Thinning and electrolytic machining device for inner wall of static cutter cover of shaver and machining process method of device

A processing technology and a processing device technology are applied in the field of electrolytic processing devices for thinning the inner wall of a razor static blade cover, and can solve the problems of the deterioration of the flow field conditions in the processing gap, the complex structure of the inner wall of the static blade cover, and the easy generation of flow marks on the surface of the inner wall. , to achieve the effect of good flow field stability, stable processing process, and avoidance of liquid shortage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

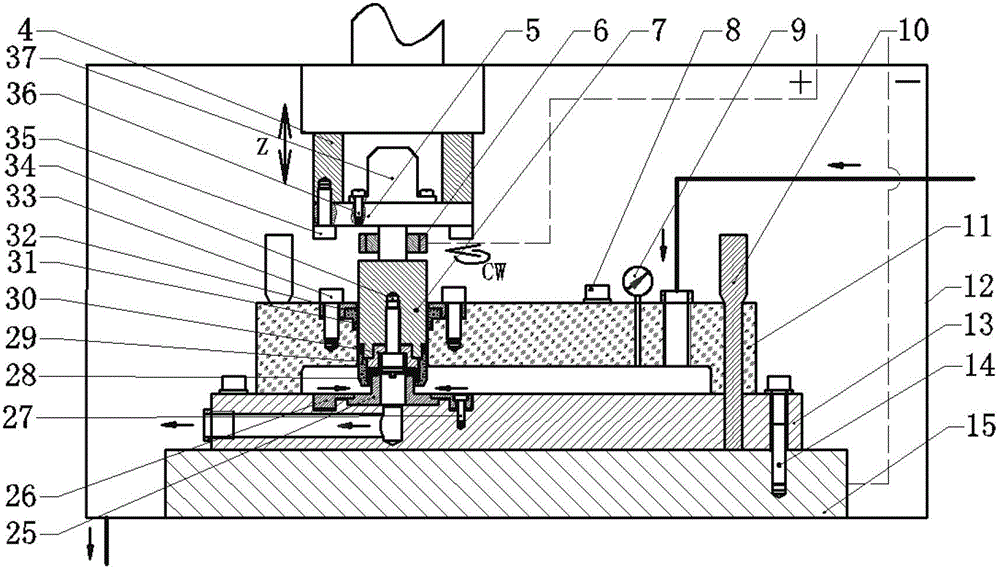

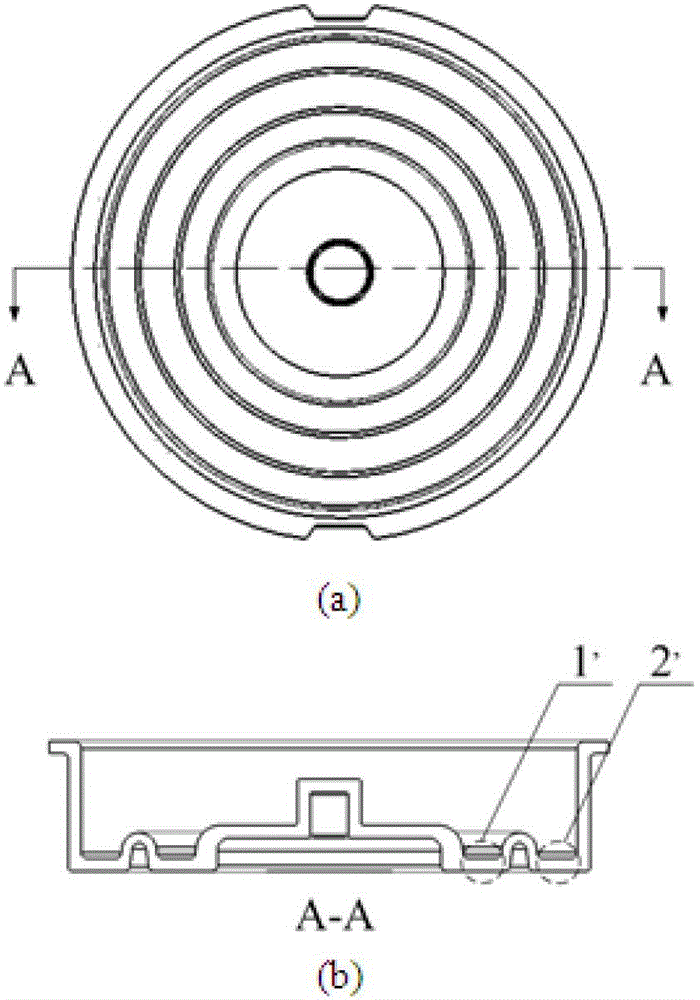

[0026] The accompanying drawings disclose non-restrictive structural schematic diagrams of preferred embodiments involved in the present invention, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

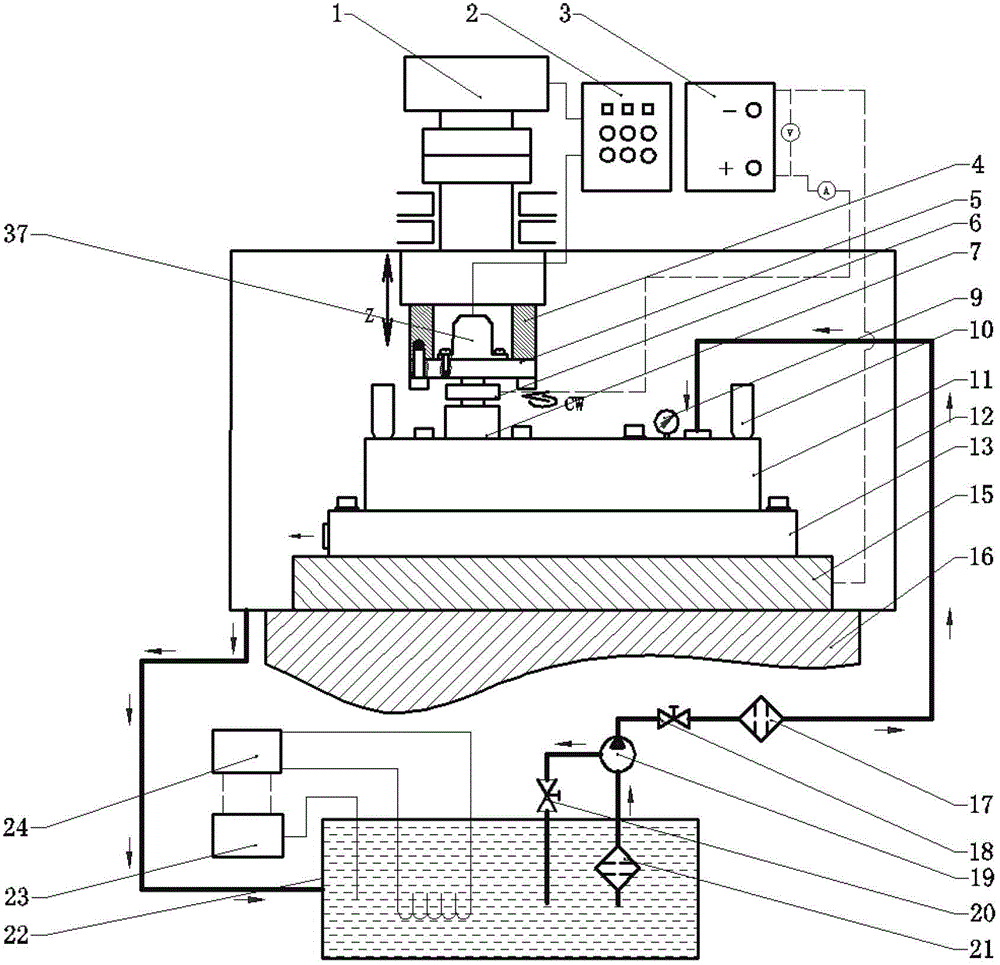

[0027] Such as figure 1 As shown, the electrolytic machining device for thinning the inner wall of the static blade cover of the razor according to the present invention includes: an electrolytic machining system and an electrolyte circulating filtration system. The electrolytic machining system includes: a working box 12, a machine tool workbench 16, a work platform 15, a transmission device 1, a pulse power supply 3, and a machine tool motion control system 2. The bottom of the work box 12 is fixed on the machine tool workbench 16 through the work platform 15. The electrolyte circulating filtration system includes: filter 17, pressure regulating valve 18, electrolyte pump 19, overflow valve 20, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com