Patents

Literature

132results about How to "High quality processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

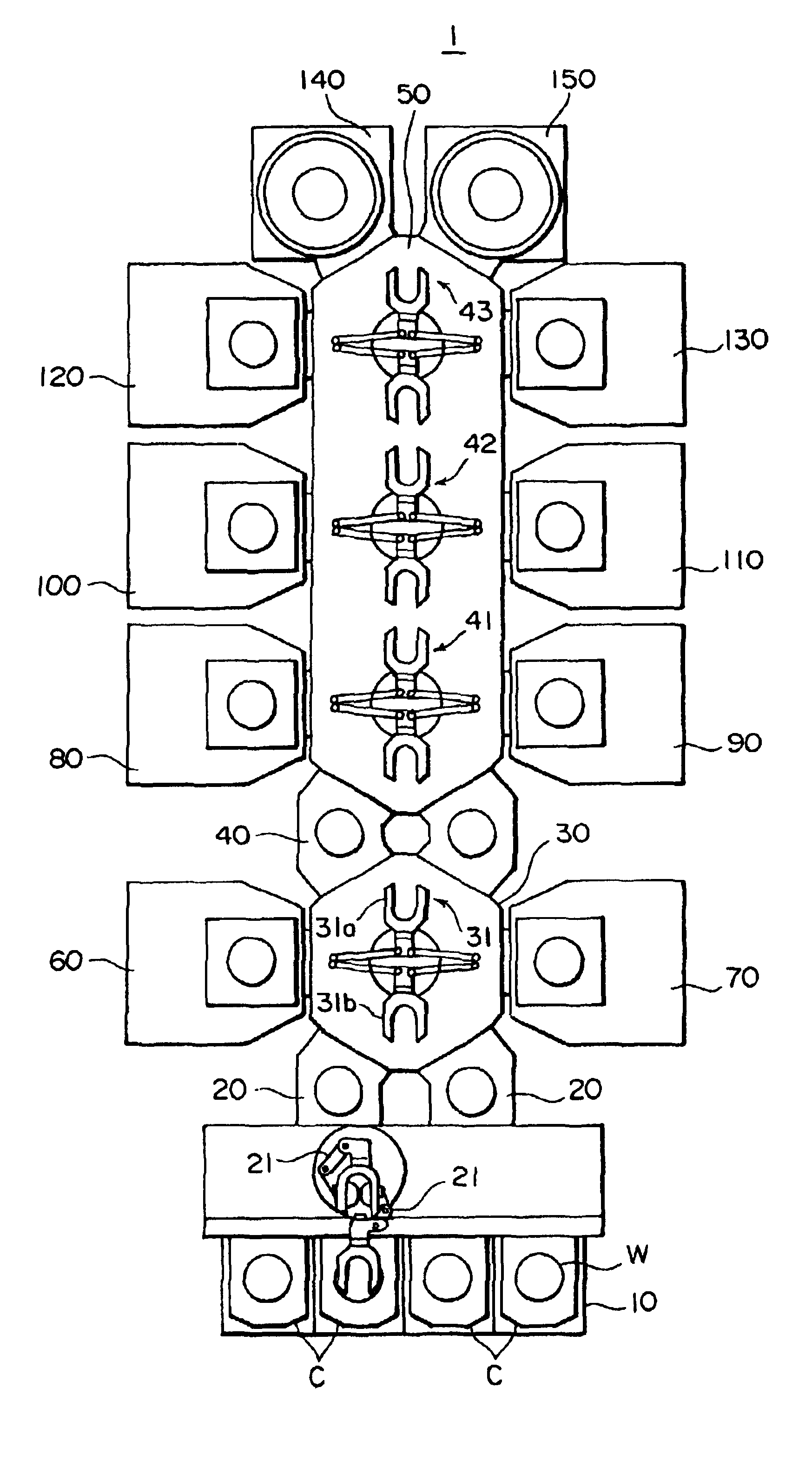

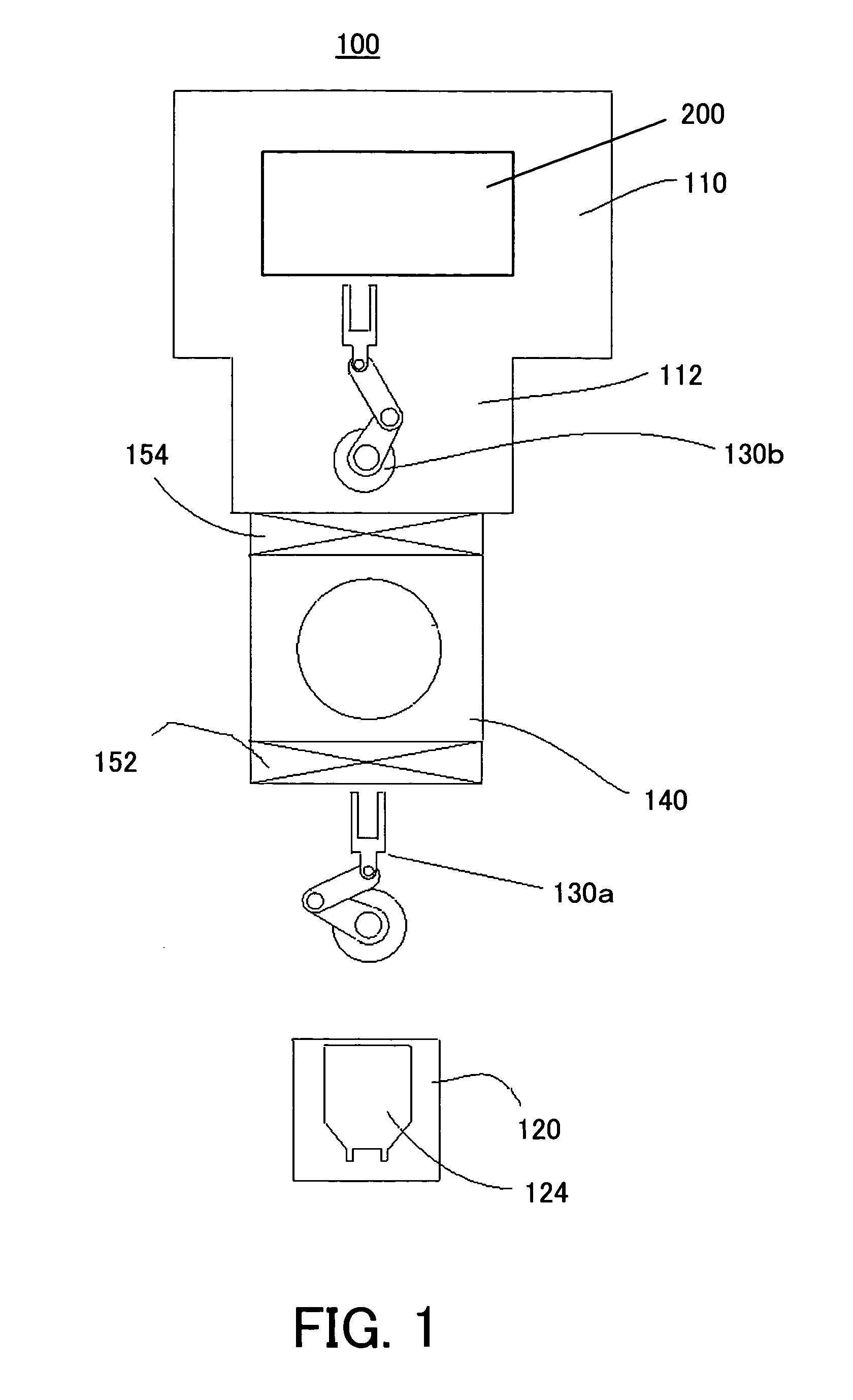

Processing apparatus, transferring apparatus and transferring method

InactiveUS6852194B2Improve processing effectivenessQuality improvementCellsVacuum evaporation coatingEngineeringTransfer mechanism

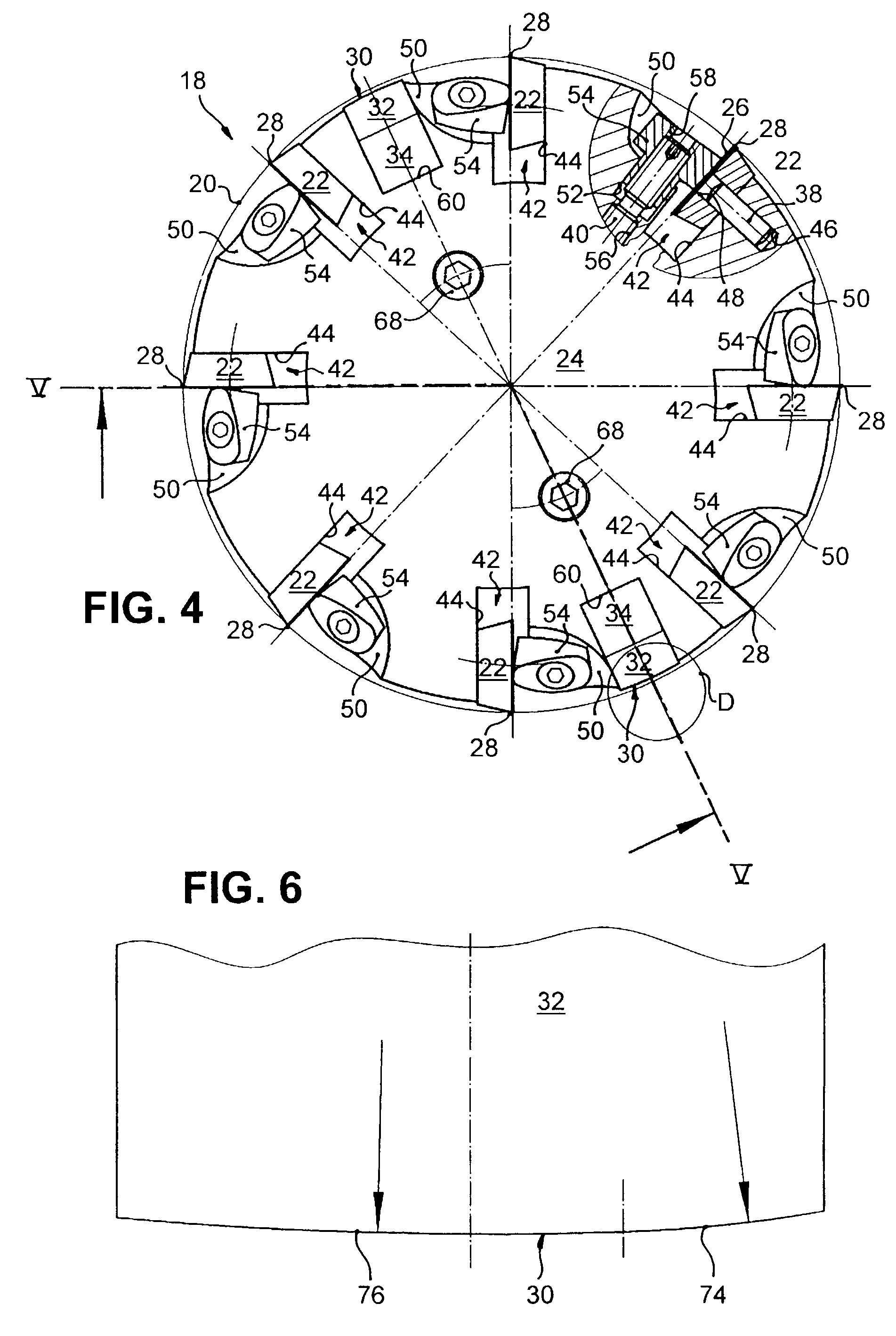

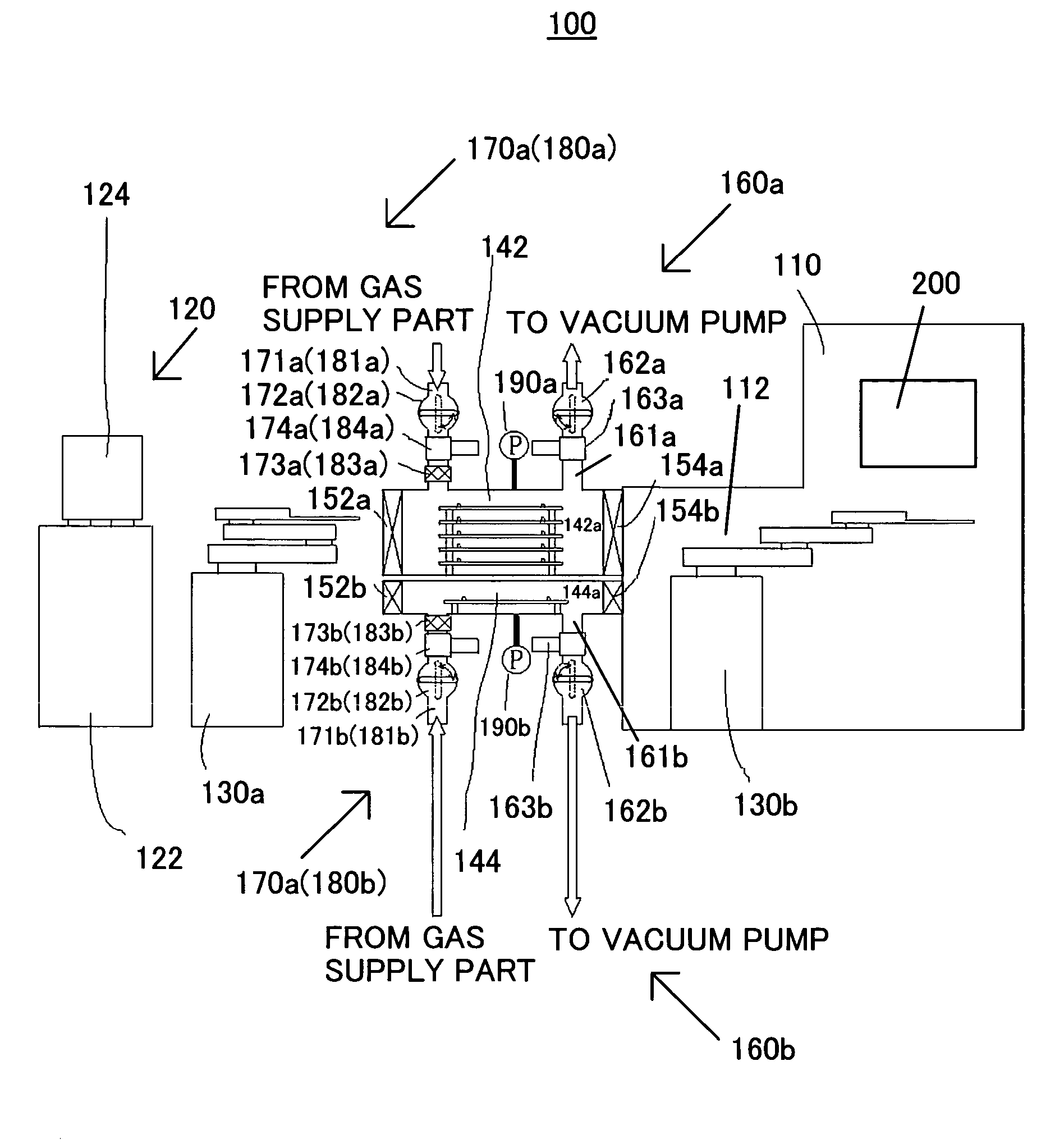

Processing apparatus is disclosed, that comprises substrate container holding table that can hold substrate container that contains plurality of target substrates, first transferring chamber, disposed adjacent to the substrate container holding table, that maintains the interior at first pressure, first processing unit group, disposed around the first transferring chamber, that processes target substrate at the first pressure, first transferring mechanism, disposed in the first transferring chamber, that transfers target substrate, second transferring chamber, disposed adjacent to the first transferring chamber, that maintains the interior at second pressure, second processing unit group, disposed around the second transferring chamber, that processes target substrate at the second pressure, and second transferring mechanism, disposed in the second transferring chamber, wherein the first transferring mechanism and / or the second transferring mechanism has at least two transferring arms.

Owner:TOKYO ELECTRON LTD

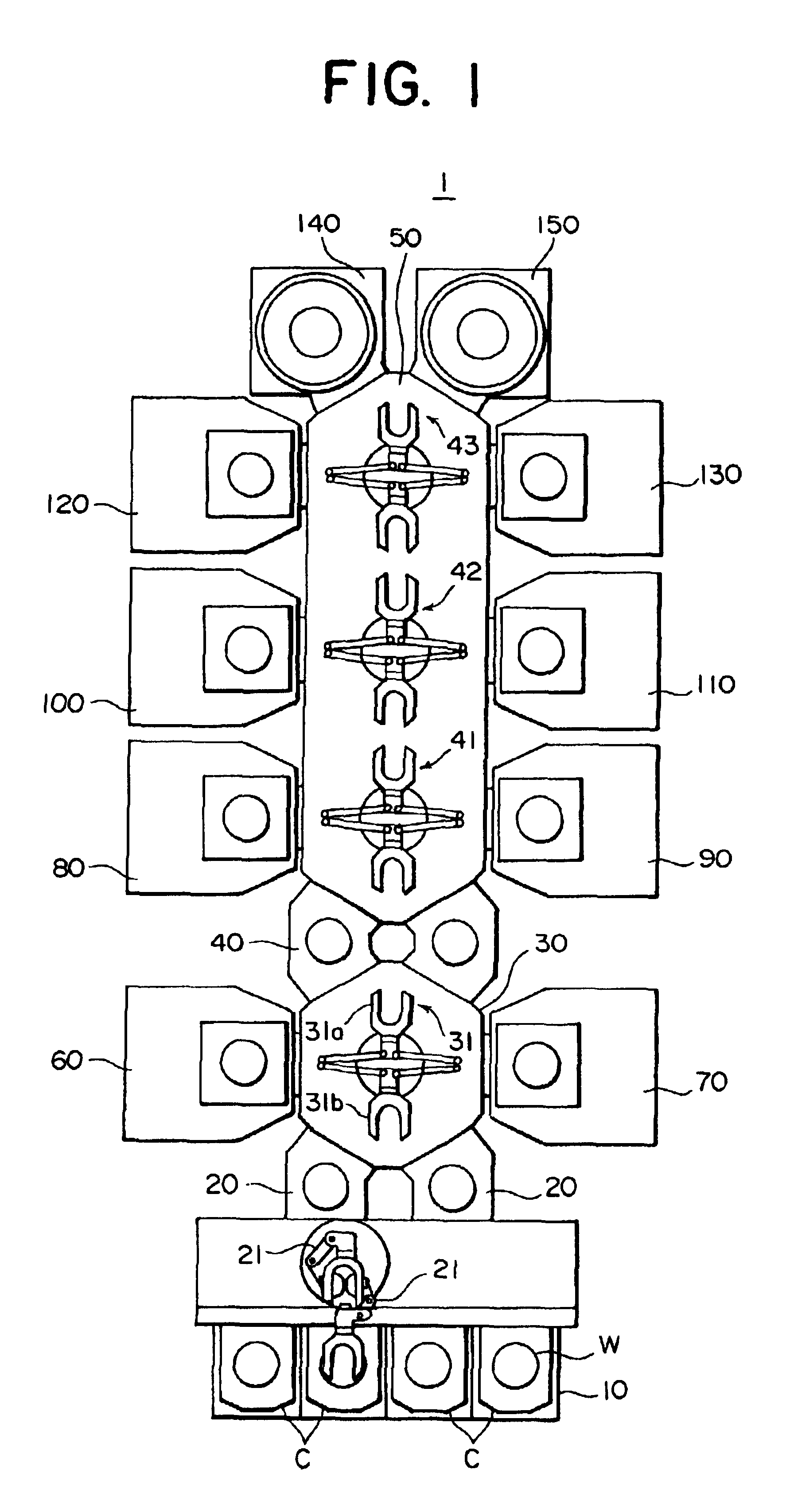

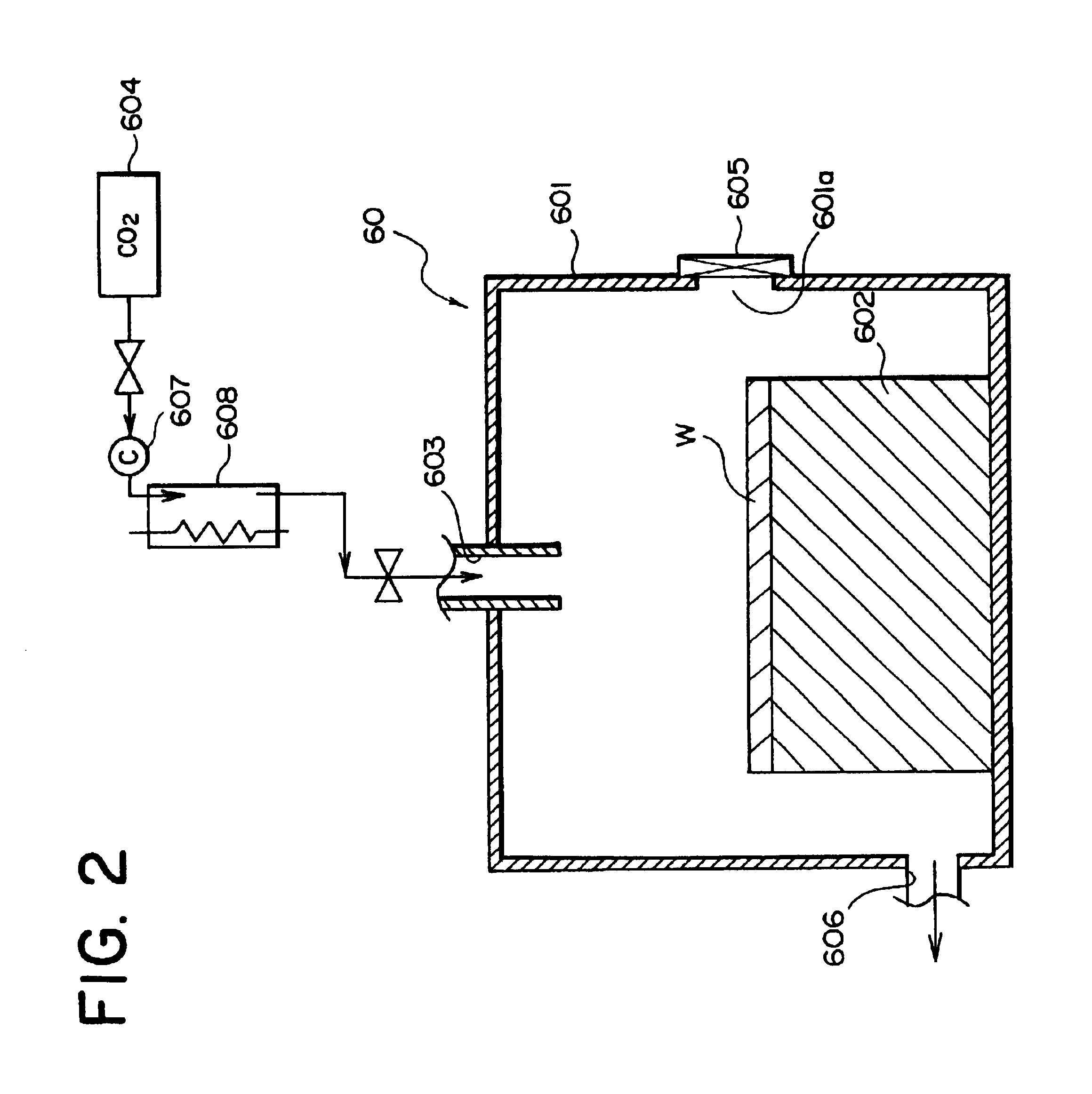

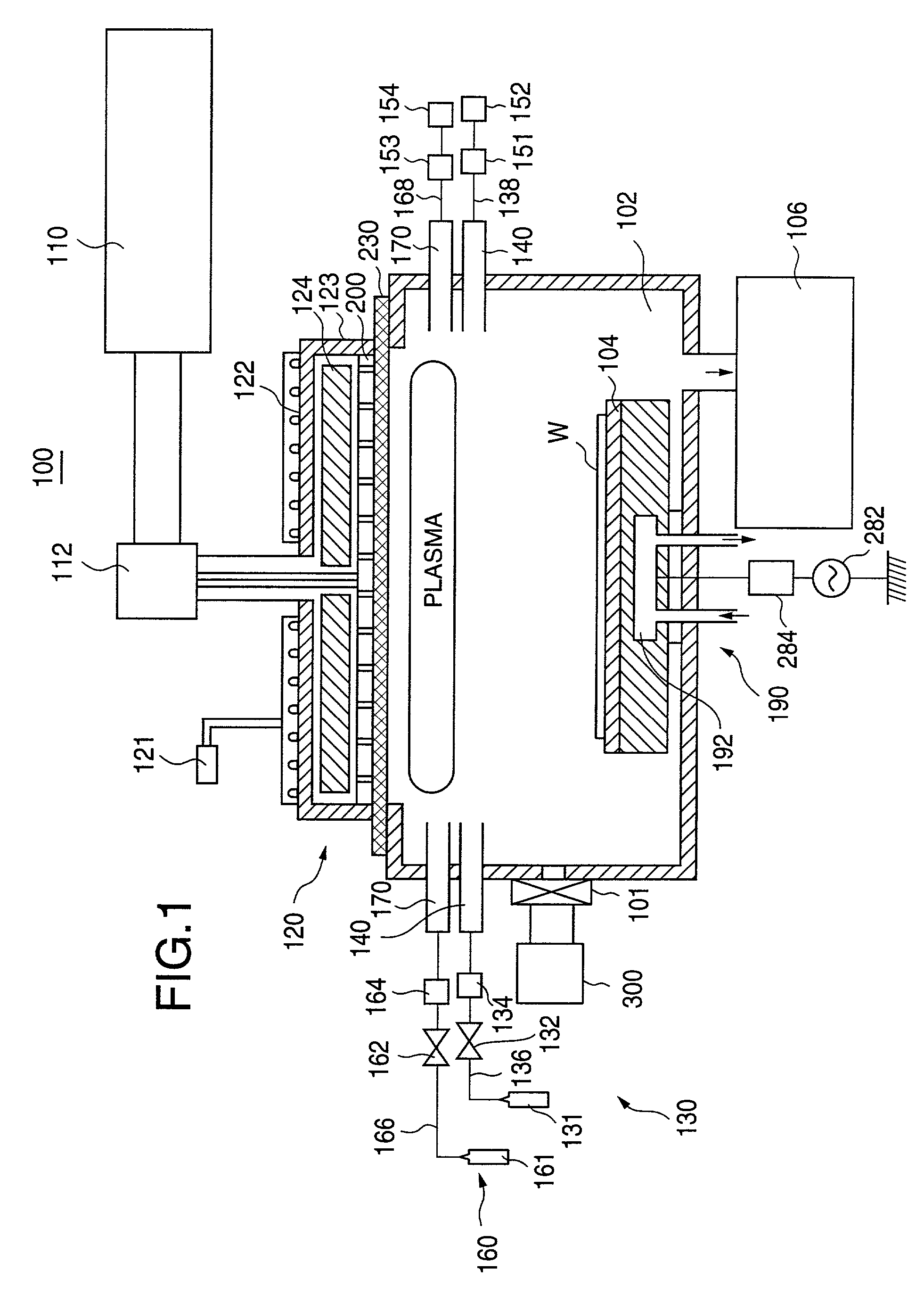

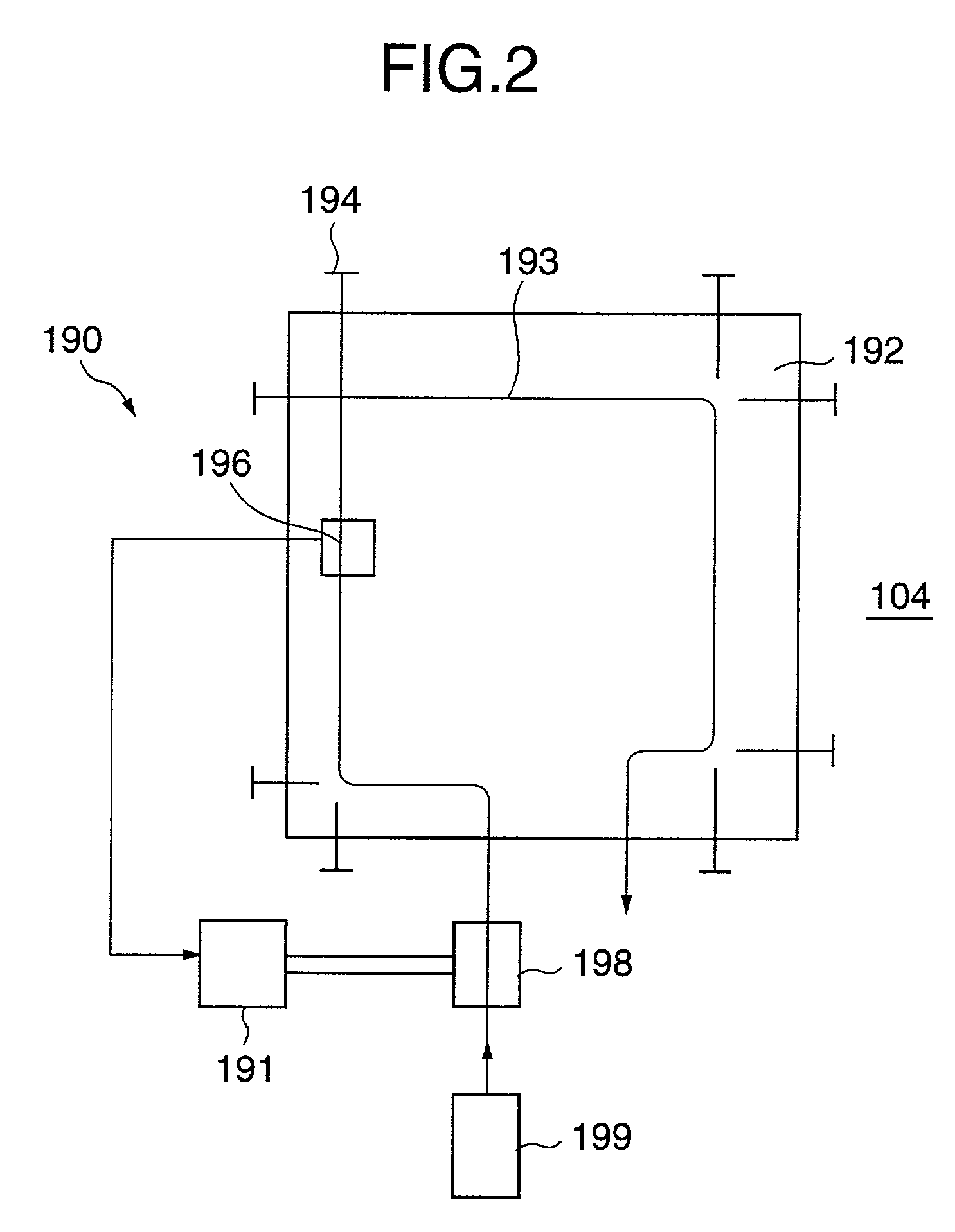

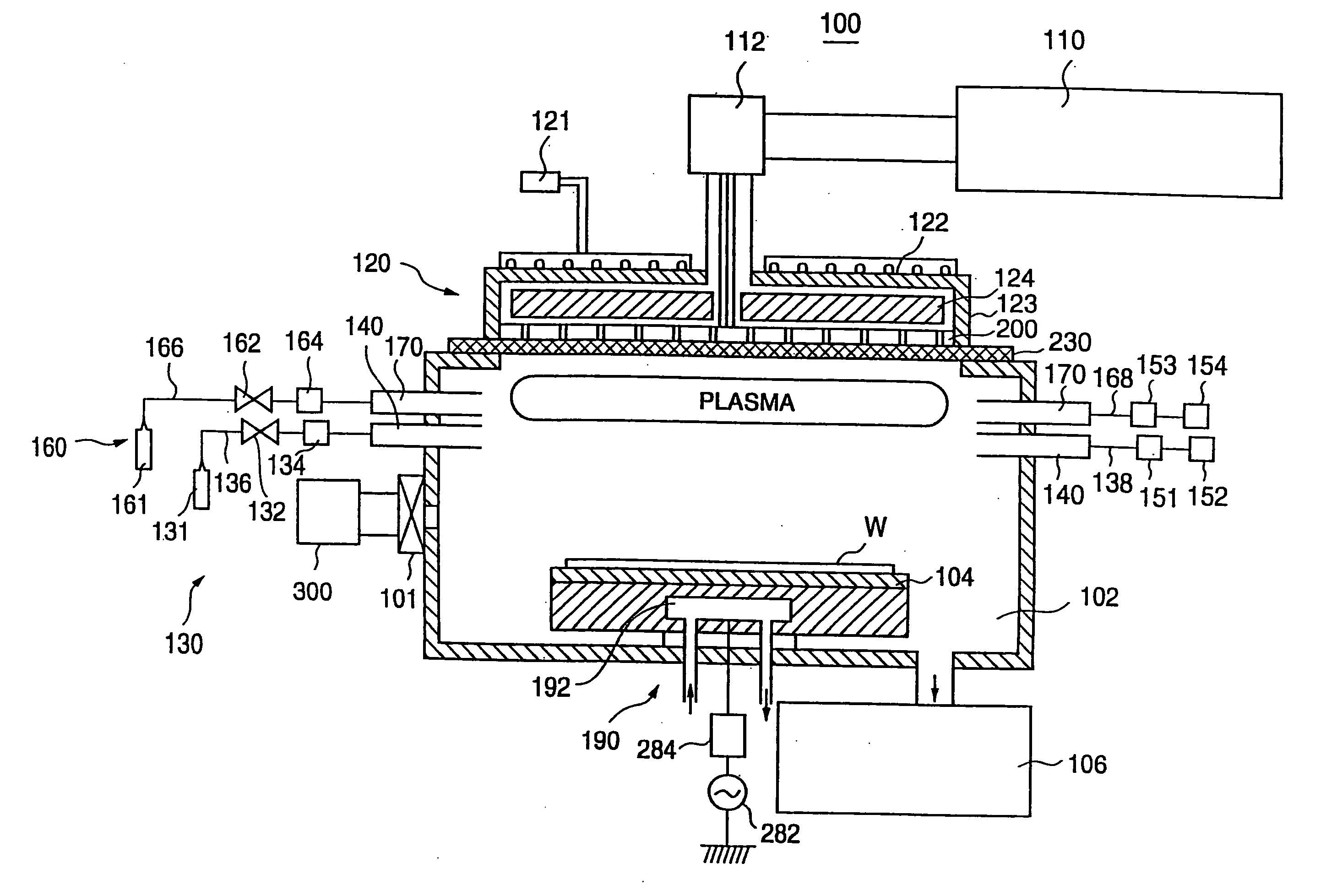

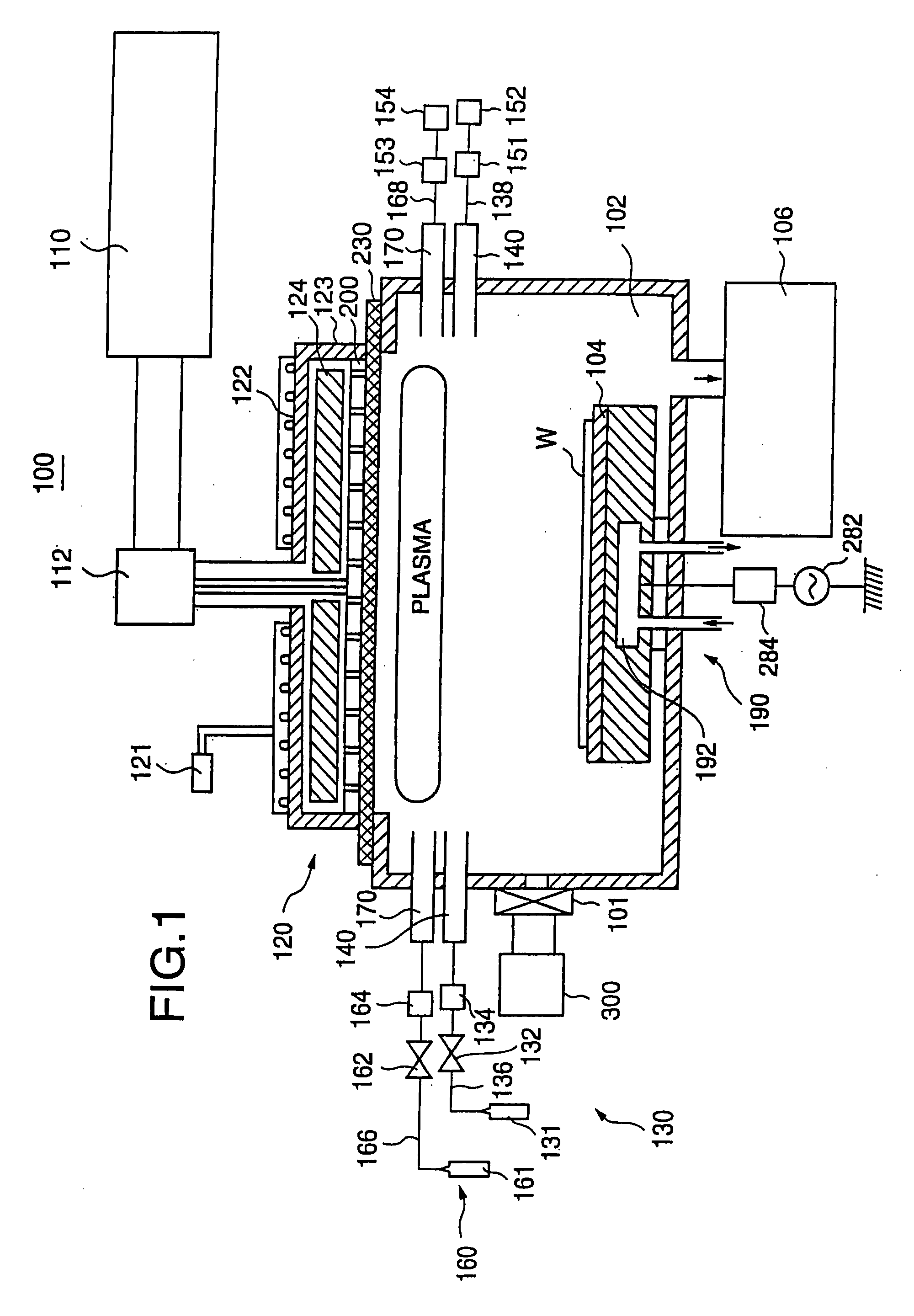

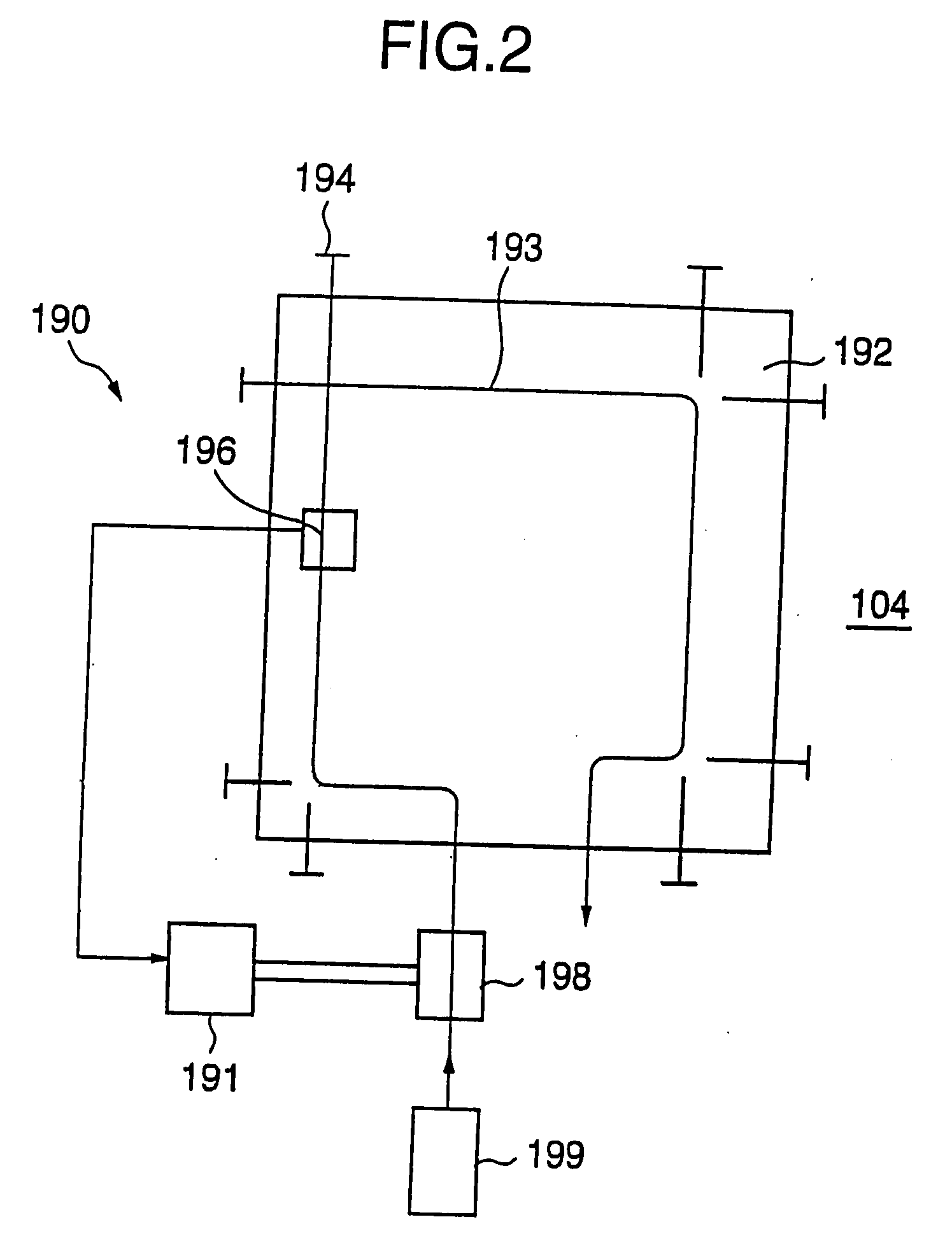

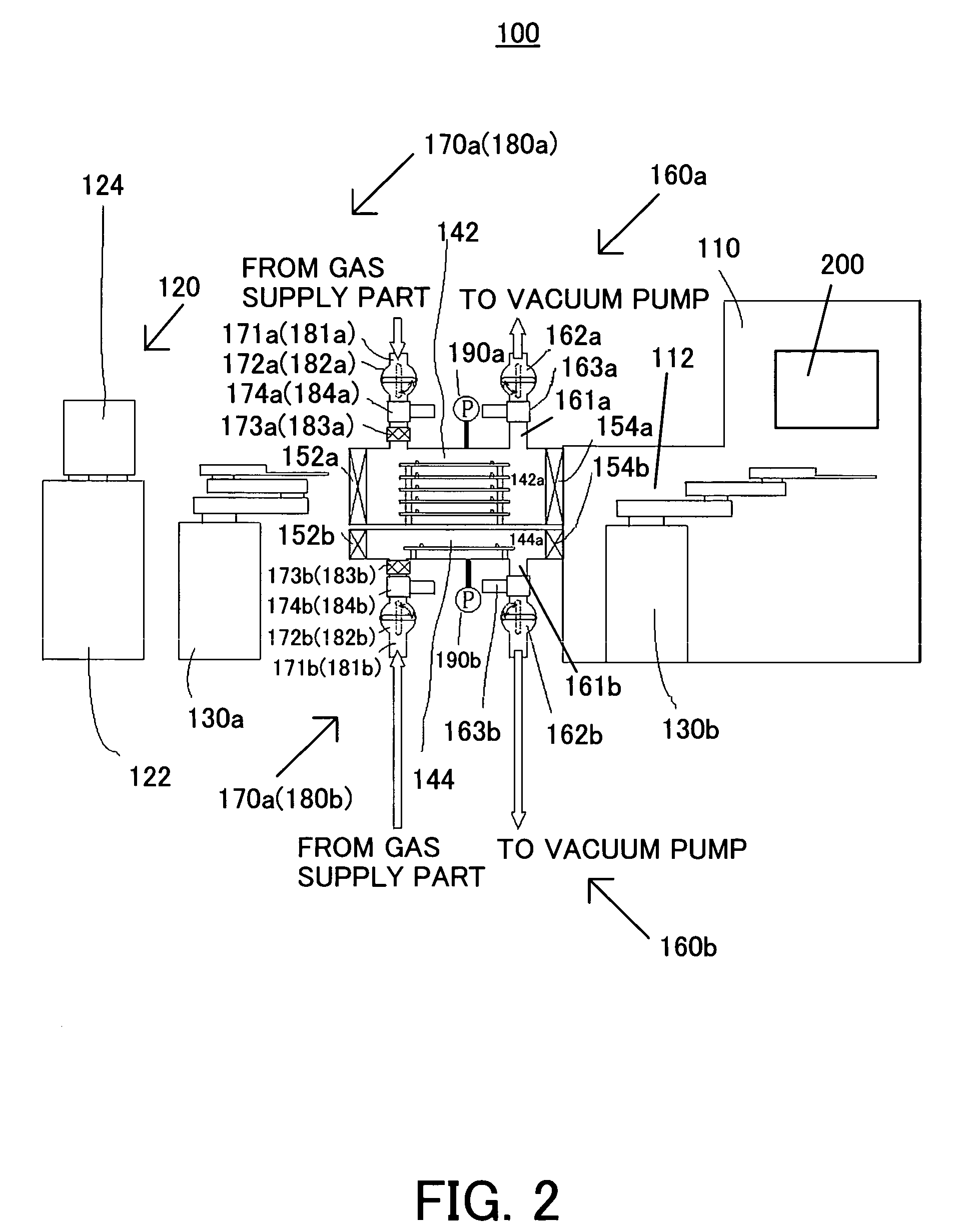

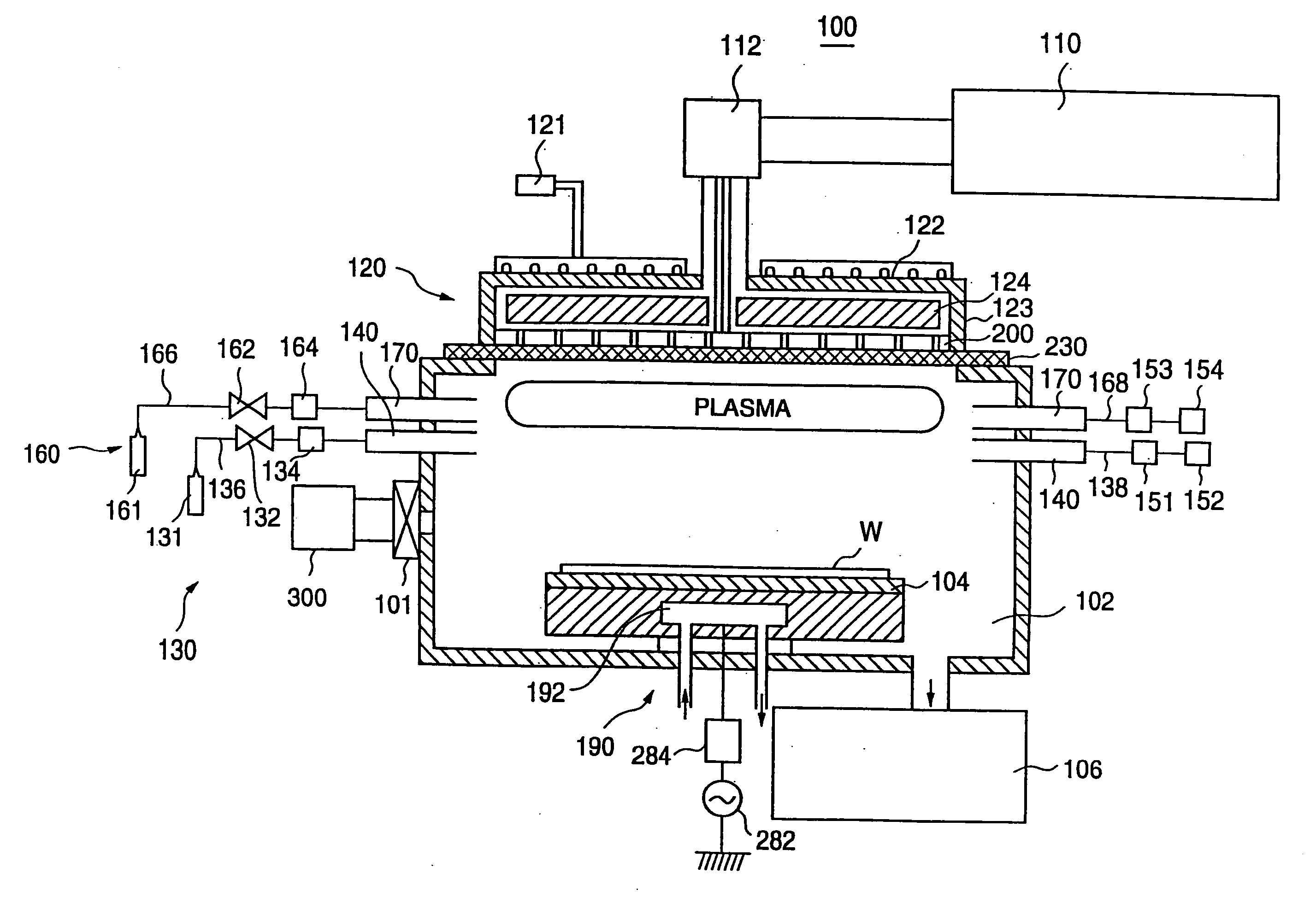

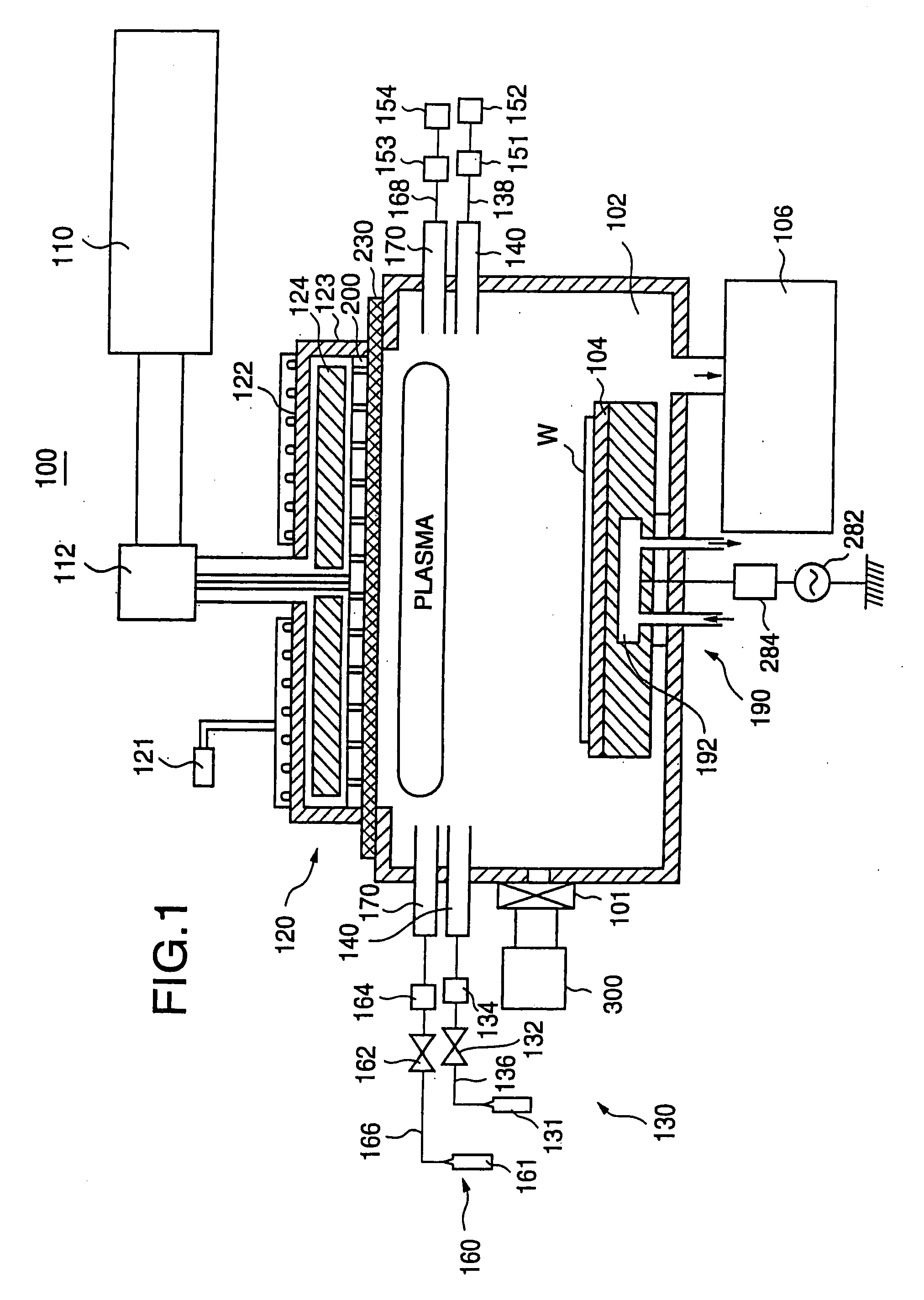

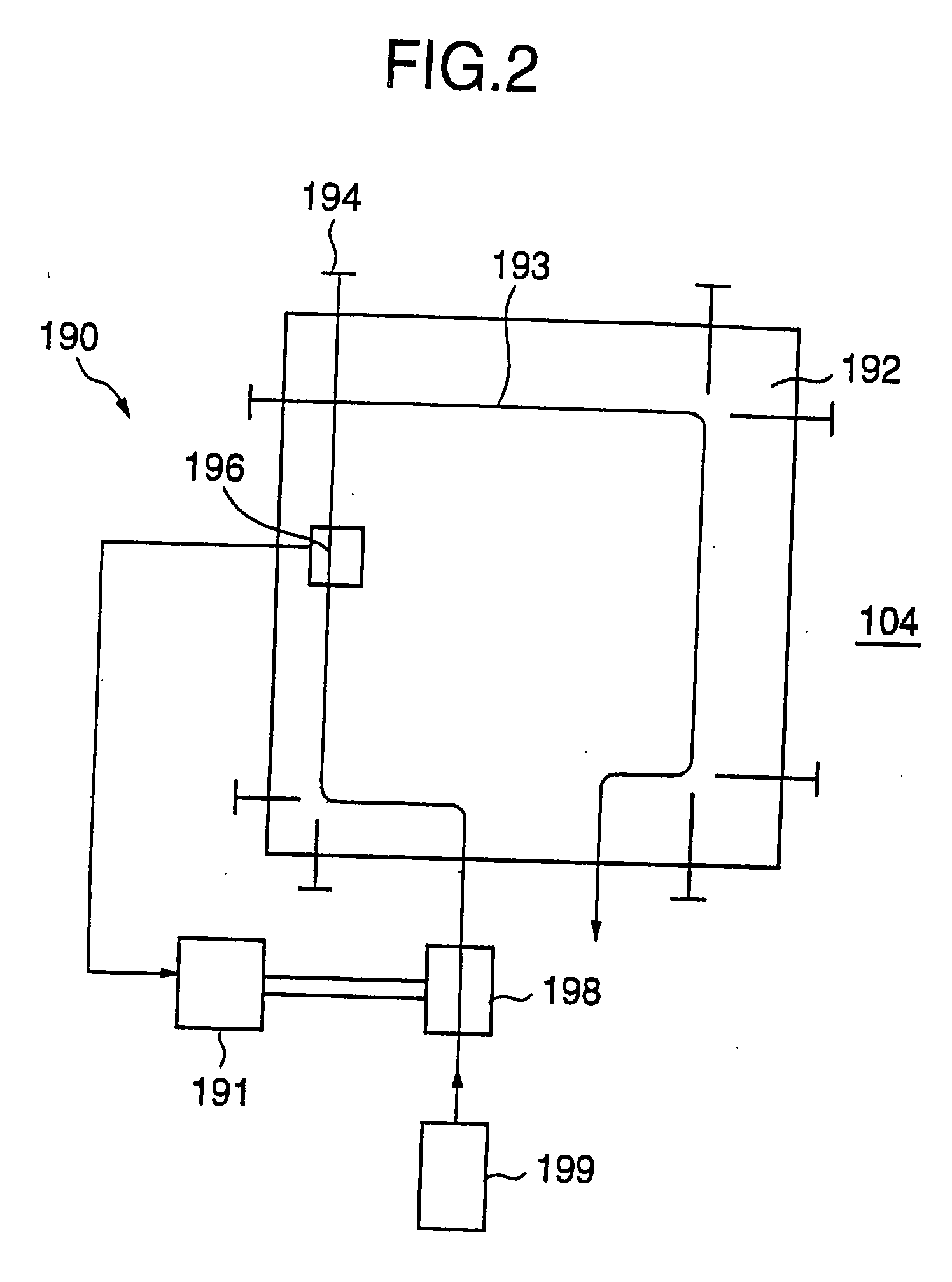

Plasma processing apparatus having an evacuating arrangement to evacuate gas from a gas-introducing part of a process chamber

InactiveUS20020002948A1High quality processingRapid and efficient evacuationElectric discharge tubesSemiconductor/solid-state device manufacturingQuality processProcess engineering

A plasma processing apparatus can apply a high-quality process to an object to be processed by removing impurities from a gas-introducing part of a process chamber. The gas-introducing part connected to the process chamber so as to introduce a reactant gas into the process chamber. A first vacuum pump is connected to the process chamber so as to evacuate gas from the process chamber so that the process chamber is maintained at a negative pressure. A gas-evacuating arrangement is connected to the gas-introducing part so as to exclusively evacuate the reactant gas from the gas-introducing part. The gas-evacuating arrangement includes a second vacuum pump directly connected to the gas introducing part or a bypass passage connecting the gas-introducing par to the first vacuum pump by bypassing the process chamber.

Owner:TOKYO ELECTRON LTD

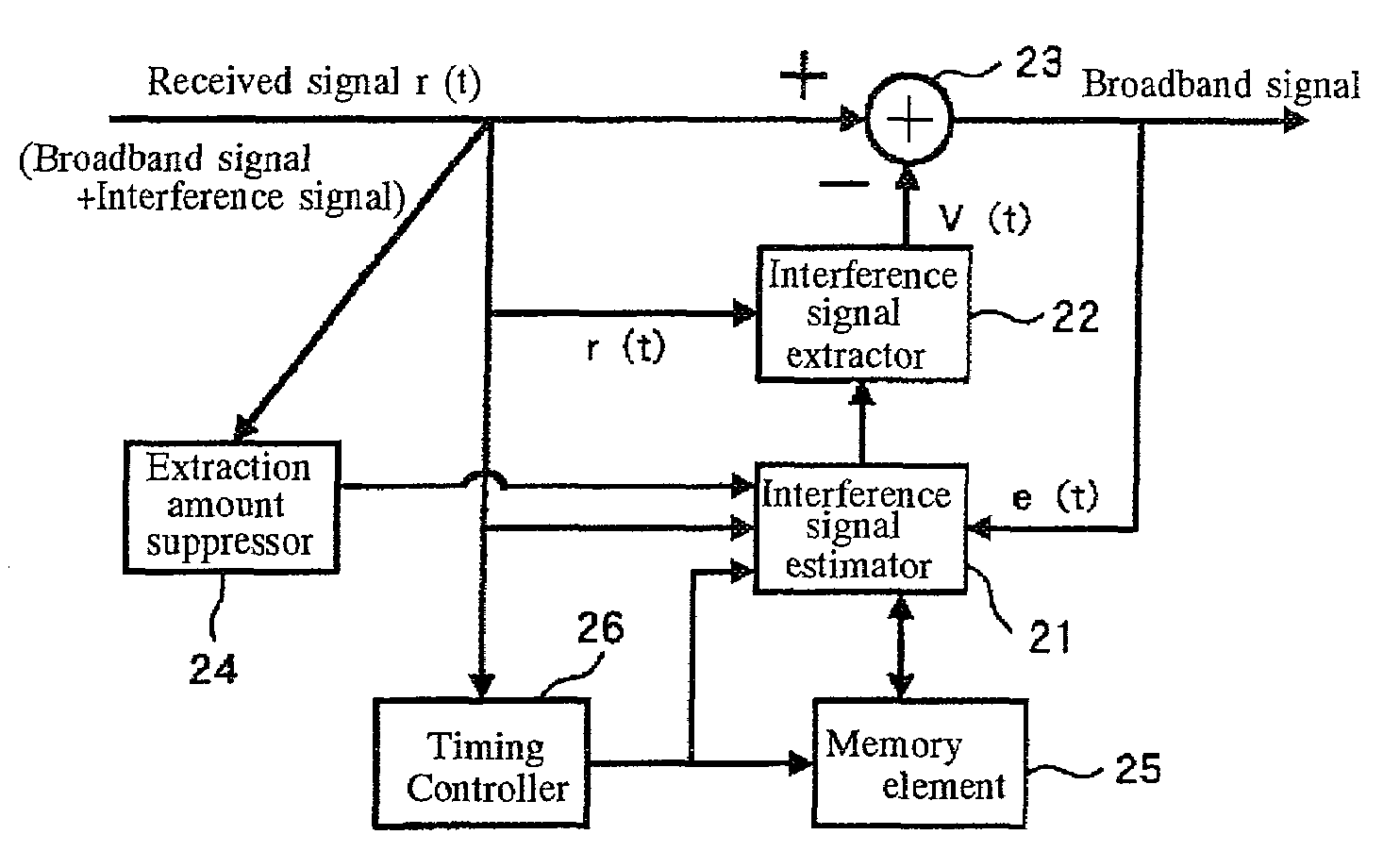

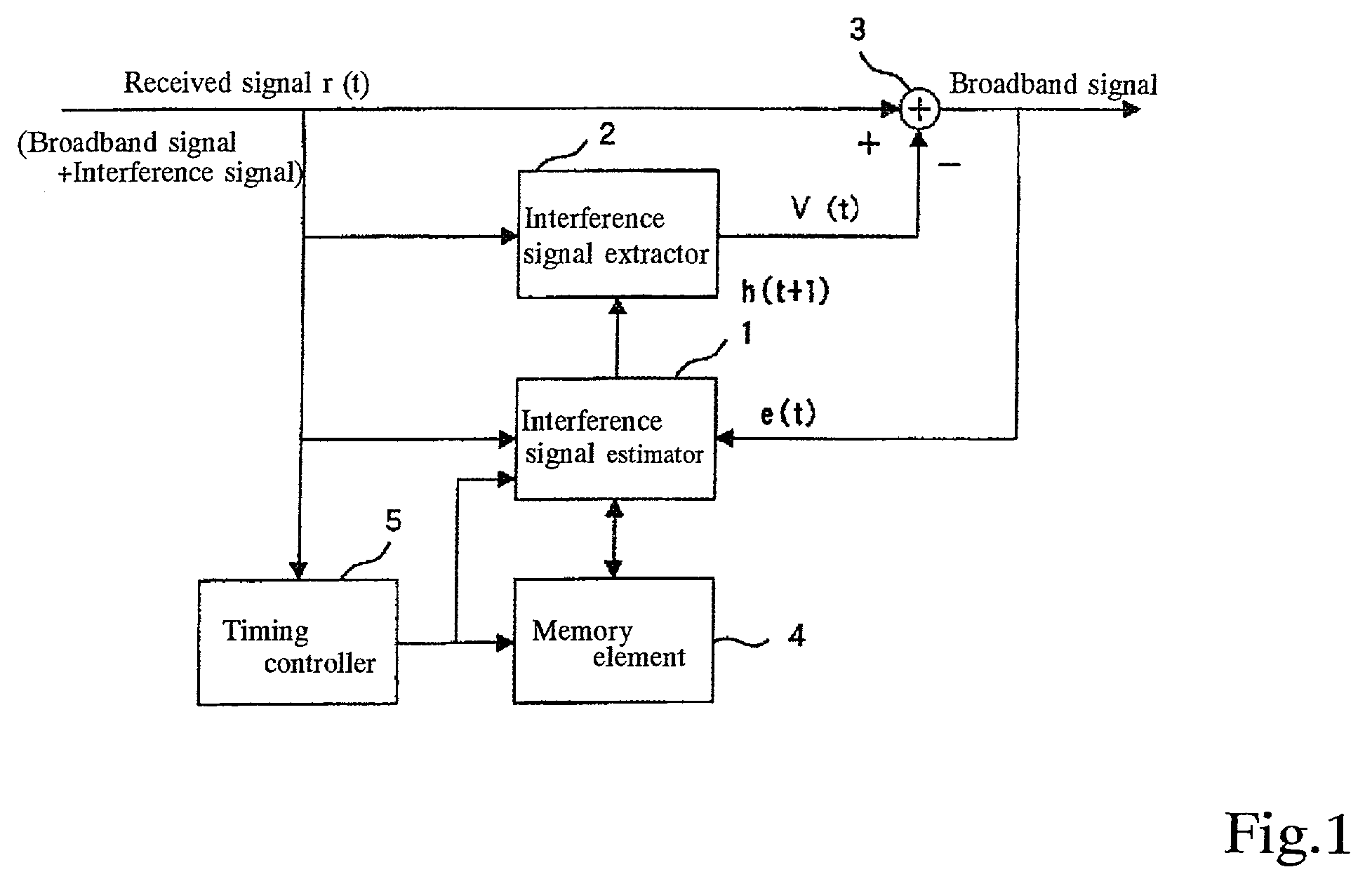

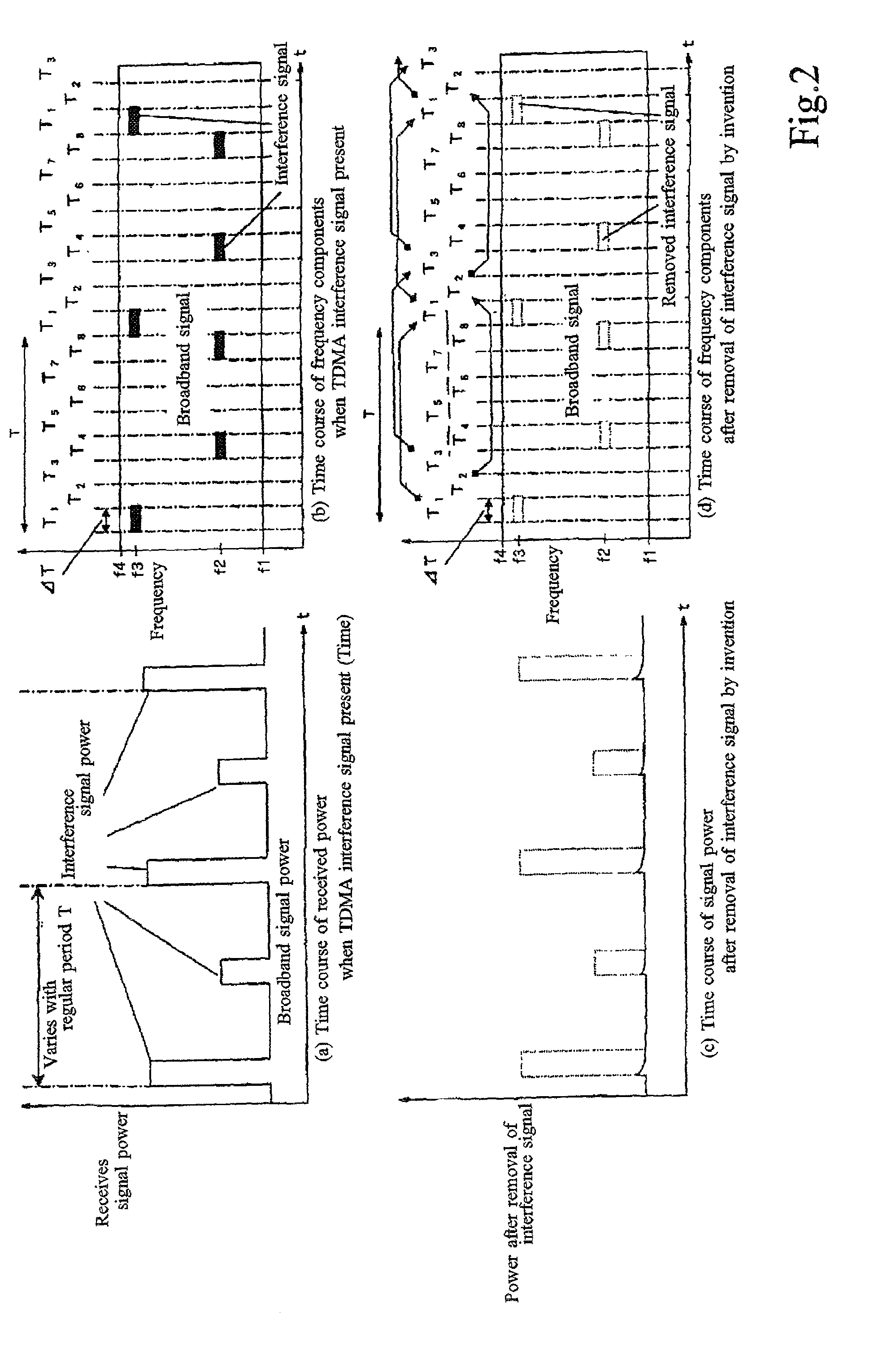

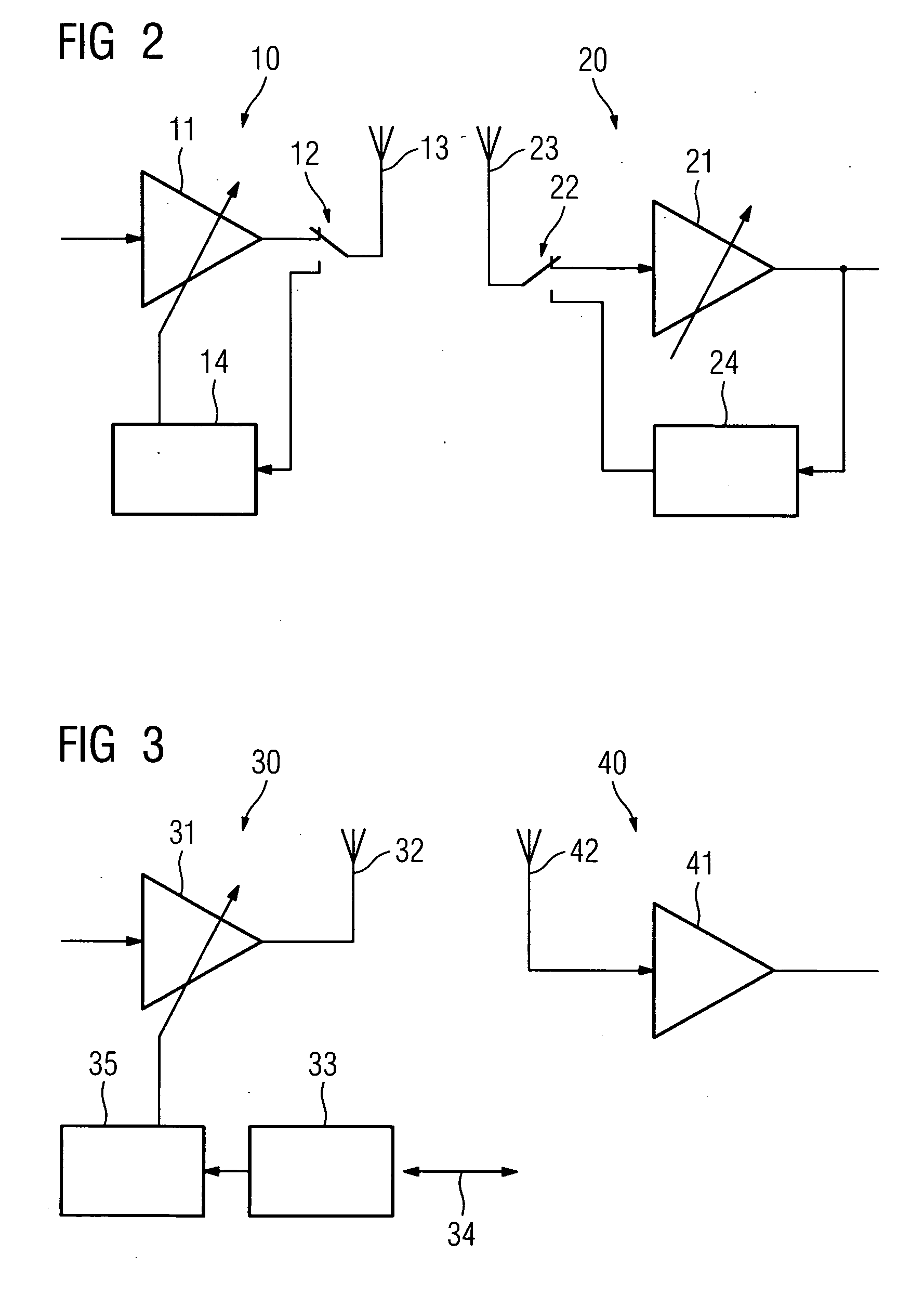

Interference signal removal system

InactiveUS7031402B2Prevent removalHigh quality processingPolarisation/directional diversityLine-faulsts/interference reductionEngineeringEstimation result

An interference signal removal system includes interference signal estimating means for estimating an interference signal contained in a received signal based on the received signal and a result obtained by removing an interference signal from the received signal, interference signal removing means for removing from the received signal the interference signal estimated by the interference signal estimating means; and interference signal estimation controlling means for storing the interference signal estimation result of the interference signal estimating means in memory and controlling the interference signal estimation by the interference signal estimating means so as to estimate an interference signal contained in the received signal based on a past interference signal estimation result stored in memory.

Owner:KOKUSA ELECTRIC CO LTD

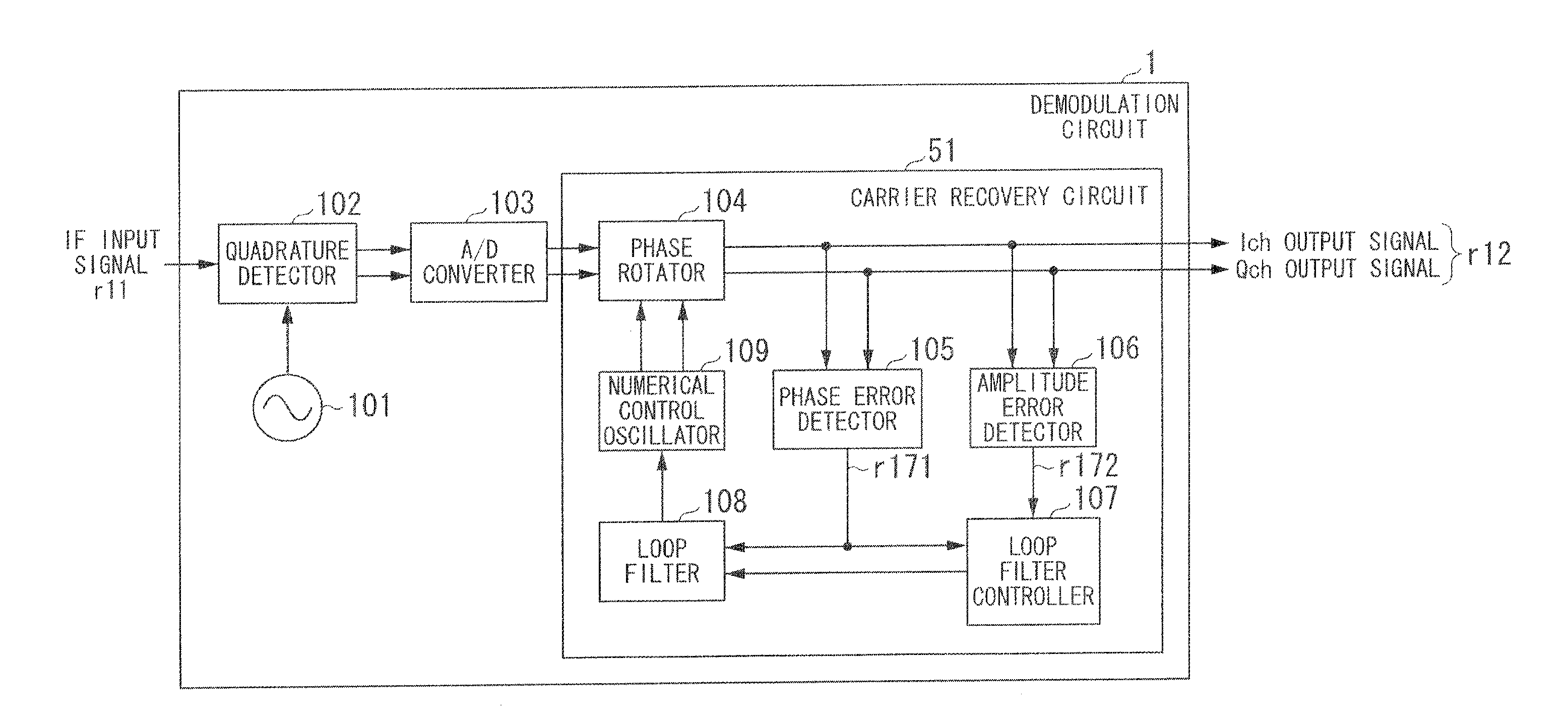

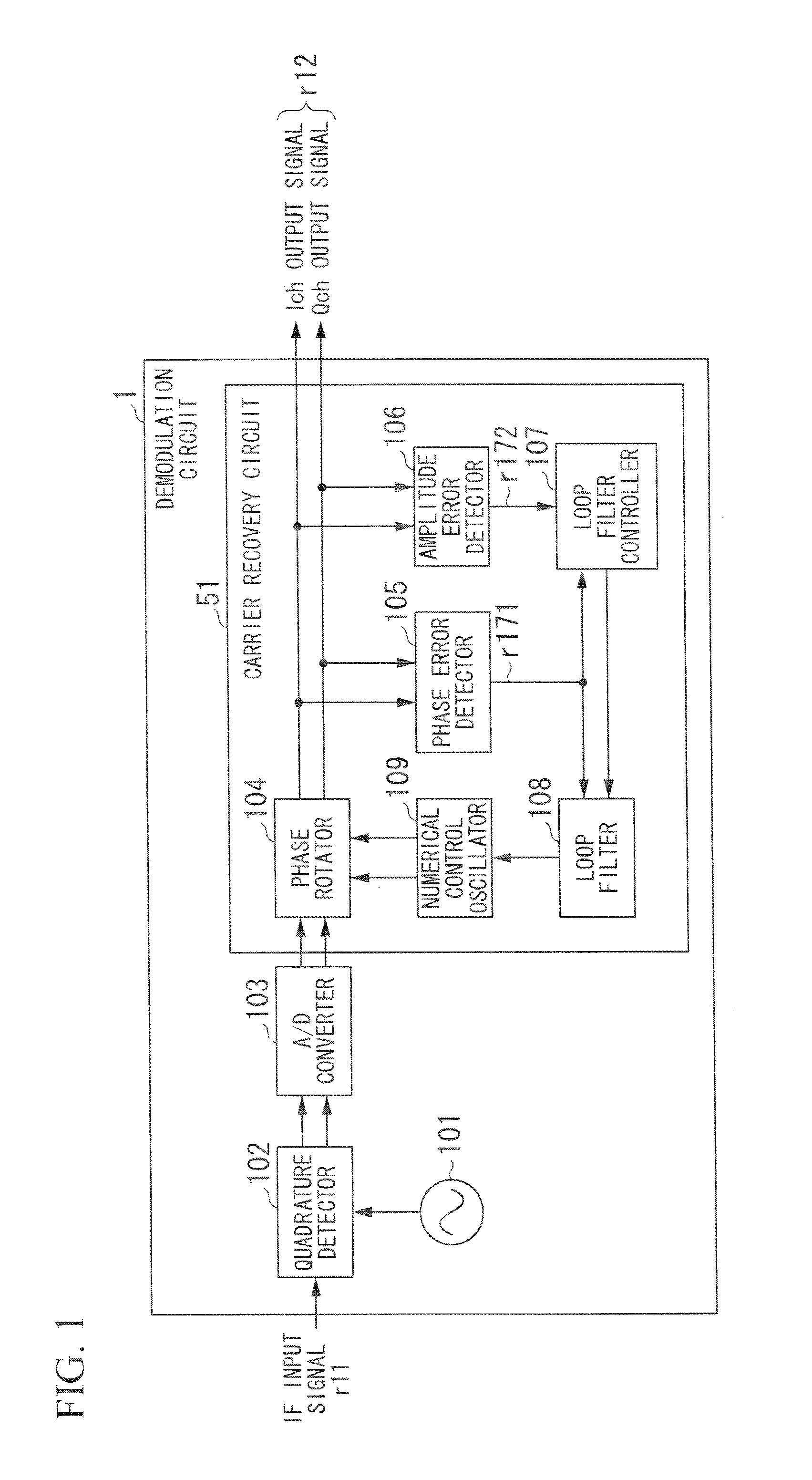

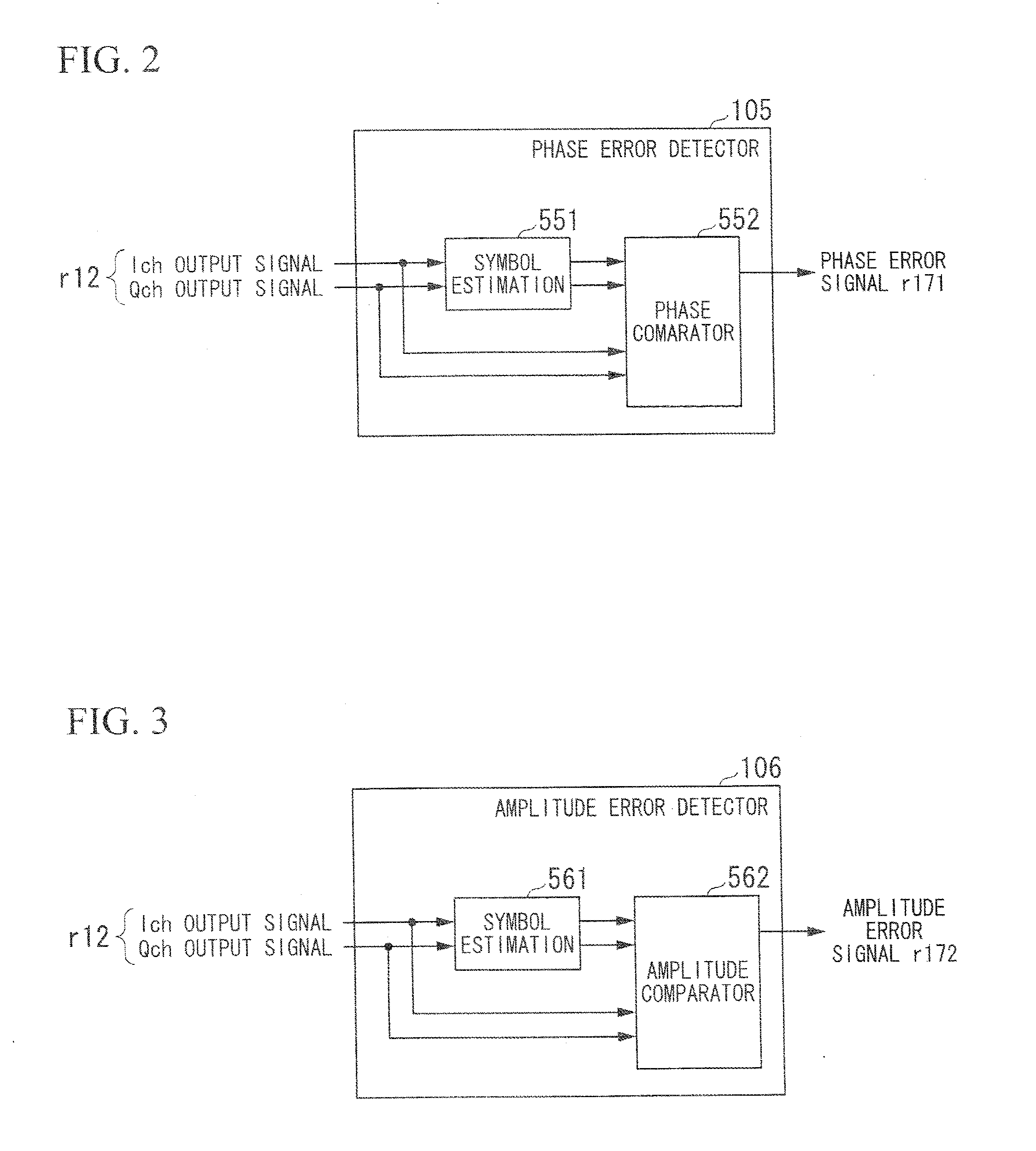

Carrier recovery circuit and demodulation circuit under quasi-coherent detection method

InactiveUS20120224657A1Error rateHigh quality processingPhase-modulated carrier systemsLoop filterIntermediate frequency

A carrier recovery circuit, adapted to a demodulation circuit according to a quasi-coherent detection method for generating baseband signals by way of quadrature detection on a received signal having an intermediate frequency, rotates phases of baseband signals; detects a phase error and an amplitude error; controls a bandwidth of a loop filter based on its difference, eliminates a high-frequency component from the phase error; and performs phase rotation based on the phase error eliminating its high-frequency component. It expands the bandwidth of the loop filter when a difference between the phase error and the amplitude error is greater than a predetermined threshold, whilst reducing bandwidth of the loop filter upon determining that the amplitude error decreases due to a reduction of the bandwidth of the loop filter. This optimizes the bandwidth of the loop filter to follow variations of the C / N ratio of the received signal, improving bit error rate.

Owner:NEC CORP

Transmission method with dynamic transmission power adjustment and corresponding hearing device system

ActiveUS20080226107A1Minimal power consumptionReducing distortion and artifactPower managementRadio transmissionEngineeringQuality information

With the date transmission in a hearing device system, overloads are to be avoided and the energy consumption during transmission is to be kept as low as possible. To this end, a transmission method and a corresponding system for the inductive transmission is proposed, in which the receiver returns an item of quality information relating to the received signal back to the transmitter. The transmission power of the transmitter is then dynamically varied as a function of the item of quality information. With unidirectional transmission, the transmitter can obtain an item of distance information relating to the distance of the receiver from the transmitter and thereupon adjust the transmission power accordingly.

Owner:SIVANTOS PTE LTD

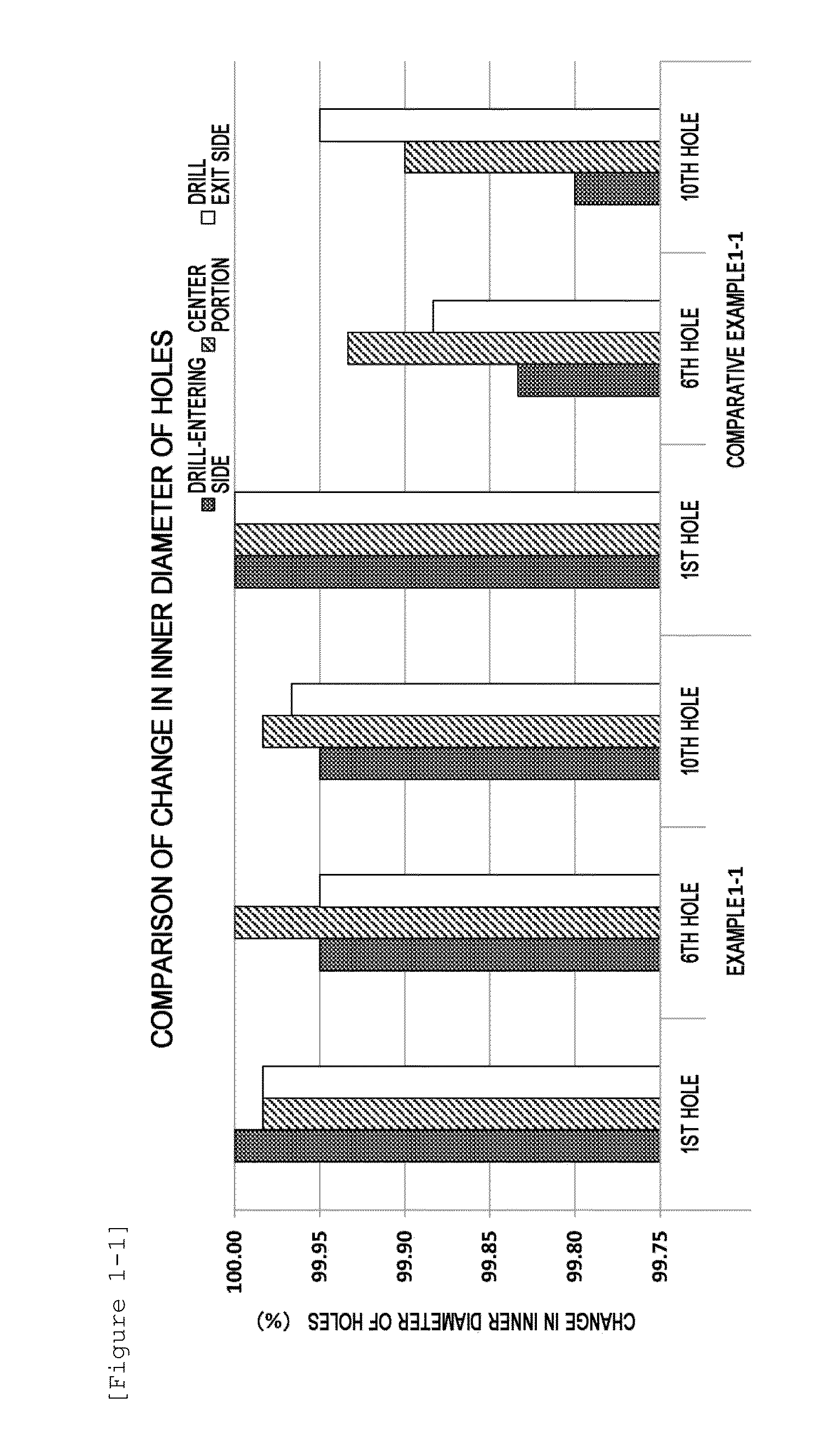

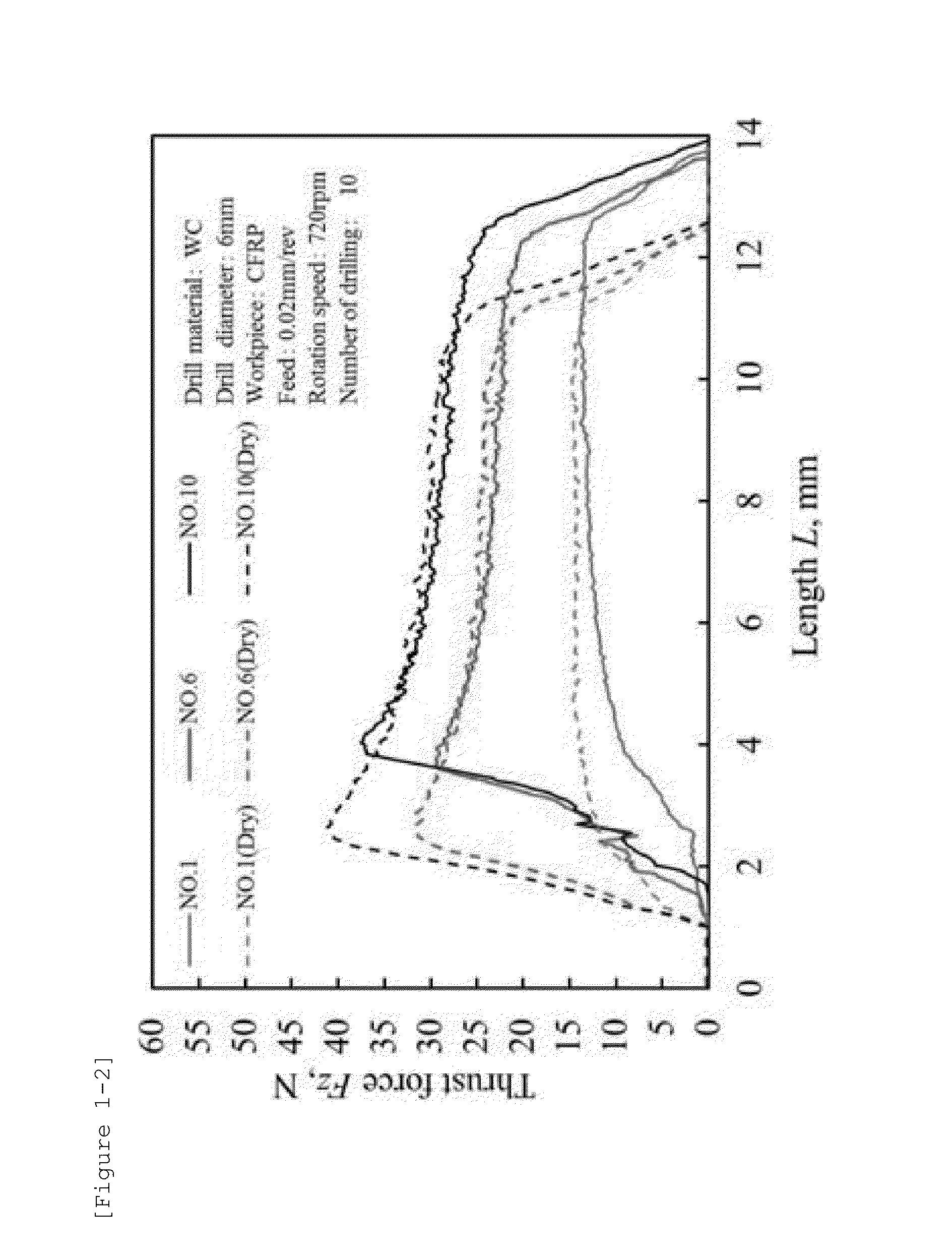

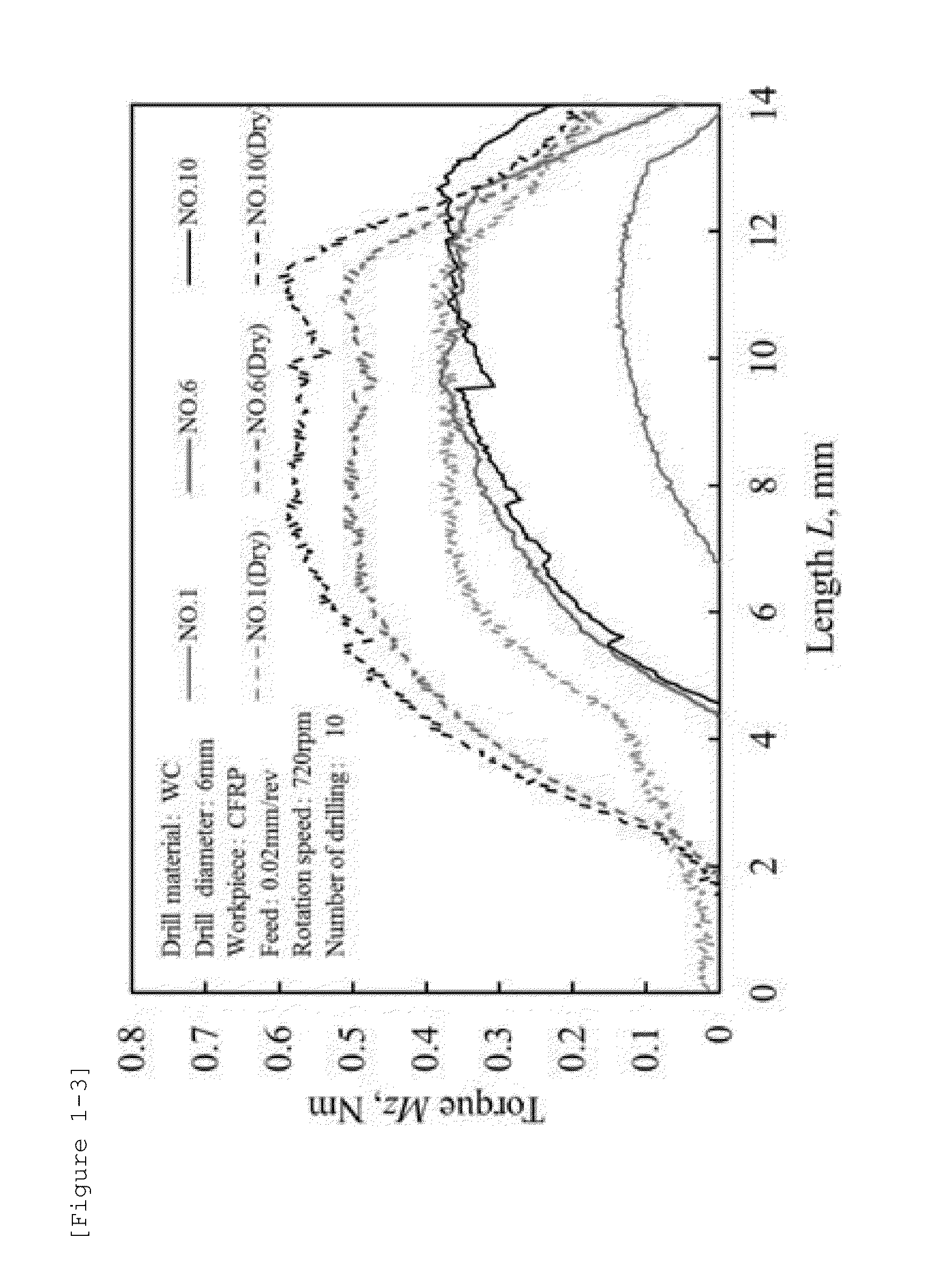

Entry sheet for cutting fiber reinforced composite material or metal, and cutting method for cutting fiber reinforced material or metal

InactiveUS20160045961A1Inhibit wearIncrease production capacityAircraft componentsSynthetic resin layered productsFiber-reinforced compositeMaterials science

An entry sheet of the present invention is used in cutting a fiber reinforced composite material and / or a metal. Moreover, in a cutting method of the present invention, cutting of a fiber reinforced composite material and / or a metal is performed using the entry sheet.

Owner:MITSUBISHI GAS CHEM CO INC

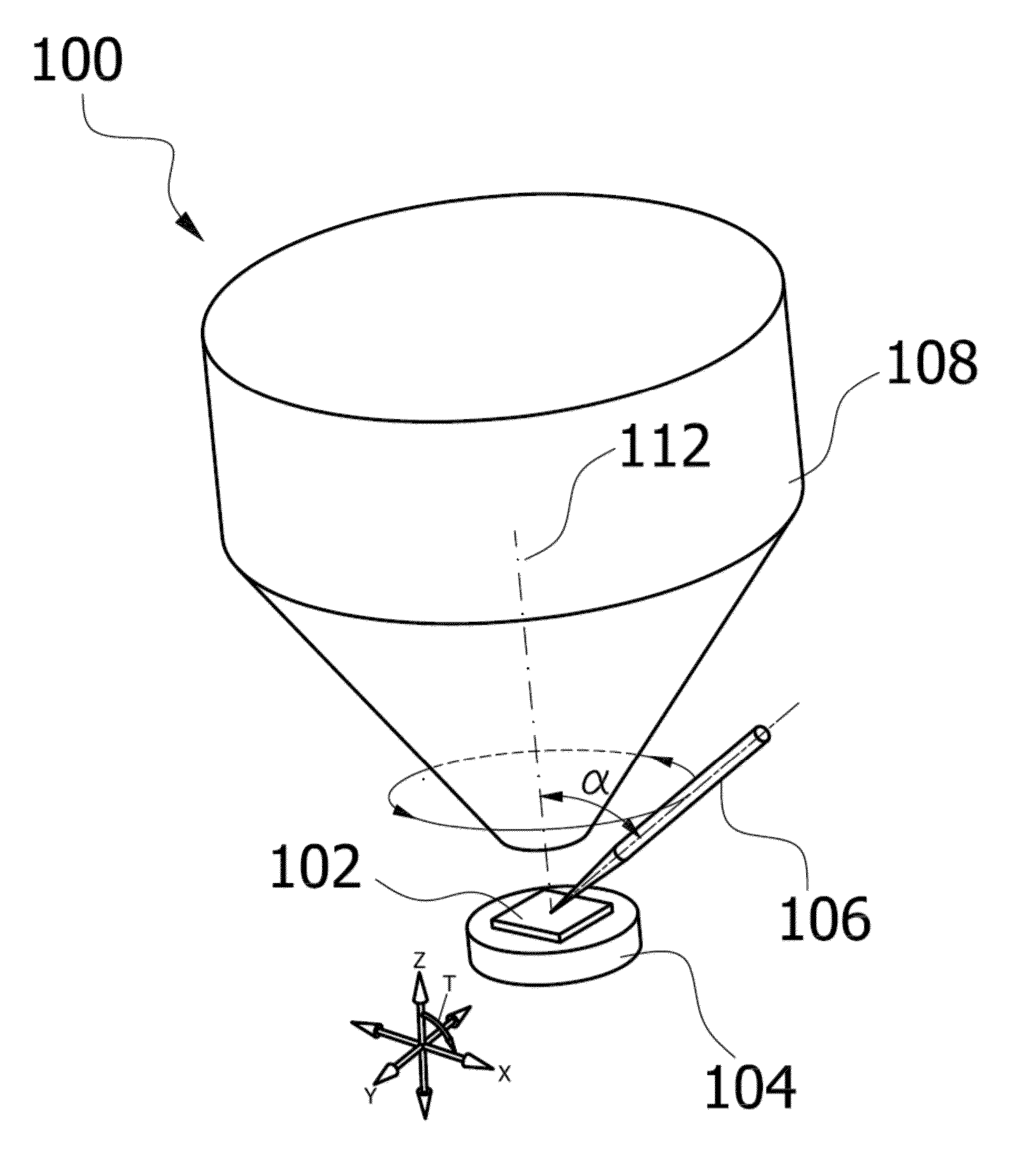

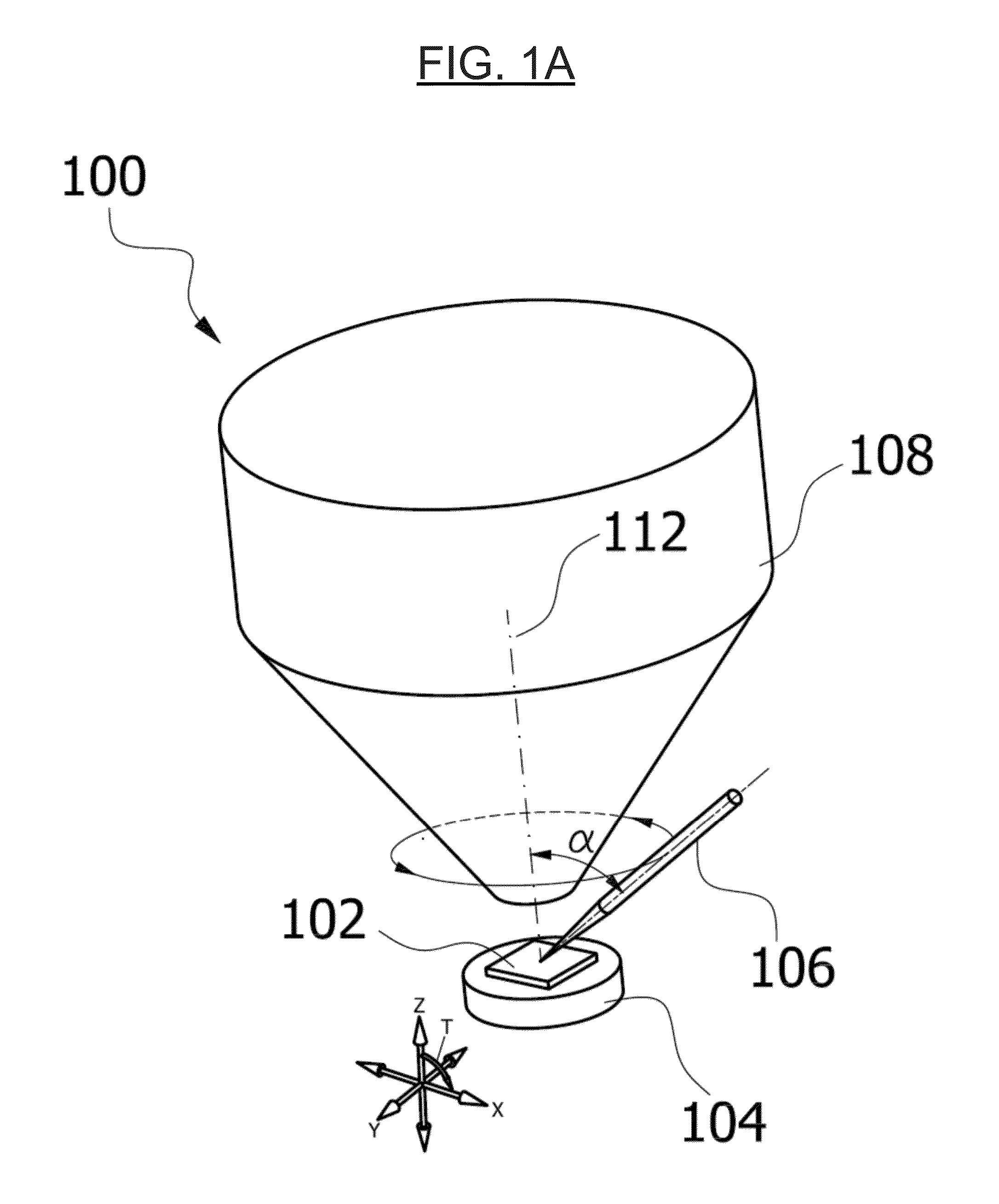

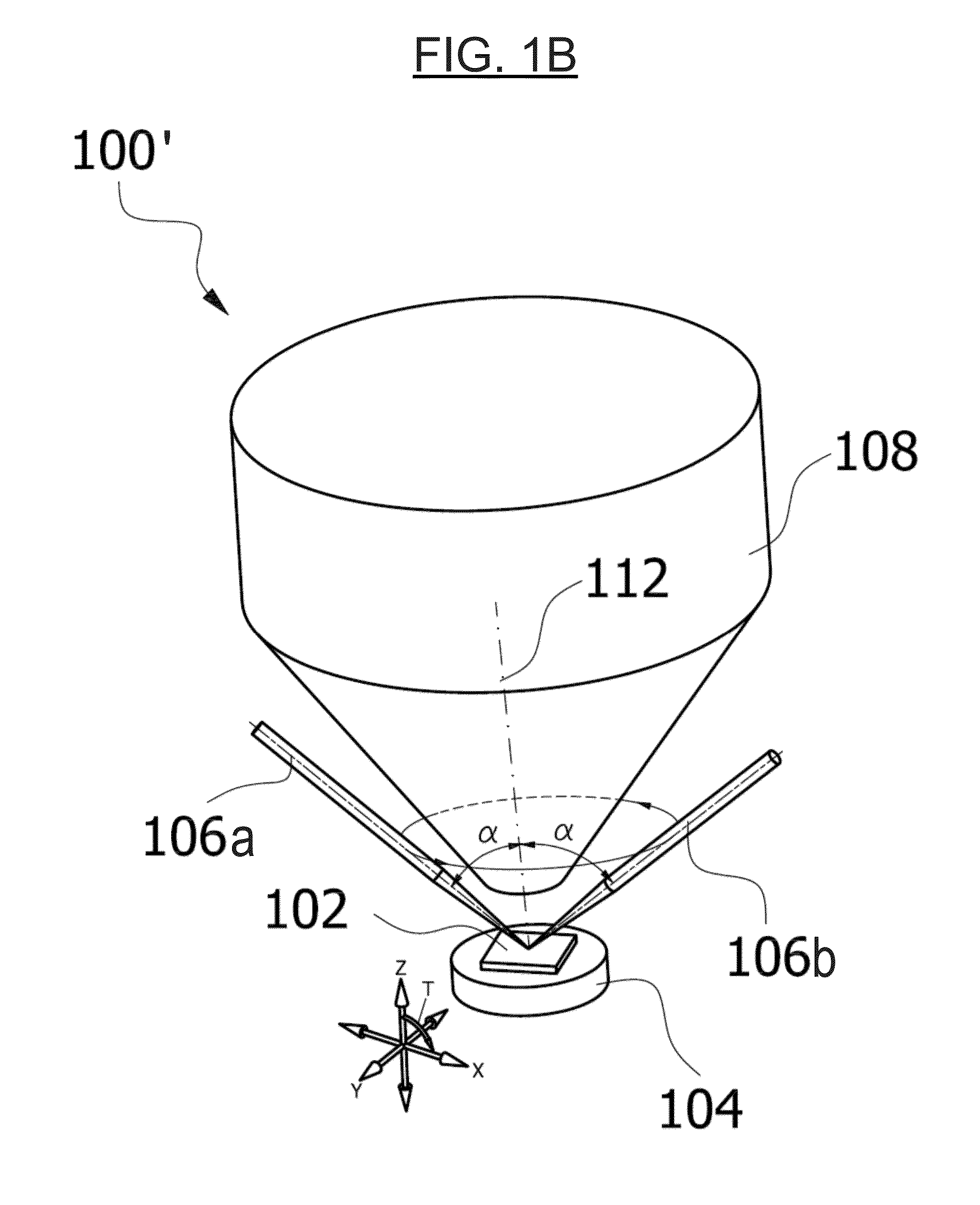

Methods, Apparatuses, Systems and Software for Treatment of a Specimen by Ion-Milling

ActiveUS20150255248A1Increase speedConvenient platformCellsElectric discharge tubesIon beamMachining process

Methods, apparatuses, systems and software for ion beam milling or machining are disclosed. The apparatus includes a specimen holder, a table, one or more ion sources, rotatable ion optics, and an imaging device. The specimen holder is configured to hold a specimen in a stationary position during milling or machining. The table is configured to change the stationary position of the specimen holder in any of three orthogonal linear directions and an angular direction. The rotatable ion optics are configured to emit an ion beam towards a predetermined location on the specimen from any of the one or more ion sources at any angle around an axis that is orthogonal to a horizontal surface of the table when the angular direction of the table is 0°. The imaging device is configured to generate an image of the specimen including the predetermined location, thereby enabling real-time monitoring of the milling or machining process.

Owner:IB LABS

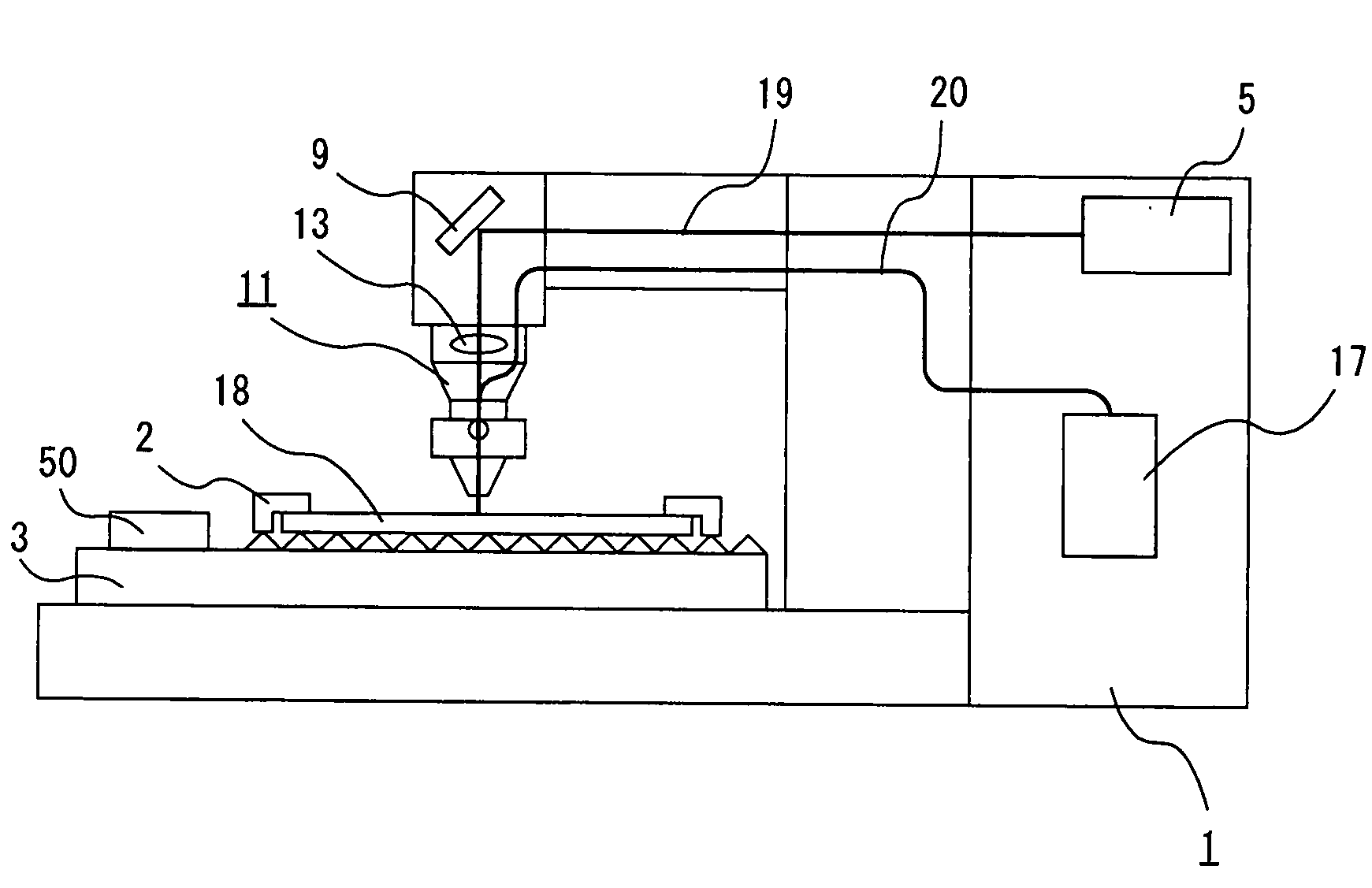

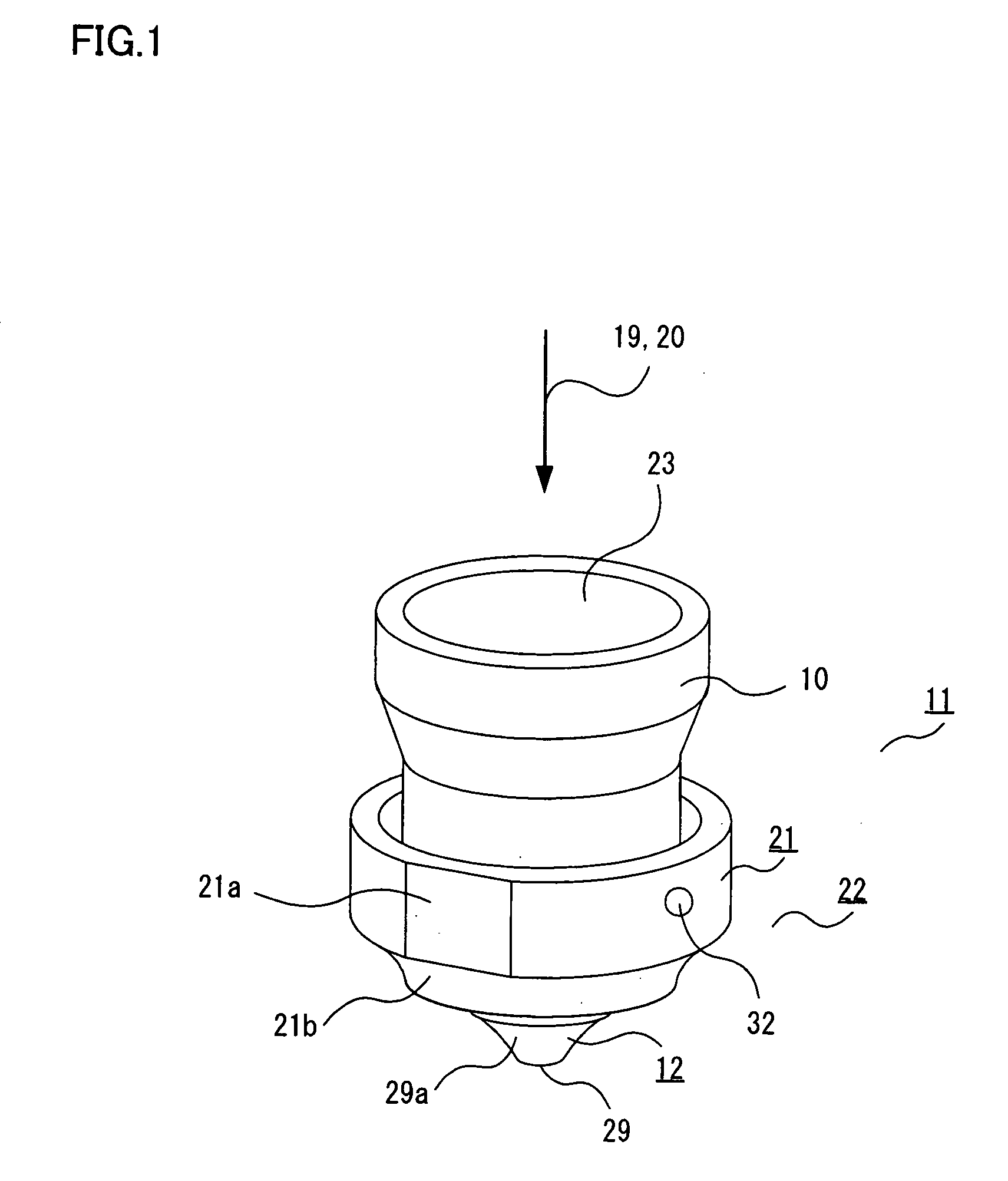

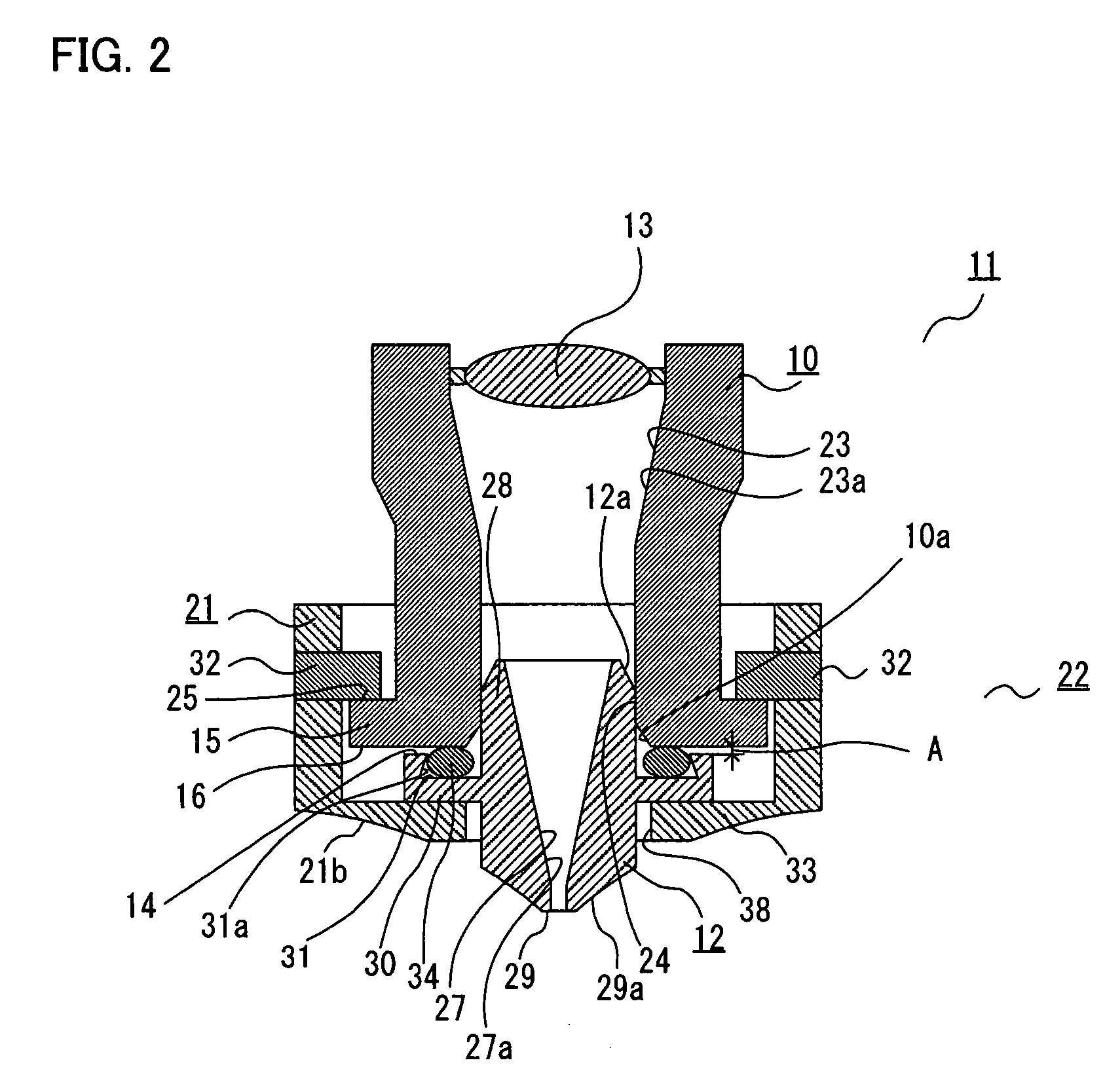

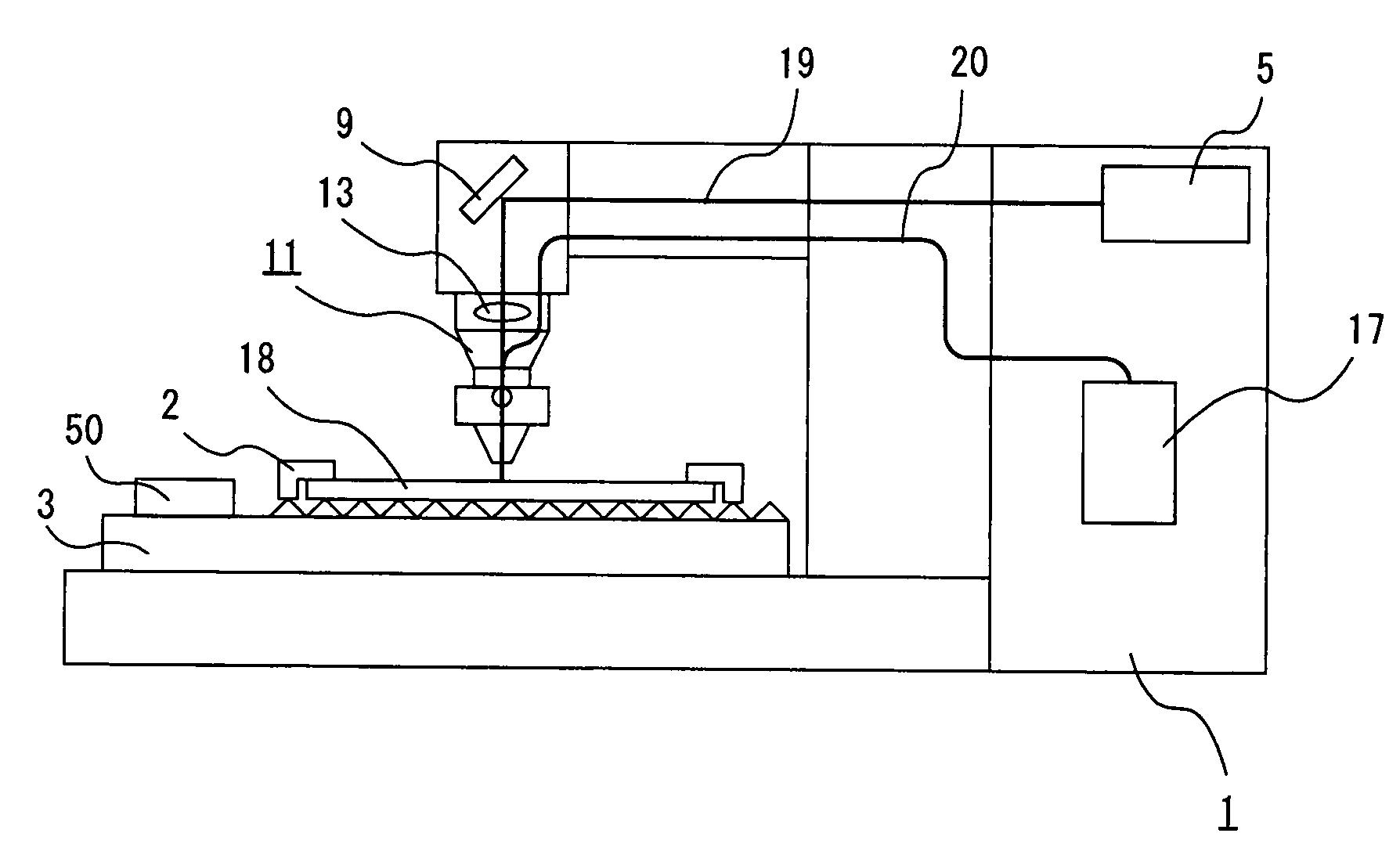

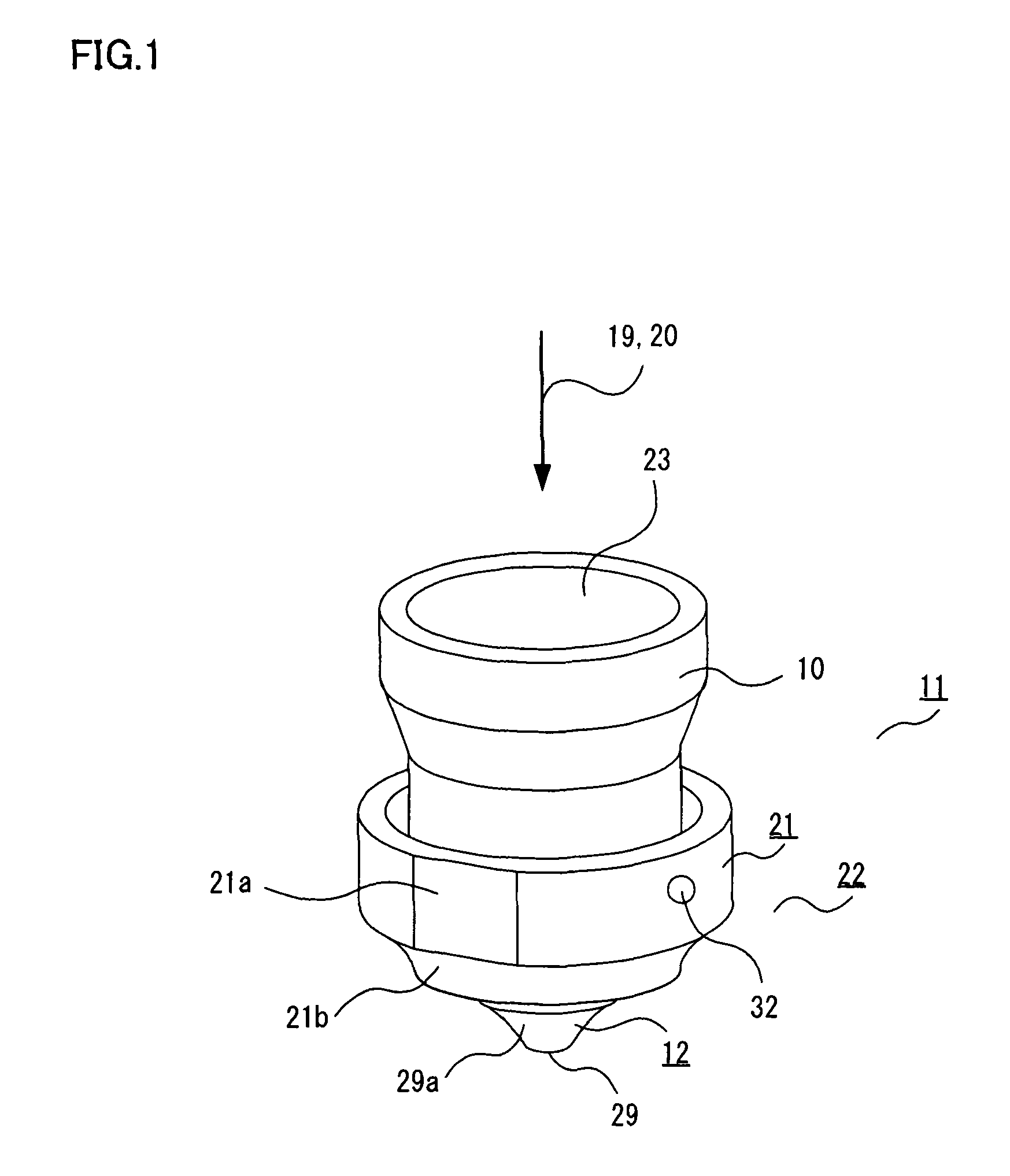

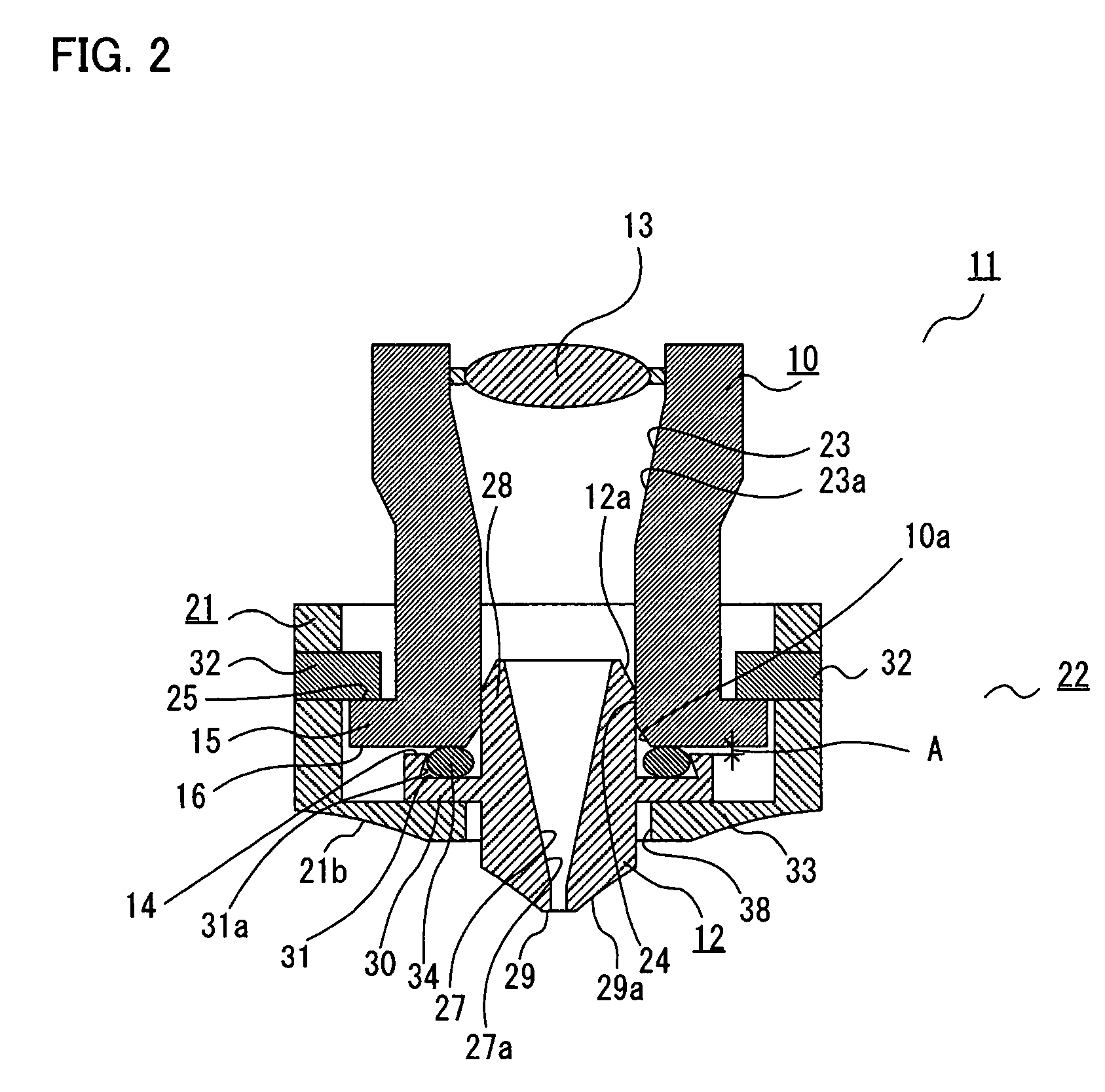

Machining head, nozzle changer and laser beam machining apparatus

InactiveUS20080099452A1Easy to replaceHigh quality processingTool changing apparatusPositioning apparatusLaser beam machiningLaser light

A machining head includesa machining head element having an inner-head channel for passing laser light and assist gas,the nozzle having an inner-nozzle channel connecting to the inner-head channel and a nozzle orifice,pins protruding radially inward from a curved inner surface of the nozzle,a pin-locking part formed on the outside of the machining head element, the pin-locking part having pin-fitting openings,a head alignment part formed on a nozzle-side end surface of the machining head element,a nozzle alignment part formed on the nozzle at a location where the nozzle is aligned with the machining head element, andan O-ring fitted between the head alignment part and the nozzle to create a clearance between the head alignment part and the nozzle alignment part for mutual alignment.

Owner:MITSUBISHI ELECTRIC CORP

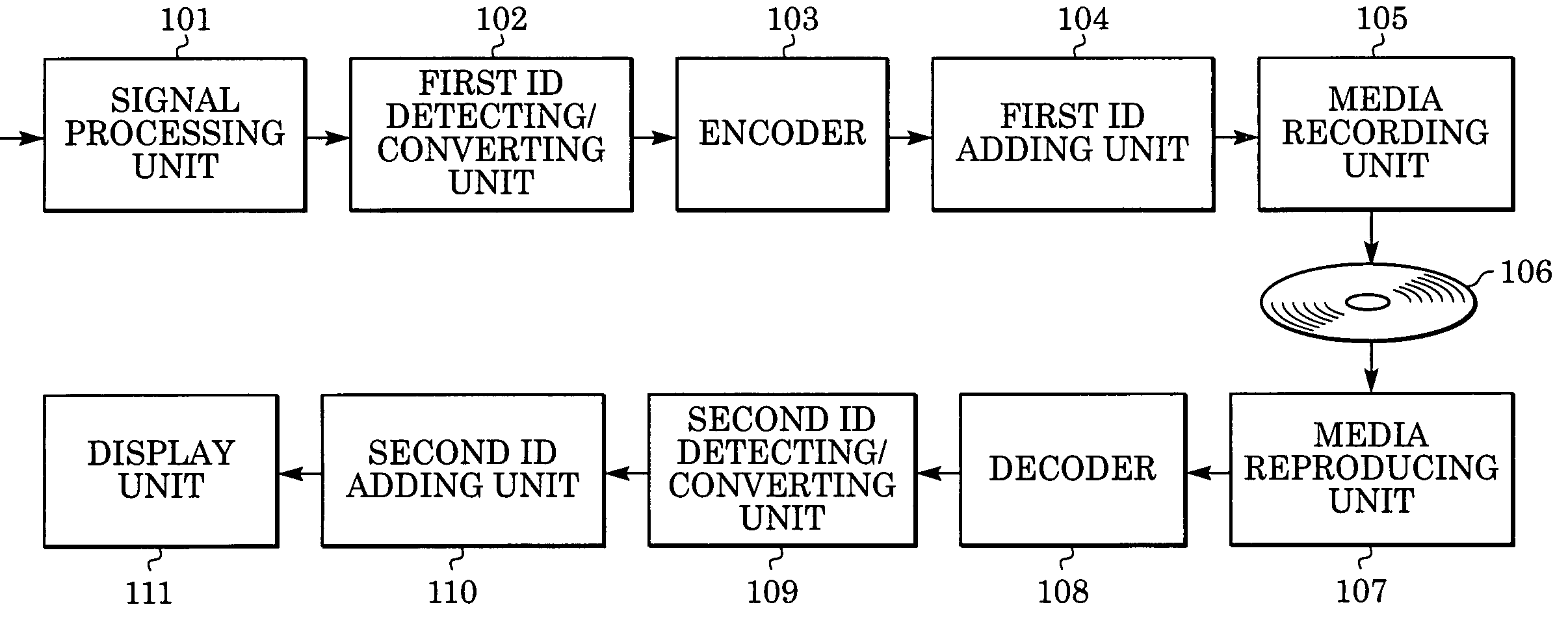

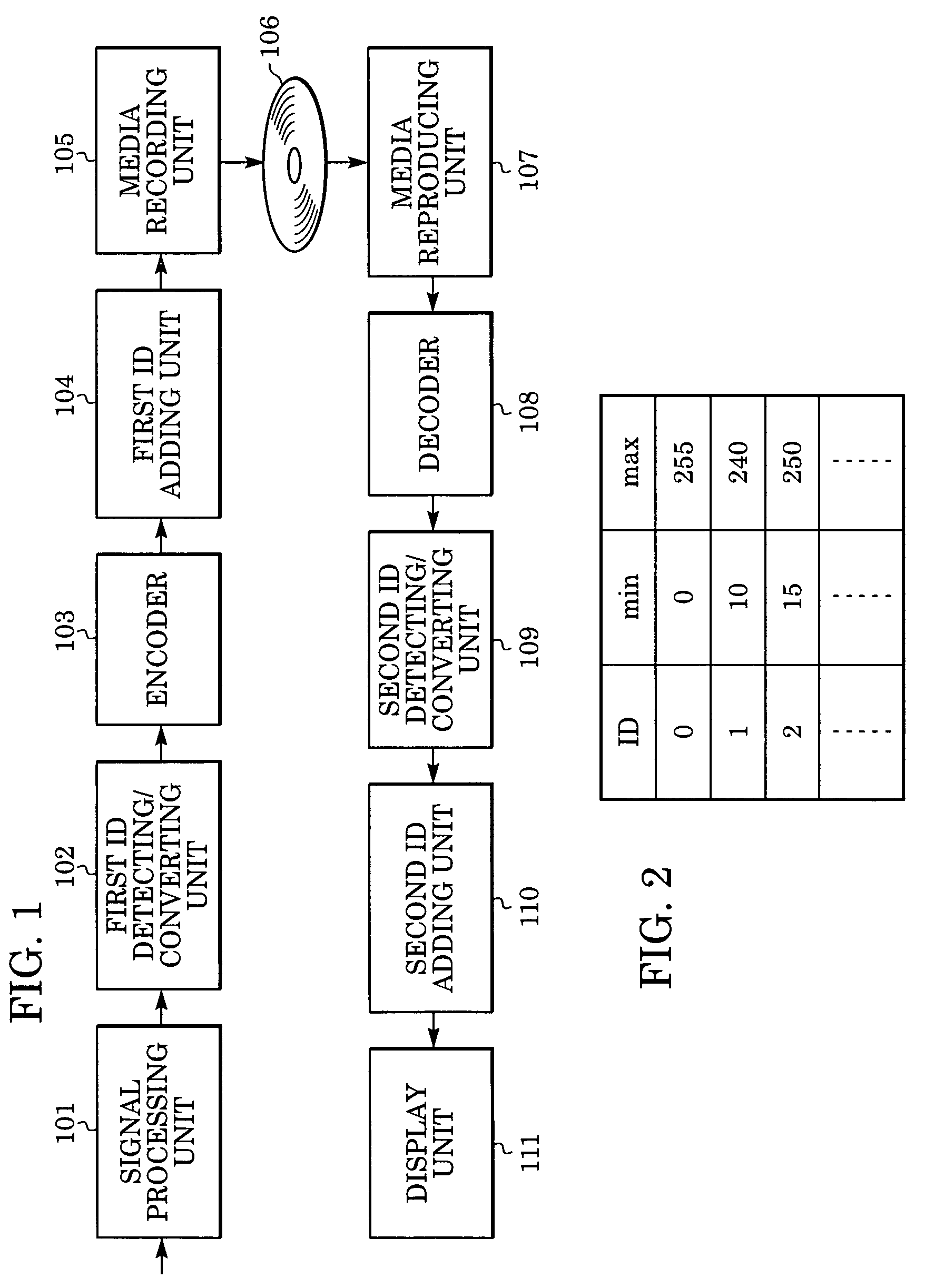

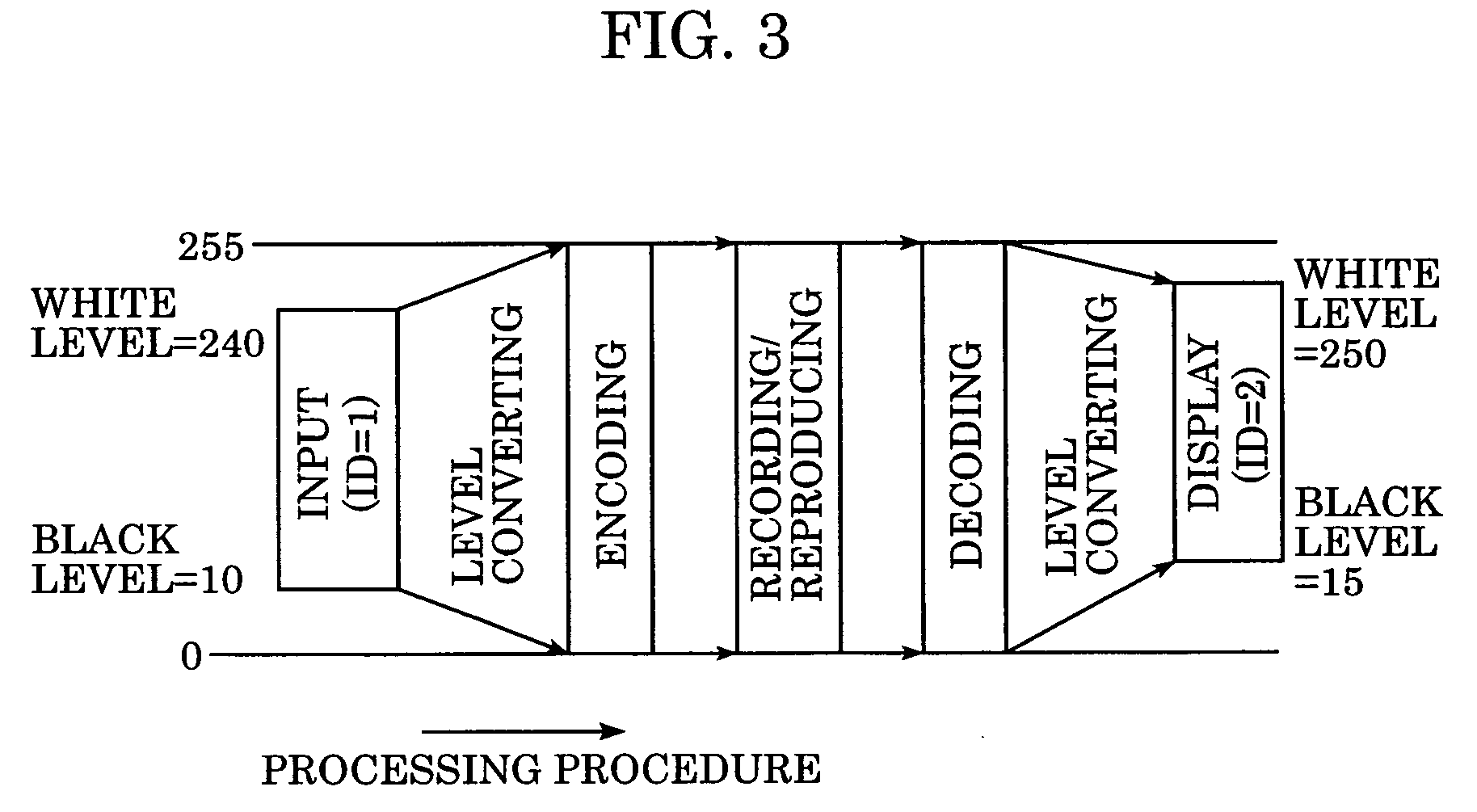

Image processing apparatus and image processing method

InactiveUS20050286870A1Quality improvementHigh quality processingTelevision system detailsColor television signals processingPattern recognitionImaging processing

There is provided an image processing apparatus including a converting unit for converting a level range of an input image signal into a predetermined level range, and an outputting unit for outputting the converted image signal and first identification information which indicates the predetermined level range, the first identification information being correlated with the converted image signal.

Owner:CANON KK

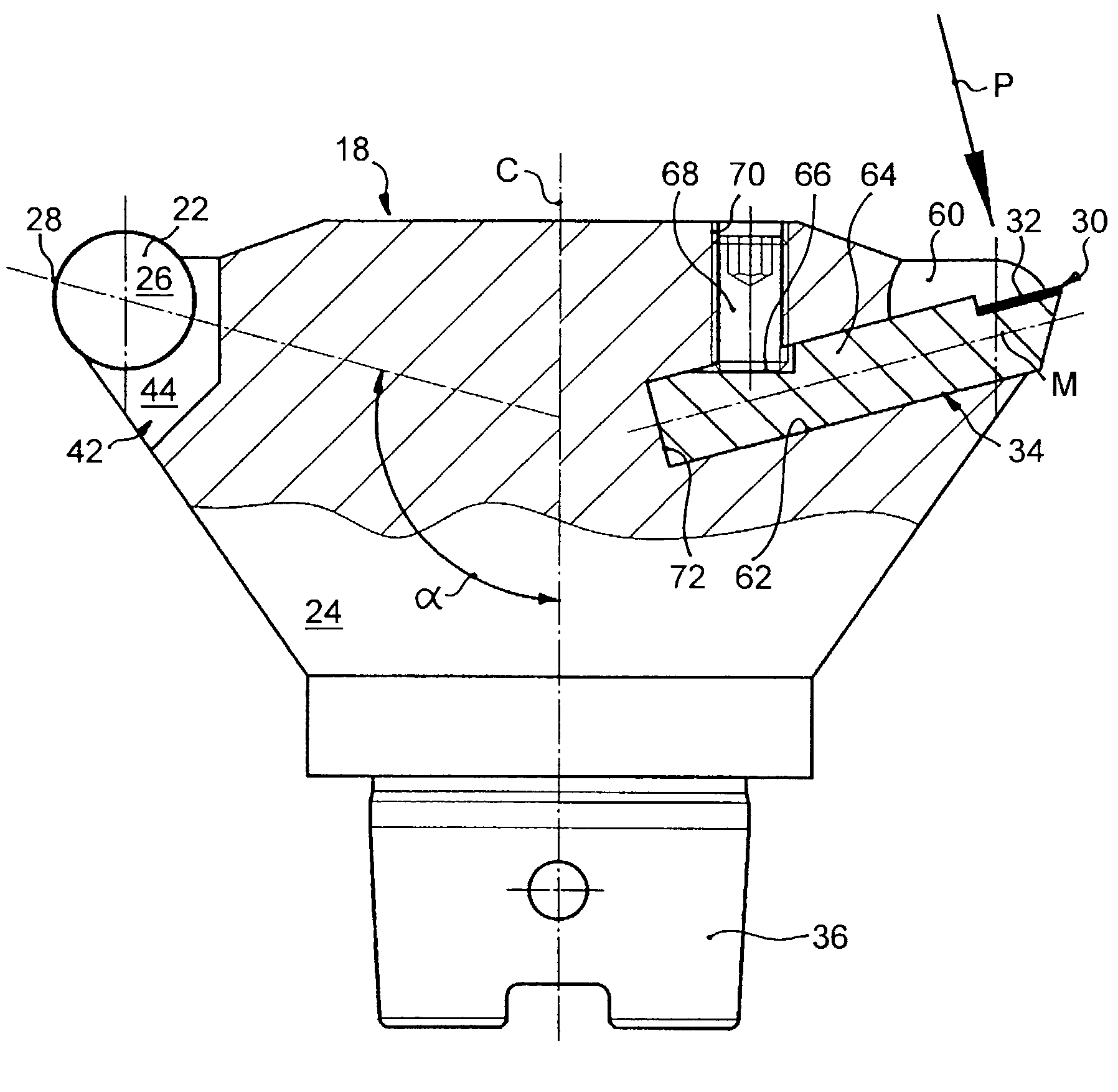

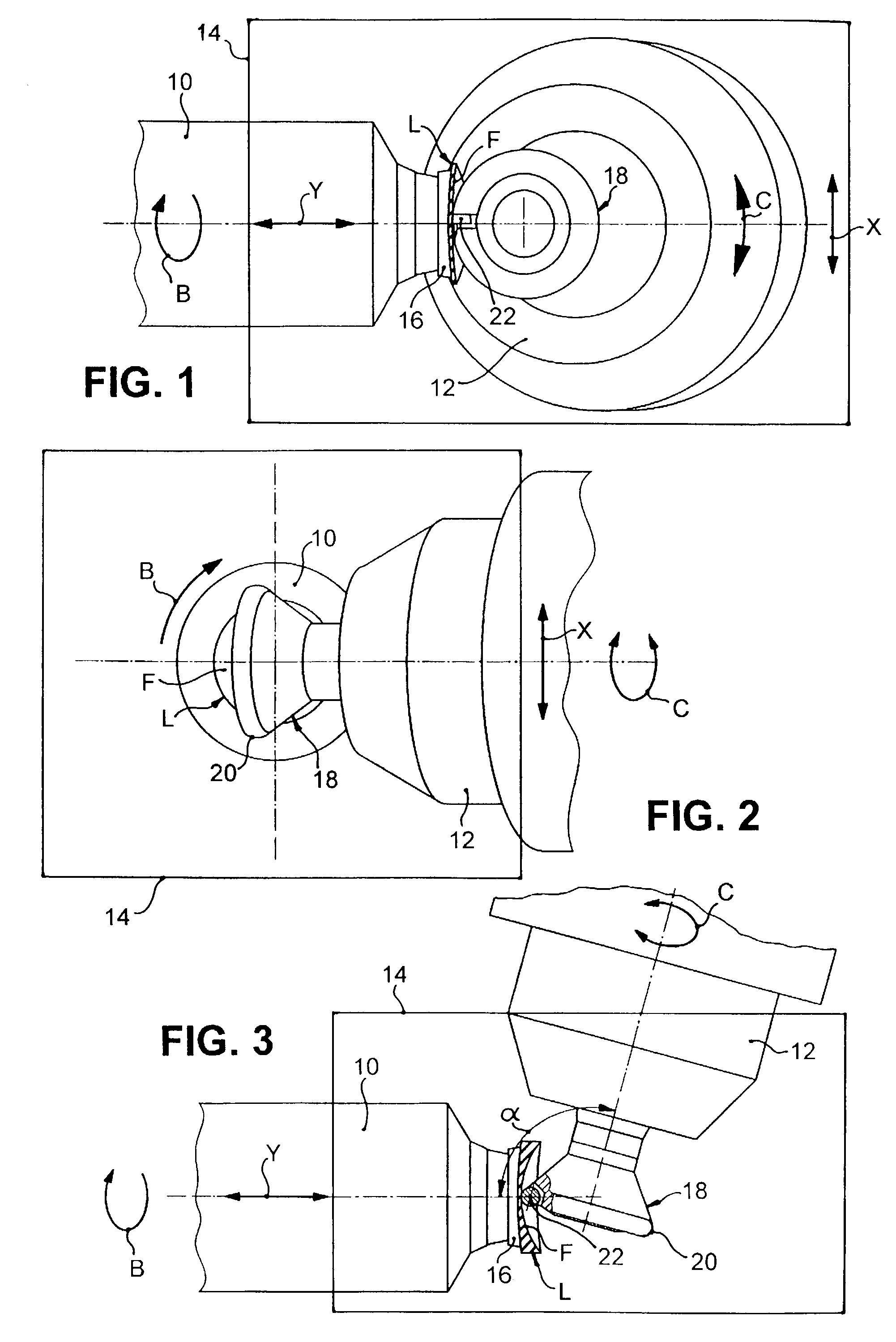

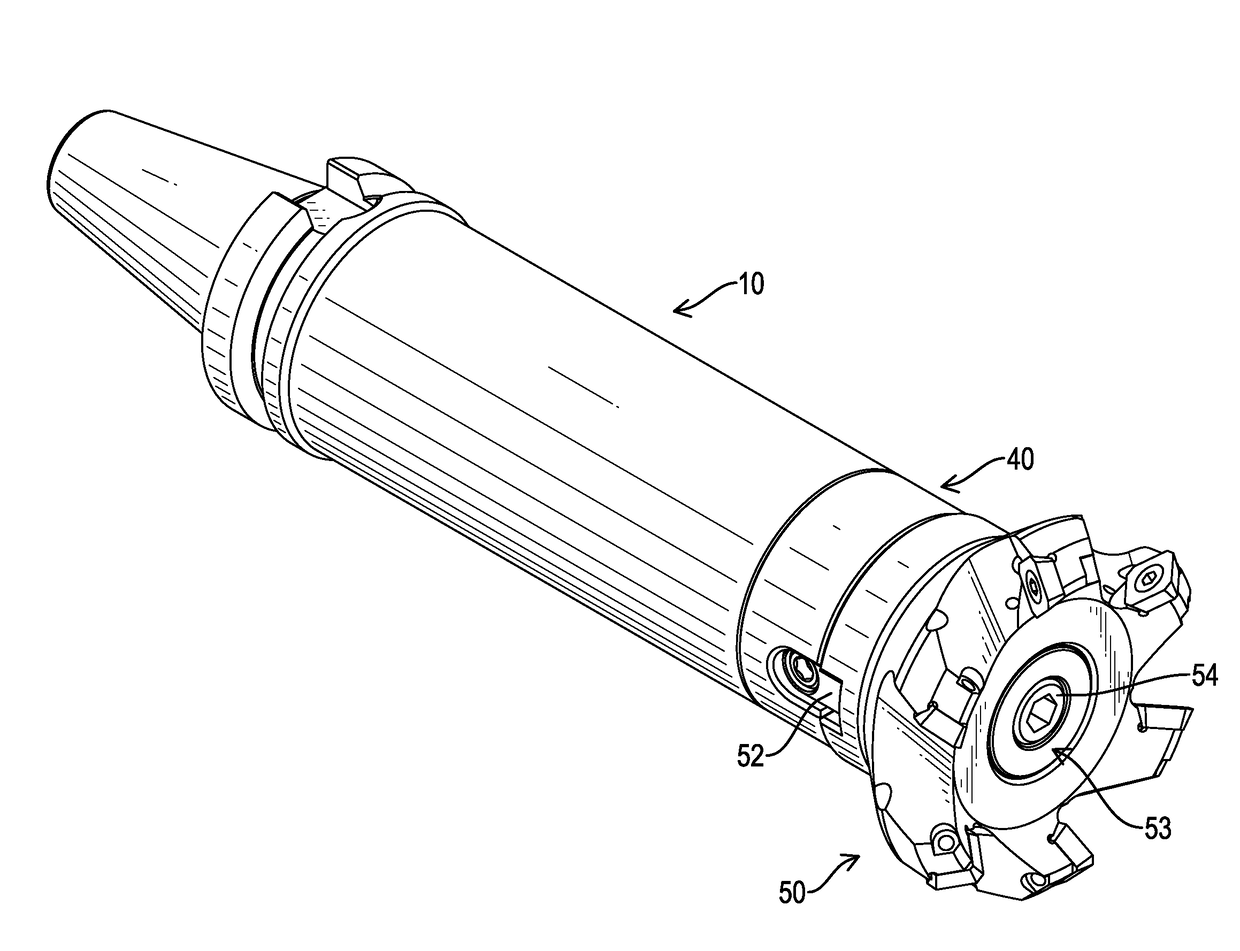

Method and device for the surface machining of workpieces composed of non-brittle materials in optical lens manufacturing and tool for this purpose

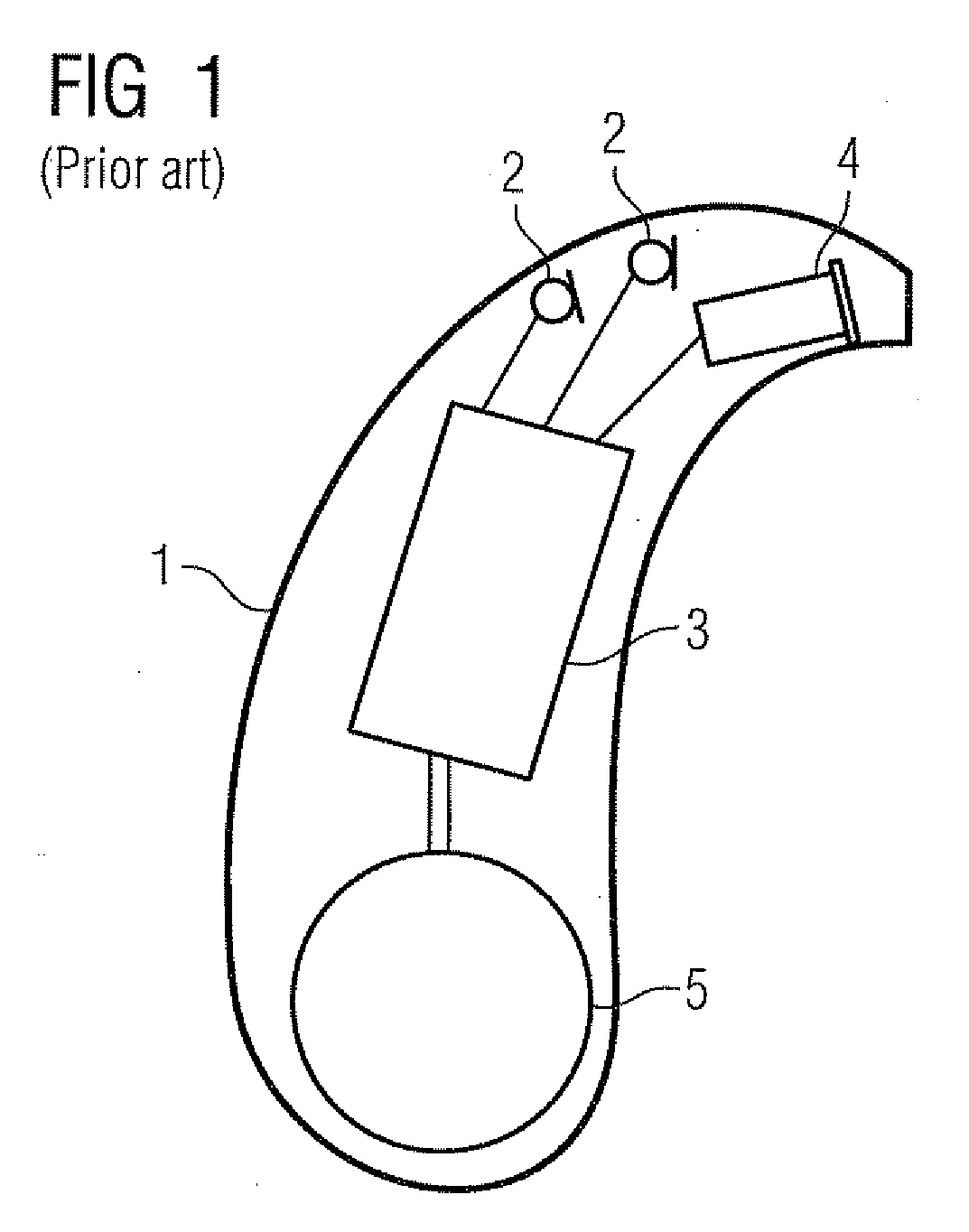

InactiveUS6991525B2Easy loadingRapidly and reliably machinedMilling cuttersOptical articlesRotational axisEngineering

A device is disclosed for the surface machining of, among other things, plastic spectacle lenses, which has a work spindle, by means of which the spectacle lens can be driven with a controlled angle of rotation about an axis of work rotation, and a tool spindle, by means of which a tool can be driven to rotate about an axis of tool rotation, work and tool spindle being movable relative to one another with their positions controlled in two axes running at right angles. For rotational machining of the surface of the spectacle lens to be machined, the tool can also be swiveled by means of the tool spindle with a controlled angle of rotation about the axis of tool rotation, so that a rotational cutting edge provided on the tool can be brought into a defined rotational machining engagement with the surface of the spectacle lens to be machined as a function of the angle of rotation of the spectacle lens. Also included is a combined milling and rotational machining tool and a combined milling and rotational machining method. As a result, high cutting rates and very good surface qualities can be easily and efficiently achieved in the surface machining.

Owner:SATISLOH GMBH

Plasma processing apparatus having an evacuating arrangement to evacuate gas from gas-introducing part of a process chamber

InactiveUS20070254113A1High quality processingRapid and efficient evacuationElectric discharge tubesSemiconductor/solid-state device manufacturingQuality processProcess engineering

A plasma processing apparatus can apply a high-quality process to an object to be processed by removing impurities from a gas-introducing part of a process chamber. The gas-introducing part connected to the process chamber so as to introduce a reactant gas into the process chamber. A first vacuum pump is connected to the process chamber so as to evacuate gas from the process chamber so that the process chamber is maintained at a negative pressure. A gas-evacuating arrangement is connected to the gas-introducing part so as to exclusively evacuate the reactant gas from the gas-introducing part. The gas-evacuating arrangement includes a second vacuum pump directly connected to the gas introducing part or a bypass passage connecting the gas-introducing par to the first vacuum pump by bypassing the process chamber.

Owner:TOKYO ELECTRON LTD

Method for the Classification of Banknotes

InactiveUS20130034291A1Computationally complexLess probabilityPaper-money testing devicesCharacter and pattern recognitionDigital imageFeature vector

The invention group relates to the banknote detecting means. The technical result is increase in the banknote identification accuracy. The method is based on a computational processing of the banknote scan formed in the device during scanning. The banknote digital image is separated into areas; for each area a function is calculated and a feature vector is composed with further calculation of the distance to the known classes represented by the parameters available beforehand. Moreover, the calculated function of the banknote digital image allows calculation of its signature in a form of binary number that is compared with the classes known beforehand.

Owner:OBSHCHESTVO S OGRANICHENNOJ OTVETABTVENNOSTJU KONSTRUKTORSKOE BJURO DORS OOO DORS

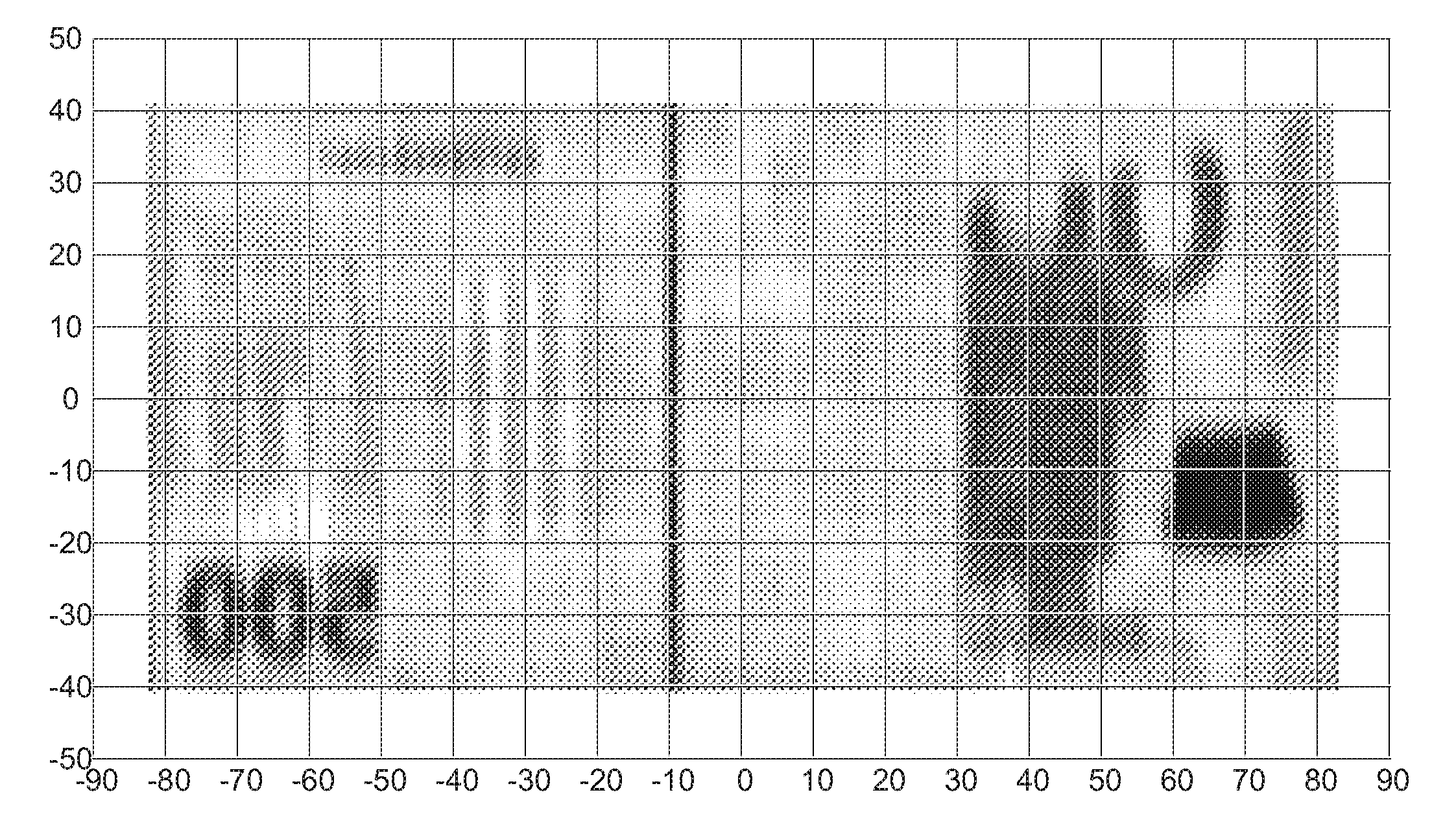

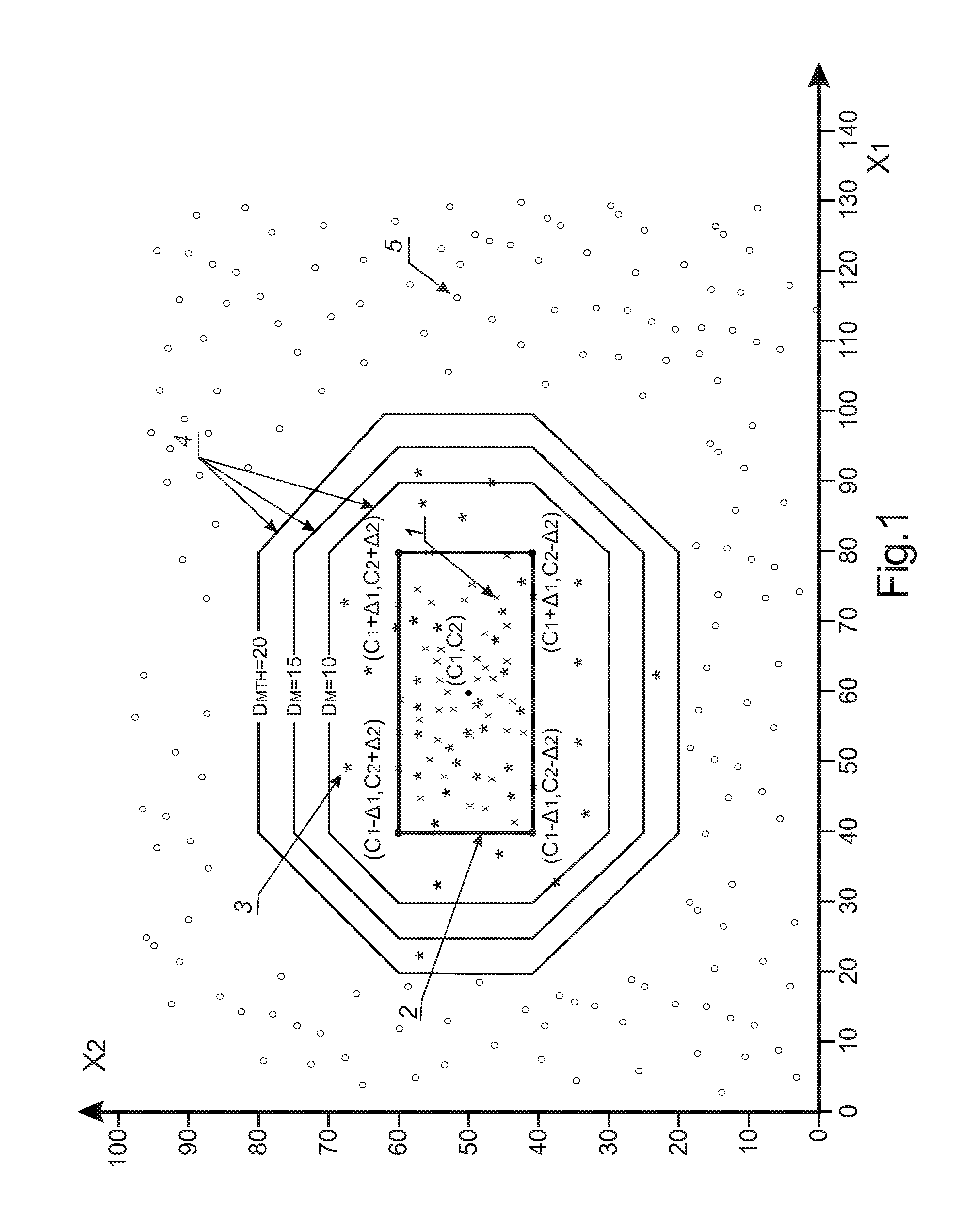

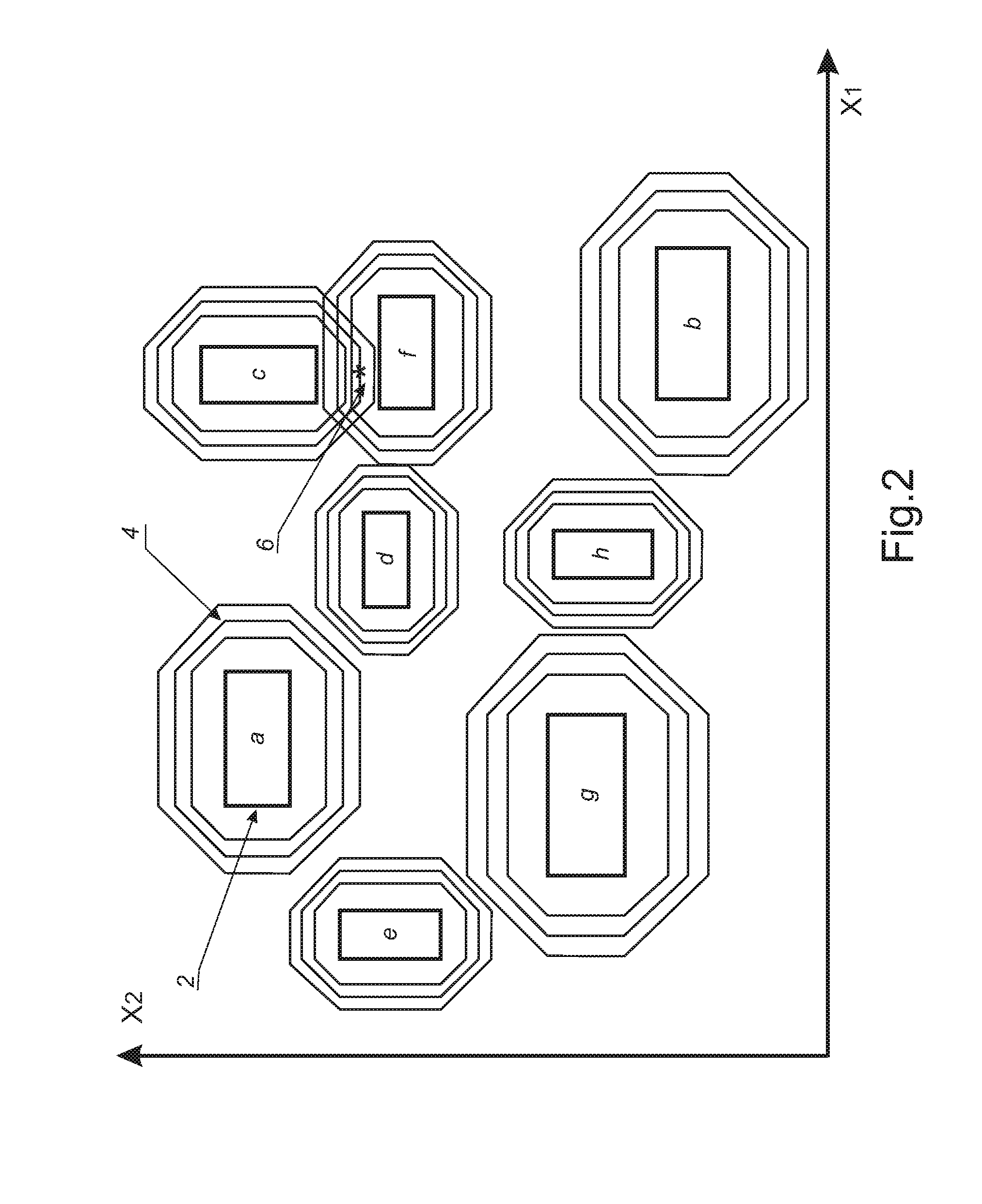

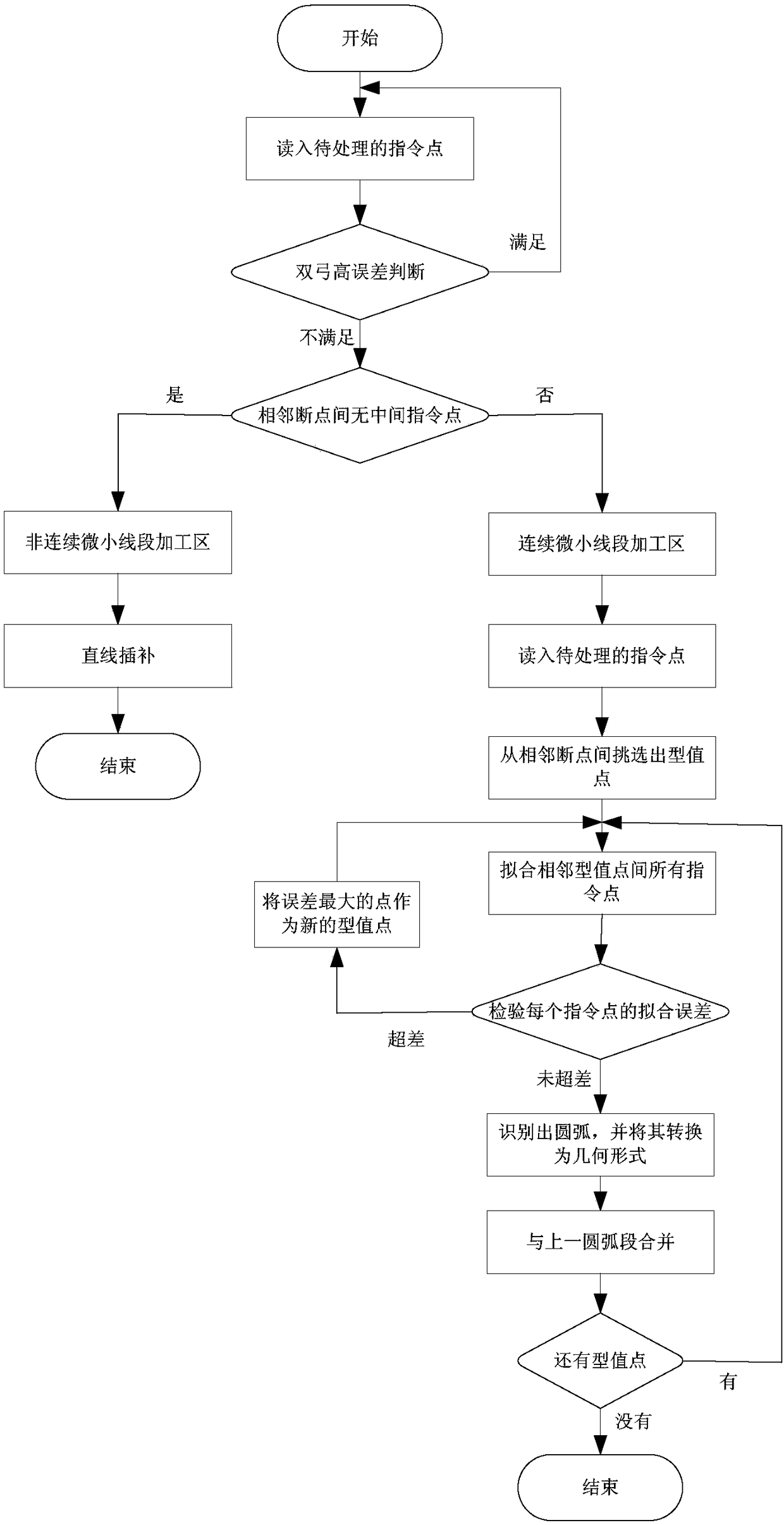

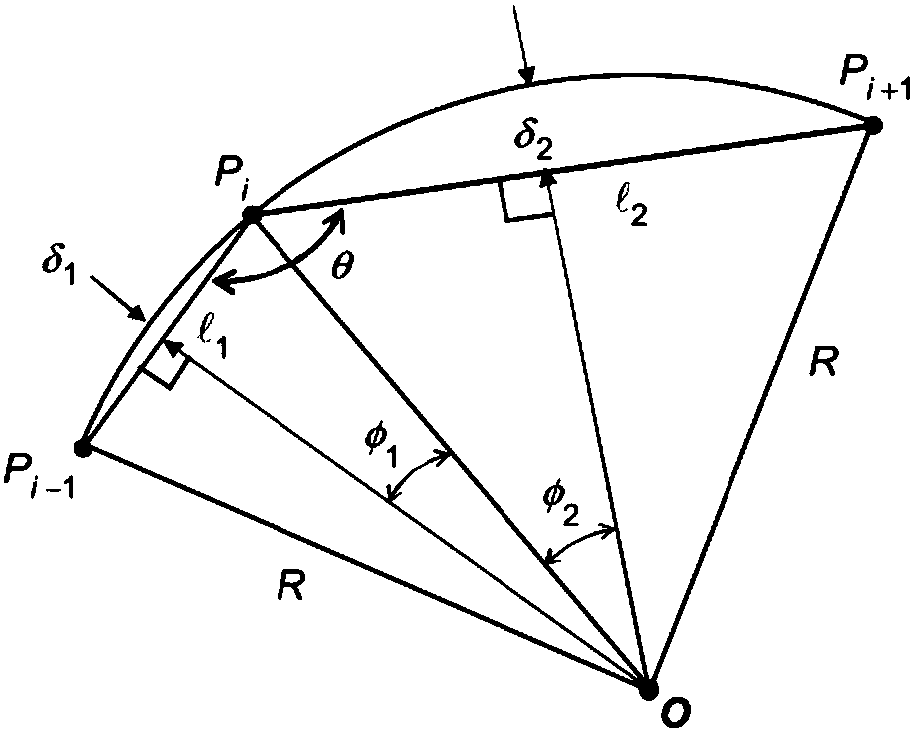

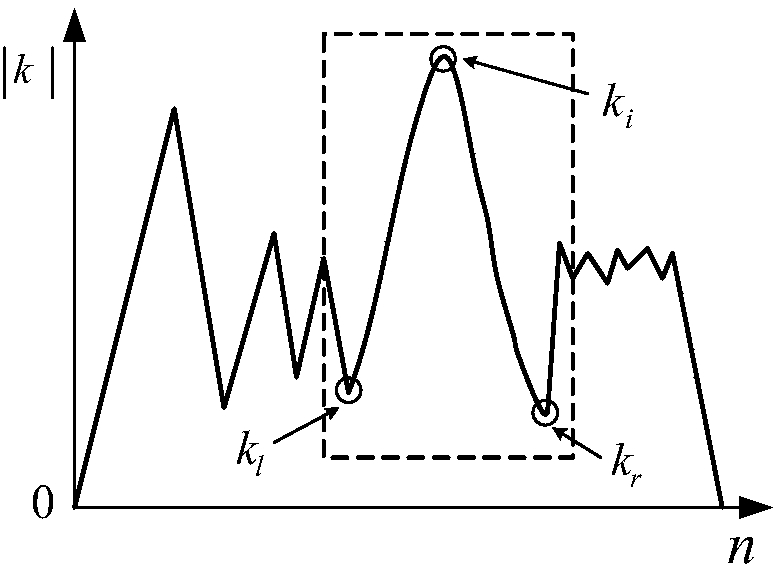

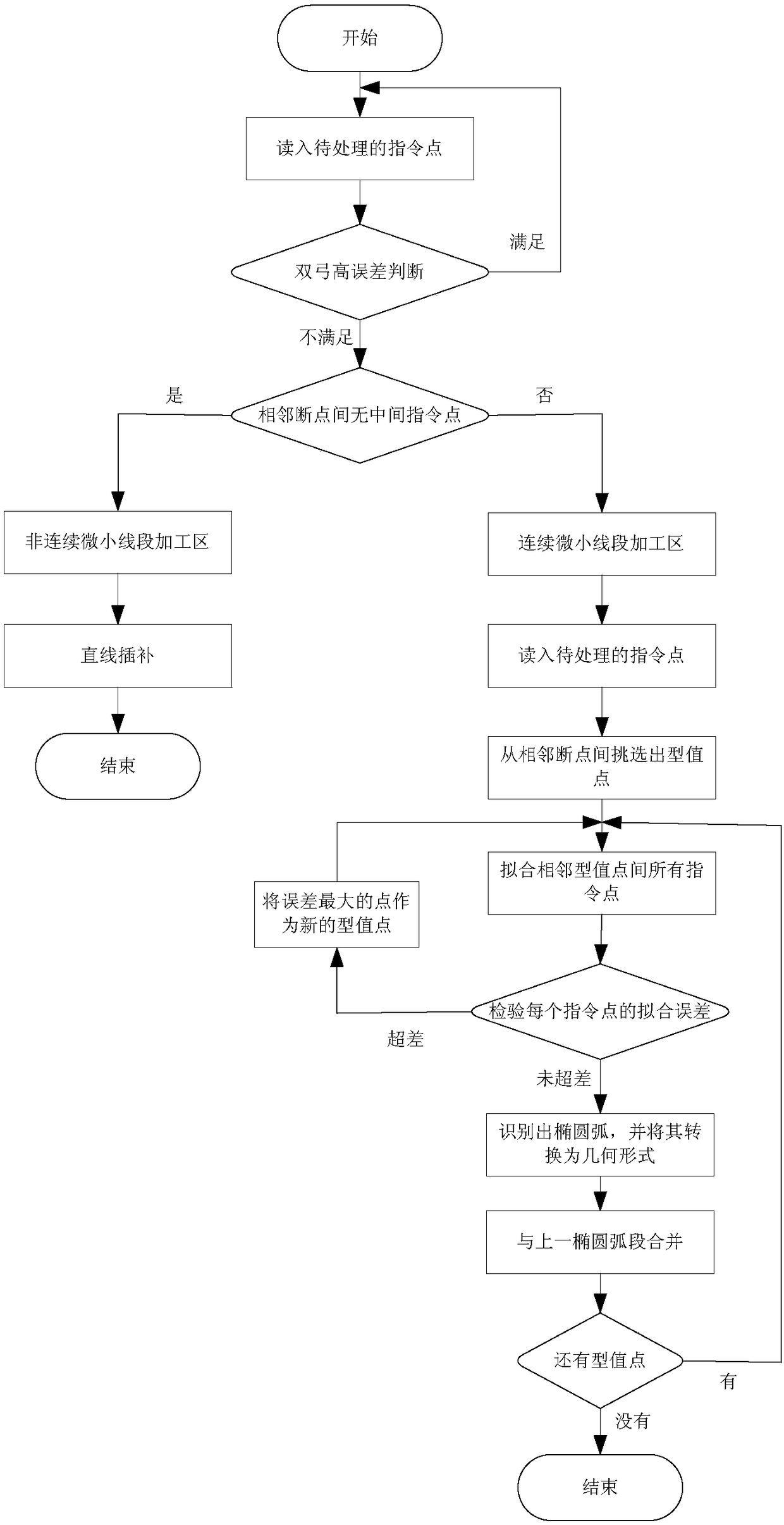

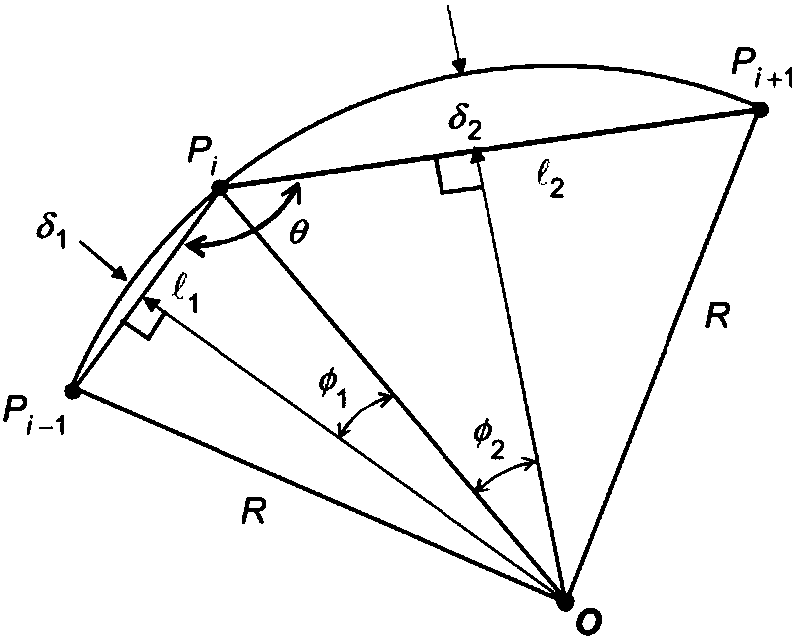

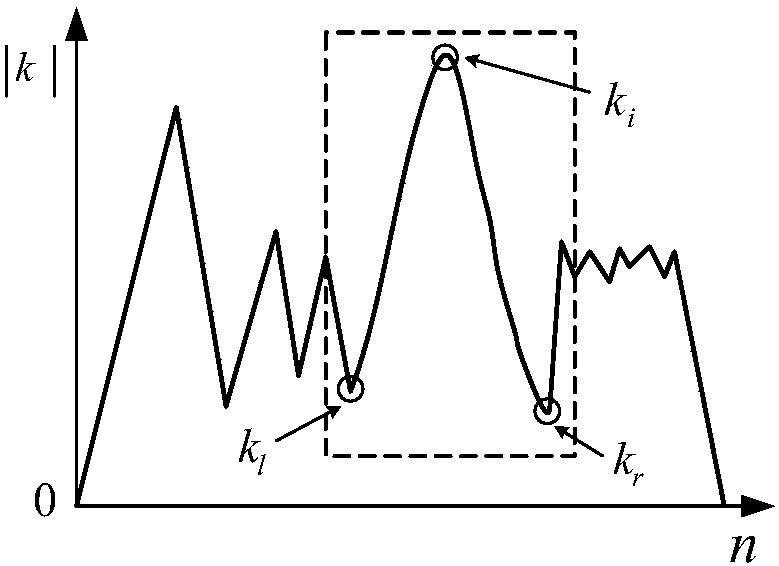

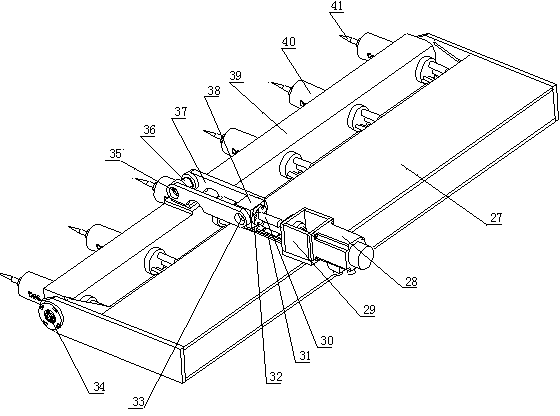

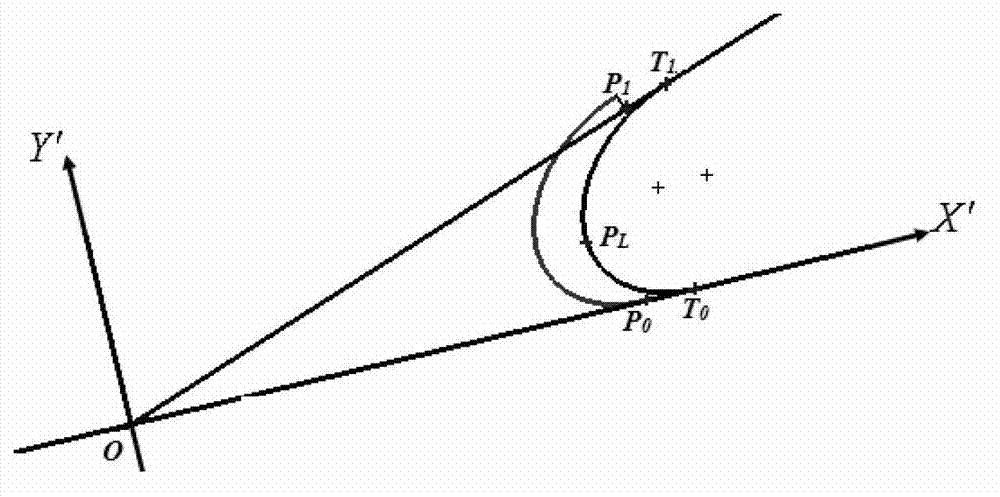

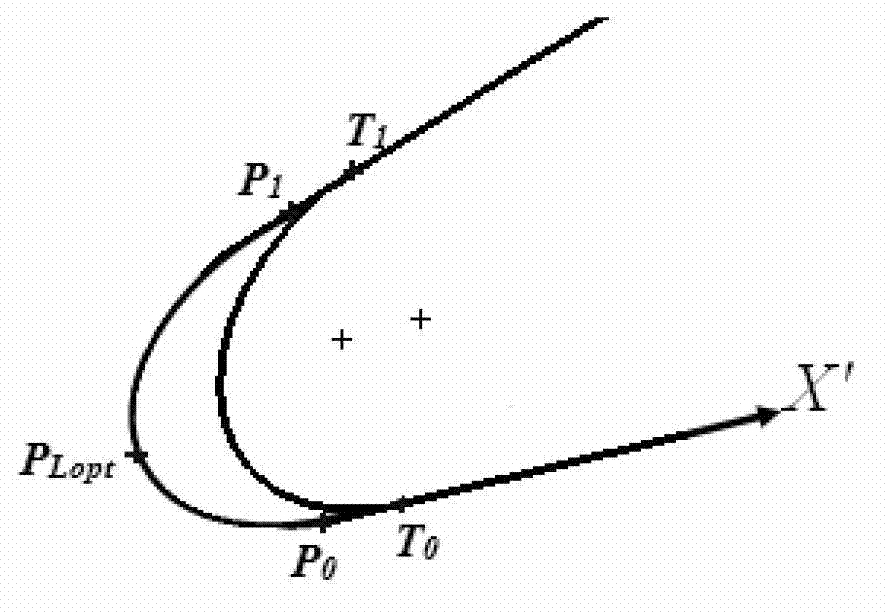

Arc smooth compression interpolation algorithm for high-quality processing

ActiveCN108062073AReduce frequent fluctuationsHigh quality processingProgramme controlComputer controlAlgorithmArc length

The invention relates to an arc smooth compression interpolation algorithm for high-quality processing, and the method comprises the following steps: recognizing a continuous processing region; selecting data points in the continuous processing region, carrying out the fitting of the data points, and obtaining a secondary rational Bezier curve; recognizing arcs according to the curve, and carryingout the transformation of the geometric forms of the arcs; merging the adjacent arcs which belong to the same circle, and obtaining an interpolation curve; and carrying out the arc interpolation on the interpolation curve. The algorithm is high in processing precision and processing efficiency. The method employs the arcs in the geometric forms for interpolation, can precisely calculate the interpolation parameters corresponding to the arc length, reduces the calculation complexity and the frequent fluctuation of speed during processing, and improves the processing quality and efficiency.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

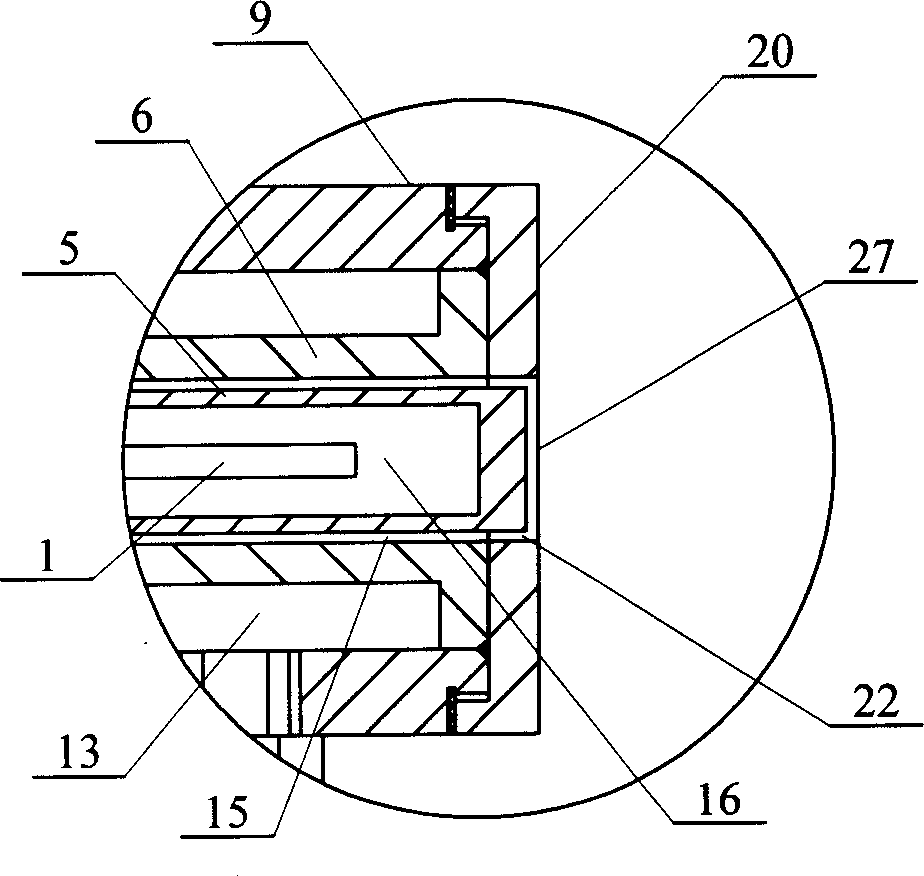

Capacitive coupling radio frequency normal pressure plasma torch for machining ultra-smooth surface

The invention relates to a capacitor coupling radio normal-voltage plasma saw used in ultra-smooth surface machining, especially providing a plasma polishing device. Wherein, the invention is purposed to solve the problems of general mechanical polishing method, as low efficiency, high cost and worse maintenance, etc. It forms a water cold annular space (13) between the outer wall of cathode (6) and the inner wall of outer sheath (9), and arranges the anode water cold tube (1) inside the chamber (16) of anode (5). The invention can avoid vacuum room, while its efficiency is 10 times of traditional polish method, and it will not hurt the surface. The invention can realize high-efficiency high-quality treatment on the optical element.

Owner:HARBIN INST OF TECH

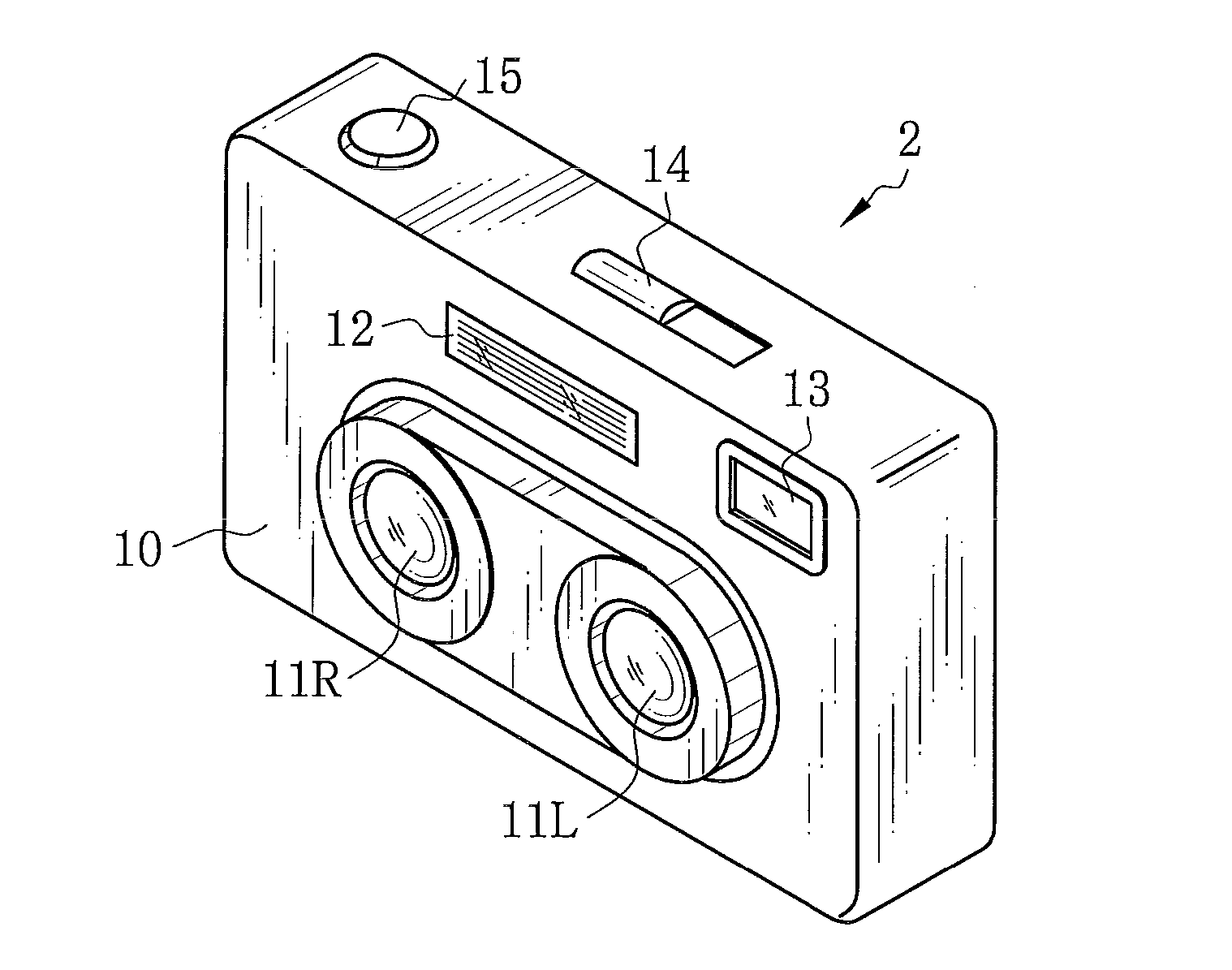

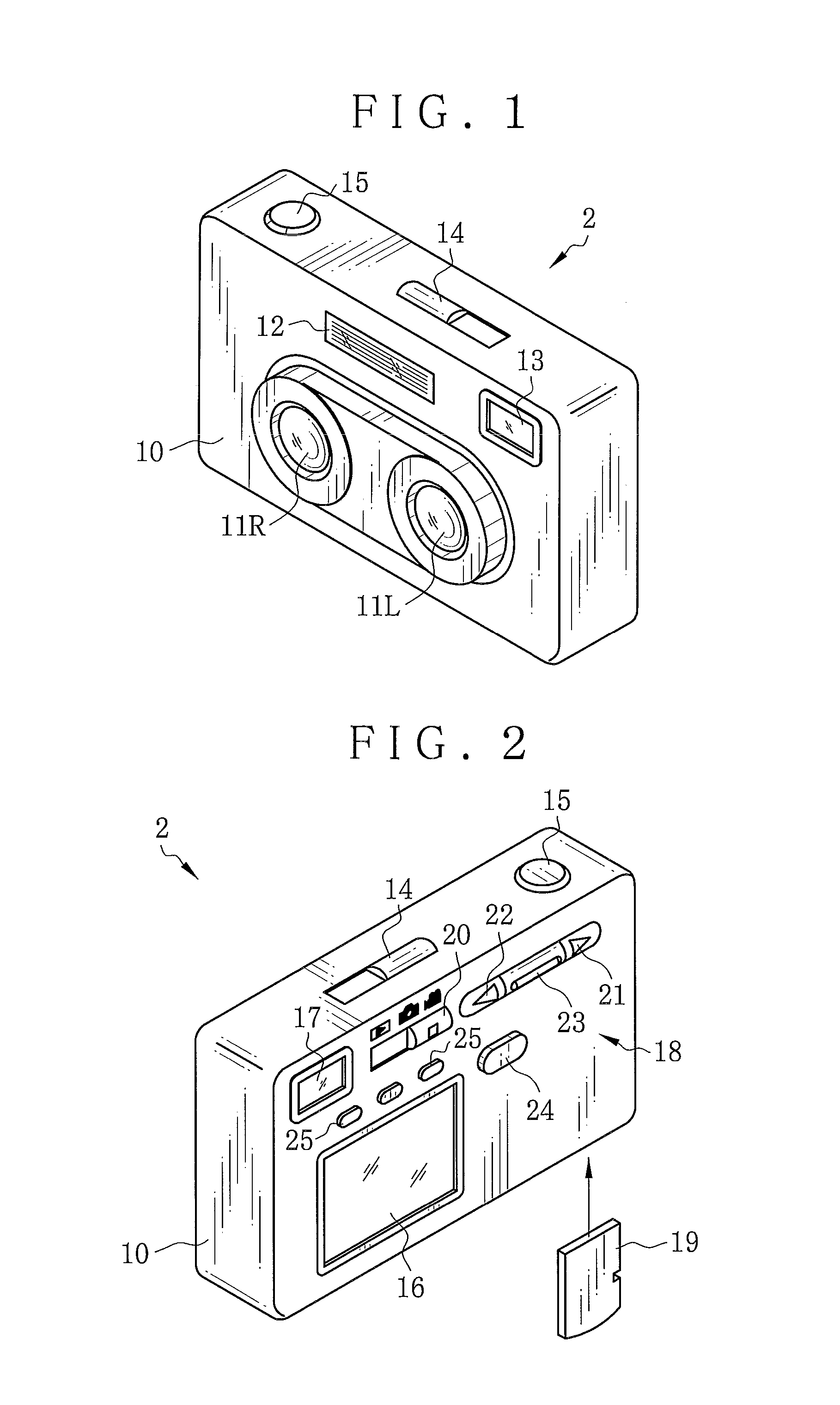

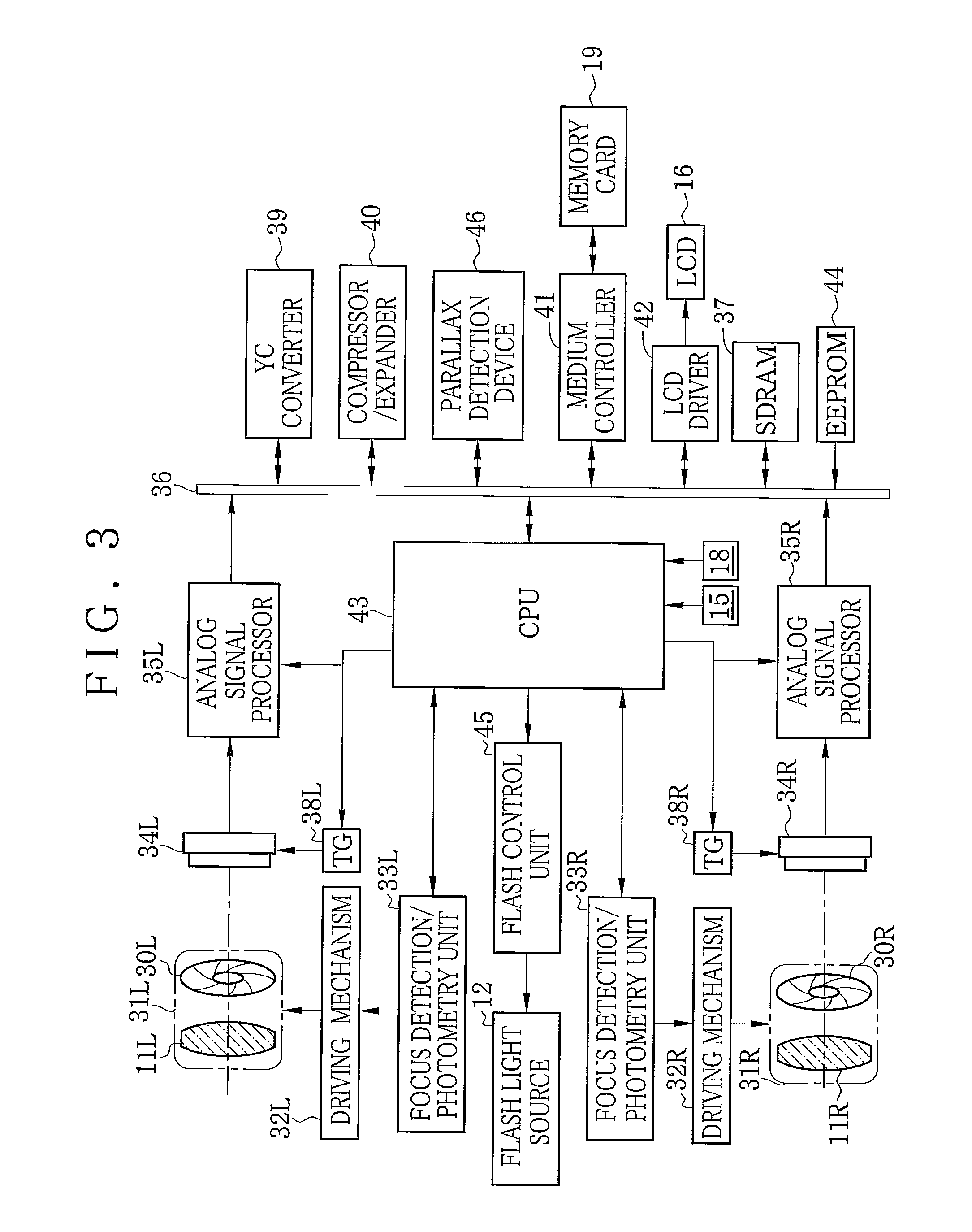

Moving image recording method and apparatus, and moving image coding method and moving image coder

InactiveUS20110012991A1Quality improvementHigh quality processingTelevision system detailsColor television detailsParallaxJPEG

A moving image recording apparatus for a moving image file of a three dimensional moving image is provided, and includes a parallax detection device for determining parallax information of parallax of one principal object commonly present in images of an image set from multiple view points among image sets of a stream for the three dimensional moving image. A compressor compresses the images in still image compression coding for separately coding the images in the three dimensional moving image, to obtain compressed image data. A recording control unit records in a storage medium the moving image file constituted by plural blocks each of which includes the compressed image data of the image set and the parallax information from the parallax detection device. Preferably, the object is a face region of a person. The still image compression coding is JPEG coding.

Owner:FUJIFILM CORP

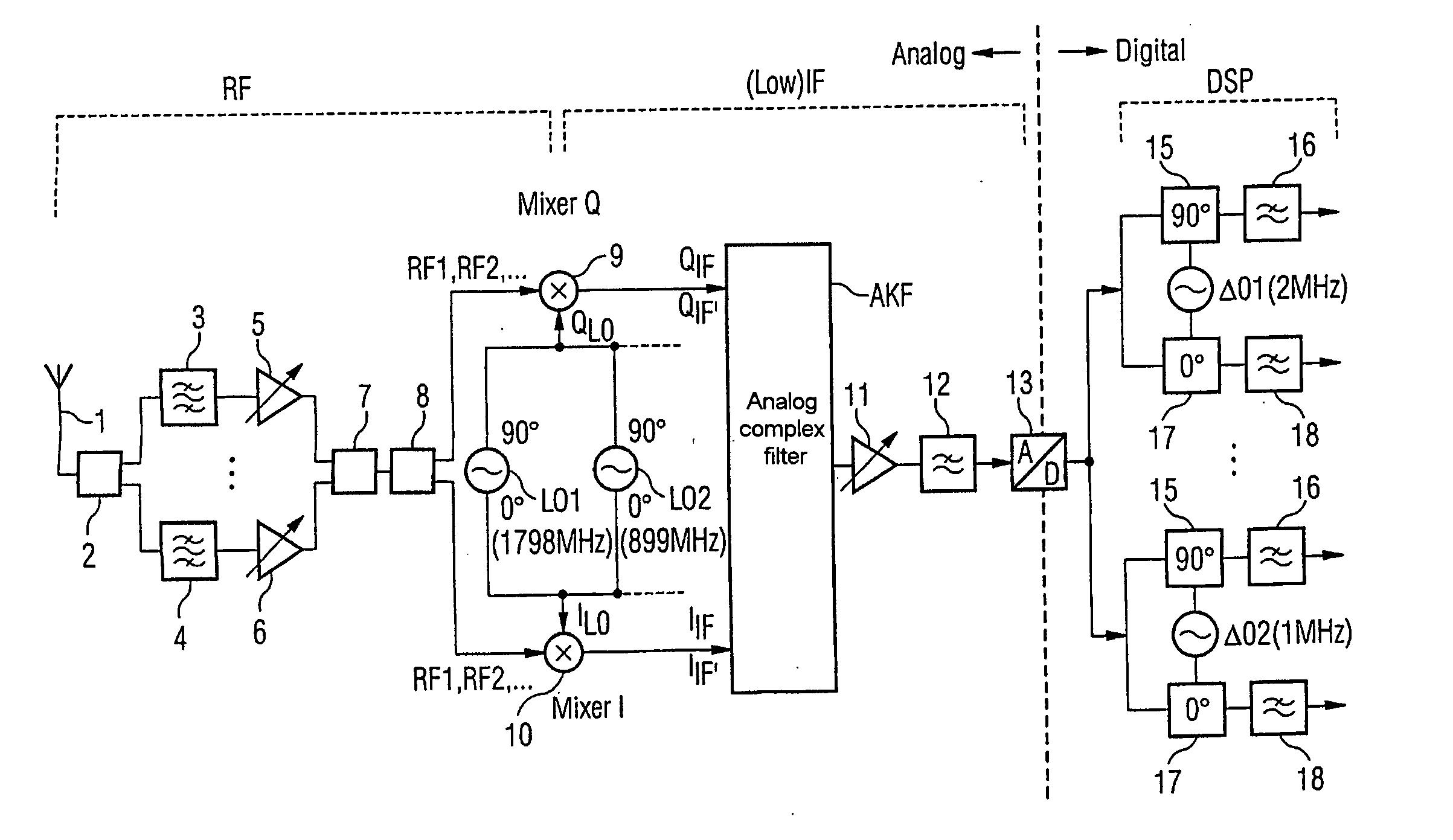

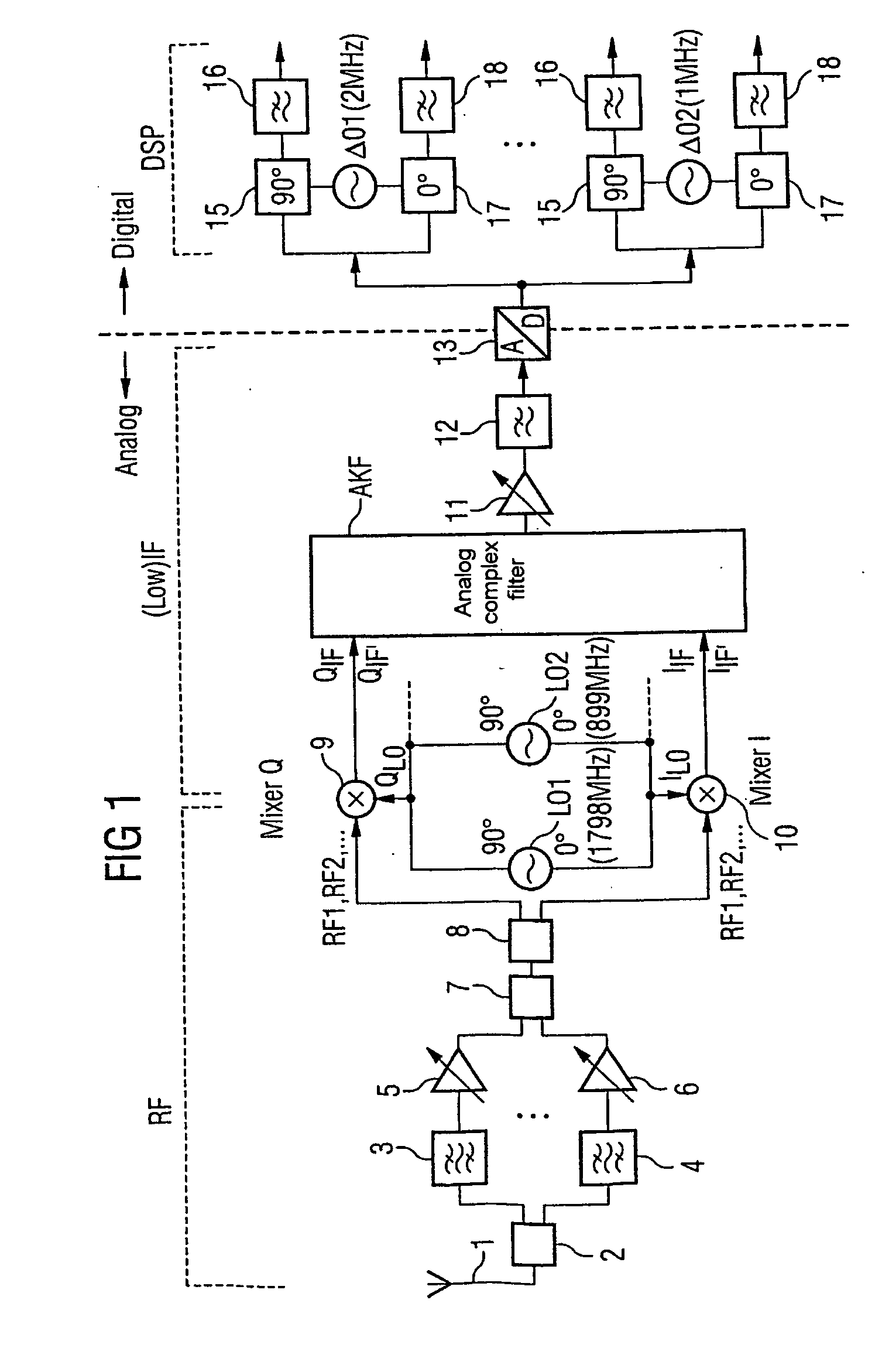

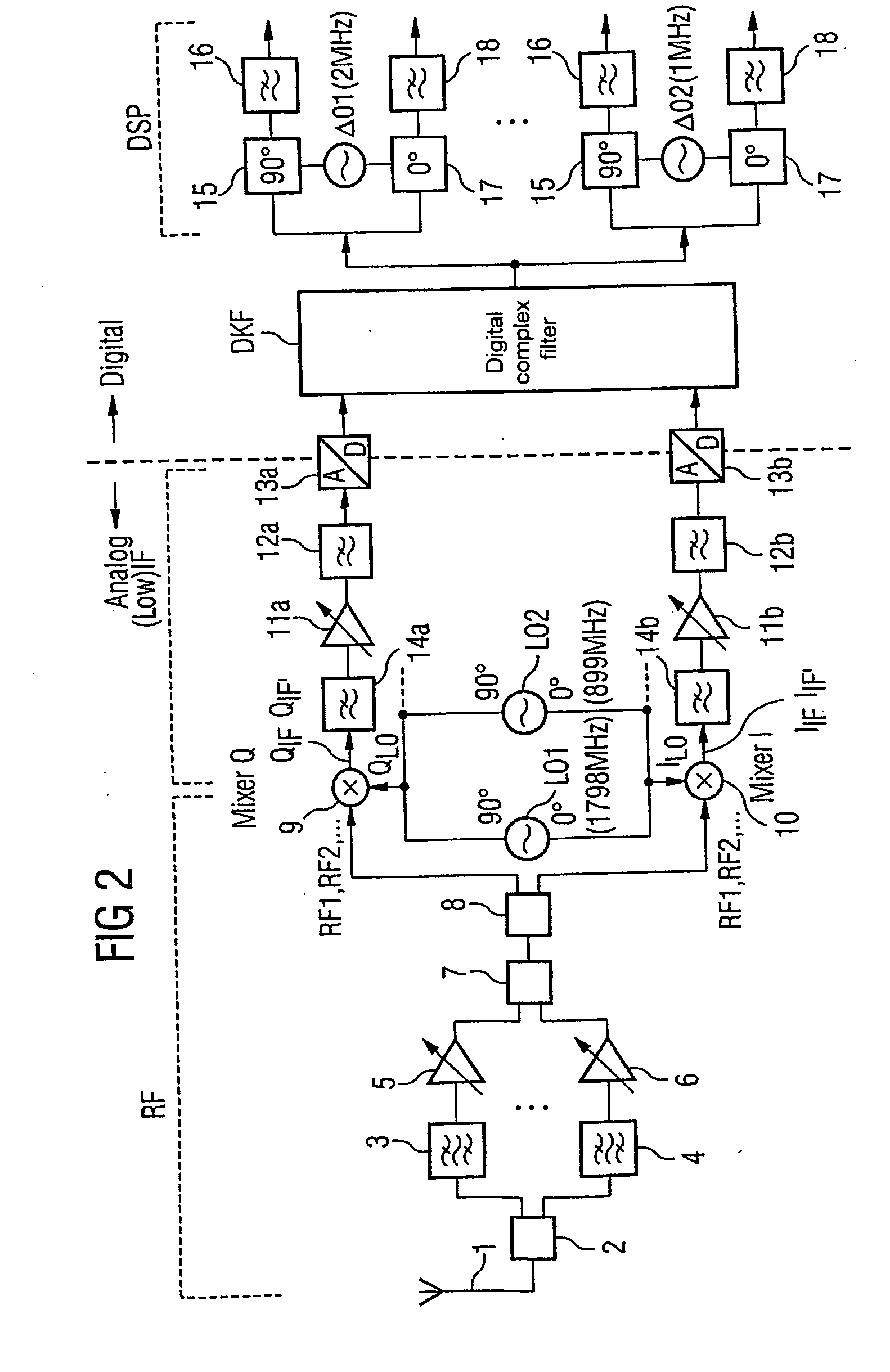

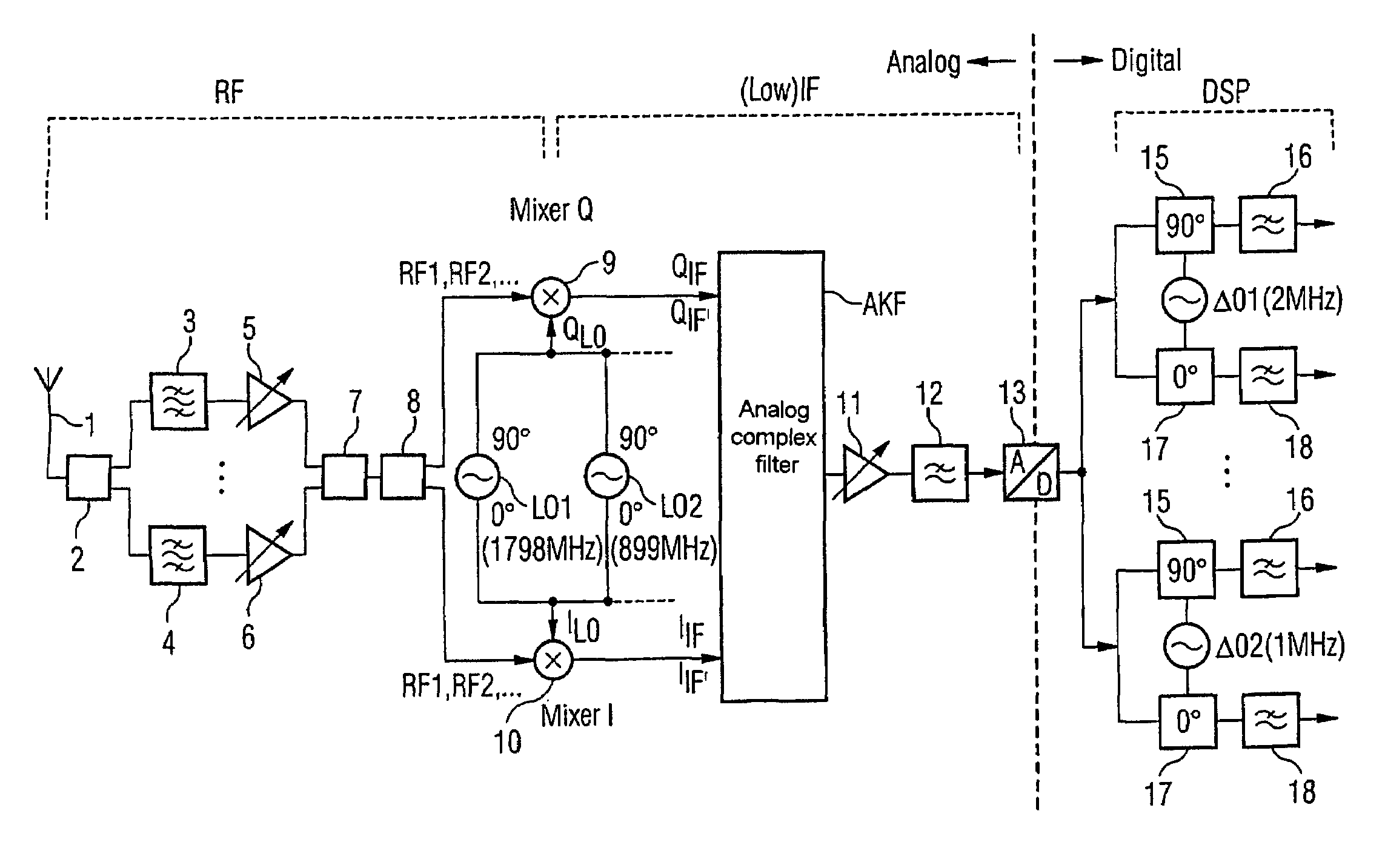

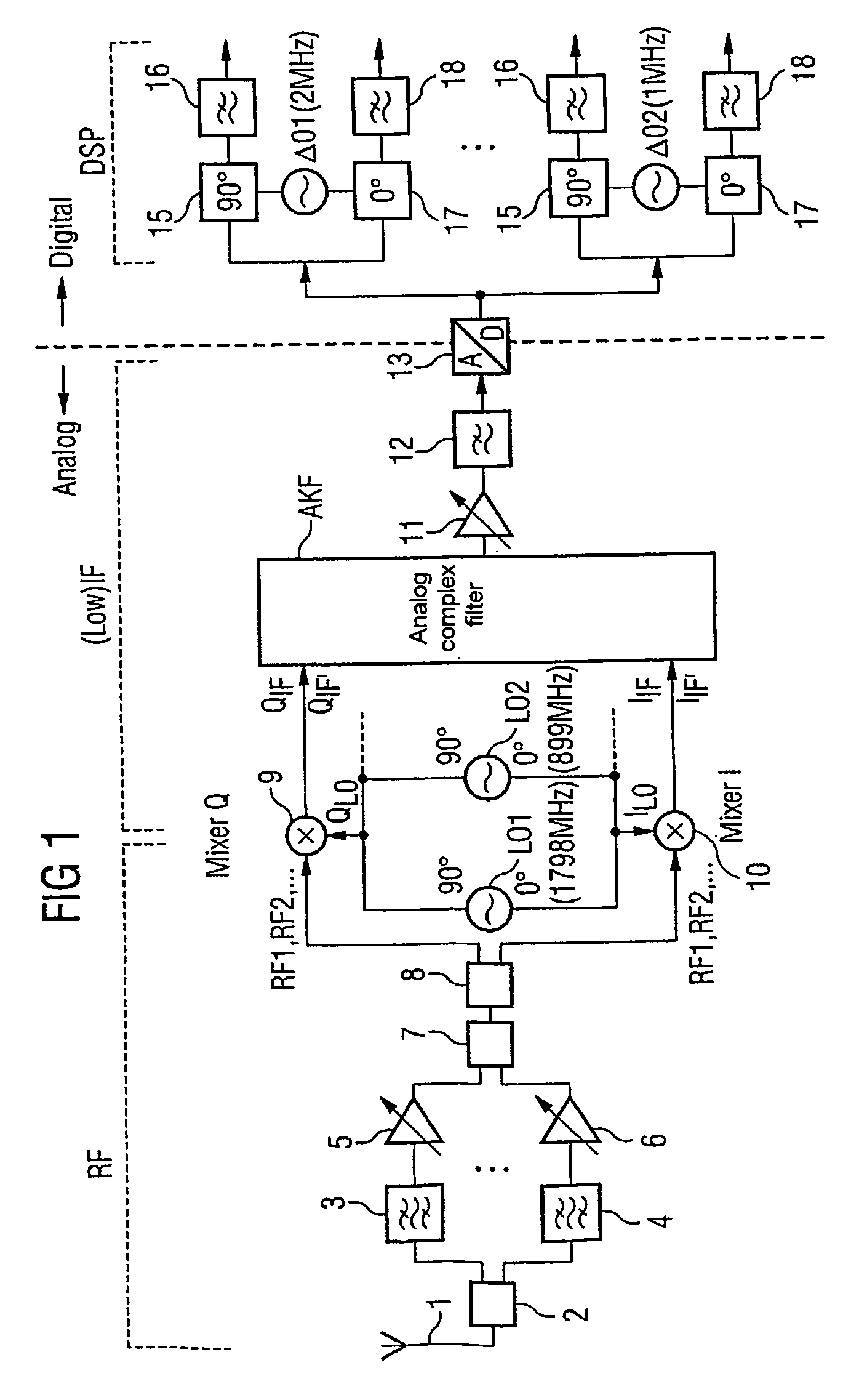

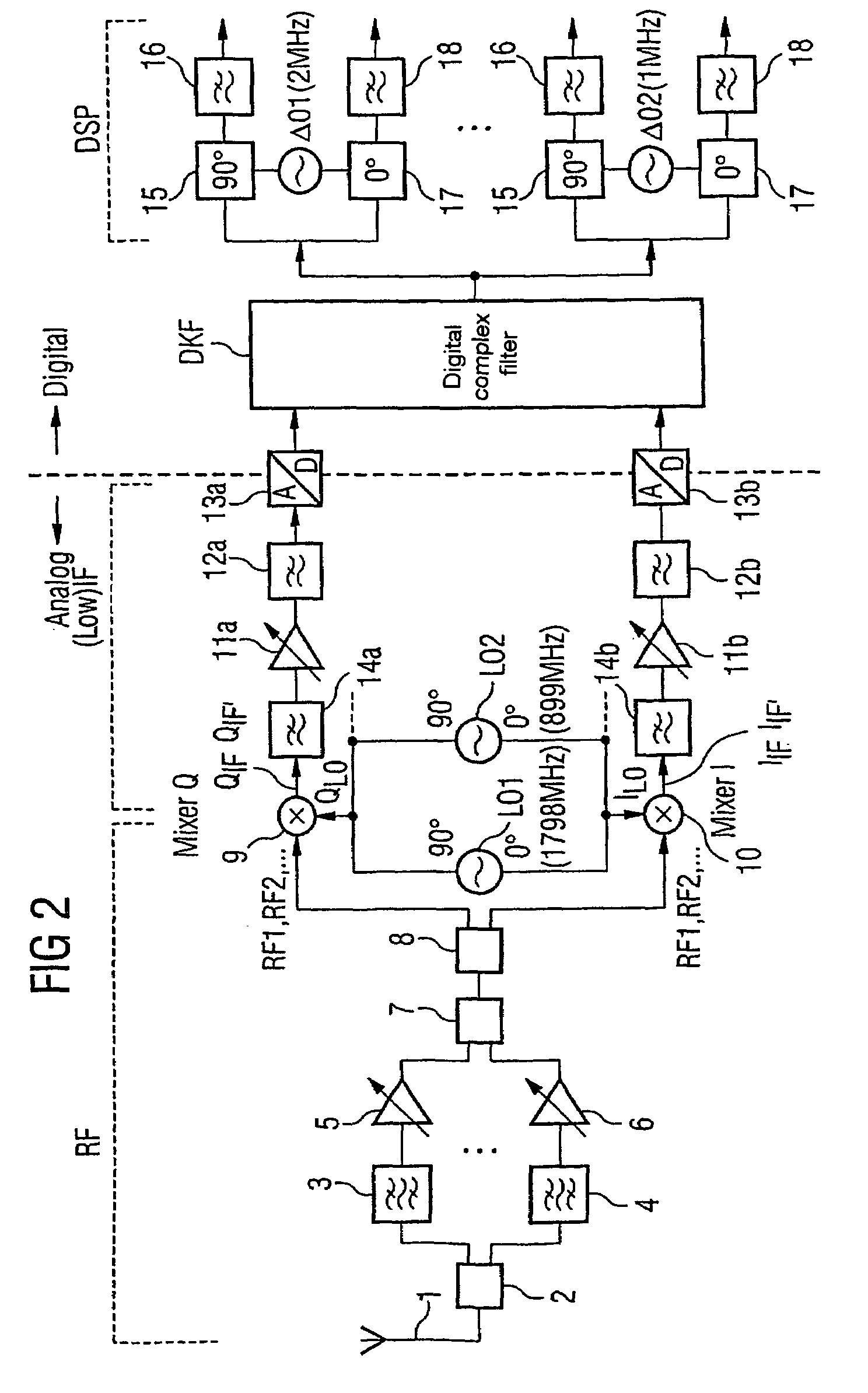

Multiband receiver and method associated therewith

InactiveUS20050003853A1Flexible configurationEasy to implementFrequency-division multiplexSubstation equipmentFiberIntermediate frequency

A multiband receiver and associated method are provided for simultaneous reception of a number of RF signals with partially different carrier frequencies. An RF / IF converter is provided with a number of local oscillators corresponding to a number of RF signals in order to produce L0 in phase components corresponding to the carrier frequencies and quadrature components; in addition to an in-phase mixer and a quadrature mixer for mixing the respective L0 in-phase and quadrature components with the RF signals in order to produce intermediate frequency signals with IF in-phse components and IF quadrature components. A complex fiber carries out complex filtering on the basis of the intermediate frequency signals in order to suppress reflected intermediate frequency signals.

Owner:GIGASET COMMUNICATIONS

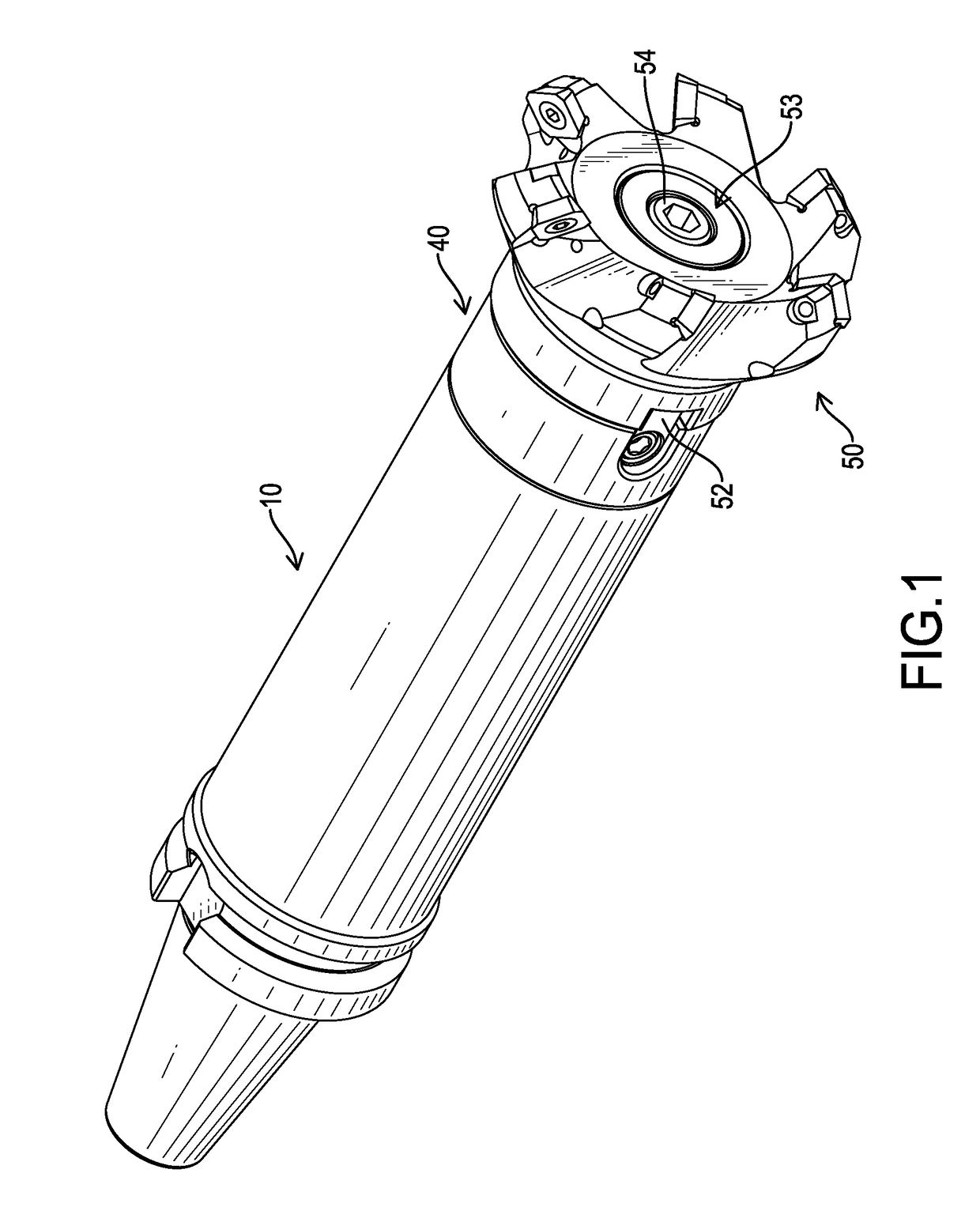

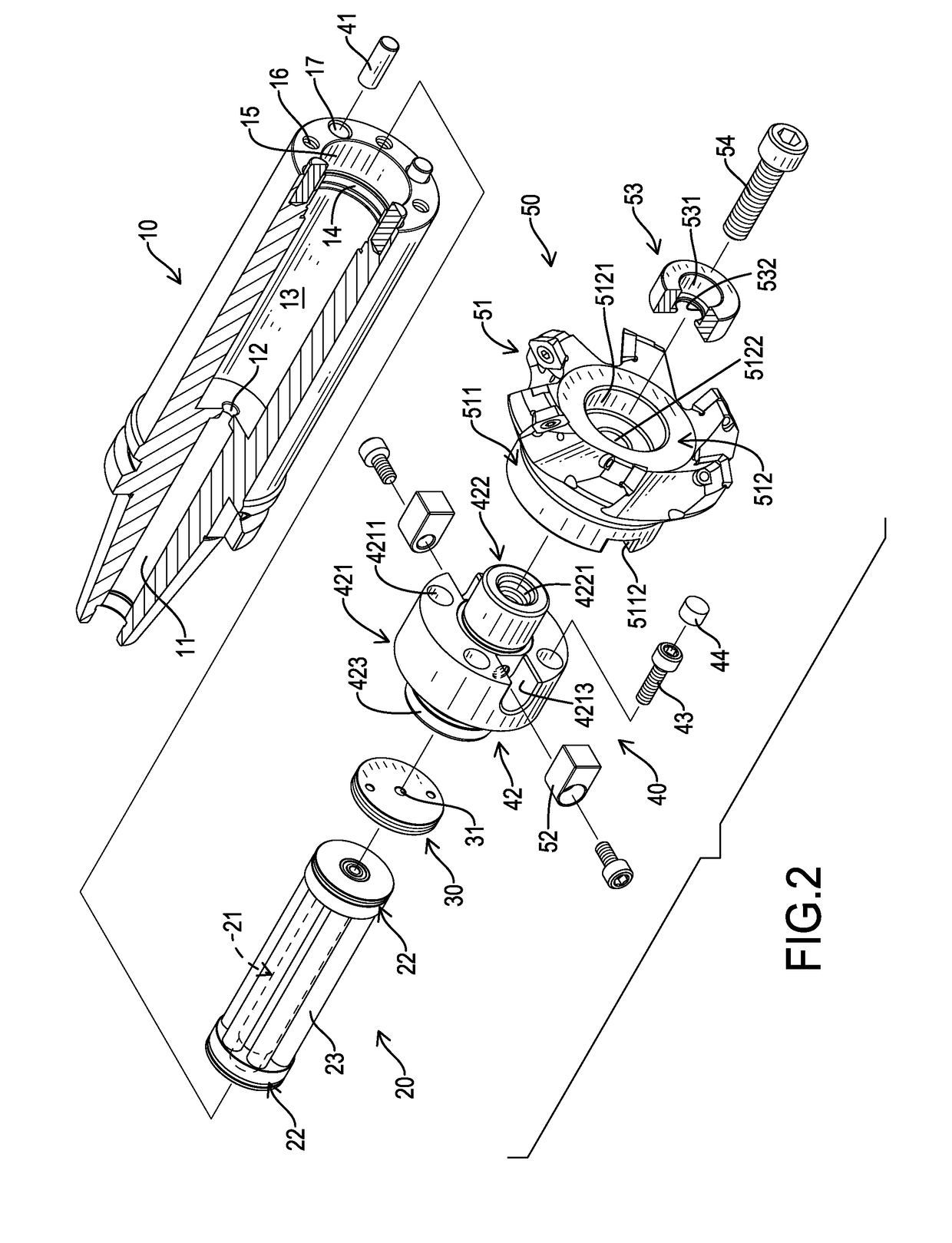

Cutter holder with vibration resistant structure

InactiveUS20180009042A1Avoid negative effectsHigh quality processingMilling cuttersBoring barsEngineeringMechanical engineering

A cutter holder has a body and a damping assembly. The damping assembly is contained inside the body. The damping assembly has a central damping pole and six auxiliary damping poles. The six auxiliary damping poles are arranged around the central damping pole. The body has a specific weight. The central damping pole has a specific weight larger than the specific weight of the body. Each one of the six auxiliary damping poles has a specific weight larger than the specific weight of the body. The damping assembly is utilized to reduce vibrations caused by machining.

Owner:CHEN CHING TING

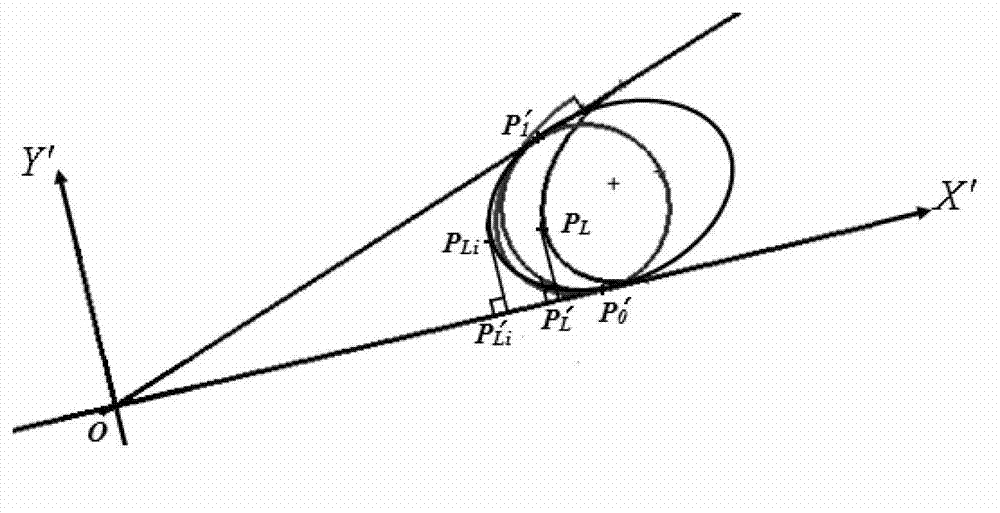

Elliptical arc smooth compression interpolation algorithm suitable for high-speed and high-precision processing

The invention relates to an elliptical arc smooth compression interpolation algorithm suitable for high-speed and high-precision processing. The elliptical arc smooth compression interpolation algorithm includes the following steps: identifying continuous minimal line segment processing areas; selecting, among the continuous minimal line segment processing areas, data points and carrying out fitting on the data points to obtain a quadratic rational Bezier curve; identifying elliptical arcs on the basis of features of the curve, and conducting geometrical transformation on the elliptical arcs;combining the adjacent elliptical arcs belonging to the same ellipse and obtaining an interpolation curve; and carrying out elliptical arc interpolation on the interpolation curve. On the basis of thefeatures of the spline curve, the elliptical arcs in a processing path are identified, and interpolation is carried out by using geometrical forms of the elliptical arcs. In this way, interpolation parameters corresponding to the arc length can be calculated accurately, computational complexity and frequent fluctuations of speed during processing can be reduced, and high-speed and high-precisionprocessing can be realized.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

Machining head, nozzle changer and laser beam machining apparatus

InactiveUS8212176B2Easy to replaceHigh quality processingTool changing apparatusPositioning apparatusLaser beam machiningEngineering

A machining head includesa machining head element having an inner-head channel for passing laser light and assist gas,the nozzle having an inner-nozzle channel connecting to the inner-head channel and a nozzle orifice,pins protruding radially inward from a curved inner surface of the nozzle,a pin-locking part formed on the outside of the machining head element, the pin-locking part having pin-fitting openings,a head alignment part formed on a nozzle-side end surface of the machining head element,a nozzle alignment part formed on the nozzle at a location where the nozzle is aligned with the machining head element, andan O-ring fitted between the head alignment part and the nozzle to create a clearance between the head alignment part and the nozzle alignment part for mutual alignment.

Owner:MITSUBISHI ELECTRIC CORP

Yuanbaofeng nervonic acid soft capsule and its preparation process

InactiveCN1535710AHigh in fatty acidsReduce manufacturing costNervous disorderUnknown materialsBrain developmentAtrophy

The present invention relates to an yuangboafeng (a Chinese medicinal plant) nervonic acid soft capsule and its preparation process, and provides a health-care food with the functions of preventing nerve fibre atrophy, promoting brain development, delaying senility, raising immunity of human body and digestive function. Its preparation method includes the following steps: shelling yuanbaofeng seeds, making crude oil, dewatering and filtering, low-temp. chromatography, separating saturated fatty acid to produce health-care edible oil, finally making said health-care edible oil into the soft capsule. Its nervonic acid content is stable, and its health-care function effect is good.

Owner:王性炎 +2

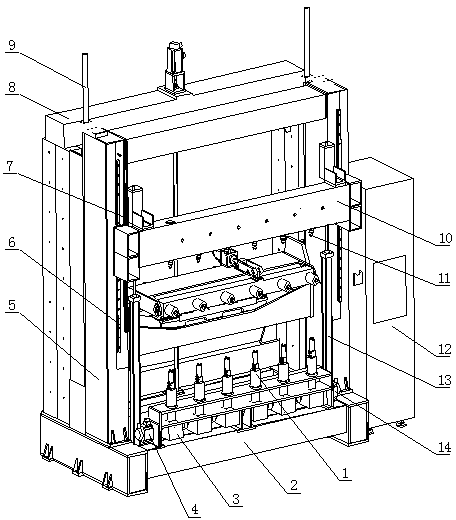

Multi-station spindle-swinging-type five-axis numerical control engraving and milling machine

InactiveCN103950335ACompact structureHigh quality processingModel makingEngravingServoStructural engineering

The invention provides a multi-station spindle-swinging-type five-axis numerical control engraving and milling machine. The multi-station spindle-swinging-type five-axis numerical control engraving and milling machine comprises a machining rack which is formed by a machine body base, stand columns on the two sides and a fixed transverse beam at the tops of the stand columns, wherein a C-axis system is installed on the machine body base, a Z-axis seat frame is arranged at the rear between the machine body base and the fixed transverse beam, an X-axis moving system is arranged on the Z-axis seat frame, a Y-axis moving system is arranged on the X-axis seat frame, a spindle seat frame is installed on the Y-axis seat frame, and a plurality of spindle motors and cutters are installed on the spindle seat frame. The spindle seat frame is connected to the Y-axis seat frame through two rotatable joint mechanisms, and the spindle seat frame drives spindles and the cutters to swing around rotatable joints under the effect of a driving system which is formed by a servo motor, a lead screw and nut pair, a connecting rod and a hinging mechanism to realize the swinging of the spindles. The multi-station spindle-swinging-type five-axis numerical control engraving and milling machine can be applied to processing engraved parts made of wood, bamboo, stone, organic glass, PVC (Polyvinyl Chloride), aluminum alloy, copper alloy and the like, the intact, high-speed, stable and high-quality processing of the engraved parts can be realized, and the processing at multiple stations can be realized at the same time.

Owner:FUZHOU UNIVERSITY

Multiband receiver and method associated therewith

InactiveUS7120406B2Flexible configurationEasy to implementFrequency-division multiplexSubstation equipmentFiberIntermediate frequency

A multiband receiver and associated method are provided for simultaneous reception of a number of RF signals with partially different carrier frequencies. An RF / IF converter is provided with a number of local oscillators corresponding to a number of RF signals in order to produce L0 in phase components corresponding to the carrier frequencies and quadrature components; in addition to an in-phase mixer and a quadrature mixer for mixing the respective L0 in-phase and quadrature components with the RF signals in order to produce intermediate frequency signals with IF in-phse components and IF quadrature components. A complex fiber carries out complex filtering on the basis of the intermediate frequency signals in order to suppress reflected intermediate frequency signals.

Owner:GIGASET COMMUNICATIONS

Aviation blade oval leading and trailing edge process model generation method

InactiveCN103116679AHigh quality processingSpecial data processing applicationsAviationProcess error

Owner:NORTHWESTERN POLYTECHNICAL UNIV

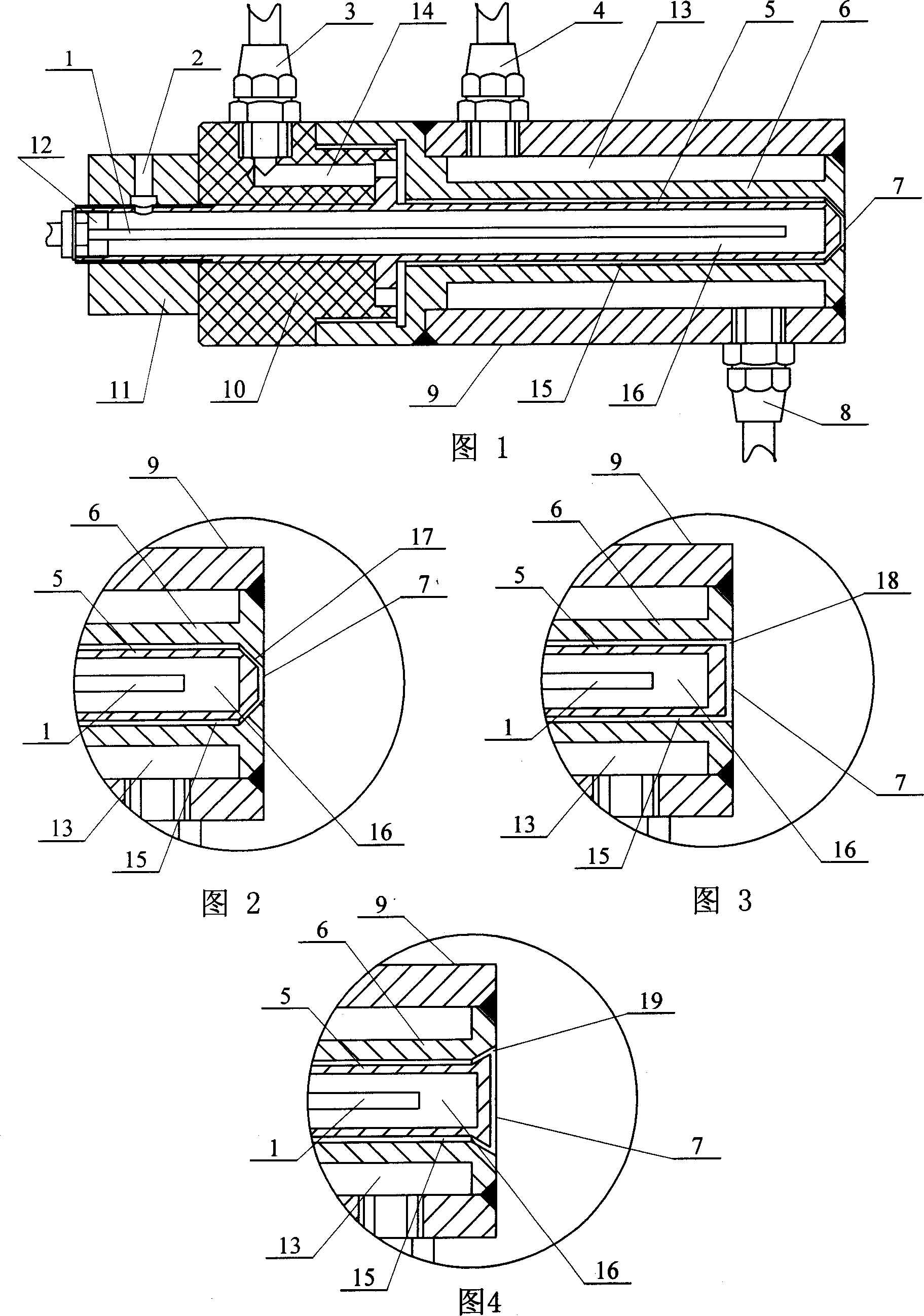

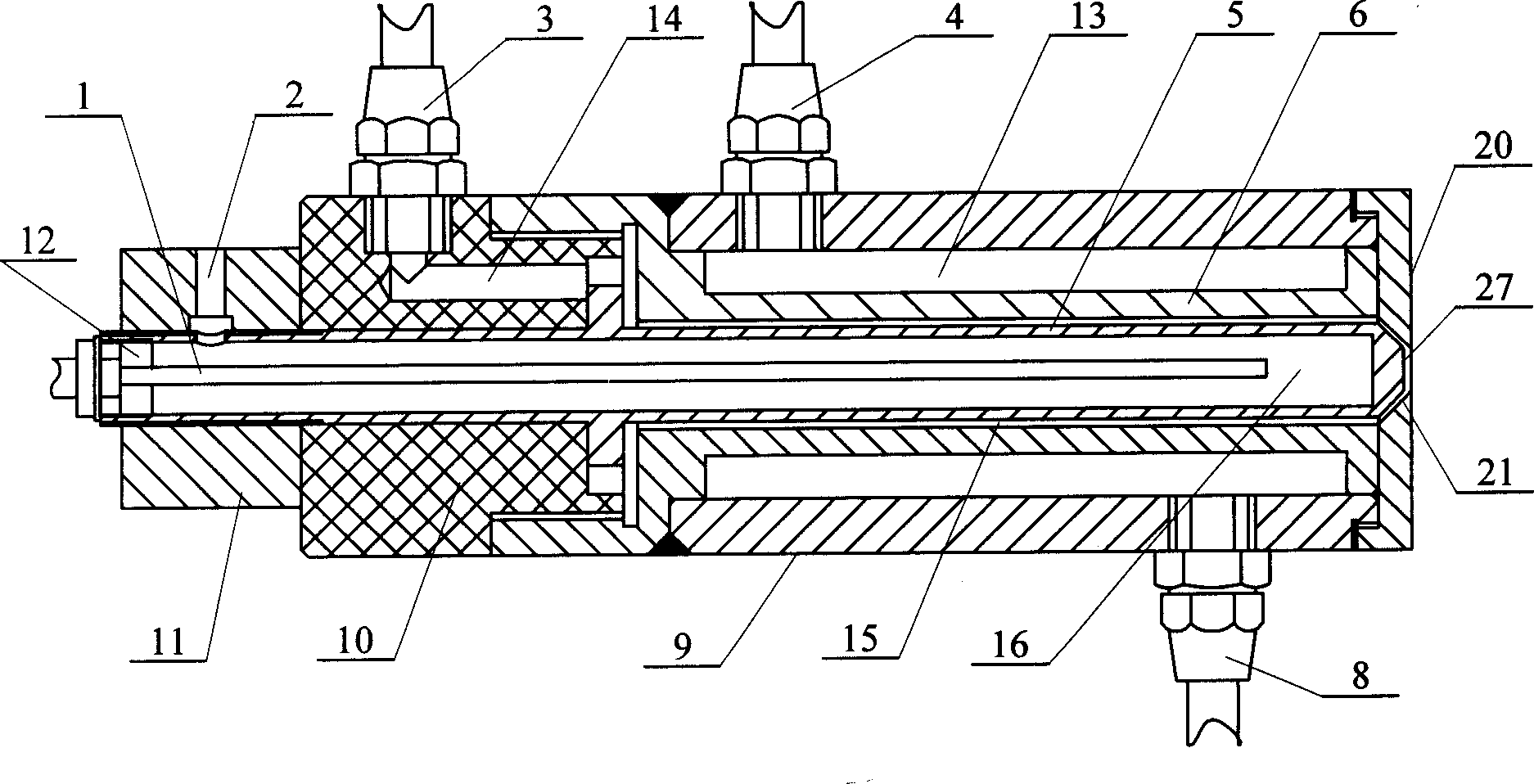

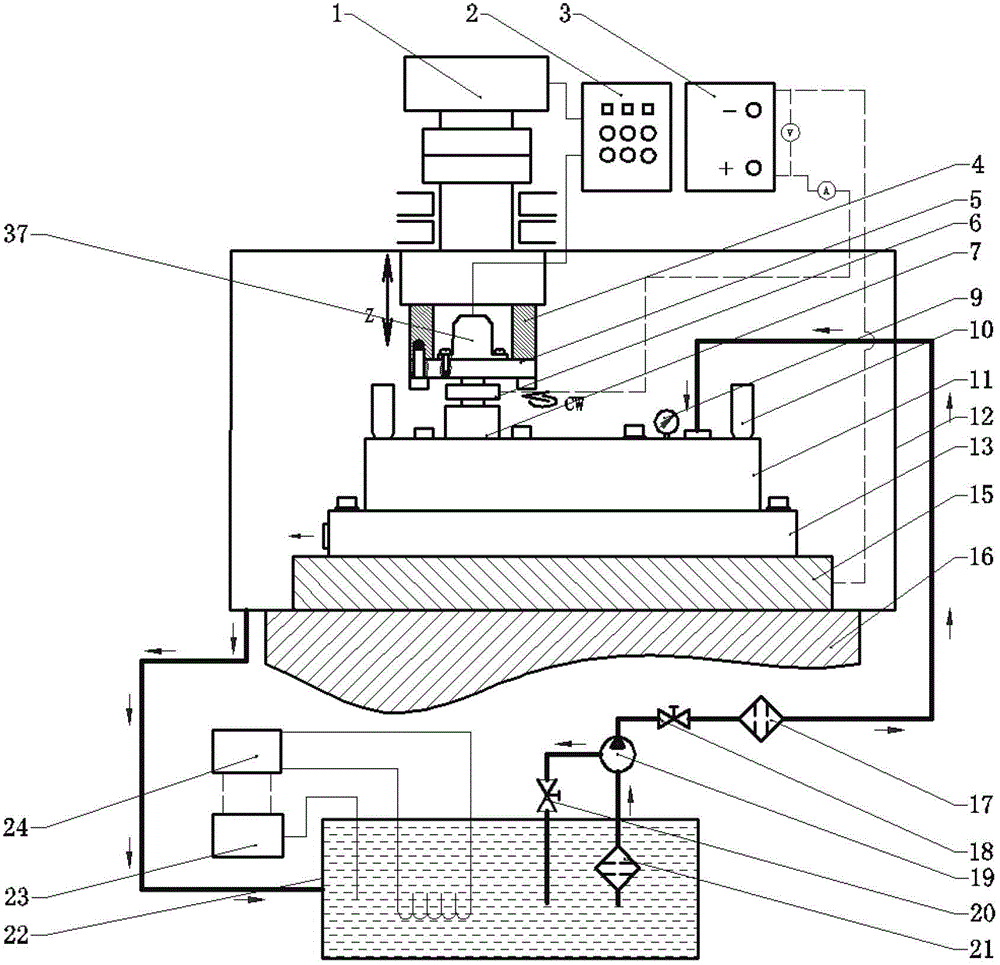

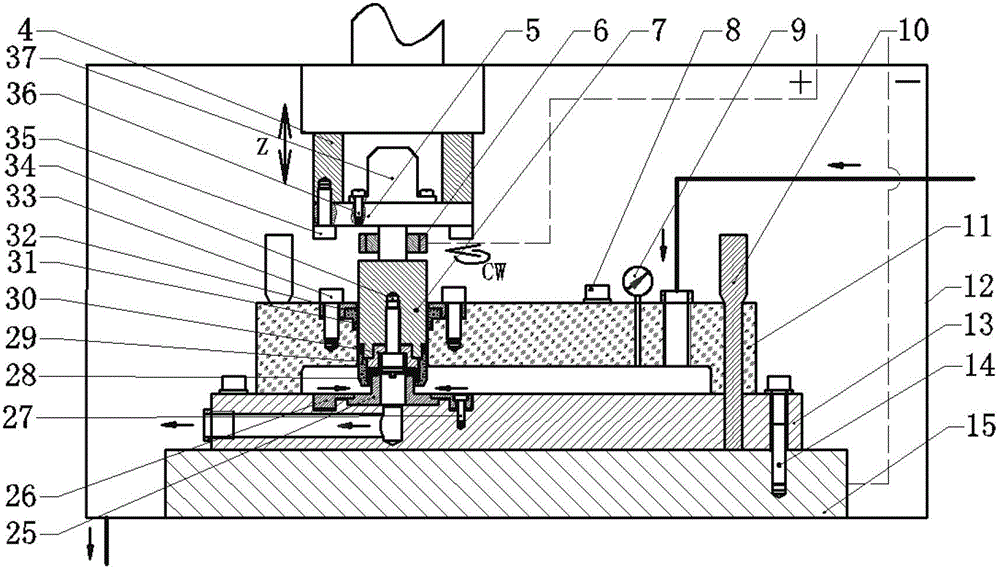

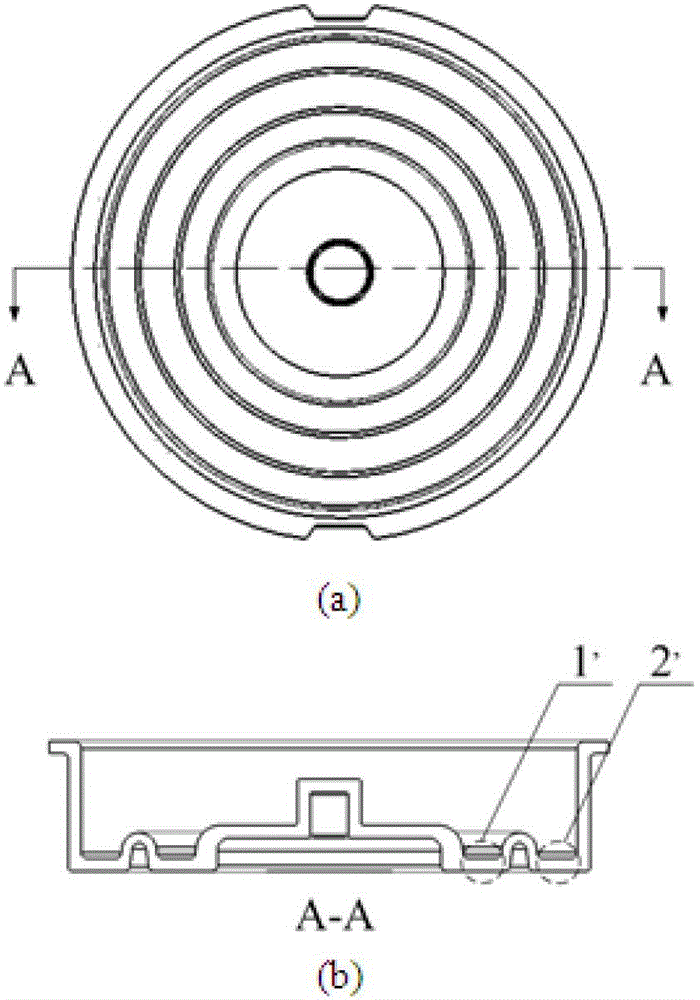

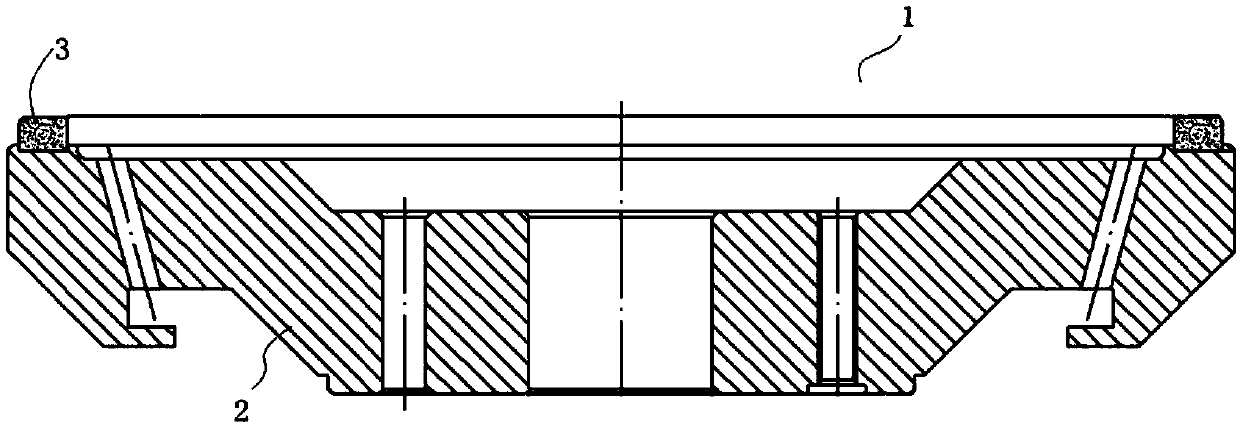

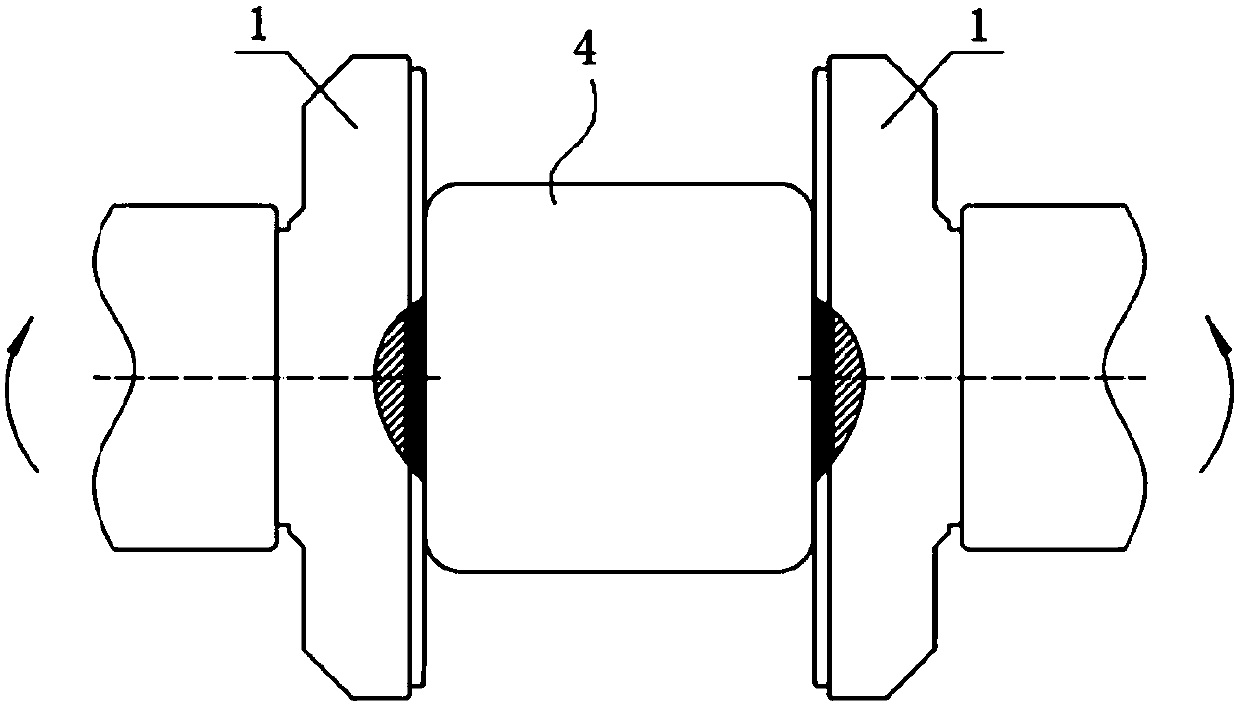

Thinning and electrolytic machining device for inner wall of static cutter cover of shaver and machining process method of device

InactiveCN102941383AHigh quality processingEfficient processingMachining electrodesElectrical-based machining electrodesThinningMachining process

The invention relates to a thinning and electrolytic machining device for the inner wall of a static cutter cover of a shaver and a machining process method of the device and belongs to the technical field of machining of the static cutter cover of the shaver. The thinning and electrolytic machining device is based on an electrolytic machining principle and adopts a tool cathode to carry out thinning and machining forming on the inner wall of a blank of the static cutter cover; and in the process of carrying out electrolytic machining on the blank of the static cutter cover, the blank of the static cutter cover rotates around the axis of the blank of the static cutter cover when linearly fed relative to the tool cathode, and electrolyte required for the electrolytic machining flows through a machining gap formed by the blank of the static cutter cover and the tool cathode continuously at a high speed (10 m / s to 20 m / s). The thinning and electrolytic machining device not only has a high machining efficiency, a stable machining process and a high accuracy, but also realizes high-quality and high-efficiency machining on the inner wall of the static cutter cover.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Load lock chamber, processing system

InactiveUS7236229B2Reduce temperature dropHigh quality processingSemiconductor/solid-state device manufacturingPhotographic printingAmbient pressureEngineering

A load lock chamber provided between a port that accommodates an object to be processed and is maintained at an ambient pressure, and a process chamber that is maintained at a reduced pressure or vacuum environment and performs a predetermined process for the object, said load lock chamber replacing an atmosphere in said load lock chamber and delivering the object between the port and the process chamber includes a first load lock chamber that includes a first holder for holding the object received from the port, and a second load lock chamber that includes a second holder for holding the object received from the process chamber, wherein the first holder holds more objects than the second holder.

Owner:CANON KK

Plasma processing apparatus having an evacuating arrangement to evacuate gas from a gas-introducing part of a process chamber

InactiveUS20070251453A1High quality processingRapid and efficient evacuationElectric discharge tubesSemiconductor/solid-state device manufacturingQuality processEngineering

A plasma processing apparatus can apply a high-quality process to an object to be processed by removing impurities from a gas-introducing part of a process chamber. The gas-introducing part connected to the process chamber so as to introduce a reactant gas into the process chamber. A first vacuum pump is connected to the process chamber so as to evacuate gas from the process chamber so that the process chamber is maintained at a negative pressure. A gas-evacuating arrangement is connected to the gas-introducing part so as to exclusively evacuate the reactant gas from the gas-introducing part. The gas-evacuating arrangement includes a second vacuum pump directly connected to the gas introducing part or a bypass passage connecting the gas-introducing par to the first vacuum pump by bypassing the process chamber.

Owner:TOKYO ELECTRON LTD

Finishing-free composite binding agent ultrahard grinding wheel for silicon ingot grinding and preparation method and application of finishing-free composite binding agent ultrahard grinding wheel

ActiveCN109676541AGood self-sharpeningGood continuous cutting stabilityAbrasion apparatusGrinding devicesMetal coatingHexagonal boron nitride

The invention relates to a finishing-free composite binding agent ultrahard grinding wheel for silicon ingot grinding and a preparation method and application of the finishing-free composite binding agent ultrahard grinding wheel. The finishing-free composite binding agent ultrahard grinding wheel is prepared from following raw materials in percent by weight: 8-14% of monocrystal diamond, 35-68% of bronze powder with the Sn content not smaller than 15%, 6-10% of silver powder, 1.5-8% of high-temperature-resistant resin, 2-10% of filler, 3-8% of hollow microspheres containing surface metal coatings, 0.5-2% of hexagonal boron nitride and 0.25-1.5% of a wetting agent. The finishing-free composite binding agent ultrahard grinding wheel for silicon ingot grinding has excellent self-sharpening performance in the grinding process, under the condition that the requirements of the surfaces of silicon ingots are met, the one-time cutting depth is larger than 0.5 mm, the polishing feeding speed is larger than or equal to 500 mm / min, the service life (represented by the machining length) of the grinding wheel is larger than or equal to 2,000 m, and the grinding wheel does not need to be finished in the using process.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Method and device for preparing organic fertilizer by utilizing fecal sewage in urban septic tank

ActiveCN104628436AHigh quality processingEasy to processBio-organic fraction processingClimate change adaptationFecesWork in process

The invention discloses a method and a device for preparing an organic fertilizer by utilizing fecal sewage in an urban septic tank, belonging to the technical field of preparation of organic fertilizers. According to the technical key points, the method comprises the following steps: (1) collecting faeces, feces and sewage; (2) conveying and discharging the liquid dung mixture consisting of the faeces, feces and sewage into a faeces storage tank, adding quicklime powder, and stirring, so that the liquid dung mixture is subjected to solid-liquid separation; (3) standing, and discharging the intermediate dung sewage into a liquid pool for later use by virtue of a pipeline; (4) adding crop straw powder and the residual faeces and feces after the intermediate dung sewage is completely discharged, stirring and forming a semi-finished product; and (5) conveying the semi-finished product into a fermentation tank for fermenting for 15-25 days, packaging after the fermentation is ended, thereby obtaining the powdered organic fertilizer. The invention aims at providing a method and a device for preparing the organic fertilizer by utilizing the fecal sewage in the urban septic tank. According to the method and the device, the operation is easy and convenient, the urban dung sewage can be effectively treated, and the aim of changing wastes into valuable materials is achieved. The method and the device are used for manufacturing organic fertilizers.

Owner:张仲元

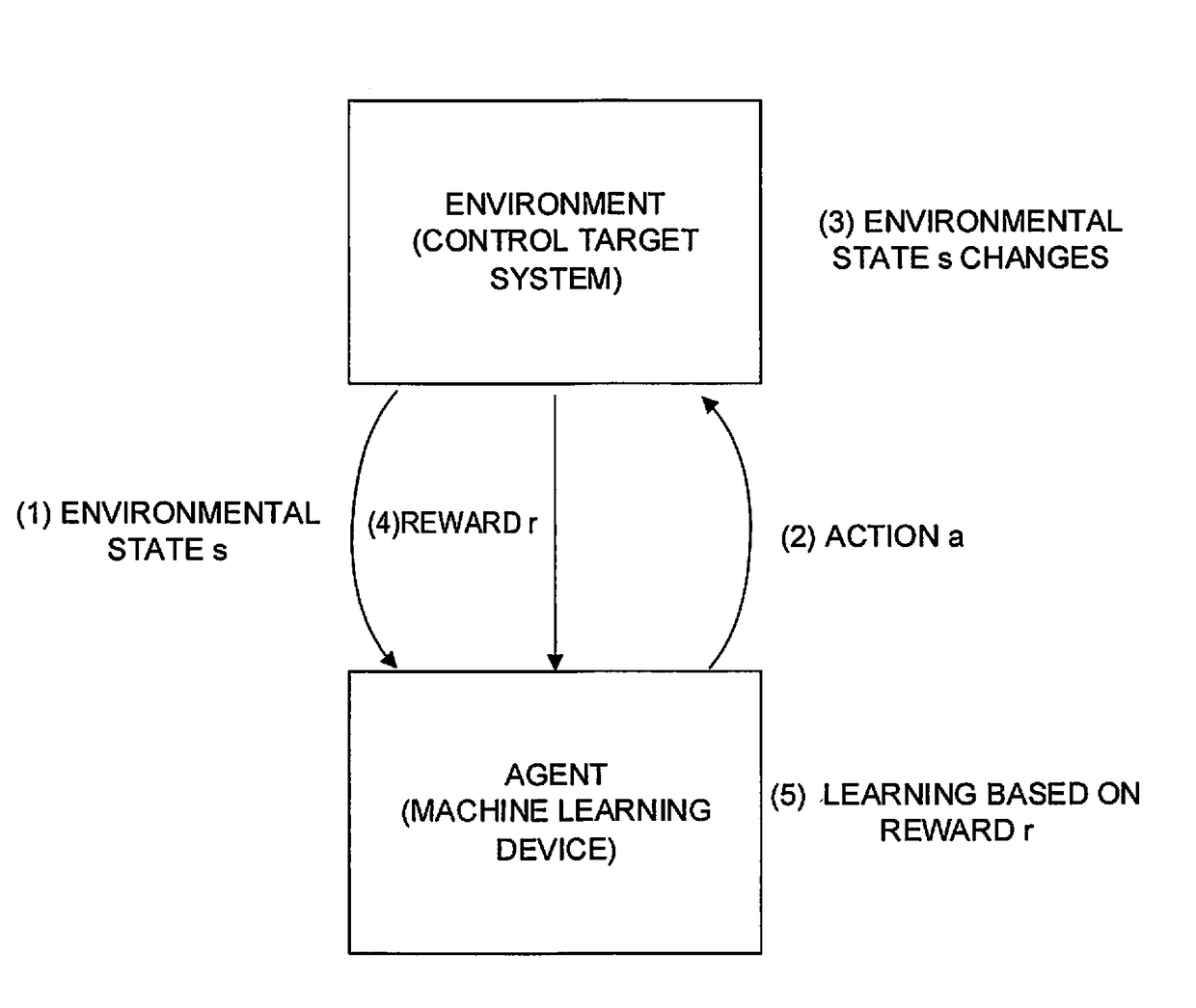

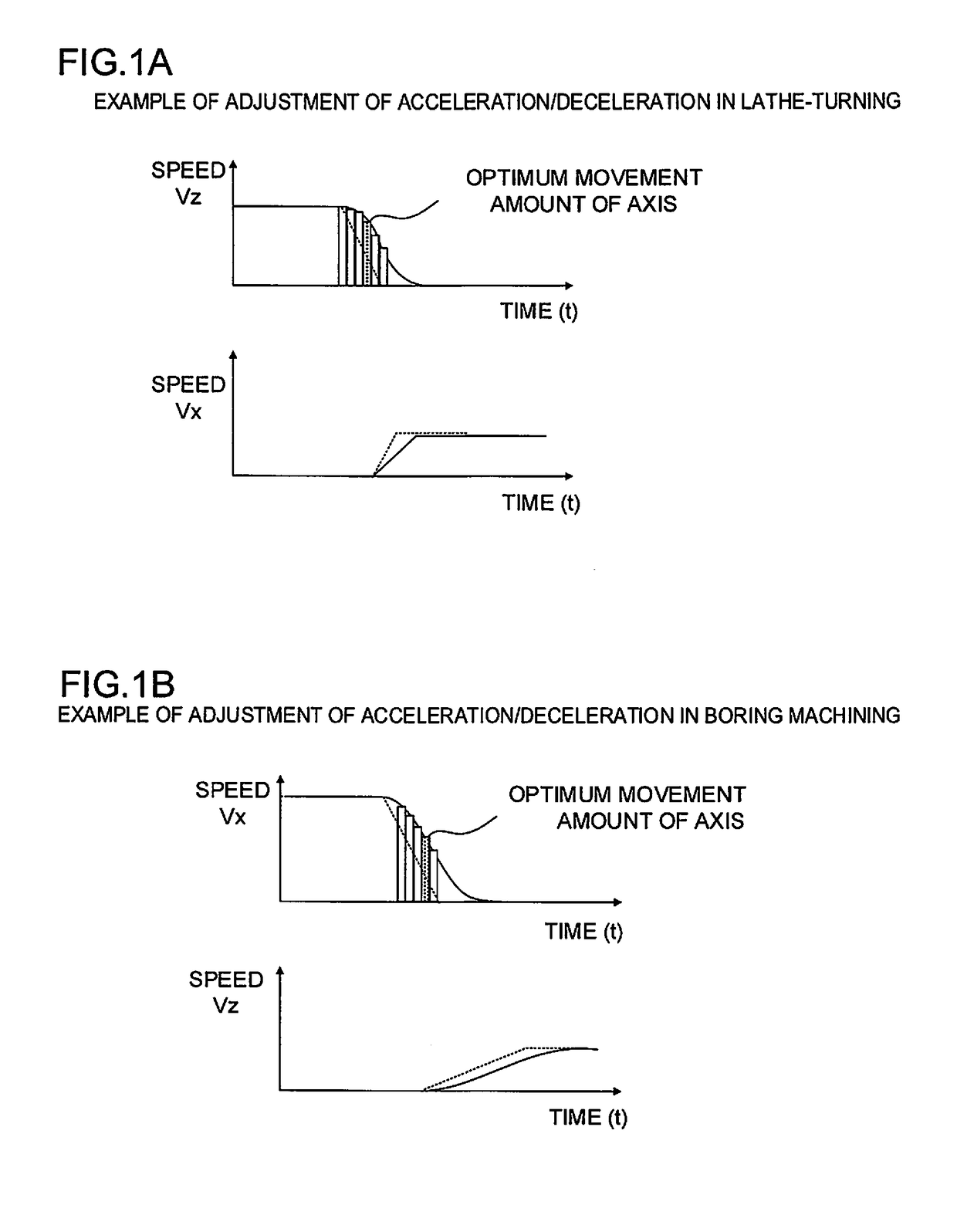

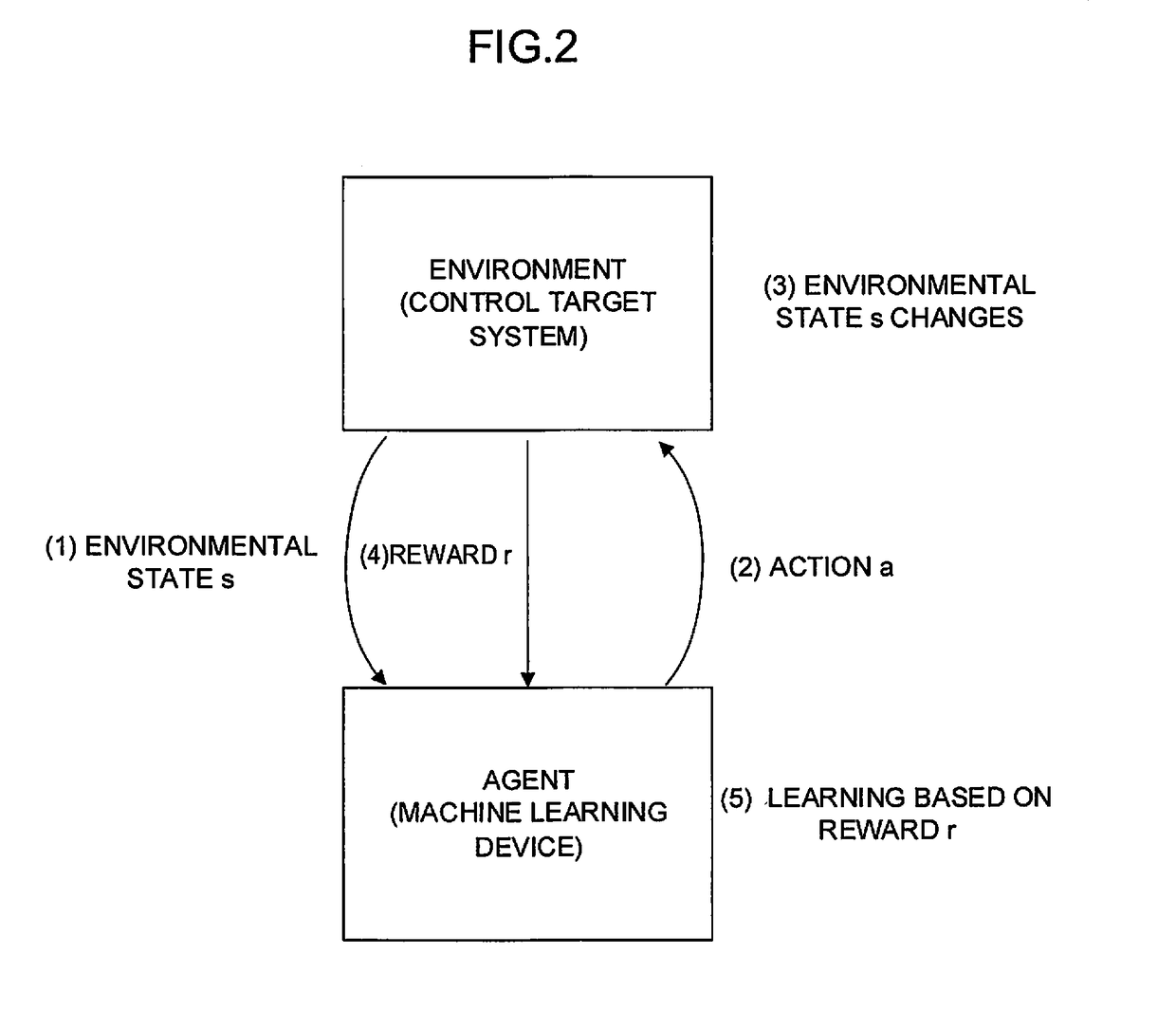

Machine tool for generating optimum acceleration/deceleration

ActiveUS20170090459A1Little changeHigh quality processingComputer controlSimulator controlEngineeringMachine tool

A machine tool includes an operation evaluation section that evaluates an operation thereof and a machine learning device that performs the machine learning of a movement amount of an axis thereof. The machine learning device calculates a reward based on state data including the output of the operation evaluation section, performs the machine learning of the determination of the movement amount of the axis, and determines the movement amount of the axis based on a machine learning result and outputs the determined movement amount. The machine learning device performs the machine learning of the determination of the movement amount of the axis based on the determined movement amount of the axis, the acquired state data, and the calculated reward.

Owner:FANUC LTD

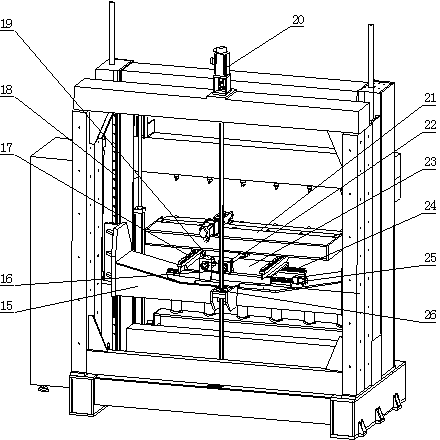

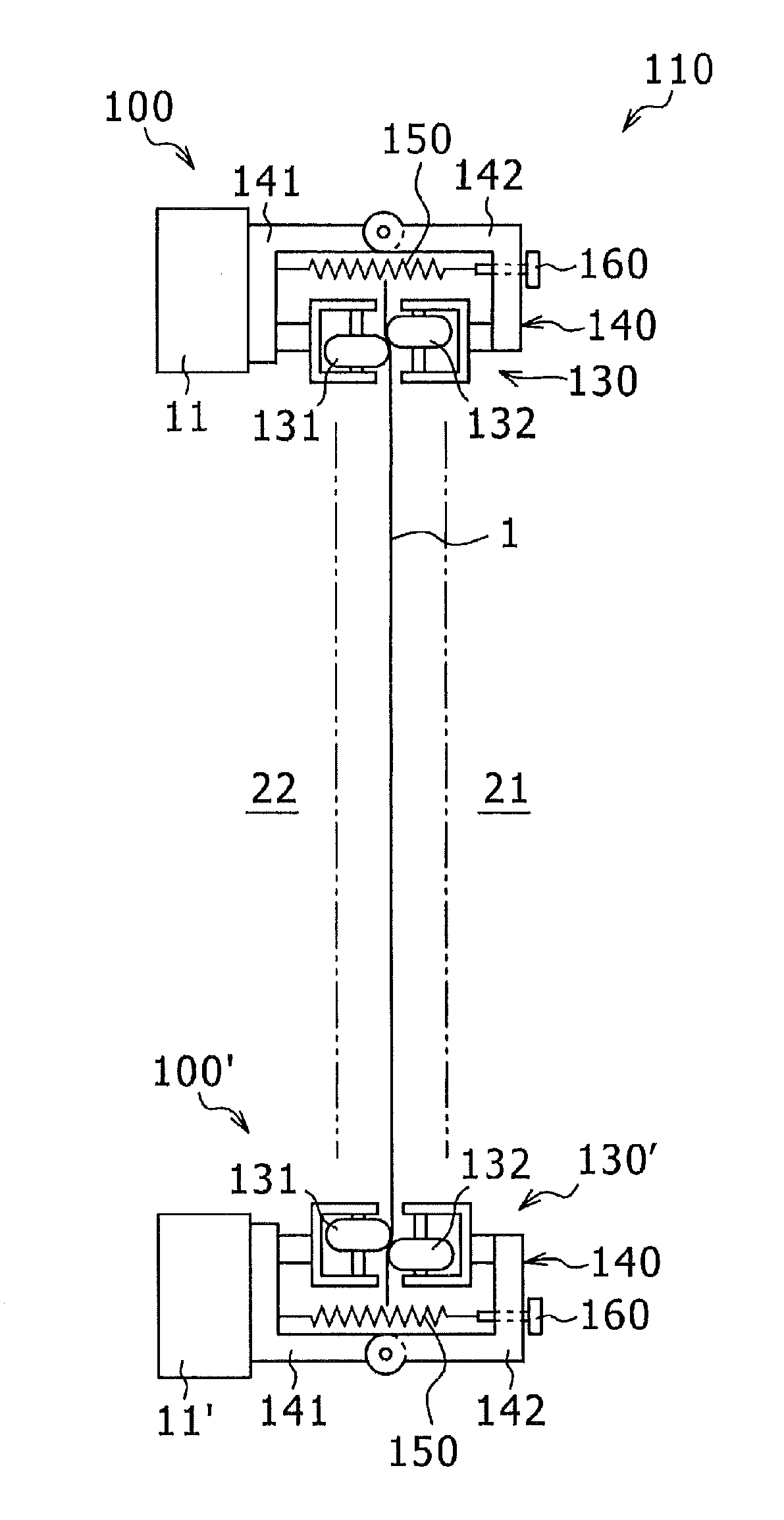

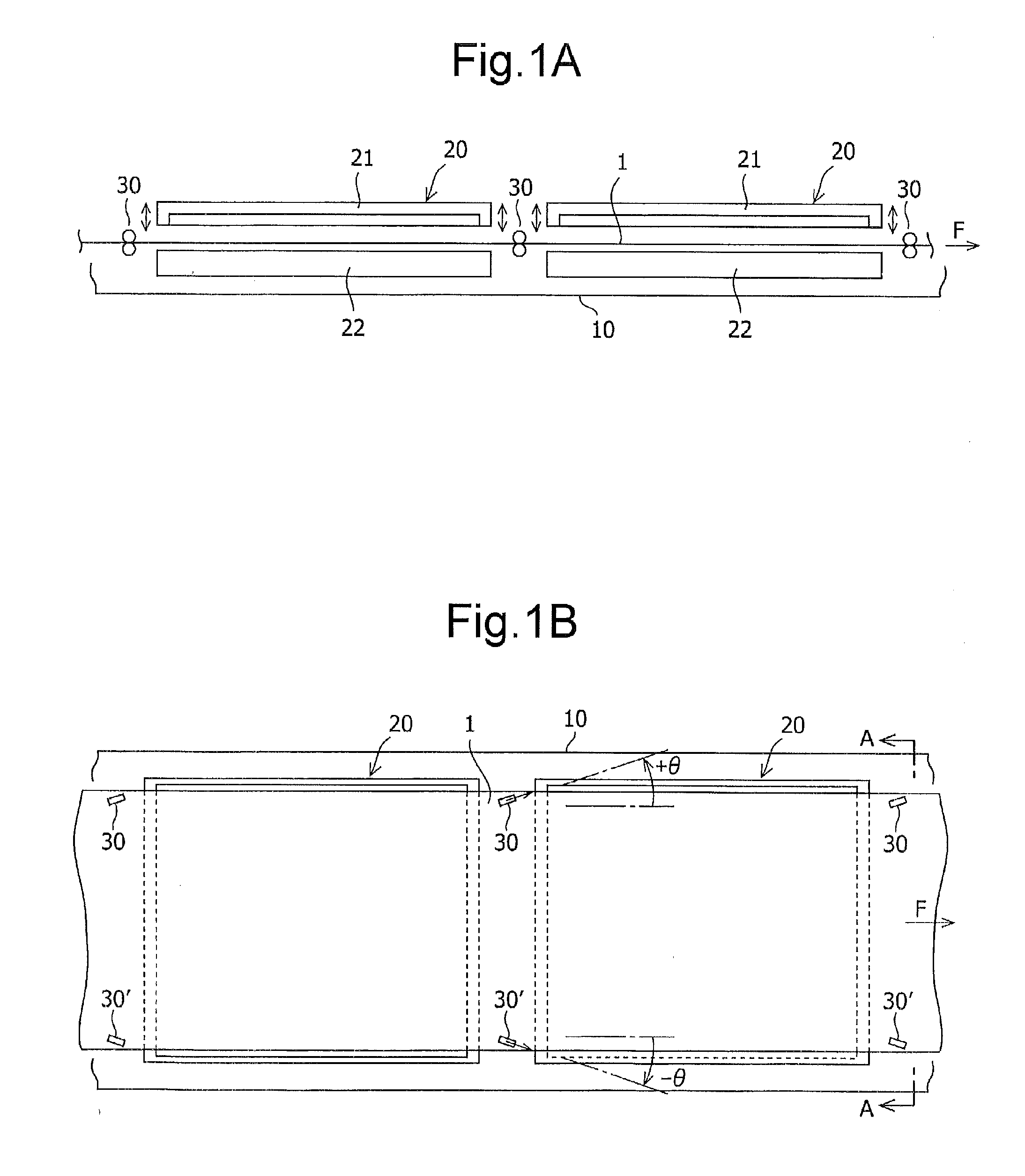

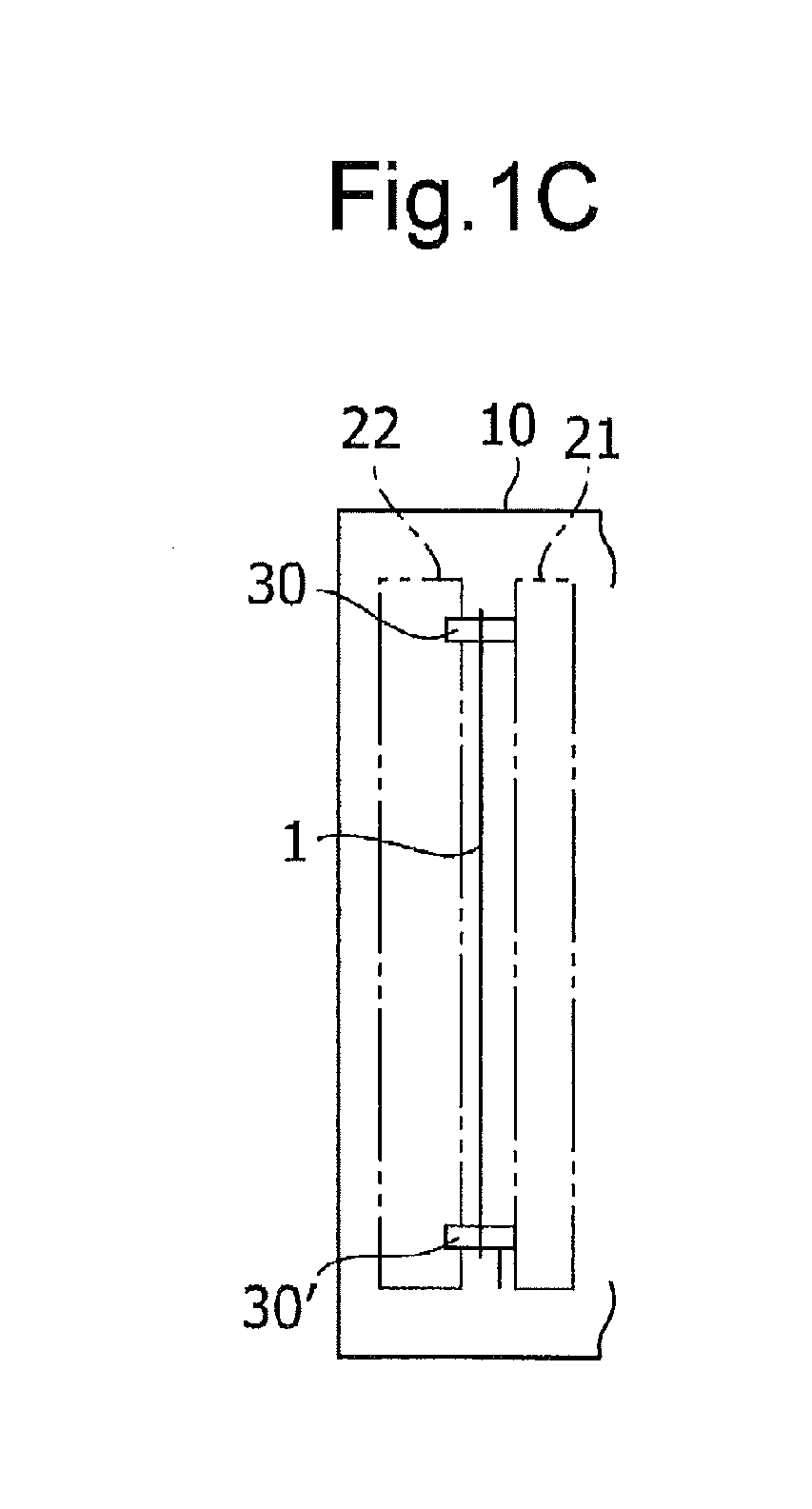

Flexible substrate position control device

InactiveUS20120031565A1Avoid it happening againHigh quality processingFinal product manufactureVacuum evaporation coatingPosition controlVertical orientation

A flexible substrate position control device in a processing device, which transports a flexible substrate in a horizontal direction and in a vertical orientation and carries out processing of the substrate by processing units installed in a transport path of the substrate, is provided with a pair of clamping rollers that clamp an upper edge of the substrate, a support mechanism that rotatably supports the pair of clamping rollers, urging means for applying pressing force to the pair of clamping rollers, and adjusting means for adjusting the pressing force applied by the urging means. The pair of clamping rollers has an inclination, in which the direction of pressing relative to the clamping surface of the substrate is towards the edge of the substrate in the width direction, and is supported such that the rotating direction at the clamping surface is the same direction as the transport direction of the substrate.

Owner:FUJI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com