Good-applicability treatment method of mercury-containing wastewater

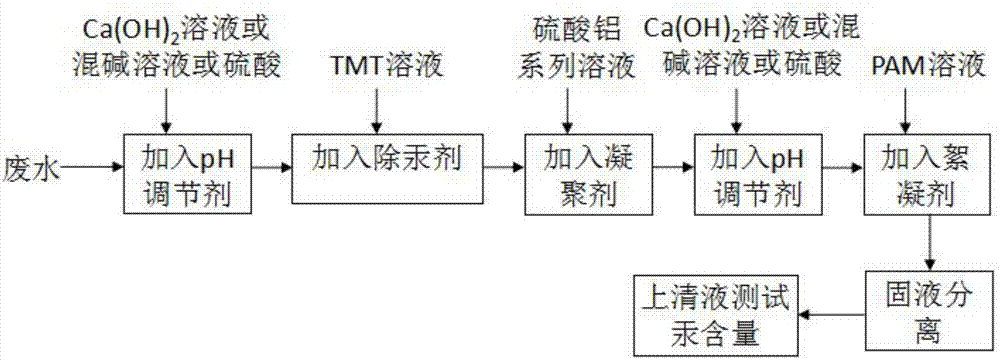

A treatment method and technology of applicability, applied in the field of mercury-containing wastewater treatment, can solve the problems of long standing time, unfavorable personnel operation, inapplicability, etc., and achieve the effect of high degree of industrialization, wide application range and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Embodiment 1-for the processing method of general inorganic mercury-containing waste water, comprise the steps:

[0072] (1) The water intake is 4m 3 Inorganic mercury-containing waste water, the Hg before treatment is 12.3mg / L, and the pH value is 6.7, at first adding the calcium hydroxide solution of 10% mass concentration to the inorganic mercury-containing waste water to adjust the pH to be 11;

[0073] (2) Next, add 4L of TMT-15 solution with a concentration of 10%, and stir for 5 minutes;

[0074] (3) adding 60L of aluminum sulfate solution with a concentration of 10% subsequently, after reacting for 5 minutes, the pH value dropped to about 5;

[0075] (4) adding the calcium hydroxide solution of 10% mass concentration again to adjust the pH to 6;

[0076] (5) Finally, 10 L of PAM solution with a concentration of 0.1% was added and stirred for 5 minutes; after standing for 10 minutes, the supernatant was clear and the mercury ions were precipitated into the slud...

Embodiment 2

[0077] Embodiment 2-for the processing method of general inorganic mercury-containing waste water, comprise the steps:

[0078] (1) The water intake is 4m 3 Inorganic mercury-containing wastewater, before treatment, the Hg was 13.4mg / L, and the pH value was 6.1. First, a mixed alkali solution with a mass ratio of calcium hydroxide and NaOH of 2:1 was added to the wastewater to adjust the pH to 8;

[0079] (2) Next, add 4L of TMT-18 solution with a concentration of 10%, and stir for 5 minutes;

[0080] (3) adding 60 L of potassium aluminum sulfate solution with a concentration of 10% subsequently, after reacting for 5 minutes, the pH value dropped to about 5;

[0081] (4) add calcium hydroxide and NaOH mass ratio again and be 2: 1 mixed alkali solution and adjust pH to be 6;

[0082] (5) Finally, 10 L of PAM solution with a concentration of 0.1% was added and stirred for 5 minutes; after standing for 10 minutes, the supernatant was clear and the mercury ions were precipitated...

Embodiment 3

[0083] Embodiment 3-for the processing method generally containing organic matter mercury-containing wastewater, comprises the steps:

[0084] (1) The water intake is 4m 3 The organic mercury-containing wastewater, the COD concentration before treatment is 7772mg / L, the Hg is 1.8mg / L, and the pH value is 5.0; firstly, the calcium hydroxide solution of 10% mass concentration is added to the organic mercury-containing wastewater to adjust the pH to 9.8;

[0085] (2) Next, add 2L of TMT-15 solution with a concentration of 10%, and stir for 10 minutes;

[0086] (3) adding 80 L of polyaluminum sulfate solution with a concentration of 10% subsequently, after reacting for 10 minutes, the pH value dropped to about 5;

[0087] (4) adding the lime water of 10% mass concentration again to adjust the pH to 9;

[0088] (5) Finally, 15 L of PAM solution with a concentration of 0.1% was added and stirred for 10 minutes; after standing for 10 minutes, the supernatant was clear and mercury i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com