Aviation blade oval leading and trailing edge process model generation method

An aviation blade and process model technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of difficulty in establishing process models for elliptical leading and trailing edge blades

Inactive Publication Date: 2013-05-22

NORTHWESTERN POLYTECHNICAL UNIV

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to overcome the deficiency that it is difficult to establish a process model for processing elliptical leading and trailing edge blades

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

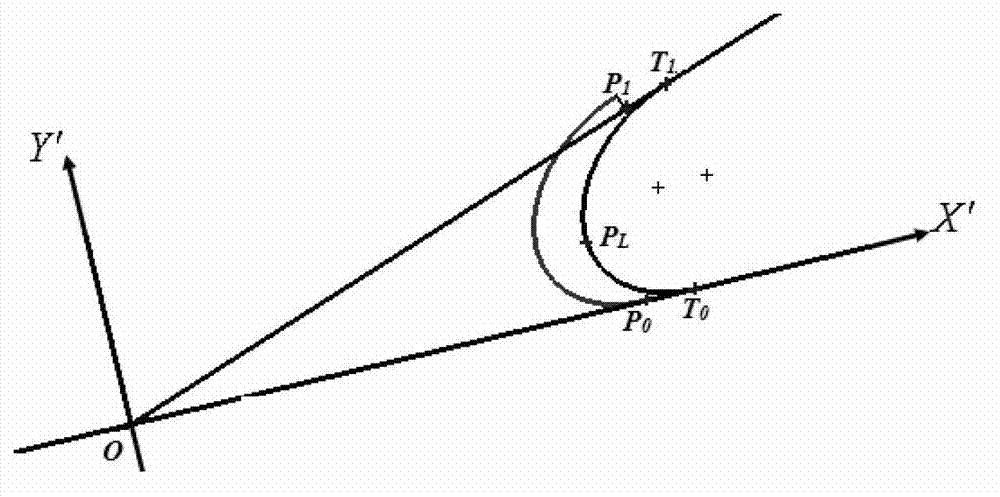

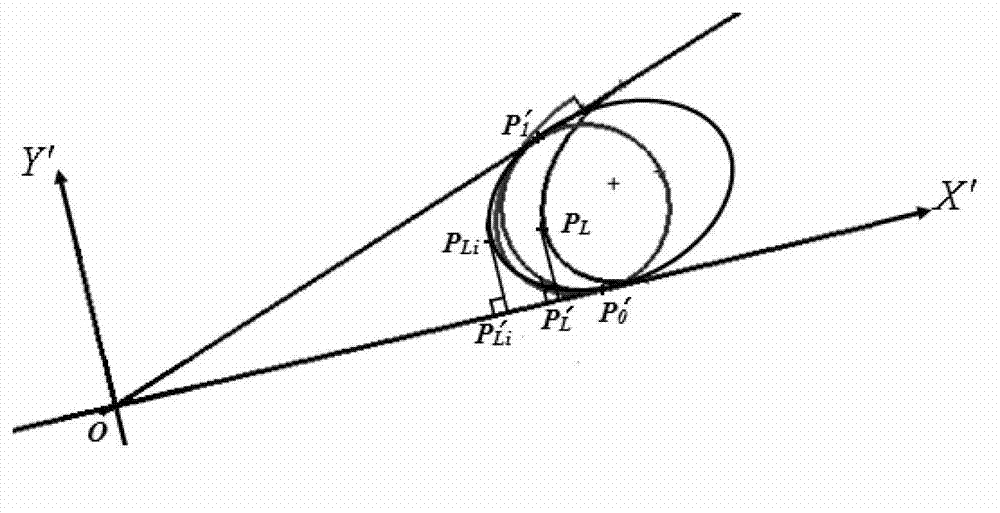

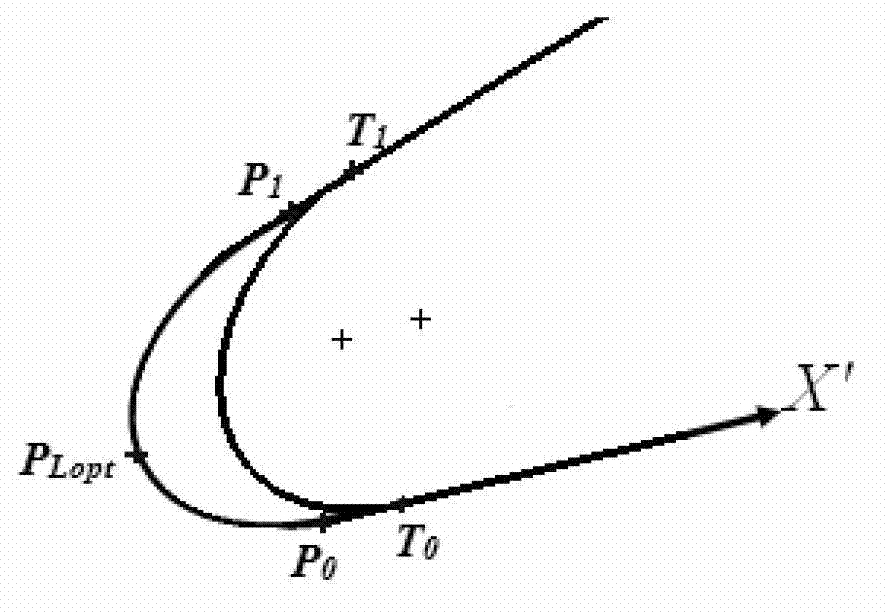

The invention discloses an aviation blade oval leading and trailing edge process model generation method which is used for solving the technical problem that a process model is difficult to be built during processing of oval leading and trailing edge blades in the prior art. The technical scheme includes: firstly establishing an affine coordinate system, and then utilizing affine relationship between a circle and an oval to build an oval leading and trailing edge blade process model. A user can quickly obtain an accurate oval leading and trailing edge blade process model only by setting a process error according to actual needs in engineering application so as to guide high-quality processing of aviation blades.

Description

technical field [0001] The invention relates to a method for generating a process model of the leading and trailing edges of an aviation blade, in particular to a method for generating a process model of an elliptical leading and trailing edge of an aviation blade. Background technique [0002] The interior of an aero-engine is basically composed of a series of blades, such as turbine blades, compressor blades, fan blades, etc.; as the core part of the engine, the models of aero-blades are mostly free-form surfaces, and the molding process is relatively complicated; at the same time, the shape of the blade surface Design and manufacturing levels largely determine engine performance. [0003] As a typical thin-walled structural part, thin-walled blades are prone to large deformation during processing; in addition, due to the problems of the process system itself composed of workpieces, tools, fixtures and machine tools, it is easy to produce overcut or under-processed blades ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F17/50

Inventor 程云勇朱真真汪文虎王增强杨杰李维亮王丽雅

Owner NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com