Patents

Literature

553 results about "CALCIUM HYDROXIDE SOLUTION" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In calcium: Compounds Calcium hydroxide, also called slaked lime, Ca(OH)2, is obtained by the action of water on calcium oxide. When mixed with water, a small proportion of it dissolves, forming a solution known as limewater, the rest remaining as a suspension called milk of lime.

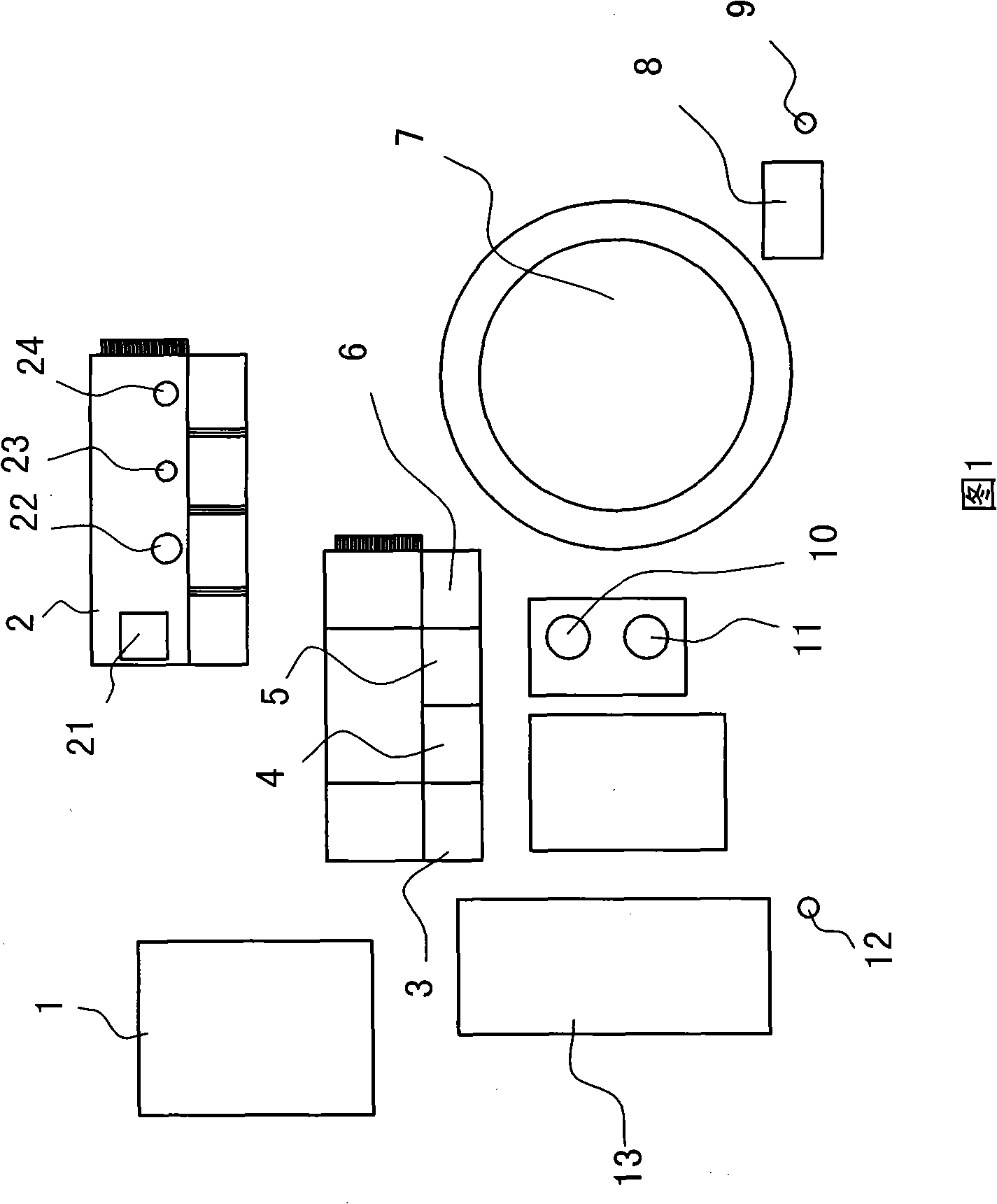

Method and means for capture and long-term sequestration of carbon dioxide

InactiveUS20090081096A1High heat of reactionHigh regeneration energyCombination devicesGas treatmentSolubilityAmbient pressure

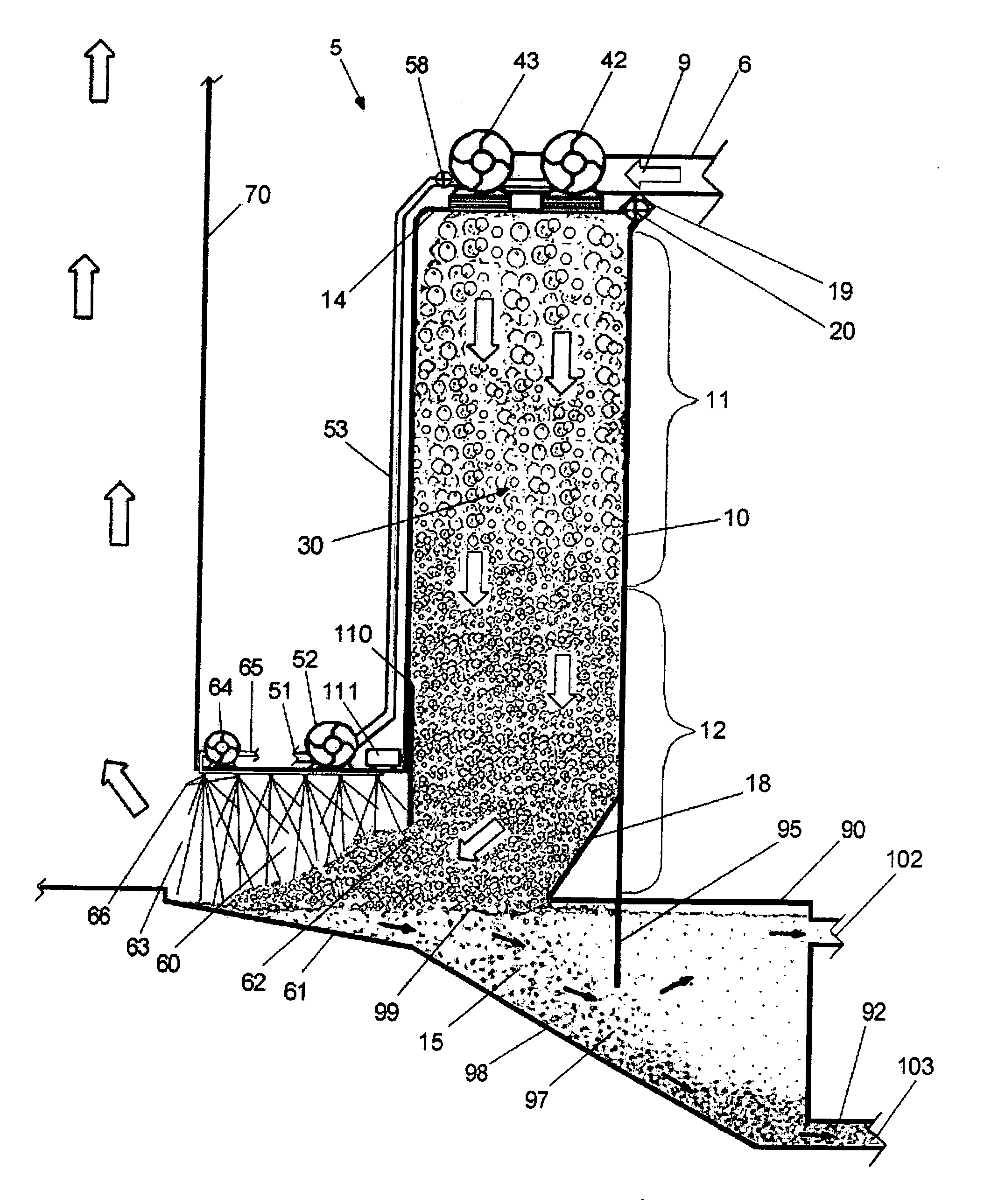

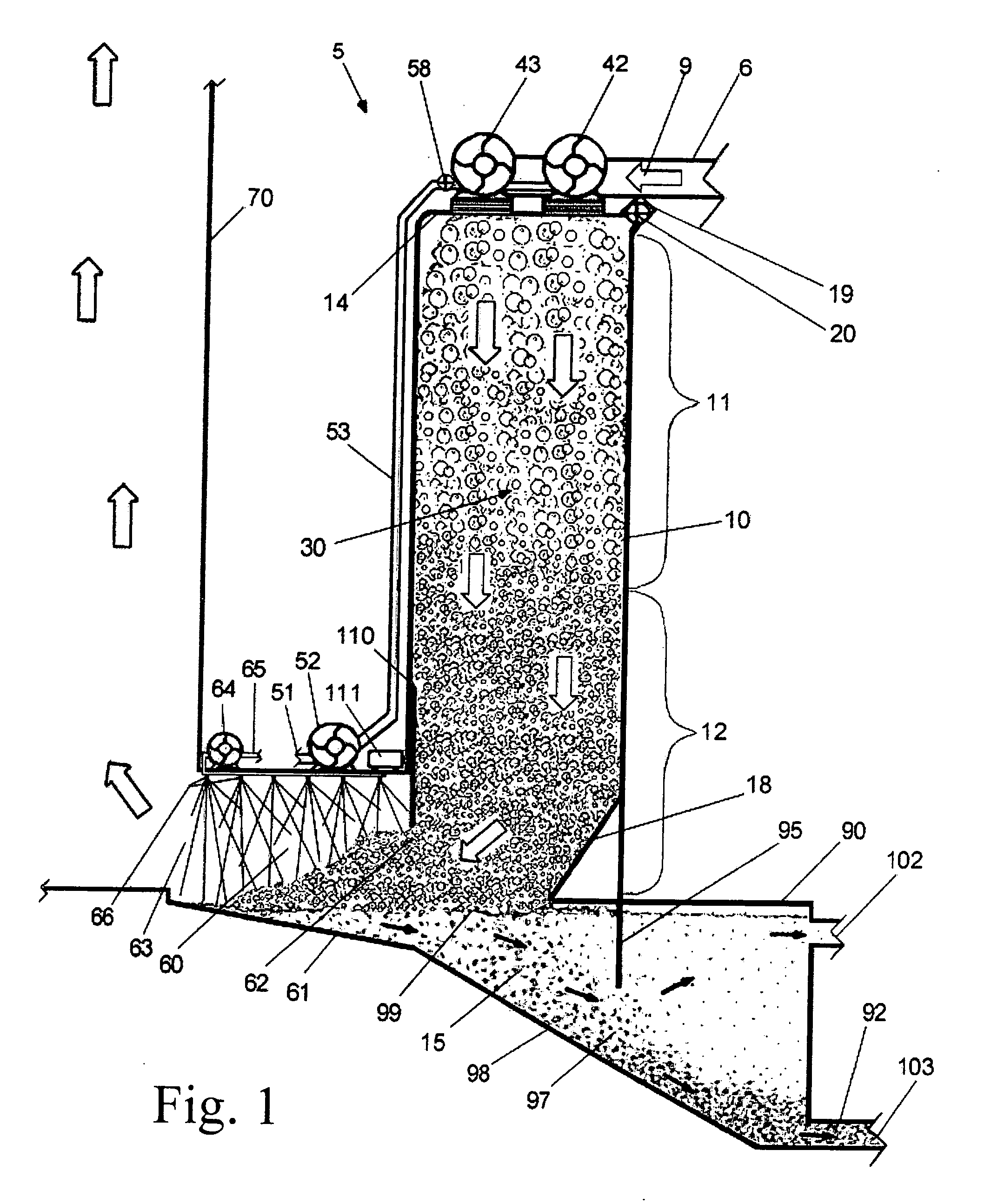

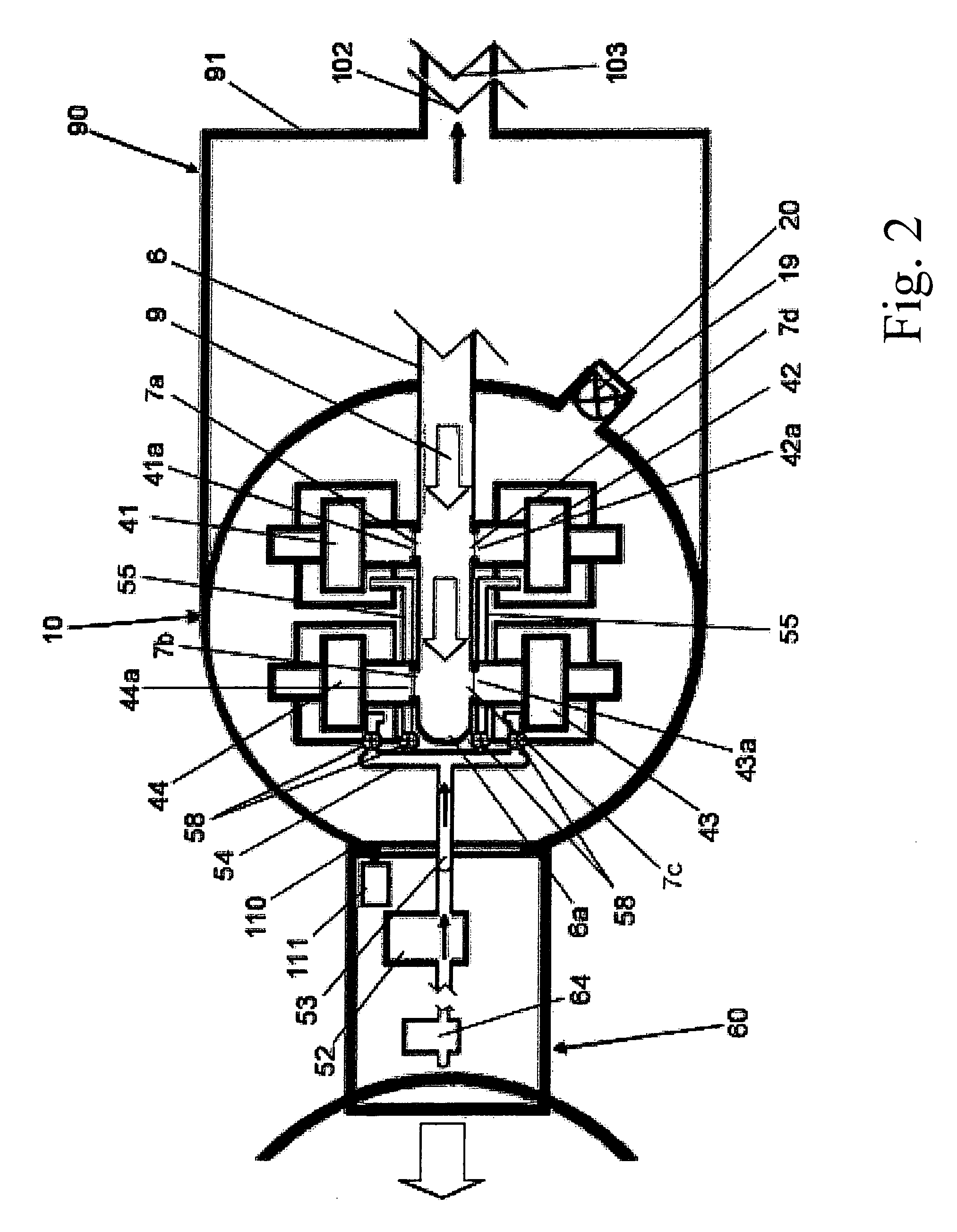

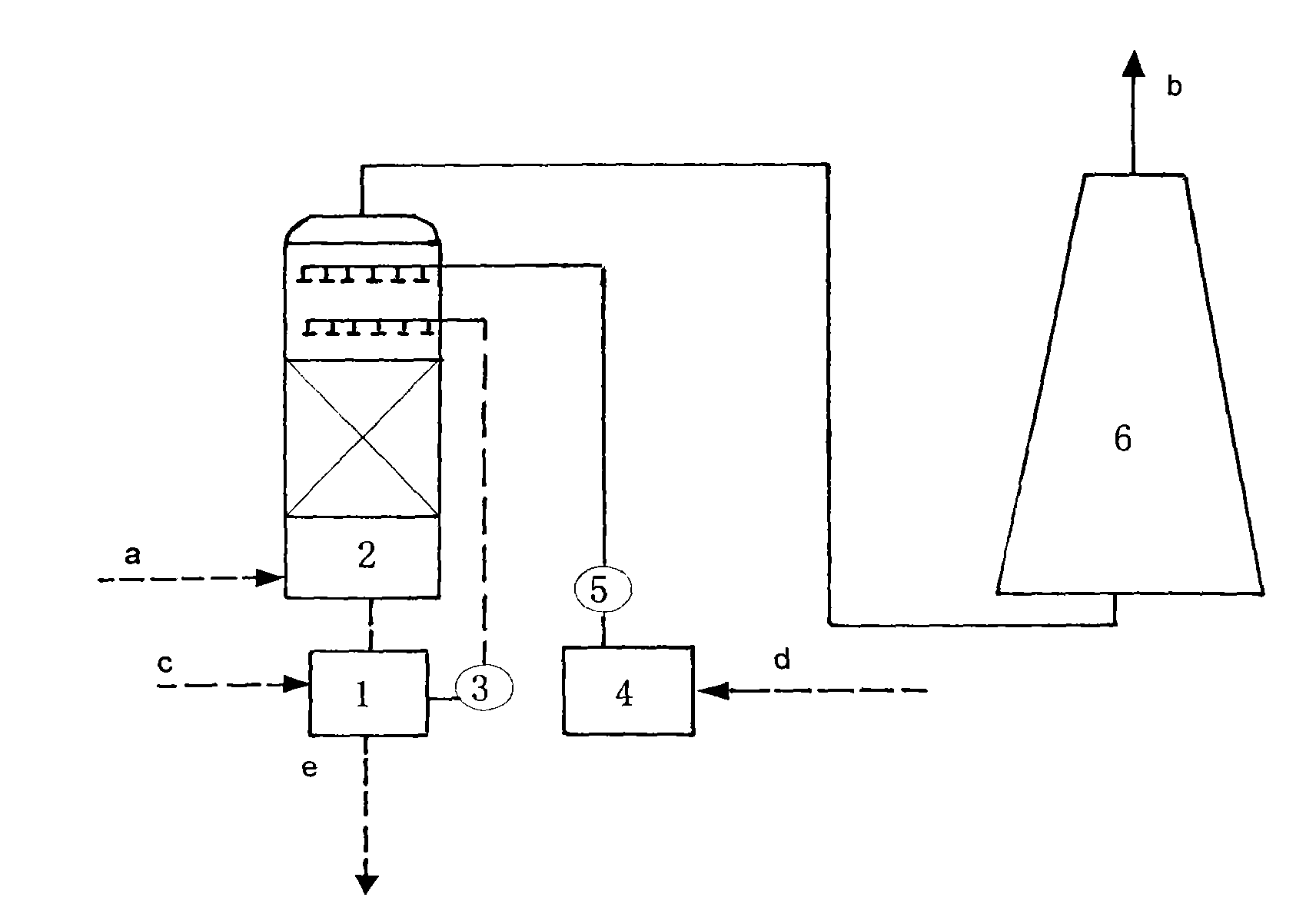

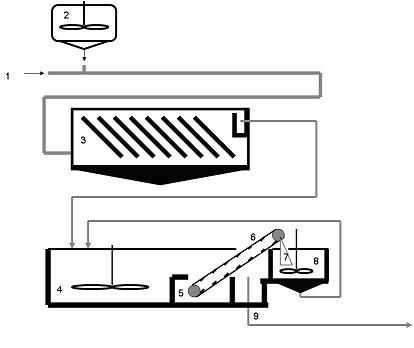

The invention teaches a practical method of recovering CO2 from a mixture of gases, and sequestering the captured CO2 from the atmosphere for geologic time as calcium carbonate and provides a CO2 scrubber for carbon capture and sequestration. CO2 from the production of calcium oxide is geologically sequestered. A calcium hydroxide solution is produced from the environmentally responsibly-produced calcium oxide. The CO2 scrubber incorporates an aqueous froth to maximize liquid-to-gas surface area and time-of-contact between gaseous CO2 and the calcium hydroxide solution. The CO2 scrubber decreases the temperature of the liquid and the mixed gases, increases ambient pressure on the bubbles and vapor pressure inside the bubbles, diffuses the gas through intercellular walls from relative smaller bubbles with relative high vapor pressure into relative larger bubbles with relative low vapor pressure, and decreases the mean-free-paths of the CO2 molecules inside the bubbles, in order to increase solubility of CO2 and the rate of dissolution of gaseous CO2 from a mixture of gases into the calcium hydroxide solution.The CO2 scrubber recovers gaseous CO2 directly from the atmosphere, from post-combustion flue gas, or from industrial processes that release CO2 as a result of process. CO2 reacts with calcium ions and hydroxide ions in solution forming insoluble calcium carbonate precipitates. The calcium carbonate precipitates are separated from solution, and sold to recover at least a portion of the cost of CCS.

Owner:WESTEC ENVIRONMENTAL SOLUTIONS

Method for preparing sodium hydrosulfide

InactiveCN101337661AQuality improvementIncrease profitSulfur compoundsHydrogenCALCIUM HYDROXIDE SOLUTION

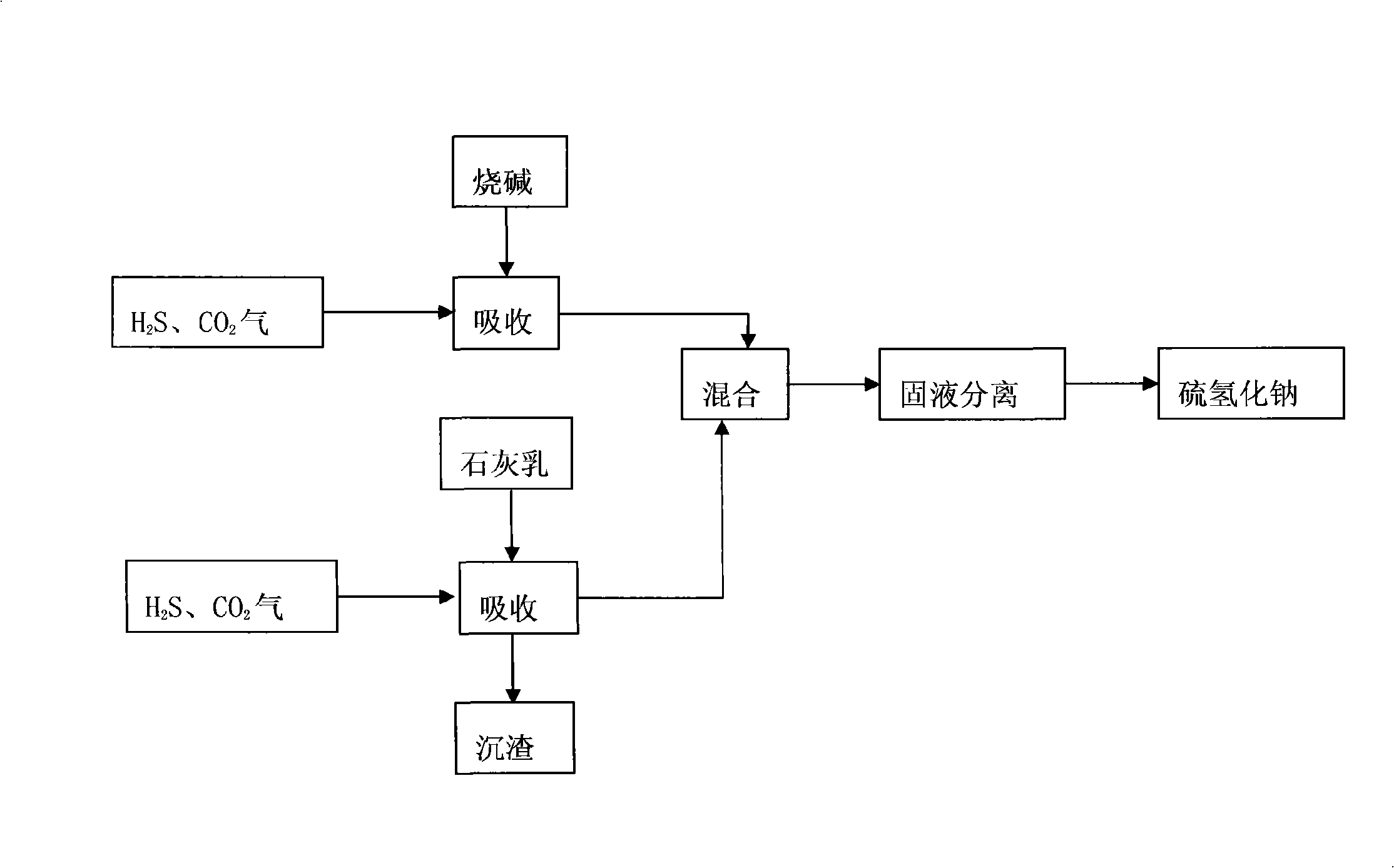

The invention discloses a method for preparing sodium hydrosulfide. The production process is as follows: introducing a mixed gas containing sulfureted hydrogen H2S with the content larger than 10 percent and carbon dioxide CO2 with the content not larger than 90 percent into lime cream of about 12 percent of concentration, under the condition of a certain temperature and pressure and under agitation; stopping reaction when CaS is less than or equal to 0.5 percent; separating sediments out to obtain a sulfur calcium hydroxide solution; introducing a mixed gas of sulfureted hydrogen and carbon dioxide into a caustic soda solution with concentration larger than 30 percent under the condition of a certain temperature and pressure and under agitation; stopping reaction when Na2S is less than or equal to 0.5 percent to obtain a sodium hydrosulfide solution containing carbonate ions; and adding slightly not enough sodium hydrosulfide solution under agitation according to the amount of the carbonate ions in the sodium hydrosulfide solution, and separating sediments out to obtain sodium hydrosulfide with low carbonate ions.

Owner:褚亚华

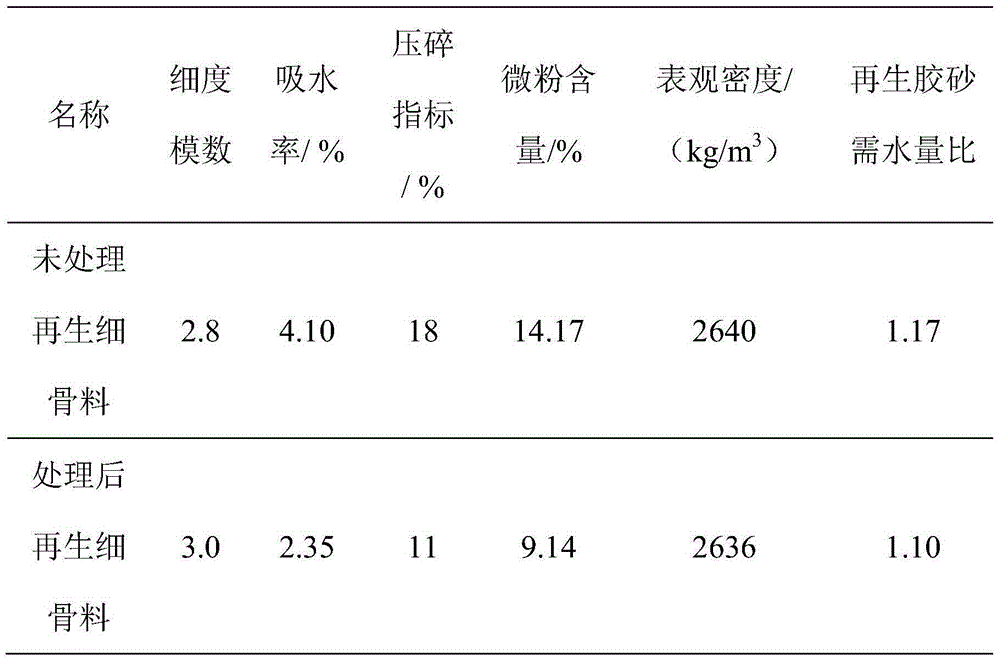

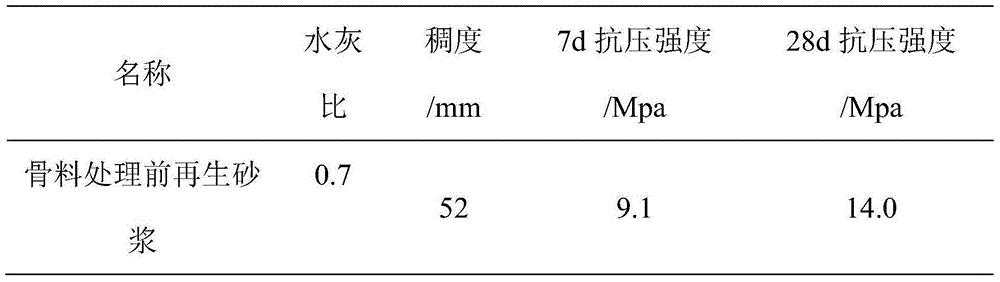

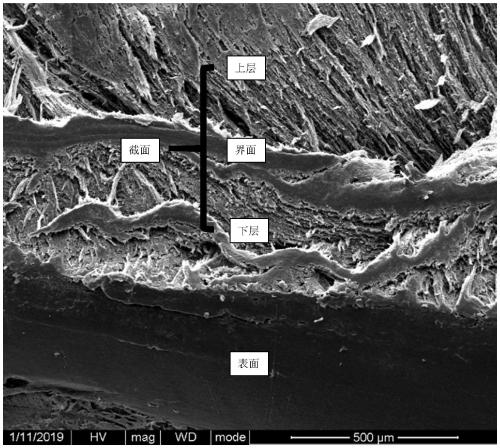

Method for reinforcing recycled concrete fine aggregate by using carbon dioxide

ActiveCN105174766AImprove water absorptionLow water absorptionSolid waste managementCALCIUM HYDROXIDE SOLUTIONCalcification

The invention discloses a method for reinforcing recycled concrete fine aggregate by using carbon dioxide, which comprises the following steps: (1) calcium hydroxide solution or calcium salt calcification treatment: spreading recycled fine aggregate prepared from construction waste on a tray, spraying a calcium hydroxide or calcium salt solution, and stirring uniformly; (2) CO2 curing: putting the recycled fine aggregate subjected to calcium hydroxide solution or calcium salt calcification treatment in a closed carbonization box, and carrying out carbonization curing until the surface is completely carbonized; and (3) recycled mortar preparation: preparing recycled mortar with the substitution rate of 100% by using the treated recycled fine aggregate. Compared with the unreinforced recycled aggregate, the crushing value of the recycled fine aggregate prepared by the method is lowered by nearly 45%, and the water absorptivity is lowered by nearly 53%. Compared with the recycled mortar prepared from the unreinforced recycled aggregate, the consistency of the recycled mortar prepared by the method is enhanced by 42% or so, the 7d strength of the mortar is enhanced by 15-26%, and the 28d strength can be enhanced by 17-24%.

Owner:SOUTHEAST UNIV +1

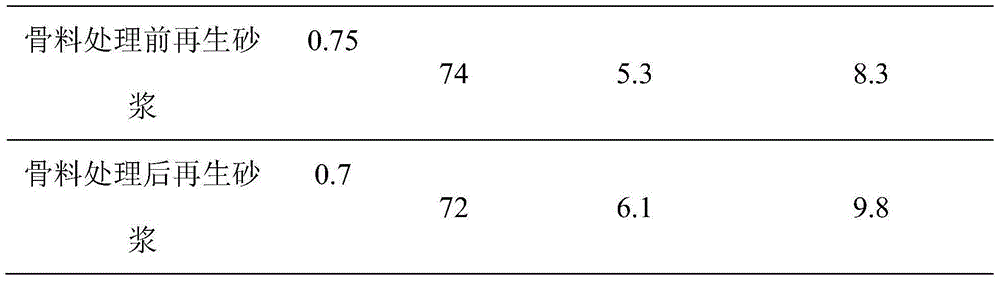

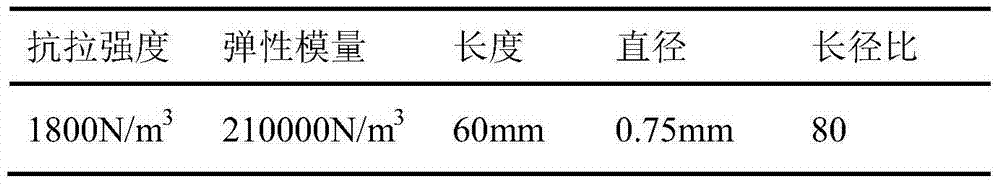

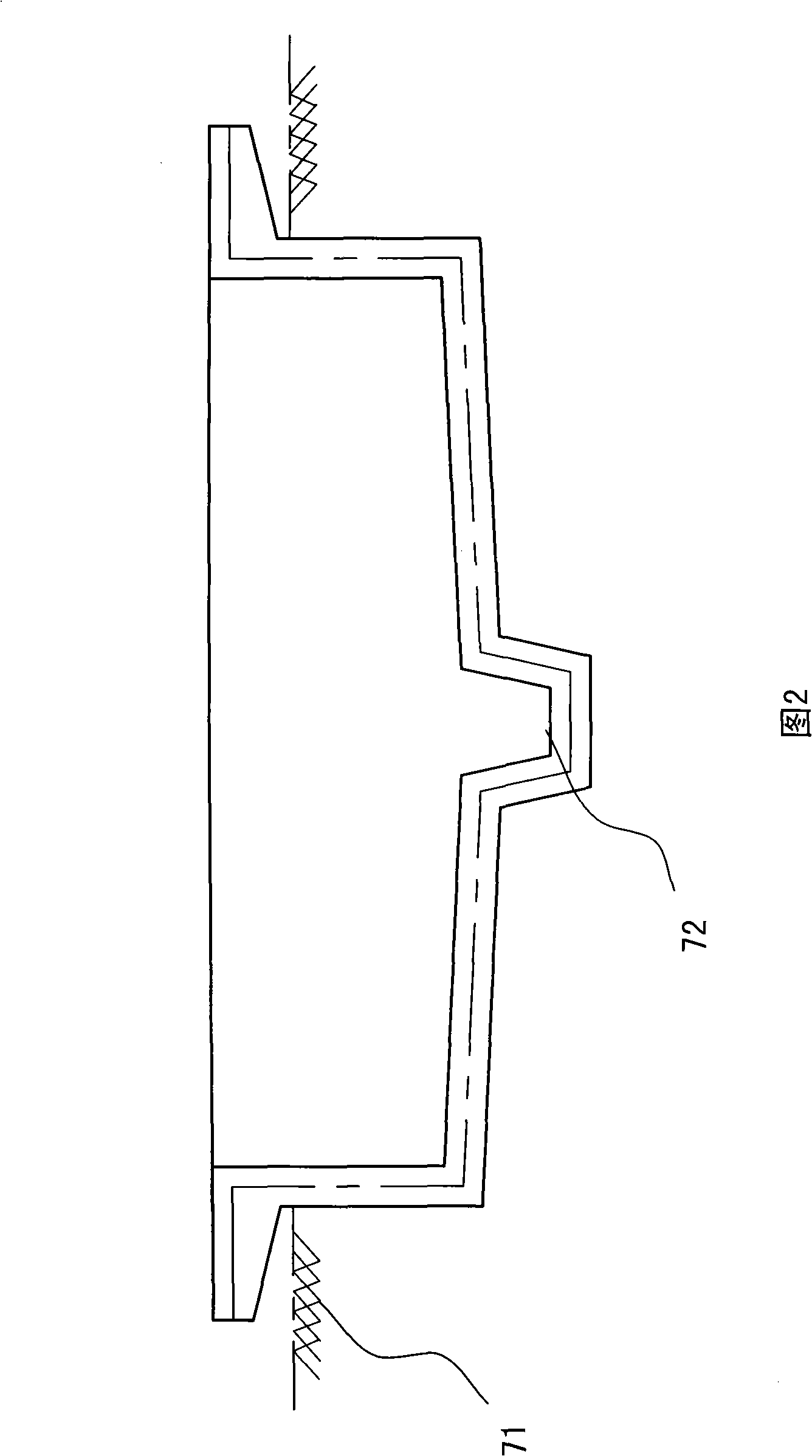

Steam-curing-free early-strength steel fiber concrete pipe segment and preparation method thereof

InactiveCN104773988AHarden fastSimplify maintenanceSolid waste managementFiberCALCIUM HYDROXIDE SOLUTION

The invention discloses a steam-curing-free early-strength steel fiber concrete pipe segment comprising ordinary Portland cement, early-strength sulphoaluminate cement, fly ash, slag, fine aggregate, coarse aggregate, water, a polycarboxylic acid type water reducer and end hook type steel fibers. The invention also discloses a preparation method of the steam-curing-free early-strength steel fiber concrete pipe segment. The steam-curing-free early-strength steel fiber concrete pipe segment is quick in coagulation and hardening and high in early strength, can reach the strength of 15MPa required by pipe segment demolding in 6-8 hours, and can be prepared into a concrete pipe segment for an underground structure by performing water curing in a 20 DEG C saturated calcium hydroxide solution for 24 hours and then performing natural curing for 28 days. The steam-curing-free early-strength steel fiber concrete pipe segment does not need steam curing, so that the curing mode of the pipe segment can be simplified, the curing time is shortened, a lot of manpower and resources are saved, and the popularization and application values are high.

Owner:SOUTHEAST UNIV +1

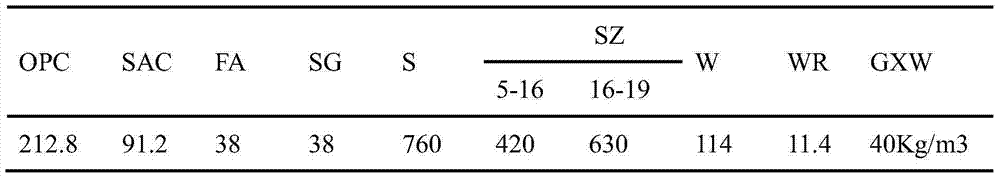

Method for extracting titanium slag, tungsten and vandic salt from waste SCR catalyst

ActiveCN106119544ASolve harmless disposalLow investment requirementProcess efficiency improvementSlurryCalcium tungstate

The invention provides a method for extracting titanium slag, tungsten and a vandic salt from a waste SCR catalyst. The method comprises the steps that the waste SCR catalyst is preprocessed and crushed into slurry by use of a wet method; a sodium hydroxide solution is added into the slurry for reaction; coarse titanium slag power and compression filtrate are obtained by filter-pressing and separating the slurry by use of a plate-and-frame filter press; the coarse titanium slag power is placed into a sulfuric acid solution for cleaning, cleaned with clear water, and then filtered and separated for obtaining titanium slag powder containing titanium dioxide; and the compression filtrate is treated through a waste alkali nanofiltration recovery device, the compression filtrate containing sodium tungstate and sodium vanadate is added into a saturated calcium hydroxide solution for reaction, products from the reaction are subjected to filter pressing, and then calcium vanadate and calcium tungstate mixed solid bodies are obtained through filtering and separating.

Owner:安徽思凯瑞环保科技有限公司

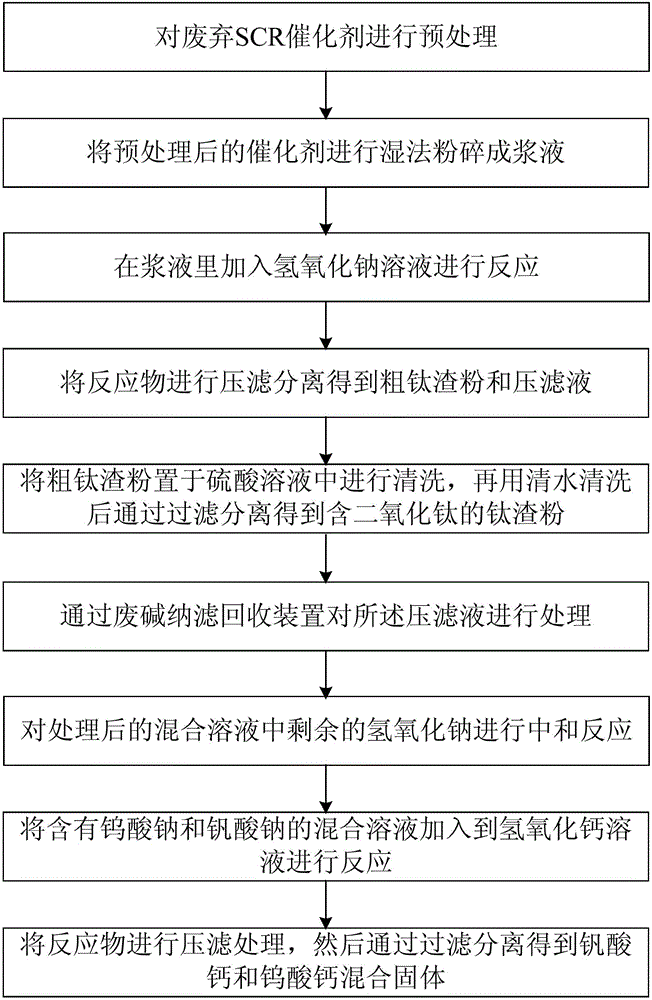

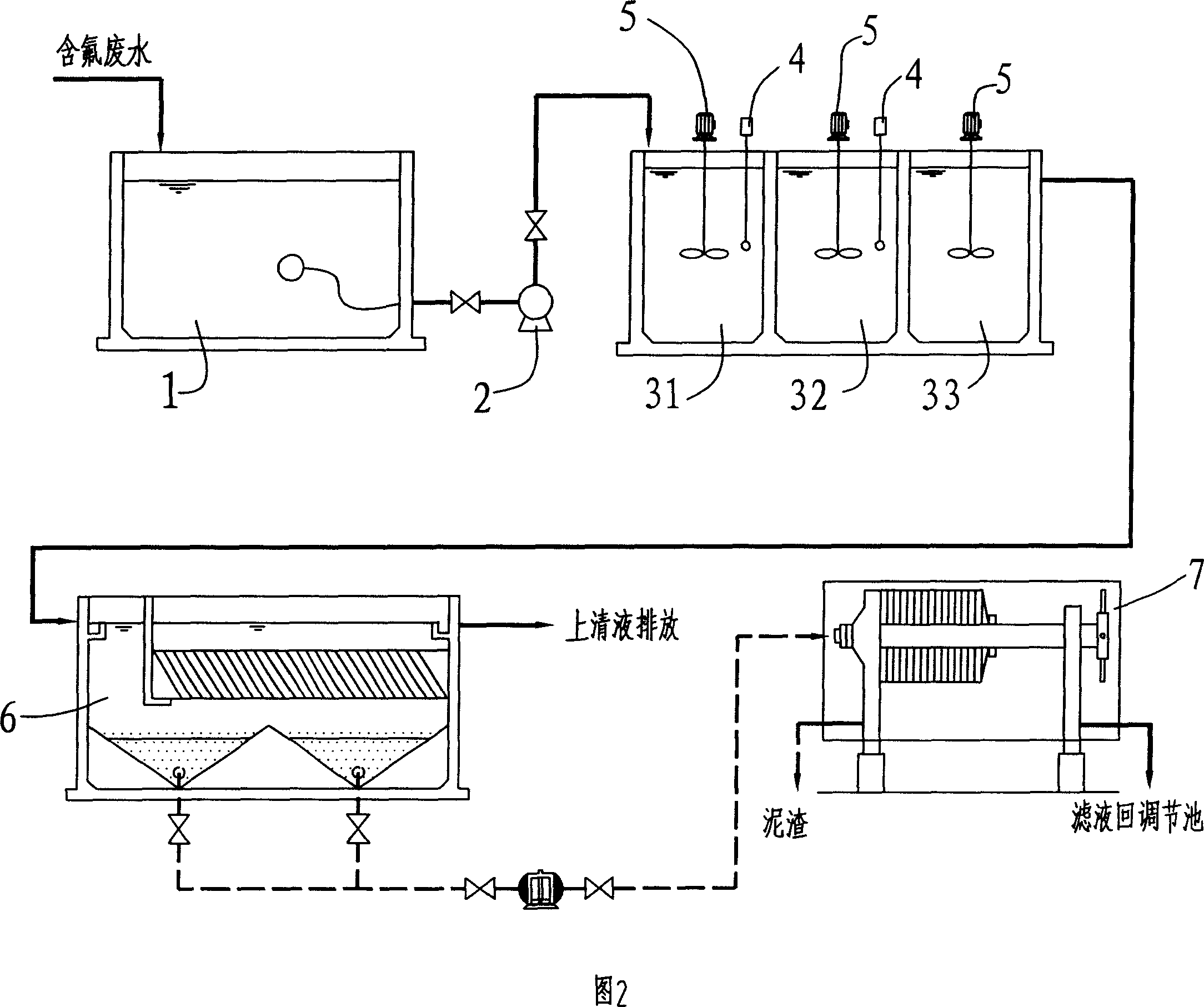

Method for removing fluorinion in waste water

ActiveCN101062817AIncrease displacementEasy to settleMultistage water/sewage treatmentWater/sewage treatment by neutralisationCALCIUM HYDROXIDE SOLUTIONIndustrial waste water

The invention discloses a method to remove fluorinion in waste water, which comprises the following steps: a, adding calcium hydrate solution into industrial waste water with fluorinion; stirring; adjusting the pH value of the waste water at 8. 5-9. 5; setting the reacting time at 15-20 min; b, adding aluminum sulfate solution into the waste water of the step a; stirring; adjusting the pH value of the waste water at 6. 0-6. 5; setting the reacting time at 20-25 min; c, adding polymeric flocculant into the waste water from the step b, stirring; injecting the waste water into desilter; proceeding flocculate deposition; discharging supernatant fluid; getting sediment; proceeding solid-liquid separation; outer-transporting or imbedding the solid sludge. This craft possesses simple procedure and convenient operation, which is fir for the plant with higher waste water output volume.

Owner:JIANGXI JDL ENVIRONMENTAL PROTECTION CO LTD

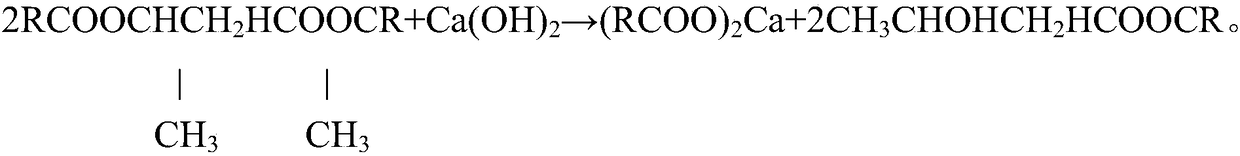

Rice bran calcium cerotate soap wax and preparation method thereof

ActiveCN108191602AHigh glossReduce manufacturing costOxygen-containing compound preparationOrganic compound preparationAcetic acidPolyol

The invention provides a preparation method of a rice bran calcium cerotate soap wax. The preparation method comprises the following steps: deoiling, soaking the deoiled but undecolorized rice bran wax into ethyl acetate, heating to melt, cooling, and cutting into slices for later use; oxidizing, heating the sliced rice bran wax and dilute sulphuric acid together to melt the rice bran wax, addinga sodium bichromate solution, constantly stirring and oxidizing, heating the oxidized rice bran wax into a liquid, then adding the dilute sulphuric acid, stirring, standing, layering, stirring while adding water, raising the temperature until the wax is completely melted, continuing to stir, standing and layering to obtain the rice bran wax cerotate; esterifying, heating and melting the rice branwax cerotate, raising the temperature, adding a polyhydric alcohol to have esterification reaction to obtain rice bran cerotate ester wax; saponifying, heating and melting the rice bran cerotate esterwax, and adding a calcium hydroxide solution to implement partial saponification to obtain the rice bran calcium cerotate soap wax. The invention further provides the rice bran calcium cerotate soapwax. The preparation method provided by the application is low in production cost, and the product is harder and has the performances of high temperature resistance and high gloss, and can substitutemouton wax soap.

Owner:重庆合才化工科技有限公司

Method for treating high-fluorine sewage water

InactiveCN101402493AEmission complianceRapid precipitation separationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSludgeTreated water

The invention provides a method for treating highly fluorine-contained wastewater, wherein four reaction tanks orderly overflowed are used, according to the weight ratio of calcium to fluorine of 3 to 1, the wastewater is fully mixed with calcium hydroxide solution with the concentration of 5 percent in the No. 1 reaction tank; in the No. 2 reaction tank, the overflowed water of the No. 1 reaction tank is fully mixed with calcium chloride solution of calcium hydroxide emulsion of which the concentration is 8 percent and the weight is 40 percent of the weight of the overflowed water of the No. 1 reaction tank; in the No. 3 reaction tank, the overflowed water of the No. 2 reaction tank is mixed with polyaluminum solution of which the concentration is 1 percent and the weight is 40 mg for each liter of the overflowed water of the No. 2 reaction tank; in the No. 4 reaction tank, the overflowed water of the No. 3 reaction tank is mixed with the polyacrylamide solution of which the concentration is 10 percent and the weight is 20 mg for each liter of the overflowed water of the No. 3 reaction tank; and the treated water from the No. 4 reaction tank is sent in a radial flow type sedimentation tank, and the supernatant of the radial flow type sedimentation tank is discharged into a clear water tank, and lower layer sludge is pumped in a sludge thickener for further sedimentation and separation. The fluoride concentration of the industrial wastewater is reduced to below 10 mg / L after being treated, thereby meeting the national pollution discharge standards.

Owner:浙江汉盛氟化学有限公司

Method for extracting stevioside from stevia rebaudiana leaves

InactiveCN106046075AKeep active ingredientsHigh dissolution rateSugar derivativesSugar derivatives preparationCALCIUM HYDROXIDE SOLUTIONDistillation

The invention discloses a method for extracting stevioside from stevia rebaudiana leaves. The method comprises the following steps of washing, soaking, drying stevia rebaudiana leaves and sieving to obtain stevia rebaudiana leaf powder; mixing the stevia rebaudiana leaf powder with water, adding complex enzyme, adjusting the pH value and heating by microwave, extracting and filtering by ultrasound to obtain an extracting solution and a filter residue; mixing the filter residue with diethyl ether, performing centrifugal separation to obtain a total extract; mixing the total extract with a ferric trichloride solution and a calcium hydroxide solution; after performing heating, heat preservation and cooling, mixing with a sodium hydroxide solution; after adjusting the pH value, mixing with an aluminum sulfate solution, after stirring, performing supercritical extraction to obtain an extract liquor; using AB-8 type macroporous resin to adsorb the extract liquor; performing elution, distillation, concentration and drying, so as to obtain a stevioside crude product; putting the stevioside crude product into water; ultrasonically dissolving and adding active aluminium oxide for adsorbing; and then filtering, washing, subsiding, combining filter liquor and washing liquor, and concentrating and drying.

Owner:BENGBU HUADONG BIOLOGICAL TECH

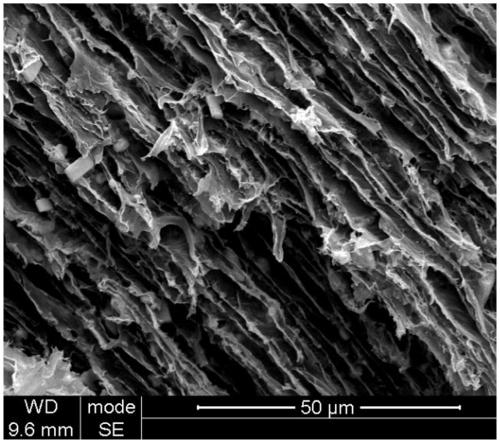

Method for recovering and reinforcing concrete aggregate

InactiveCN105884230AConserve waterIncrease the content of carbonizable substancesSolid waste managementCALCIUM HYDROXIDE SOLUTIONReinforced concrete

The invention discloses a method for recovering and reinforcing concrete aggregate. According to the method, waste concrete discharged during cleaning of a stirring vehicle is scientifically and effectively utilized, and water for separating cement and sand is saved. When the content of carbonatable substances in recycled aggregate is increased during treatment of a calcium hydroxide solution or a calcium salt solution with the method, calcium carbonate formed after carbonization treatment effectively fills microcracks, the porosity of the recycled aggregate is effectively reduced, and the crushing value and the water absorption of the aggregate are further reduced.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

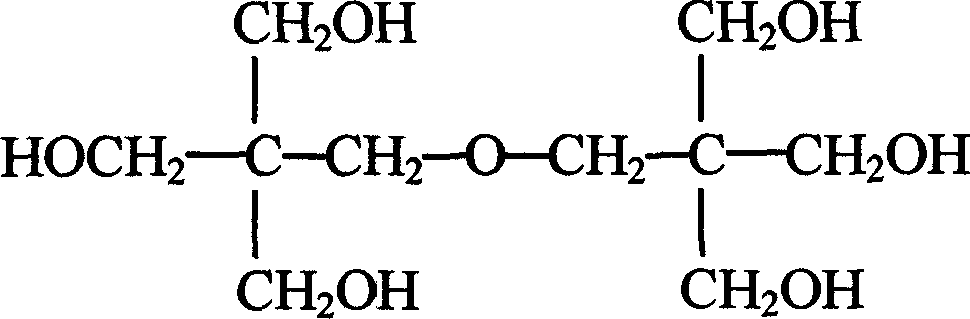

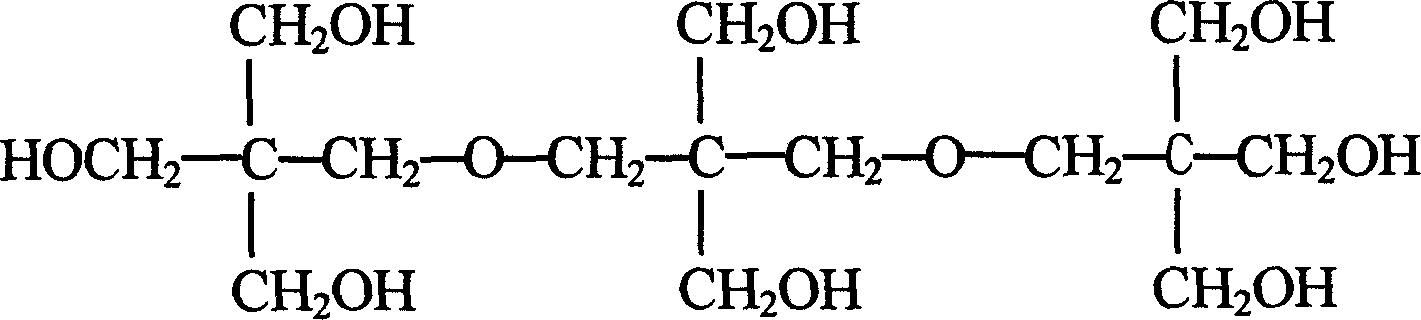

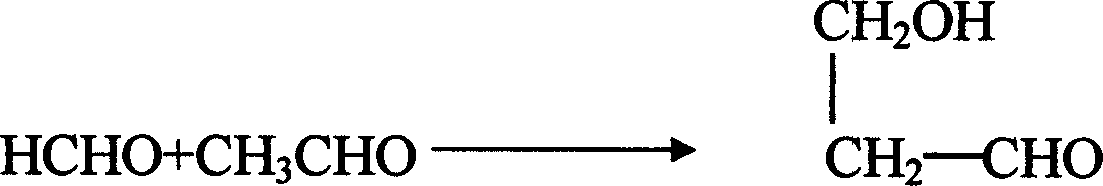

Process of preparing dipentaerythritol and/or tripentaerythritol

InactiveCN101012156AReduce energy consumptionEasy to separateOrganic compound preparationHydroxy compound preparationCalcium formateAldehyde

The invention discloses a manufacturing technique of dipentaerythritol and / or tripentaerythritol, which comprises the following steps: 1. condensing acetaldehyde, formaldehyde and calcium hydroxide solution with molar rate at 2.0-15.2:1:0.3-1.9 under 15-70 deg.c for 0.5-4h; 2. removing aldehyde in the condensing reacting liquid; 3. evaporating condensing reacting liquid; dehydrating; 4. crystallizing calcium formate; centrifuging; drying; 5. controlling the temperature at 80-150 deg.c; blending with active charcoal for 0.1-10h to make the mother liquid of Di-Pentae, Tri-Pentae and Pentae; 6. transmitting upper suspension in the mother liquid into 30-80 order screen to separate; entering into the processing procedure of dipentaerythritol and tripentaerythritol; centrifuging to hydrate for lower crystal liquid; washing to obtain the semiproduct of pentaerythritol.

Owner:PUYANG YONGAN CHEM IND

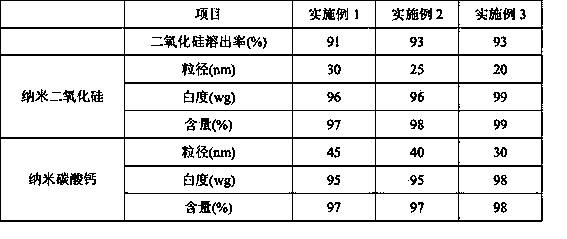

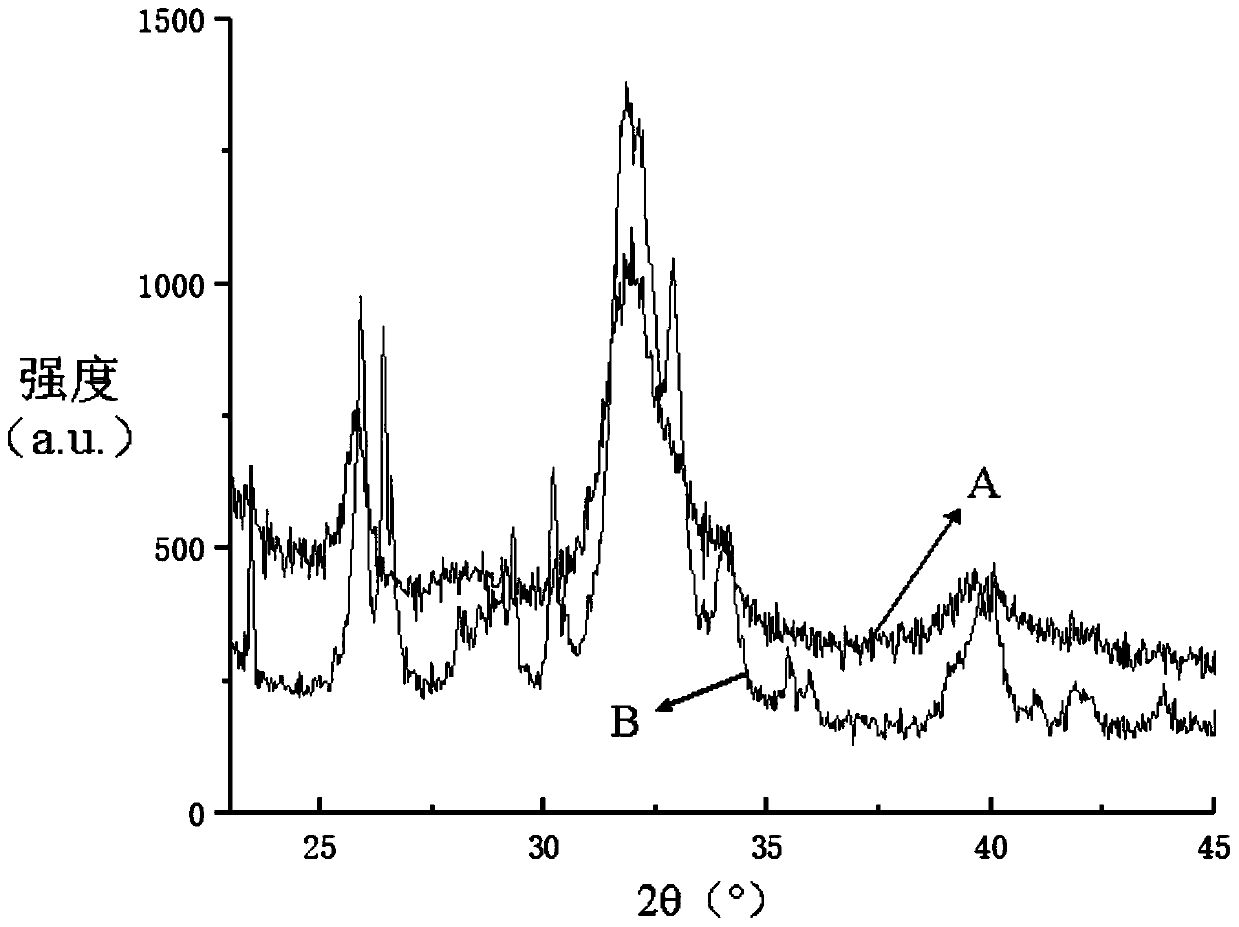

Method for producing nano silicon dioxide and nano calcium carbonate by using rice hull ash and flue gas of biomass power plant

ActiveCN103693650AEasy to operateOperational securityCalcium/strontium/barium carbonatesMaterial nanotechnologyCombustionCALCIUM HYDROXIDE SOLUTION

The invention relates to a method for producing nano silicon dioxide and nano calcium carbonate by using rice hull ash and flue gas of a biomass power plant. The method comprises the following steps: adding the rice hull ash, obtained by combustion in the biomass power plant for power generation, into 10-20% sodium hydroxide solution by weight, fully reacting the mixture at the temperature of 95-1,000 DEG C for 3-4 hours, and performing filtration; adding water into filtrate to dilute the filtrate, controlling sodium silicate in a system to be 8-15 percent by mass in silicon dioxide, heating to 60-800 DEG C, adding a dispersing agent, continuously feeding the flue gas of the biomass power plant under a normal pressure condition, fully stirring to react for 2-4 hours to obtain the nano silicon dioxide; mixing the filtrate and washing liquor, adding a calcium hydroxide solution at the temperature of 5-700 DEG C, and fully stirring to react for 0.5-2 hours to obtain the nano calcium carbonate. The particle sizes of the silicon dioxide product and the nano calcium carbonate product which are obtained by the method are extremely small and can both reach the nano level.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

Method for preparing xylitol and mixing syrup from xylose mother liquor

ActiveCN109503676ALow viscosityGood effectSugar derivativesOrganic compound preparationChromatographic separationFiltration

The invention discloses a method for preparing xylitol and mixing syrup from xylose mother liquor. The method comprises the steps: pretreatment, specifically, a calcium hydroxide solution is added into the xylose mother liquor to adjust the pH to 8.5-9.0, carbon dioxide is introduced to adjust the pH to 6.6-7.0, and part of calcium ions are removed by cation exchange resin; chromatographic separation to obtain an extracting solution and raffinate; decolorization and filtration; hybridization and purification; evaporation, specifically, the extracting solution subjected to hybridization and purification is vacuum-concentrated till the mass percentage concentration of dry matter is 75-85%, and the raffinate is vacuum-concentrated till the mass percentage concentration of the dry matter is 65-75%, so that a finished mixing syrup product is obtained; crystallization; centrifugation and drying; dissolution and hydrogenation; and refining to obtain xylitol crystals. According to the invention, the xylose mother liquor is pretreated by calcium hydroxide and carbon dioxide; the method is simple and easy; the effect is obvious; impurities are removed; the viscosity of the xylose mother liquor is lowered; and the filtration speed is increased. All monosaccharide components of the xylose mother liquor are utilized, so that the additional value of the xylose mother liquor is increased.

Owner:ZHEJIANG HUAKANG PHARMA +1

Mercury removal process based on lime-gypsum method desulphurization system and mercury removal absorption liquid

ActiveCN101590369APromote absorptionHigh removal rateDispersed particle separationAir quality improvementCALCIUM HYDROXIDE SOLUTIONNitric oxide

The invention discloses mercury removal absorption liquid based on a lime-gypsum method desulphurization system. Main components of the mercury removal absorption liquid comprise desulphurization slurry and oxidant; the desulphurization slurry is at least one of calcium hydroxide solution and calcium sulfite solution, and the mass concentration of the desulphurization slurry is 1 to 30 percent; and the oxidant is soluble salt or mixture of soluble salt of which positive ions contain ammonium radical and negative ions contain peroxosulfuric acid radical or peroxosulfuric acid hydrogen radical. Moreover, a soluble transition metal salt as an oxidation catalyst can be added into the mercury removal absorption liquid to increase the removal efficiency of mercury. The invention also discloses a specific mercury removal process using the mercury removal absorption liquid; and the process has the characteristics of high mercury removal effect, little byproduct and low transformation cost, does not introduce other corrosive ions, does not influence the quality of gypsum, and can promote the system to absorb sulfur dioxide and nitric oxide to a certain extent.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

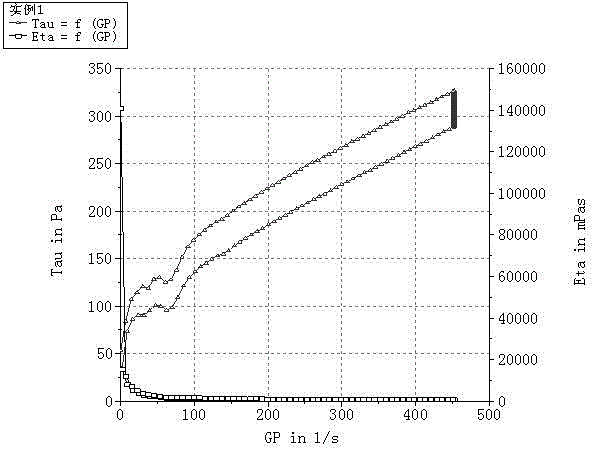

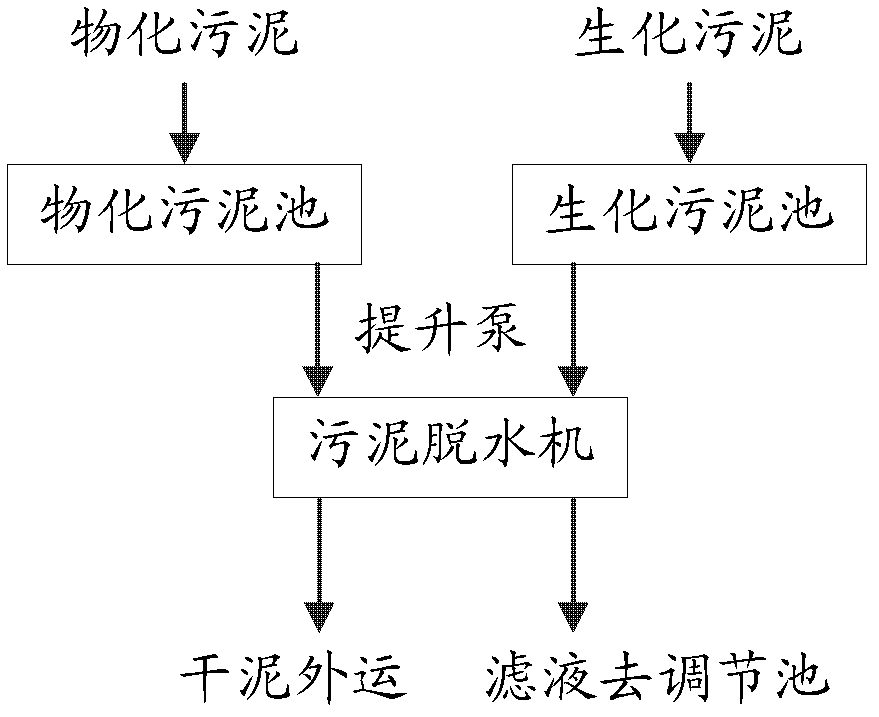

Preparation method and thixotropy test method of nano calcium carbonate with negative thixotropy

InactiveCN104098928AHas negative thixotropic propertiesGood dispersionMaterial nanotechnologyFlow propertiesBiological activationSaponification

The invention discloses a preparation method and a thixotropy test method of nano calcium carbonate with negative thixotropy, and the preparation method includes (1) calcining limestone at 800-1000DEG C to obtain calcium oxide, adding water to digest, sieving to remove coarse particles, refining into calcium hydroxide emulsion; (2) adjusting the calcium hydroxide emulsion concentration and temperature, then sending into a bubbling carbonation tower, leading in certain concentrations of carbon dioxide for bubbling carbonation, carbonating to the pH value to be less than 7 for carbide carbonation end point, selecting calcium carbonate boiled pulp with the dry powder specific surface area of 25 m<2> / g-40 m<2> / g; (3) sending the calcium carbonate boiled pulp into an activation reaction tank, adding a certain proportion of medium and long chain fat fatty acid saponification liquid for wet activation treatment; and (4) filtering by pressing, drying and crushing the activated activation solution, sending into a high-speed mixer, adding a certain proportion of hydroxy fatty acids for dry activation for a certain time at the temperature of 50-70DEG C, and after the activation packing to obtain the nano calcium carbonate with the negative thixotropy.

Owner:福建省万旗非金属材料有限公司

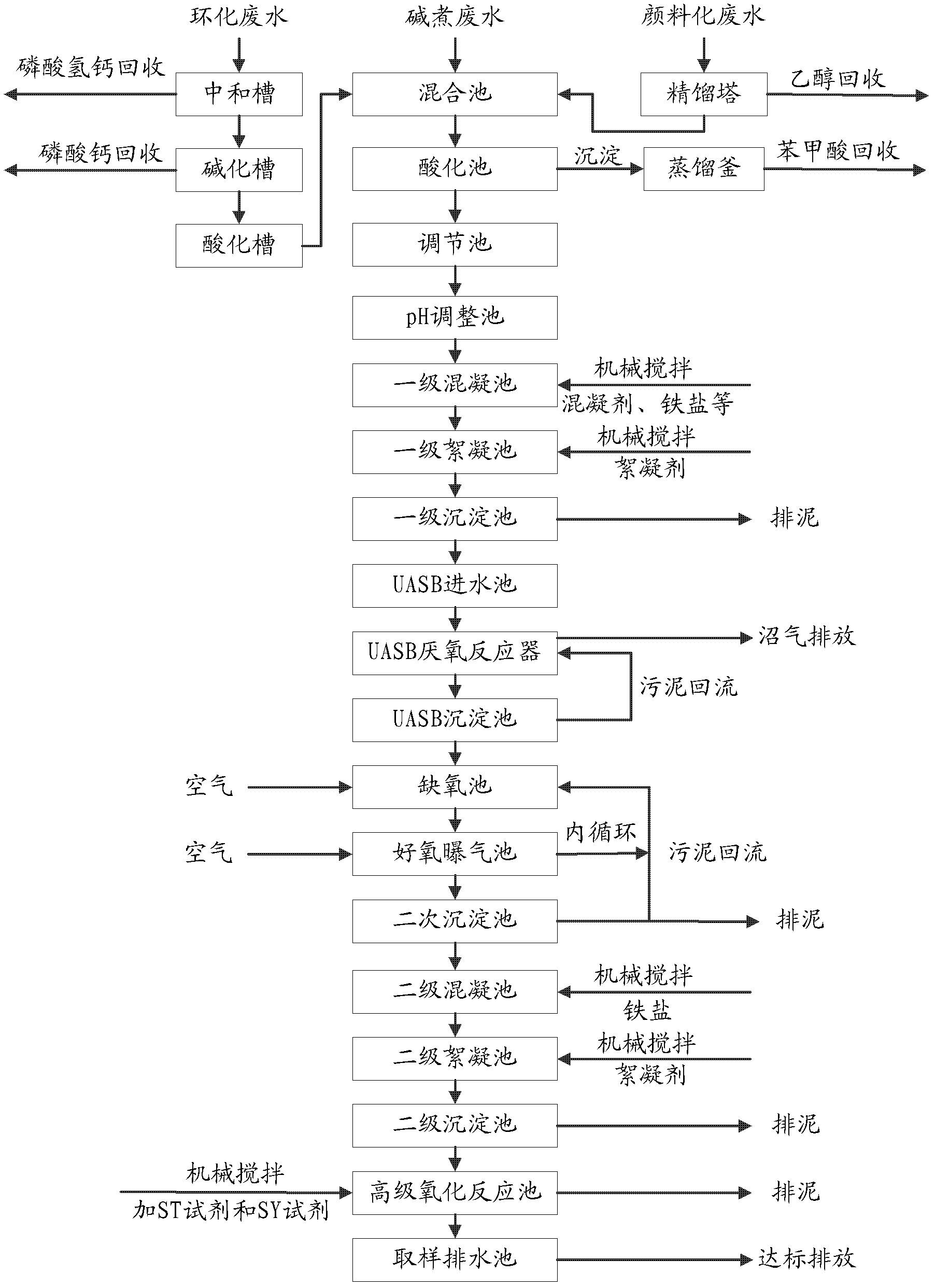

Process for treating and recovering dye industrial wastewater

ActiveCN102659283AGuaranteed emission standardsSave investment in environmental protectionMultistage water/sewage treatmentWaste water treatment from textile industryBenzoic acidDistillation

The invention discloses a process for treating and recovering dye industrial wastewater. The process comprises the following steps of: collecting cyclizing wastewater, adding a calcium hydroxide solution, reacting until the pH value is 5 to 7, and recovering a precipitate to obtain calcium hydrophosphate; adding the calcium hydroxide solution continuously, reacting until the pH value is 10 to 12,and recovering a precipitate to obtain calcium phosphate; adding an acidulant for neutralizing; collecting pigment wastewater, rectifying at the temperature of between 75 and 85 DEG C, and recoveringfractions to obtain ethanol; collecting soda boiling wastewater, mixing the soda boiling wastewater and the treated cyclizing wastewater and pigment wastewater to obtain mixed wastewater, adding the acidulant into the mixed wastewater, regulating the pH value to be 2 to 4, separating a precipitate out, and performing suction filtration and distillation on the precipitate to obtain benzoic acid; and performing primary materialization treatment, biochemical treatment and advanced treatment on the treated mixed wastewater sequentially, and discharging. According to the process, useful substancesin the dye wastewater are recovered, so that the production cost is saved, the load of the subsequent wastewater treatment process is reduced, the discharge of the wastewater can reach the standard, and the economic benefit is improved effectively.

Owner:浙江博世华环保科技有限公司

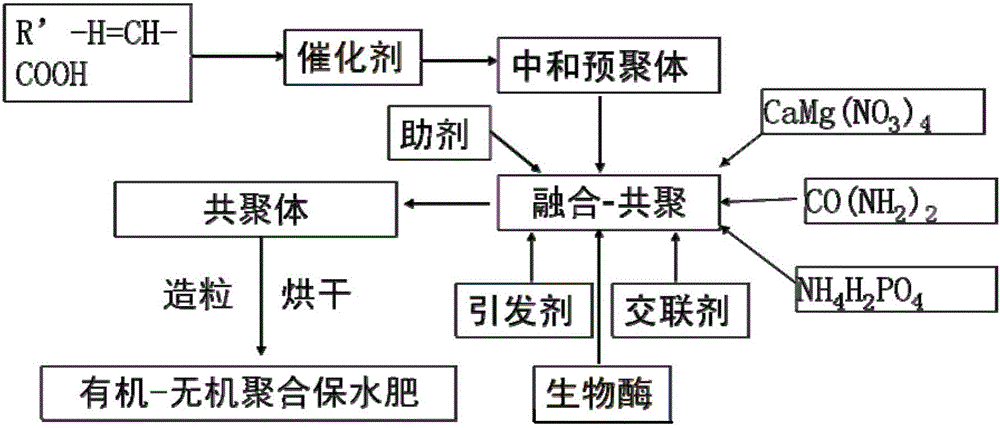

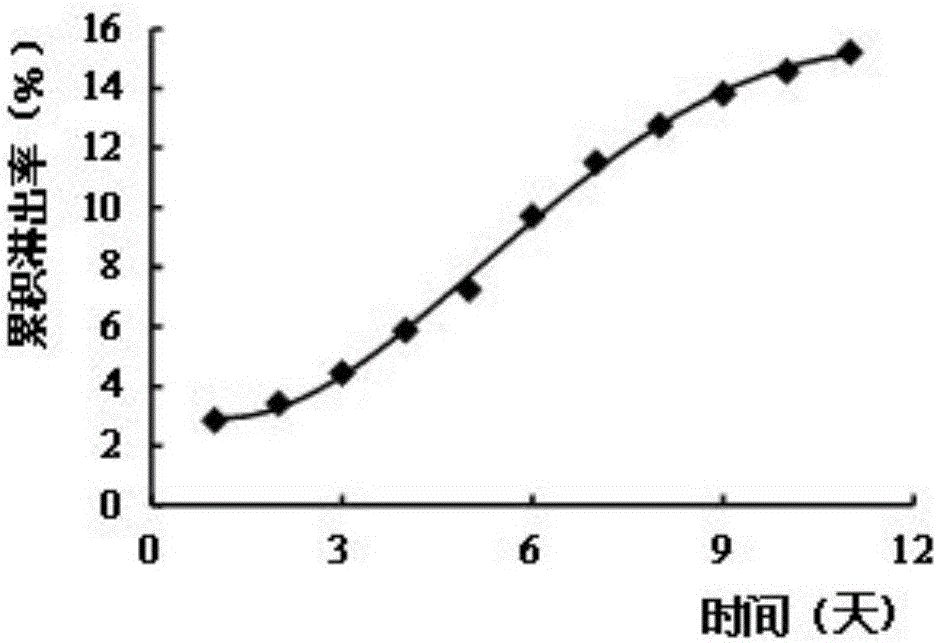

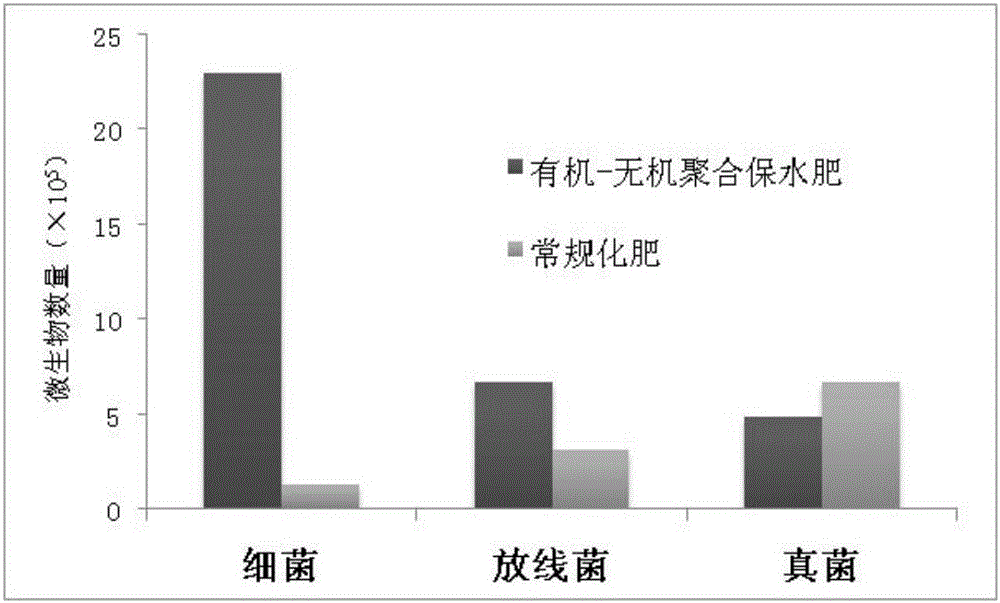

Organic-inorganic polymerization water retention fertilizer and preparation method thereof

InactiveCN106146156AActivated bioactive ingredientsImprove fertilizer efficiencyBio-organic fraction processingMagnesium fertilisersMetasilicatePotassium hydroxide

The invention provides an organic-inorganic polymerization water retention fertilizer. The organic-inorganic polymerization water retention fertilizer is a copolymer formed by fusing and copolymerizing organic water retention monomers and inorganic nutrients under the action of a catalyst, biological enzymes and a modifying agent, and the copolymer has a three-dimensional netty hydrophilic group structure. A preparation method of the organic-inorganic polymerization water retention fertilizer comprises the steps that after a neutralized prepolymer is obtained through the organic monomers under the action of the catalyst, an initiator and a cross-linking agent are added, meanwhile, the inorganic nutrients and metasilicate are added, a solution is formed through full stirring, the biological enzymes are added for catalyzing, the copolymer is obtained after fusion and copolymerization, and pelleting and drying are carried out. Preferably, the catalyst is an inorganic alkaline solution. Preferably, the catalyst is selected from a sodium hydroxide solution, a potassium hydroxide solution, ammonia water and a calcium hydroxide solution.

Owner:QINGDAO HEZIFEI BIOTECH CO LTD

Method for preparing absorbent with phosphor concentration and phosphor reclaim function

InactiveCN1765488ALarge particlesProportionally largeSilicon compoundsWater/sewage treatment by sorptionCalcium in biologySorbent

Disclosed a method for preparing the adsorbent with the phosphor collection and recycle functions, utilizes the natural mineral as raw material to mix the calcium material in 100 weight and the silicon material in 80-200 weight uniformly, then adds the water and synthetic adjuvant as natrium hydrate or calcium hydrate solution to be laid for activation, puts it into water heat reaction kettle to for heated and pressurized synthesis while the synthesis temperature is 120-280 Deg. C and the synthesis pressure is 10-40mpa and the synthesis time is 3-24 times; then cools and dries the material after aforementioned process to be milled or processed into grains which is said high effective absorbent with the phosphor collection and recycle functions. Wherein, said calcium material can be selected from lime hydrate, burnt lime and conch; said silicon material can be selected from silica dioxide, sodium silicate, ganister, bermehl and rice husk ash, which have wide resource and lower cost. The prepared absorbent has the characters that large process handling capacity of unit weight phosphor, lower producing cost, and realization of absorbing and recycling phosphor.

Owner:SHANGHAI JIAO TONG UNIV

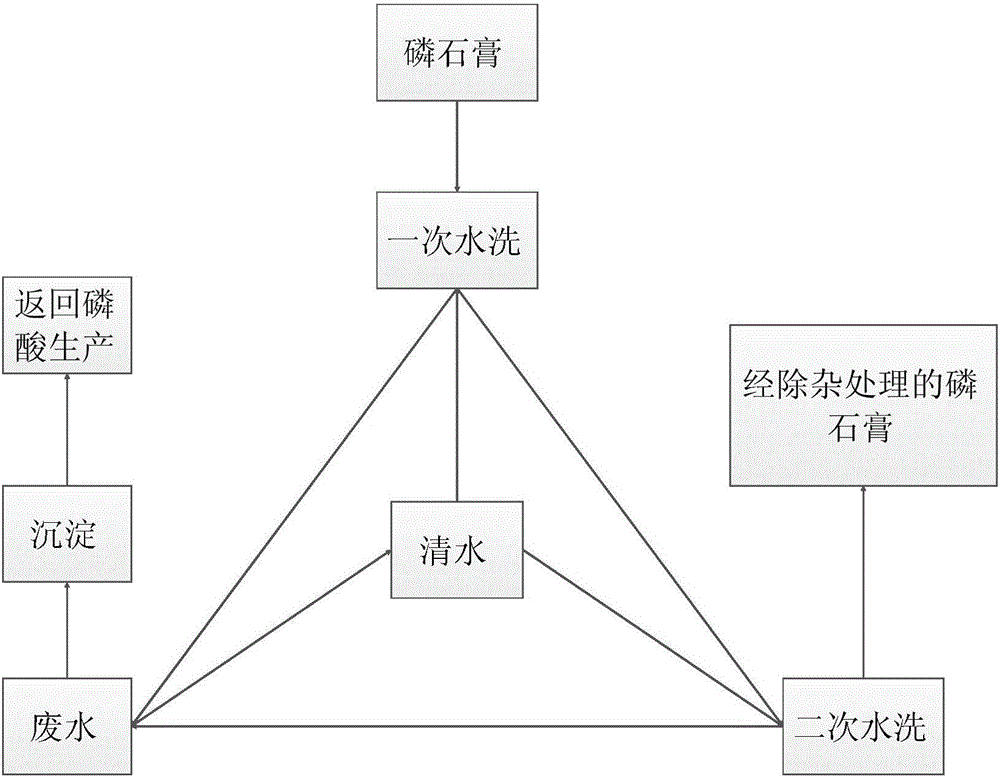

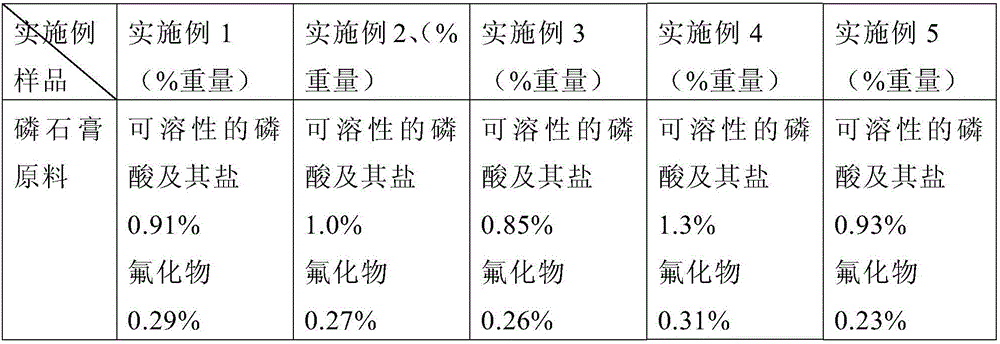

Phosphorus gypsum purification treatment method

ActiveCN106006698AEfficient RemovalEfficient reductionCalcium/strontium/barium sulfatesPhosphorus compoundsWater useCALCIUM HYDROXIDE SOLUTION

The invention provides a phosphorus gypsum purification treatment method, which comprises the following steps: (1) adding washing water into a phosphorus gypsum raw material, performing standing demixing to remove an organic matter layer floating at the top after uniform stirring, and performing solid-liquid separation on a residual material to obtain washed phosphorus gypsum solids and washing wastewater; (2) neutralizing the washing wastewater by virtue of a saturated calcium hydroxide solution, and performing standing demixing to obtain upper-layer clear water used as the washing water in step (1) and precipitates used as a raw material for preparing phosphoric acid. Preferably, between steps (1) and (2), the method further comprises the following step: (11) adding cleaning water into the washed phosphorus gypsum solids, and performing solid-liquid separation to obtain cleaned phosphorus gypsum solids and cleaning wastewater after uniform mixing. In step (2), the cleaning wastewater is mixed with the washing wastewater, and the upper-layer clear water is further used as the cleaning water in step (11). According to the method, impurities can be efficiently removed or reduced, and the method is economical, environment-friendly, high in treatment capacity, ingenious in design, easy to operate and suitable for large-scale popularization and application.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Kaolin composite material and preparation method thereof

InactiveCN102504617AIncrease bulkHigh pore volumeInorganic pigment treatmentPaper coatingCALCIUM HYDROXIDE SOLUTIONNanometre

The invention discloses a kaolin composite material and a preparation method thereof. The preparation method of the kaolin composite material comprises the following steps: adding kaolin into calcium hydroxide solution, and dispersing to form a suspension; controlling the temperature of the suspension at 3-60 DEG C, adding an additive into the suspension, introducing carbon dioxide, and stirring at the temperature to carry out carbonation reaction; stopping introducing the carbon dioxide when the pH value of the suspension reaches 7.8-8.2, stopping reaction, filtering the suspension, drying and dispersing to obtain the kaolin composite material coated by nano calcium carbonate. The kaolin composite material disclosed by the invention is white, has an open surface and can be used for producing the coating pigment for paper making to obtain the high-whiteness and high-bulk coating layer.

Owner:GUANGDONG IND TECHN COLLEGE

Process method for preparing magnesium hydroxide from magnesium sulfate

InactiveCN103950957AHigh yieldIncrease productionMagnesiaMagnesium hydroxideSolubilityResource utilization

The invention relates to a method for preparing magnesium hydroxide from magnesium sulfate. The method comprises the steps of separating out gypsum by precipitation reaction of a magnesium sulfate solution and a calcium chloride solution to obtain a magnesium chloride solution; further performing calcium-magnesium separation reaction on the magnesium chloride solution and dolomite milk to enable calcium hydroxide in dolomite milk to form the calcium chloride solution with high solubility to enter a liquid phase and enable magnesium hydroxide in dolomite milk to enter a solid phase, washing and drying a solid-phase matter, namely magnesium hydroxide after solid-liquid separation to obtain magnesium hydroxide or calcining to obtain magnesium oxide; returning a liquid-phase matter, namely calcium chloride liquid to perform circulating reaction process with the magnesium sulfate solution. The method is particularly suitable for treatment of a flue gas desulfurization product, namely magnesium sulfate to realize resource utilization and reutilization and realize high-added value economic benefits.

Owner:彭振超 +1

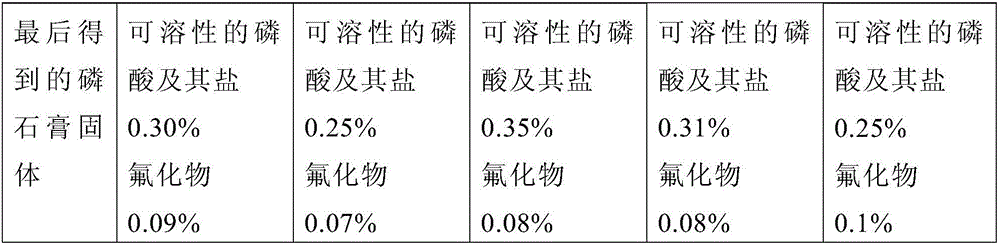

Method for extracting forsythin from weeping forsythia leaves

InactiveCN101974047AReduce manufacturing costMeet production requirementsSugar derivativesSugar derivatives preparationCALCIUM HYDROXIDE SOLUTIONForsythia

The invention relates to a method for extracting forsythin from weeping forsythia leaves. The method comprises the following steps of: smashing the weeping forsythia leaves serving as raw materials; adding solution of calcium hydroxide in an amount of 6 to 15 times that of the raw materials; heating until the temperature is between 50 and 70 DEG C; dynamically extracting for 1 to 3 hours for 2 to 3 times; preserving the heat of extracting solution at the temperature of between 80 and 1 DEG C; adjusting the extracting solution to neutral state; filtering and adding a macro-porous resin column for adsorbing; eluting impurities with water; eluting the forsythin with 50 to 80 percent solution of ethanol; condensing and crystallizing; dissolving an alumina short column with ethanol; recrystallizing and the like so as to obtain the forsythin. The forsythin produced by the method has high content and low cost and can be directly taken as a raw material for a health-care medicament. The method is easy to industrialize.

Owner:NANJING ZELANG AGRI DEV

Calcium chloride solution producing method

InactiveCN104229854ARealize recycling of resourcesIncrease concentrationCalcium/strontium/barium chloridesCALCIUM HYDROXIDE SOLUTIONFiltration

The invention discloses a calcium chloride solution producing method and belongs to the technical field of comprehensive carbide slag utilization and calcium chloride solution production. The calcium chloride solution producing method comprises the steps of pouring limestone into a reaction tank, adding excessive hydrochloric acid to perform steeping reaction, wherein the hydrochloric acid is industrial hydrochloric acid or waste hydrochloric acid, and the mass concentration of hydrogen chloride is 25%-31%; introducing produced acid mist during limestone and hydrochloric acid reaction into an absorption tower to be reacted with a carbide slag solution and re-feeding the calcium chloride solution obtained through reaction and absorption into the reaction tank; then adding the carbide slag solution into the reaction tank to adjust a pH value to be 7-9, performing filtration and clarification through a plate-and-frame filter press to obtain a calcium chloride solution product with mass concentration ranging from 25% to 32%. By means of the calcium chloride solution producing method, carbide slag waste resources are reasonably utilized, the concentration of the produced calcium chloride is high, cost is low, and the method is suitable for large-area popularization and application.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

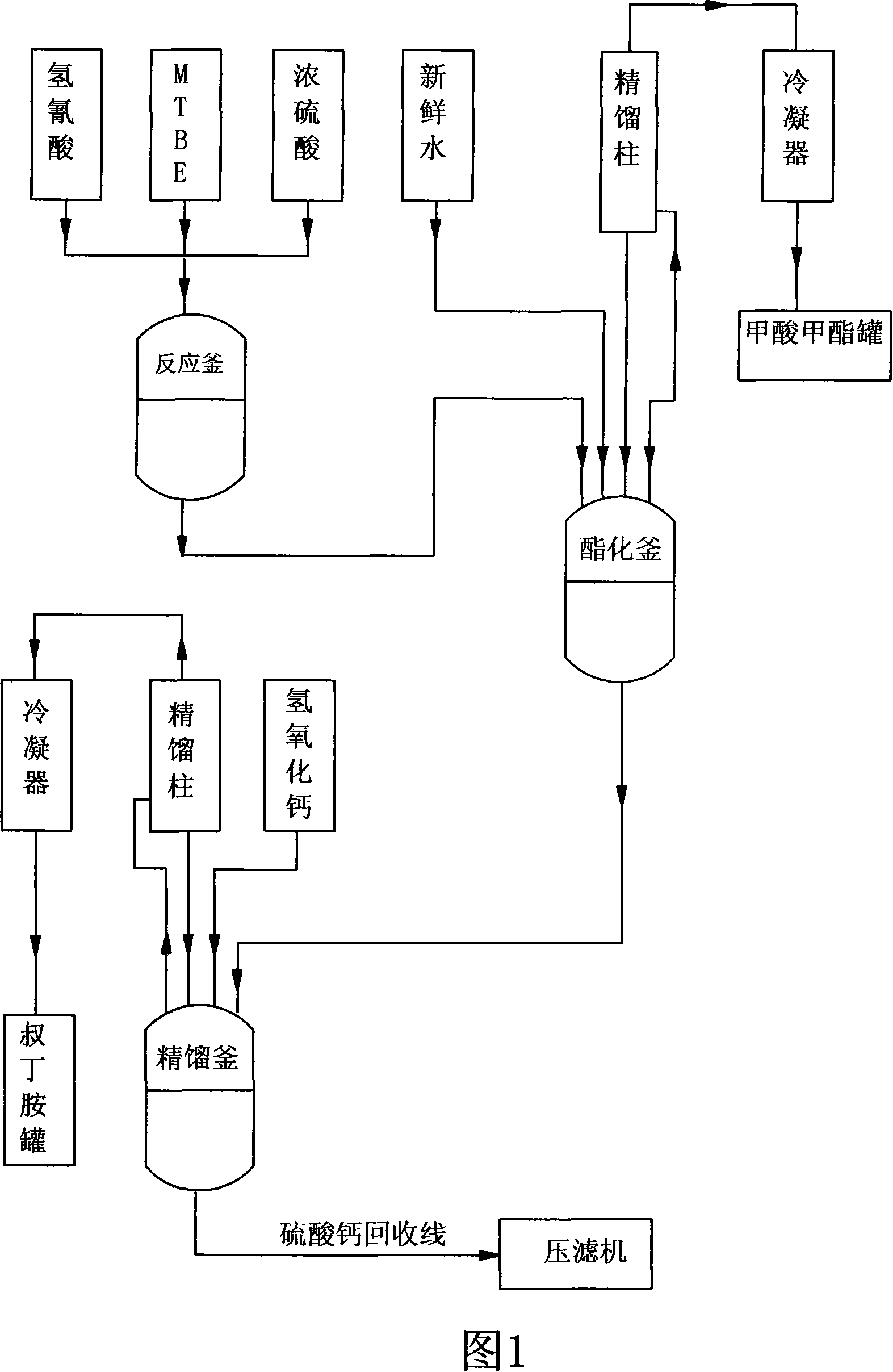

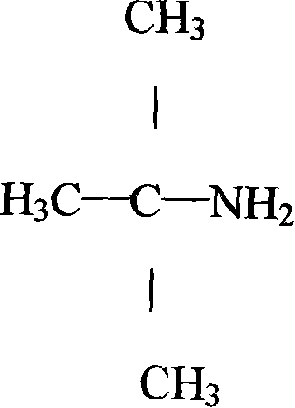

Technique for synthesizing tert-butylamine

ActiveCN101108806APromote hydrolysisPromote esterification reactionOrganic compound preparationAmino compound preparationTert-ButylamineCALCIUM HYDROXIDE SOLUTION

The invention belongs to the fine chemical field, which is mainly used for the synthesis of rubber accelerator NS and the intermediate raw material of the rifampicin-tert-butylamine. The invention is characterized in that: the methyl tert-butyl ether-hydrocyanic acid method is adopted to produce tert-butylamine; under normal pressure, the methyl tert-butyl ether is added with hydrocyanic acid and is added with concentrated sulphuric acid to carry out fully catalytic reaction; the methanol produced in the catalytic reaction is fully adopted and is added with water to perform hydrolysis, deep hydrolysis and esterification, and methyl formate and methanol without react completely are distilled; sulphates in calcium hydroxide solution and the butylamine to replace the butylamine to gain the butylamine through rectification and produce the byproduct calcium sulfate. The invention adopts the water instead of the methanol to carry out the hydrolysis and esterification and neutralizes the raw materials and adopts the calcium hydroxide to produce butylamine, which has the advantages of simple process, short production period, high yield, stable product quality, low production cost and small environment pollution.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

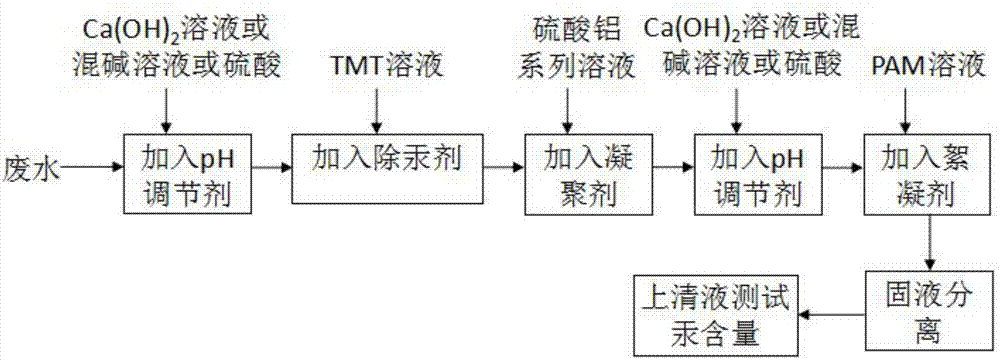

Good-applicability treatment method of mercury-containing wastewater

InactiveCN107140763AAvoid turbidityFavorable settlement effectWater contaminantsMultistage water/sewage treatmentPolyacrylamideChelation

The invention provides a good-applicability treatment method of mercury-containing wastewater. The treatment method comprises the following steps of 1, taking an appropriate amount of the mercury-containing wastewater, adding any one of a calcium hydroxide solution, mixed alkali liquor composed of calcium hydroxide and sodium hydroxide or a sulfuric acid solution as a PH regulator, and regulating PH value to be 8-11; 2, adding an organic sulfur heavy metal ionic capturing agent as a mercury removing agent, so that mercury ions precipitate to generate insoluble chelate particles; 3, adding an aluminum sulfate series solution as a coagulant, so that the chelate particles are destabilized for coalescence to form coarse small particles; 4, adding the pH regulator to regulate the pH value back to be 6-9; 5, adding a polyacrylamide series solution as an organic flocculant, so that the coarse small particles generate coalescence, the precipitation is accelerated, solid and liquid are separated, and supernatant is taken to test the mercury content. The treatment method of the mercury-containing wastewater with the good applicability not only achieves efficient and high-quality treatment of the mercury-containing wastewater, but also has the advantages of being wide in applicability, easy to operate and high in industrialized degree.

Owner:FOSHAN COMWIN LIGHT & ELECTRICITY

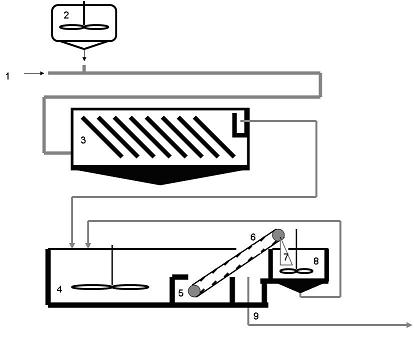

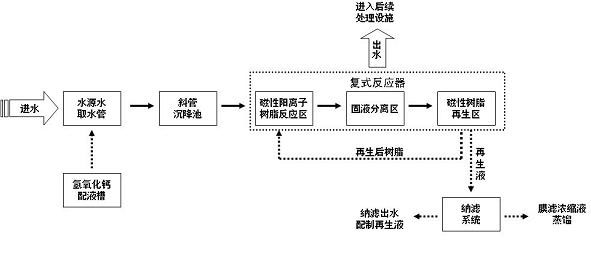

Emergency pretreatment system of source water with excessive iron and manganese and treatment method thereof

ActiveCN102107965AEfficient removalTake advantage ofWater contaminantsMultistage water/sewage treatmentCALCIUM HYDROXIDE SOLUTIONWater source

The invention discloses an emergency pretreatment system of the source water with excessive iron and manganese and a treatment method thereof, belonging to the source water treatment field. In the system of the invention, a water inlet pipe is connected with a calcium hydroxide solution preparation tank; a mixing and reacting region is communicated with a solid-liquid separation region; and the solid-liquid separation region is connected with a resin regeneration tank and a water outlet pipe. The treatment method comprises the following steps: calcium hydroxide solution is added in the water inlet pipe to perform coagulation reaction, the coagulation effluent is precipitated and treated in an inclined tube sedimentation tank, the effluent enters a complex reactor integrating ion exchange,solid-liquid separation and regeneration to remove residual manganese ions and calcium ions, a magnetic conveyor belt is used to separate magnetic cation exchange resin in the effluent from water, the conventional treatment of the effluent is performed, and magnetic cation exchange resin is regenerated in the regeneration tank by using diluted hydrochloric acid and sent back to the mixing and reacting region. The system of the invention is convenient to operate and the concentrations of iron and manganese in water can fast meet the water quality standard of the drinking source water. The system is stable to run and can fully utilize the original water purification equipment of the water plant.

Owner:NANJING UNIV

Waste concrete aggregate recycling and treating method

InactiveCN105776928AConserve waterAvoid wastingSolid waste managementCALCIUM HYDROXIDE SOLUTIONCarbonization

The invention discloses a waste concrete aggregate recycling and treating method. By means of the method, the purpose of recycling building waste can be effectively achieved, and the production cycle for preparing recycled concrete through the method is short; in the method, by means of treatment with a calcium hydroxide solution or a calcium salt solution to increase the content of substances, capable of being carbonized, in recycled aggregate, cracks are effectively filled with formed calcium carbonate after carbonization treatment, and the porosity of the recycled aggregate is effectively decreased, so that the crushing value and the water absorption of the aggregate are decreased.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

Preparation method of modified fly ash for treating ammonia nitrogen waste water

InactiveCN102357355ALow costGood removal effectOther chemical processesWater contaminantsCALCIUM HYDROXIDE SOLUTIONWater flow

The invention discloses a preparation method of modified fly ash for treating ammonia nitrogen waste water. The preparation method comprises the following steps of immersing a raw material of fly ash in 0.5 to 8 mol / L of a sodium hydroxide solution for 0.5 to 10 hours under the conditions of a temperature of 10 to 90 DEG C and a solid-liquid ratio of 1: (2 to 10); washing by soft water which does not contain calcium and magnesium, and drying to obtain the modified fly ash. When ammonia nitrogen waste water flows through a device loaded with the modified fly ash, ammonia nitrogen in the ammonia nitrogen waste water can be removed and an ammonia nitrogen removal rate reaches above 75%.

Owner:HUAQIAO UNIVERSITY

Preparation method of conductive double-layer hydrogel for integral regeneration of bone and cartilage by electrical stimulation

InactiveCN110128679AEasy to fixInsufficient improvement of mechanical propertiesTissue regenerationProsthesisFreeze thawingConductive polymer

The invention discloses a preparation method of a conductive double-layer hydrogel for integral regeneration of bone and cartilage by electrical stimulation. The preparation method comprises the following steps: step 1, dispersing conductive particles and dopamine monomers in water to form a suspension liquid, adding a calcium hydroxide solution to adjust the suspension liquid to be alkalescent, and carrying out a full reaction to generate a calcium hydroxide solution A containing dopamine-modified conductive particles; step 2, preparing a polyvinyl alcohol solution B, adding the polyvinyl alcohol solution B into the solution A to obtain a mixed solution C; step 3, dropwise adding phosphoric acid into the mixed solution C for a reaction, then carrying out forming, and carrying out freeze-thawing circulation to obtain a lower-layer hydrogel; step 4, dissolving polyvinyl alcohol, natural macromolecules and dopamine in deionized water to form a mixed solution, and carrying out a completereaction under a weak alkaline condition to obtain a solution D; and step 5, placing the solution D on the lower-layer hydrogel, and carrying out freeze-thawing circulation to obtain the required double-layer hydrogel. The double-layer hydrogel disclosed by the invention is good in tissue adhesion and electrical stimulation response capability.

Owner:SOUTHWEST JIAOTONG UNIV

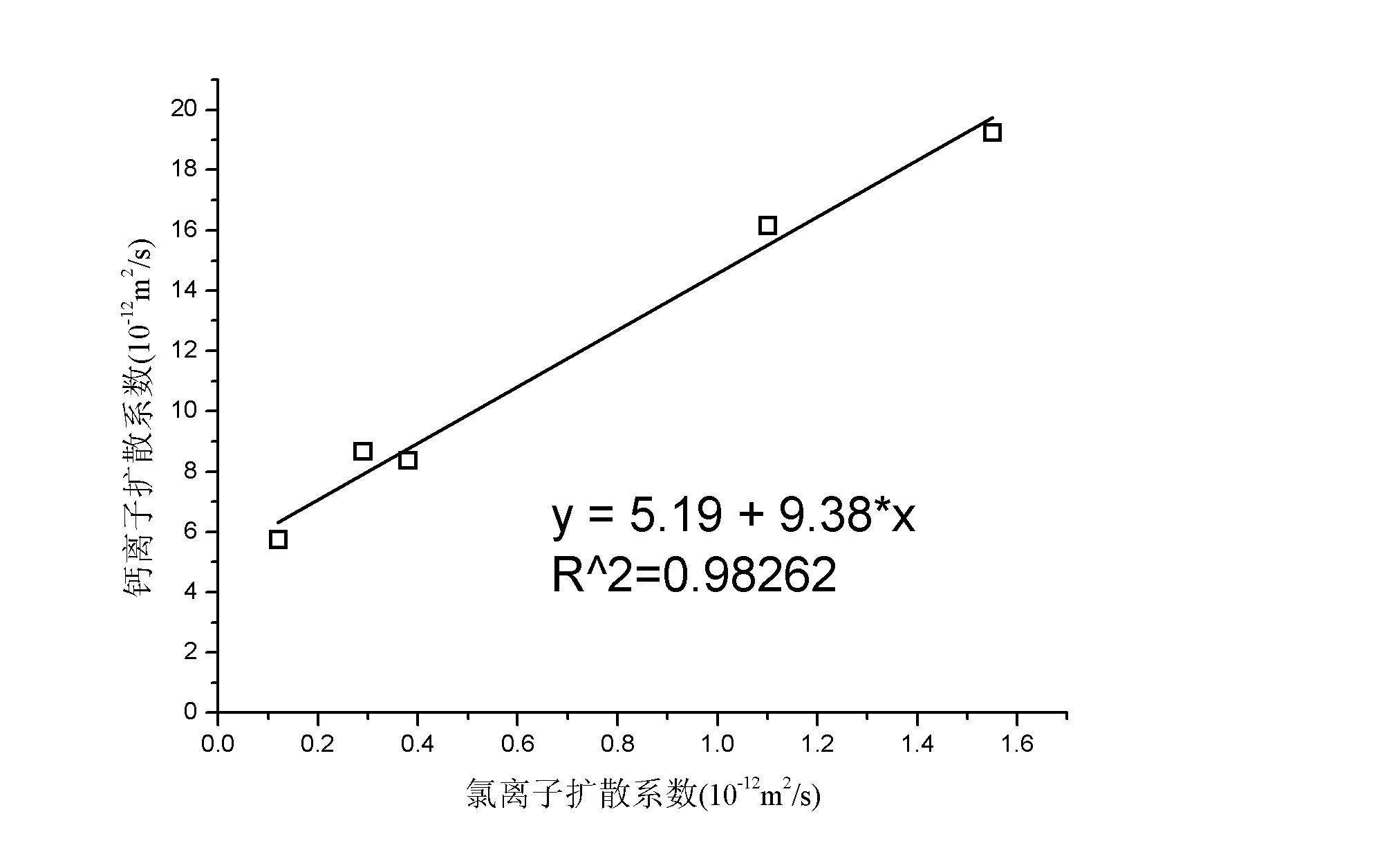

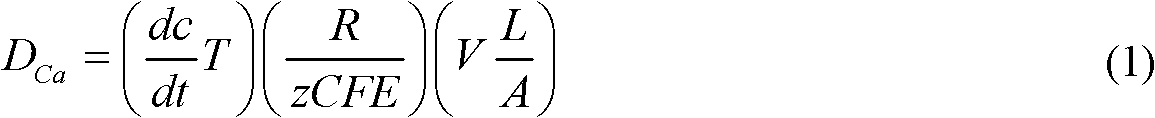

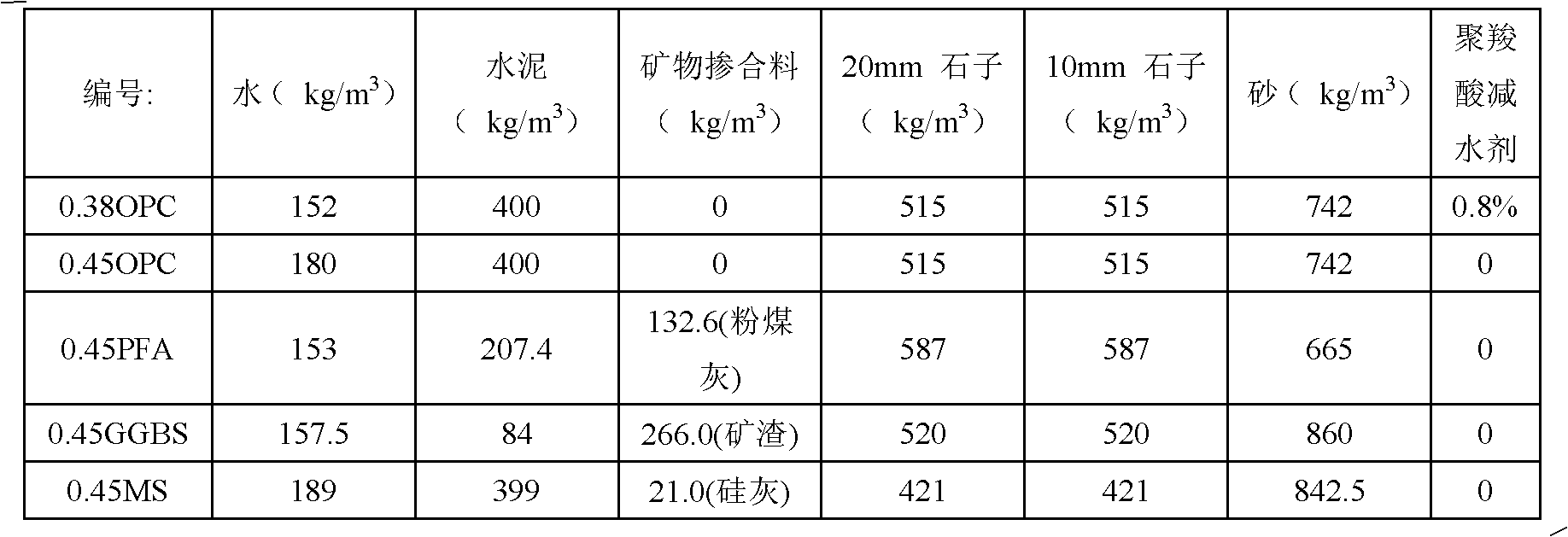

Method for testing calcium ion diffusion coefficient of concrete

The invention relates to a method for testing calcium ion diffusion coefficient of concrete, and the method comprises the following steps: cutting concrete into a sheet test sample, placing into a vacuum water holding device, dry-vacuuming, injecting a calcium hydroxide saturated solution into a vacuum chamber, and wet-vacuuming to form saturate concrete in the calcium hydroxide solution; applying voltage to the test sample, and measuring the calcium ion migration rate; and calculating the calcium ion diffusion coefficient according to Nernst-Plank equation. The calcium ion diffusion coefficient of concrete can be used for evaluating the permeability of concrete. The method provided by the invention has the following advantages: the method can be used for measuring the calcium ion diffusion coefficient of concrete, the method is simple, the data are accurate and reliable, and the method is suitable for both ordinary concrete and high performance concrete.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com