Method for extracting titanium slag, tungsten and vandic salt from waste SCR catalyst

A technology of SCR catalyst and titanium slag, which is applied in the field of extracting titanium slag from tungsten and vanadium salts, can solve the problems of raw material resource occupation, high equipment requirements, and environmental pollution, and achieve the goal of reducing environmental damage, low equipment requirements, and low investment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be clearly and completely described below in conjunction with the drawings and specific embodiments of the present invention.

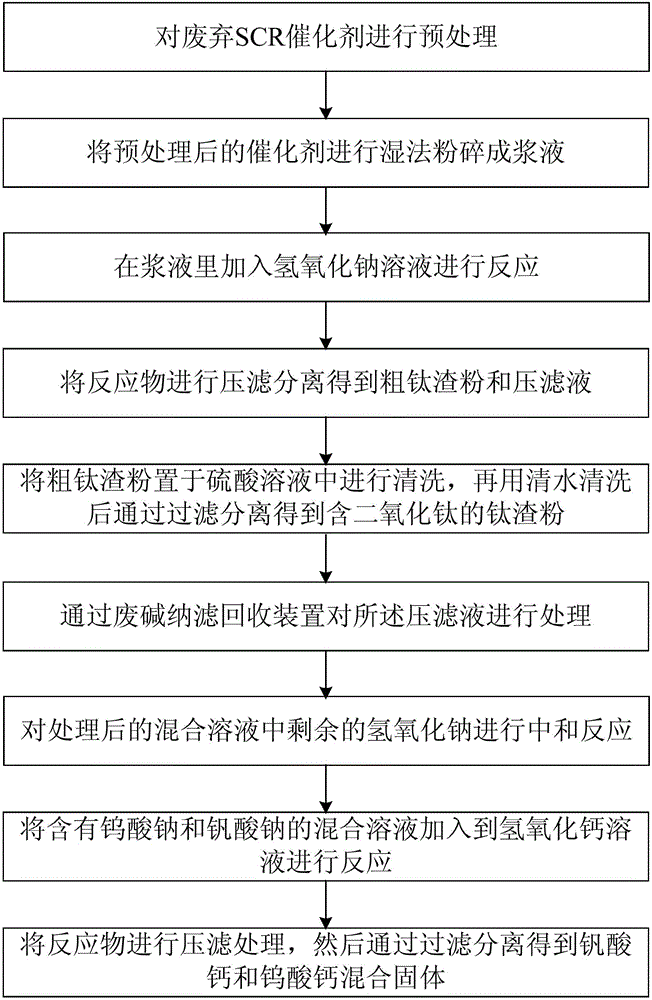

[0039] figure 1 It is the flow chart of the method for extracting titanium slag, tungsten and vanadium salt from waste SCR catalyst of the present invention. As shown in the figure, the method for extracting titanium slag, tungsten and vanadium salt from waste SCR catalyst of the present invention comprises:

[0040] 1) Pretreating the waste SCR catalyst to remove the adsorbed impurities;

[0041] 2) wet crushing the pretreated waste SCR catalyst into a slurry with a certain particle size, for example, a slurry with a particle size of 150-200 mesh;

[0042] 3) Add a sodium hydroxide solution with a mass percentage concentration of 20% to the slurry, and the mass ratio of the waste SCR catalyst to the sodium hydroxide solution is 5:1, and stir the reaction in a reaction kettle at a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com