Method for biologically leaching heavy metal from heavy metal-contained waste based on pH and potential co-regulation

A bioleaching and heavy metal technology, applied in the direction of improving process efficiency, can solve the problems of high acid consumption, low processing efficiency, and simple processing objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

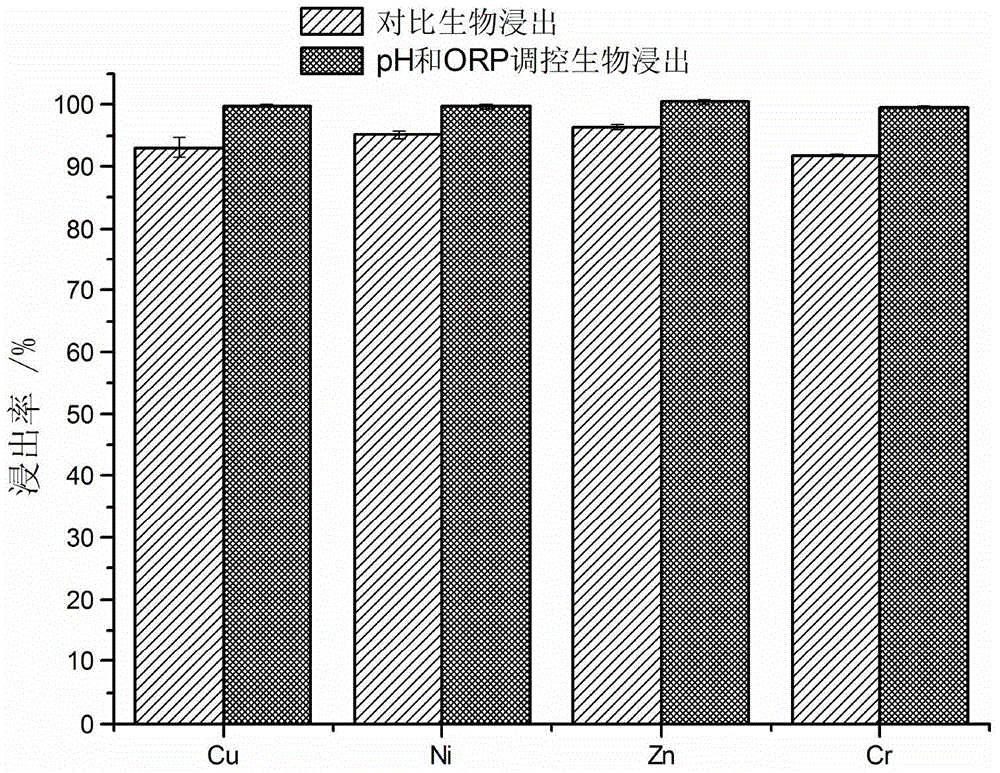

Embodiment 1

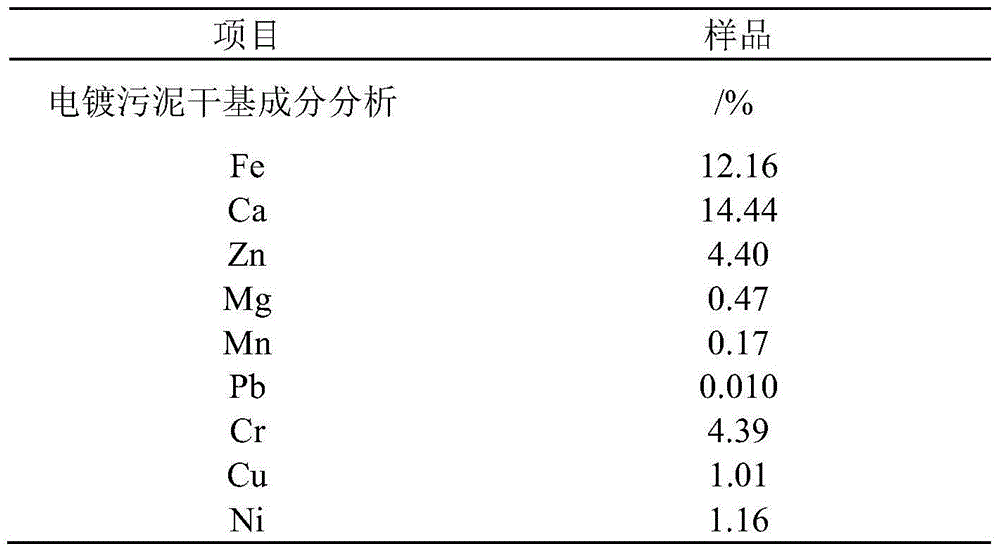

[0055] A method for bioleaching heavy metals from wastes containing heavy metals based on pH and potential co-regulation. The wastes containing heavy metals used in this example is mainly electroplating sludge from an electroplating factory in Hunan. Its appearance is green, and the waste containing zinc and chromium Iron is the main material, followed by copper and nickel, and the moisture content is about 65.41%. The dry basis of the electroplating sludge mainly consists of metal elements and their contents are: Fe 12.16%, Zn 4.4%, Cr 4.39%, Cu 1.01% and Ni 1.16%, etc. (see Table 1 below).

[0056] Table 1: Main metal element content of electroplating sludge dry basis in Example 1

[0057]

[0058] The above-mentioned electroplating sludge is treated by adopting the method for biologically extracting heavy metals in electroplating sludge based on pH and potential co-regulation of the present invention, specifically comprising the following steps:

[0059] (1) Adaptive pr...

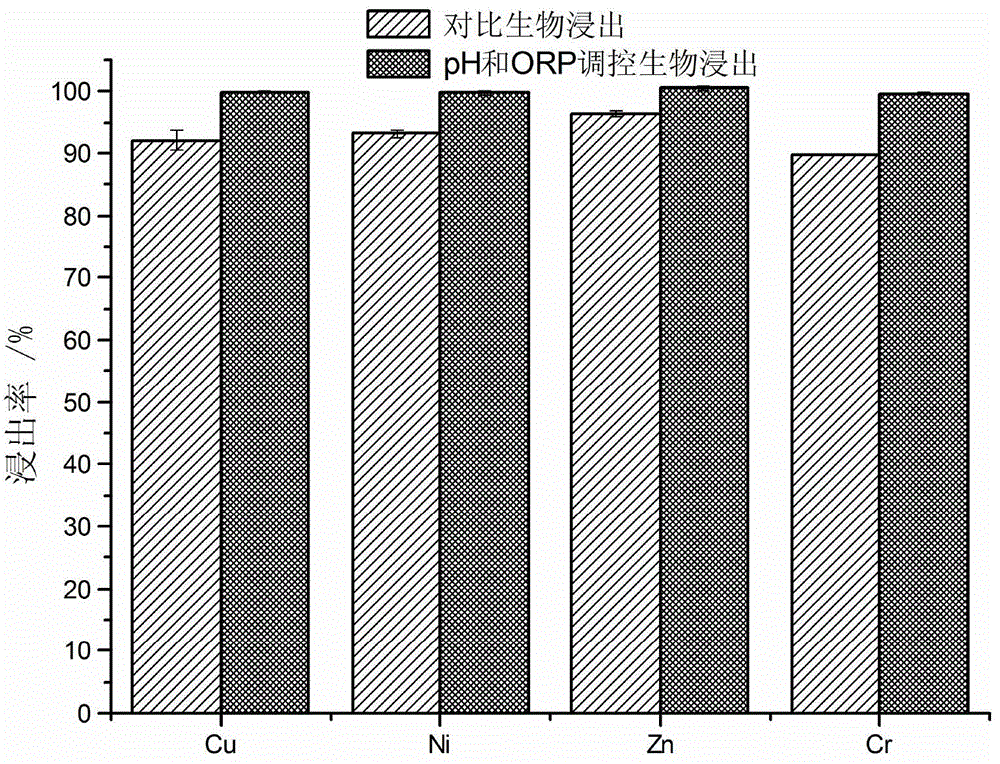

Embodiment 2

[0067] A method for biologically extracting heavy metals from wastes containing heavy metals based on pH and potential co-regulation. The wastes containing heavy metals used in this example is mainly electroplating sludge from an electroplating industrial park in Guangdong. Its appearance is green, and the waste containing copper It is mainly composed of heavy metals such as nickel and chromium, and the moisture content is about 73.2%. The main metal elements in the dry base of the electroplating sludge include: Cu 9.02%, Ni 5.72%, Cr 10.22%, Zn 1.12% and Fe 5.35% (see Table 2 below).

[0068] Table 2: Main metal element content of electroplating sludge dry basis in Example 2

[0069]

[0070]

[0071] The above-mentioned electroplating sludge is treated by adopting the method for biologically extracting heavy metals in electroplating sludge based on pH and potential co-regulation of the present invention, specifically comprising the following steps:

[0072] (1) Adapti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com