Phosphorus gypsum purification treatment method

A treatment method, phosphogypsum technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of small treatment volume, high price, secondary pollution, etc., achieve large treatment volume, efficiently remove or reduce impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

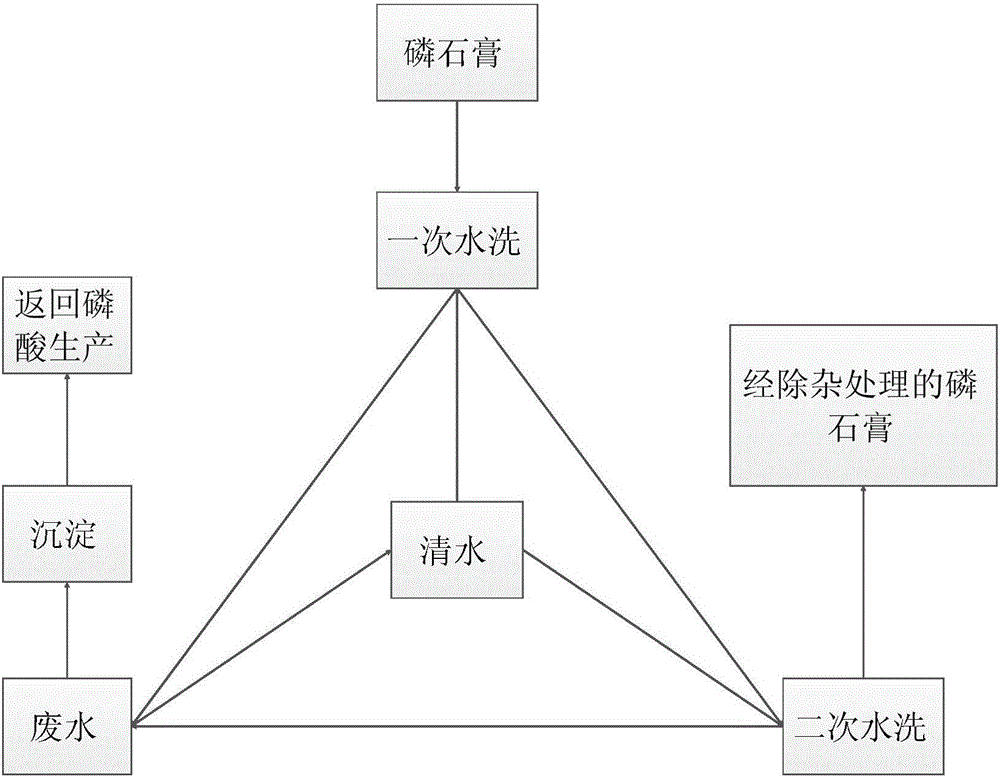

Method used

Image

Examples

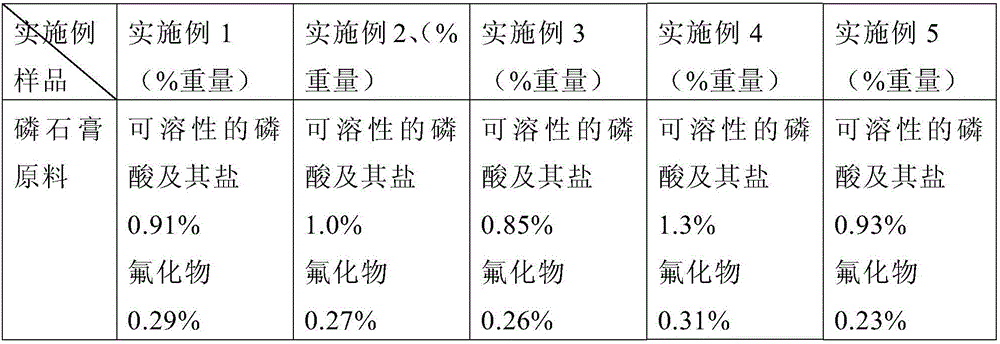

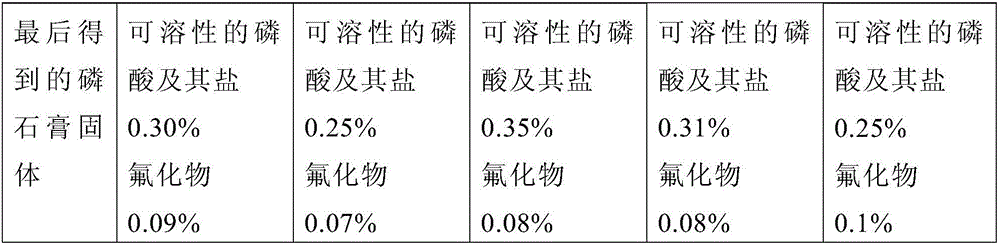

Embodiment 1

[0028] Add washing water to the phosphogypsum raw material, the weight ratio of washing water and phosphogypsum raw material is 2:1, stir evenly, let it stand for layering, remove the organic layer floating on it, and use a suspension separator to separate the solid and liquid of the remaining material Obtain washed phosphogypsum solids and washing wastewater; add cleaning water to the washed phosphogypsum solids, the ratio of cleaning water to washed phosphogypsum solids is 2.5:1 by weight, and use a suspension separator to separate the solid and liquid after stirring evenly Separation of washed phosphogypsum solids and cleaning wastewater; neutralizing the washing wastewater and cleaning wastewater with saturated calcium hydroxide solution and then standing for stratification, the obtained upper layer of clear water is recycled and used as the washing water for the next batch of phosphogypsum raw materials and wash water, resulting in Ca 3 (PO 4 ) 2 Precipitation is used a...

Embodiment 2

[0030] Add washing water to the phosphogypsum raw material, the weight ratio of washing water and phosphogypsum raw material is 3:1, stir evenly, let it stand for layering, remove the organic layer floating on it, and use a suspension separator to separate the remaining material from solid to liquid Obtain washed phosphogypsum solids and washing wastewater; add cleaning water to the washed phosphogypsum solids, the ratio of cleaning water to washed phosphogypsum solids is 3:1 by weight, and use a suspension separator to separate the solid and liquid after stirring evenly Separation of washed phosphogypsum solids and cleaning wastewater; neutralizing the washing wastewater and cleaning wastewater with saturated calcium hydroxide solution and then standing for stratification, the obtained upper layer of clear water is recycled and used as the washing water for the next batch of phosphogypsum raw materials and wash water, resulting in Ca 3 (PO 4 ) 2 Precipitation is used as a r...

Embodiment 3

[0032] Add washing water to the phosphogypsum raw material. The weight ratio of washing water and phosphogypsum raw material is 2.5:1. Stir evenly and let it stand for layering. Remove the organic layer floating on the top, and use a suspension separator to separate the remaining material from solid to liquid. Obtain washed phosphogypsum solids and washing wastewater; add cleaning water to the washed phosphogypsum solids, the ratio of cleaning water and washed phosphogypsum solids is 2:1 by weight, and use a suspension separator to Separation of washed phosphogypsum solids and cleaning wastewater; neutralizing the washing wastewater and cleaning wastewater with saturated calcium hydroxide solution and then standing for stratification, the obtained upper layer of clear water is recycled and used as the washing water for the next batch of phosphogypsum raw materials and wash water, resulting in Ca 3 (PO 4 ) 2 Precipitation is used as a raw material for the preparation of phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com