Preparation method of chicken soup cream, chicken soup cream, application and use method

A technology of chicken soup paste and chicken soup, which is applied in the direction of food science, etc., can solve the problems that the production method of chicken soup is not suitable for large-scale industrialization and professional production, chicken nutrients cannot be well dissolved in soup, and the utilization rate of nutrients is low. , to achieve the effect of convenient cooking process, preventing the loss of nutrients and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method for chicken soup paste, comprising the following steps:

[0041] Step (1) Cooking: Weigh 100 parts of whole chicken as raw material, steam and high-pressure cook in a reaction kettle: 118°C, 120min;

[0042] Step (2) crushing: take the cooked chicken in step (1), crush it with a bone mud machine to make chicken pulp;

[0043] Step (3) Enzymolysis: Take the chicken pulp prepared in step (2), add it to the reaction tank, then add 1 part of compound flavor enzyme, 0.5 part of papain and 0.5 part of trypsin for enzymolysis, during the enzymolysis process Stirring and ultrasonic treatment, the ultrasonic frequency is 40Hz, the enzymolysis temperature is controlled at 50°C, the pH is adjusted to 4.5, the enzymolysis time is 60min, and the chicken enzymolysis slurry is obtained;

[0044] Step (4) Maillard reaction: take the chicken enzymolysis slurry prepared in step (3), add 0.4 parts of L-cysteine hydrochloride, 0.2 parts of glucose, 5 parts of chicke...

Embodiment 2

[0048] A kind of preparation method of chicken soup cream, is characterized in that, comprises the following steps:

[0049] Step (1) Cooking: Weigh 100 parts of whole chicken as raw material, steam and high-pressure cook in a reaction kettle: 120°C, 140min;

[0050] Step (2) crushing: take the cooked chicken in step (1), crush it with a bone mud machine to make chicken pulp;

[0051]Step (3) Enzymolysis: Take the chicken pulp prepared in step (2), add it to the reaction tank, then add 1.5 parts of compound flavor enzyme, 0.75 parts of papain and 0.75 parts of trypsin for enzymolysis, and carry out the enzymolysis process Stirring and ultrasonic treatment, the ultrasonic frequency is 45Hz, the enzymolysis temperature is controlled at 55°C, the pH is adjusted to 4.7, the enzymolysis time is 75min, and the chicken enzymolysis slurry is obtained;

[0052] Step (4) Maillard reaction: take the chicken enzymolysis slurry prepared in step (3), add 0.5 parts of L-cysteine hydrochlo...

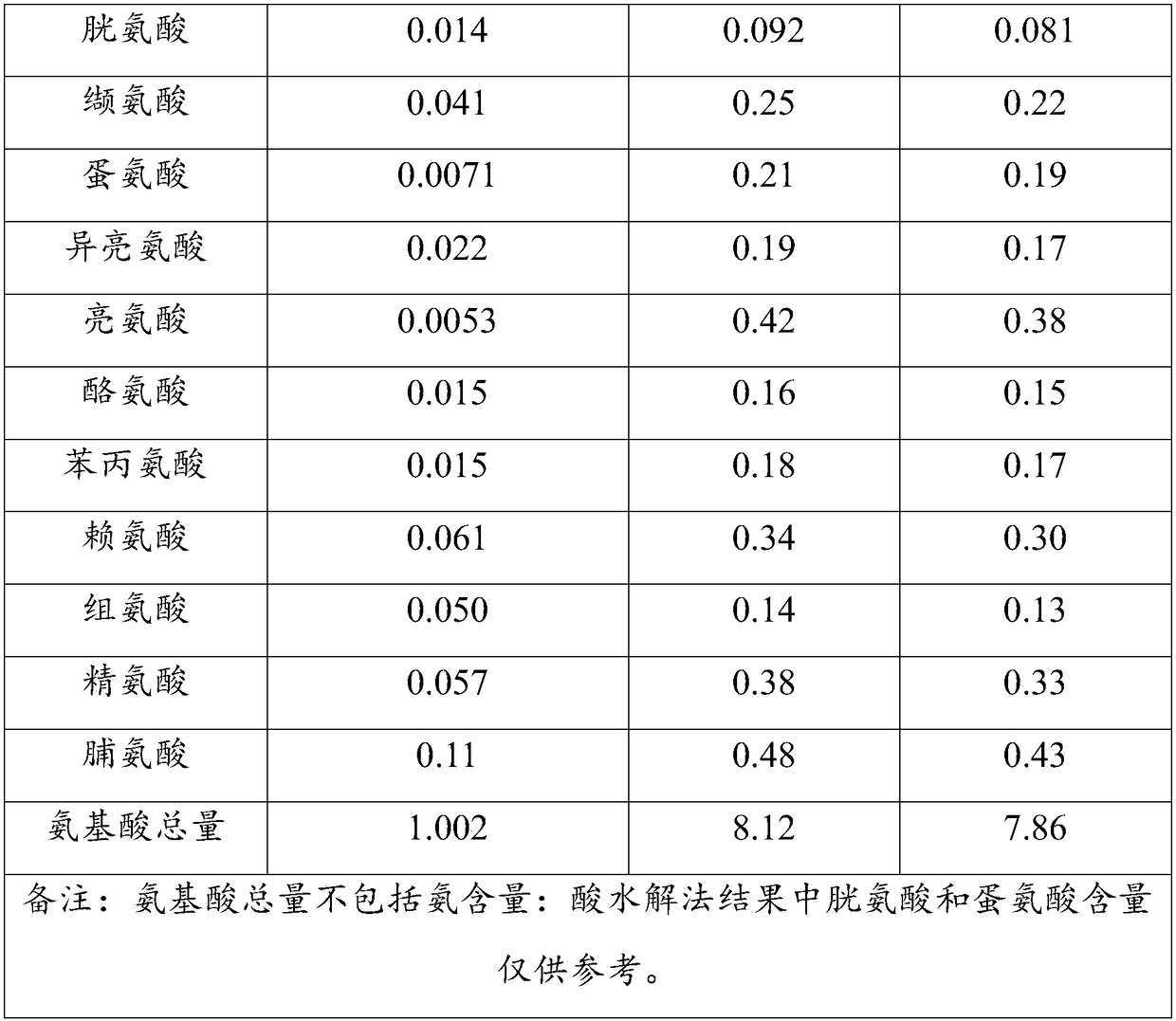

Embodiment 3

[0056] A kind of preparation method of chicken soup cream, is characterized in that, comprises the following steps:

[0057] Step (1) Cooking: Weigh 100 parts of whole chicken as raw material, steam and high-pressure cook in a reaction kettle: 121°C, 150min;

[0058] Step (2) crushing: take the cooked chicken in step (1), crush it with a bone mud machine to make chicken pulp;

[0059] Step (3) Enzymolysis: Take the chicken pulp prepared in step (2), add it to the reaction tank, then add 2 parts of compound flavor enzyme, 1 part of papain and 1 part of trypsin for enzymolysis, during the enzymolysis process Stirring and ultrasonic treatment, the ultrasonic frequency is 50Hz, the enzymolysis temperature is controlled at 63°C, the pH is adjusted to 5, the enzymolysis time is 90min, and the chicken enzymolysis slurry is obtained;

[0060] Step (4) Maillard reaction: take the chicken enzymolysis slurry prepared in step (3), add 0.6 parts of L-cysteine hydrochloride, 0.6 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com