Method for innocent treatment of low-concentration arsenic-containing waste residue and recovery of arsenic

A harmless treatment, low-concentration technology, applied in chemical instruments and methods, inorganic chemistry, arsenic compounds, etc., can solve the problems of low-concentration arsenic-containing waste residues that are difficult to handle, dispose and recycle, and achieve the effect of alleviating hoarding and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The object of treatment is the gold extraction tailings produced by a gold mine. It is gray-green fine-grained decemented matter with a moisture content of 13.90-16.14%. X-ray fluorescence spectroscopy (XRF) detection shows that the tailings mainly contain Si, Al, Fe, Ca, K and other elements, the content of arsenic is 0.263%. X-ray diffractometer detection shows that the arsenic in the tailings is mainly As 2 o 3 Exists in the form of As 2 S 3 , FeAsS and other forms exist.

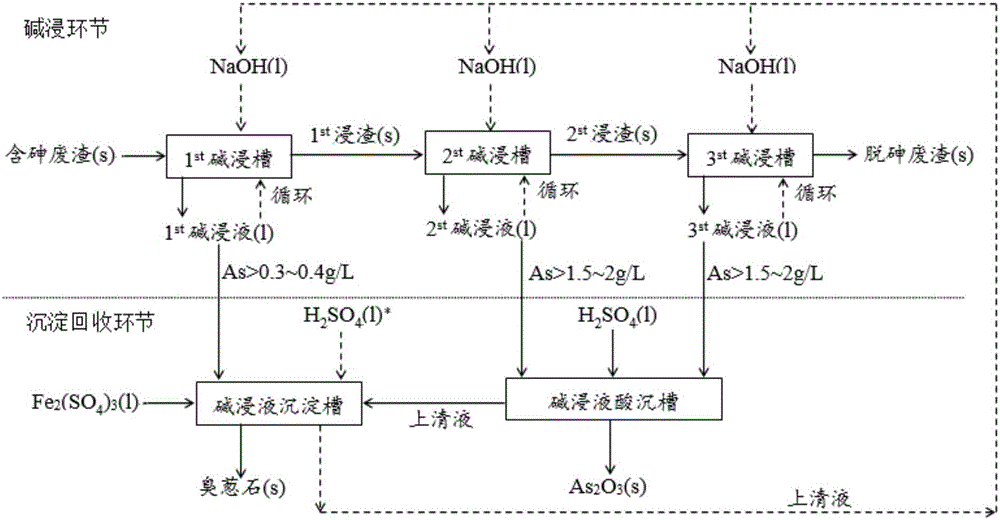

[0036] The harmless treatment of the tailings and the arsenic recovery process are as follows: figure 1 as shown, figure 1 middle * The dotted line at the top indicates whether sulfuric acid is added according to the demand, and the rest of the dotted lines indicate the cycle. The specific process is as follows:

[0037](1) Mix the sodium hydroxide solution with a concentration of 1.2mol / L and the tailings slag at a ratio of 3L / kg, heat the solution to 60°C, stir it mechanically for 12 hours...

Embodiment 2

[0041] The processing object is the same as that in Embodiment 1.

[0042] Harmless and arsenic recovery processes such as figure 1 as shown, figure 1 middle * The dotted line at the top indicates whether sulfuric acid is added according to the demand, and the rest of the dotted lines indicate the cycle. The specific process is as follows:

[0043] (1) Mix the sodium hydroxide solution with a concentration of 1.2mol / L and the tailings slag at a ratio of 3L / kg, heat the solution to 60°C, stir it mechanically for 12 hours, and separate the solid and liquid through natural sedimentation to obtain the first-grade alkali leaching residue and the first-grade 1 time Alkaline leaching solution, the first-level alkaline leaching solution is supplemented with NaOH solution and then continued to be used for leaching of arsenic-containing waste residues to obtain first-level 2 times of alkaline leaching solutions, and the first-level alkaline leaching solution is repeatedly used for lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com