Plasma processing apparatus having an evacuating arrangement to evacuate gas from a gas-introducing part of a process chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

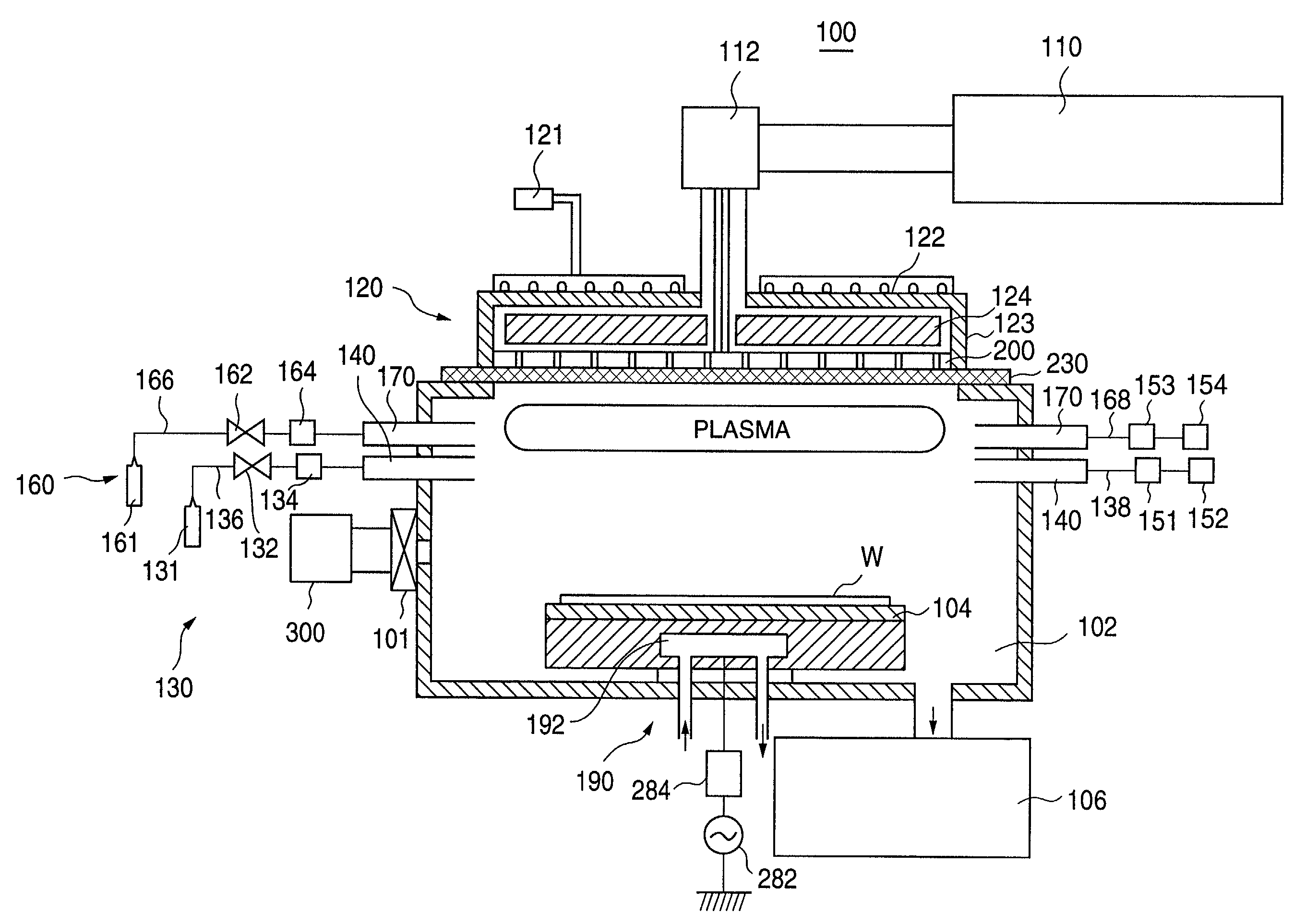

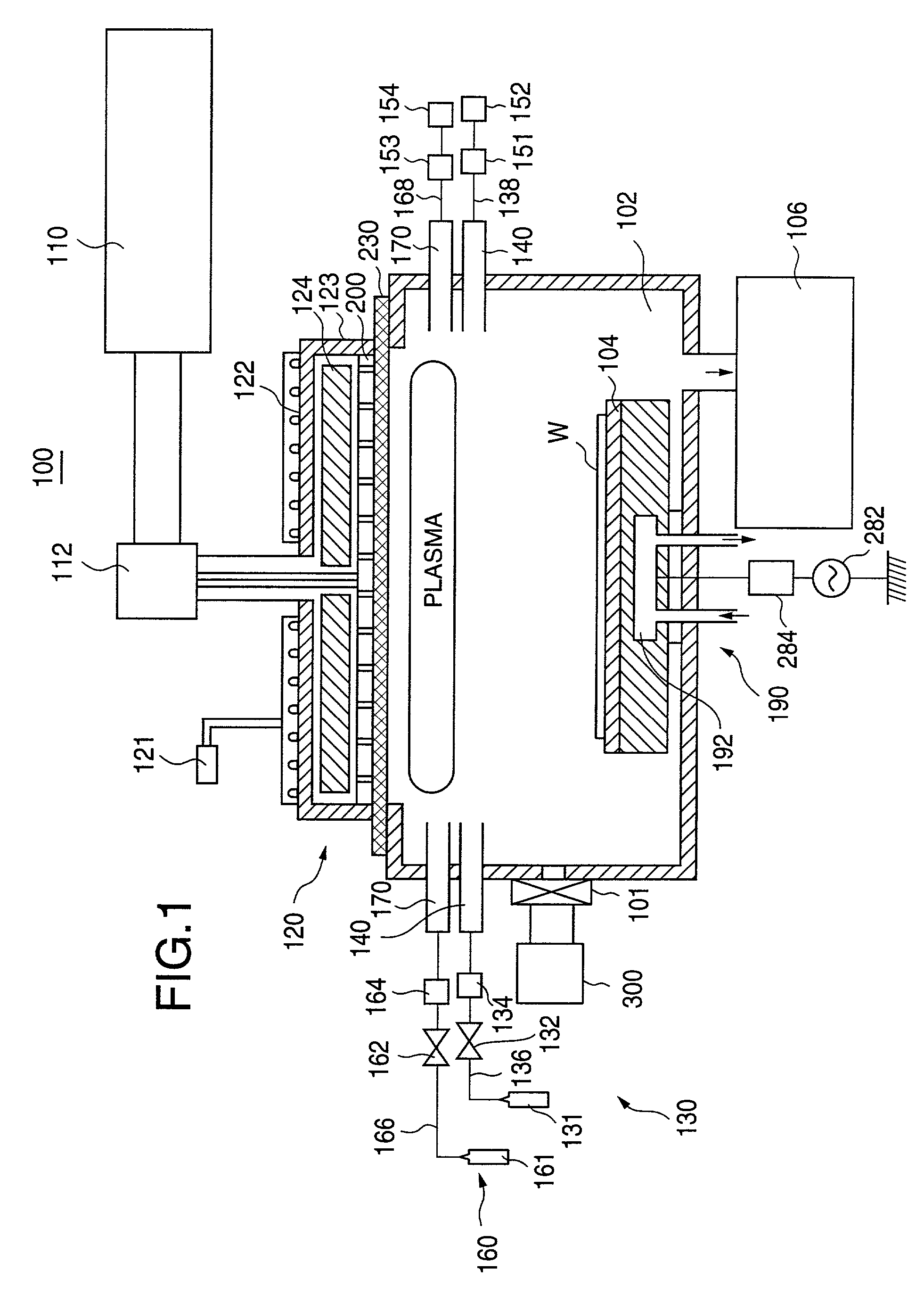

[0048] A description will now be given, with reference to FIG. 1, of a first embodiment of the present invention. FIG. 1 is an illustration of a structure of a microwave plasma processing apparatus 100 according to the first embodiment of the present invention. The first embodiment of the present invention is specifically related to an evacuating arrangement to evacuate gas from a gas-introducing part provided in a process chamber of the microwave plasma processing apparatus 100.

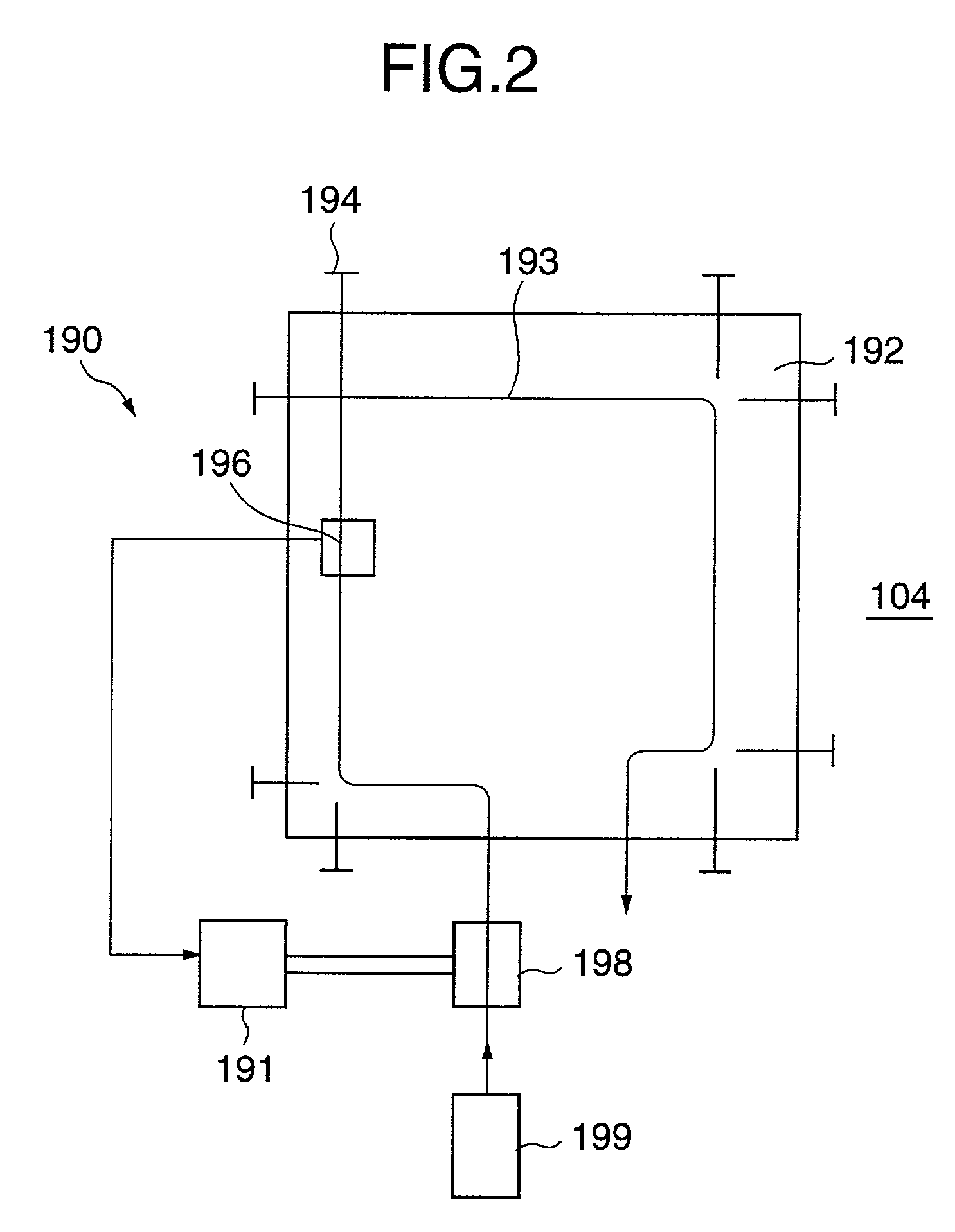

[0049] The microwave plasma processing apparatus 100 shown in FIG. 1 comprises: a gate valve 101 connected to a cluster tool 300; a process chamber 102 which can accommodate a susceptor 104 on which an object to be processed such as a semiconductor wafer or an LCD substrate; a high-vacuum pump 106 connected to the process chamber; a microwave supply source 110; an antenna member 120; and gas supply systems 130 and 160. It should be noted that a control system of the plasma processing apparatus 100 is not ill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com