Electric potential regulating and controling differential flotation process for copper-plumbum-zinc vulcanizing mine

A potential control, priority flotation technology, applied in the field of zinc beneficiation, complex polymetallic sulfide flotation separation of copper and lead, can solve the problems of poor concentrate quality, high cost, difficult copper-zinc separation, etc. The ore adaptability is strong, the production index is stable, and the seasonal temperature difference has little effect on the index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

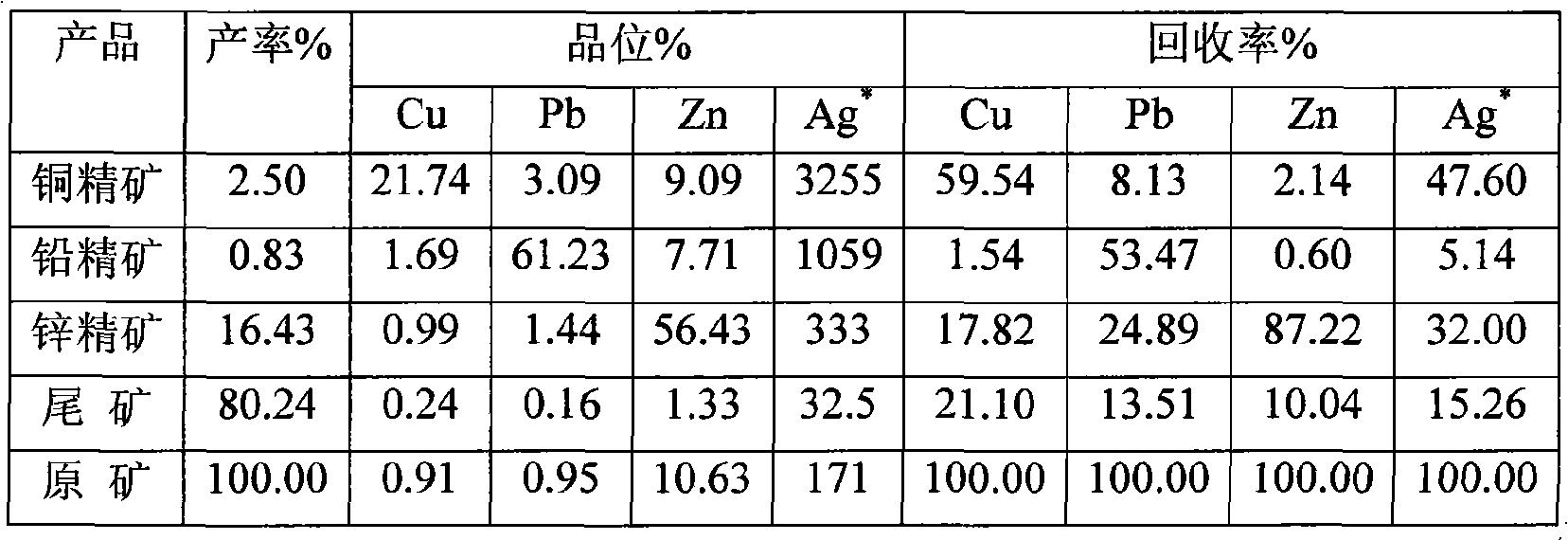

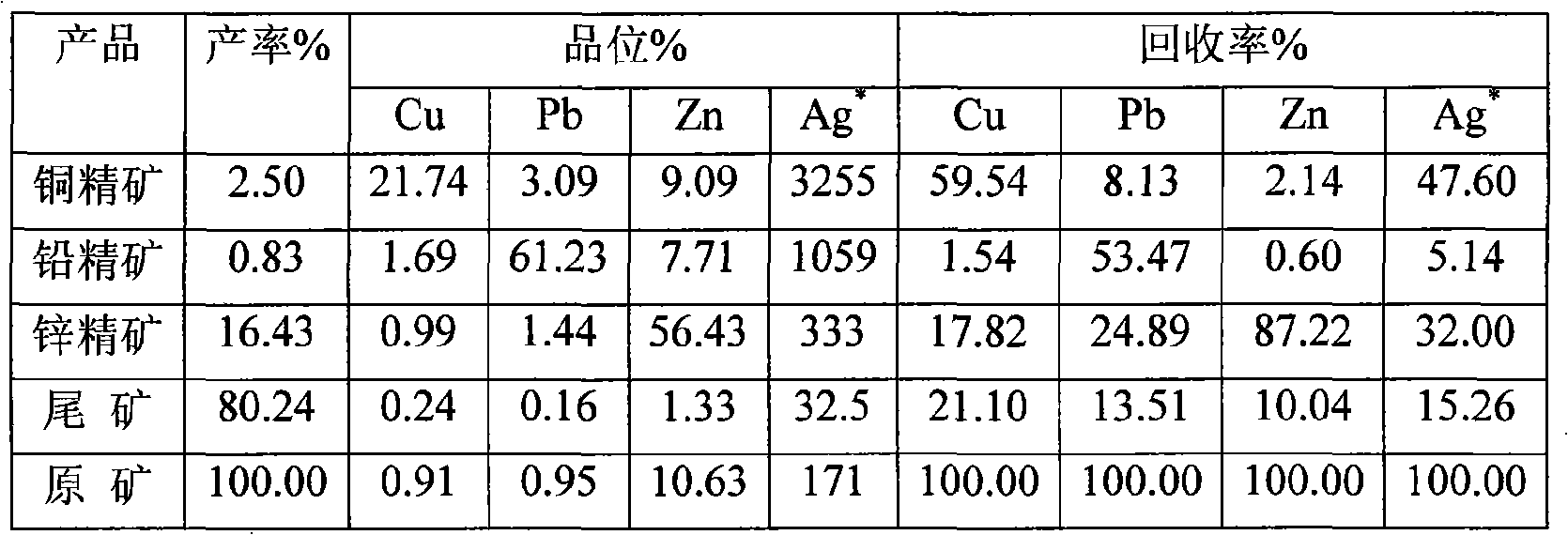

[0027] The raw ore is a copper-lead-zinc sulfide ore composed of chalcopyrite, galena, sphalerite and associated silver (gold) precious metals. The correlation between silver and copper minerals is strong, and the grade of the raw ore is: Cu0.91 %, Pb0.95%, Zn10.63%, Ag171g / t.

[0028] Inhibitor ZnSO added during ball milling 4 1000g / t and YN 1000g / t, grinding fineness -200 mesh is 83%, add collector LP-01 21g / t, foaming agent LQ-01 7g / t, preferentially float copper minerals, float Lime is added to the copper rough concentrate to control the potential of the pulp, and two beneficiation is carried out, and the amount of lime is 100g / t each time; after copper roughing, two copper sweeps are carried out, and LP-01 7g / t is added each time. After copper separation, add lime 6000g / t to the pulp to adjust the potential, and add inhibitor ZnSO 4 1000g / t and YN1000g / t, add collector 20g / t ethion, add foaming agent 2 # Oil 7g / t is used for lead mineral flotation, and the floating lea...

Embodiment 2

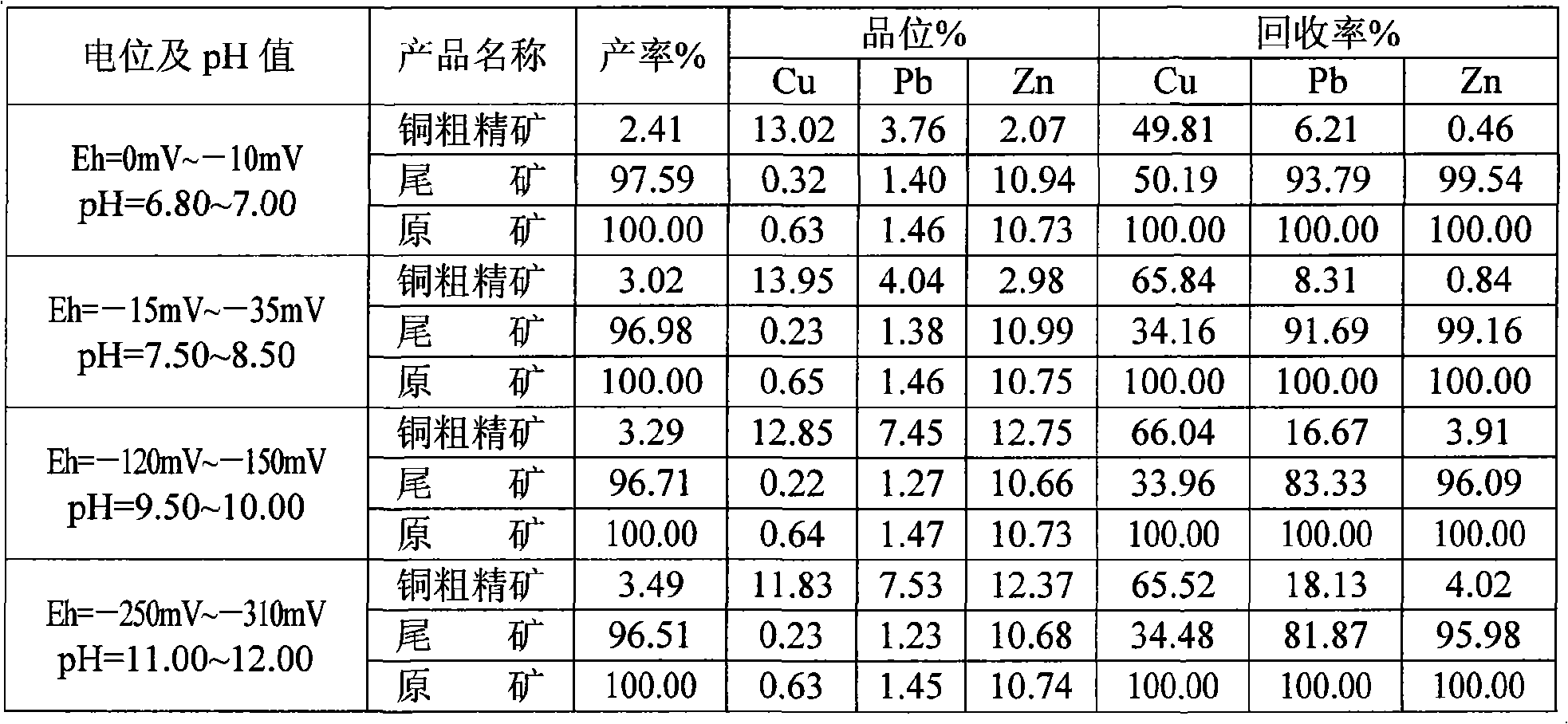

[0033] For another raw ore with different grades, the difference in the properties of the raw ore compared with Example 1 is mainly reflected in the increase in copper grade, forming copper-lead-zinc polymetallic complex refractory sulfide ore. Inhibitor ZnSO added during ball milling 4 1000g / t and YN 1000g / t, grinding fineness -200 mesh is 83%, add collector LP-01 49g / t, foaming agent LQ-01 14g / t, preferentially float copper minerals, float Lime is added to the copper rough concentrate to adjust the potential of the pulp, and two selections are carried out, and the amount of lime is 100g / t each time; after copper roughing, two copper sweeps are carried out, and the dosage of one agent for sweeping is: LP-01 14g / t t, the dosage of the second agent for scanning is: LP-01 7g / t. After copper separation, add lime 8000g / t to the pulp to regulate the potential, and add inhibitor ZnSO 4 2000g / t and YN 2000g / t, add collector 20g / t ethylthiazide, add foaming agent 2 # Oil 7g / t is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com