Method for industrially producing ethyl alcohol through crop straw

A technology for crop straw and ethanol, which is applied in the directions of biofuel, waste fuel, fermentation, etc., can solve the problems of high production cost, high energy consumption, low utilization rate of straw, etc., and achieves reduction of energy consumption and production cost, and simple pretreatment steps. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

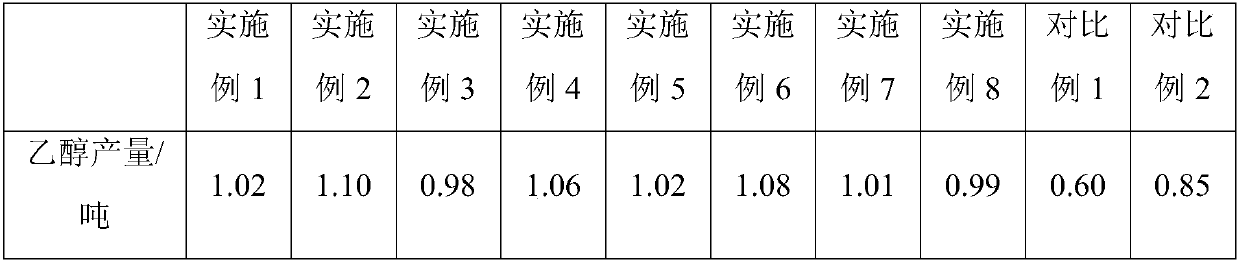

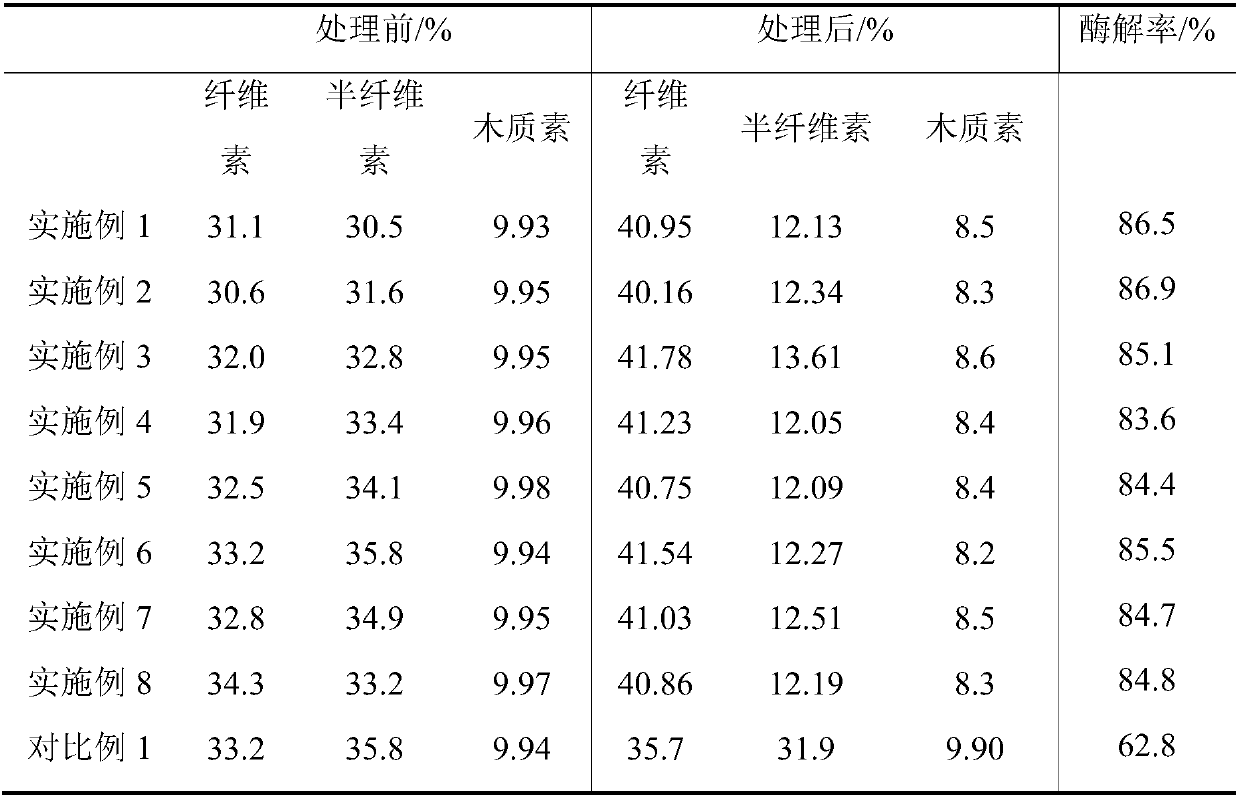

Embodiment 1

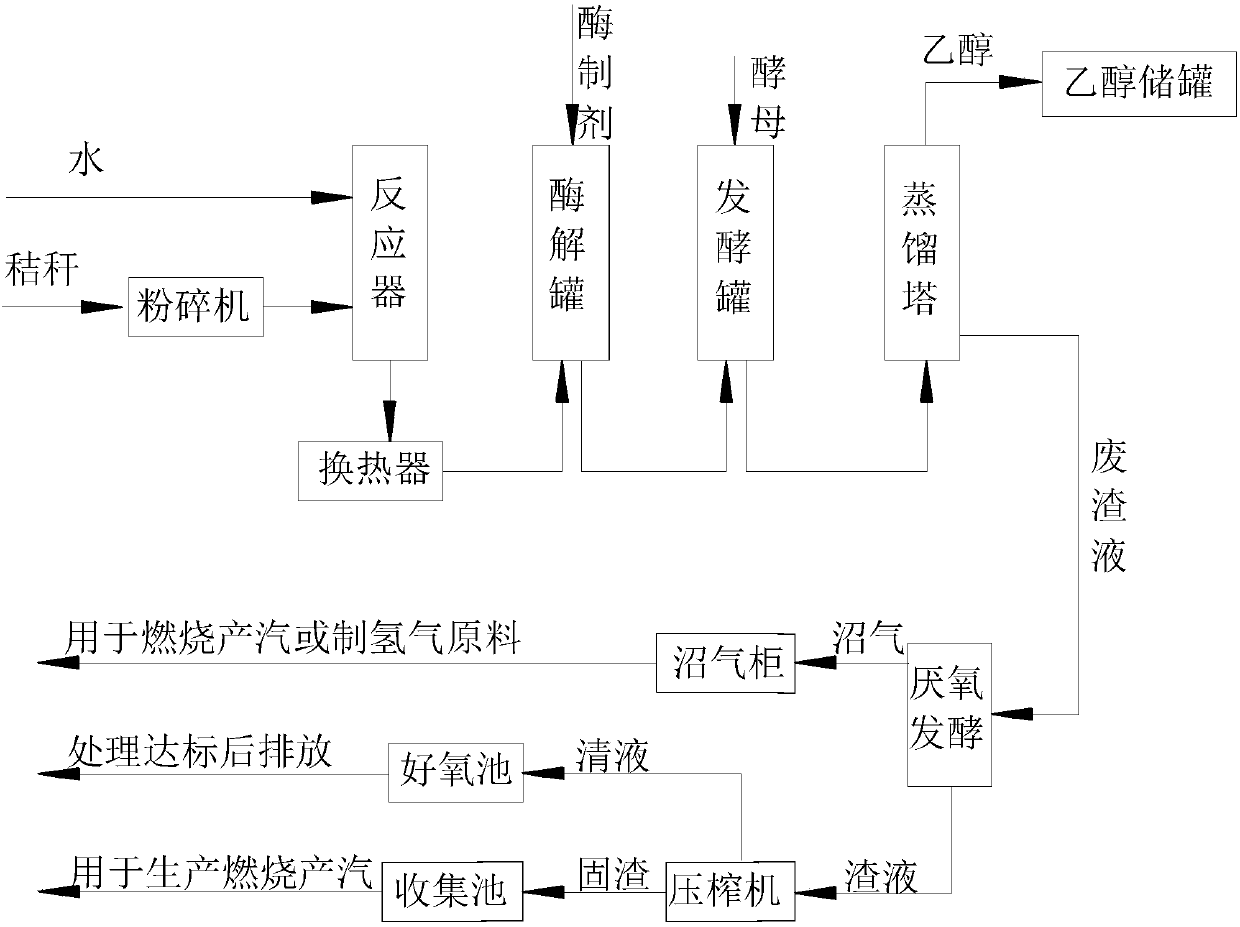

[0041] A method for the industrial production of ethanol using crop stalks, comprising the steps of:

[0042] (1) Pretreatment: Add the crushed crop straw and water to the pretreatment reactor at a ratio of 1:3, control the temperature at 194°C and the pressure at 1.38MPa for 52 minutes to obtain the pretreated material;

[0043](2) Enzymolysis: The material obtained after the pretreatment in step (1) is introduced into the enzymolysis tank, and is cooled by heat exchange with the next batch of unpretreated straw and water mixture, and recovered at the same time Heat energy, use sodium hydroxide to adjust the pH to 4.4, then add cellulase for enzymatic hydrolysis, the enzymatic hydrolysis temperature is 50°C, and the enzymatic hydrolysis time is 48h;

[0044] (3) Fermentation: import the material after enzymolysis in step (2) into a fermenter, control the fermentation temperature to 38°C, add common Saccharomyces cerevisiae, and ferment for 120 hours to produce ethanol, wherei...

Embodiment 2

[0050] A method for the industrial production of ethanol using crop stalks, comprising the steps of:

[0051] (1) Pretreatment: Add the crushed crop straw and water to the pretreatment reactor at a ratio of 1:5, control the temperature at 150°C and the pressure at 0.48MPa for 60 minutes to obtain the pretreated material;

[0052] (2) Enzymolysis: The material obtained after the pretreatment in step (1) is introduced into the enzymolysis tank, and is cooled by heat exchange with the next batch of unpretreated straw and water mixture, and recovered at the same time Heat energy, use calcium hydroxide to adjust the pH to 4.7, then add cellulase, cellobiase and xylanase for enzymolysis, the enzymolysis temperature is 50°C, and the enzymolysis time is 72h;

[0053] (3) Fermentation: import the material after enzymolysis in step (2) into a fermenter, control the fermentation temperature to 34°C, add genetically engineered Saccharomyces cerevisiae, and ferment for 96 hours to produce ...

Embodiment 3

[0059] A method for the industrial production of ethanol using crop stalks, comprising the steps of:

[0060] (1) Pretreatment: Add the crushed crop straw and water to the pretreatment reactor at a ratio of 1:6, control the temperature at 208°C and the pressure at 1.85MPa to react for 27 minutes to obtain the pretreated material;

[0061] (2) Enzymolysis: The material obtained after the pretreatment in step (1) is introduced into the enzymolysis tank, and is cooled by heat exchange with the next batch of unpretreated straw and water mixture, and recovered at the same time Heat energy, use sodium hydroxide to adjust the pH to 4, then add cellulase, cellobiase, and laccase for enzymolysis, the enzymolysis temperature is 48°C, and the enzymolysis time is 48h;

[0062] (3) Fermentation: import the material after enzymatic hydrolysis in step (2) into a fermenter, control the fermentation temperature to 42°C, add genetically engineered Saccharomyces cerevisiae, and ferment for 86 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com