Method for removing fluorinion in waste water

A fluoride ion and waste water technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of complicated steps, many kinds of chemical agents, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

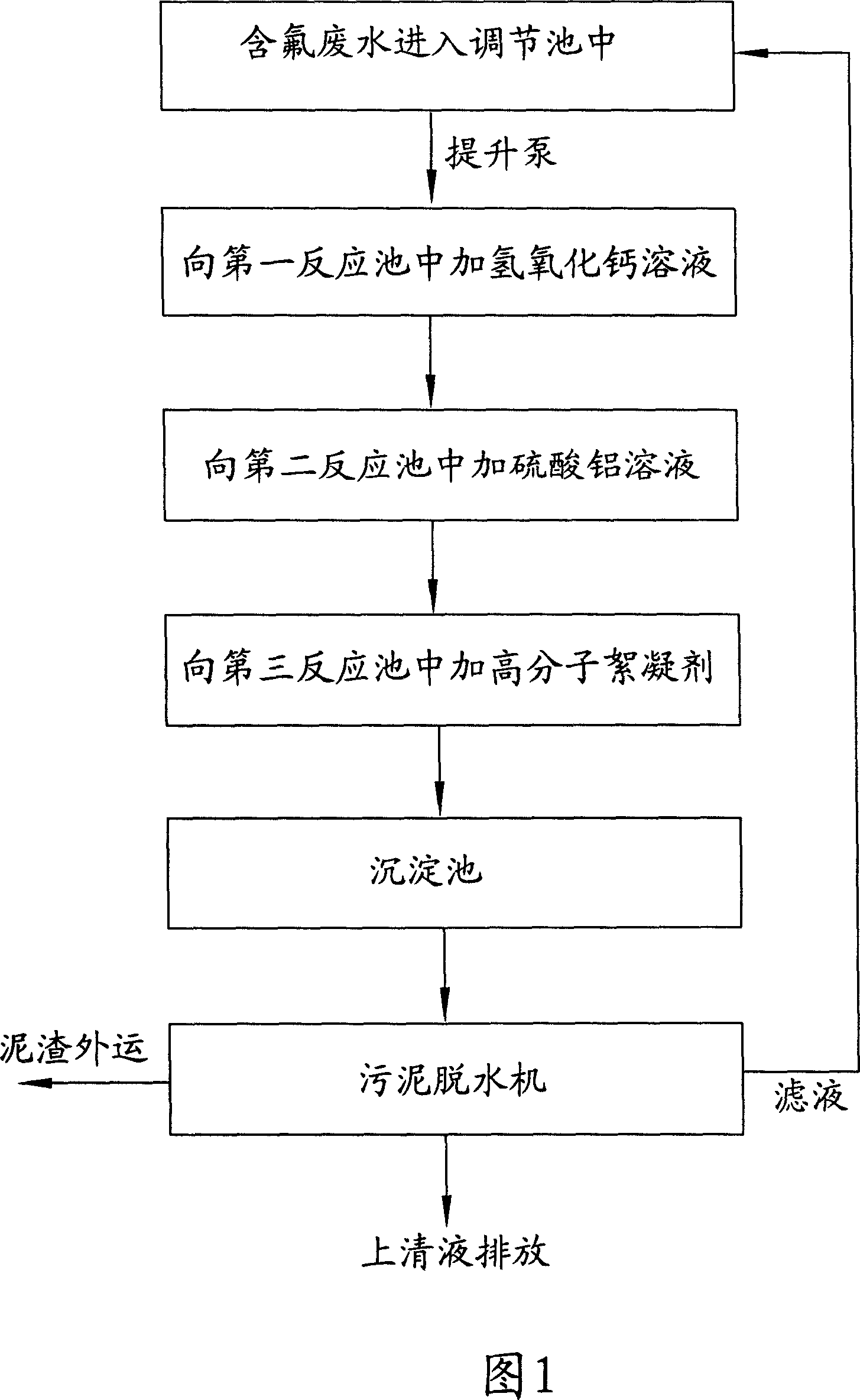

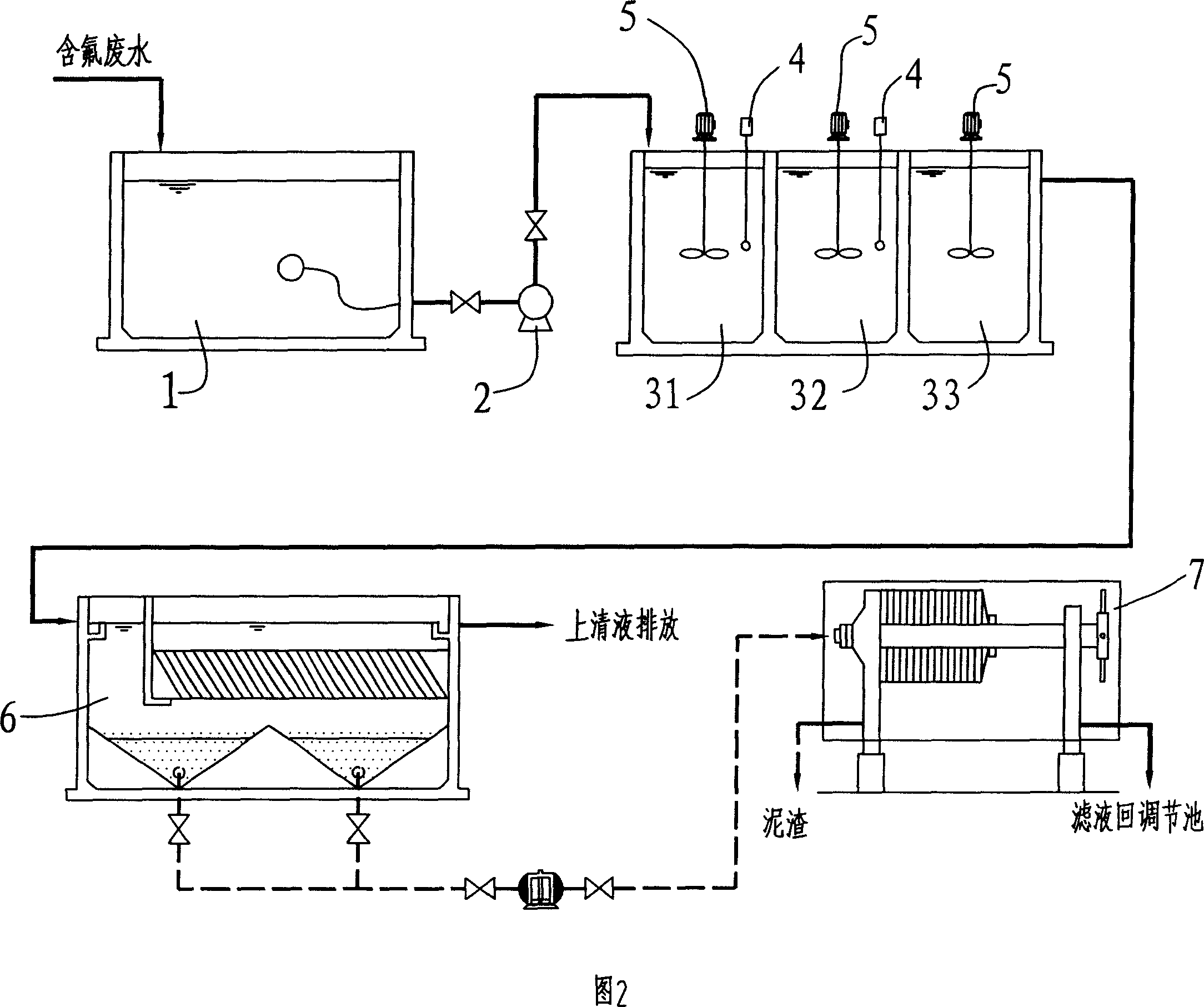

[0014] With reference to accompanying drawing 1 and Fig. 2, in one embodiment of the present invention, the waste water to be treated is the industrial waste water containing the high concentration fluorine ion discharged by the semiconductor production plant, and its pH value is about 2.5, and the fluorine ion concentration is 300mg / L or so, the waste water flow rate is 25-30m 3 / h, the volume of waste water entering is 180m 3 After adjusting the tank 1, pump it into the tank with a volume of 10m by the lift pump 2 3 In the first reaction tank 31, the dosing pump is controlled by the pH meter 4 to inject calcium hydroxide solution into the first reaction tank 31, so that the pH value of the waste water reaches 8.5, 9.0, and 9.5 respectively, and the stirring pump 5 is used to stir to increase the reaction intensity of the stirring. 600s-~700s-, the wastewater residence time is 15-20 minutes;

[0015] The resulting waste water injection volume is 15m 3 In the second reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com