Load lock chamber, processing system

a technology of processing system and lock chamber, which is applied in the direction of thin material processing, printers, instruments, etc., can solve the problems of gas temperature drop, wafer temperature drop exceeding the temperature stability budget required, particle adhesion to the wafer, etc., and achieves high-quality processing and reduces the temperature drop of the wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

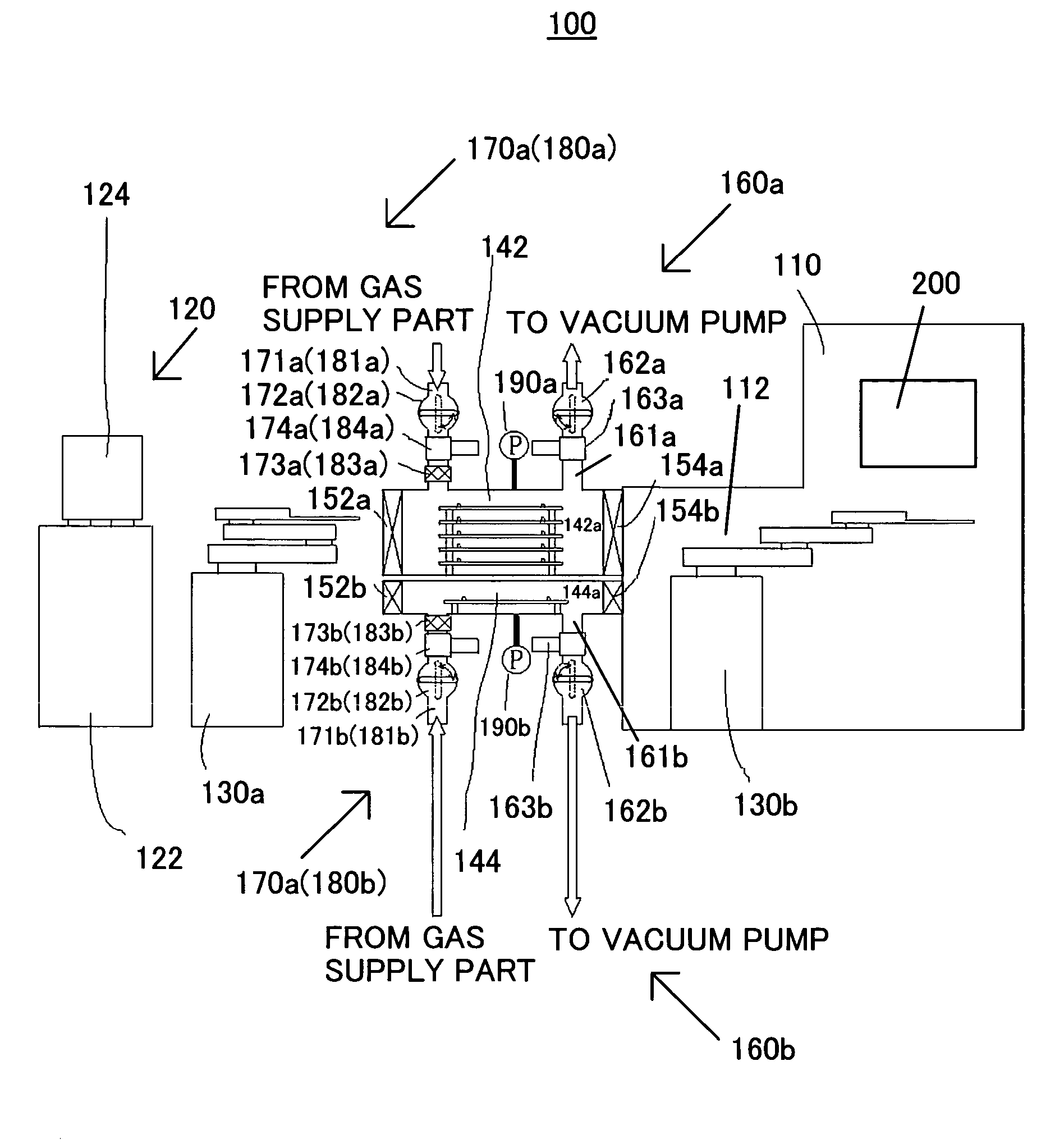

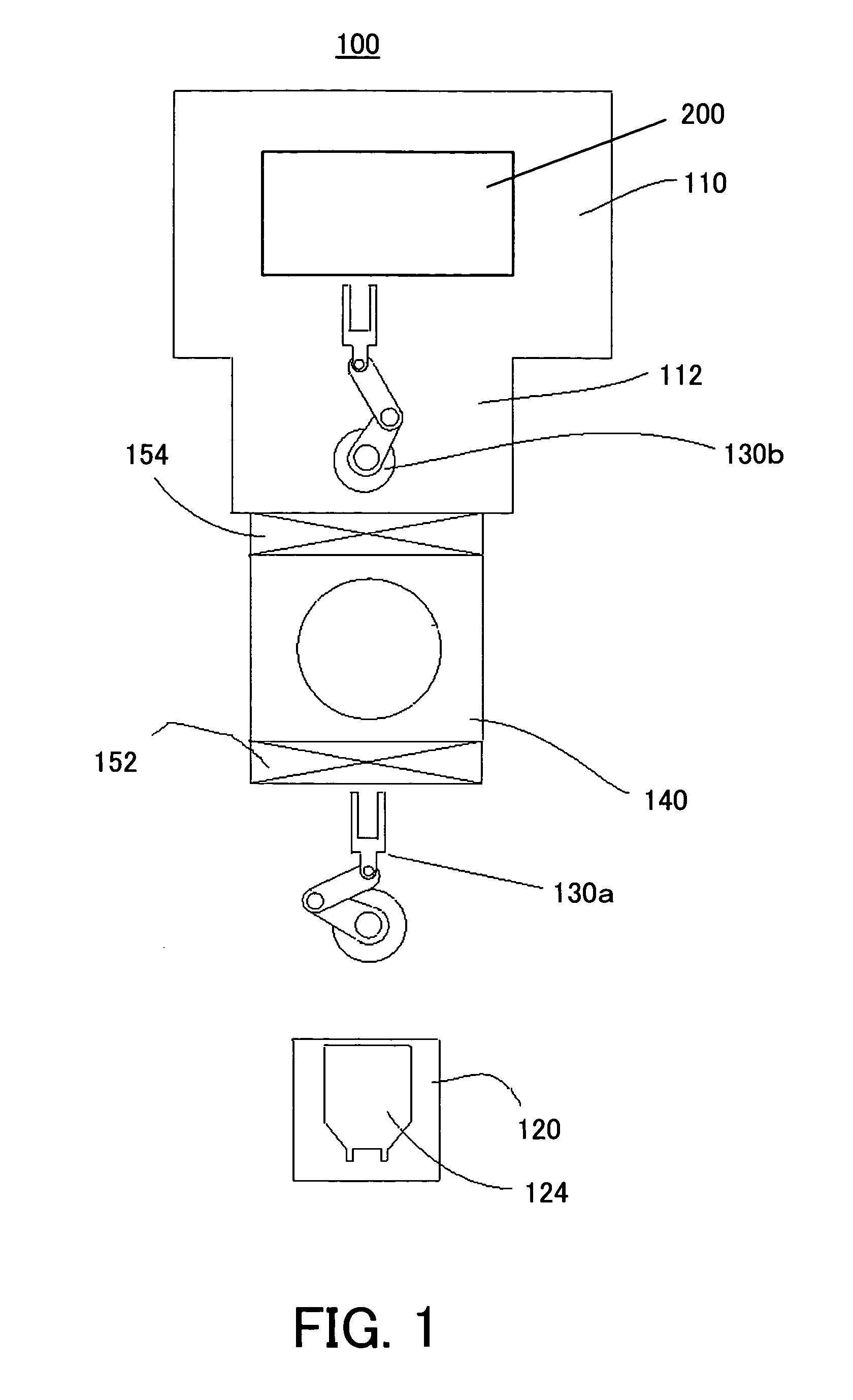

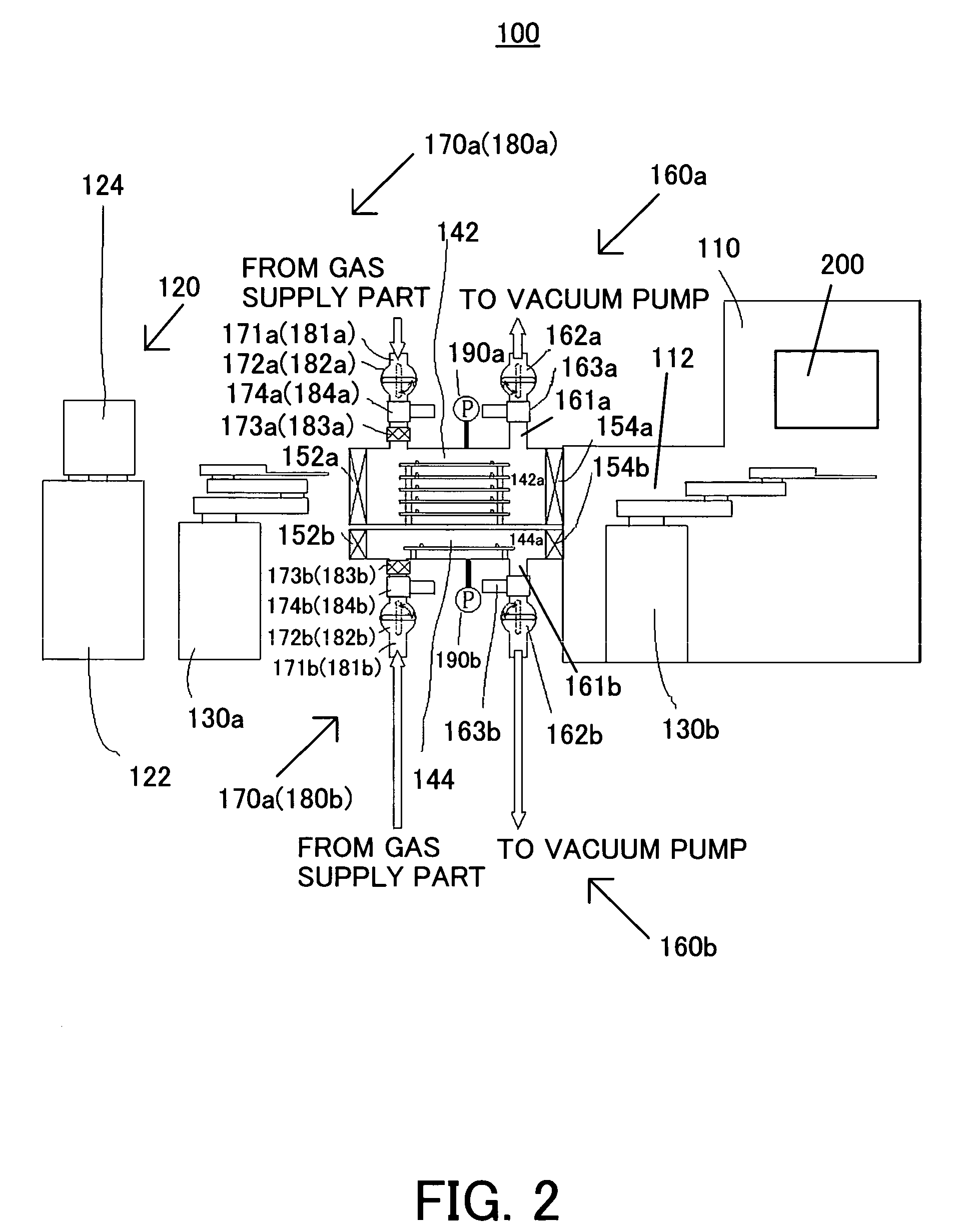

[0033]A description will now be given of a processing system 100 as one aspect of the present invention with reference to the accompanying drawings. The same reference numeral in each figure denotes the same element, and a description thereof will be omitted. Here, FIG. 1 is a schematic block diagram of the processing system 100. FIG. 2 is a schematic block diagram of a detailed structure of the processing system 100.

[0034]While the processing system 100 of the instant embodiment exposes a wafer as an object to be exposed, the present invention does not limit the process by the processing apparatus to exposure. Of course, the exposure process is suitable for the present invention since the exposure process requires high throughput as discussed above.

[0035]The processing system 100 includes, as shown in FIG. 1, a process chamber 110, a preliminary chamber 112, a port 120, a first transport means 130a, a second transport means 130b, a load lock chamber 140, a first gate valve 152 (tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com