Method for treating arsenic-containing wastewater with recyclable composite salt precipitation agent

A compound salt and precipitant technology, applied in flocculation/sedimentation water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. The effect of resource recovery and recycling, fast filtration, and large concentration range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]With n(Ca) / n(As)=1.05, n(Cu) / n(As)=0.45, n(Fe) / n(As)=1.20, n(Zn) / n(As)=1.20 After mixing calcium chloride, zinc chloride, ferrous sulfate and copper sulfate pentahydrate, add it to 4L 9.8g / L As(III)-containing wastewater (initial pH=1.8), stir at room temperature for 10min, and then use The sodium hydroxide solution was stirred to adjust the pH of the solution to 8.5, continued to stir for 0.5 h, and then filtered to obtain arsenic-containing slag and arsenic-precipitated liquid. The content of each component in the solution after arsenic precipitation is shown in Table 1:

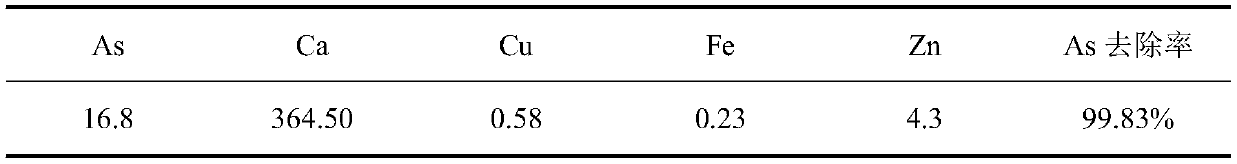

[0032] Table 1 Contents of each component in the liquid after arsenic precipitation (mg / L)

[0033]

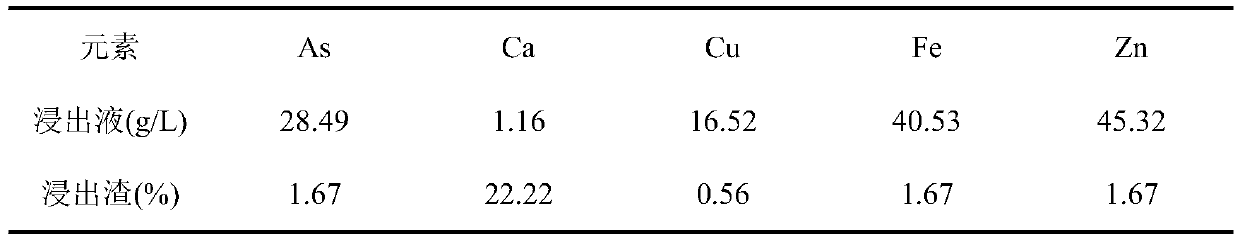

[0034] Under the conditions of liquid-solid ratio 3:1 (mL:g), sulfuric acid concentration 0.8mol / L, and leaching temperature 25°C, the arsenic-containing slag was leached for 0.5h, and the leaching slag and leaching liquid were obtained by filtration, and the content of each component in the leac...

Embodiment 2

[0048] With n(Ca) / n(As)=1.0, n(Cu) / n(As)=0.6, n(Fe) / n(As)=1.5, n(Zn) / n(As)=1.5 After mixing calcium chloride, zinc chloride, ferrous sulfate and copper sulfate pentahydrate, add it to 4L 2.39g / L arsenic-containing wastewater (initial pH=1.9), stir at room temperature for 10min, and then add sodium hydroxide The pH of the solution was adjusted to 8.5 under the condition of stirring, and the stirring reaction was continued for 1.5 hours, and then filtered to obtain arsenic-containing slag and arsenic-precipitated liquid. The content of each component in the solution after arsenic precipitation is as shown in Table 4:

[0049] Contents of each component in the solution after table 4 arsenic precipitation (mg / L)

[0050]

[0051] The arsenic-containing slag was leached for 1 hour under the conditions of sulfuric acid concentration 1.7mol / L, liquid-solid ratio 5:1, and leaching temperature 30°C, and the leaching residue and leaching solution were obtained by filtration. The ars...

Embodiment 3

[0063] With n(Ca) / n(As)=16.8, n(Cu) / n(As)=7.2, n(Fe) / n(As)=19.2, n(Zn) / n(As)=19.2 Mix calcium chloride, zinc chloride, ferrous sulfate and copper sulfate pentahydrate and add them to 4L 50mg / L arsenic-containing wastewater (initial pH=1.9), stir at room temperature for 10min, and then use sodium hydroxide solution Adjust the pH of the solution to 8.7 under stirring conditions, continue to stir and react for 1.5 hours, and then filter to obtain arsenic-containing slag and arsenic-precipitated liquid. The contents of each component in the solution after arsenic precipitation are shown in Table 7:

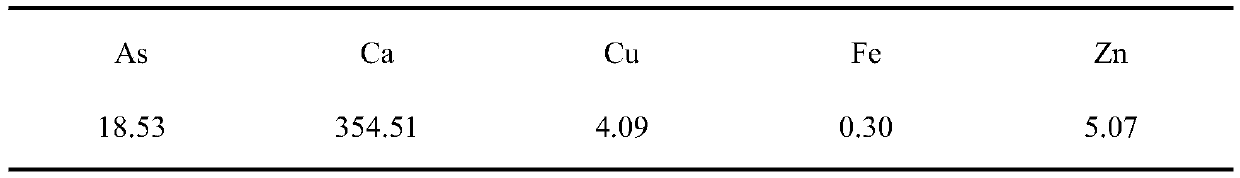

[0064] Contents of each component in the solution after table 7 arsenic precipitation (mg / L)

[0065]

[0066] It can be seen from Table 7 that the concentration of each element in the waste water can be kept within the range of the "Comprehensive Wastewater Discharge Standard" (GB8978-1996) by expanding the compound salt ratio and treating low-concentration arsenic-containing was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com