Emergency pretreatment system of source water with excessive iron and manganese and treatment method thereof

A water source water and pretreatment technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Manganese sand filter material clogging and other problems, to achieve the effect of saving coagulation reaction pool, reducing equipment investment and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

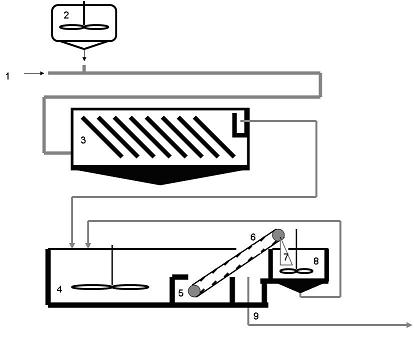

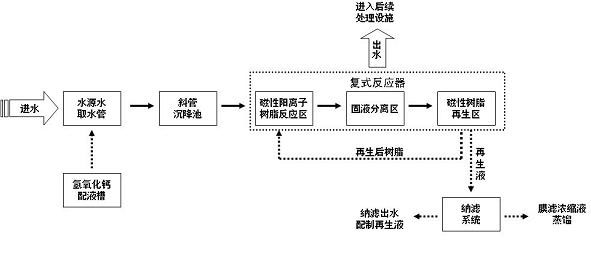

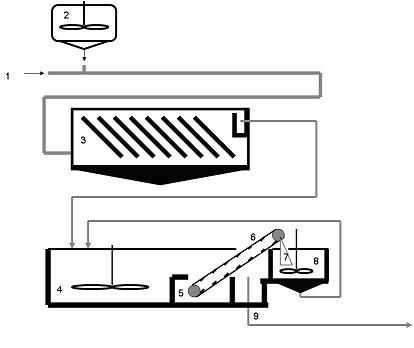

[0022] The emergency pretreatment system for source water with iron and manganese exceeding the standard, including source water inlet pipe 1, outlet pipe 9, inclined pipe sedimentation tank 3 and mixed reaction area 4, the inclined pipe is made of polypropylene and forms an angle of 45 degrees with the bottom; It also includes a calcium hydroxide solution preparation tank 2 connected to the water inlet pipe 9, the mixing reaction zone 4 communicates with the solid-liquid separation zone 5, and the solid-liquid separation zone 5 is connected with the resin regeneration tank 8 and the water outlet pipe 9. The solid-liquid separation zone 5 communicates with the resin regeneration tank 8 through a magnetic conveyor belt 6, and the mixed reaction zone 4 has a magnetic cation exchange resin, a magnetic polyacrylic acid series cation exchange resin MD213. The magnetic conveyor belt is a magnetic crawler conveyor with a rubber scraper 7 on the top. The reactor is a compound reactor ...

Embodiment 2

[0031] The basic structure of the system and the basic steps of the processing technology are the same as in Embodiment 1, specifically:

[0032] 1.1 According to the ratio of 1:5000 (volume ratio), add saturated calcium hydroxide solution from the front end of the water intake pipe to the source water (flow rate 0.1m / s), mix and react in the water pipe and then enter the inclined tube sedimentation tank;

[0033] 1.2 The effluent enters the mixed reaction zone of the compound reactor. There is 50ml of magnetic cation exchange resin MD213 in the reaction zone, and the stirring rate of the built-in stirrer is 120r / min; the intermittent effluent has an iron ion concentration of 0.24mg / L and a manganese ion concentration of 0.07mg / L;

[0034] 1.3 The magnetic track transports the magnetic resin to the regeneration zone at a rate of 1cm / s, regenerates the magnetic cation exchange resin with 3% HCl solution, stirs at 120r / min for 20min, and after standing for 10min, settles at the ...

Embodiment 3

[0037] Other operating conditions remain unchanged, but the dosage of calcium hydroxide solution in step 1.1 is adjusted to 1:6000, except that iron ions rise to 0.32 mg / L and manganese ions rise to 0.064 mg / L, other results are the same as in Example 1 same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com