Patents

Literature

266results about How to "Meet the requirements of cleaner production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

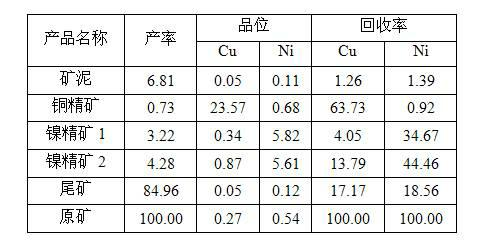

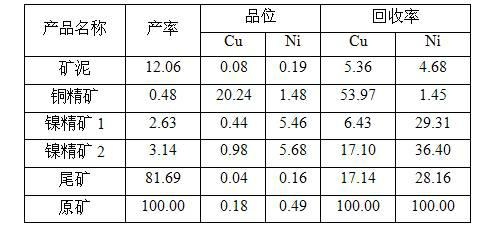

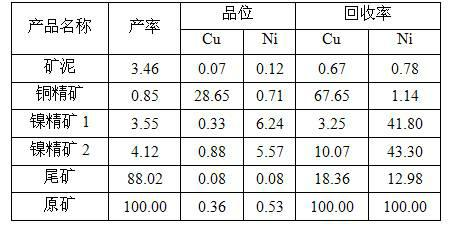

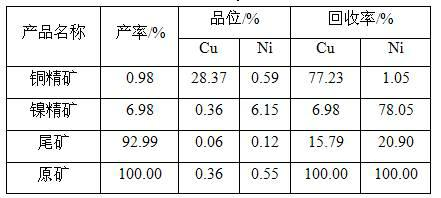

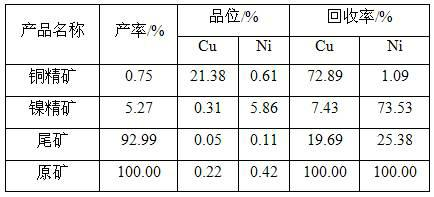

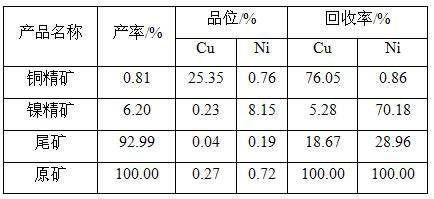

Benefication method for copper nickel

The invention relates to a benefication method for copper nickel. The benefication method for the copper nickel is characterized by comprising the following steps of: (1) finely grinding and desliming on raw copper nickel; (2) performing copper ore flotation on the deslimed raw ore; (3) performing copper concentration on mixed copper rough concentrate obtained in the step (2); (4) performing copper scavenging on copper middling ore I in the step (3); (5) regrinding the mixed copper nickel concentrate of copper and part of nickel in the step (3) and then performing copper nickel separation; (6) performing copper concentration on the copper rough concentrate in the step (5) and performing copper scavenging on the nickel rough concentrate in the step (5); (7) performing copper scavenging II on the nickel concentrate in the step (6); and (8) performing nickel roughing on the reground copper tailings in the step (4). In the benefication method for the copper nickel of the invention, the adaptability of a flotation separation process is high; complex low-grade particle-embedded copper and nickel minerals can be recycled; flotation separation of the copper and nickel minerals can be realized; and the quality and the recovery rate of copper and nickel concentrate are obviously improved.

Owner:西部矿业集团科技发展有限公司

Multifunctional aqueous adhesive and preparation method thereof

ActiveCN101058704AAvoid poisoningAvoid the chance of occupational diseasesMonocarboxylic acid ester polymer adhesivesNatural rubber adhesivesPolymer scienceAdjuvant

The invention discloses a multipurpose aqueous adhesive, which comprises the following parts: 10-35% thermoplastic rubber or emulsion, 0. 5-35% solvent, 28-45% emulsion, 20-80% viscosifying resin or its emulsion, 0. 5-5% functional adjuvant and 1-20% water. The making method comprises the following steps: putting the solvent into autoclave; stirring at middle speed and adding thermoplastic rubber and its modifying product until dissolving completely; or putting into copolymerized rubber emulsion directly; stirring to add the viscosifying resin or the viscosifying resin in the invention; blending evenly; adding emulsion; fetching the sample to test the viscosity; adding fitful quantity of water and corresponding functional adjuvant according to the purpose and viscosity; dispersing at high speed until even condition; cooling; filtering; packing; obtaining the product for shoe-making, hand pocket and decorative aspect with low cost.

Owner:林润强

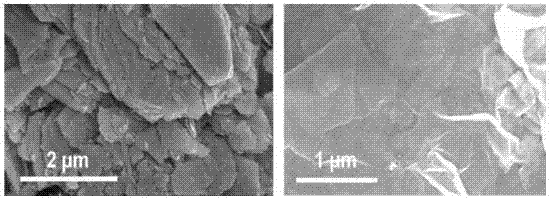

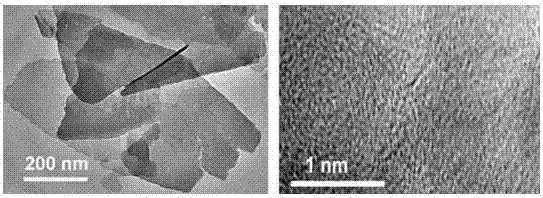

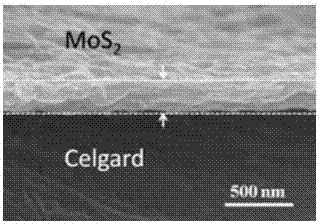

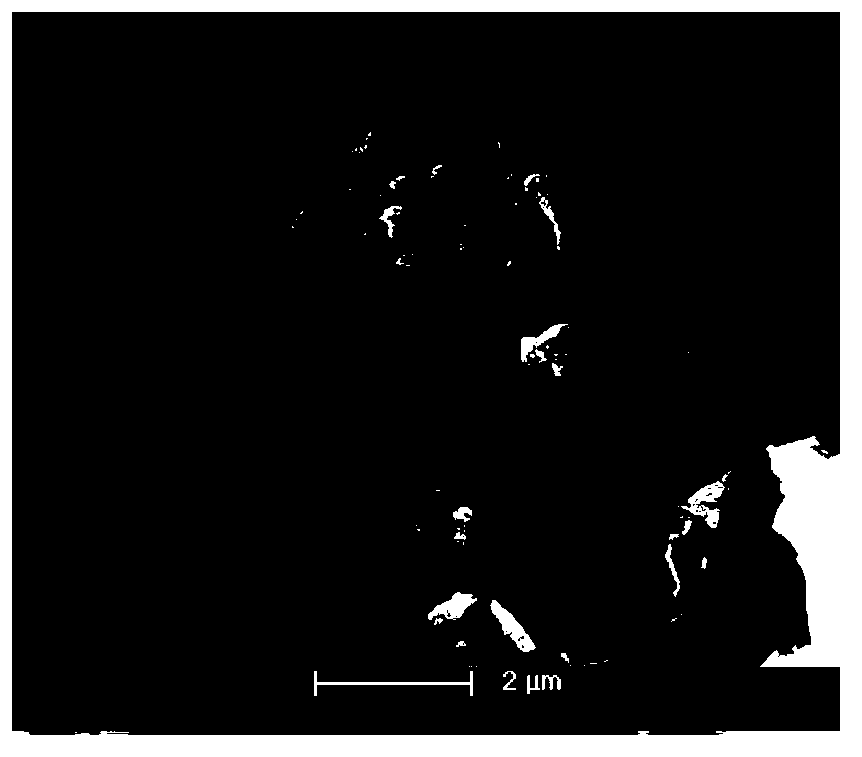

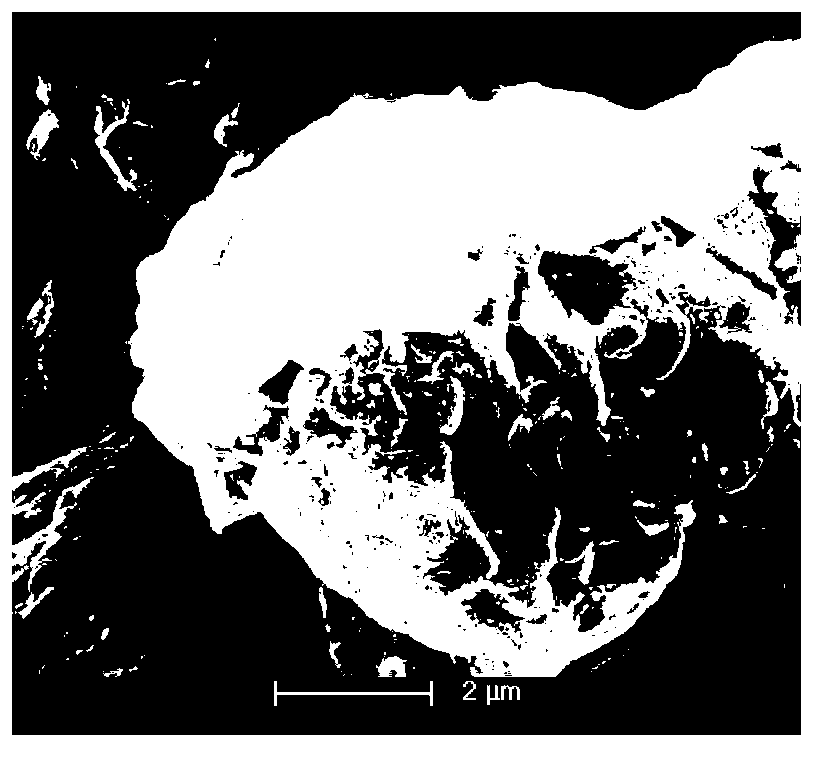

Molybdenum disulfide diaphragm of lithium-sulfur battery and preparation method therefor

InactiveCN107068944AImprove cycle lifeDoes not constitute pollutionLi-accumulatorsCell component detailsFiltrationSpectroscopy

The invention discloses a molybdenum disulfide diaphragm of a lithium-sulfur battery and a preparation method therefor, belonging to the field of lithium-sulfur batteries. According to the molybdenum disulfide diaphragm of the lithium-sulfur battery, the molybdenum disulfide diaphragm has high lithium conductivity, and is capable of inhibiting the migration of polysulfides between a positive electrode and a negative electrode so as to improve a cycle life of the lithium-sulfur battery. In addition, the high-temperature resistance of molybdenum disulfide is used to improve the overall temperature resistance of the diaphragm; a vacuum filtration method is used to deposit a molybdenum disulfide nanosheet on the surface layer of the lithium-sulfur battery diaphragm; and a relative position of pore size of a funnel on the surface of the molybdenum disulfide diaphragm is relatively small in thickness under the vacuum filtration condition, so that good air permeability can be achieved, and battery capacity is not affected. The MoS2 / Celgard prepared is applied to the lithium-sulfur battery; an electrochemical impedance spectroscopy result shows that the lithium ion conductivity of the MoS2 / Celgard diaphragm is about 2.0*10<-1> mS.cm<-1>, thereby substantially prolonging the cycle life of the lithium-sulfur battery. The whole preparation method is short in process flows, the conditions are simple, the cost is low, and no pollution is caused to the environment, so that a requirement of cleaner production can be achieved.

Owner:NORTHWEST NORMAL UNIVERSITY

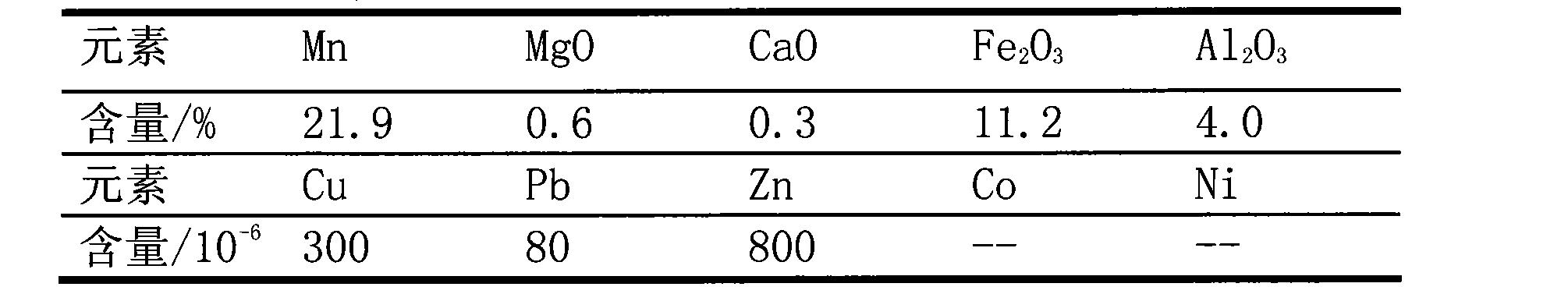

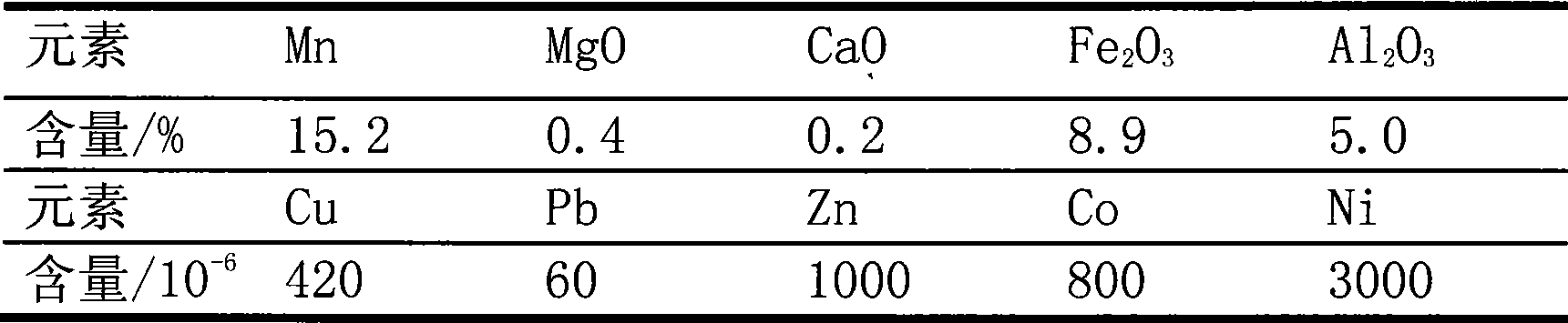

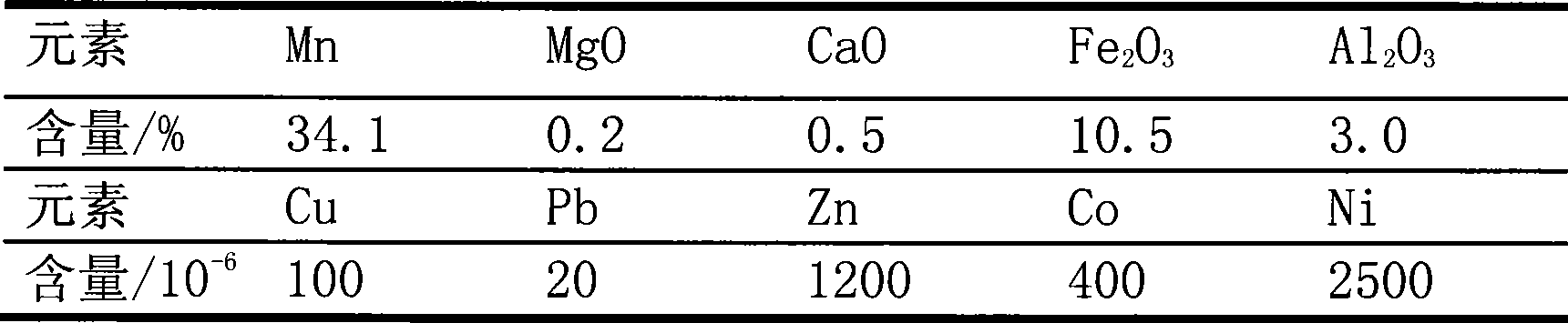

Method for preparing manganese sulfate by biomass self-heating reduction of low grade manganese oxide ore

InactiveCN101439878AAchieving zero emissionsLow reduction temperatureEnergy inputManganese sulfatesManganese oxideCoal

The invention discloses a method for preparing manganese sulfate through the biomass self heating reduction of low-grade manganese oxide ore. The method comprises the following steps: 1) respectively crushing the low-grade manganese oxide ore and biomass material; 2) weighing the low-grade manganese oxide ore, the biomass material and an initiating additive according to the weight ratio of 100:10-30: 0.5-3; 3) mixing evenly and roasting the low-grade manganese oxide ore, the biomass material and the initiating additive; 4) leaching the roasted mass through dilute sulfuric acid at a temperature of between 40 and 80 DEG C, regulating the mixed liquor to make the pH value more than or equal to 6, carrying out solid-liquid separation, and keeping the obtained filtrate for standby; and 5) removing impurities from the filtrate to obtain the manganese sulfate solution. The method adopts renewable energy source of the biomass material to replace coal to reduce the manganese oxide ore and prepare manganese sulfate which can be the raw material for producing electrolytic manganese. The leaching efficiency of manganese can reach more than 95 percent. The method not only saves energy sources, but also reduces the production cost.

Owner:李学军 +2

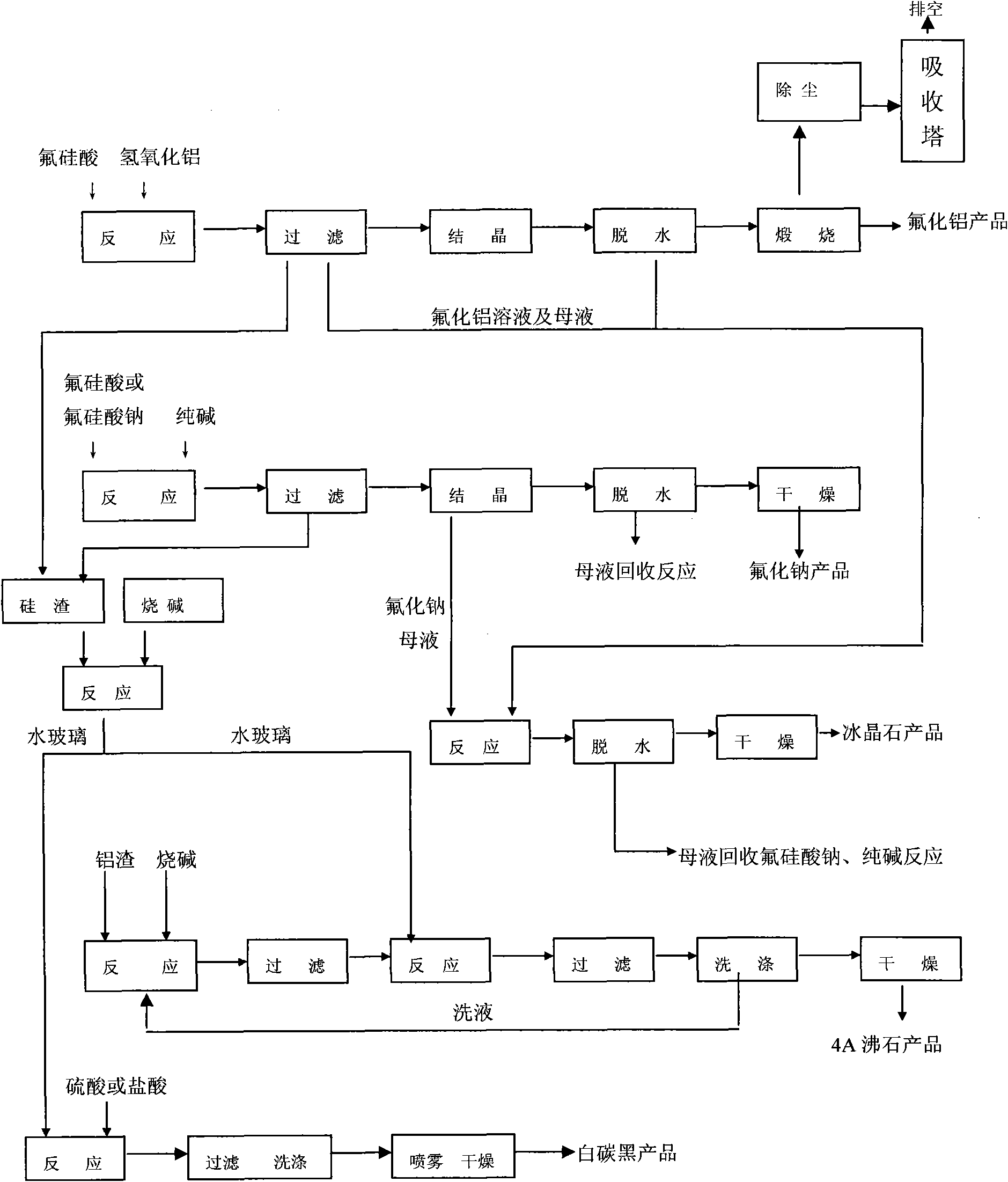

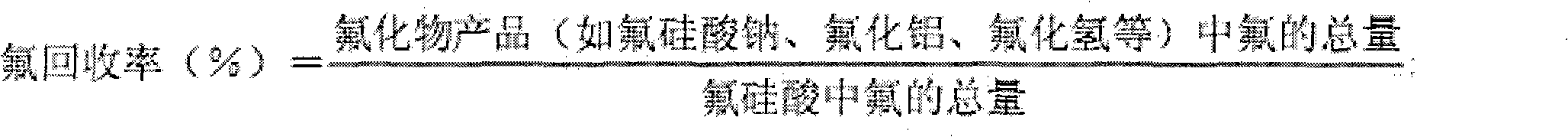

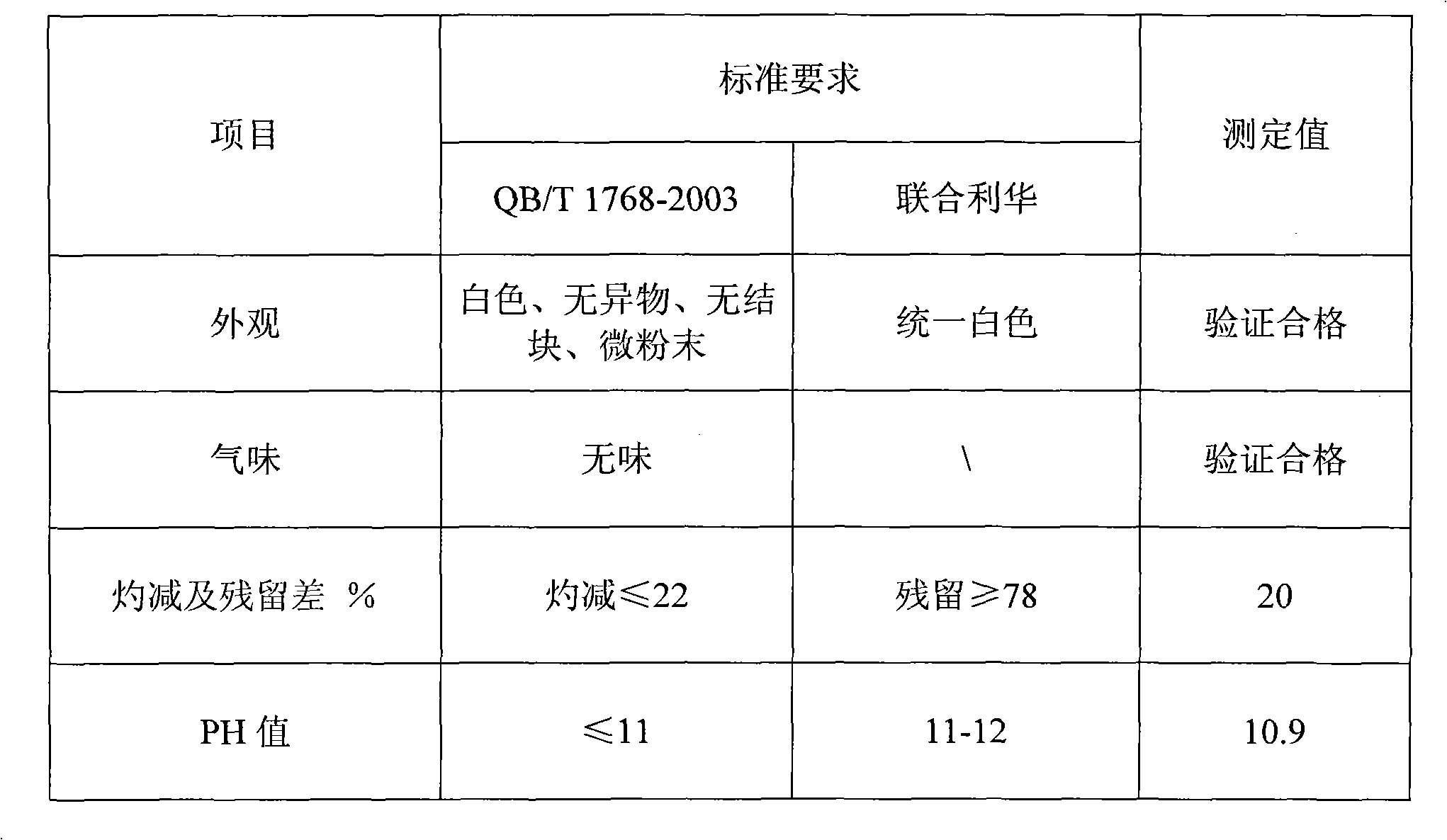

Process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid

ActiveCN101913637AHigh recovery rateTake advantage ofSilicaAlkali metal silicatesChemical industrySlag

The invention discloses a process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid. The process method comprises the following steps of: preparing fluosilicic acid as a phosphorus chemical by-product into an anhydrous aluminum fluoride product, a sodium fluoride product and a cryolite product, and combining with other industrial waste silicon slags and aluminum slags to prepare a 4A zeolite product. The process method comprehensively utilizes the fluosilicic acid and has high resource recovery rate, wherein the recovery rate of the fluorine element reaches higher than 90 percent. Waste silicon dioxide slags generated in the process can be recycled to produce white carbon black and the 4A zeolite, and a mother liquor, a cleaning solution and waste gas which are generated in the production process are all recycled, thereby the environmental pollution is reduced, and the purposes of zero emission and no pollution are truly achieved, thus the method completely meets the requirement for clean production. The invention has the advantages of advanced production process, good product quality and high value, wherein the fluorine content of the aluminum fluoride is high and between 63-65 percent; the quality index of the obtained white carbon black meets the requirement on the standard of the chemical industry; and the quality of the 4A zeolite product meets the requirements on the national standard and the standard of European and American developed countries.

Owner:四川励志环保科技有限公司

Beneficiation method for copper nickel sulfide ore

The invention relates to a beneficiation method for copper nickel sulfide ore. The beneficiation method is characterized in that a beneficiation process of the method comprises the following steps of: grinding crude copper nickel ore; preferably floating copper mineral from the ground crude ore; performing copper selection on the obtained rough copper concentrate I for five times to obtain copperconcentrate and five selected copper middlings; performing copper scavenging on copper tailing I twice to obtain copper tailing II and two scavenged copper middlings; performing rough selection of nickel mineral on the obtained copper tailing II to obtain rough nickel concentrate and nickel tailing I; performing nickel selection on the obtained rough nickel concentrate for three times to obtain the nickel concentrate and three selected nickel middlings; performing nickel scavenging on the obtained nickel tailing I twice to obtain the nickel tailing and two scavenged nickel middlings; and sequentially returning the two scavenged nickel middlings to the previous layer respectively. By the method, the copper and the nickel have high adaptability to the sequential preferred floatation and separation process, so that the copper and nickel mineral embedded into complex low-grade fine particles can be recovered, the preferred floatation and separation of the copper and nickel mineral can be realized, the quality and the recovery rate of the copper and nickel concentrate are obviously improved, and the method is simple in operation and high in controllability, and has strong adaptability to the ore.

Owner:西部矿业集团科技发展有限公司

Novel sea-island fiber synthetic leather base cloth and production technology thereof

ActiveCN108589028ASolve pollutionNo emissionsConjugated synthetic polymer artificial filamentsNon-woven fabricsPolyethylene terephthalate glycolDecomposition

The invention discloses novel sea-island fiber synthetic leather base cloth. The novel sea-island fiber synthetic leather base cloth is a net which is prepared from water-soluble sea-island fibers byneedle punching and is of a three-dimensional network structure; a sea-island fiber needle-punched fabric layer is prepared from the sea-island fibers with water-soluble PVA (polyvinyl acetate) as a marine component and a PA (polyamide) or PET (polyethylene terephthalate) material as an island phase component by lapping and needle punching, wherein the island phase component accounts for 60%-85% of a fiber section area, the marine component accounts for 40%-15% of the fiber section area, denier of the sea-island fibers is 1.6-14 dtex, breaking strength is 3-6 cN / dtex, elongation at break is 7%-10%, single fiber denier of the island phase component is 0.8 dtex or lower, PVA is water-soluble PVA mater batch, and the melting point is 180-190 DEG C; the melting range is 175-195 DEG C, and thethermal decomposition temperature is 210-220 DEG C. The invention further discloses a production technology of the base cloth. The problem of pollution caused by the fact that complex fibers are treated and prepared from traditional PVA chips by adopting an organic solvent is solved, and the purpose of composite melt spinning with island phase resin is achieved.

Owner:浙江泓泰德建新纤维有限公司

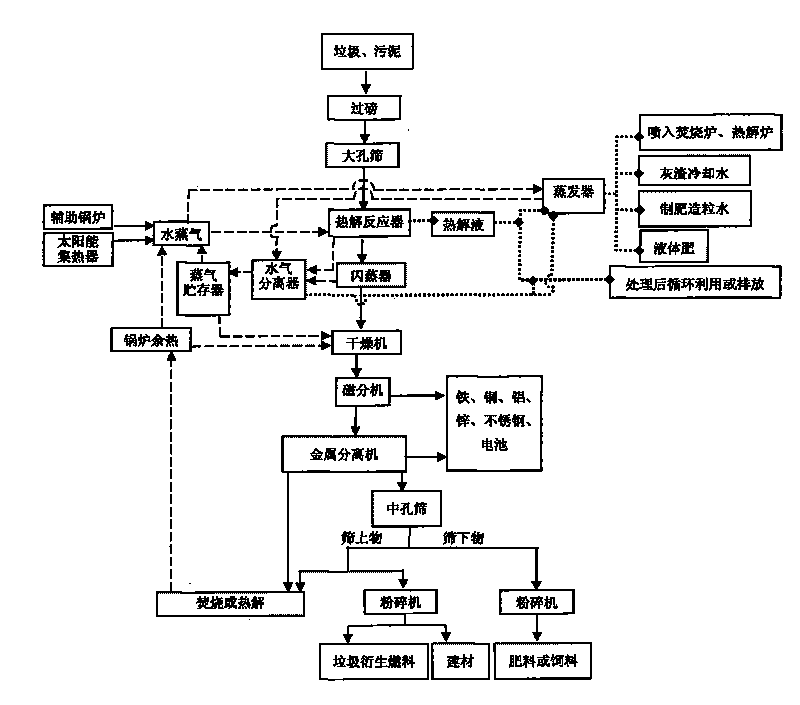

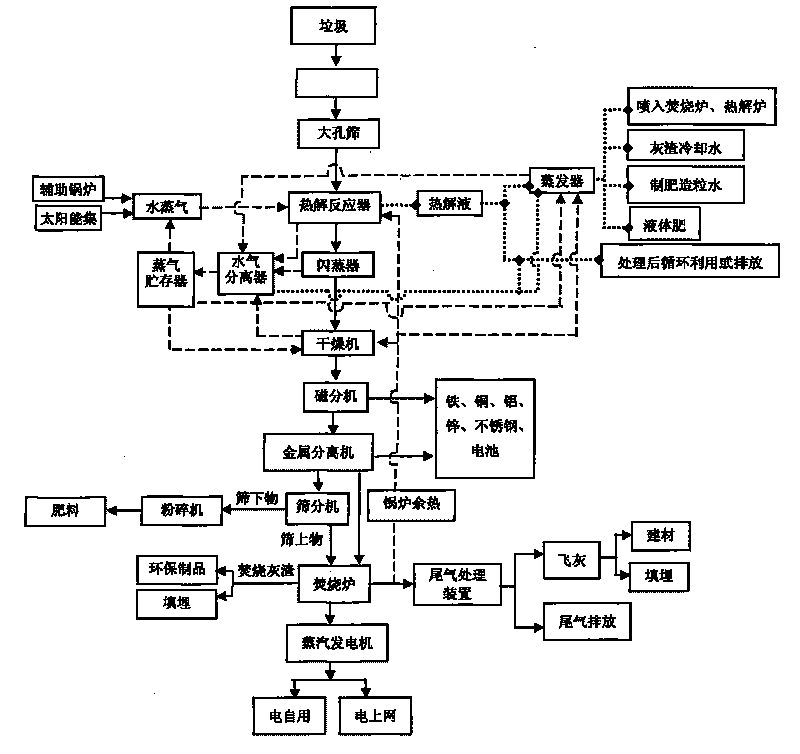

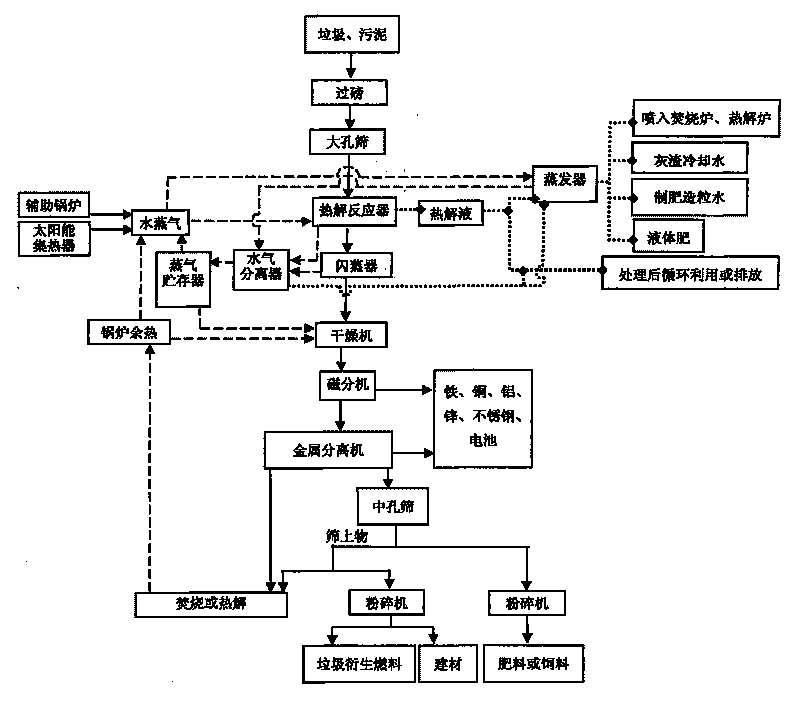

Garbage and sludge high pressure themolysis processing method, system and application thereof

ActiveCN101758059AReduce moisture contentReduce the chance of occurrenceSolid waste disposalSludge treatment by pyrolysisDecompositionSludge

The invention discloses a garbage and sludge high pressure themolysis processing method, system and application thereof. The invention carries out themolysis reaction for 5min-1.5h under the conditions of 8-80atm and 150-320 DEG C and three times of dehydration drying, not only heat value of garbage and sludge is greatly improved, dehydration, benzene removing, dechloridation, deodorization, disinfection, sterilization, volume reduction, bag breaking and degradation decomposition are carried out on garbage and / or sludge and percolation liquid is treated, and clean energy and recycled self-circulation heat are taken as heat supply energy source, energy consumption is reduced; but also method in material is rejected, so as to reduce the production probability of dioxin in garbage incineration smoke. The invention realizes garbage and sludge comprehensive reclamation, including power supply, heat supply, production of multiple organic compound fertilizers and environmentally friendly building materials and direct recovery of metal, battery and plastic. The invention can realize preparation of garbage and sludge organic compound fertilizer and feed, pre-treatment of garbage incineration generating and pre-treatment of garbage themolysis generating and has the characteristics of environmental protection, energy conservation and wide application range.

Owner:SOUTH CHINA AGRI UNIV

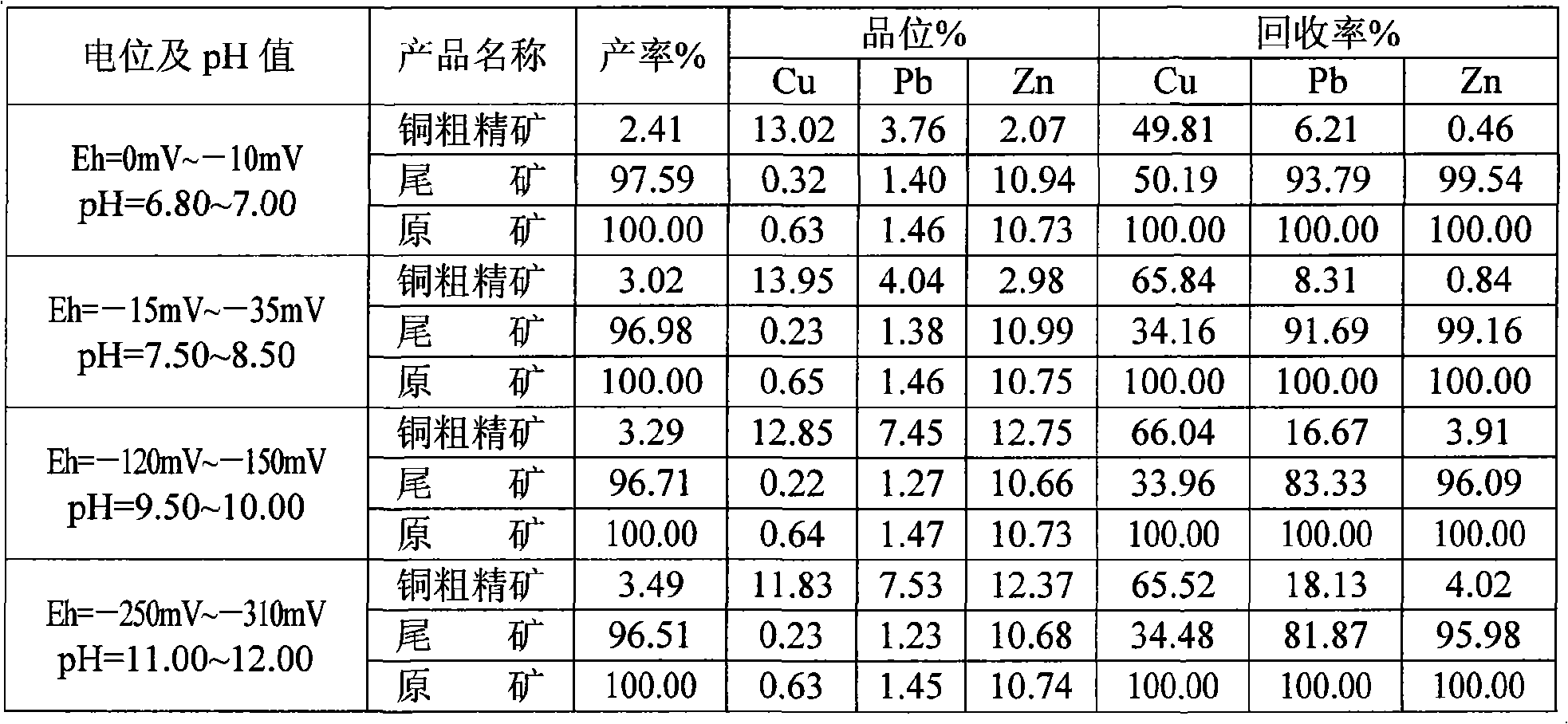

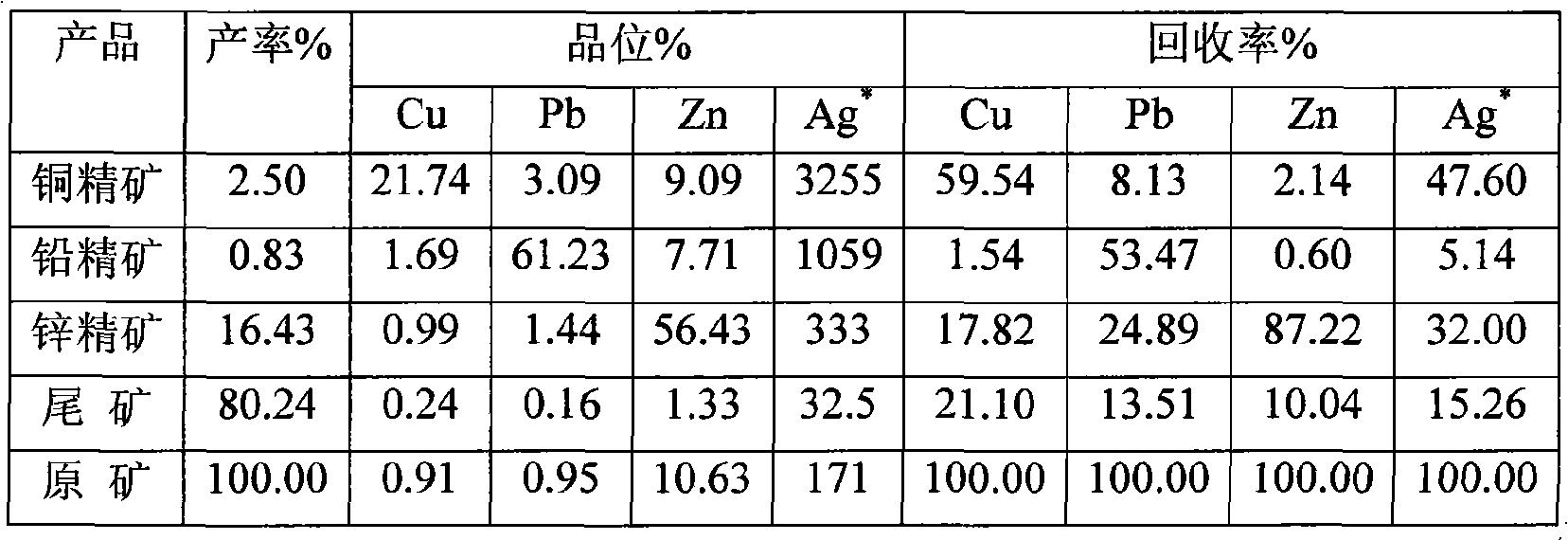

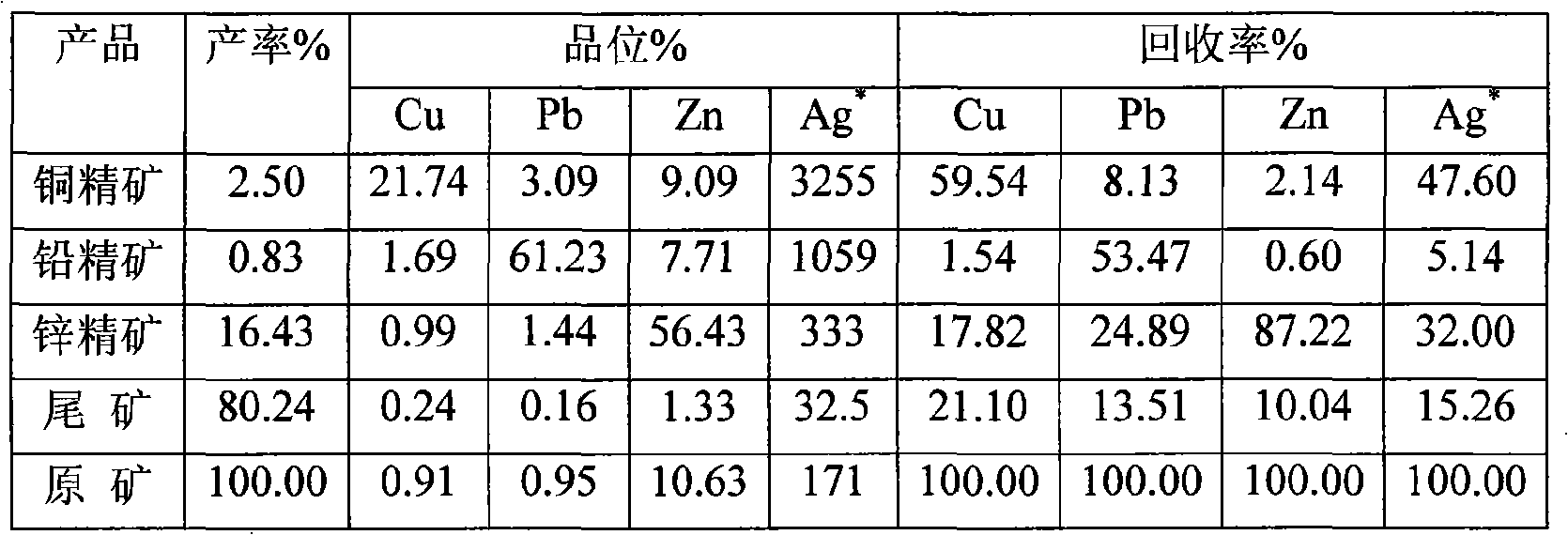

Electric potential regulating and controling differential flotation process for copper-plumbum-zinc vulcanizing mine

InactiveCN101402071AAdaptableAvoid defects that are difficult to grasp with precisionMultistage water/sewage treatmentFlotationSlurryCopper

The invention relates to an ore dressing technology for separating copper, lead and zinc in complex polymetallic sulphide ores, in particular to an electric potential modulation and preferential flotation process for copper-lead-zinc sulphide ores, which comprises the steps of copper, lead and zinc selection; copper is preferentially floated; the electric potential Eh of an ore slurry is between 35 below zero and 15 below zero mV; the PH value of the ore slurry is between 7.50 and 8.50; LP-01 is used as a collecting agent; and YN and ZnSO4 are used as inhibitors. The process has the advantages of solving the problems that the prior flotation process has large difficulty in separating the copper and lead and the copper and zinc, poor quality of concentrated ore and higher cost.

Owner:罗仙平

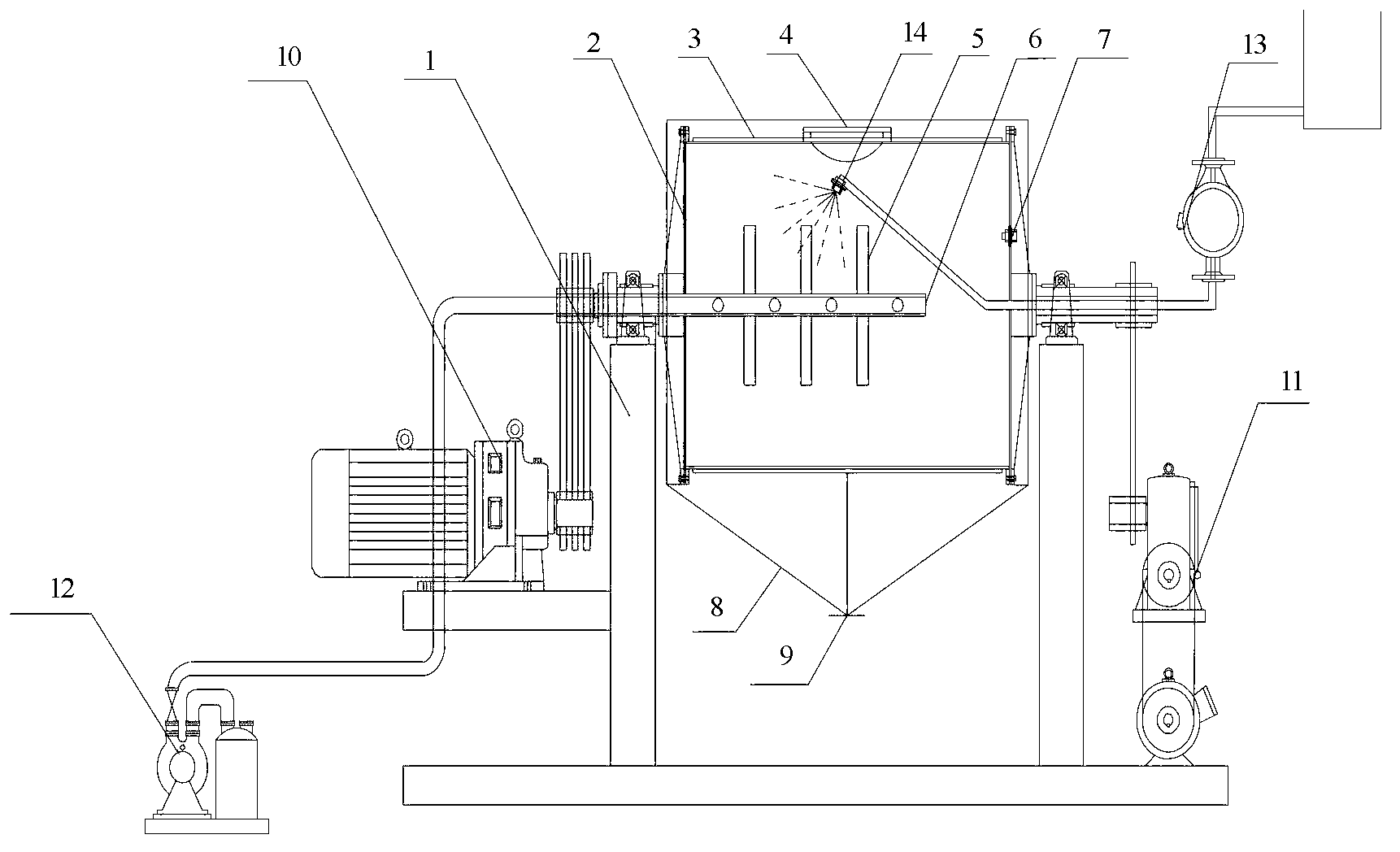

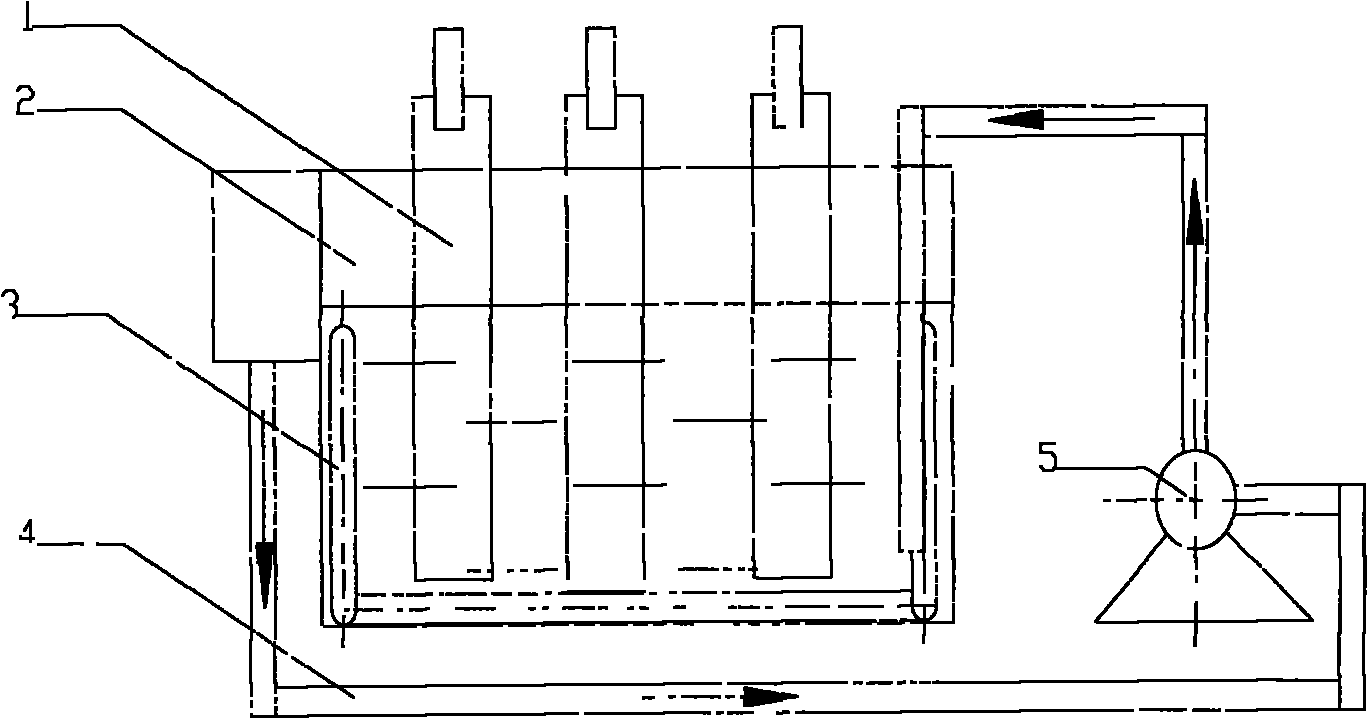

Mechanochemical preparation method and equipment of magnetic water treatment agent

ActiveCN102795698AWell mixedRealize continuous dosingRotating receptacle mixersTransportation and packagingEngineeringCore shell

The invention discloses a mechanochemical preparation method and equipment of a magnetic water treatment agent. The preparation method comprises the following steps of: (1) adding magnetic powder and a ball milling medium in a mass ratio of 1: (2-4) to the cylinder of horizontal double-screw stirring mixing equipment, vacuumizing the inner space of the cylinder, driving a horizontally arranged rotating shaft to drive the cylinder into rotation, and performing stirring type ball milling through an internal-rotation stirring stick arranged in the cylinder in opposition to the rotation direction of the cylinder; (2) spraying an atomized modifier into the cylinder through the cavity of the rotating shaft in the ball milling process, wherein the quantity of addition of the modifier is 20-50% of the weight of the magnetic powder; and (3) carrying out stirring type ball milling reaction of the materials under the condition of 50-80 DEG C for 1.5-4 hours, thereby obtaining the magnetic water treatment agent. The mechanochemical preparation method is the mechanochemical method which is simple in preparation process, low in energy consumption and high in efficiency; and the product prepared has a core-shell structure, and is high in surface activity and excellent in magnetic responsiveness.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

Preparation method of imino disuccinate chelator

InactiveCN104447370AMild reaction conditionsHigh reaction yieldOrganic compound preparationAmino-carboxyl compound preparationReaction temperatureAlkaline hydrolysis

The invention discloses a preparation method of an imino disuccinate chelator. The reaction raw materials comprise a raw material A, a raw material B, alkali metal hydroxide and water, and the pH value of the reaction system is 6-12. The preparation method comprises the following steps: reacting at 65 DEG C under normal pressure until the raw materials are boiled to the reflux temperature; and after the reaction finishes, obtaining a mixed solution containing the imino disuccinate chelator, wherein the raw material A is a butene diacid radical compound prepared by alkaline hydrolysis, and the raw material B is an aspartate radical compound prepared by alkaline hydrolysis. The preparation method has the advantages of mild reaction conditions, short reaction time and high reaction yield, shortens the production process, enhances the production efficiency, lowers the production cost, and is an efficient and environment-friendly preparation method which is very suitable for industrialized mass production.

Owner:HEBEI XIETONG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing V2O5-WO3/TiO2 powder for making denitration catalyst

ActiveCN102921403AReduce dosageReduce ammonia nitrogen contentDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSlurryAmmonia

The invention discloses a V2O5-WO3 / TiO2powder for making a denitration catalyst, which comprises the following steps of: 1) making metatitanic acid into pulp at a concentration of 280 to 320g / L based on TiO2, heating the pulp to 60 DEG C, regulating the pH value to 5.0 with caustic soda, regulating the pH value to 5.5 to 5.7 with ammonia water, and filtering the pulp by pressure and washing the filter cake by water; 2) preparing an impregnation solution; 3) making the filter cake made by the step 1) into pulp at a concentration of 280 to 320g / L based on TiO2, heating to 60 DEG C, adding the pulp into the impregnation solution obtained by the step 2), stirring the mixture for 2 to 4 hours, and filtering the solution by pressure; 4) calcining the filter cake obtained by the step 3) at 400 to 550 DEG C for 2 to 5h; and 5) crushing the calcined material obtained by the step 4).

Owner:LOMON BILLIONS GRP CO LTD

PET/PVA sea-island fiber with water-soluble sea facies, and production process of PET/PVA sea-island fiber

ActiveCN108486683AEnables thermoplastic processingNo emissionsFilament/thread formingConjugated synthetic polymer artificial filamentsPolyolSpinning

The invention discloses a PET / PVA sea-island fiber with water-soluble sea facies. The PET / PVA sea-island fiber with the water-soluble sea facies is obtained through stretching and heat setting a nascent fiber formed by adopting PET as an island face component and PVA as a sea face component, wherein the island face component of the nascent fiber accounts for 60 percent to 85 percent of the cross section area of the fiber; the sea component accounts for 40 percent to 15 percent of the cross section area of the fiber; water-soluble PVA master batch is prepared by blending the following raw materials in parts by weight: 50 to 70 parts of polyvinyl alcohol, 15 to 25 parts of polyhydric alcohol or salt compound modifier, 3 to 7 parts of an antioxidant, 3 to 7 parts of a lubricating agent, and 25 to 35 parts of deionized water. The invention also provides a production process of the sea-island fiber. Compared with traditional PVA, according to the PET / PVA sea-island fiber with the water-soluble sea facies, provided by the invention, the melting point is reduced, so that the PVA sea component can be melt and compositely spun with the PET with a high melting point, the problem of PVA decomposition cannot happen while the melting point is reached, and the problem that the traditional PVA is decomposed when encountering the high-temperature PET so that melting and composite spinning cannot be achieved is solved.

Owner:浙江泓泰德建新纤维有限公司

Method for producing purified high-whiteness quartz sand and silica micropowder from quartz sand tailings

The invention discloses a method for producing purified high-whiteness quartz sand and silica micropowder from quartz sand tailings. According to the method, mud-sand separation, acid leaching, oxidation alkali washing, drying and screening are carried out so as to produce purified high-whiteness quartz sand from quartz sand tailings; a product which is still unqualified after purification is subjected to grinding and grading to produce silica micropowder; so full utilization of resources is realized. According to detection results, after purification, the indexes of the quartz sand tailings are that SiO2 is 99.2 to 99.5% and Fe2O3 is 0.002 to 0.012%, and whiteness is improved by more than 11%. The high-whiteness quartz sand can replace high-grade konilite and be used in industries like alkali-free electronic glass fibers, high-grade ceramic glazes, silica micropowder, vacuum glass tubes, high-whiteness glass and high-grade sodium metasilicate.

Owner:临沂晟泉矿业有限公司

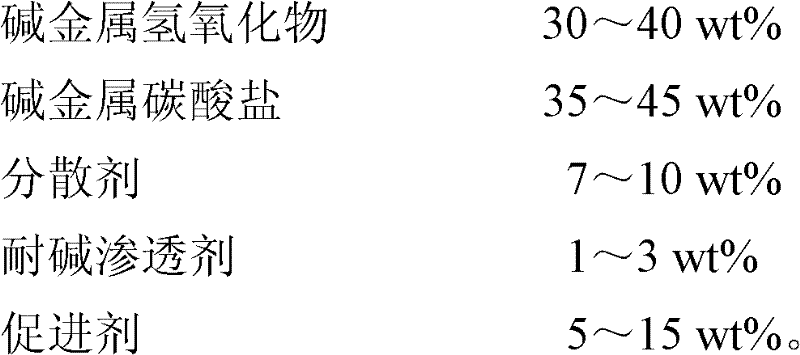

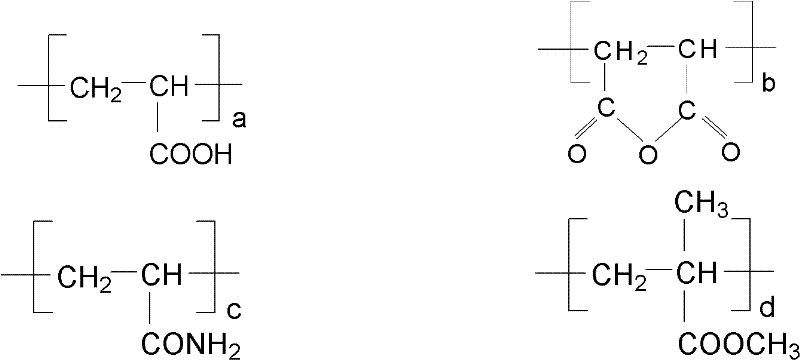

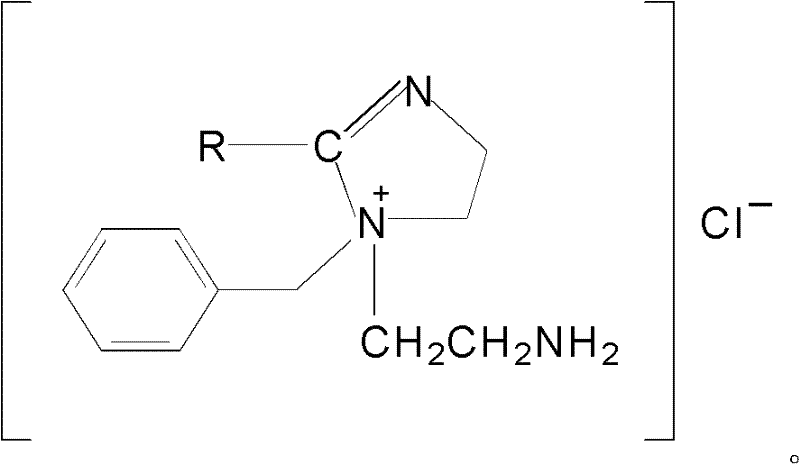

Color fixing substitution alkali for low-salt dyeing by using reactive dye pad steaming process

The invention relates to color fixing substitution alkali for low-salt dyeing by using a reactive dye pad steaming process, and the color fixing substitution alkali can be applied to low-salt color-fixing treatment on a cotton fabric dyed with a reactive dye. The color fixing substitution alkali is an organic / inorganic composite buffer system consisting of alkali metal hydroxide, alkali carbonate, a dispersing agent, an alkali-resistant penetrating agent and an accelerating agent. The traditional color-fixing alkali agent for the reactive dye is replaced and low-salt dyeing is realized under the condition of not changing the traditional technological equipment and flow. The color-fixing substitution alkali agent has the characteristics of low consumption, favorable stability, convenience for operation, and the like, meanwhile, is beneficial to reduction of production cost and environment pollution, has little influence on the equipment and meets the requirements on energy saving, emission reduction and efficiency increase.

Owner:FUJIAN QINGYUAN TECH

Aromatic hydrocarbon-free environment-protection chloroprene rubber adhesive with high adhesive strength

InactiveCN101177599AHigh bonding strengthWide range of usesMineral oil hydrocarbon copolymer adhesivesConjugated diene hydrocarbon adhesivesThermoplasticMethyl carbonate

The invention discloses aromatic hydrocarbon-free neoprene adhesive with high adhesive strength, which is characterized in that graft adhesive is firstly prepared according to the following formula: 10 percent-40 percent of methyl cyclohexane, 5 percent -30 percent of ethyl acetate, 0 percent-10 percent of butanone, 5 percent -30 percent of dimethyl carbonate, 8 percent-15 percent of chlorobutadiene rubber, 0 percent-2.5percent of SBS (thermoplastic styrene-butadiene rubber), 7 percent-15 percent of MMA (methyl methacrylate), 0.1percent-0.2 percent of initiator and 0.1 percent-0.5percent of antioxidant; then the invention is prepared by 100 portions of the graft adhesive prepared according to the formula, 0-10 portions of tackifying resin, 0-3 portions of strengthening agent , 0-3 portions of plasticizers and 0-20 portions of diluents. The product of the invention has the advantages of environmental protection, and high adhesive strength, etc.

Owner:GOOD CHEM SCI & TECH

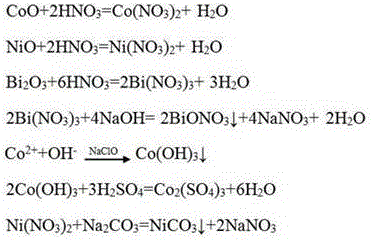

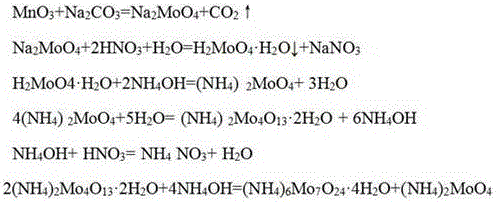

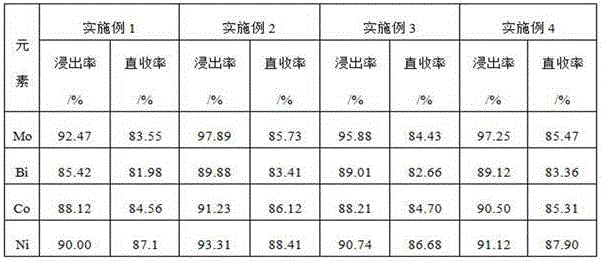

Technology for recycling molybdenum, bismuth, cobalt and nickel from dead catalyst

InactiveCN106222418ATo achieve the purpose of turning harm into profitEasy to separateProcess efficiency improvementCobaltPetroleum

The invention discloses a technology for recycling molybdenum, bismuth, cobalt and nickel from a dead catalyst and belongs to the technical field of dead catalyst recycling and comprehensive utilization in the petroleum industry. According to the technology for recycling the molybdenum, the bismuth, the cobalt and the nickel from the dead catalyst, the molybdenum in the dead catalyst is dissolved in a solution through alkaline leaching, and then the molybdenum is separated from the solution through molybdenic acid precipitation, tetramolybdate conversion and ammonia neutralization; and acid leaching, hydrolyzing bismuth precipitation, oxidizing cobalt precipitation and sodium carbonate nickel precipitation are conducted on alkaline leaching residues containing the bismuth, the cobalt and the nickel, so that separation of the bismuth, the cobalt and the nickel is achieved. By the adoption of the technology for recycling the molybdenum, the bismuth, the cobalt and the nickel from the dead catalyst, the molybdenum, the bismuth, the cobalt and the nickel in the dead catalyst are recycled at the same time, the separation effect on the metals is good, and the leaching rate and the direct recovery rate both reach over 80%; and valuable metals in the dead catalyst are recycled in a product manner, the environment pollution caused by long-term piling storage of the dead catalyst or in the selling transport process of the dead catalyst in the petroleum industry is eliminated, and the cleaner production requirement is met.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Water-soluble spraying glue and method for preparing same

InactiveCN101333424AGood adhesionFast dryingAcid polymer adhesivesChloroprene adhesivesPolymer scienceAdhesive

The invention discloses waterborne spray gel which is characterized in that the waterborne spray gel contains(based on weight portion) 100-150portions of waterborne neoprene latex, 20-60 portions of acrylic latex, 60-100 portions of waterborne tackifying resin, and 5-20 portions of waterborne dope drier. The preparation method includes the following steps: firstly, putting the materials of 100-150portions of waterborne neoprene latex, 20-60 portions of acrylic latex and 60-100 portions of waterborne tackifying resin into a reactor, mixing and blending to be even; putting the waterborne dope drier into the reactor, blending to be even, then cooling and discharging. The adhesive prepared can be used for spraying and splicing furniture such as sofas, folding screens and swivel chairs, for splicing inside automobiles and for splicing foams; the waterborne spray gel has the advantages of excellent adhesive property, good heat resisting property and low VOC content and is flame-retardant, anti-corrosion, waterborne and environment-friendly; the waterborne spray gel can effectively protect the work environment and greatly reduce the accidents of poisoning caused by solvent spray gel products and industrial diseases; therefore, the waterborne spray gel is an ideal substitute for part of current solvent spray gel.

Owner:林润强

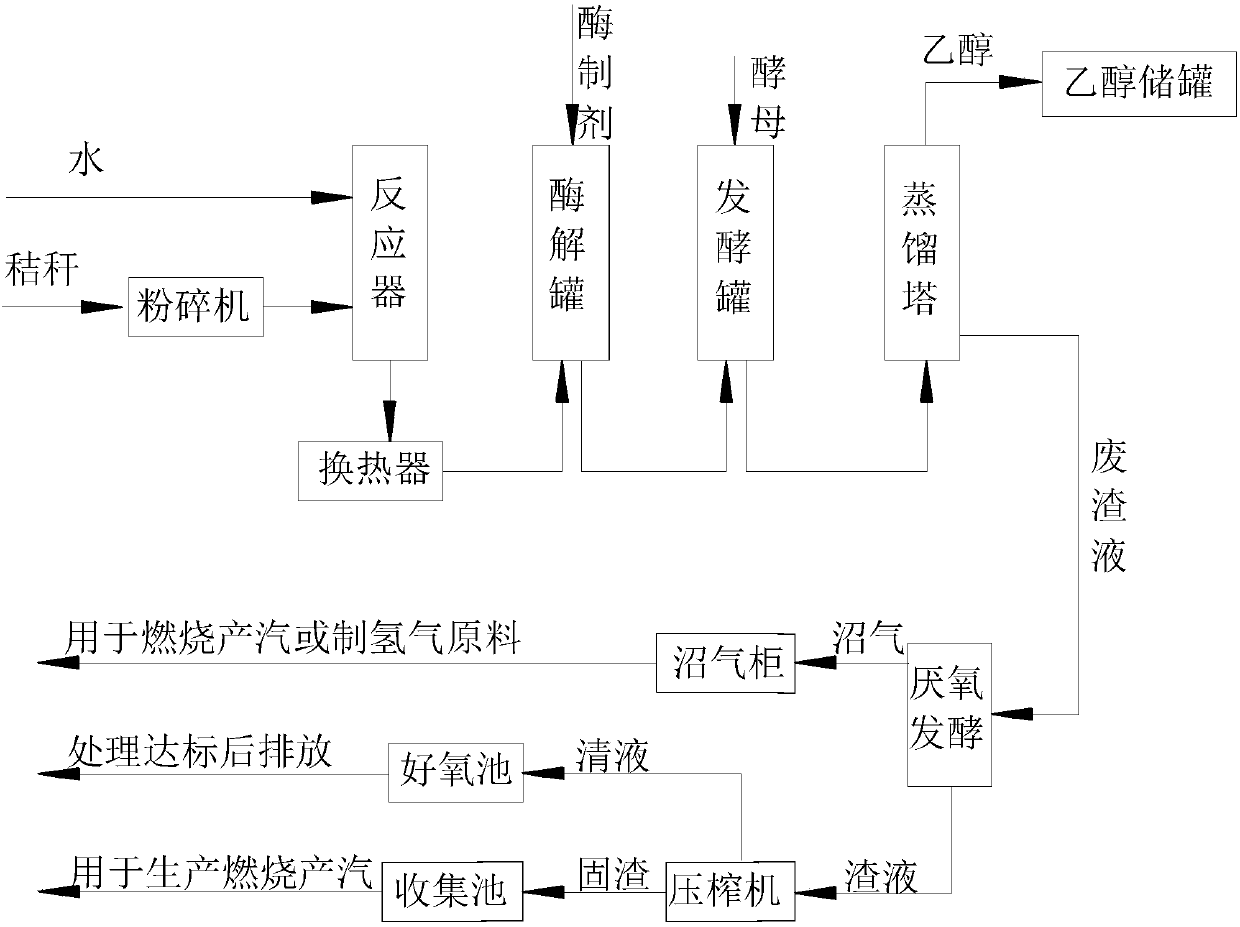

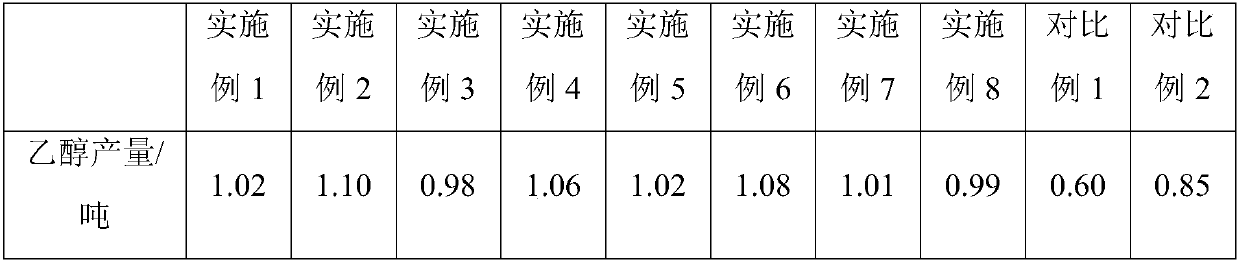

Method for industrially producing ethyl alcohol through crop straw

The invention discloses a method for industrially producing ethyl alcohol through crop straw. The method includes the following steps of pulverizing the crop straw, adding the pulverized crop straw and water into a preprocessing reactor in proportion to be preprocessed, guiding the materials into an enzymolysis tank, conducting cooling, adjusting the pH, adding an enzyme preparation for enzymolysis, guiding the materials into a fermentation tank, adding yeast for ethyl alcohol fermentation production, guiding the materials into a distilling device to be distilled to obtain ethyl alcohol and waste slag liquid, inoculating high-temperature activated sludge to the waste slag liquid for anaerobic fermentation to obtain biogas and digestive slag liquid, making the biogas combusted to generate vapor or used as a production raw material and supplied outward to an urban gas pipe network, squeezing the digestive slag liquid to obtain clear liquid and solid slag, discharging the clear liquid after the clear liquid is processed to reach the standard, combusting the solid slag to generate vapor, and reusing the vapor in the steps of the method. The whole method is advanced in process, high inethyl alcohol yield, sufficient in raw material utilization, low in cost and suitable for industrial production.

Owner:ZHONGRONG TECH CORP LTD

Comprehensive utilization method of acidic and alkaline waste etching solution

InactiveCN101654275ALarge amount of processingMeet the requirements of cleaner productionPhotography auxillary processesCopper oxides/halidesEtchingEconomic benefits

The invention provides a comprehensive treatment method of acidic and alkaline waste etching solution of circuit boards, belonging to the technology in the field of environmental protection. The method is characterized by neutralizing and precipitating the acidic waste etching solution and the alkaline waste etching solution under the condition that the pH value is 5-6.5, pulping and then mixing the precipitates and quicklime, dehydrating and then roasting the mixtures at 400-600 DEG C, dissolving calcium chloride in the roasted product by water, separating and removing the residual lime by gravity separating to obtain the copper oxide products with purity being over 98%, or taking the generated copper oxide as the raw material to produce other products. The calcium chloride and ammonia generated in the process are also subjected to concentration, crystallization, ammonia evaporation and absorption to obtain the calcium chloride and ammonia products. The comprehensive treatment methodhas the advantages of total recycle, zero discharge, large treatment capacity, low treatment cost, high product quality, diverse product categories and the like, can not only eliminate environmental pollution radically but also create higher economic benefits.

Owner:广州市白云区南溪化工厂

Production method for crystalline tagatose

InactiveCN102876752AHigh purityCompletely hydrolyzedSugar derivativesSugar derivatives preparationPhosphoric acidChemistry

The invention belongs to the biological and chemical engineering fields, and particularly discloses a production method for crystalline tagatose. The method comprises the following steps: using lactose as a raw material; dissolving the lactose; hydrolyzing by acidic lactase; leaching and separating by a simulated moving bed; enabling the content of tagatose to reach up to 75% by only using calcium oxide as an isomerizing agent and phosphoric acid or CO2 as neutralization acid; and finally separating, evaporating and crystallizing the tagatose by the simulated moving bed. According to the production method for the crystalline tagatose, the condition of separating and the optimal condition of crystallizing by the simulated moving bed are determined; the purity of the obtained product reaches more than 98.5%, and the yield is over 40; and the cost and pollution are low, and the method meets the condition of industrialization production.

Owner:山东绿健生物技术有限公司

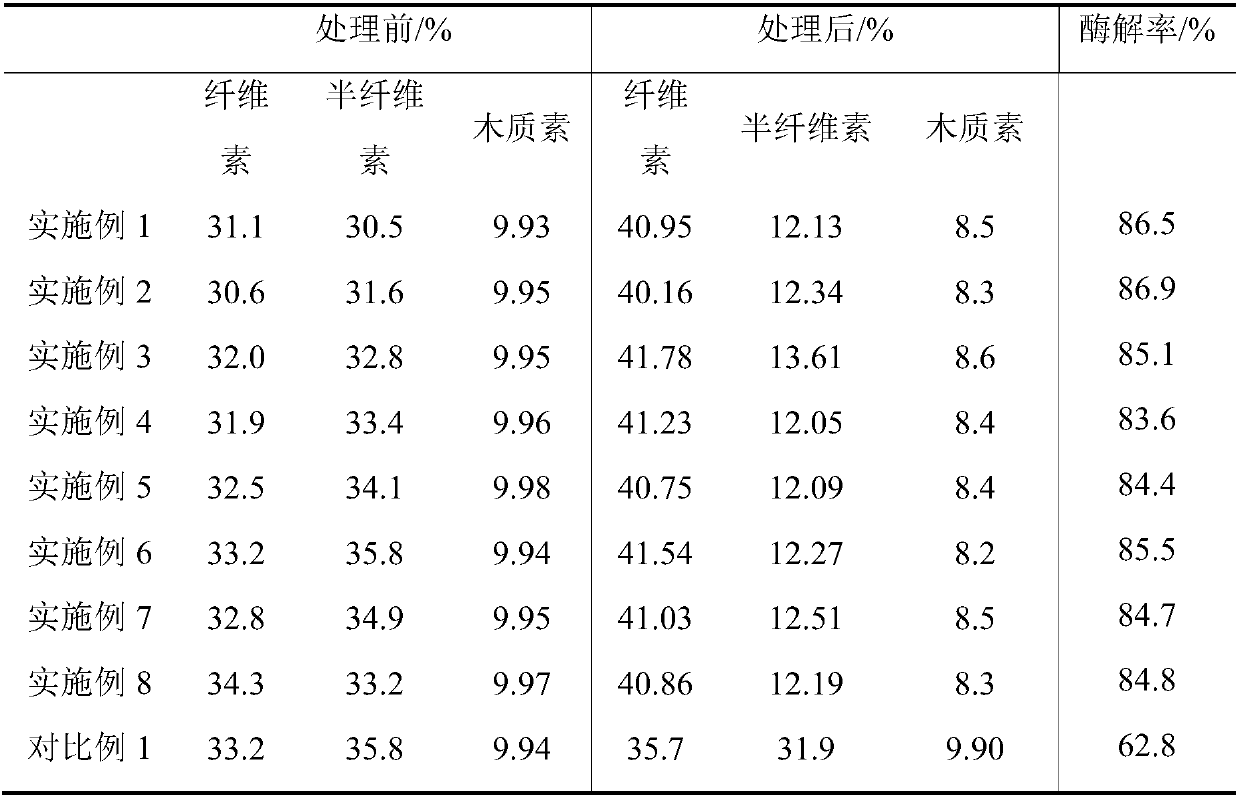

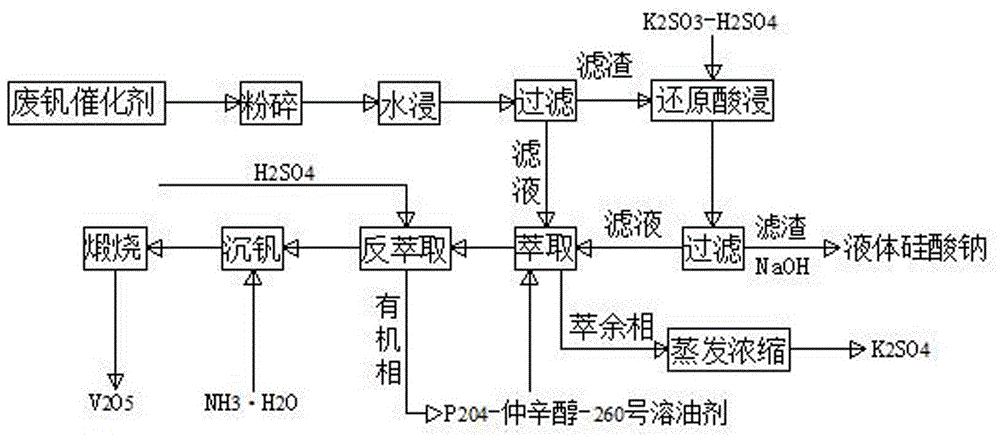

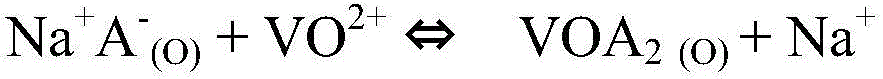

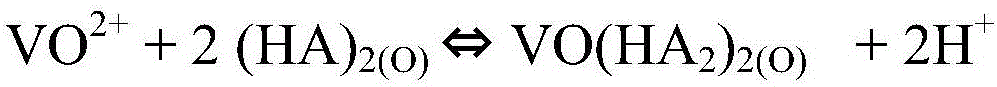

Comprehensive recovery and utilization method for waste vanadium catalyst

ActiveCN107177737AHigh purityQuality improvementAlkali metal silicatesChemical recyclingEvaporationRaffinate

The invention discloses a comprehensive recovery and utilization method for a waste vanadium catalyst. The method comprises the steps that water leaching and reductive acid leaching are sequentially conducted on the waste vanadium catalyst; silicon is separated and recycled by being prepared into sodium silicate through alkaline leaching in a residue leaching mode; single-stage extraction is conducted on leachate through saponification P204, vanadium and potassium are extracted and separated through vanadium extraction technologies of tail liquid concentration and separate re-extraction, potassium is separated by preparing potassium sulphate from raffinate through evaporation and concentration, and vanadium is recycled by preparing vanadium pentoxide from an extraction phase through the processes of back extraction, vanadium precipitation, calcination and the like. Through the extremely high selection characteristic of the saponification P204, not only are the extraction capacity, the utilization rate and the vanadium extraction rate increased, but also influences of iron, phosphorus and arsenic on V2O5 purity are effectively avoided, vanadium precipitation can be directly conducted after back extraction, a high-purity vanadium product is prepared, and the phenomenon that chlorine is released in the oxidization process to pollute the environment is avoided. The method has the advantages that the extraction stages and part of the processes are reduced, the technological process is simplified, the cost is reduced, the economic benefit is increased, and the double effects of making the best use of everything and protecting the environment are achieved.

Owner:KAIFENG UNIV

Comprehensive utilization method of precious metal containing iron slag

InactiveCN106119559AReduce energy consumptionEfficient use ofProcess efficiency improvementLead smeltingFlash smelting

The invention discloses a comprehensive utilization method of precious metal containing iron slag, and belongs to the technical field of recovery and utilization of metal smelting tailings. The method is characterized in that the iron slag is treated as a fire lead smelting fluxing material to be fed into a smelting system; gold, silver and the like can be enriched to crude lead under the precious metal gathering effect of lead, so that the precious metal and the iron slag can be preliminarily separated; the crude lead is electrolyzed so as to enrich gold, silver and the like into lead anode sludge, and then the lead anode sludge is conveyed to a precious metal recovery system for directly recycling; the iron slag is reduced into crude iron and silicon slag through a reducing roasting technology, thus achieving high-value utilization. The method is in seamless transition with a lead smelting system; the iron slag is prevented from being individually briquetted, so that the energy consumption is low, a main system is prevented from any influence, and the process is clean and environmentally; the precious metals are effectively utilized, so that secondary pollution can be avoided, and the requirement of clean production is met.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

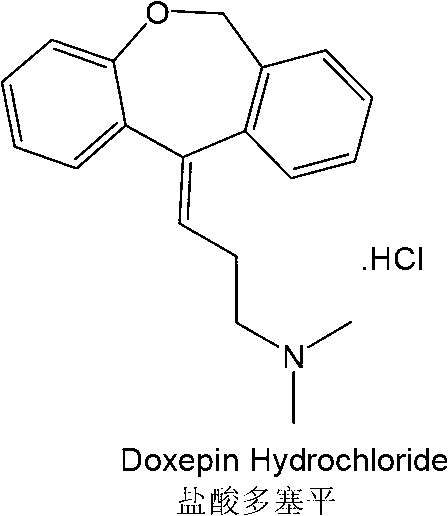

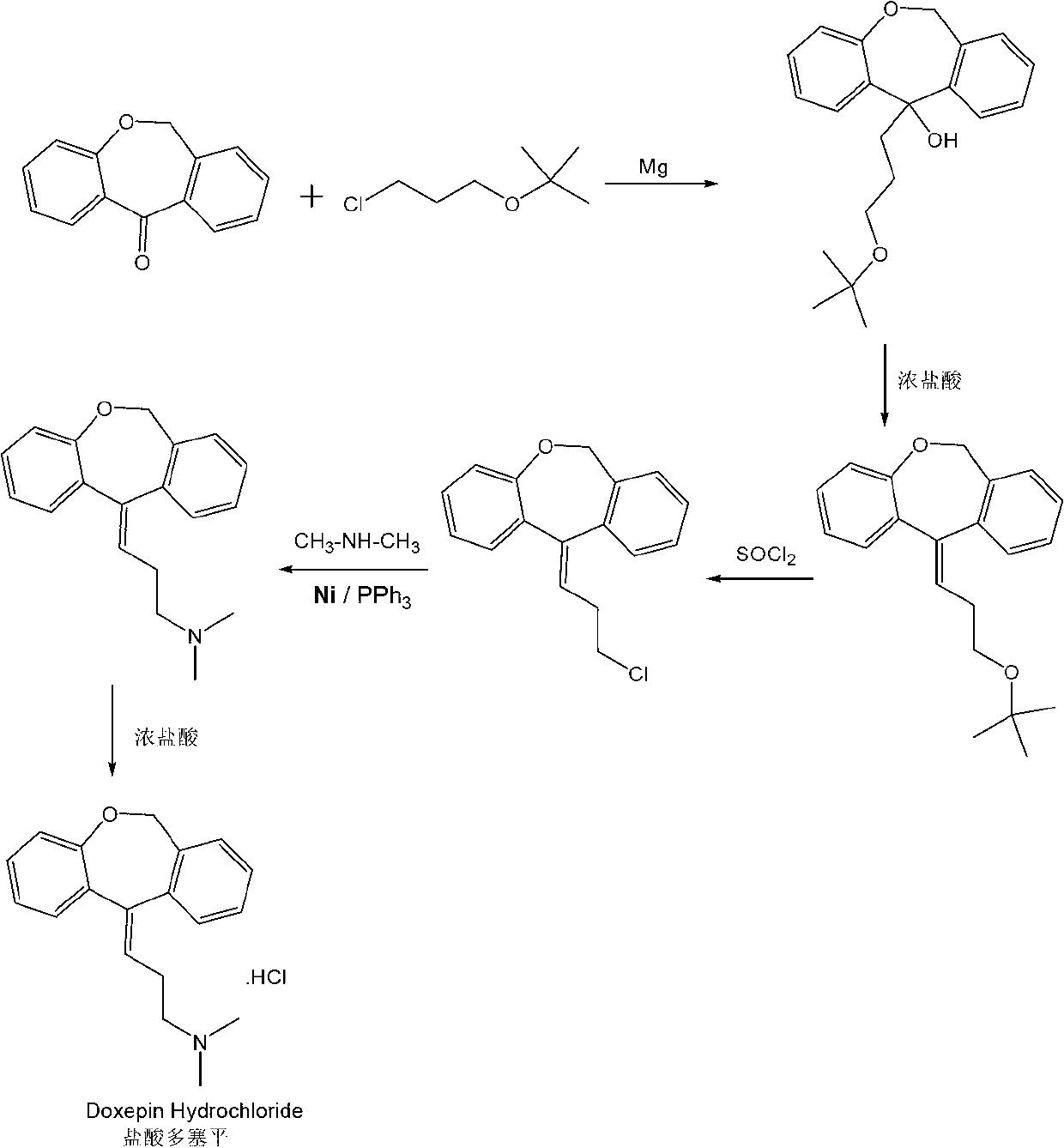

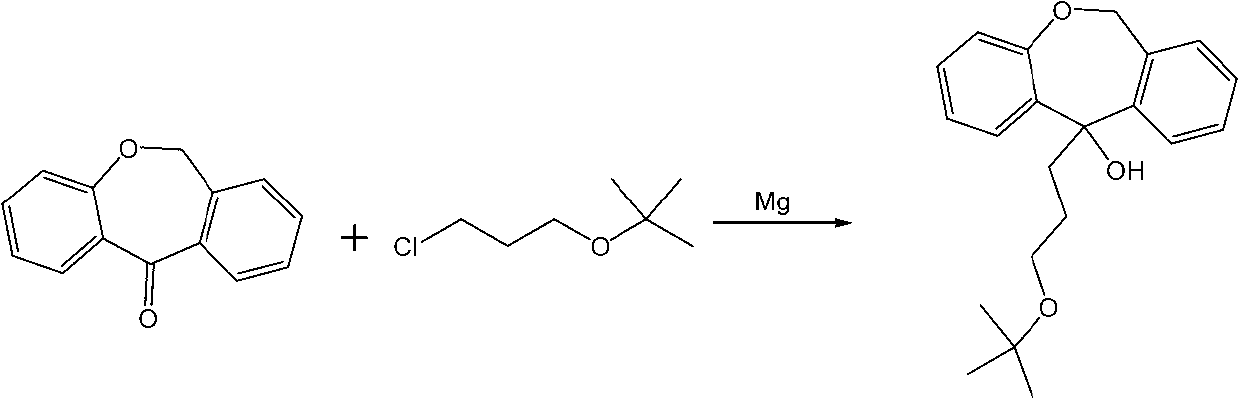

Method for synthesizing doxepin hydrochloride

ActiveCN102924424AThe synthesis method is simple and controllableThe reaction path is scientific and reasonableOrganic chemistryChemical recyclingDoxepin HydrochlorideSolvent

The invention provides a method for synthesizing doxepin hydrochloride. The method comprises the following steps of: 1, carrying out an addition reaction on 6,11-dihydrobenz [b,e] oxepin-11-one and 3-chloropropyl-methyl tert-butyl ether to obtain alcohol compounds; 2, removing hydroxyl from the alcohol compounds under the condition of concentrated hydrochloric acid to obtain olefin compounds; 3, reacting the olefin compounds with thionyl chloride in a reaction solvent to obtain chloride; 4, coupling the chloride with N,N-dimethyl methylamine to obtain doxepin; and 5, preparing the doxepin into hydrochloride of the doxepin to obtain the doxepin hydrochloride. An Ni(OAc)2 / PPh3 system is creatively used in C-N coupling reaction in the step 4, thus the doxepin hydrochloride has the characteristics of good reaction selectivity, high yield and environmental friendliness; and the catalyst is can be recycled after being simply filtered, thus the production cost is greatly lowered. The whole method has the advantages of simpleness in operation, and easy obtaining and low cost of raw materials, accords with the requirement of industrial production, and is expected to be industrially applied.

Owner:SUZHOU HOMESUN PHARMA

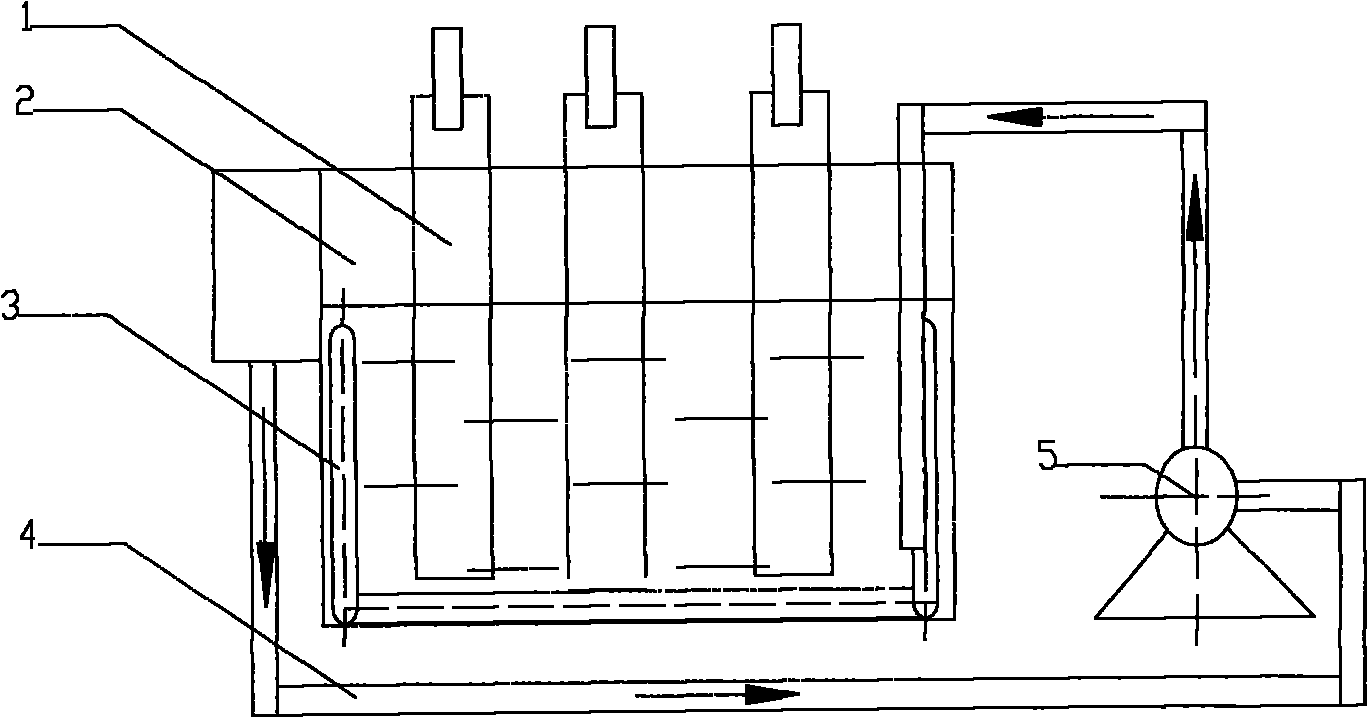

Process and special equipment for plating copper on special steel piece with deep/blind hole

InactiveCN101942682AImprove stabilitySimple and fast operationElectrolysis componentsCopper platingAlcohol

The invention discloses a process for plating copper on a special steel piece with a deep / blind hole, namely render copper. The process comprises the following steps of: chemical deoiling, washing with hot water, electrolytic deoiling, washing with hot water, washing with cold water, acid washing, secondary washing with cold water, neutralizing, washing with cold water, plating copper without cyanide, secondary washing with cold water, plating tin, secondary washing with cold water, neutralizing, washing with hot water, passivating, secondary washing with hot water, washing with hot pure water, dehydrating with alcohol, removing the residual water, drying and inspecting, wherein electroplate liquid used in the step of plating copper without cyanide has the following formula: 400 to 600ml / L of BH-580 non-cyanide alkaline copper cylinder plating bath solution, 1 to 2ml / L of BH-580 non-cyanide alkaline copper brightening agent and 7.5 to 12g / L of metal copper; and the pH value is 9.2 to 9.8. The process has the advantages of good stability of a plating liquid, simple and convenient operation, good dispersibility and good covering capability; the formed plating layer has the advantages of fine and compact crystallization, good adhesive force, stable and reliable production; and the method can effectively protect environment and the physical and psychological health of operators.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

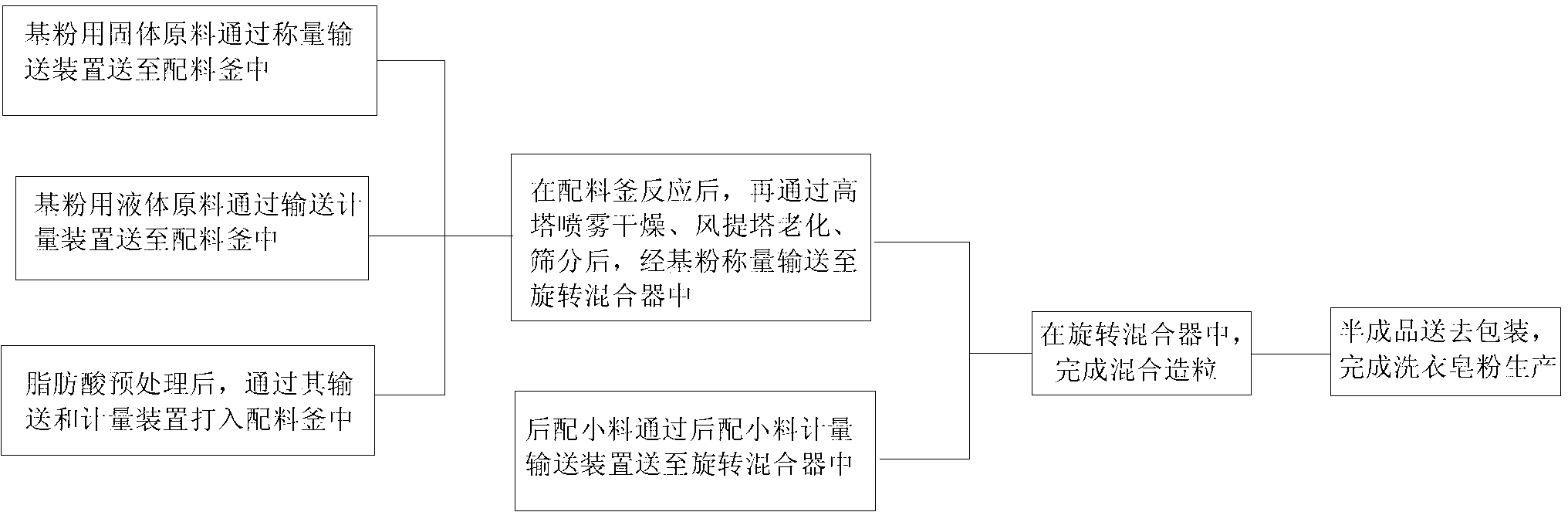

Laundry soap powder slurry, preparation method thereof and industrial production technology of laundry soap powder

ActiveCN103074182AUniform dispersion and adhesion stateLow viscositySurface-active non-soap compounds and soap mixture detergentsDetergent powders/flakes/sheetsWork in processLaundry

The invention discloses laundry soap powder slurry, a preparation method thereof and an industrial production technology of laundry soap powder. The industrial production technology mainly comprises the steps of: 1) directly adopting fatty acid and liquid alkali to conduct neutralization reaction in a batching kettle of a front preparation system to participate in slurry preparation, 2) allowing the slurry after technical optimization treatment to be capable of smoothly entering a high-tower powder spraying system through a high pressure pump to produce base powder, and 3) adding the base powder and other post preparation raw materials, continuously and evenly mixing with a screw mixer, preparing a semifinished product of the laundry soap powder, conveying to a powder bin with a conveyor belt, and packaging into a finish product. According to the technology, high-tower powder spraying equipment is adopted for production, and no other additional special device is added. Compared with the laundry soap powder produced by the original technology (adding powdered to granular sodium aliphatate during post preparation), the produced laundry soap powder has the characteristics of uniform dispersion and adhesion of sodium aliphatate, short product solution time, low agglomeration resistance and good liquidity, and automatic packaging and continuous mass production of the soap powder can be realized.

Owner:GUANGZHOU LIBY

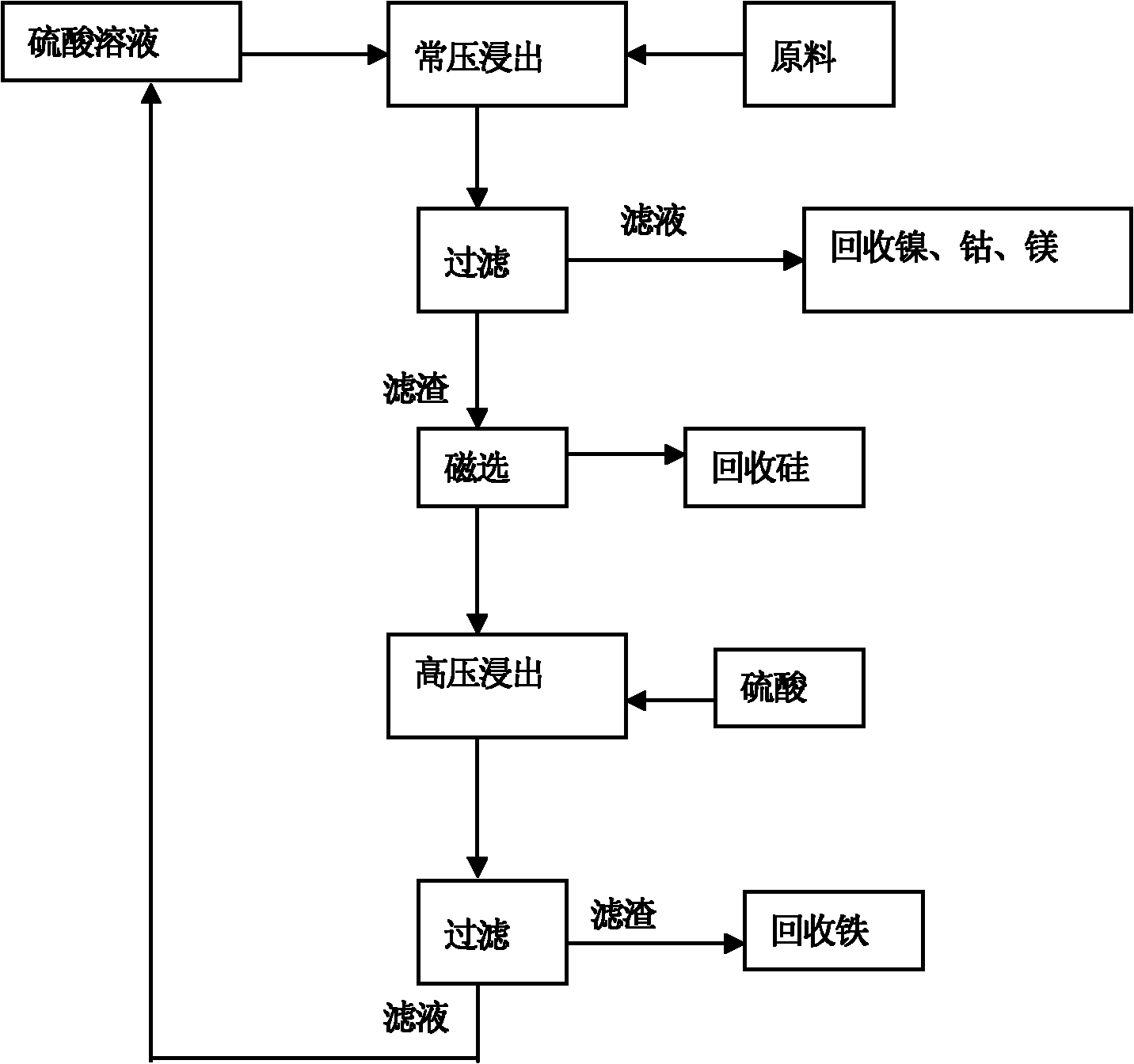

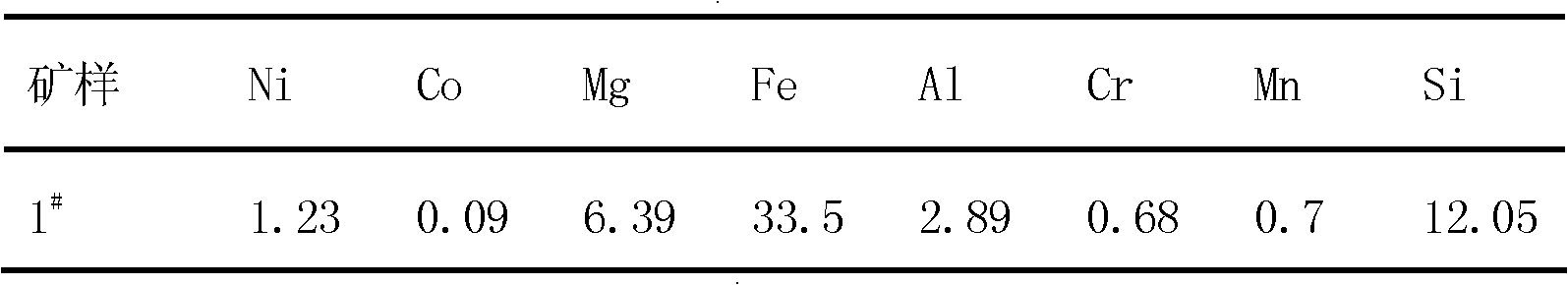

Low-cost method for disposing red soil nickel ore

InactiveCN101805828AReduce foulingReduce volumeProcess efficiency improvementVulcanizationIon exchange

The invention relates to a low-cost method for disposing red soil nickel ore, comprising the following steps: leaching the red soil nickel ore from a normal pressure pickling tank; carrying out magnetic separation on the filter residue obtained from the filtered red soil nickel ore, wherein the filtered red soil nickel are divided into a magnetic part and a non-magnetic part. The non-magnetic part can be directly used for deep-processing of silicon product. The magnetic part can be leached at pressure higher than atmospheric pressure, the leached residue can be used as raw material for iron industry, and leachate is recycled to the normal pressure leaching tank to serve as the needed acid materials for atmospheric pressure leaching. The normal pressure leachate can be used to recover nickel, cobalt and magnesium by methods such as solvent extraction, ion exchange and vulcanization precipitation. The method of the invention can be applied to various red soil nickel ores containing Fe and Magnesium, realizes cyclic utilization of acid and comprehensive recovery of nickel, cobalt, iron, silicon, magnesium and other metals and greatly reduces volume and amount of scale buildup of a high pressure autoclave, thus being a low-cost environment-friendly technology for efficiently disposing the red soil nickel ore.

Owner:CENT SOUTH UNIV

Method for synthesizing compound of asymmetric substituted carbamide class from carbonyl

InactiveCN1415601AEasy to separateCleaning processUrea derivatives preparationOrganic compound preparationNitro compoundOxidation-Reduction Agent

A process for synthesizing the asymmetrically substituted urea compounds features that the arylnitro compound and organic amine take part in selective redox and carbonylation reaction at 50-200 deg.C under the existance of CO and the catalysis of Se as catalyst and triethylamine as cocatalyst. Its advantages are cyclic use of catalyst, high output rate, and high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

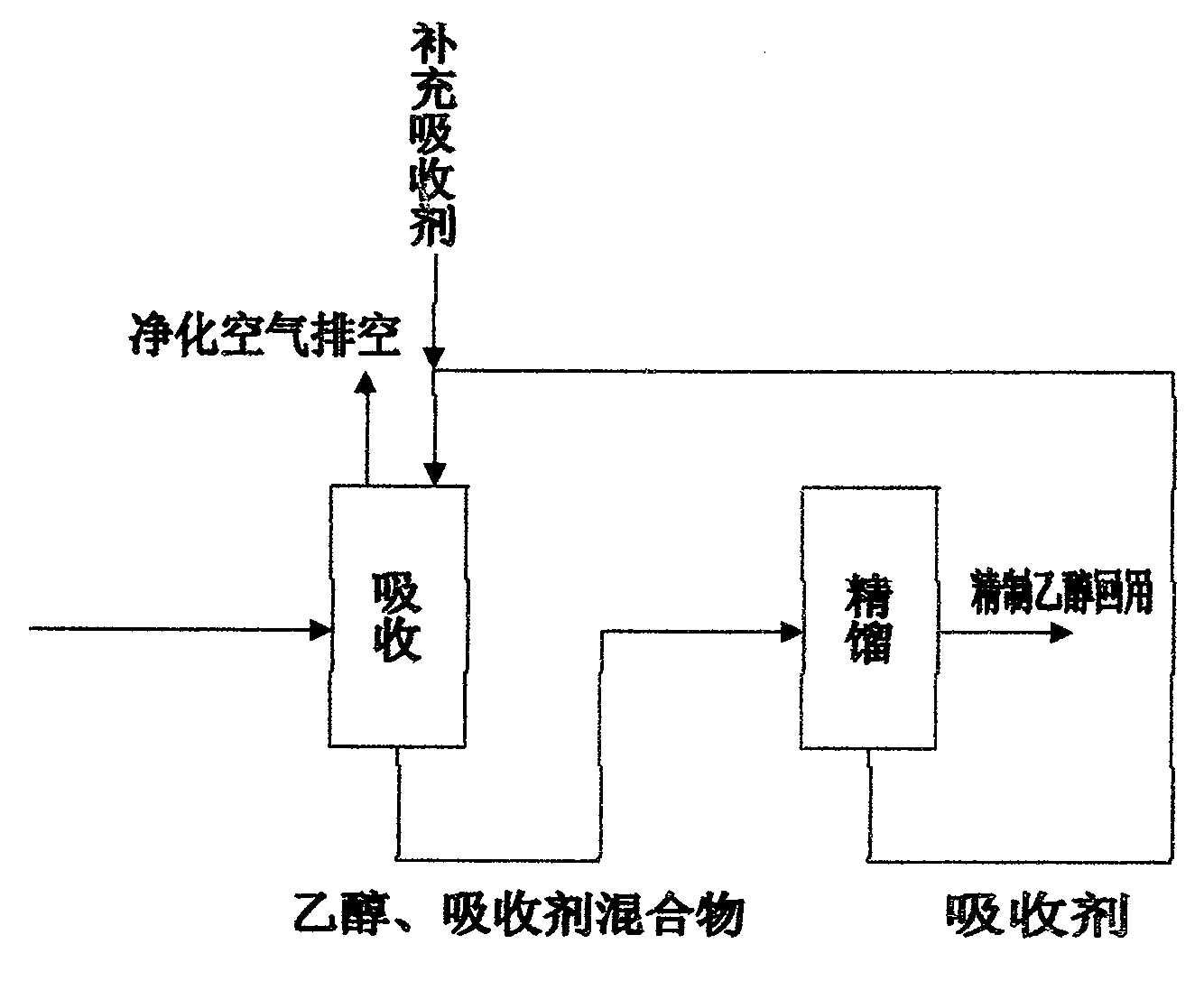

Ethanol-containing waste-gas treatment process flow

InactiveCN101810982AMeet the needs of industrial production process designOperating pressure dropDispersed particle separationHydroxy compound separation/purificationCompound (substance)Environmental engineering

The invention provides an ethanol-containing waste-gas treatment process flow, which adopts a recycling method to recycle and to utilize the organic matters in the waste gas so as to realize the reduction of the environmental pollutants, and adopts the technical scheme that: after the ethanol-containing waste gas enters a purification unit, the ethanol-containing waste gas is contacted with absorbent inside the purification unit, ethanol in the ethanol-containing waste gas is absorbed by the absorbent to form absorption solution, and the absorption solution is discharged from the purification unit, so the ethanol-containing waste gas is purified; the discharged absorption solution is purified and concentrated by a recycling unit so as to separate the ethanol and the absorbent, the separated absorbent is recycled after passing through a filtering unit, and the absorption efficiency of the purification unit during the absorption process is more than 99 percent. The ethanol-containing waste-gas treatment process flow has the advantages that the resource can be saved, can be popularized in the resource treatment process of the similar waste gas, and develops a new way for processing the waste gas which is produced during the chemical engineering and the pharmaceutical production process.

Owner:QINGDAO UNIV OF SCI & TECH

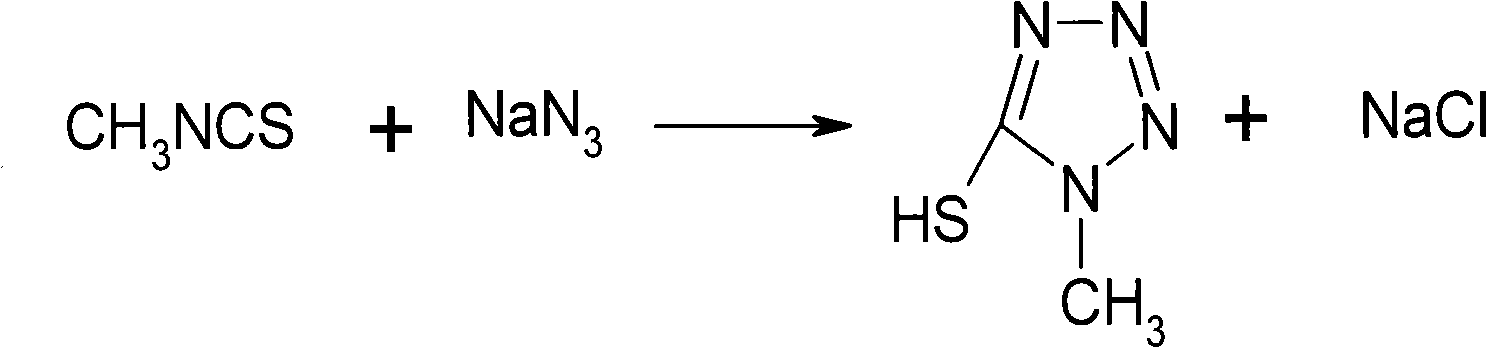

Production method of 1-methyl-5-mercapto-1,2,3,4-tetrazole

The invention discloses a production method of 1-methyl-5-mercapto-1,2,3,4-tetrazole, which comprises the following steps of: dropwise adding methyl isorhodanate into a system of sodium azide, a high-efficiency phase transfer catalyst and deionized water, reacting at 50-100 DEG C for 1-10 hours, concentrating, cooling, acidizing, crystallizing, and centrifuging to obtain rough 1-methyl-5-mercapto-1,2,3,4-tetrazole; after carrying out alkali dissolving, active carbon decoloring, filtering and impurity removing, acidizing, crystallizing and centrifuging on the rough product, adding hydrogen peroxide and water, recrystallizing, centrifuging and drying to obtain a finished product. The method has simple operation, high product yield, no use of organic solvent with reaction processes and product fining process which are all carried out under an aqueous solvent environment, thereby greatly reducing the production cost and the environmental pollution, meeting requirements of clean production and having remarkable economical and social benefits.

Owner:山东艾孚特科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com