can destroy an arsenious vitreous body structure with high chemical stability in the copper slag, and arsenic is reduced into arsenic oxide and arsenic sulfide to be released; the problem that arsenic and copper slag in high-arsenic copper slag are hard to separate during actual production is solved; and the purposes of efficiently volatilize and directionally collecting arsenic and using waste to treat waste are achieved.

Owner:CENT SOUTH UNIV

Method of comprehensively recycling valuable metals from gold concentrate acid leachate

InactiveCN108893603AReduce processing costsReduce the impactPhotography auxillary processesArsenic oxides/hydroxides/oxyacidsIonZinc

The invention relates to a method of comprehensively recycling valuable metals from gold concentrate acid leachate. The method comprises the steps of subjecting copper-bearing acid leachate, attainedby subjecting gold and silver concentrate to roasting and acid leaching, to multistage oxidation, adsorbing gold and silver by carbon, extracting and electrodepositing, chelating zinc ions, disintegrating chelate and other steps; the very stable chelate is formed by means of the chelating agent tetrapyridine methylethylenediamine and divalent zinc ions; zinc ions can be separated from a mixed solution containing copper ions, iron ions and otherness by means of organic solvent extraction; the zinc ion are effectively utilized accordingly. After both the copper ions and the zinc ions are separated from the acid leachate, the rest iron is recycled. Compared with traditional neutralizing methods, the method herein helps effectively recycle zinc and iron, with reduced cost to treat acid leachate and reduced ambient influence caused.

Owner:SHANDONG GUODA GOLD

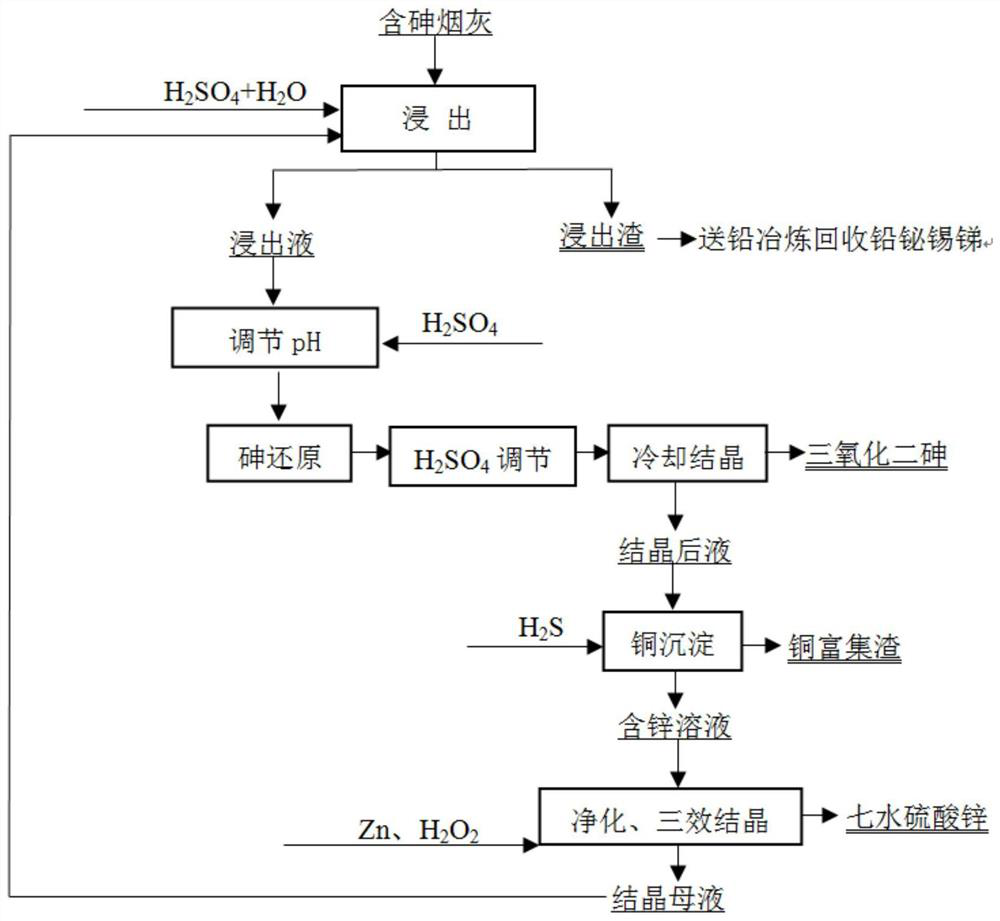

Method for recovering arsenic and valuable metals from arsenic-containing soot

ActiveCN113337720AAchieve recyclingHigh purityZinc sulatesArsenic oxides/hydroxides/oxyacidsLead smeltingSoot

The invention discloses a method for recovering arsenic and valuable metals from arsenic-containing soot. The method comprises the following steps: leaching the arsenic-containing soot through acid oxidation, enabling arsenic, copper and zinc to enter a solution, and enabling bismuth, lead, antimony and tin to enter a slag phase; selectively reducing arsenic from leachate through sulfur dioxide gas, recovering arsenic in the form of arsenic trioxide, and vulcanizing and precipitating the remaining solution containing copper and zinc through hydrogen sulfide gas to obtain copper-enriched slag and a zinc-containing solution; and performing purifying and impurity removal on the zinc-containing solution, performing concentrating and crystallizing to obtain a zinc sulfate heptahydrate product, and returning crystallization mother liquor to the arsenic-containing soot leaching process. According to the method, the arsenic in the arsenic-containing soot is efficiently recovered in the form of high-grade arsenic trioxide, the copper and the zinc are separated and recovered, enriched slag of lead, bismuth, tin, antimony and the like is obtained to serve as lead smelting raw materials, no industrial wastewater is discharged in the whole production process, no valuable hazardous waste is generated, and comprehensive treatment of the hazardous waste is facilitated.

Owner:CENT SOUTH UNIV

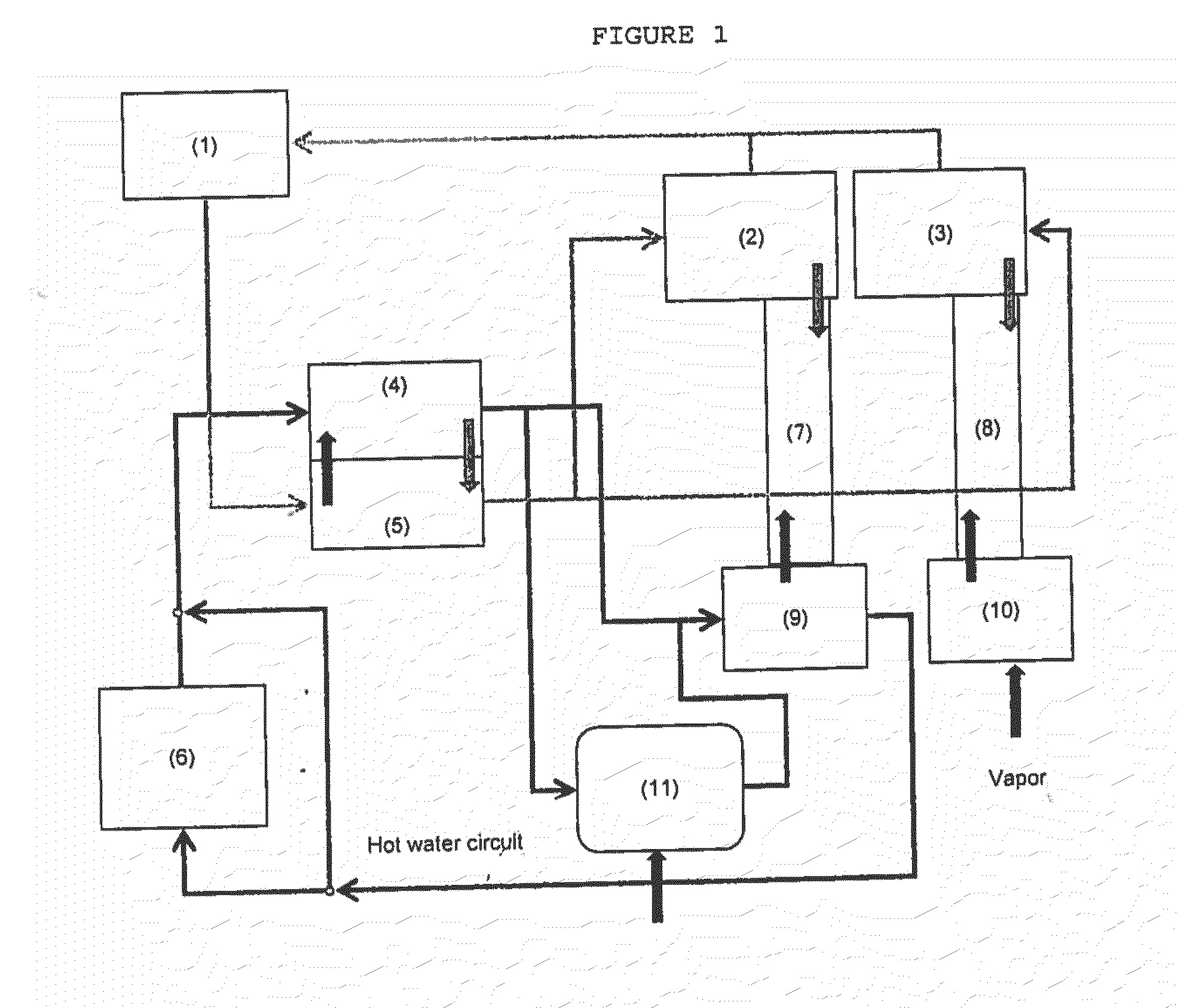

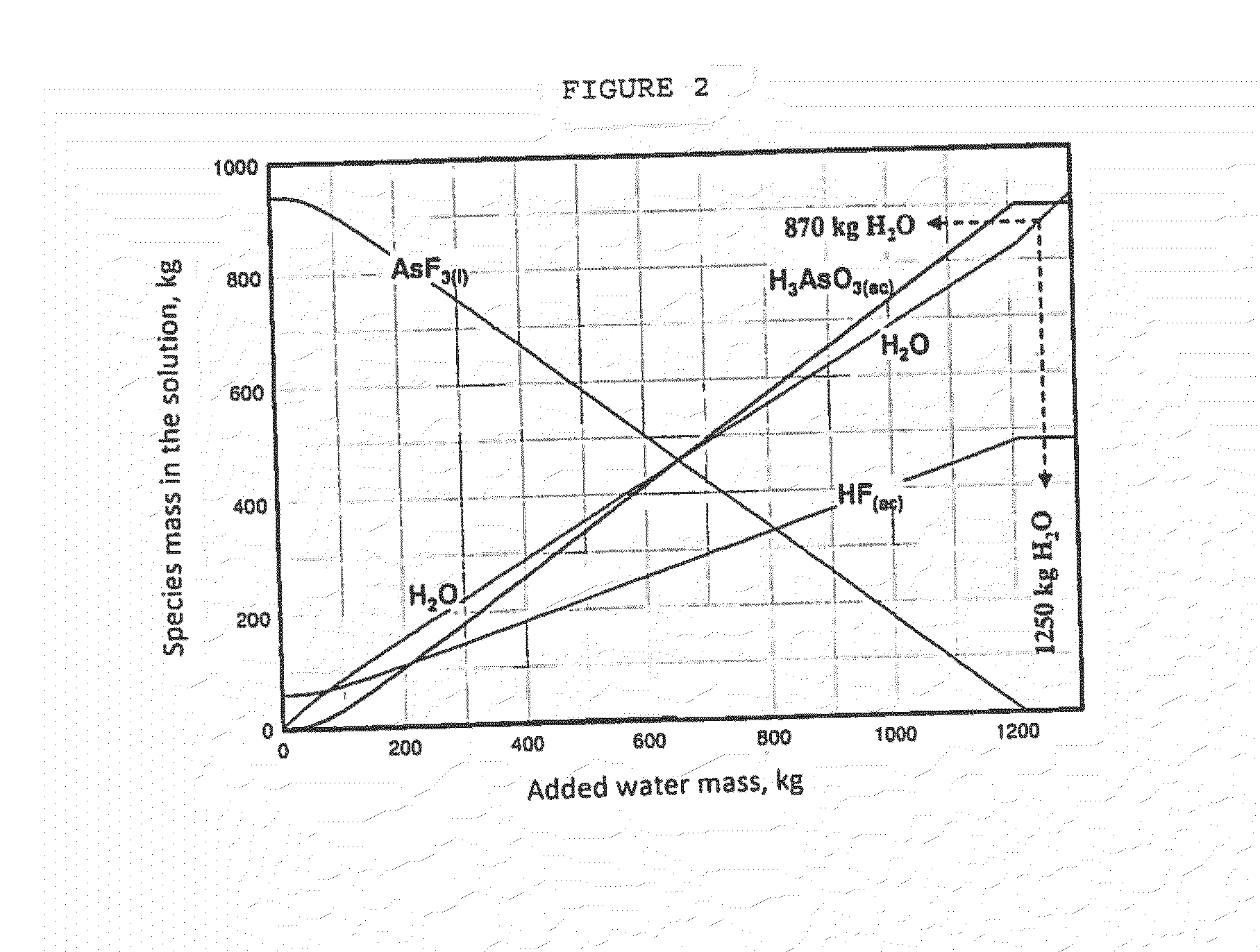

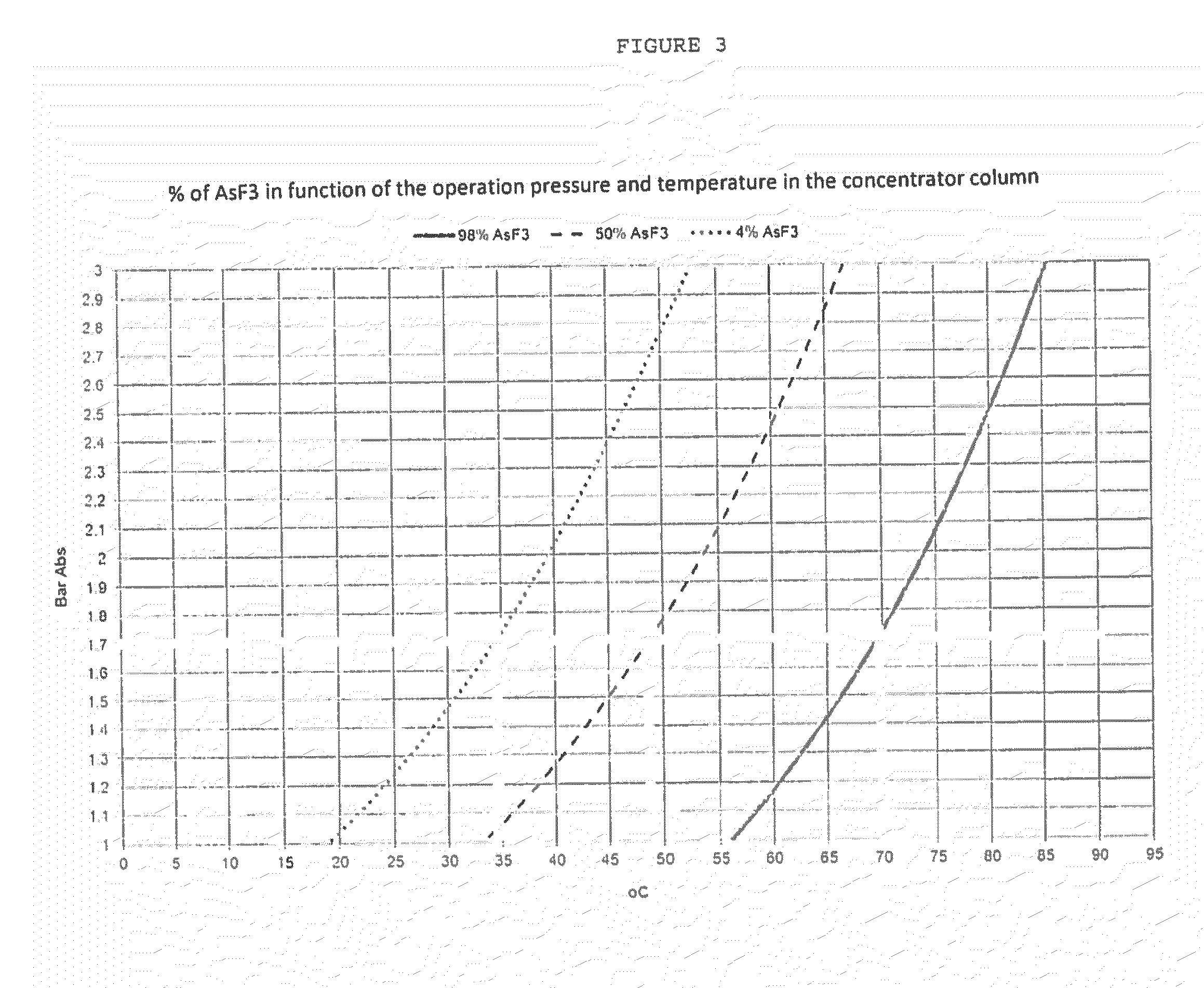

Process for purification of hydrofluoric acid including obtaining arsenious acid by-product

ActiveUS20160176711A1Arsenic oxides/hydroxides/oxyacidsDistillation regulation/controlProcess engineeringEnvironmental engineering

The process for purification of hydrofluoric acid as herein disclosed is able to reduce the content of heavy metals, including arsenic, to values lower than 5 ppm without using any chemicals and with an integrated design of hot and cold streams that provide low energy consumption. Likewise, it achieves the extraction of heavy metals, especially arsenic, with minimal waste generation and maintaining its original oxidation state, which for the case of arsenic is +3, so that the residue can be converted into a product with commercial value, that in this process is obtained as arsenious acid.The process consists of four systems: HF purification system, arsenic concentration system, hot water system, and cold water system. This document discloses the synchronized operation of these 4 systems that together achieve what is mentioned in the previous paragraph.

Owner:MEXICHEM FLUOR DE CAPITAL VARIABLE

Method for reducing arsenic content in copper smelting soot leaching slag

ActiveCN111349790AAvoid secondary pollutionReduce arsenic levelsArsenic oxides/hydroxides/oxyacidsProcess efficiency improvementSlagSulfite salt

The invention discloses a method for reducing the arsenic content in copper smelting soot leaching slag, and belongs to the technical field of wet process metallurgy. Copper smelting soot is subjectedto weak acid leaching, the final pH value of a leaching solution is controlled to be 2 or below, the leaching slag is subjected to secondary reducing leaching at 50-115 DEG C, the initial pH value ofthe solution is controlled to be about 2, slow leading-in of sulfur dioxide or adding of sodium sulfite+sulfuric acid and the like is conducted, arsenate in the slag is leached out and enters the solution, the arsenic content in the slag is reduced, and copper, zinc, arsenic and the like are comprehensively recycled from the primary leaching solution. The method for reducing the arsenic content in the copper smelting soot leaching slag is provided, the system acid concentration can be effectively reduced, later solution treatment is facilitated, meanwhile, the arsenic content in the slag is reduced, and secondary pollution of the arsenic is avoided.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

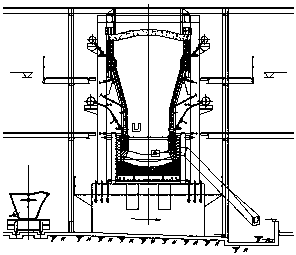

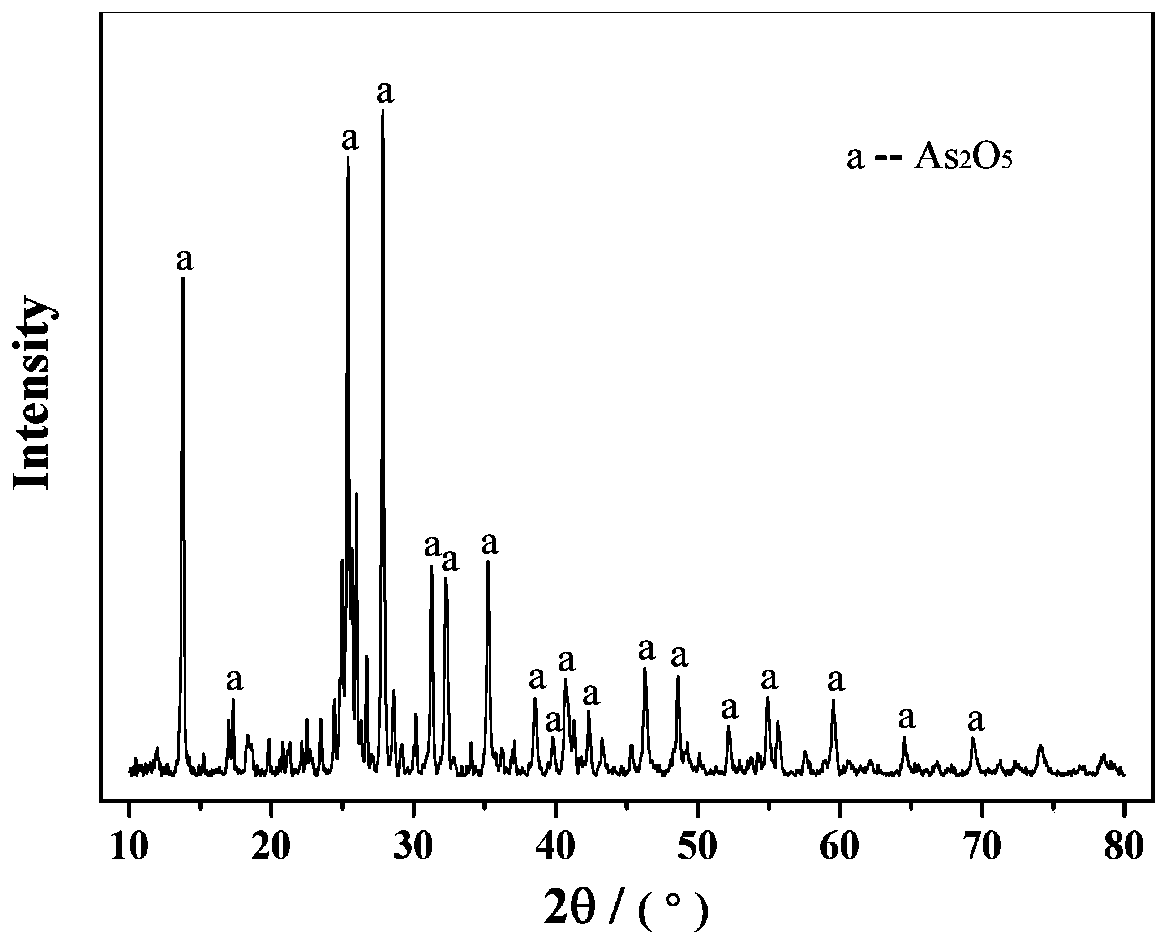

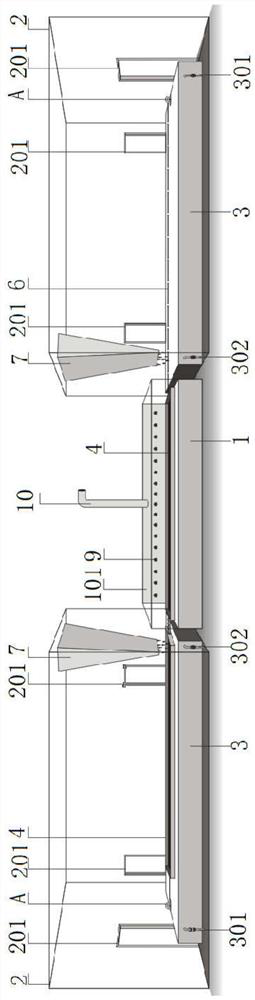

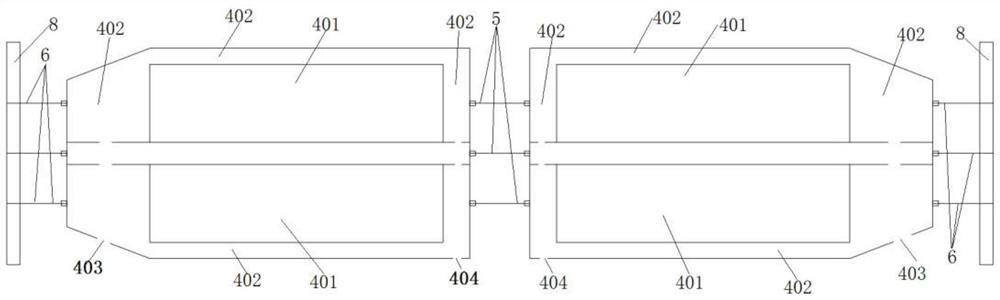

Arsenic trioxide purification system and arsenic trioxide purification method

InactiveCN111704163ACompact structureImprove processing efficiencyArsenic oxides/hydroxides/oxyacidsChemical industryPurification methodsPhysical chemistry

The invention relates to an arsenic trioxide purification system, which comprises a purification furnace, two operation chambers, two material carrying boxes with openings in the tops and two feedingmechanisms, the two ends of the purification furnace are each provided with a first opening, and the two operation chambers are symmetrically distributed at the two ends of the purification furnace; wherein one material carrying box is arranged in the operation chamber, the other material carrying box is arranged in the purification furnace, one ends of the two material carrying boxes are connected through a connecting piece, the other ends of the two material carrying boxes are respectively connected with a cable, and winding mechanisms are respectively arranged in the two operation chambers;a second opening opposite to the first opening is formed in the side wall, close to the purification furnace, of the operation chamber, a bearing table is arranged in the purification furnace, and acooling bed as high as the bearing table is arranged in the operation chamber; and the two feeding mechanisms are symmetrically arranged at the two ends of the purification furnace. The arsenic trioxide purification system is compact in structure and high in treatment efficiency, and the uninterrupted purification effect of the purification furnace can be achieved; and direct water spraying cooling is not needed, the smoke generation amount is greatly reduced, and energy conservation and environmental protection are achieved.

Owner:湖南锐异资环科技有限公司

Continuous hydrolysis of hexafluoroarsenic acid

InactiveUS20080003172A1Efficiently and effectively removedImproves many characteristic of reaction processArsenites/arsenatesArsenic oxides/hydroxides/oxyacidsHydrogen fluorideHydrolysis

Provided is a method for treating an aqueous feed stream containing an admixture of hexafluoroarsenic acid, or any salt thereof, and hydrogen fluoride, by contacting the feed stream with a counter-current stream of steam to remove substantially all of the hydrogen fluoride from the feed stream, and optionally to heat the feed stream. Further, provided is a method for continuously converting hexafluoroarsenic acid in an aqueous admixture, or any salt thereof, into arsenic acid by contacting the admixture with a counter-current stream of steam.

Owner:SZUCH COLLEEN ESQUIRE

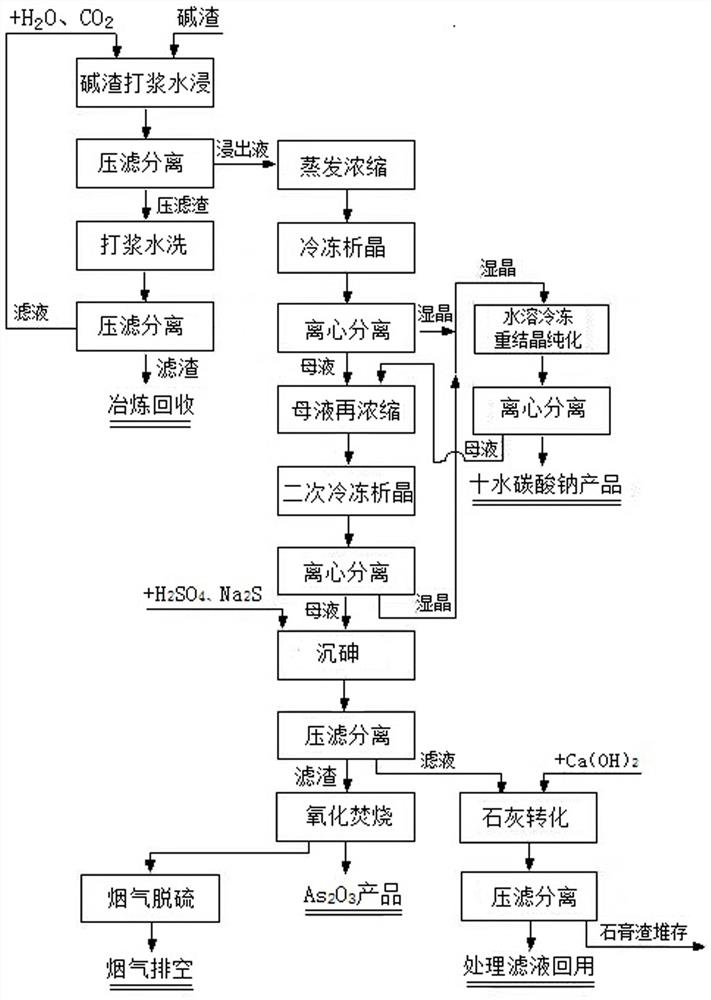

A method for recycling and processing arsenic slag resources by freezing and separating arsenic and alkali in the immersion solution of alkali slag

ActiveCN111118301BImprove recycling ratesReduce manufacturing costArsenic oxides/hydroxides/oxyacidsCalcium/strontium/barium sulfatesSlagSlurry

The invention relates to a method for recycling and treating arsenic slag resources by freezing and separating arsenic and alkali in alkaline slag water extract. The method comprises the following steps of adding water into alkaline slag, pulping, leaching with water, introducing CO<2> gas to convert NaOH in the slurry into Na<2>CO<3>, evaporating and concentrating the separated Na<2>CO<3>-containing arsenic alkaline water extract, cooling, freezing and crystallizing, dissolving the separated wet crystals, cooling, freezing and recrystallizing again to obtain sodium carbonate, concentrating the separated arsenic-containing mother liquor, carrying out secondary freezing crystallization treatment, precipitating arsenic by using a Na<2>S saturated aqueous solution, maintaining the pH value at1-2 by using H<2>SO<4>, adding pulverized coal into filter residues separated from an arsenic precipitation mixed solution, and carrying out oxidation incineration to obtain As<2>O<3>, and convertingthe filtrate with lime. According to the method, arsenic and alkali in the alkaline slag water extract are separated through freezing crystallization, Na<2>CO<3>.10H<2>O is obtained through freezingrecrystallization, and Na<2>S is used for precipitating arsenic, so that arsenic slag resources can be well recycled.

Owner:YAN XIN ENVIRONMENTAL PROTECTION & TECH CO LTD

Method for collecting arsenic from smelting flue gas by dry process

InactiveCN109553131ADoes not increase water vapor contentNot corrodedArsenic oxides/hydroxides/oxyacidsWhite arsenicBaghouse

The invention discloses a method for collecting arsenic from smelting flue gas by a dry process, and belongs to the field of comprehensive recycling of metallurgical waste gas. The method comprises the steps of: 1) quenching: arsenic-containing high-temperature smelting flue gas rapidly passes through a quencher for indirect cooling; 2) settling collection of arsenic: after the quenched flue gas enters a settler, white arsenic and smoke dust in the flue gas in the settler naturally settle to the bottom of the settler, and the flue gas subjected to settling is discharged from an upper flue gasoutlet, and arsenic is collected from an outlet at the bottom of the settler; and 3) electrostatic collection of arsenic: the flue gas discharged from the top of the settler enters an electrostatic demister, a small amount of residual white arsenic and smoke dust in the flue gas is collected, and the collected white arsenic and smoke dust fall into the settler. The method of the invention does notintroduce water into the flue gas, and does not reduce the dew point of the flue gas; the settler can collect dust with dew; no corrosion to equipment and pipelines are ensured; glass arsenic and thelike are prevented from blocking a bag type deduster and causing paralysis of a system; the method is applicable to smelting flue gas under different working conditions through a frequency-conversionfan; and the method can reduce sewage generated by the process.

Owner:CINF ENG CO LTD

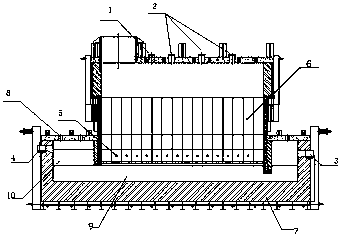

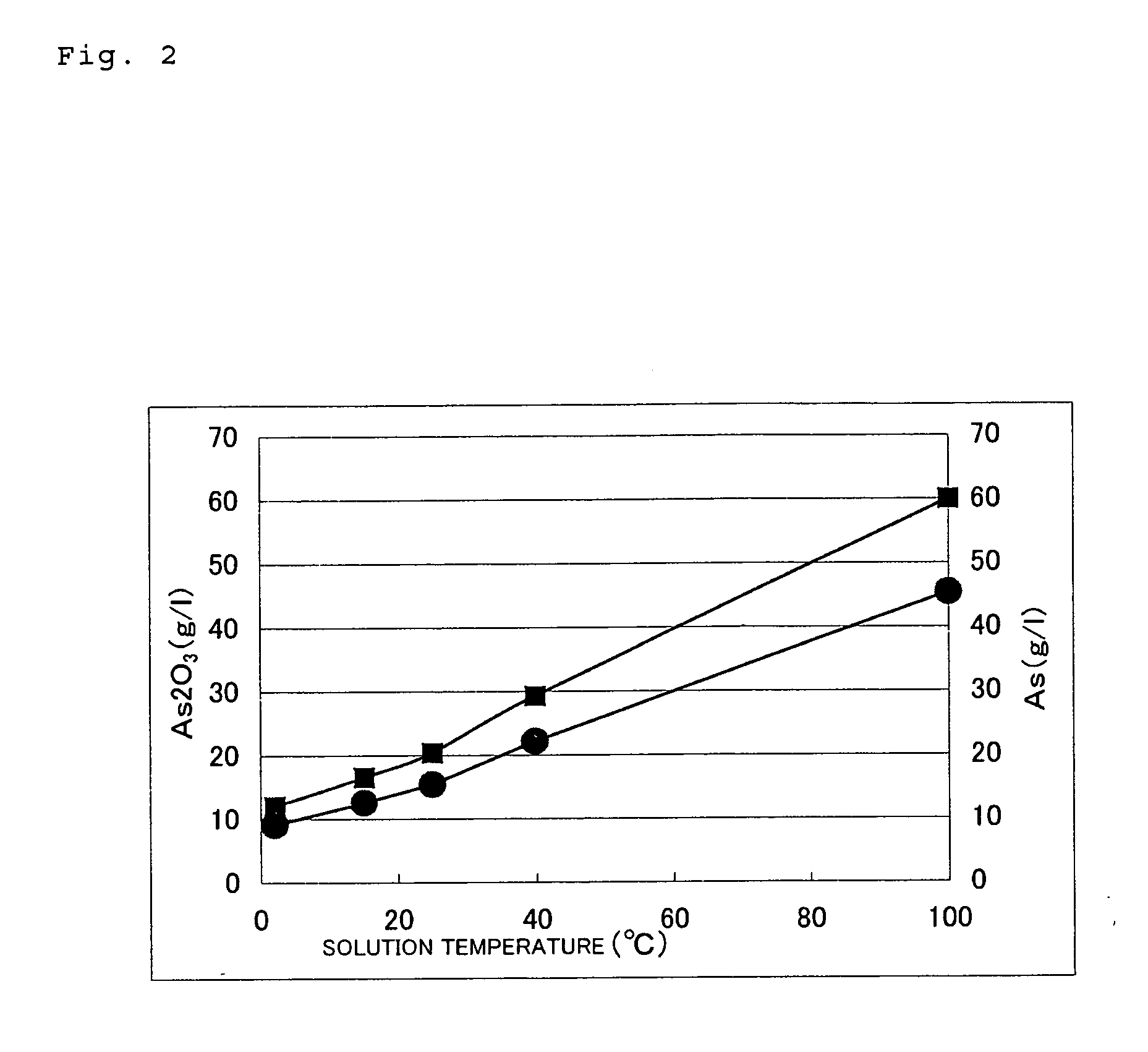

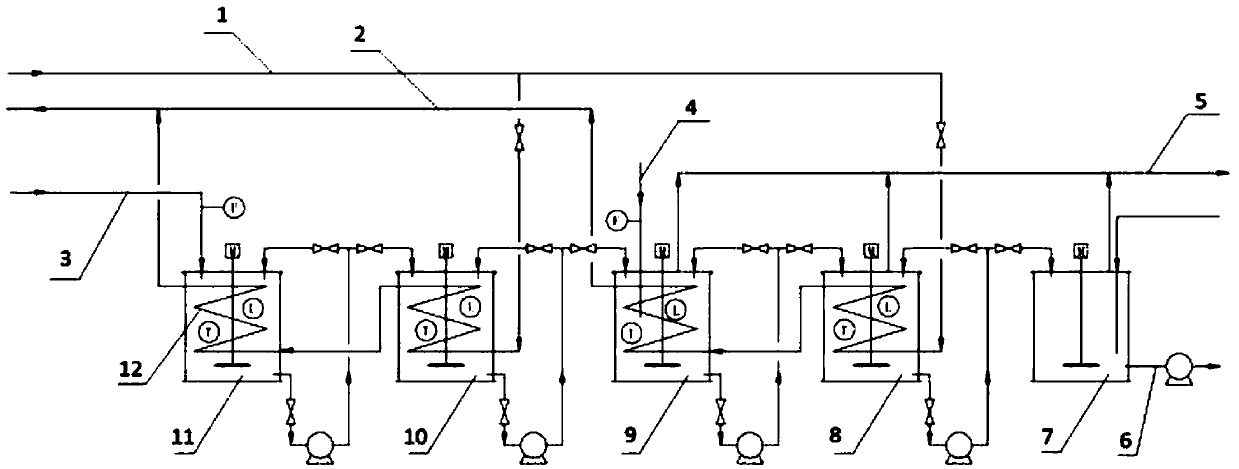

Method for cooling reduction crystallization of As2O3

InactiveCN109607611AReduce cleaning timesAvoid rapid foulingArsenic oxides/hydroxides/oxyacidsSolution crystallizationLiquid temperatureCentrifugation

The invention provides a method for cooling reduction crystallization of As2O3. The method comprises the steps: sending a high temperature liquid containing arsenic into a No. 1 cooling trough provided with a water-cooling coil, introducing cooling water into the water-cooling coil for first-stage cooling, sending the cooled liquid obtained after first-stage cooling to a No. 2 cooling trough provided with a water-cooling coil, introducing cooling water into the water-cooling coil for second-stage cooling until the liquid temperature is lower than 40 DEG C, transferring the cooled liquid into aNo. 1 reaction trough, introducing sulfur dioxide gas into the No. 1 reaction trough for reduction for a reduction period of 2-3 hours, then transferring the reduced liquid into a No. 2 reaction trough, performing still standing for 3 hours or above, introducing air into the reduced solution, performing stirring for 20-30 minutes, and performing centrifugation on the aerated solution so as to obtain a centrifuge mother liquor and the As2O3 crystal. Through the method, the scaling phenomenon caused by adhesion of As2O3 to the cooling coils can be avoided, and the purity of the prepared As2O3 crystal is more than 98%.

Owner:郴州金铖环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com