Capacitive coupling radio frequency normal pressure plasma torch for machining ultra-smooth surface

An ultra-smooth surface, atmospheric pressure plasma technology, applied in the field of plasma polishing equipment, can solve the problems of difficult surface cleaning, easy corrosion of the inner torch, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

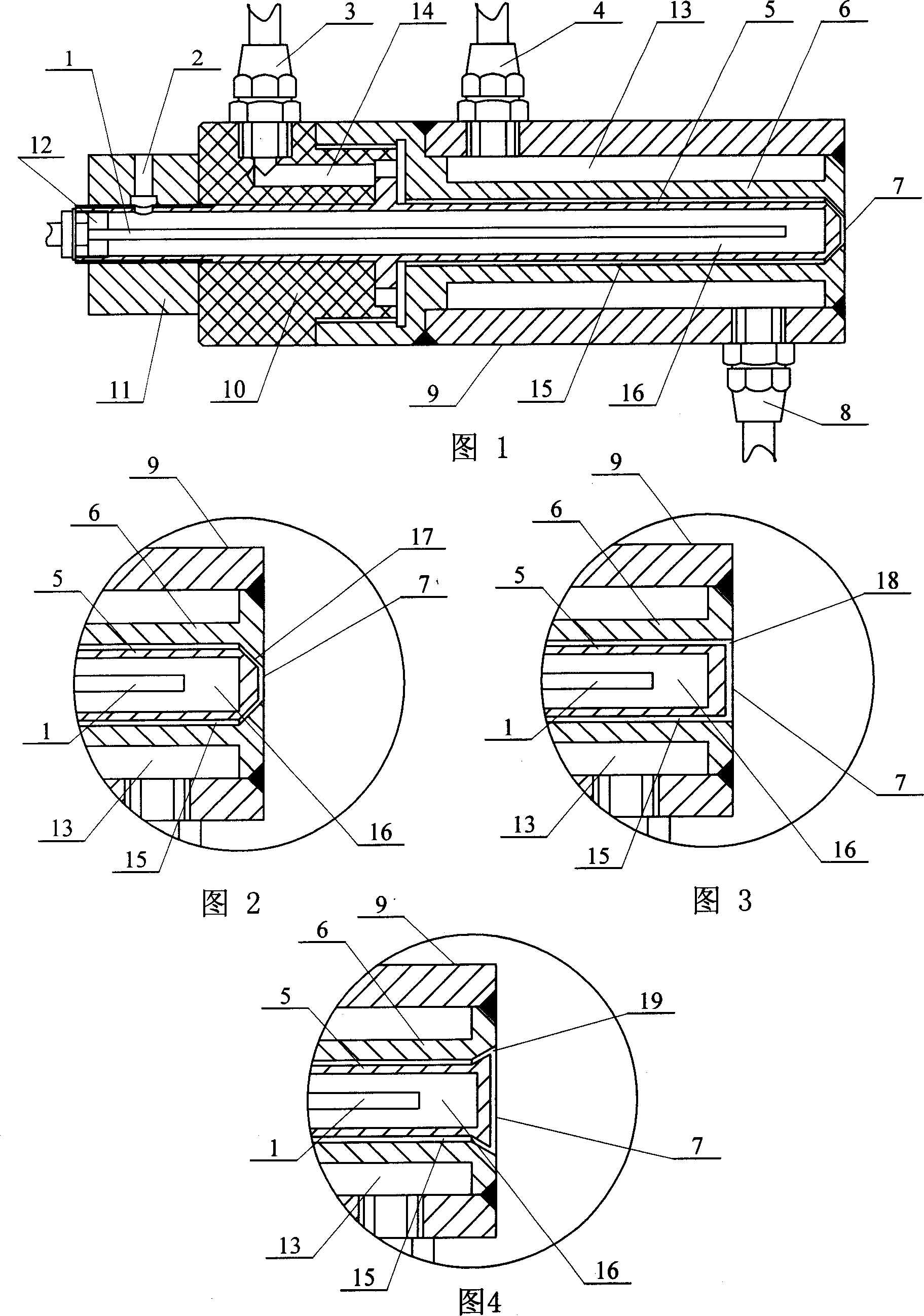

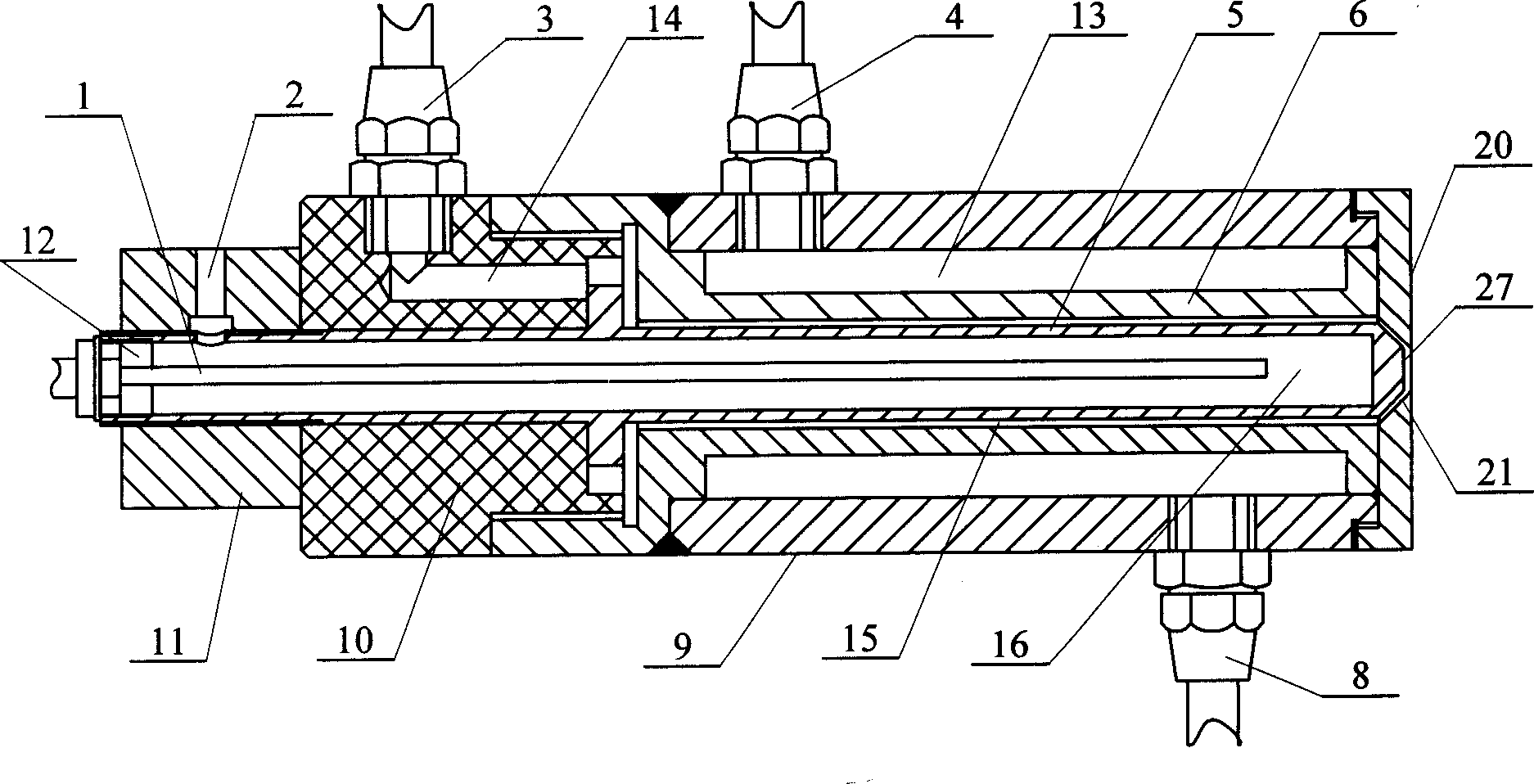

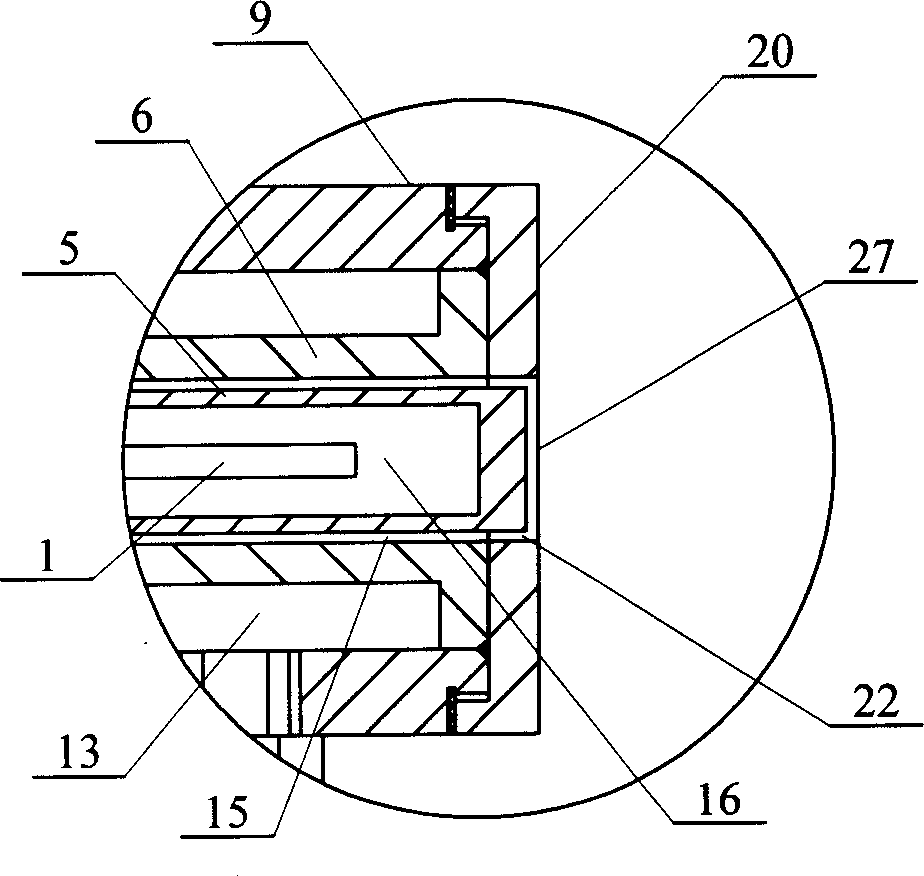

[0005] Specific embodiment one: (see Fig. 1, Fig. 2) this embodiment is composed of anode water-cooling conduit 1, air intake joint 3, cathode water-cooling joint one 4, anode 5, cathode 6, cathode water-cooling joint two 8, jacket 9, ceramic nut 10. The connecting body 11 and the sealing seat 12 are composed, the cathode 6 is fixedly connected with the jacket 9, a water-cooled annular space 13 is formed between the outer wall of the cathode 6 and the inner wall of the jacket 9, and the cathode water-cooling joint 4 is fixed on the outer wall of one side of the jacket 9 And communicated with the water-cooled annular space 13, the cathode water-cooled connector 2 8 is fixed on the outer wall of the other side of the jacket 9 and communicated with the water-cooled annular space 13, the right end of the ceramic nut 10 is fixedly connected with the left end of the cathode 6, and the connecting body 11 The right end is fixedly connected with the left end of the ceramic nut 10, the l...

specific Embodiment approach 2

[0006] Specific embodiment two: (referring to Fig. 1, Fig. 2) the outlet 7 of the cathode 6 of the present embodiment is a small truncated cone shape 17 with a large inner mouth and a small outer mouth, and the right end of the anode 5 corresponds to the truncated cone shape 17 of the outlet 7 of the cathode 6. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0007]Specific Embodiment Three: (See FIG. 3 ) The outlet 7 of the cathode 6 in this embodiment is straight-shaped 18 , and the right end of the anode 5 corresponds to the straight-shaped 18 of the outlet 7 of the cathode 6 . Other composition and connection relationship with

[0008] The specific embodiment one is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com