Improved aeration settling tank

A sedimentation tank and aeration technology, applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of cumbersome operation, difficult control, high investment cost, etc., and reduce chemical cleaning Frequency, beneficial to collision and precipitation, and the effect of reducing investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but this is not a limitation of the present invention. The scope of protection of the present invention is subject to the contents recorded in the claims, and any equivalent technical means replacement made according to the specification will not depart from protection scope of the present invention.

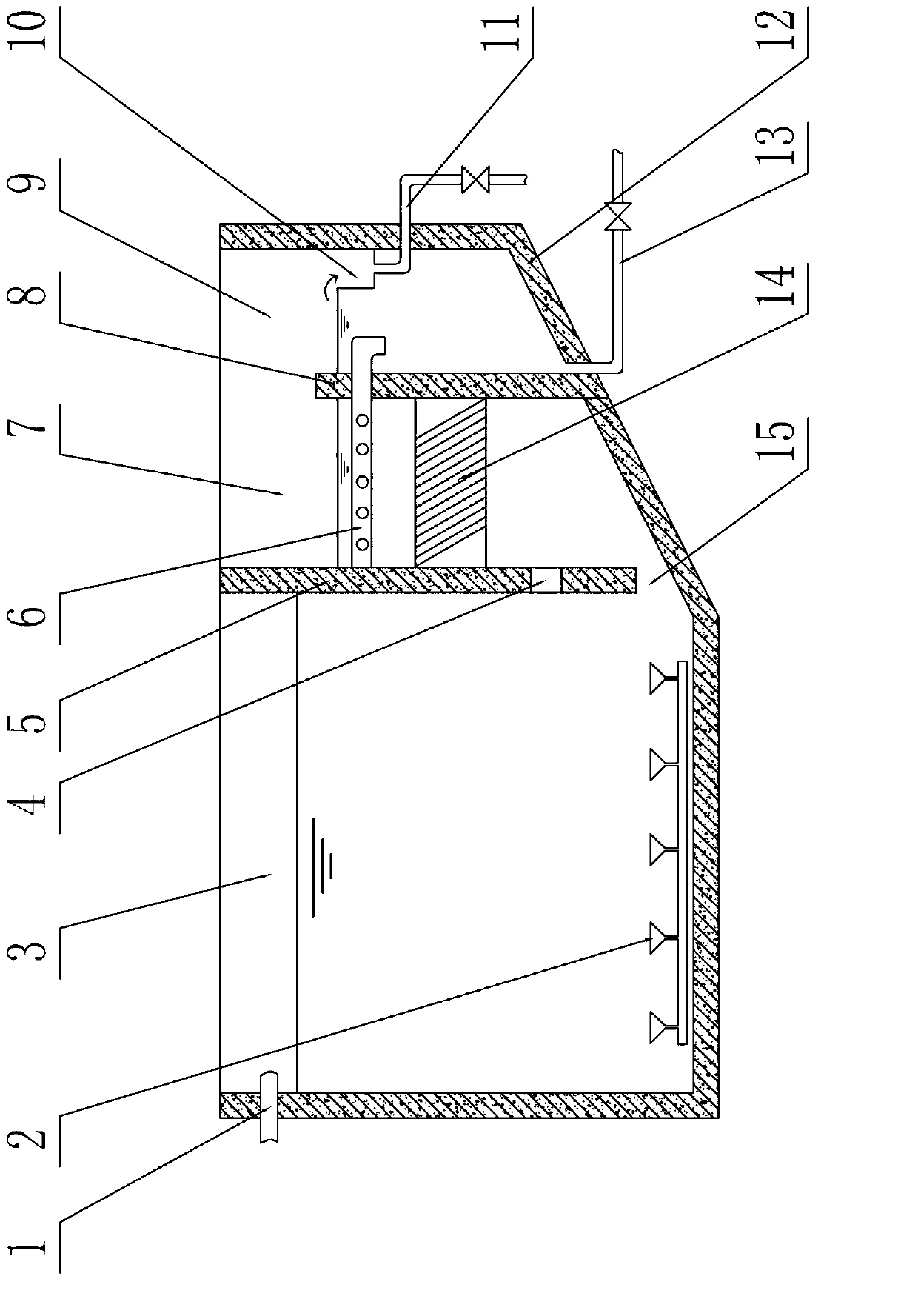

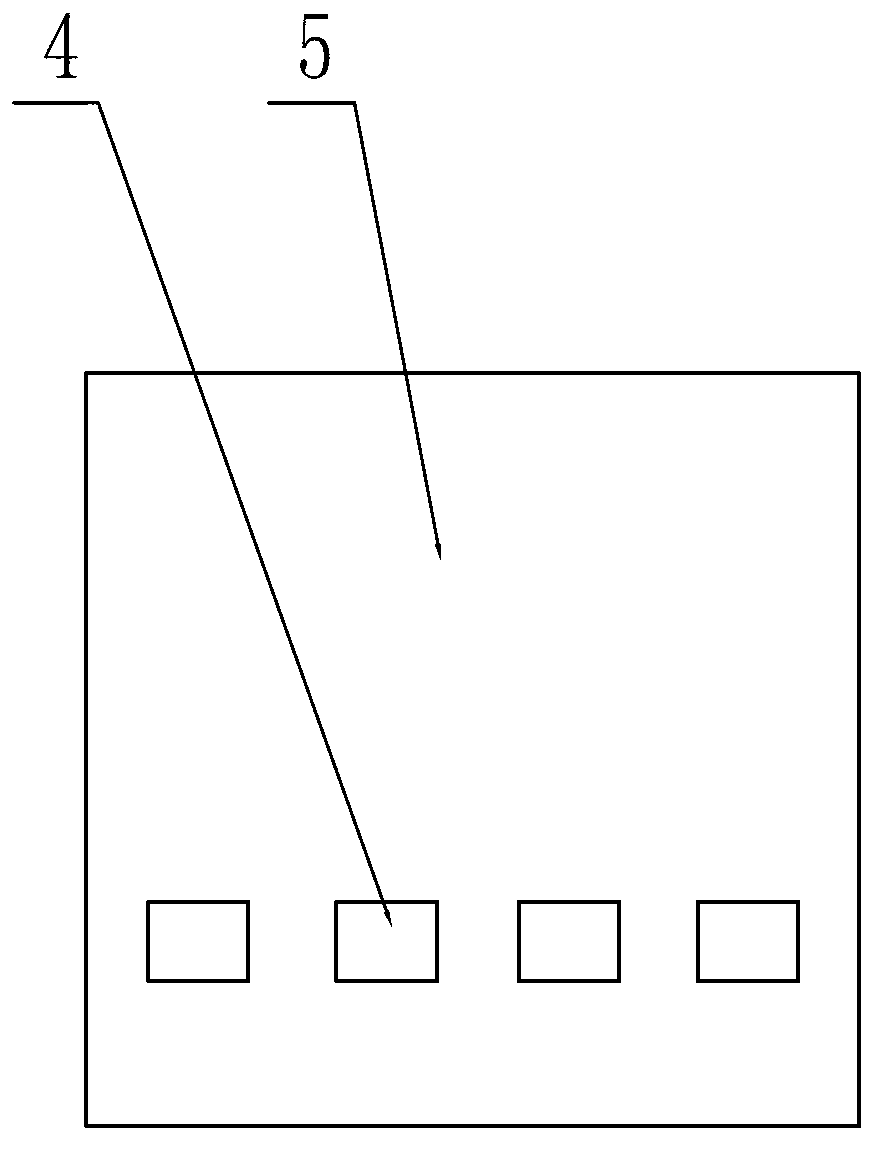

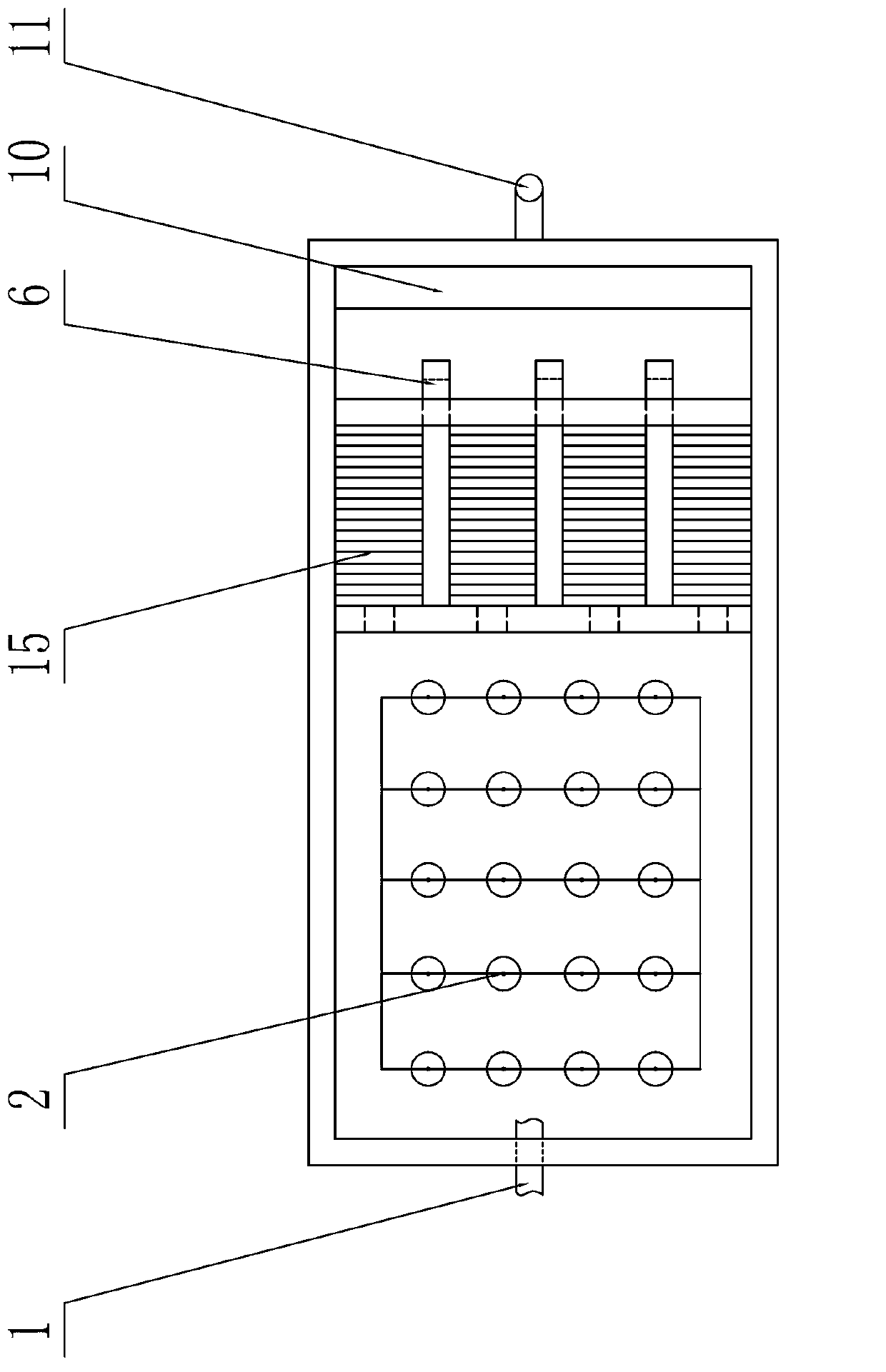

[0036] The overall technical structure of this embodiment is shown in the figure, which includes the pool body, the water inlet pipe 1 set in the front of the side wall of the pool body, the bottom of the pool body is a slope 12 inclined downward from the end to the beginning, and the bottom of the pool is provided with an aeration Device 2, the inner side of the pool wall at the end of the pool body is provided with a sump 10, and the front of the sump 10 is provided with inclined plates 14 distributed in parallel intervals; the front and rear sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com