Patents

Literature

96results about How to "Improve enzymatic hydrolysis rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technology for preparing docosahexaenoic acid (DHA)-rich feed additive by grain dreg raw material through fermentation

ActiveCN104256086AReduce carbon sourceLow costFood processingAnimal feeding stuffChemistryMicrobiological growth

The invention discloses a technological method for preparing an animal feed additive which is rich in polyunsaturated fatty acid, namely, docosahexaenoic acid (DHA), protein and xylo-oligosaccharide by taking a grain dreg raw material as a culture medium through a microbiological fermentation method. The method concretely comprises the steps of (1) mixing the grain dreg raw material with water to prepare a material with a certain solid-liquid mass ratio; (2) carrying out pretreatment on the mixed grain dreg raw material by a hydrothermal extraction method; (3) carrying out enzymolysis on the pretreated grain dregs; (4) culturing microorganism capable of producing DHA by the grain dregs treated by enzymolysis; and (5) concentrating or drying fermentation liquor of schizochytrium limacinum to prepare a liquid or solid-state feed. The method fully utilizes the principle that the grain dregs contain rich hemicellulose and cellulose so as to be used for preparing xylo-oligosaccharide and cello-oligosaccharide with a probiotic function, and soluble lignin is used for preparing a polyphenol antioxidant; and the degraded cellulose and starch can be used as a carbon source for microbial growth, and the protein can be used as a nitrogen source for cell growth, so that the costs of the carbon source and the nitrogen source for microbial fermentation can be lowered.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

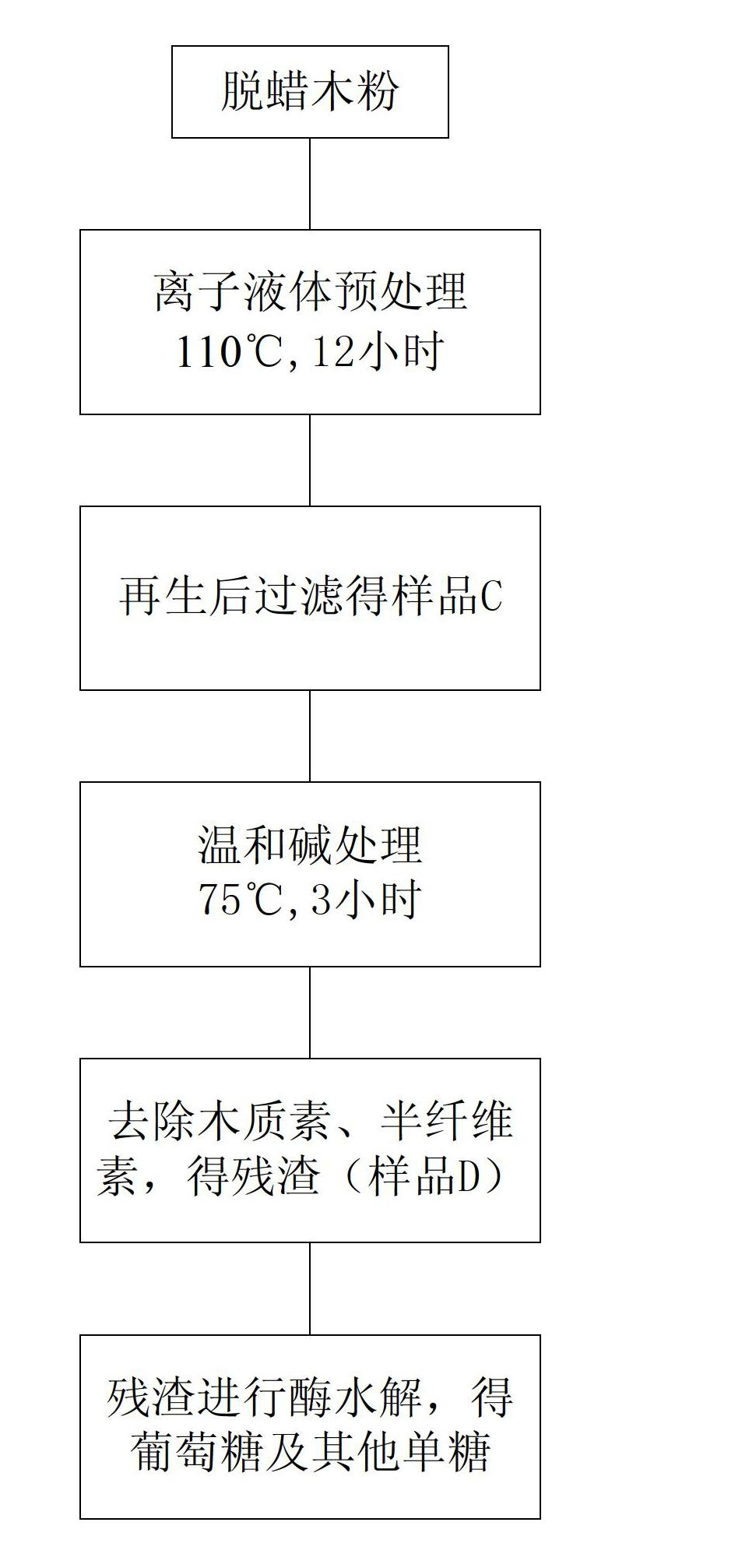

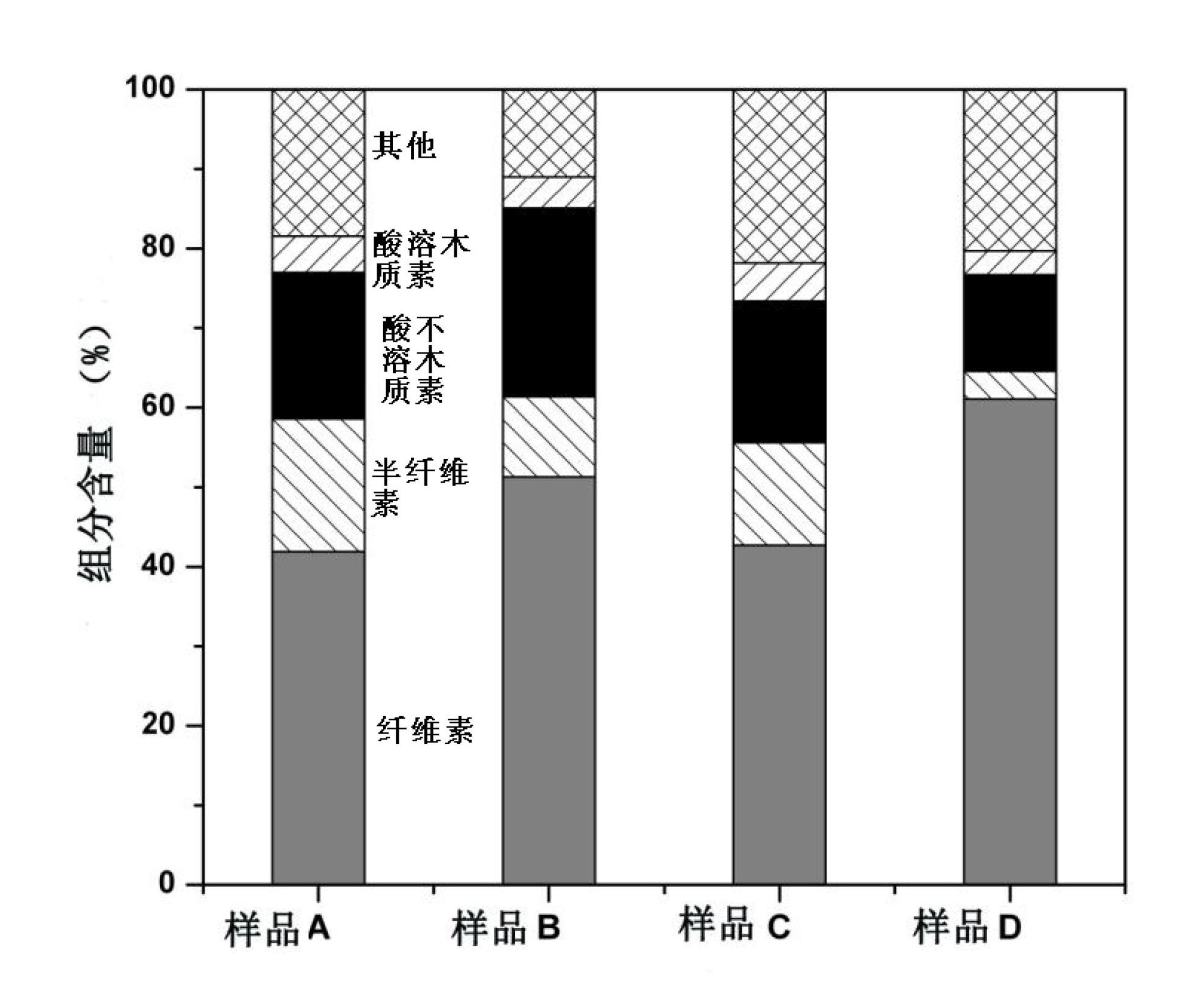

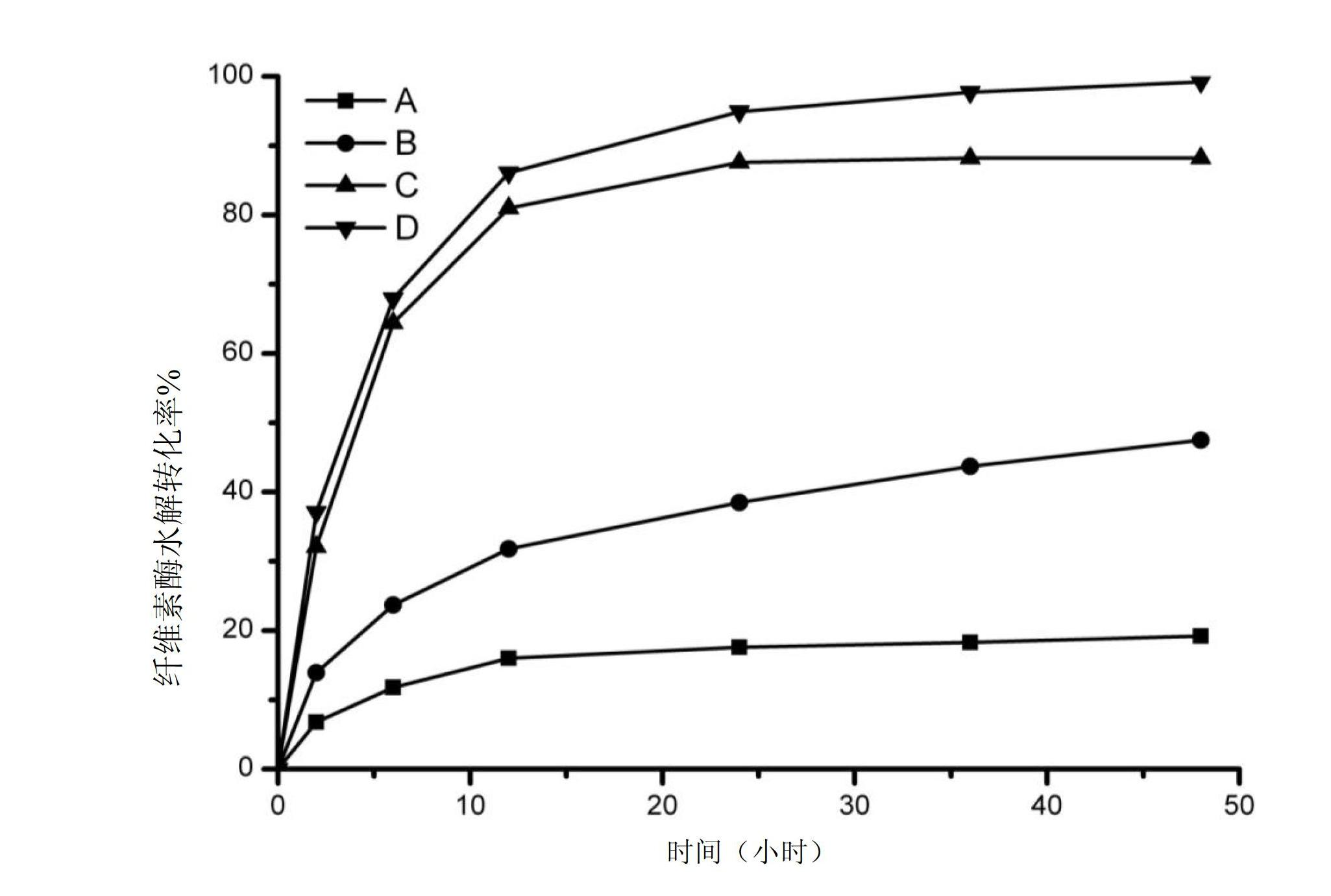

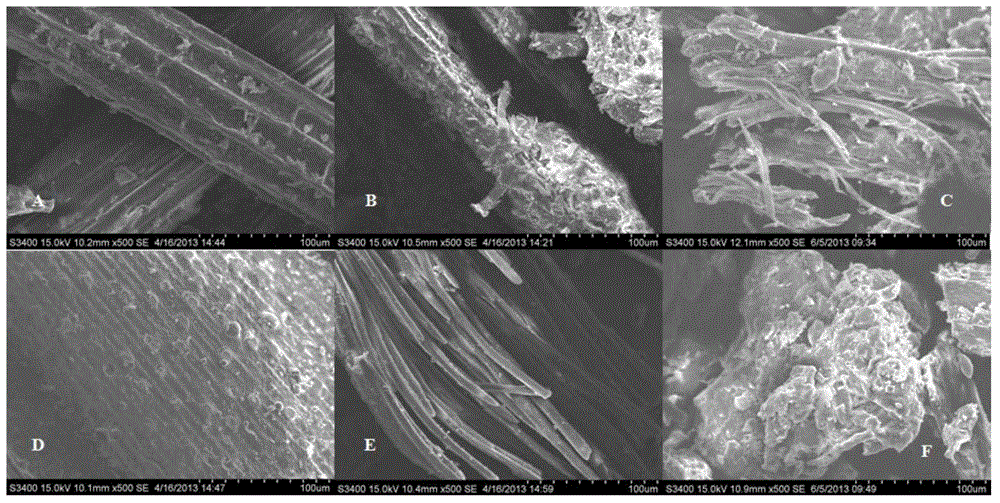

Pretreatment method for improving enzyme hydrolysis rate of lignocellulose

ActiveCN102676612AClean and efficient separationImprove enzymatic hydrolysis rateFermentationPretreatment methodFreeze-drying

The invention discloses a pretreatment method for improving the enzyme hydrolysis rate of lignocellulose. The method comprises the following steps of: a, dissolving dewaxed wood flour into an ionic liquid to obtain an ionic liquid solution; b, transferring the ionic liquid solution into a reversed phase solvent to perform regeneration; c, filtering the ionic liquid solution which is subjected to the regeneration in the reversed phased solvent, and performing freeze-drying to obtain regenerated wood flour; d, performing mild alkali treatment on the regenerated wood flour which is obtained in the step c for removing lignin components and hemi-cellulose components to obtain residues after the alkali treatment; and e, performing enzyme hydrolysis on the residues after the alkali treatment to obtain glucose. By using the method, the enzyme hydrolysis conversion rate of cellulose in the lignocellulose is improved.

Owner:BEIJING FORESTRY UNIVERSITY

Beef flavor development powder and preparation thereof

The invention discloses a beef flavour powder and a preparation method thereof. The beef flavour powder comprises: dust salt, white granulated sugar powder, glucose powder, gourmet powder, D- xylose, L-cysteine, enzymolysis solution, soy sauce, yeast extract, sesame oil, phosphoric acid, ethyl maltol, IMP, corn starch and beef flavor. The invention adopts the method combining microwave drying technology and compound enzyme enzymolysis technology to produce the beef flavour powder which has good taste, little environmental pollution, stable quality and high safety.

Owner:TIANNING FLAVOR JIANGSU

Pork flavour development powder and its preparation method

The invention discloses a pork-taste powder and the preparation method thereof. A chicken-taste powder comprises salt powder, white sugar powder, glucose powder, monosodium glutamate powder, D-xylose, isoleucine, enzymatic hydrolysate, soy sauce, yeast extract, sesame oil, chicken oil, Ethyl maltol, GMP, corn flour and chicken essence. The chicken-taste powder prepared by a method with combination of the microwave drying technology and the compound enzyme enzymolysis technology has the advantages of good taste, less environmental pollution, stable quality and good safety.

Owner:TIANNING FLAVOR JIANGSU

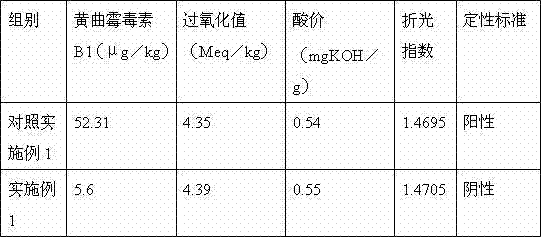

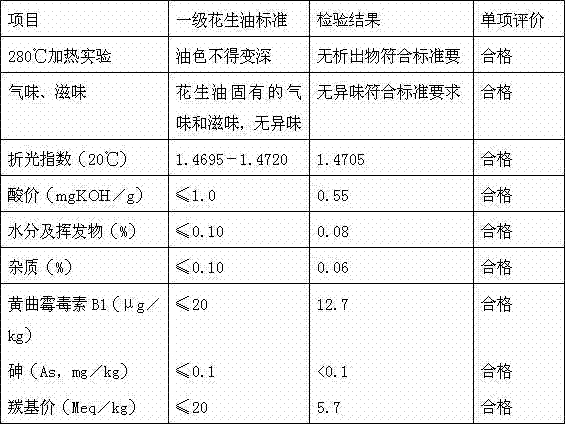

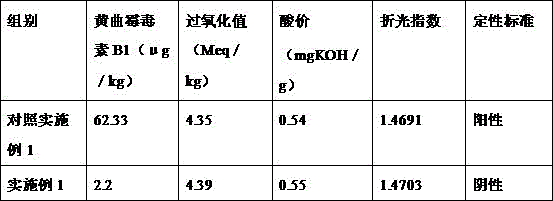

Method for removing aflatoxin out of peanut oil

ActiveCN103881805AAvoid gas guzzlingMild reaction conditionsFatty-oils/fats productionProteasesNeutral protease

The invention provides a method for removing aflatoxin out peanut oil. The method comprises the following steps: A, selecting materials; B, grading and screening peanuts; and C, feeding and squeezing oil, The method is characterized in that aflatoxin is removed by means of a compound enzyme in the step C, wherein the compound enzyme consists of phospholipase A1, laccase, neutral proteases, xylanases by adding phospholipase A1, laccase, neutral proteases and xylanases respectively according to proportions of 0.3g / kg, 0.2g / kg, 0.5g / kg and 0.1g / kg; then hydrolysis is carried out at 42 DEG C for 5-6 hours; and finally the pH of hydrolyzate is adjusted to 6.8. According to the method, aflatoxin is removed by a biological method, reaction conditions are mild and operation is simple, aflatoxin content meets national standards, and the method disclosed by the invention has a broad application prospects.

Owner:山东金胜粮油食品有限公司

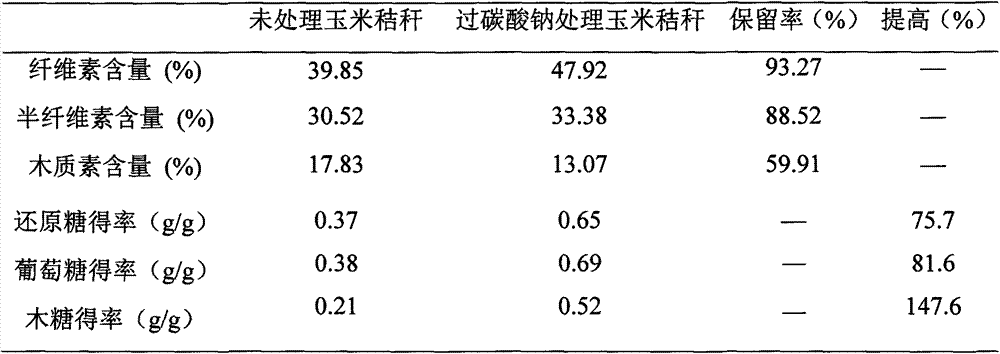

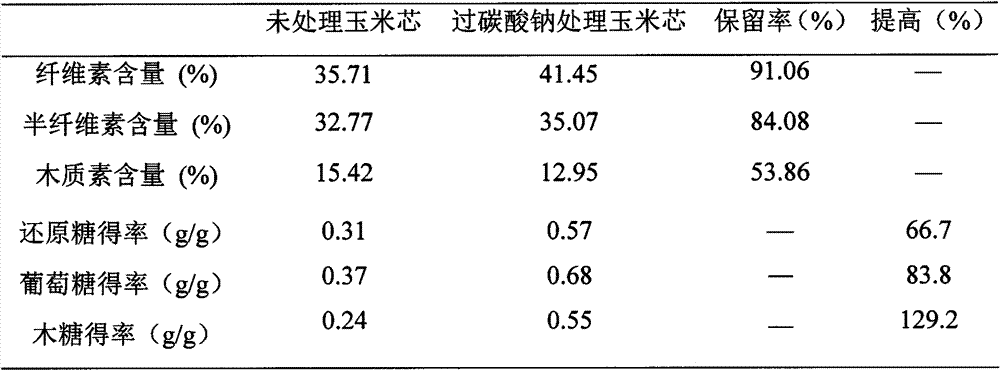

Lignocellulose pretreatment method for increasing enzyme hydrolysis rate by oxidation removal of lignin

InactiveCN107164424AImprove enzymatic hydrolysis rateHigh yieldFermentationPretreatment methodCellulase

The invention relates to a lignocellulose pretreatment method for increasing an enzyme hydrolysis rate by oxidation removal of lignin. The method includes steps: grinding and drying lignocellulose raw materials, respectively controlling sodium percarbonate concentration, solid-liquid ratio, pretreatment temperature and time in appropriate ranges, filtering, washing to neutral, and drying to obtain pretreated lignocellulose residues; adding cellulase and xylanase, dissolved in citric acid buffer solution with pH in a range of 4.5-5.0, into the pretreated lignocellulose residues to obtain fermentable reducing sugar solution through enzymolysis. By the pretreatment method, lignin can be effectively removed while the retaining rate of cellulose and hemicellulose components is high, lignocellulose enzymolysis efficiency is effectively improved, and reducing sugar yield is increased. In addition, the method has advantages of environmental friendliness, simplicity in operation, low cost and the like.

Owner:TIANJIN UNIV OF SCI & TECH

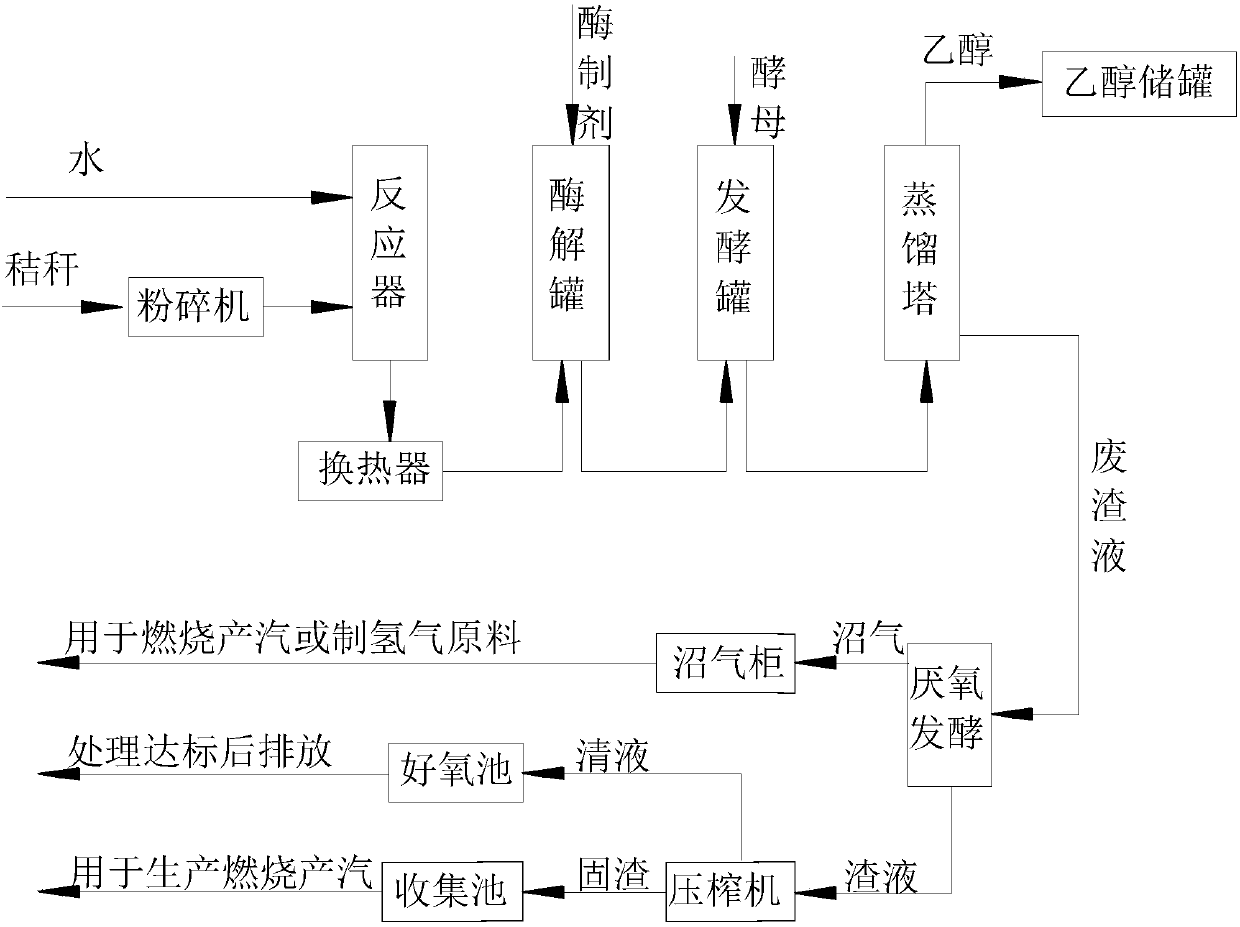

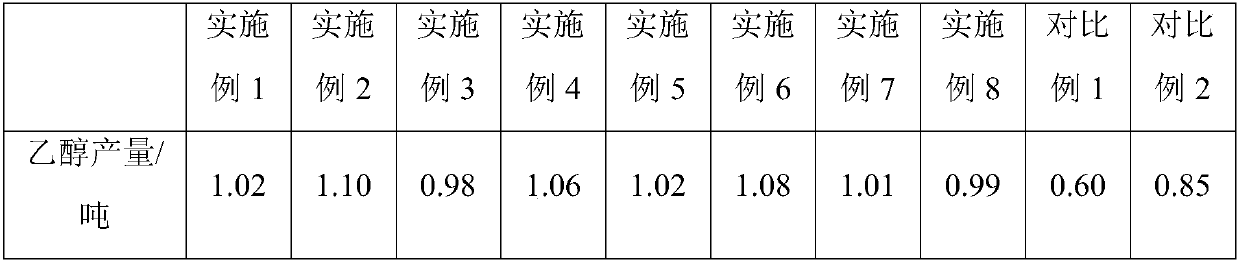

Method for industrially producing ethyl alcohol through crop straw

The invention discloses a method for industrially producing ethyl alcohol through crop straw. The method includes the following steps of pulverizing the crop straw, adding the pulverized crop straw and water into a preprocessing reactor in proportion to be preprocessed, guiding the materials into an enzymolysis tank, conducting cooling, adjusting the pH, adding an enzyme preparation for enzymolysis, guiding the materials into a fermentation tank, adding yeast for ethyl alcohol fermentation production, guiding the materials into a distilling device to be distilled to obtain ethyl alcohol and waste slag liquid, inoculating high-temperature activated sludge to the waste slag liquid for anaerobic fermentation to obtain biogas and digestive slag liquid, making the biogas combusted to generate vapor or used as a production raw material and supplied outward to an urban gas pipe network, squeezing the digestive slag liquid to obtain clear liquid and solid slag, discharging the clear liquid after the clear liquid is processed to reach the standard, combusting the solid slag to generate vapor, and reusing the vapor in the steps of the method. The whole method is advanced in process, high inethyl alcohol yield, sufficient in raw material utilization, low in cost and suitable for industrial production.

Owner:ZHONGRONG TECH CORP LTD

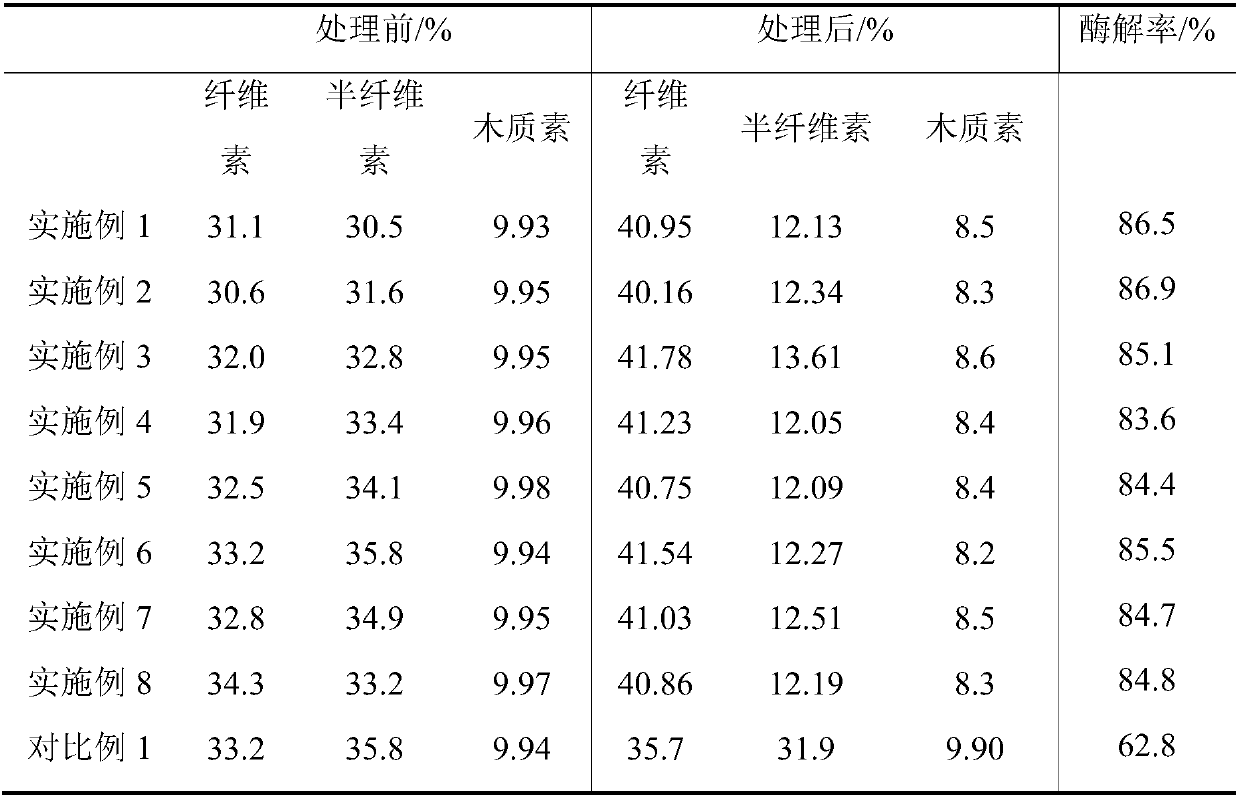

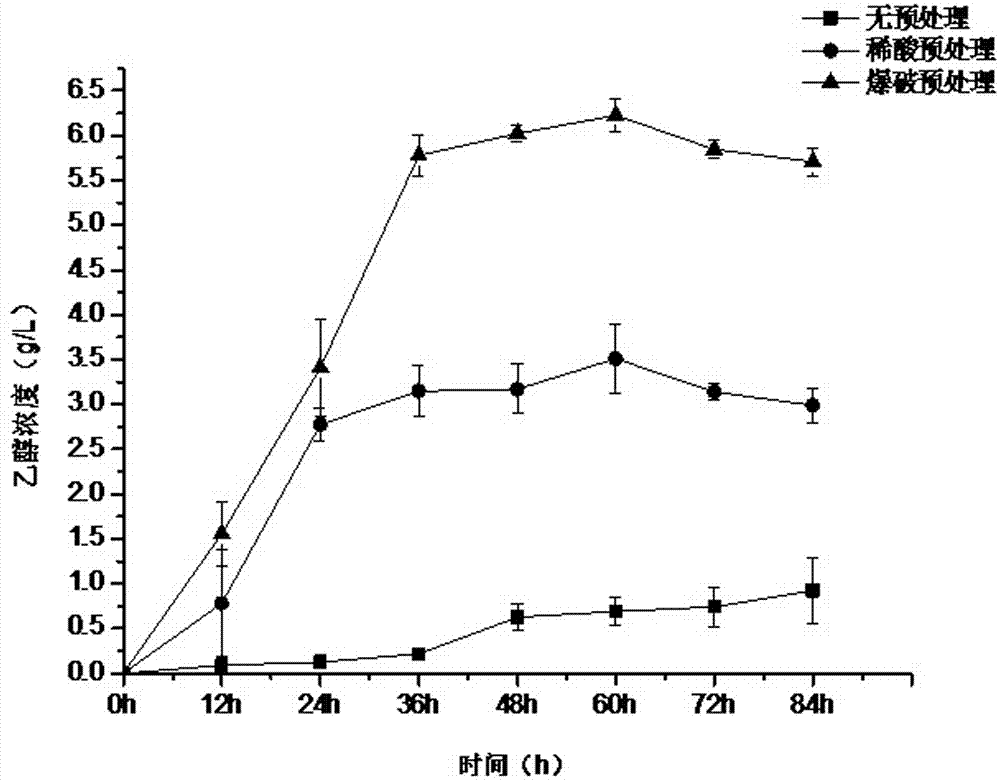

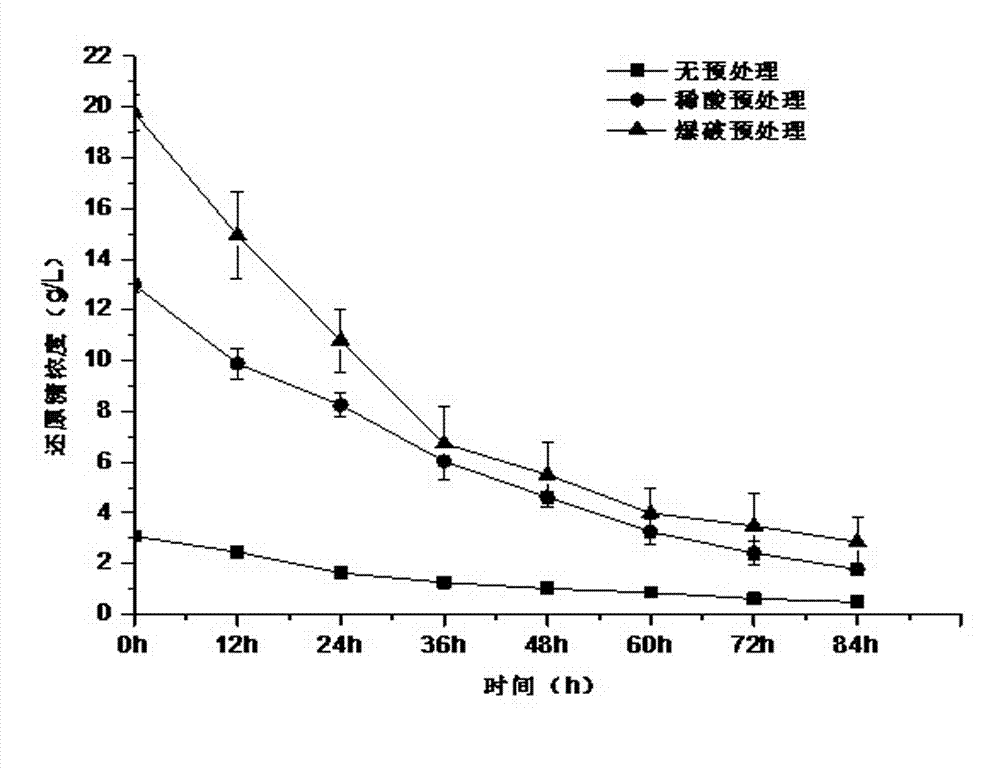

Method for producing ethanol from tobacco stems by fermentation

ActiveCN104745643ARealize rational development and utilizationImprove enzymatic hydrolysis rateBiofuelsFermentationFiberPretreatment method

The invention belongs to a method for producing ethanol from tobacco stems by fermentation; a fibrous raw material is processed under the action of high-temperature and high-pressure steam by adopting a steam explosion method; the component separation of the raw material is realized through a sudden depressurizing process; therefore, cellulose, hemicellulose and lignin in the material are degraded and dissolved out; cellulose is easily subjected to emzymolysis so as to be converted into sugar; and then, fermentation of cellulosic ethanol is carried out by selectively using an issatchenkia orientalis strain. The pre-processing method can be applied to various agricultural wastes, such as bagasse, wheat straws, rice straws, corn stalks and corncobs; the enzymatic hydrolysis ratio of cellulose can be obviously increased; ethanol is prepared by fermentation by taking tobacco wastes as the raw materials; therefore, the operation process is simple; the production cost is low; furthermore, the agricultural wastes can be changed into wealth; environmental pollution is reduced; and reasonable development and utilization of agricultural surplus resources are realized.

Owner:HENAN AGRICULTURAL UNIVERSITY

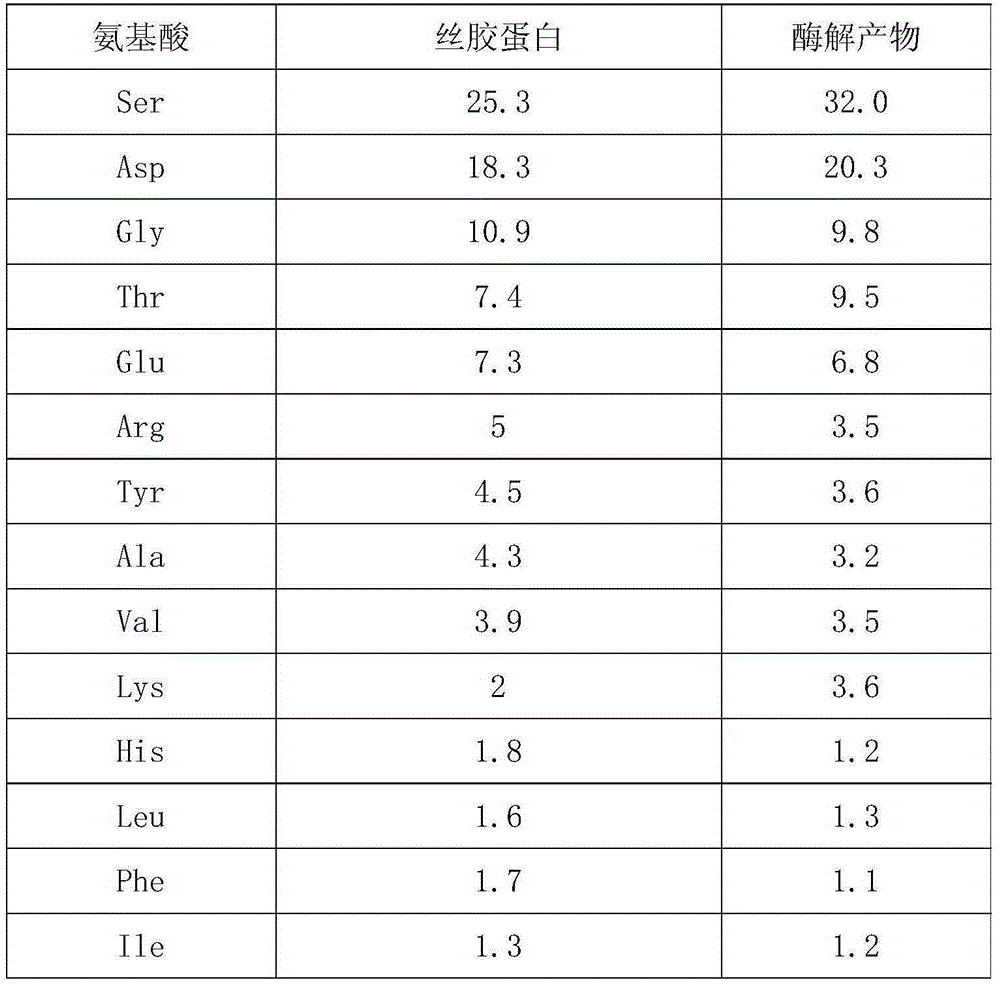

Method for preparing sericin polypeptides with aqueous enzymatic method

InactiveCN105331661AImprove qualityImprove enzymatic hydrolysis rateFermentationAlkaline proteaseNeutral protease

The invention provides a method for preparing sericin polypeptides with an aqueous enzymatic method. According to the method, sericin is taken as a raw material, a 4%-7% sericin aqueous solution is prepared, the PH is adjusted to range from 8 to 9 by the aid of a 1 mol / L sodium hydroxide solution, Alcalase2.4L alkaline protease is added, enzymolysis is performed at the temperature of 55-65 DEG C for 1-2 h, then the PH is adjusted to 7 by the aid of 1 mol / L hydrochloric acid, AS1398 neutral protease is added, enzymolysis is performed at the temperature of 45-55 DEG C for 1-2 h, inactivation is performed at the temperature of 80-90 DEG C for 20-40 min, centrifugation is performed, a supernate is taken, concentrated and freeze-dried, and the sericin polypeptides are obtained. The sericin is degraded twice by the aid of the Alcalase2.4L alkaline protease and the AS1398 neutral protease, so that the enzymolysis rate is greatly increased. Meanwhile, the technology is simple, the method is safe and environment-friendly, the cost is low, the obtained sericin polypeptides have high quality, and industrial production conditions are provided.

Owner:ZHEJIANG ESIGMA BIOTECH CO LTD

Composite enzymolysis reagent for keratin enzymolysis and application method thereof

ActiveCN104673772AImprove efficiencyTo avoidHydrolasesAnimal proteins working-upBiotechnologyPROTEIN S HEERLEN

The invention discloses a composite enzymolysis reagent for keratin enzymolysis and an application method thereof. The composite enzymolysis reagent comprises streptomycete cutin protease, yeast enzyme and a reducing agent. The application method comprises the following steps: firstly, performing ungrease treatment on a natural raw material with cornifin, a yeast enzyme and a reducing agent; adding the natural raw material with the cornifin after ungrease treatment in the step 1) into a combined enzymolysis agent liquid, pretreating for 15-25 minutes at the room temperature without oxygen, further adjusting the pH value of the combined enzymolysis agent liquid to be 7.0-7.5, controlling the temperature to be 50-60 DEG C, and performing enzymolysis for 12-24 hours, thereby obtaining a keratinase liquid; decoloring and sterilizing the keratinase liquid; and performing vacuum drying, thereby obtaining protein powder. The composite enzymolysis reagent is rapid in enzymolysis and high in keratin degradation rate, and generation of toxic substances can be effectively prevented, so that the prepared protein powder is safe and non-toxic and high in nutrition component.

Owner:湖州珍贝羊绒制品有限公司

Method for producing ethanol by using sugarcane bagasse cellulose and sugarcane molasses

InactiveCN106086085ARealize comprehensive utilizationReduce manufacturing costBiofuelsMicroorganism based processesCelluloseHydrolysate

The invention relates to a method for producing ethanol by using sugarcane bagasse cellulose and sugarcane molasses. The method comprises the following steps: sugarcane bagasse pretreatment, enzyme hydrolysis and saccharification of sugarcane bagasse cellulose, sugarcane molasses pretreatment and mixed fermenting of sugarcane bagasse cellulose hydrolysate and the sugarcane molasses. Yeast strains are fixed to carry out ethanol fermentation by using double-enzyme saccharification sugarcane bagasse cellulose and an adsorption fixing material, the density of the yeast strains can be increased, furthermore, the yeast strains can be repeatedly used, sugar consumed by yeast propagation is reduced, fermentation strength and yield of products are improved, the yield of the ethanol reaches 93.5%, comprehensive utilization of sugarcane bagasse and molasses resources is realized, comprehensive economic benefit of sugarcane sugar producing enterprises can be improved remarkably, and a win-win situation of economic benefit and economic benefit is realized.

Owner:张聪聪

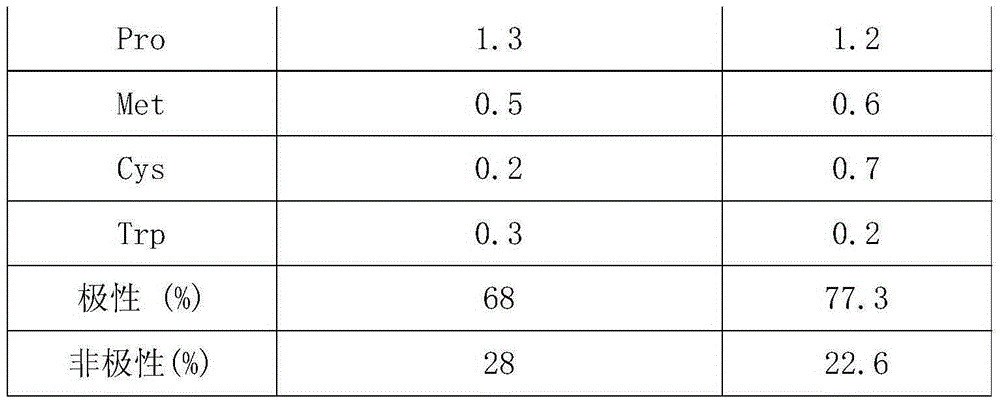

Preparation method of composite amino acid chelated calcium

InactiveCN108477619AReduce manufacturing costRemove fishy smellFermentationFood ingredient functionsChelated calciumCalcium EDTA

The invention discloses a preparation method of composite amino acid chelated calcium. The method adopts scallop outer mantles and scallop shells which are leftovers of scallop processing as raw materials, fully utilizes the characteristics that the scallop outer mantles are high in crude protein content and the scallop shells are high in calcium carbonate content, and subjects the scallop outer mantles to cooking, degreasing, enzymolysis and chelation with calcium salt so as to obtain an organic calcium product rich in a plurality of amino acids. Not only the method fully utilizes the leftovers of scallop processing and reduces production cost, but also the prepared composite amino acid chelated calcium has high nutritional value and a delicious taste so as to bring great economic value.

Owner:QINGDAO UNIV

Method for producing hemepeptide by using red blood cells of animal blood as raw materials

InactiveCN102342368ALoose double helixImprove enzymatic hydrolysis rateProtein composition from bloodAmino acid bindingThermal denaturation

The invention discloses a method for producing hemepeptide by using red blood cells of animal blood as raw materials. The method comprises the following steps of: adding water into the red blood cells of the animal blood, stirring for wall breakage, heating, performing thermal denaturation, adjusting the pH of the obtained mixture to be between 7.5 and 9.0 at the temperature of between 40 and 60 DEG C, adding special enzyme 1122 for blood cell hydrolysis in a ratio of 1,000 to 2,500U / (g protein), performing enzymolysis for 4 to 8 hours with stirring, inactivating the enzyme, filtering, concentrating the filtrate, performing spray drying, and thus obtaining the hemepeptide. According to the method, the red blood cells are subjected to wall breakage and thermal denaturation, so that the double-spiral structure of the red blood cell protein becomes loose, the special enzyme 1122 for blood cell hydrolysis enters the amino acid binding sites in the red blood cell protein more easily to perform enzymolysis, and the enzymolysis rate is improved; and the adopted special enzyme 1122 for blood cell hydrolysis can be used for simultaneous enzymolysis of multiple amino acid binding sites of the red blood cell protein, so that the enzymolysis efficiency and the yield are further improved, and the yield of the whole hydrolysis process reaches over 78 percent.

Owner:赵运生 +3

Process for producing livestock feed additive from reside and dreg materials

InactiveCN104187174AReduce consumptionEasy to separateFood processingAnimal feeding stuffFiberMixed materials

Based on the problem of preparing residues and dregs into feed in the prior art, the invention provides a process for producing a livestock feed additive from reside and dreg materials. The process comprises the following steps: (1) sufficiently mixing one or more residue and dreg materials with water according to a certain liquid and solid ratio; (2) pretreating the mixed material through a hydrothermal extraction method; (3) adding amylase, hemicellulase and proteineous enzyme for material enzymolysis into the treated material; (4) filtering and screening so as to separate solid phase from liquid phase; (5) drying the liquid phase, thereby obtaining the feed additive with high additional values. The feed additive with high additional values, which is prepared through the method, can not only provide high protein, energy and microelements for animals, but also can reduce the use amount of antibiotics due to the probiotic functions of cello-oligosaccharide and xylo-oligosaccharide, the residual cellulose, lignin and mineral substances generated after the residues and the dregs are treated can be directly used as environment-friendly bio-fertilizers which are returned to the land, so that the economic utilization values of the residues and the dregs are greatly increased, the grains for feed are saved, and the environment pollution problem caused by the residues and the dregs is solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

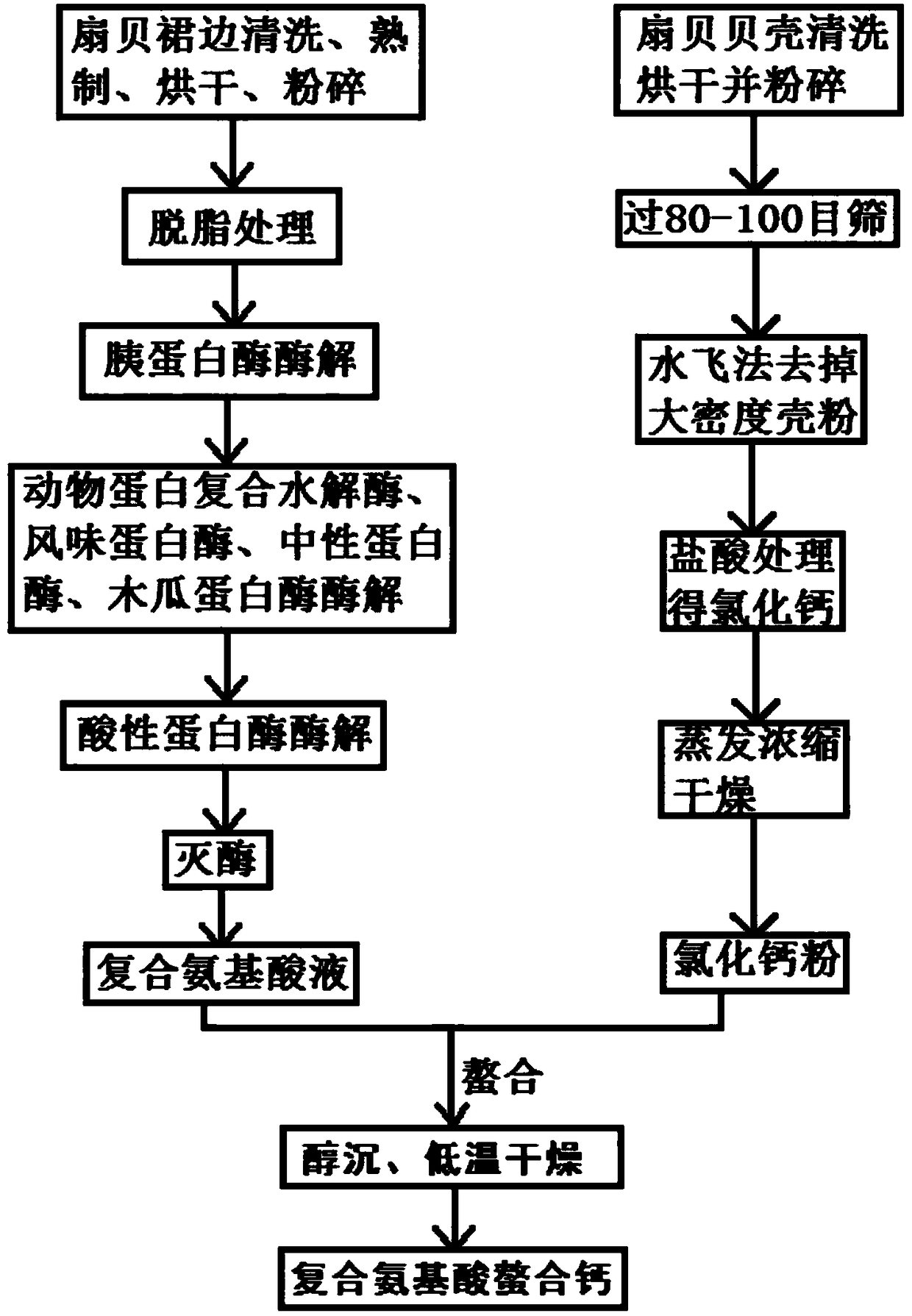

Device and method for performing continuous pretreatment on lignocellulose material by utilizing microwave-diluted acid steam explosion

ActiveCN105296329AImprove enzymatic hydrolysis rateIncrease reaction rateBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseEngineering

The invention provides a device and method for performing continuous pretreatment on lignocellulose material by utilizing microwave-diluted acid steam explosion and relates to the field of biomass pretreatment. The lignocellulose material is conveyed into a feeder, and diluted acid in a diluted acid tank is continuously sprayed to the material through a spraying valve to be steeped. The material enters an anti-back spraying pressurization screw device and undergoes kneading, extrusion dehydration, pressurization and accelerated steeping in the anti-back spraying pressurization screw device and then enters a reaction retention device; in the reaction retention device, the material undergoes combined effects of microwaves and saturated steam and performs spray explosion on a cyclone separator through a spray explosion valve, and a solid product is separated. The lignocellulose undergoes continuous treatment of combination of microwave pretreatment and diluted acid steam explosion pretreatment for the first time, and the device capable of implementing the process smoothly is designed. According to the method, the lignocellulose treatment amount is improved, the treatment cycle is shortened, the energy consumption is reduced, the enzymatic accessibility of the material after pretreatment is improved, and the cellulose enzymolysis rate is improved.

Owner:BEIJING UNIV OF CHEM TECH

Aflatoxin-effectively-removing peanut oil extracting method

InactiveCN105820869AIncrease the fragranceImprove oil yieldFatty-oils/fats refiningFatty-oils/fats separationAsperthecinAspergillus flavus

The invention provides an aflatoxin-effectively-removing peanut oil extracting method .The aflatoxin-effectively-removing peanut oil extracting method includes the following steps of pretreating, crude oil preparing, degumming, alkali refining, primary evaporating and separating of a solvent, secondary evaporating and separating of a solvent, dewaxing and deodorizing .By means of the aflatoxin-effectively-removing peanut oil extracting method, pigment and waxiness in grease are effectively removed, removing of aspergillus flavus and producing of peanut oil are combined accordingly, production of the peanut oil is not influenced, the content of the aspergillus flavus is greatly decreased, invariable nutrient substance ingredients are reserved through the produced peanut oil, taste is pure, fragrance is lasting, the requirements of persons for original-taste-and-flavor superfine peanut oil can be met, the reaction condition is wild, operation is easy, and good application prospects are achieved.

Owner:FUYANG SIBO IND DESIGN

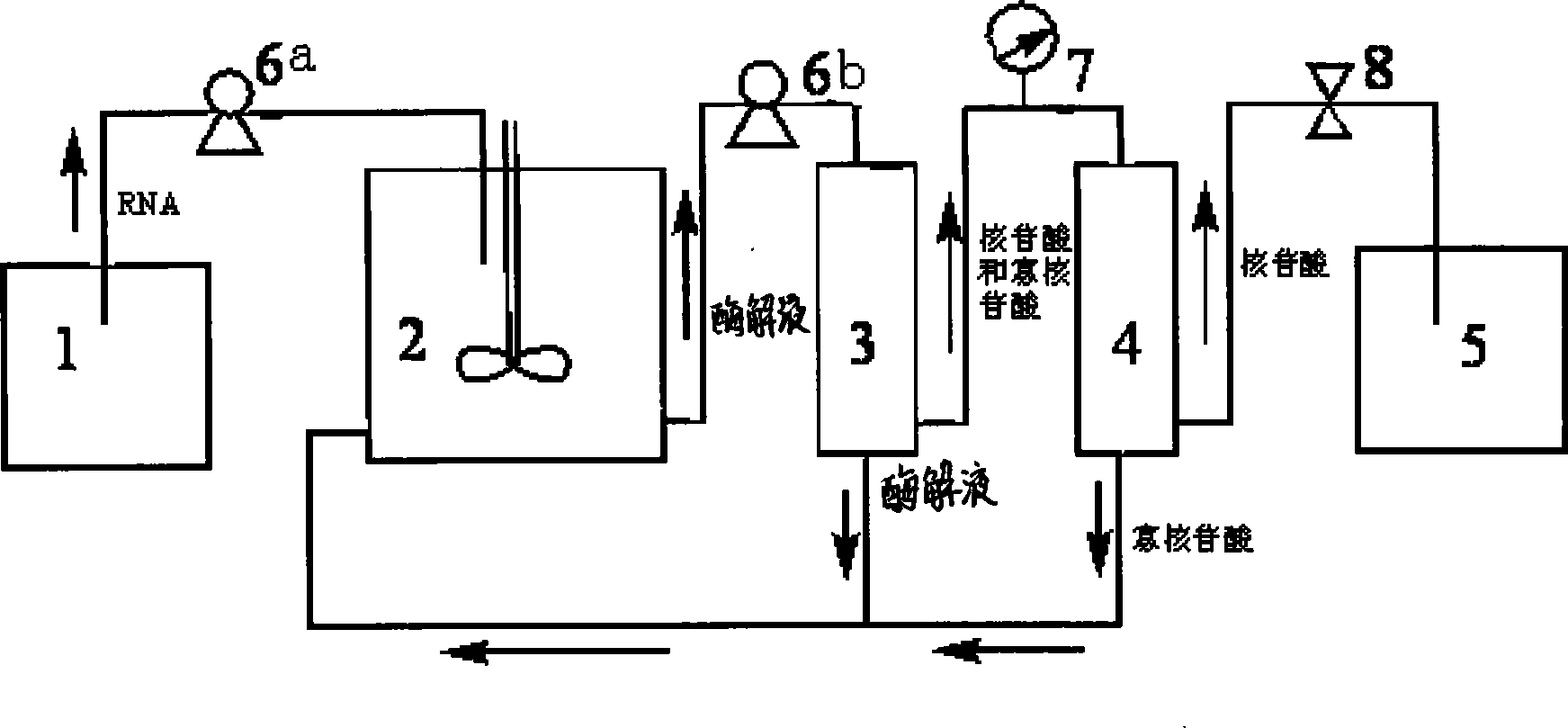

Method for preparing nucleotide by reaction separation coupling technology

The invention discloses a method for preparing nucleotide by utilizing a reaction separation coupling technique, namely the nucleotide is prepared by using nuclease P1 for enzymatic hydrolysis of ribonucleic acid and the reaction separation coupling technique combining an enzymatic hydrolysis reactor, an ultrafiltration device and a nanofiltration device. The method utilizes the ultrafiltration device to separate an enzymatic hydrolysis product from an RNA phase, overcomes the product inhibiting effect in the production of the nucleotide, improves the enzymatic hydrolysis rate of the RNA and the concentration of the nucleotide, simultaneously utilizes the nanofiltration technique to recover the oligonucleotide lost in the ultrafiltration process, and further improves the enzymatic hydrolysis rate of the RNA. The method has the advantages of realizing the continuous separation production of products, shortening the process flow, breaking through the limitation of chemical balance, greatly improving the utilization ratio and the reaction yield of the enzyme, lowering energy consumption, and reducing production cost.

Owner:NANJING UNIV OF TECH +1

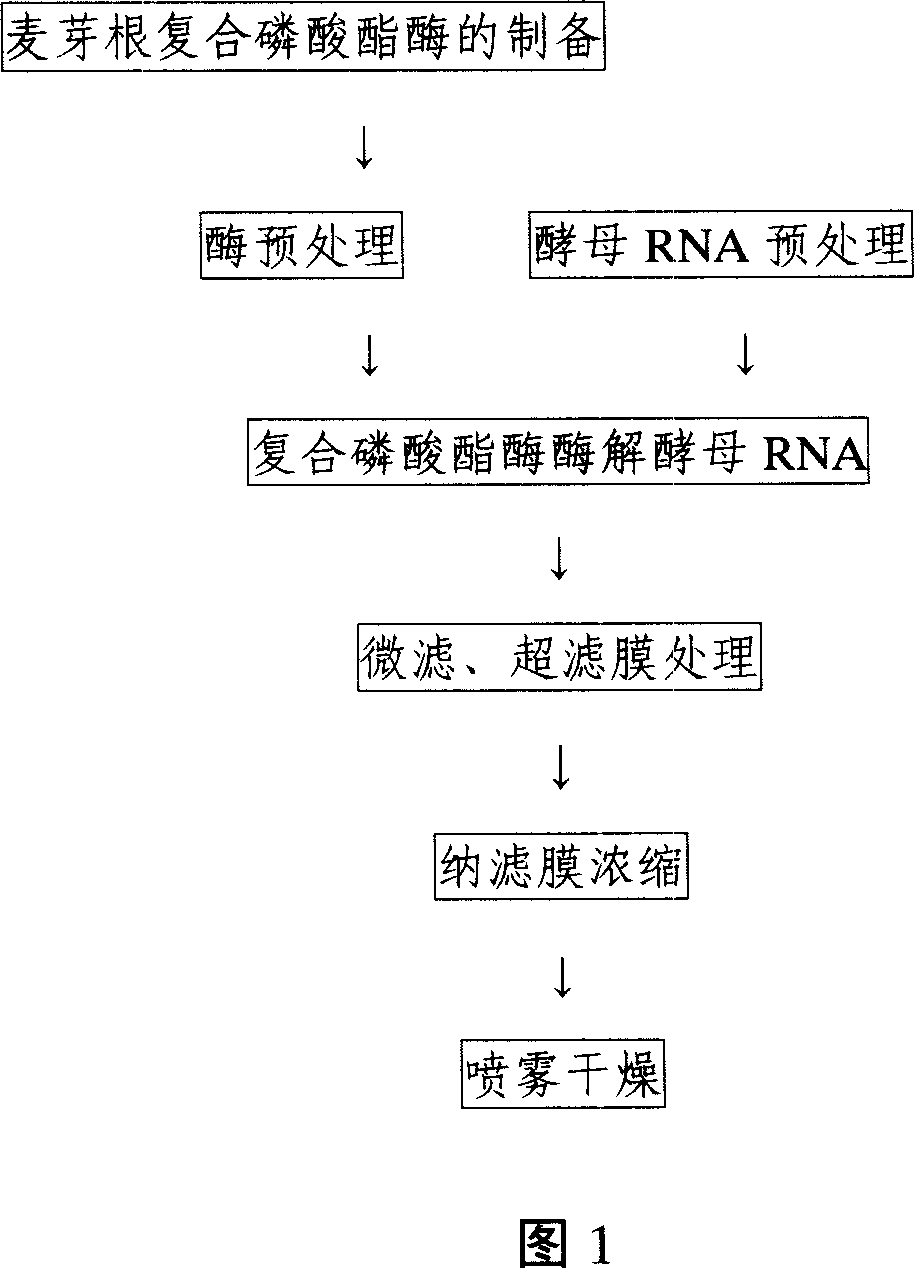

Method for preparing 5'-nucleotides using malt root complex phospho-esterase

The invention discloses a making method of 5'-nucleic acid through enzymolyzing RNA by composite phospho-esterase of malt root, which is characterized by the following: adopting liquid RNA as substrate; inhibiting the activity of phosphomonoesterase and 3'-phosphodiesterase through the activity of composite phospho-esterase; obtaining the production of 5'-nucleic acid more than 15mg / ml.

Owner:北京燕京中科生物技术有限公司

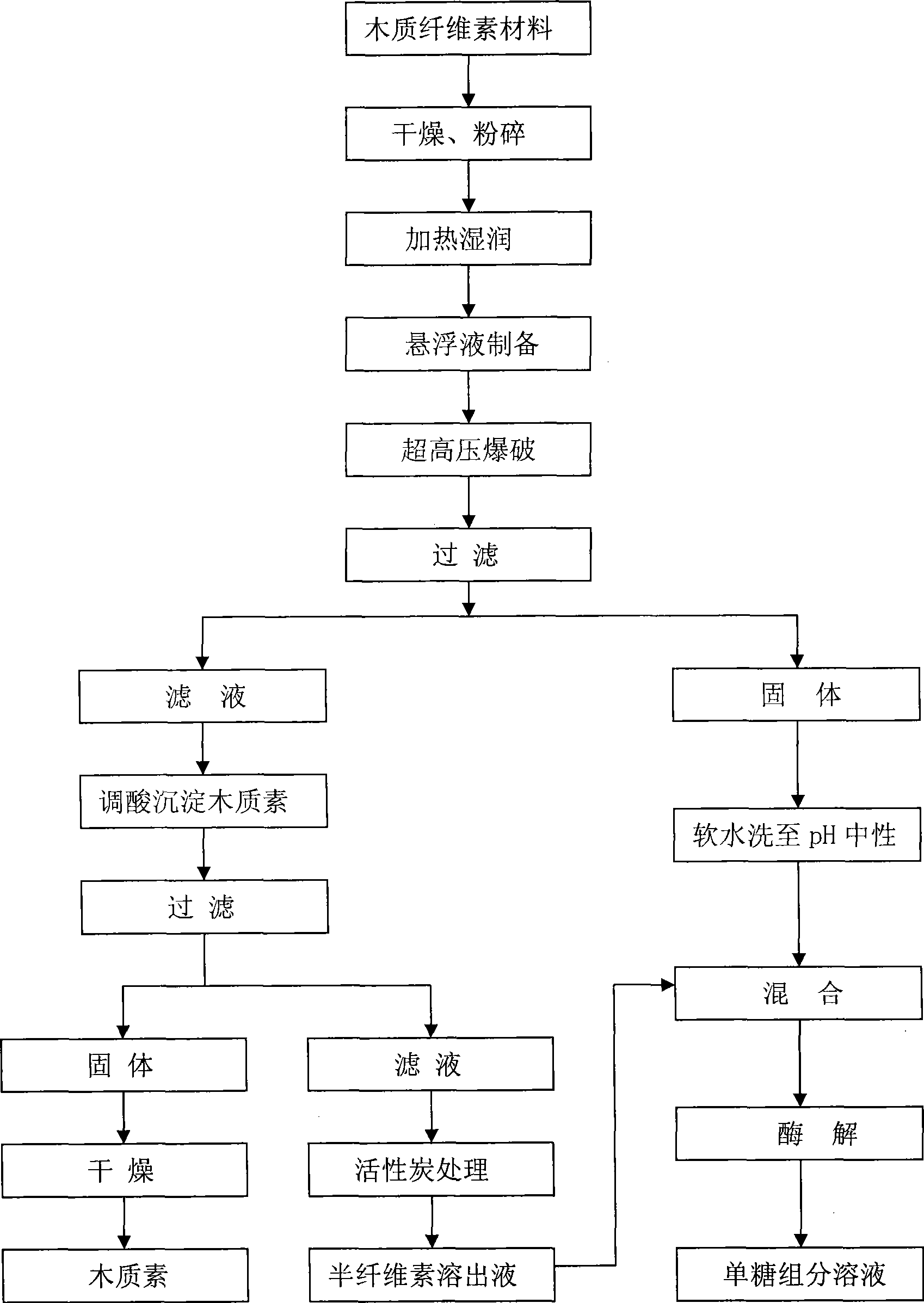

Pretreatment method for ultra-high pressure blasting wood fiber material

InactiveCN101463571AImprove enzymatic hydrolysis rateReduce processing intensityPulping with inorganic basesRaw material divisionCelluloseFiber

The invention discloses a pretreatment method for lignocellulosic materials. The method is as follows: a high-pressure homogenizer which is conventional but is currently only used for processing liquid state materials is taken as the treatment equipment, a stirring device is installed at the feed funnel of the homogenizer, the materials are exploded under ultrahigh pressure by means of transient pressure and pressure elimination in the homogenizing process. The method comprises the steps as follows: the pre-processes like drying, smashing and sieving, etc. of the lignocellulosic materials, the heating and moistening of the materials, the preparation of the suspending liquid, the ultrahigh pressure explosion and the material process after explosion, etc. Compared with various currently disclosed pretreatment methods for lignocellulosic materials, the method not only has the advantages of low requirement for equipment, mild process condition, no harmful substances which inhibit microorganism fermentation and low energy consumption, etc. but also can process the ultramicrostructure which totally changes the lignocellulosic materials and creatively realize the full hydrolyzation of the lignocellulosic materials by making use of the cellulolytic enzyme system of low beta-glucosidase activity.

Owner:GUANGXI ACAD OF SCI

Chicken flavor development powder and preparation thereof

The invention discloses a chicken flavour powder and a preparation method thereof. The chicken flavour powder comprises dust salt, white granulated sugar powder, glucose powder, gourmet powder, D- xylose, isoleucine, enzymolysis solution, soy sauce, yeast extract, sesame oil, chicken oil, ethyl maltol, IMP, corn starch and chicken flavor. The invention adopts the method combining the microwave drying technology and compound enzyme enzymolysis technology to produce the chicken flavour powder which has good taste, little environmental pollution, stable quality and high safety.

Owner:TIANNING FLAVOR JIANGSU

Chicken flavor material and preparation method thereof

The invention discloses a chicken flavor material and a preparation method of the chicken flavor material. The chicken flavor material comprises the components of chicken, a chicken bone, an egg, chicken fat, water, protease, compound flavor protease, glucose, white sugar, xylose, vitamin B1, L-cysteine, methionine, salt, aginomoto, corn starch and maltodextrin. The prepared chicken flavor material keeps the original taste and flavor of the natural chicken to the highest extent, the delicate mellow flavor is greatly improved, the taste is real, the aftertaste lasts long, the chicken flavor material is excellent in heat stability, only 10% of the chicken flavor material is denatured after being sterilized at the temperature of 121 DEG C, and the technological requirements in thermal treatment in the food industry are met.

Owner:HUNAN JIAPIN JIAWEI BIOTECHNOLOGY CO LTD

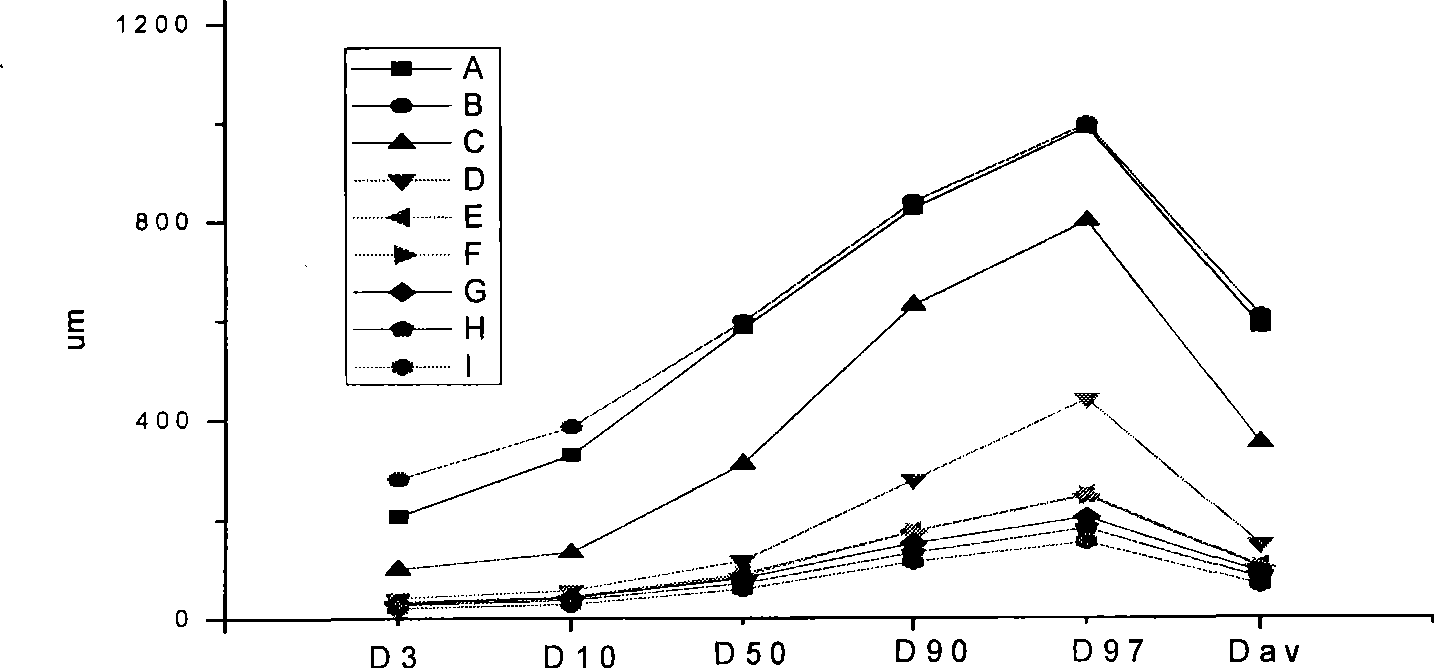

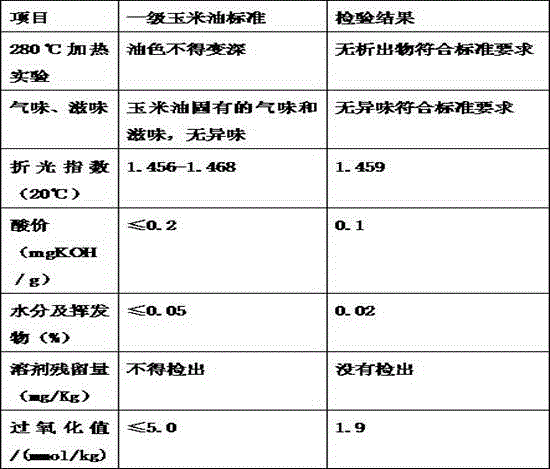

Corn oil and preparation method thereof

InactiveCN105875870AIncrease the fragranceImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionSolventAspergillus flavus

The present invention provides corn oil and a preparation method thereof. The preparation method comprises the following steps: pretreating, raw oil preparing, degumming and alkali refining, primary solvent evaporating and isolating, secondary solvent evaporating and isolating, dewaxing, and deodorizing. The method can effectively remove pigments and wax in the oil, combines the removal of aspergillus flavus and production of the corn oil together, does not affect the production of the corn oil, and greatly reduces the content of the aspergillus flavus. Besides, the produced corn oil retains the nutrient contents to be unchanged, is pure in taste and lasting in fragrance, can satisfy people's requirement for special grade corn oil with original juice and original tastes, is mild in reaction conditions and simple in operation, and has good application prospect.

Owner:SHANDONG YUHUANG GRAIN & OIL FOOD

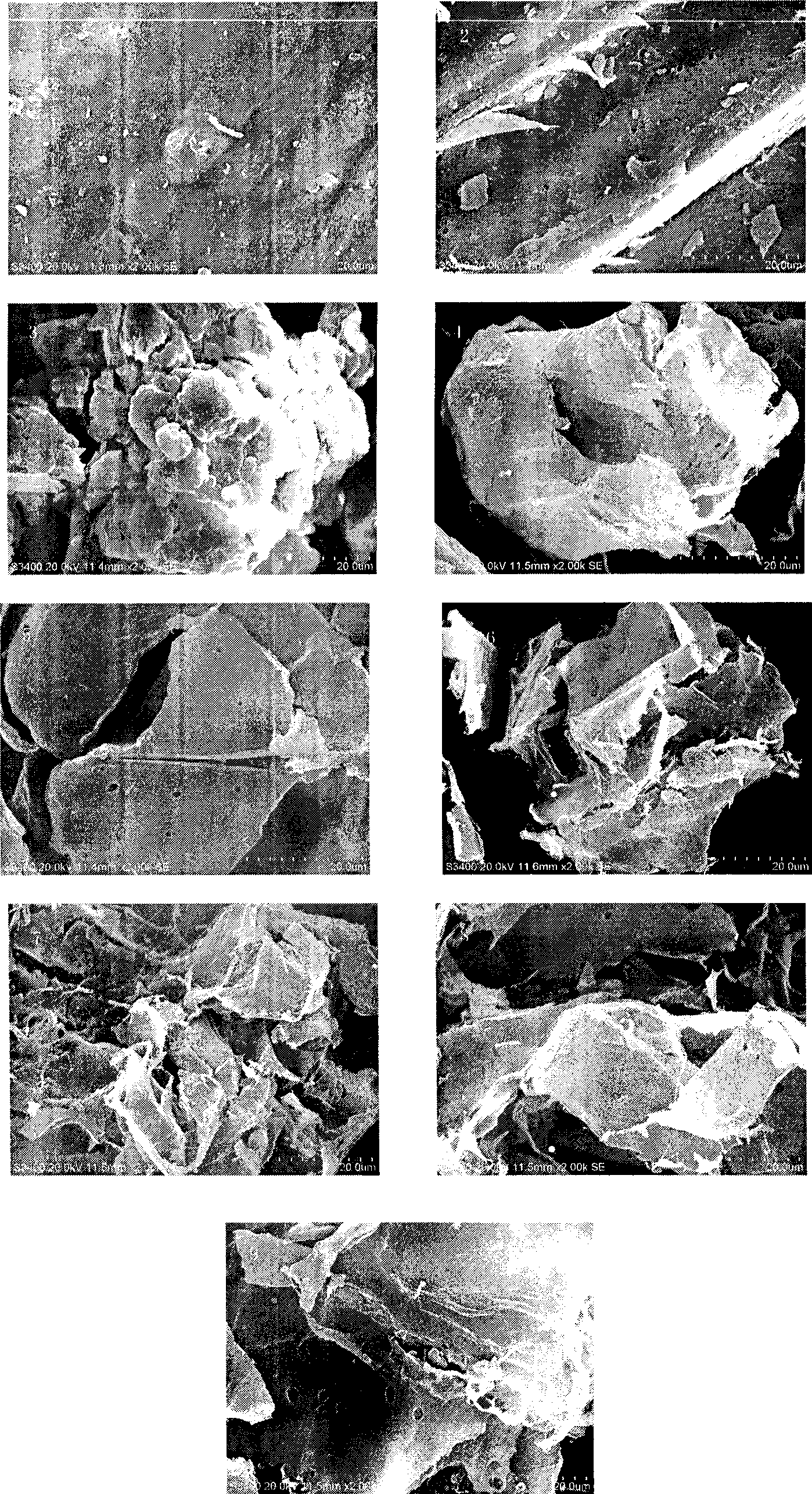

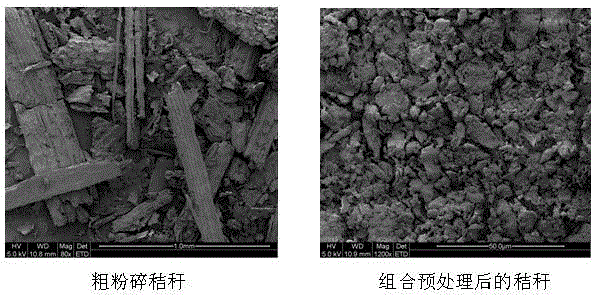

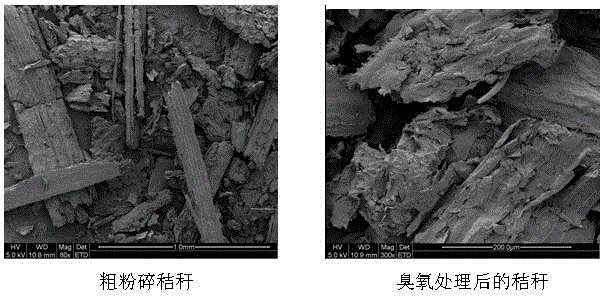

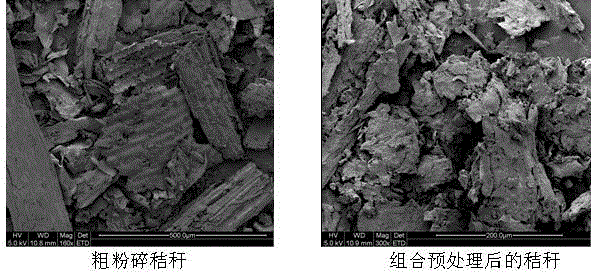

Efficient combined preprocessing method for straws

ActiveCN104131050APromote digestionMild treatment conditionsFermentationPretreatment methodCellulase

An efficient combined preprocessing method for straws employs an ozone processing method combined with a ball milling method to perform efficient combined pretreatment on straws, and concretely comprises two parts: (1) firstly performing ozone pretreatment on crushed straws, and then performing ball milling pretreatment; and (2) firstly performing ball milling pretreatment on crushed straws and then performing ozone pretreatment. After straws are subjected to combined pretreatment, water-washing acid removal and compound cellulase enzymolysis, the glycation rate is substantially improved.

Owner:JIANGNAN UNIV

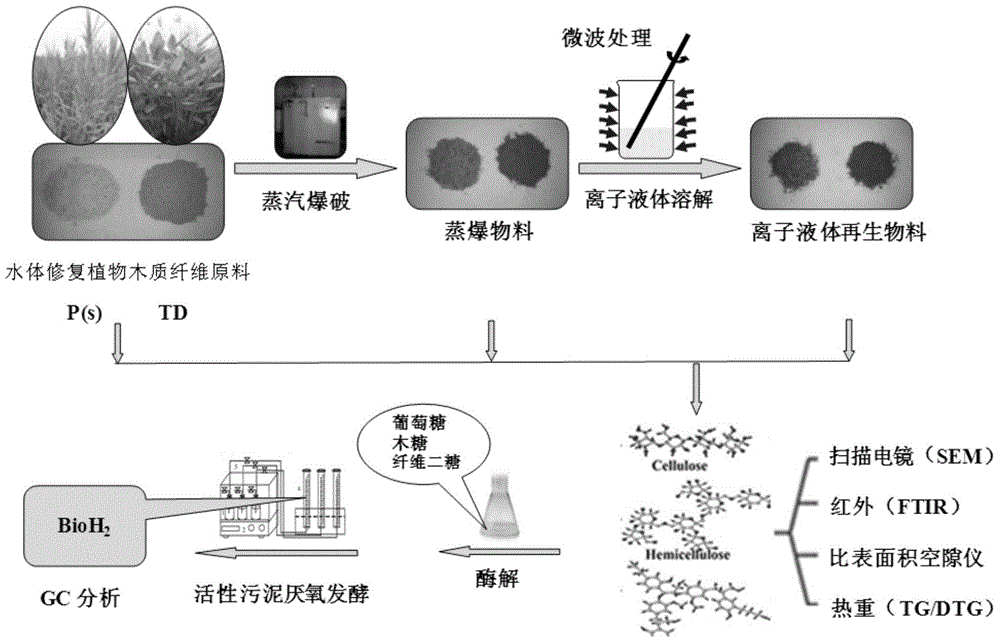

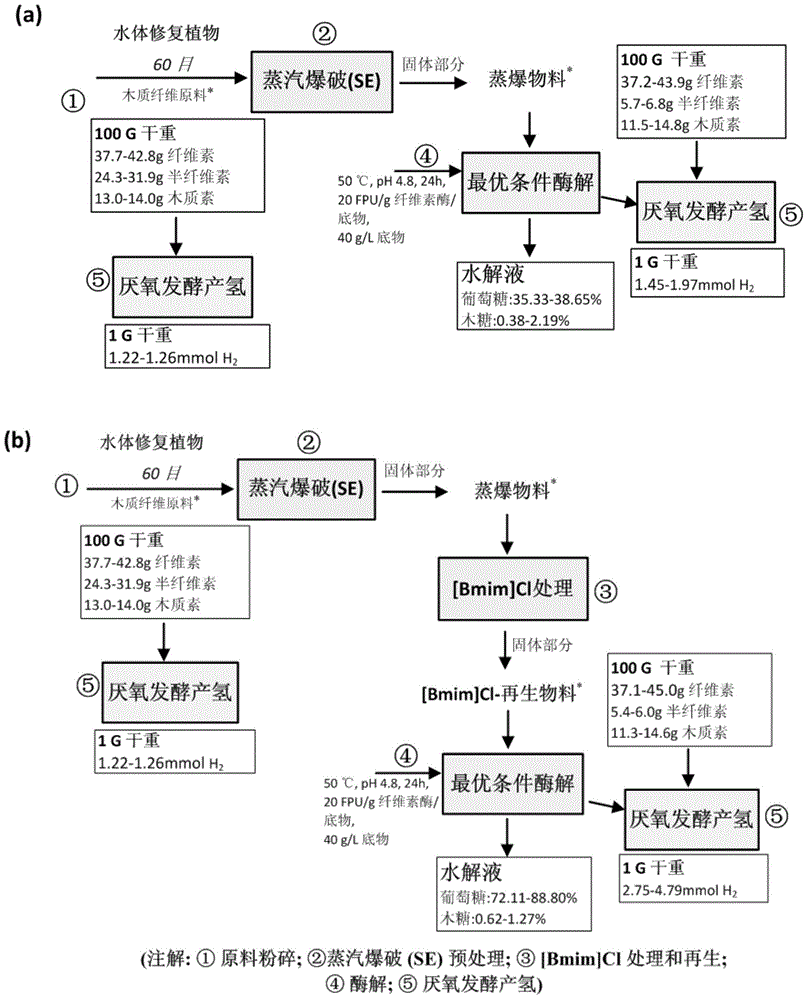

Water body remediation wood fiber raw material pretreatment method and corresponding hydrogen production method

The invention discloses a water body remediation wood fiber raw material pretreatment method sequentially comprising the following steps: (1) coarsely grinding, that is, coarsely grinding a water body remediation wood fiber raw material after air drying; (2) carrying out steam explosion, that is, carrying out steam explosion pretreatment on obtained sieving powder; (3) dissolving with an ionic liquid and regenerating a material, that is, adding the ionic liquid to a steam explosion material for dissolution treatment, and separating out solid from the steam explosion material after dissolution treatment by using water as an antisolvent; and (4) carrying out enzymatic saccharification, that is, carrying out enzymolysis by using the steam explosion material obtained from the step (2) or regeneration material obtained from the step (3) as a substrate to obtain an enzymatic saccharification liquid. The invention also provides a method for carrying out fermentation hydrogen production by utilizing the enzymatic saccharification liquid obtained from the method, that is, applying the enzymatic saccharification liquid to biological hydrogen production.

Owner:ZHEJIANG UNIV

Method for treating straws through dissolution and regeneration

InactiveCN105154495ASimple processing methodImprove enzymatic hydrolysis rateFermentationLithium chlorideOrganic solvent

The invention discloses a method for treating straws through dissolution and regeneration. The method comprises the following steps: firstly, conducting pretreatment on pulverized straws through an ethanol sulfate water solution to remove hemicellulose and lignose; then drying pretreated straws and activating the dried straws through an organic solvent; secondly dissolving the activated straws into lithium chloride / N,N-dimethylacetamide to obtain a straw solution; thirdly injecting the straw solution into water for regeneration to obtain regenerated straws; finally conducting water washing on the regenerated straws to remove the organic solvent and saline ions, and conducting enzymolysis by adopting cellulose complex enzyme. The straw treating method is simple, and the enzymolysis rates of cellulose and hemicellulose in the straws are greatly improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

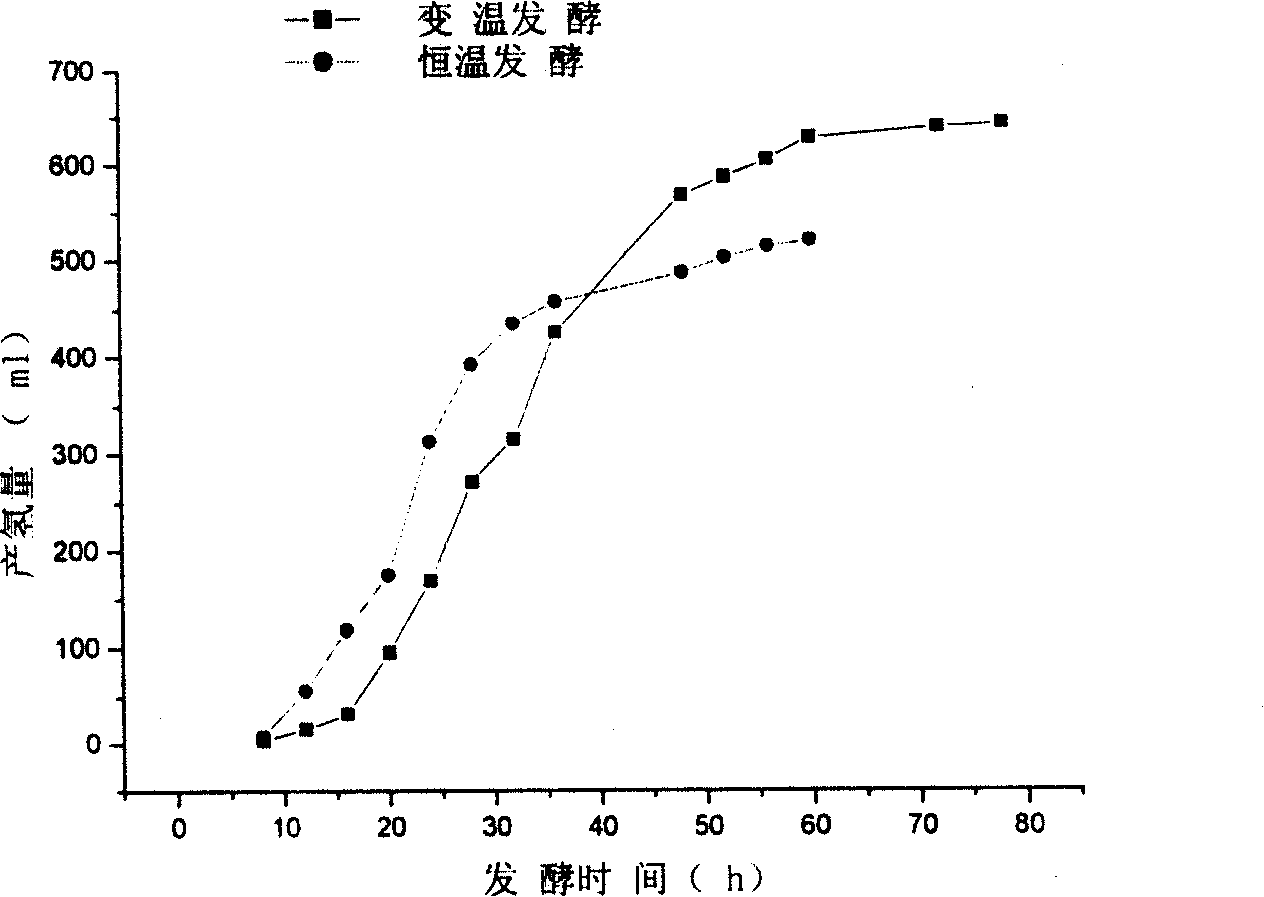

Method for steam-exploded straw hydrogen production by controlling temperature of fermentation process

InactiveCN101177694AMeet the needs of fermentationImprove enzymatic hydrolysis rateMicroorganism based processesFermentationCelluloseMicroorganism

The invention discloses a hydrogen production method by using steam-exploded straw fermentation and adjusting the temperature of the fermentation process. The method comprises the steps that: the steam-exploded straw is added with carbamide, KH2PO4, MgSO4 and water to obtain a steam-exploded straw culture medium; the butyric acid clostridium is inoculated in a seed culture medium and an anaerobic culture at 35 DEG C is conducted to logarithmic phase so as to obtain seed liquid; the steam-exploded straw is inoculated with the seed liquid and is deoxidized through introducing nitrogen; the obtained material is fermented for 6 to 12 hours under the temperature of 35 DEG C, then fast heated to 40 to 46 DEG C and maintained for 1 to 3 hours; the temperature of the obtained material is fast lowered to 35 DEG C to continuously ferment under constant temperature; the ferment lasts 22 to 36 hours, and then the temperature is heated once again to 40 to 46 DEG C and maintained for 1 to 3 hours; the temperature of the obtained material is lowered to 35 DEG C to ferment under constant temperature till no gas produces; the generated gas is separated to make pure hydrogen. By using the method, the temperatures are enhanced a plurality of times for a short time during fermentation process, which can promote substrate cellulose to be degraded; since the temperature enhancing time is shorter, the microorganism activity has a little effect and the hydrogen yield is greatly enhanced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing fumaric acid fermentation liquor by fermenting corncob cellulose

InactiveCN103789360AReduce loss rateEfficient removalMicroorganism based processesFermentationMicroorganismMicrobial transformation

The invention provides a method for preparing fumaric acid fermentation liquor by fermenting corncob cellulose. After corncob is pretreated by using alkaline hydrogen peroxide, lignin and hemicellulose in the corncob can be removed effectively, the purity of the cellulose is increased, the cellulose is loose in structure and easier to hydrolyze, and the loss ratio of the corncob is reduced to 26.85-27.16 percent. On the basis, the pretreated corncob raw material is subjected to pre-enzymolysis, a part of the cellulose in the raw material is converted into small-molecular sugar, a rhizopus delemar seed solution is introduced, enzymolysis and fermentation are performed synchronously, glucose is converted into fumaric acid continuously in an enzymolysis process, the feedback inhibition action of a large amount accumulated glucose on enzyme in a subsequent enzymolysis process is relieved, and the cellulose conversion rate and the fumaric acid yield are increased. According to the method, the corncob is taken as a raw material, so that a novel way is opened up for the production of the fumaric acid, and the economical significance of industrial microorganism production is great.

Owner:HEFEI UNIV OF TECH

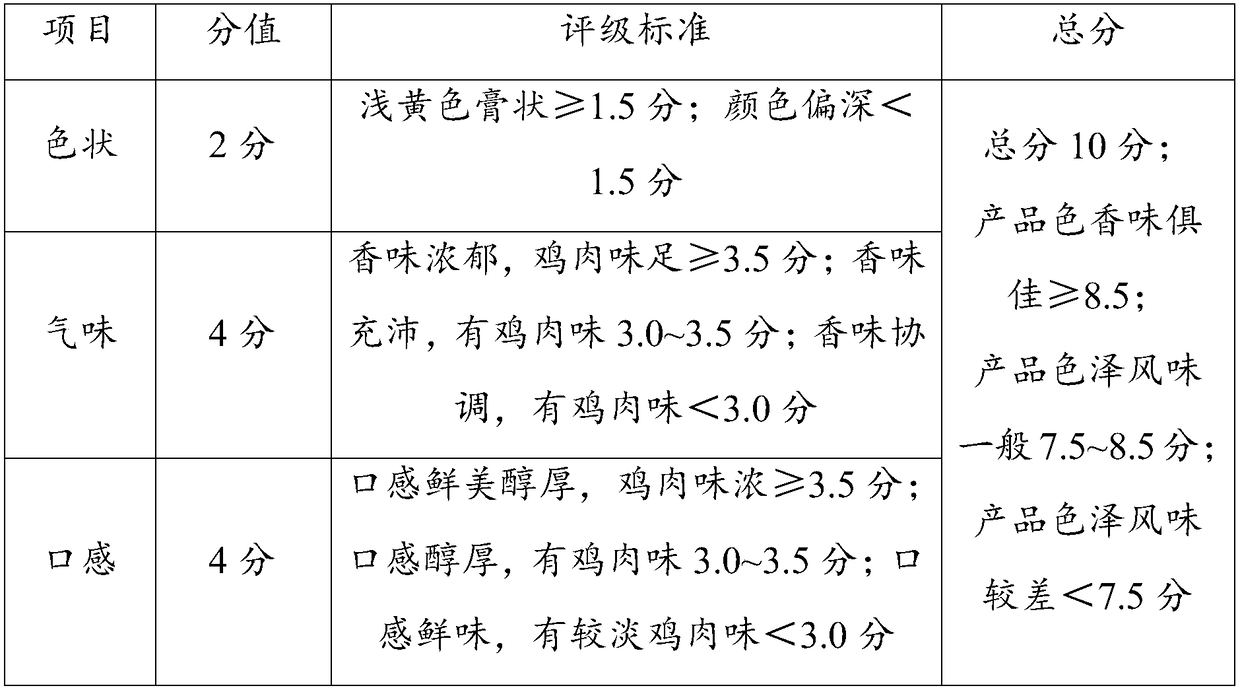

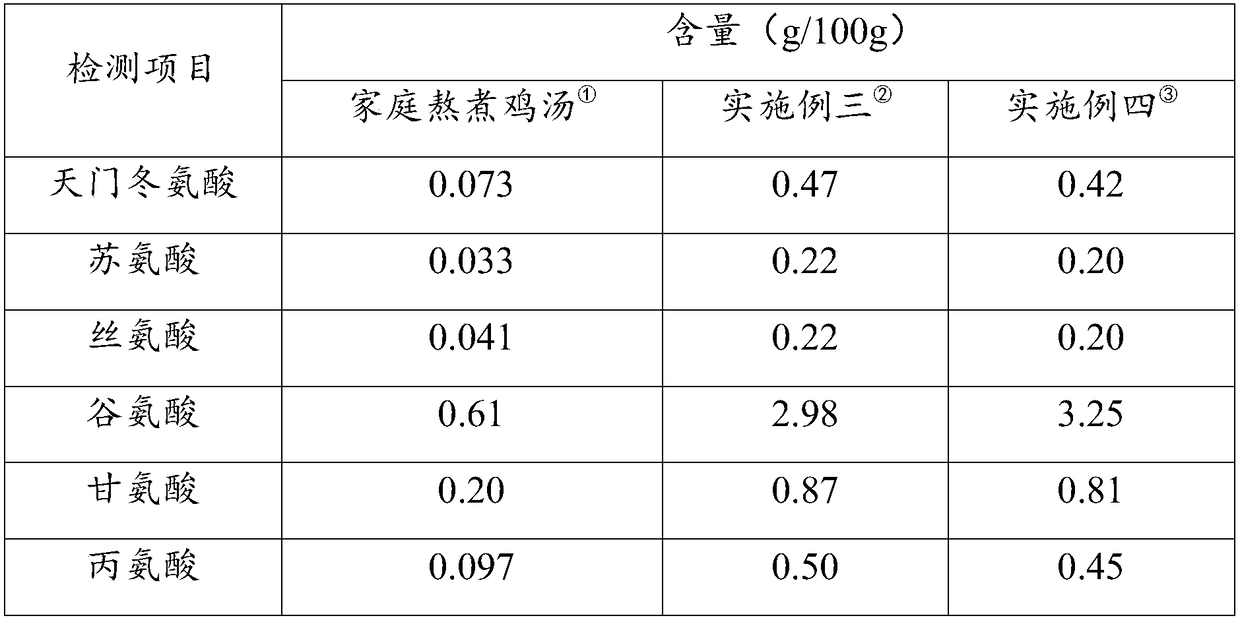

Preparation method of chicken soup cream, chicken soup cream, application and use method

InactiveCN109222054AIncrease concentrationReduce volumeFood scienceMaillard reactionMonosodium glutamate

The invention provides a preparation method of chicken soup cream, the chicken soup cream, application and a use method. The chicken soup cream is prepared by the following steps of boiling whole Sanhuang chicken, crushing into a chicken pulp, and adding multiple types of enzyme to perform ultrasonic enzyme hydrolysis reaction; adding L-cysteine hydrochloride, glucose, yeast extract and hydrolyzedvegetable protein liquid to perform maillard reaction; finally, adding chicken oil, monosodium glutamate and edible salt to flavor, and packaging, so as to obtain the chicken group cream. The chickengroup cream can be prepared into chicken soup, hotpot base soup, rice noodles, pasta soup base, stuffing and the like; the chicken soup cream and water can be mixed according to a ratio of 1:20 to 1:40, so as to obtain the soup material; the chicken soup cream and the foods can be mixed according to a ratio of 1:100 to 3:100, so as to obtain the stuffing. The chicken soup cream has the advantagesthat the nutrients are rich, the taste is delicious, the preparation time is short, the energy consumption is low, and the enzyme hydrolysis rate is high; the convenience in use is realized, and theapplication range is broad.

Owner:成都圣恩生物科技股份有限公司

Balanced-nutrient instant water-soluble fertilizer powder and preparation method thereof

PendingCN108329157AIncrease contact areaVulnerable to attackExcrement fertilisersMicroorganism based treatmentEcological environmentFreeze-drying

The invention discloses balanced-nutrient instant water-soluble fertilizer powder which is prepared from the following raw materials in parts by weight: 100-150 parts of straw, 20-30 parts of water-soluble trace elements, 2-3 parts of a chelating agent, 40-60 parts of earthworm excrement, 10-20 parts of bamboo charcoal, 6-9 parts of composite bacterial floras and proper amounts of lignin peroxidase and cellulase. According to the powder, the straw is subjected to enzymolysis through ultrasonic waves, so that the enzymolysis time can be greatly shortened while the enzymolysis rate is increased;due to freezing drying and vacuum drying, active substances and nutrient components beneficial to crops in the raw materials can be maintained to the maximum extent; due to superfine crushing, the fertilizer powder is small in particle size, high in dissolution degree, high in dissolution speed, in addition easy to absorb by the crops, small in amount of finished product fertilizers, high in croputilization rate and high in stability; and equipment such as a nozzle is not blocked, the soil fertility can be improved while the stress resistance of the crops can be improved, micro-ecological environments of soil can be improved in long-term use of the fertilizer powder, the number of microorganisms in the soil can be increased, and the pollution situations of conventional soil can be remarkably improved.

Owner:汪艳丽

Refining method for removing aflatoxin in corn oil

InactiveCN105802727AResidue reductionAvoid corrosionFatty-oils/fats refiningFatty-oils/fats productionFlavorVaporization

The invention provides a refining method for removing aflatoxin in corn oil.The refining method comprises the following steps of pretreatment, crude oil preparation, degumming alkali refining, primary vaporization for separating solvent, secondary vaporization for separating solvent, dewaxing and deodorization.By means of the method, pigment and waxiness in grease can be effectively removed, the solvent residue is reduced, aspergillus flavus removing and corn oil producing are combined, corn oil production is not affected, the content of aflatoxin is greatly reduced, the components of nutrient substances of the produced corn oil are not changed, taste is pure, fragrance is lasting, the requirement for special-grade corn oil with original taste and flavor of people can be met, reaction conditions are mild, operation is easy, and the method has good application prospects.

Owner:FUYANG SIBO IND DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com