Method for leaching and recycling fluorine in aluminum electrolysis cell waste cathode

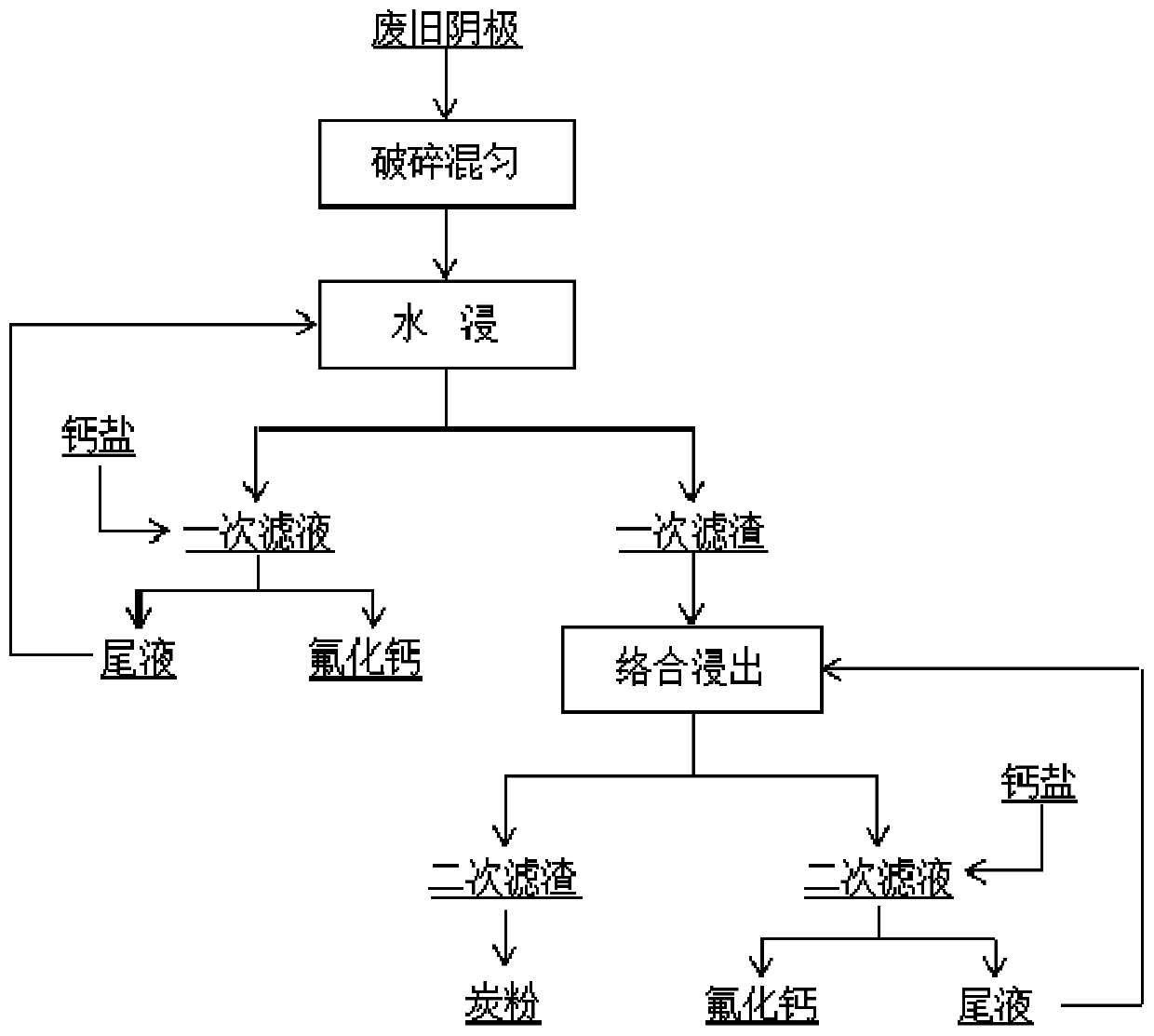

An aluminum electrolytic cell waste and leaching technology, applied in the direction of calcium/strontium/barium fluoride, calcium/strontium/barium halide, etc., can solve the problems of difficult large-scale industrial application, low recovery rate of valuable components and high processing cost , to achieve the effect of no secondary pollution, mild conditions and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take 100g of waste cathode carbon blocks from an aluminum electrolytic cell in a domestic factory, and the measured main element contents are (wt.%): C32.91, O15.9, Na 13.92, F 12.63, Al 8.93, and the TCLP leaching toxicity analysis results are fluoride ions The concentration is 5236.57mg / L.

[0041] After collecting the waste cathodes of the aluminum electrolytic cells, they were crushed and mixed to collect spare granules. Among the spare granules, the particles with a particle diameter of less than 60 mesh accounted for 90% of the total mass of the granules. Add the spare particles into deionized water at a liquid-solid ratio of 5:1, stir with a stirrer at a speed of 300r / min for 30min at 30°C, and filter after leaching to obtain a primary filtrate and a primary filter residue.

[0042] Add the primary filter residue to a 0.3mol / L ferric nitrate solution at a liquid-solid ratio of 10:1, stir with a stirrer at a speed of 300r / min for 90min at 50°C, and filter after le...

Embodiment 2

[0046] Take 100g of waste cathode carbon blocks from an aluminum electrolytic cell in a domestic factory, and the measured main element contents are (wt.%): C 32.91, O 15.9, Na 13.92, F 12.63, Al 8.93, and the fluoride ion concentration of the TCLP leaching toxicity analysis results is 5236.57mg / L.

[0047] After collecting the waste cathodes of the aluminum electrolytic cell, they were broken and mixed to collect spare particles, and the particles with a particle size of less than 60 mesh in the spare particles accounted for 80% of the total particle mass. Add the spare granules into deionized water at a liquid-solid ratio of 10:1, stir with a stirrer at a speed of 300r / min for 60min at 40°C, and filter after leaching to obtain primary filtrate and primary filter residue.

[0048] Add the primary filter residue to the mixed solution of 0.5mol / L ferric nitrate and 0.8mol / L nitric acid according to the liquid-solid ratio of 20:1, stir with a stirrer at a speed of 300r / min for 6...

Embodiment 3

[0052] Take 100g of waste cathode carbon blocks from an aluminum electrolytic cell in a domestic factory, and the measured main element contents are (wt.%): C 32.91, O 15.9, Na 13.92, F 12.63, Al 8.93, and the fluoride ion concentration of the TCLP leaching toxicity analysis results is 5236.57mg / L.

[0053] After collecting the waste cathodes of the aluminum electrolytic cell, they are broken and mixed to collect the spare granules. Among the spare granules, the particles with a particle diameter of less than 60 mesh account for 100% of the total mass of the granules. Add the spare particles into deionized water at a liquid-solid ratio of 10:1, stir with a stirrer at a speed of 200r / min for 60min at 50°C, and filter after leaching to obtain a primary filtrate and a primary filter residue.

[0054] Add the primary filter residue to the mixed solution of 0.3mol / L ferric nitrate and 0.6mol / L nitric acid according to the liquid-solid ratio of 10:1, stir with a stirrer at a speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com