Patents

Literature

124results about How to "Reduce processing intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

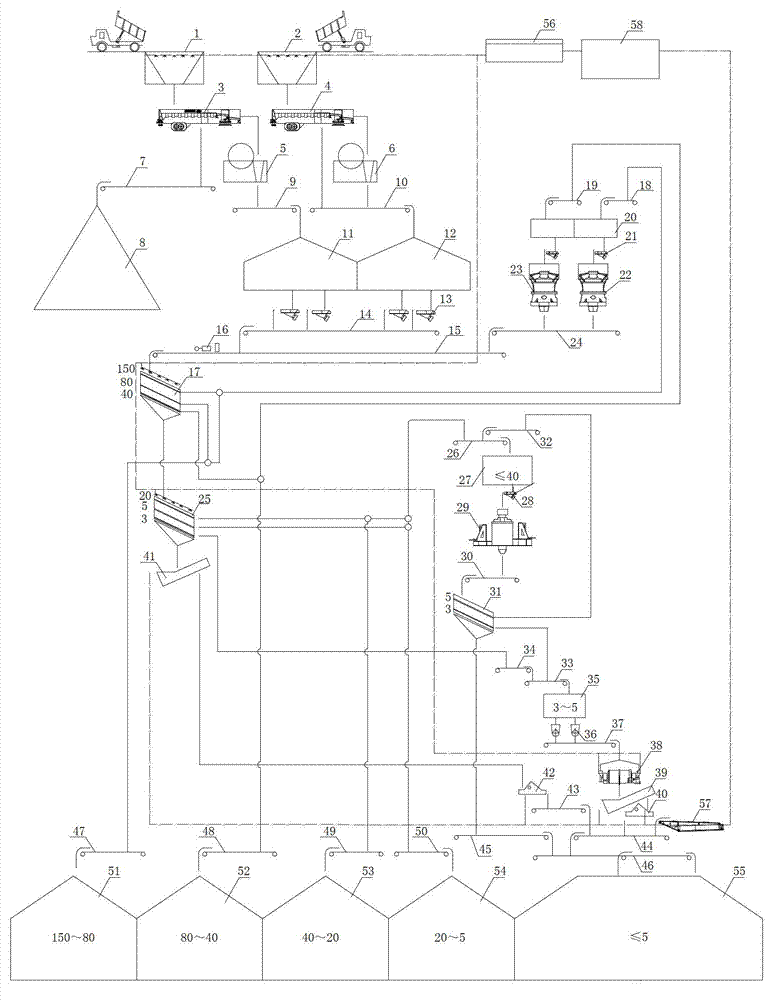

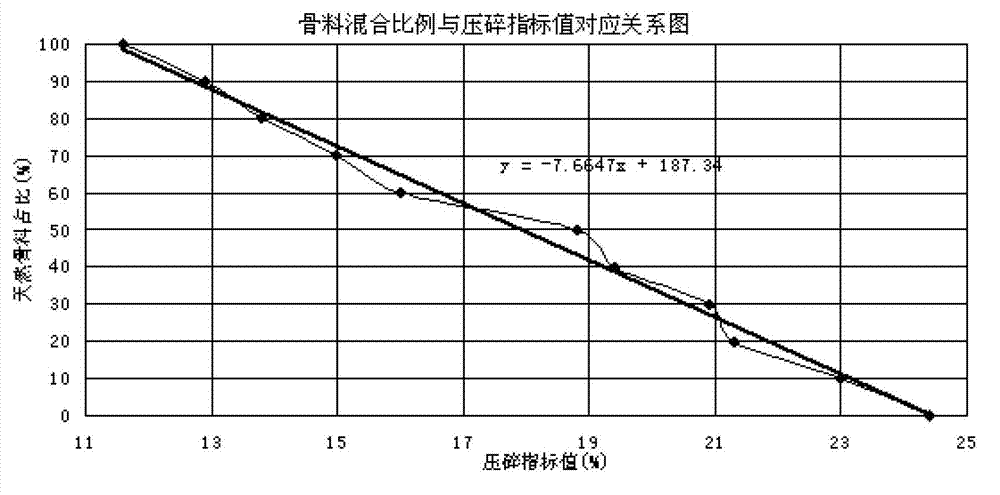

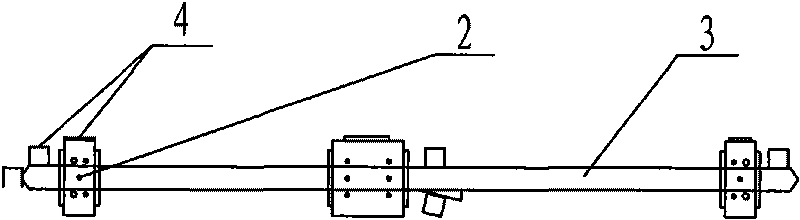

Processing system of concrete combined aggregate and construction method

InactiveCN102814862AFacilitate adjustment of gradingIncrease productivityMixing operation control apparatusControl apparatusEngineeringMachining system

The invention provides a concrete combined aggregate processing system, which comprises a first receiver bin. A first bar type feeder is disposed below the first receiver bin, the undersize part of the first bar type feeder is connected to a rejected material storage yard through a first adhesive tape machine, and the oversize part of the first bar type feeder is connected to a first jaw crusher. The discharge port of the first jaw crusher is connected to an artificial break stone storage yard through a second adhesive tape machine. A second bar type feeder is disposed below a second receiver bin. The oversize part of the second bar type feeder is connected to a second jaw crusher, and the undersize part of the second bar type feeder as well as the discharge port of the second jaw crusher is connected to a natural gravel storage yard through a third adhesive tape machine. The system provided in the invention can adopt two material sources at the same time to conduct production and processing, and the processed combined aggregate can satisfy the quality requirements of concrete aggregates, so that the work efficiency of the aggregate processing system can be enhanced. Moreover, the system is in favor of the sufficient use of project excavation ballast materials so as to reduce resource investment and project investment, and is also beneficial to environmental protection.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

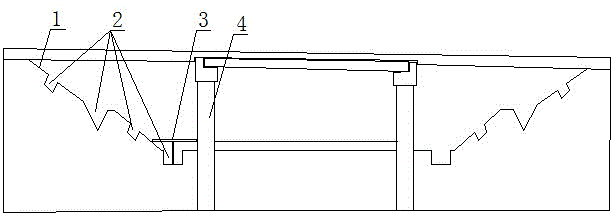

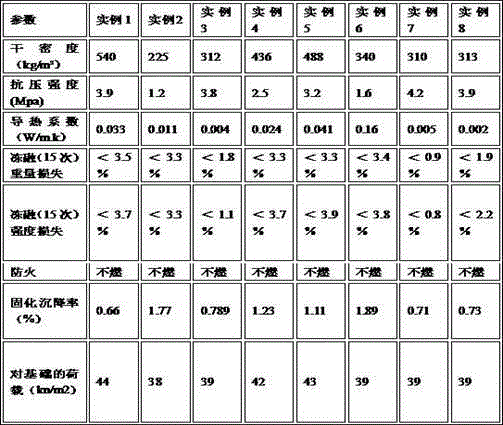

Light foamed soil for abutment back backfilling and construction method

InactiveCN105000845AImprove liquiditySelf-reliantSolid waste managementCeramicwareFoaming agentTreatment duration

The invention discloses a light foamed soil for abutment back backfilling. The light foamed soil comprises cement, a mixed material, water, a conditioning agent, a foaming agent, a micro-foam agent, and a waterproof agent. The invention also provides a preparation method of light foamed soil for abutment back backfilling. The micro-foam agent is prepared into foams by a plunger pump and an air compressor, the materials are mixed and stirred by a stirrer, and the slurry extraction speed is controlled by a frequency converter so as to control the volume weight of the finished product. The invention also provides an on-site construction method of light foamed soil applied to abutment back backfilling. The light foamed soil provided by the invention belongs to light materials, has small foundation load after filling, greatly reduces the foundation treatment intensity, and saves the foundation treatment duration. After pouring and before initial setting, light foamed soil has very good fluidity and fill self-compaction, avoids the defect of non-full filling of conventional fillers, has strong constructability, and can effectively solve the phenomenon of bumping at bridge head.

Owner:河南华泰新材科技股份有限公司

Method for making braking shoe and piece of charcoal/charcoal-silicon carbonate composite material

InactiveCN101070395AEffective control of contentIncrease coefficient of frictionFriction liningFiberBrake shoe

A preparation method of carbon / carbon-silicon carbide composite brake shoes and pads, the present invention produces C / C-SiC composite brake shoes and pads by several processes of mixing material, granulating, low-temperature hot embossing, high-temperature sintering, resin-impregnated solidifying, carbonizing, and buffing friction surface. The present invention, taking short carbon fiber as reinforced phase, can greatly reducing the cost comparing to those taking carbon fiber integer felt as reinforced phase; moreover, the content of various components can be effectively controlled by taking hot embossing; Adding SiC powder into raw material previously, can effectively increase the friction coefficient of brake shoes and pads, can achieve net-shape forming, can obviously reduce processing strength; Processing the mixture into irregular-appearance particles, and low-temperature hot embossing then, can effectively solve the bubbling and cracking problems of hot-embossed green body in sequent processes and decrease reject ratio.

Owner:CENT SOUTH UNIV

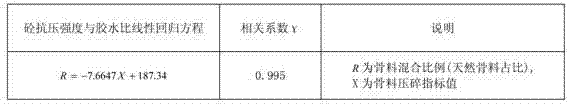

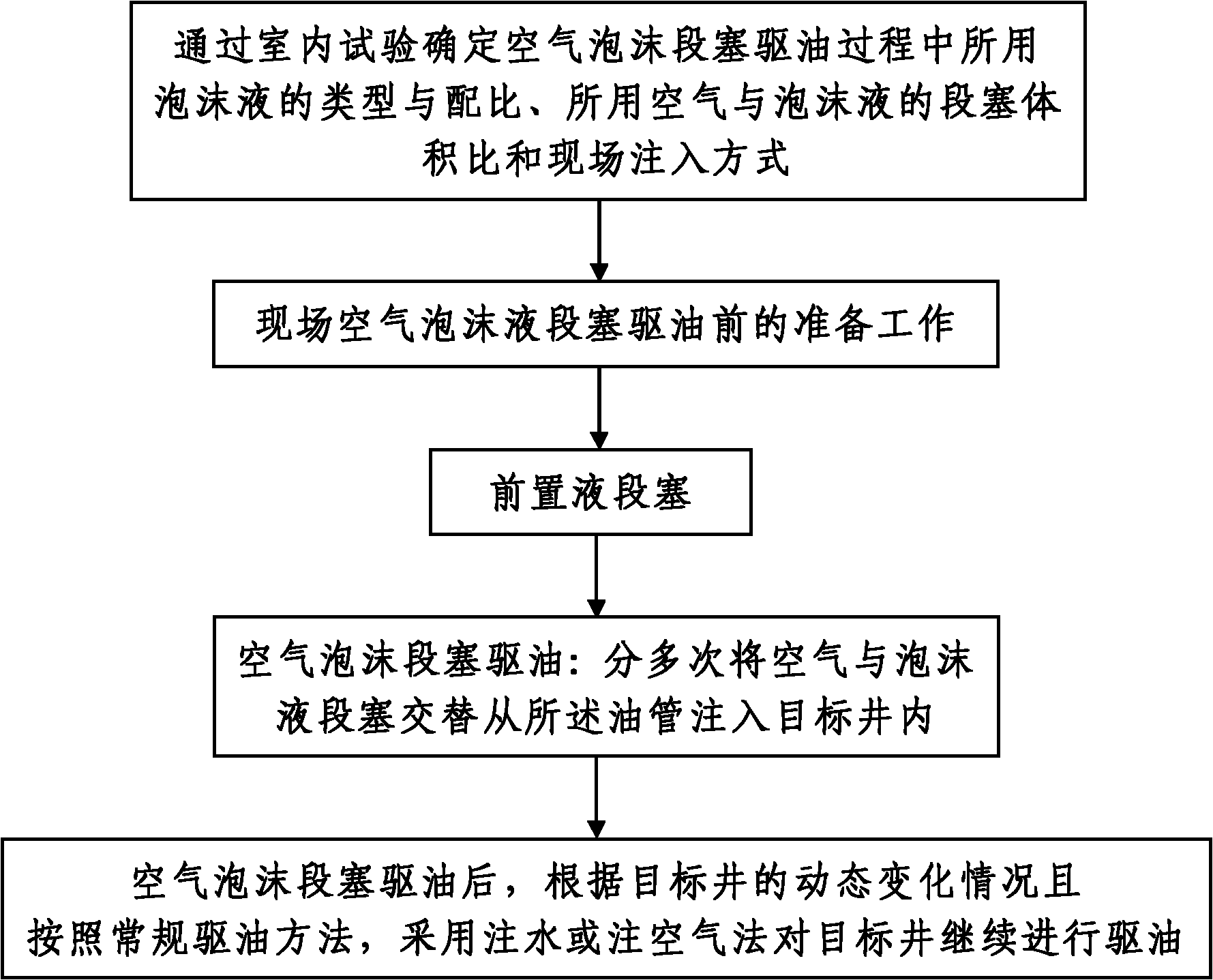

Air foam slug flow driving process for oil recovery of oil field

InactiveCN102061906ASimplify construction stepsEasy constructionFluid removalInjection airOil displacement

The invention discloses an air foam slug flow driving process for the oil recovery of an oil field, comprising the following steps of: 1 determining type and proportion of the used foam liquid, slug volume ratio and on-site injection manner of the used air and the foam liquid during the air foam slug flow driving by an indoor test; and 2 carrying out the air foam liquid slug flow driving on site,wherein the oil flow driving process comprises the following steps of: preparation before the oil flow driving; slugging a pad fluid; slugging the air foam; alternatively injecting the air and foam liquid slug from a specially manufactured device to a target well for many times; and continuously carrying out the oil flow driving on the target well by a water or air injection method according to the dynamic change condition of the target well and a conventional oil displacement method after the injection of the air foam slug is finished. The invention has the advantages of reasonable design, simple and convenient construction steps, good use effect and convenience of realizing, can effectively solve various practical problems of poor water injection effect, difficult improvement on the water injection capability, poor oil flow driving efficiency and the like during the ultralow reservoir waterflooding.

Owner:YANCHANG OIL FIELD

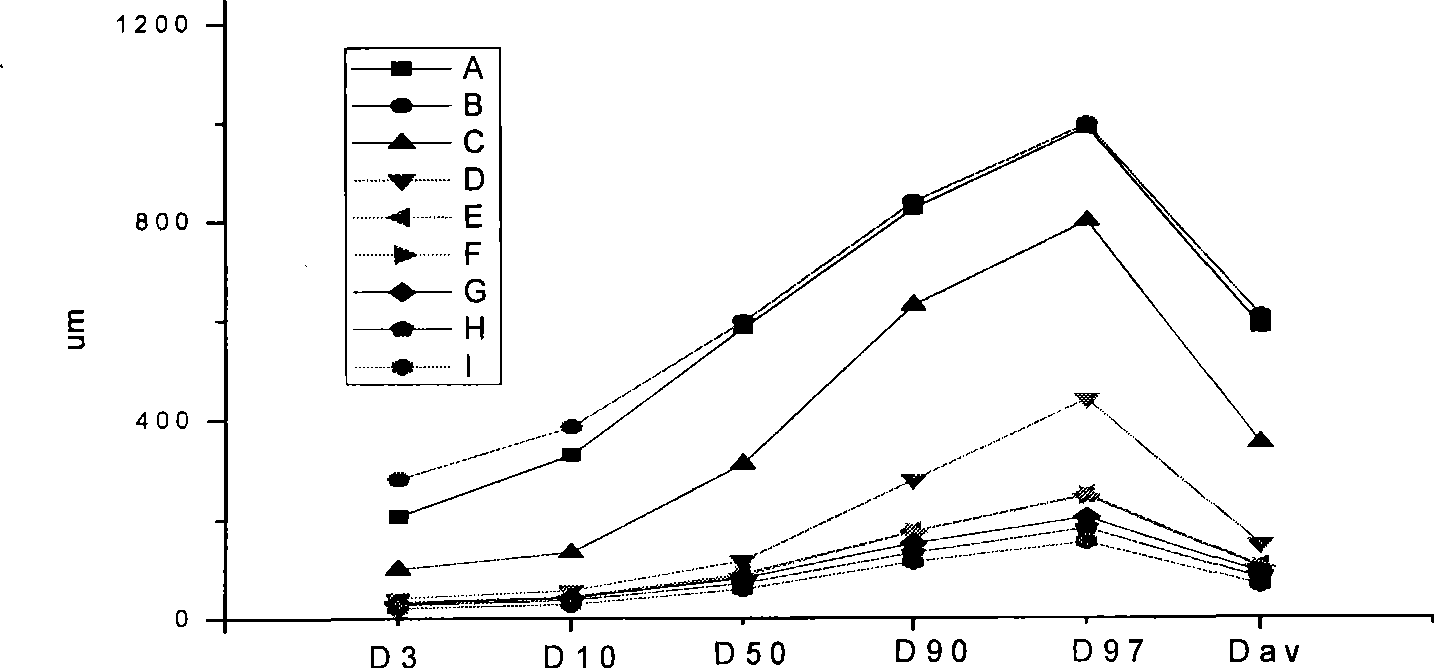

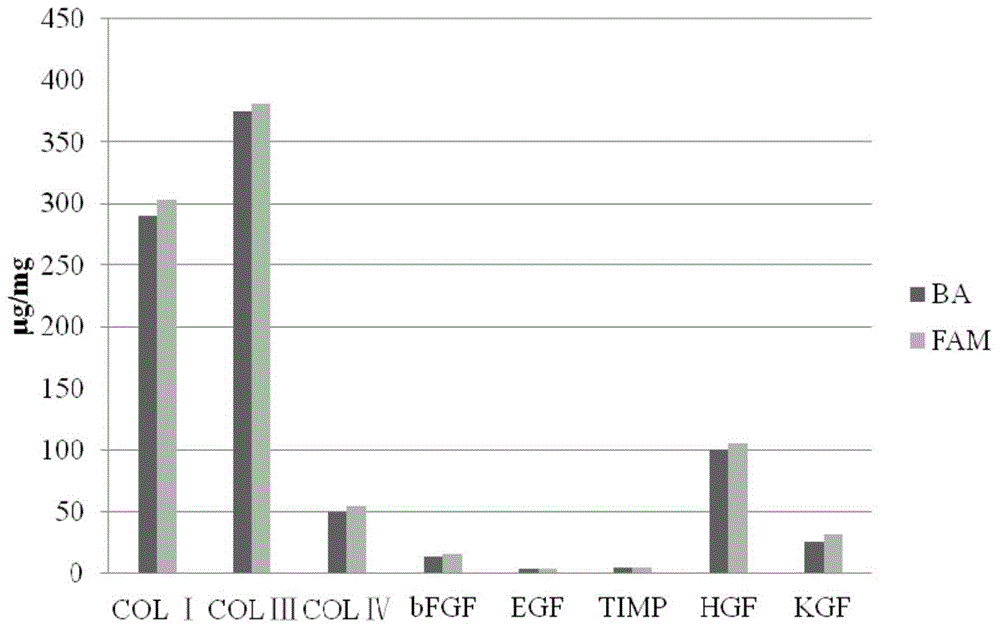

Biological amnion and preparation method thereof

ActiveCN103520780AEasy to prepareWide variety of sourcesLayered productsSurgeryFreeze-dryingDrug biological activity

The invention relates to a biological amnion and a preparation method thereof. The biological amnion has three layers including a slow release layer, an amnion layer and a collagen layer from top to bottom, wherein the slow release layer consists of collagen and biological active factors, the amnion layer consists of an amnion subjected to decellularization treatment, and the collagen layer is formed by freeze-drying and compounding collagen. The biological amnion is prepared through the steps of raw material pretreatment, virus inactivation, decellularization treatm. The biological amnion prepared by the invention has the characteristics of an effect of slowly releasing the active factors, low antigenicity on removing epithelial cells, convenience in product operation, difficulty in curling, good adhesiveness with surrounding tissues, difficulty in sliding and the like. Meanwhile, by using a process for performing the decellularization treatment on the amnion, disclosed by the invention, a natural compact collagen structure in the amnion can be effectively retained, the biological amnion can fully achieve a physical barrier effect after being applied to tenorrhaphy, and an animal experiment proves that the biological amnion can effectively achieve an effect of preventing tissue adhesion.

Owner:SHAANXI RUISHENG BIOTECH

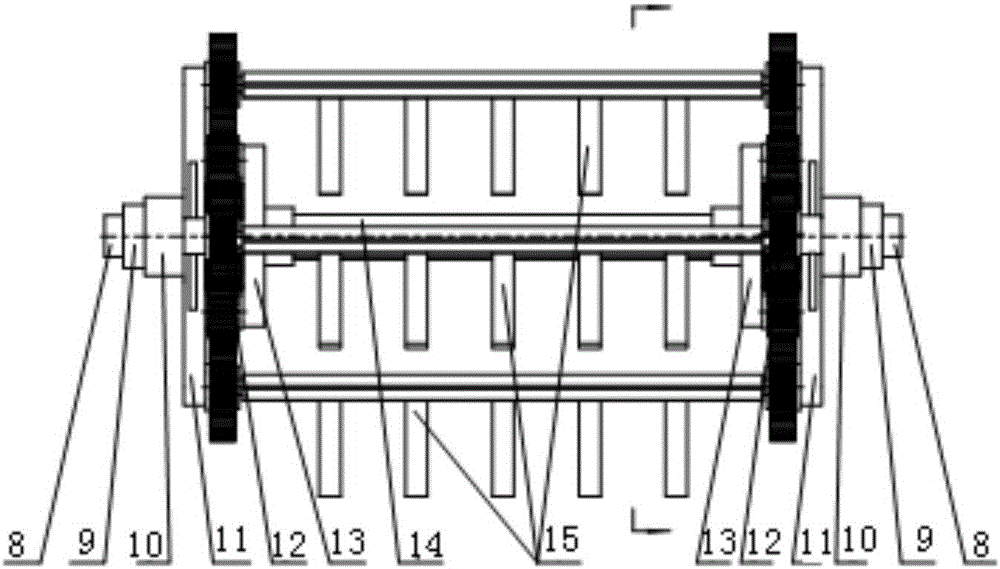

Device for directly high-efficiently treating blue-green algae in water

ActiveCN106669261ASimple designInnovative designWater cleaningMoving filtering element filtersEngineeringBlue green algae

The invention discloses a device for directly high-efficiently treating blue-green algae in water. The device comprises a device frame, a protecting cover, pulling wheels, a roller device main body and a material conveyer, wherein the protecting cover is arranged above the device frame; the pulling wheels are arranged at the four corners above the device frame; the roller device main body is arranged on the pulling wheels; the material conveyer is arranged in the roller device main body and is arranged along the interior of the roller device main body; at least two roller frames with different design structures are serially connected or arrayed through the bolts so as to form the roller device body; and at least one filtering screen is arranged on each of the roller frames. The device disclosed by the invention has the advantages of novel design, convenience in maintenance and replacement, capability of efficiently, conveniently and quickly cleaning the blue-green algae floating on the water, easiness in implementation, no secondary pollution to water, environmental protection and capability of effectively solving the problem of the blue-green algae floating in the lake, reservoir and river. On the basis of the design for the special structure, the efficient separation of algae and water in the roller device body is realized, the blue-green algae pulp meeting the next process requirement is acquired and the treating burden of the next process is relieved.

Owner:李艳华

Process for cleaning decopper nickel electrolytic solution

ActiveCN1598012ALow nickelSatisfy the requirements of copper removal for electro-nickel productionPhotography auxillary processesProcess efficiency improvementHydrometallurgyCopper

The invention relates to a purifying and removing impurity method with nickel electrolyte in the process of wet way metallurgy technics, especially purifying and removing copper with nickel electrolyte. It is adding NiS2O3 into nickel electrolyte to purify and remove copper, the technics process is adding NiS2O3 into nickel electrolyte according to the proportion of S2O3 2- / Cu2+ =4.4-7:1, at the temperature of 65-70deg.C, adding acid and adjusting Ph between 0.5 and 2, the stirring reaction time is 30-40min, finally separating and producing the deposition of CuS, attaining the liquid of purifying and removing copper. The thiosulfate is easily dissolved in water, it could not cause high content of nickel in the copper residues even excessive appending when removing copper, it is different from removing copper with nickel, nickel concentrate and sulfureted nickel, therefore with low nickel content in residues.

Owner:JINCHUAN GROUP LIMITED

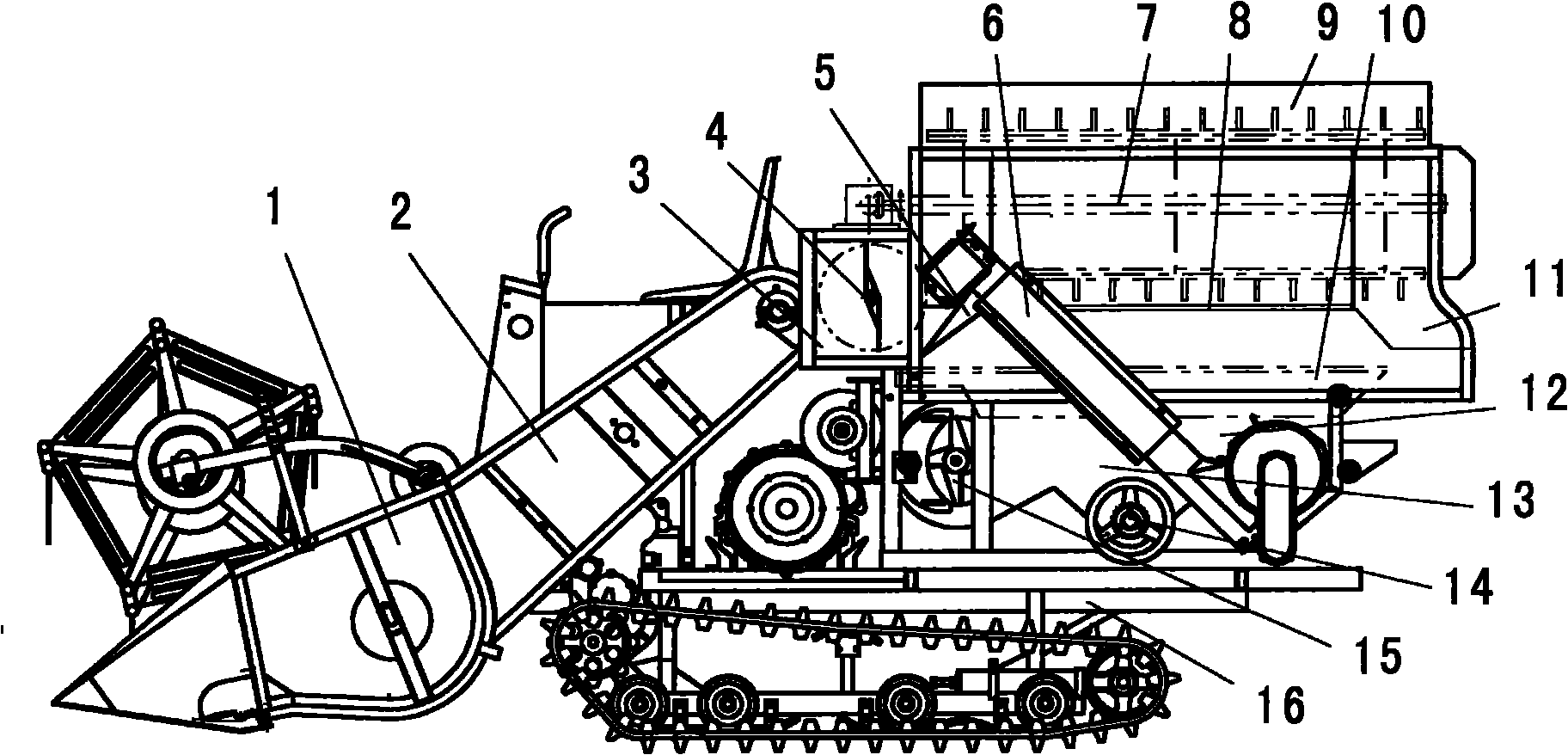

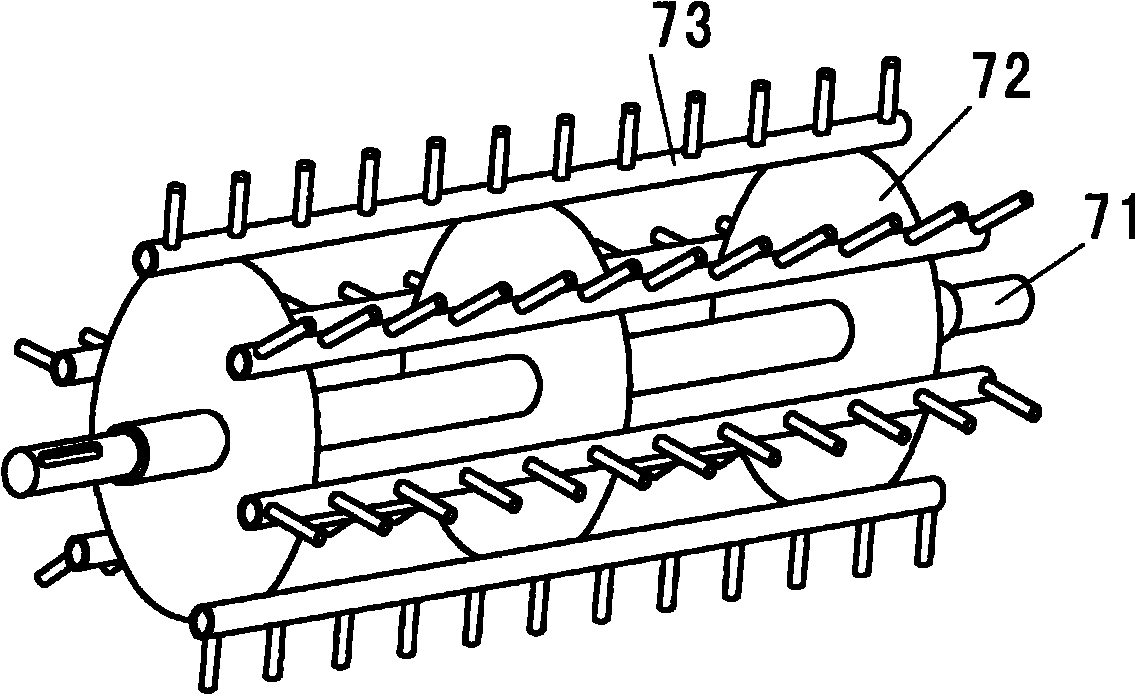

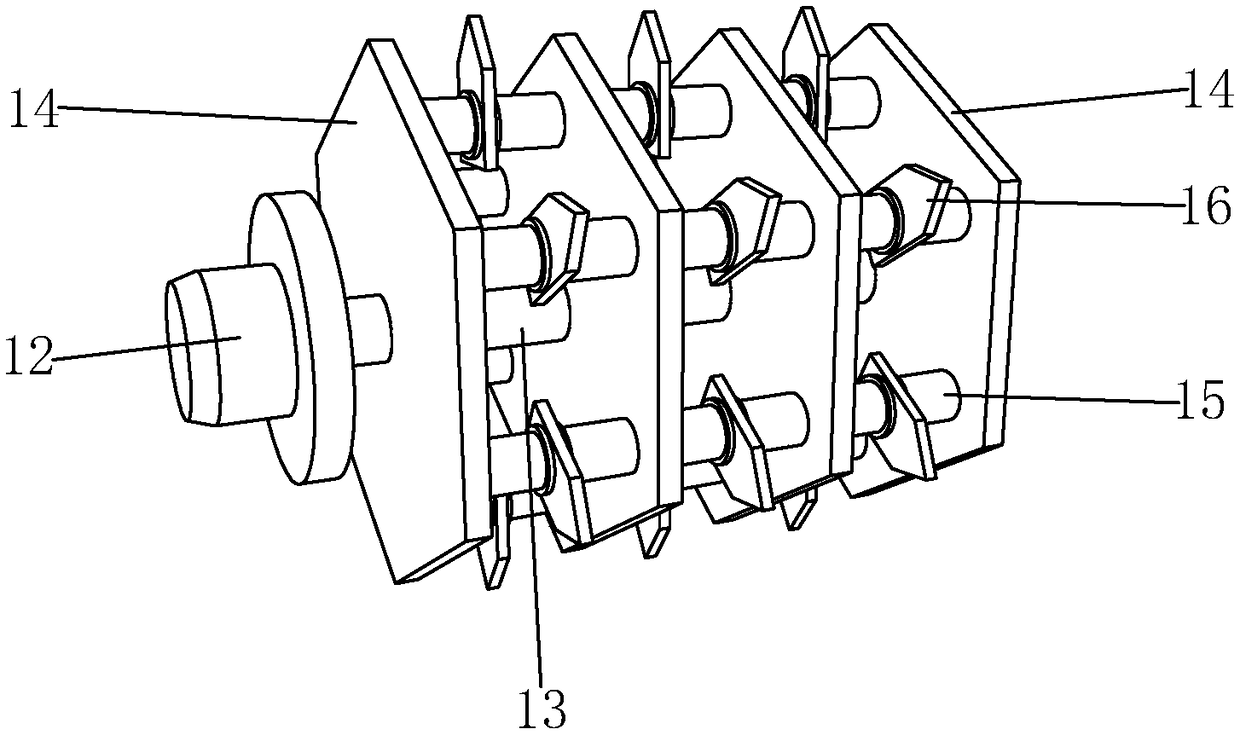

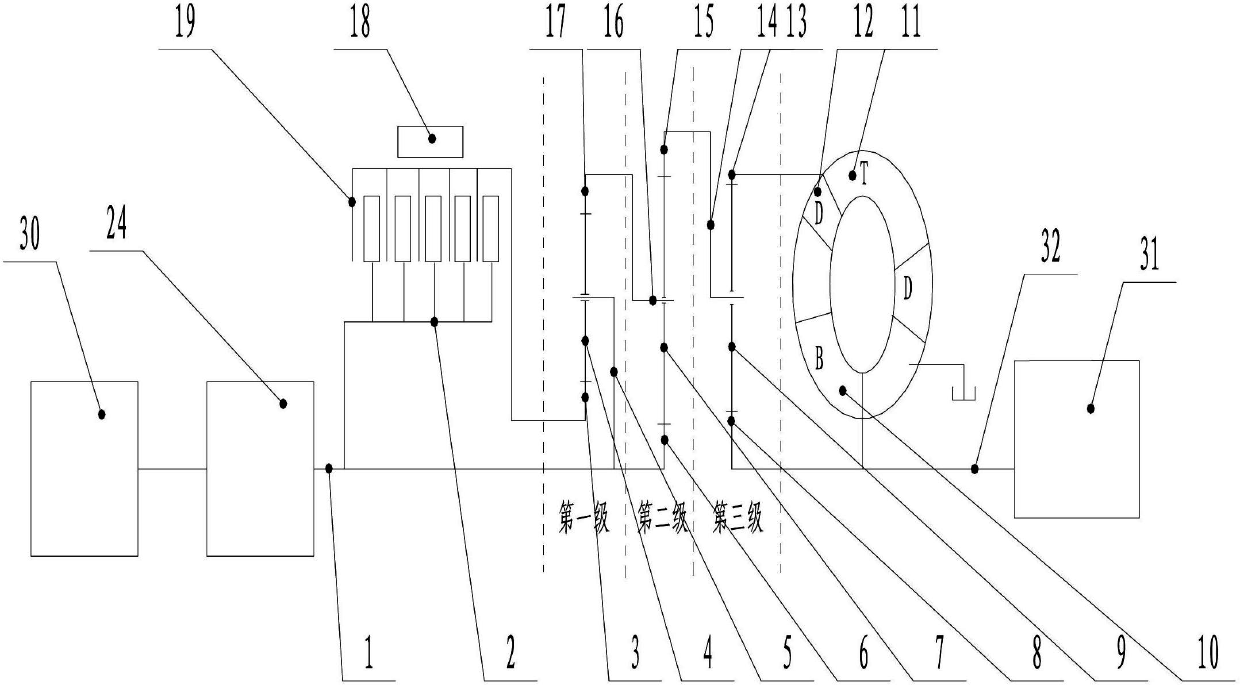

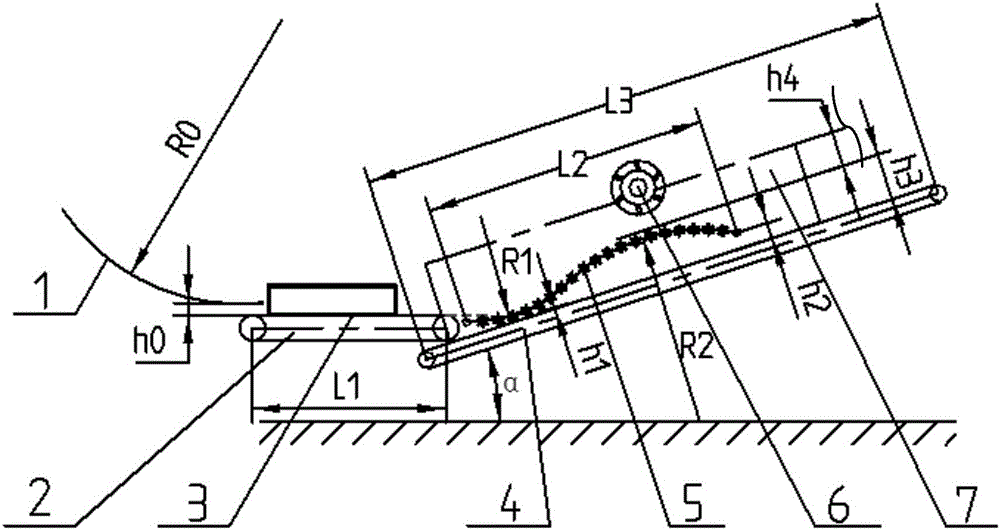

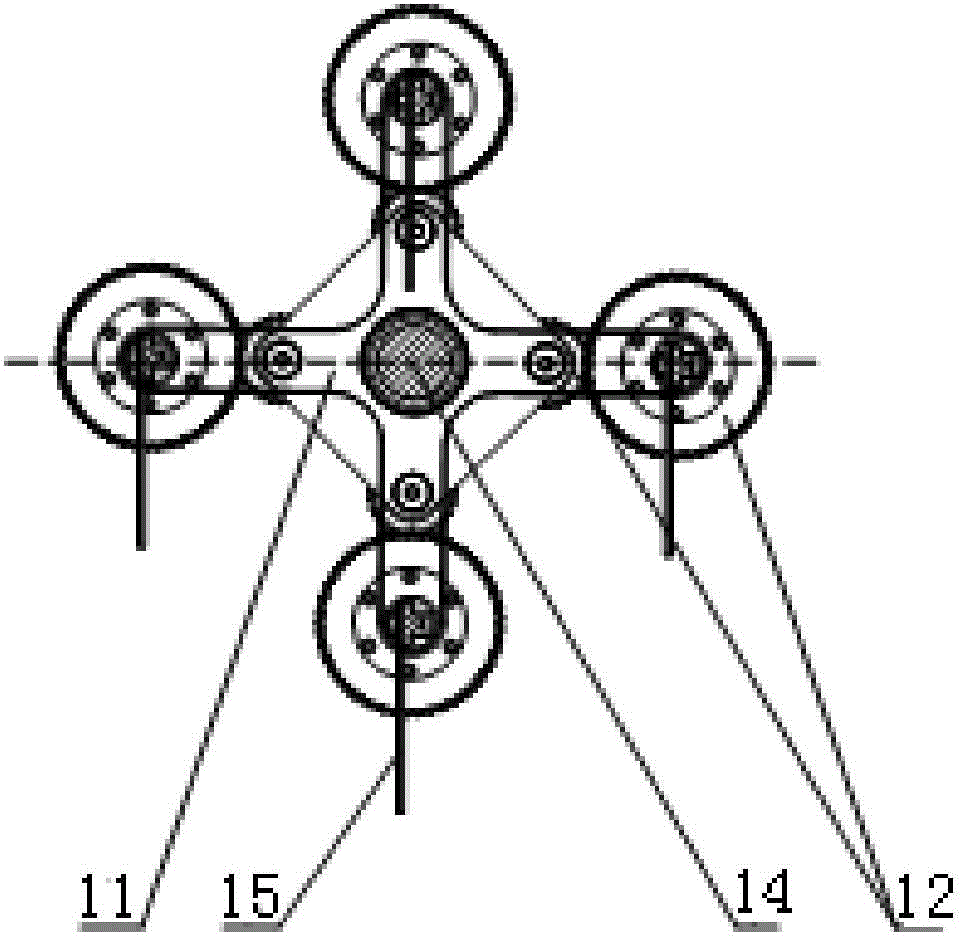

Longitudinal axial flow threshing device of whole-feed combine harvester

InactiveCN101790925AHigh speedIncrease intensityThreshersMaterials processingUltimate tensile strength

The invention discloses a longitudinal axial flow threshing device of a whole-feed combine harvester. A charging chamber connected with a threshing chamber into a whole is added between the upper end of a middle conveying trough and the front end of a longitudinal threshing cylinder; the feeding chamber is internally provided with a transverse charging cylinder; the upper end of the middle conveying trough is connected with the inlet of the charging chamber; the bottom surface of the outlet of the charging chamber is connected with a concave sieve plate by a transition plate; the output end of a secondary re-threshing transporter is connected to the front part of the left side of the threshing chamber and is connected above the transition plate. Because of adding the charging cylinder, the improved threshing device of the invention greatly strengthens feed speed and throwing strength to the threshing cylinder charging so as to effectively avoid the detect that the longitudinal axial flow threshing chamber of the whole-feed combine harvester has large possibility of blocking; meanwhile, the output end of the secondary re-threshing transporter is connected above the charging transition plate of the threshing cylinder connected with the front end of the concave sieve plate instead of being above the traditional sorting screen, thus greatly lightening the material processing strength of the sorting screen, and reducing material sorting loss.

Owner:XINGGUANG AGRI MACHINERY

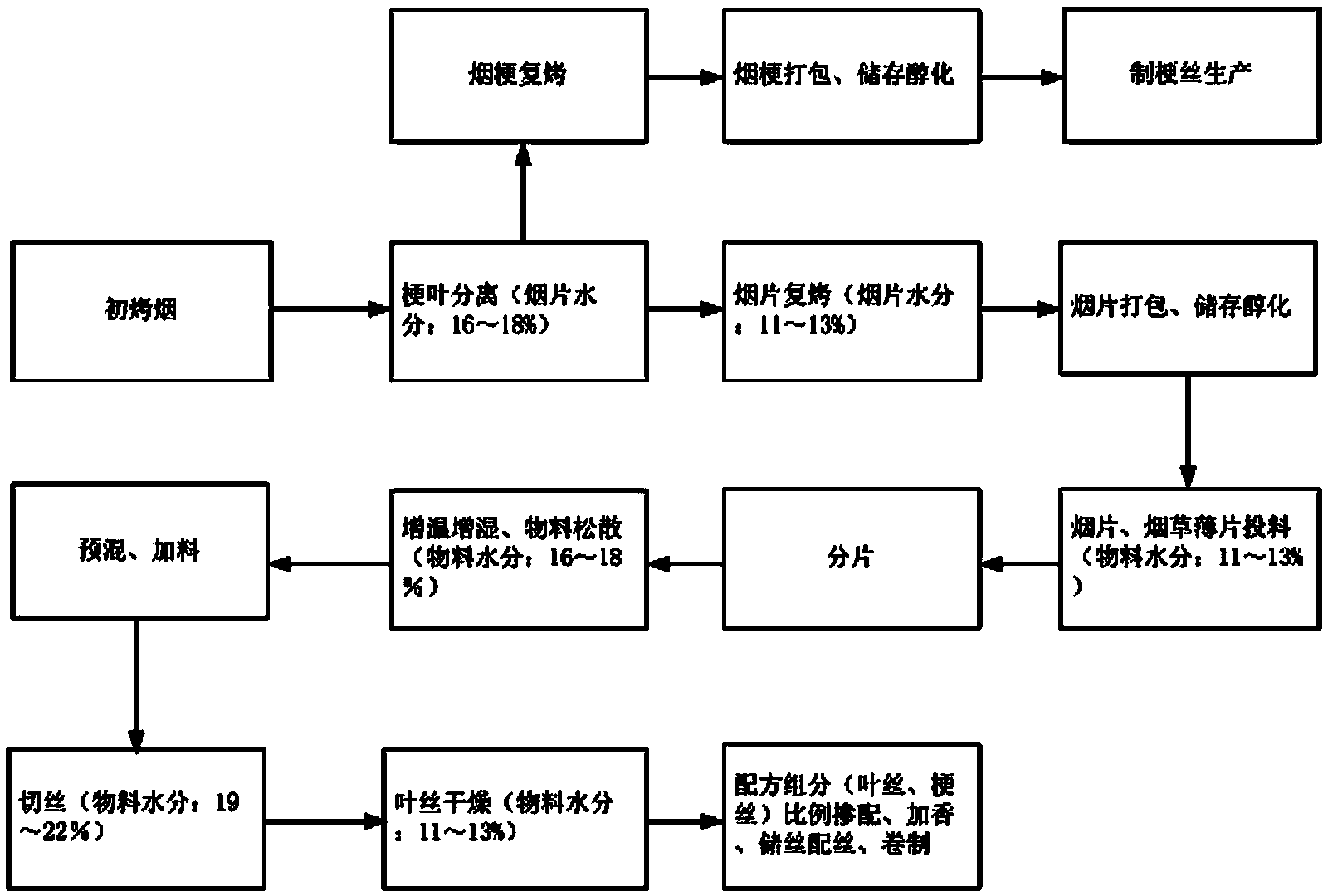

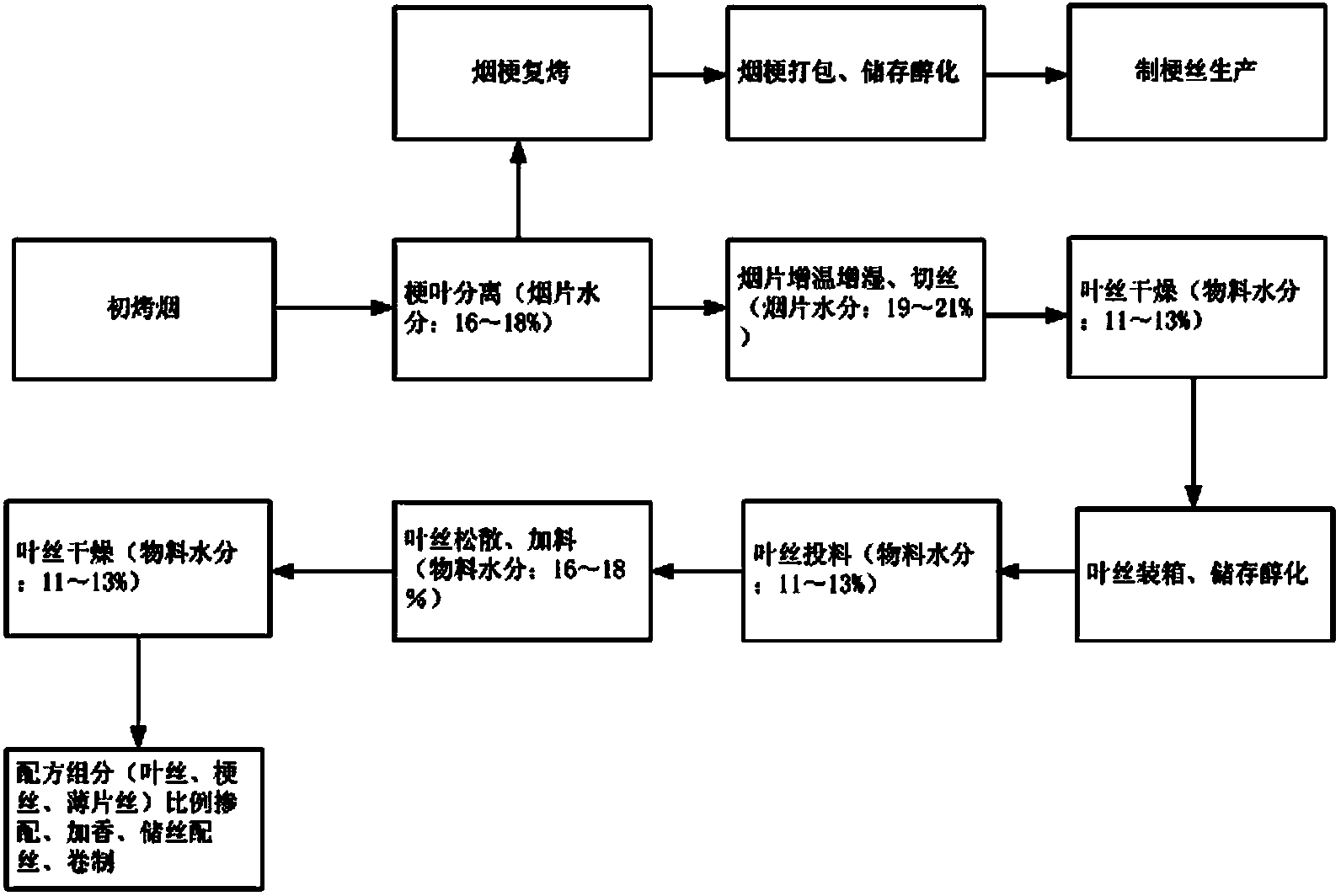

Technology for cigarette production

InactiveCN103704865AExcellent mechanical processing strengthIncrease lossTobacco preparationTobacco treatmentEngineeringMoisture

The invention discloses the technology for cigarette production, belongs to a technology for cigarette production, and particularly relates to a method for leaf-beating redrying production, cut leaf storage alcoholization and cut leaf production. According to the technology, the leaf beating redrying production technical process, the storage alcoholization production technical process and the cut leaf production technical process in the prior cigarette production mode are integrated; tobacco flakes obtained after leaves are separated from stems in the redrying process are humidified to the degree that the moisture content is, by weight, 19%-21%; after the tobacco leaves are cut, the tobacco leaves are dried to the degree that the moisture content is, by weight, 11%-13%; the cut tobacco is boxed, stored and alcoholized for 6 months to 24 months in the storage environment that the temperature is lower than or equal to 32 DEG C and the humidity is smaller than or equal to 70% RH; the alcololized cut leaves are processed in a loosened mode; feed liquid is added until the degree that the moisture content is, by weight, 16%-18%; the flow of the cut leaves is controlled and the cut leaves enter a drying device for dehydration to the degree that the moisture content is 11% to 13%; blending, flavoring, cut tobacco storage and matching and coil making are conducted according to a factory formula. The method can effectively simplify production, reduce unreasonable consumption of energy sources and raw materials and improve the economical efficiency of cigarette production.

Owner:HONGTA TOBACCO GRP

Technology for producing han-hemp knitted home fabric

InactiveCN105696177AGood moisture absorptionImprove dehumidification effectWeft knittingWarp knittingYarnWax

The invention discloses a technology for producing a han-hemp knitted home fabric. The technology includes the following steps: spinning, yarn steaming, waxing, humidifying, weaving, dyeing, sanding, and finishing. The produced han-hemp home fabric by adoption of the technology is excellent in moisture absorption performance, moisture-removing performance and wear-ability. Compound tea saponin or caustic soda and hydrogen peroxide is used to perform dyeing pretreatment on the han-hemp knitted home fabric, and then fiber damage can be reduced; a sanding technology is adopted to treat han-hemp short fiber, and then the treatment intensity of cellulose can be weakened; and a hydrophilic amino silicon oil softening agent is used, and then the moisture absorption performance of the fabric can be improved.

Owner:江阴市长泾花园毛纺织有限公司

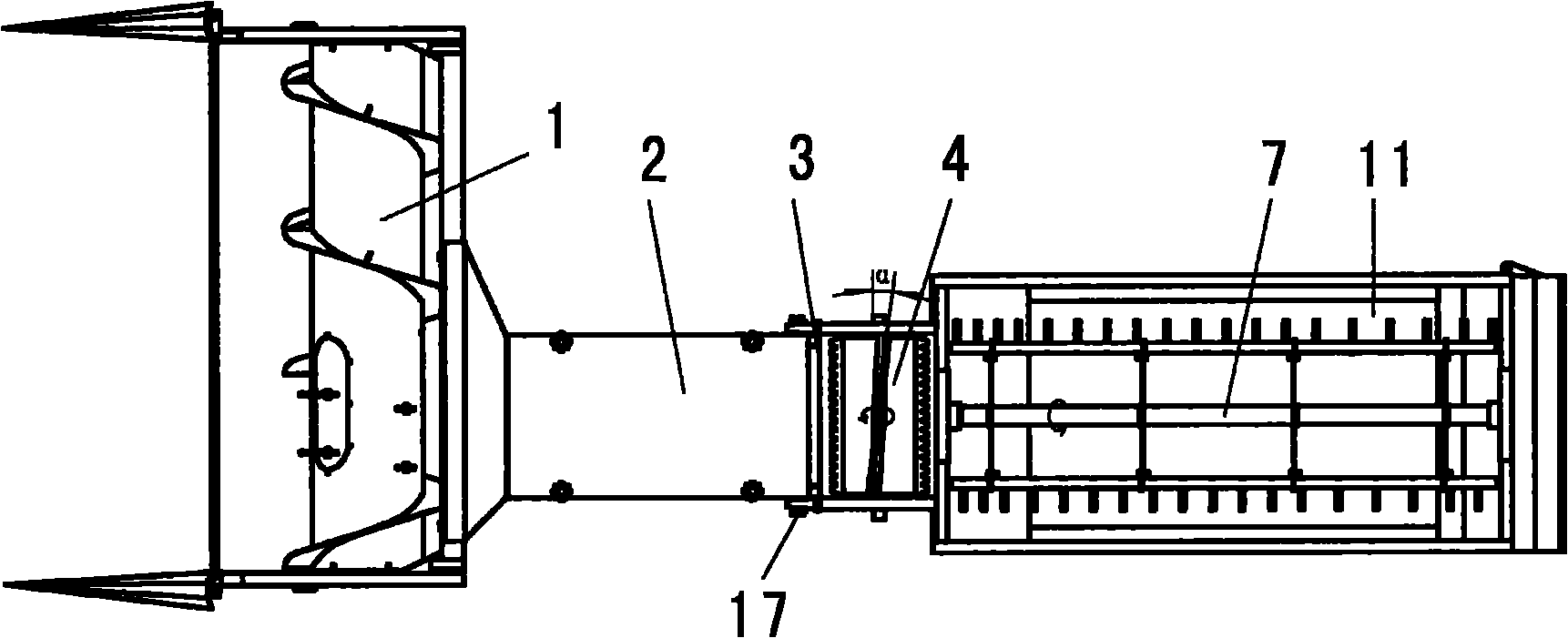

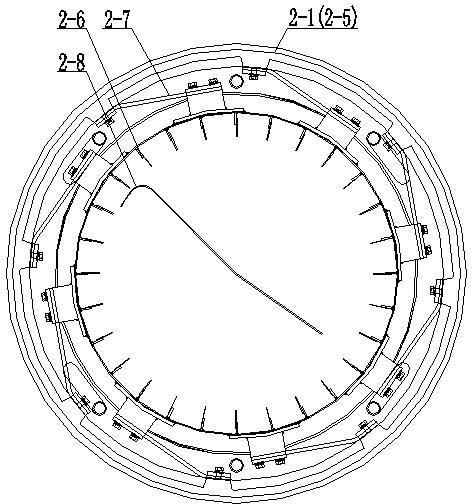

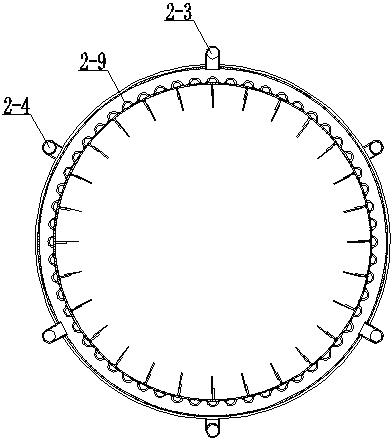

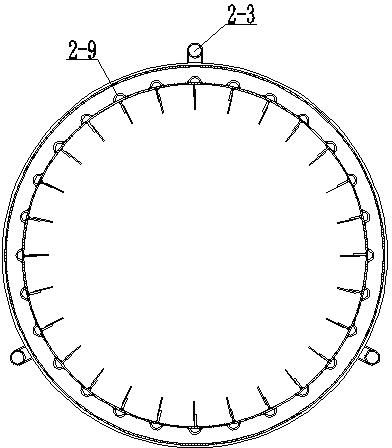

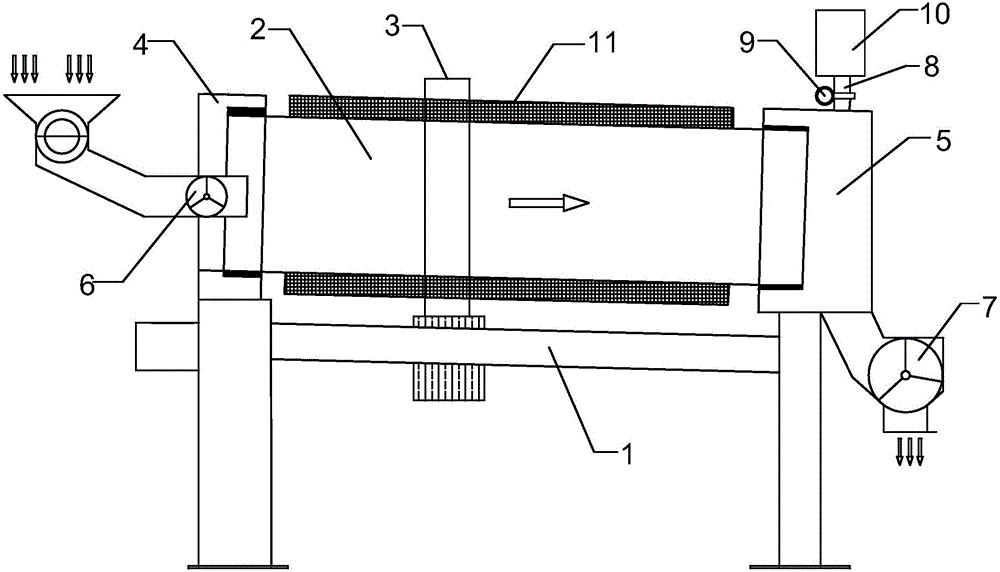

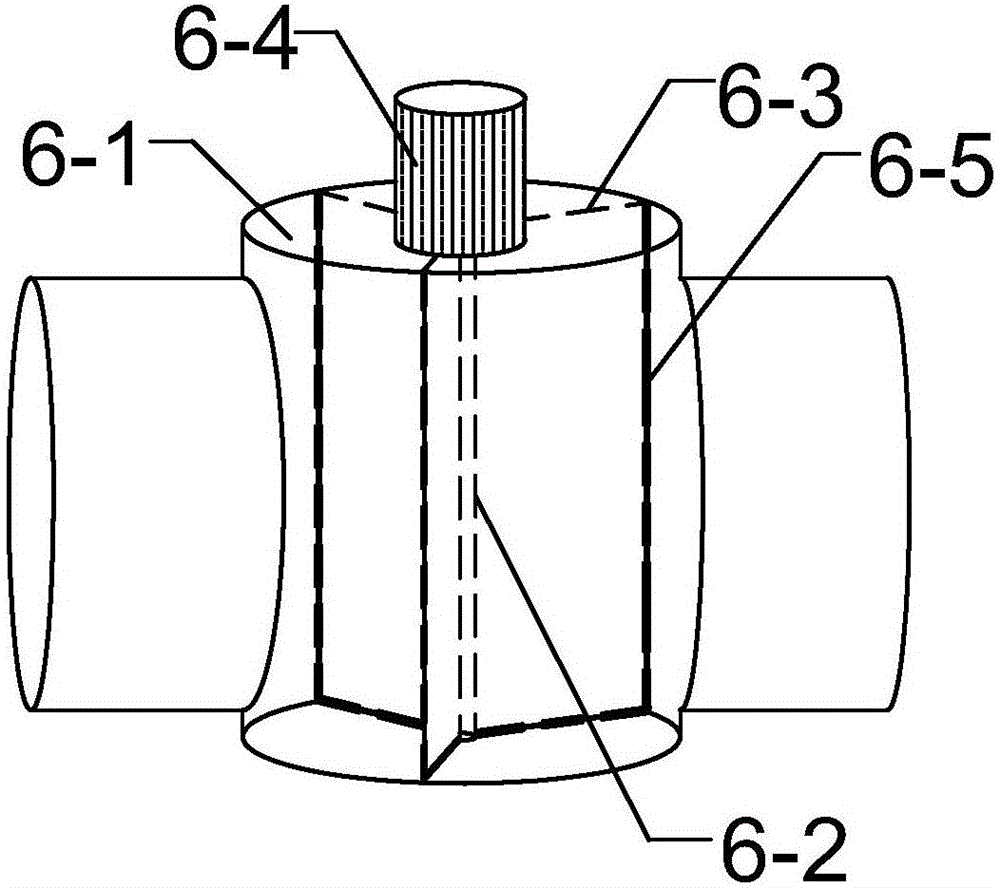

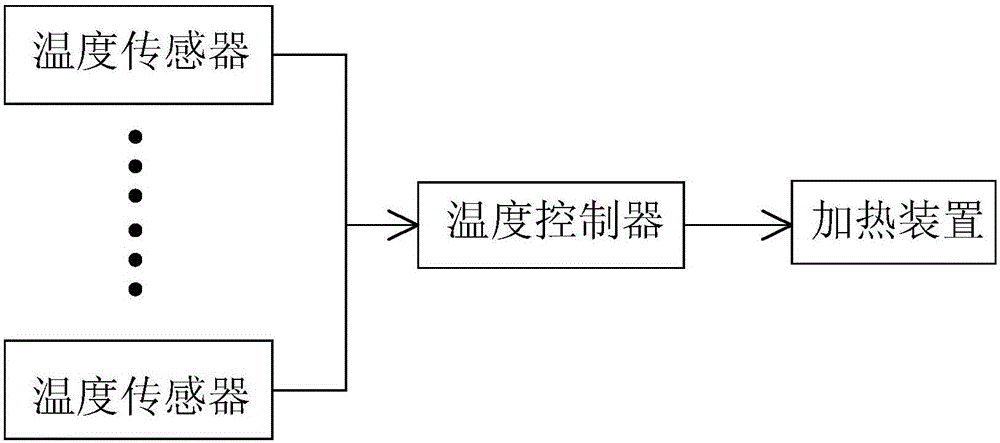

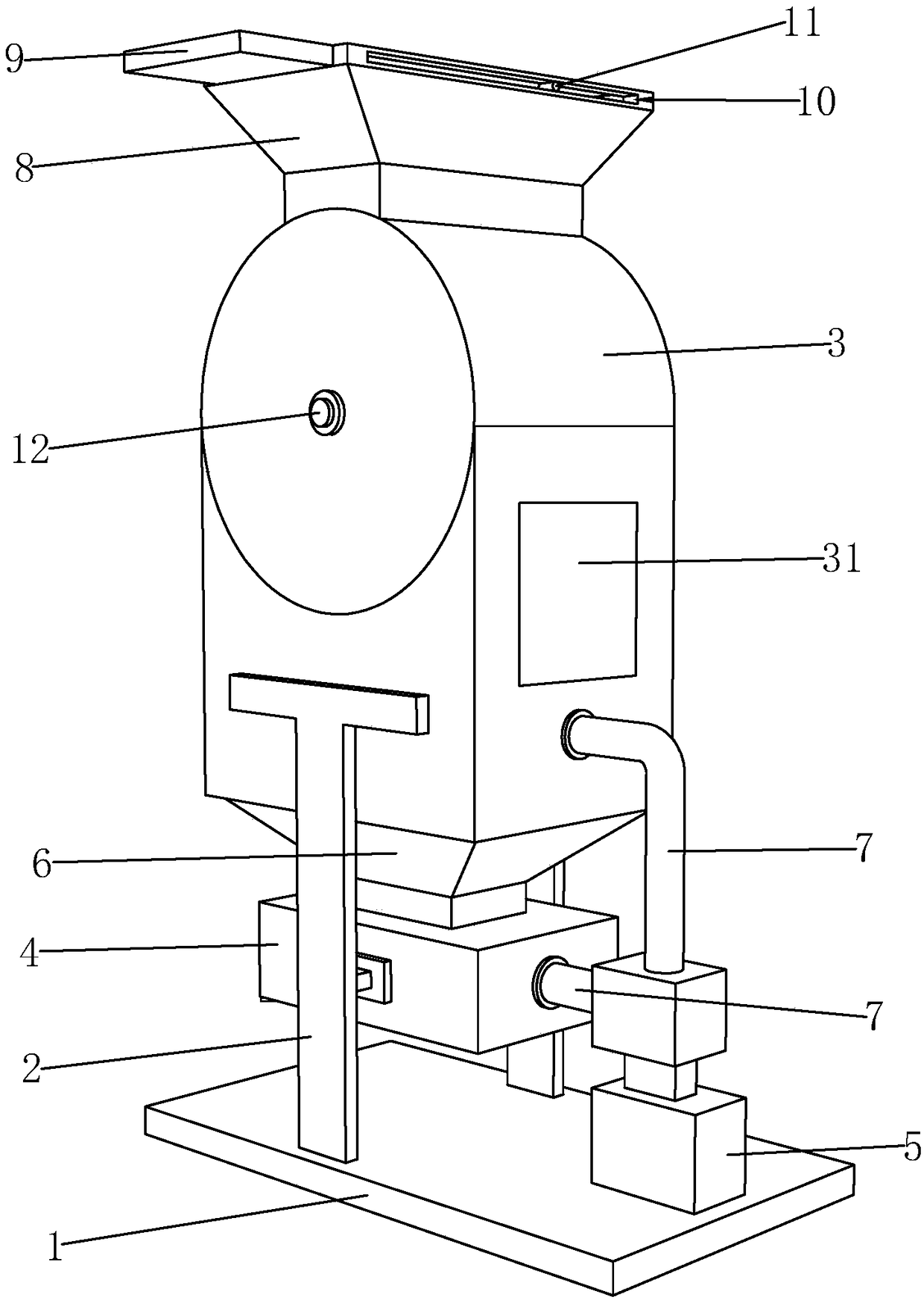

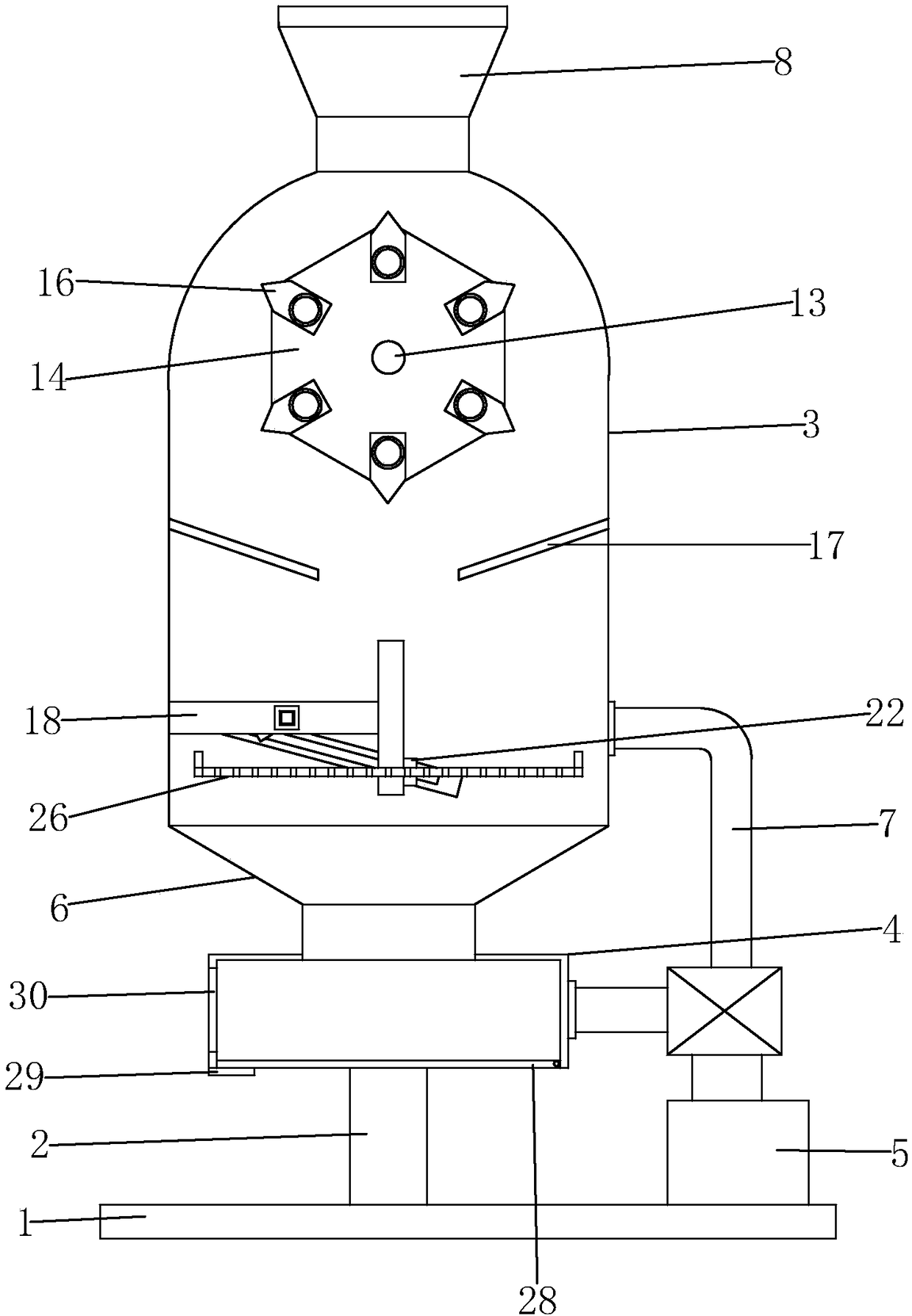

Tobacco material redrying equipment and method

ActiveCN102423109AUniform and stable temperatureReduce lossesTobacco preparationProcess engineeringSlide plate

The invention provides redrying equipment and a redrying process method for realizing simple, high-efficiency and low-processing-intensity tobacco sheets or tobacco stems which are dried uniformly. The redrying equipment comprises a baking rotary drum which is arranged on a stander, and a hot air system, wherein a plurality of heat conduction oil heat exchange pipes which are equally arranged in parallel along the outer wall surface are arranged on the outer wall surface of the baking rotary drum; the heat conduction oil heat exchange pipes are communicated with a heat conduction oil cyclic heating system; a section from the feeding end of the baking rotary drum to the position of which the length is about 1 / 3 of the total length of the baking rotary drum is a preheating section, and the residual 2 / 3 section is a drying section; the feeding end of the baking rotary drum is higher than the discharging end of the baking rotary drum; and a shovelling plate and a material-receiving sliding plate are arranged in the drum. By using the equipment, tobacco materials can be directly redried only by heating and drying processes until the moisture content and the temperature of the tobacco materials meet the requirements of the next process; and furthermore, the process is simple, efficient, energy-saving and environmentally-friendly.

Owner:ZHISI HLDG GRP

Low-oxygen low-pressure drum type cut tobacco drying machine and cut tobacco drying method

The invention provides a low-oxygen low-pressure drum type cut tobacco drying machine. The cut tobacco drying machine comprises a support frame, an electric heating cut tobacco drying drum and a drum transmission mechanism, and is characterized in that a feed gas lock is arranged at a feed port of a feed chamber of the cut tobacco drying drum, a discharge gas lock is arranged at a discharge port of a discharge chamber of the cut tobacco drying drum, an air extracting pipe for connecting with an air extracting device is arranged on the discharge chamber, an air extracting end of the air extracting pipe leads to an inner cavity of the cut tobacco drying drum, and an air pressure detection device is arranged on the air extracting pipe; and the air extracting device and the air extracting pipe are used for performing air extraction on the interior of the electric heating cut tobacco drying drum, and an electric heating control system is used for controlling and keeping the air pressure in the electric heating cut tobacco drying drum to be 0.2-0.5 standard atmospheric pressure, and the drum wall temperature of the heating drum to be 60-90 DEG C. The low-oxygen low-pressure drum type cut tobacco drying machine provided by the invention is simple in structure and convenient in operation and can achieve drying of cut tobaccos under relatively low strength; and meanwhile, the loss caused by an oxidation reaction of small-molecule aroma components during cut tobacco drying is reduced, and the small-molecule aroma components inside tobacco leaves are maintained to the maximum extent.

Owner:HUBEI CHINA TOBACCO IND

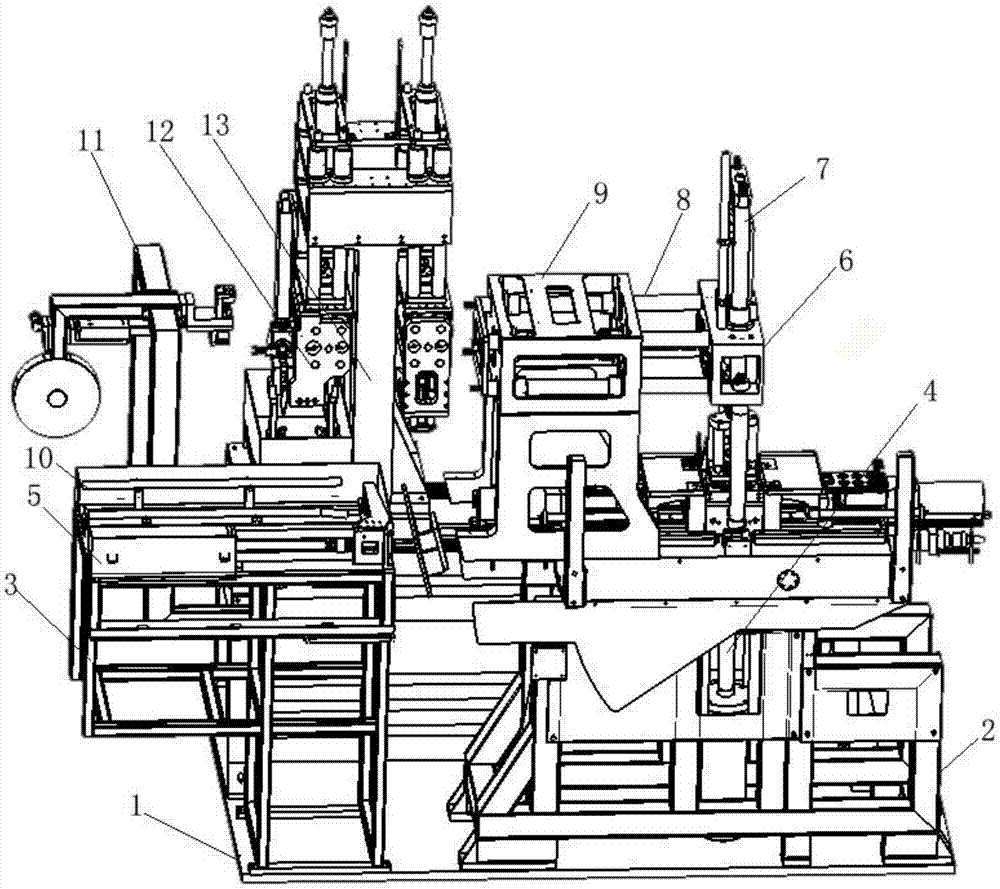

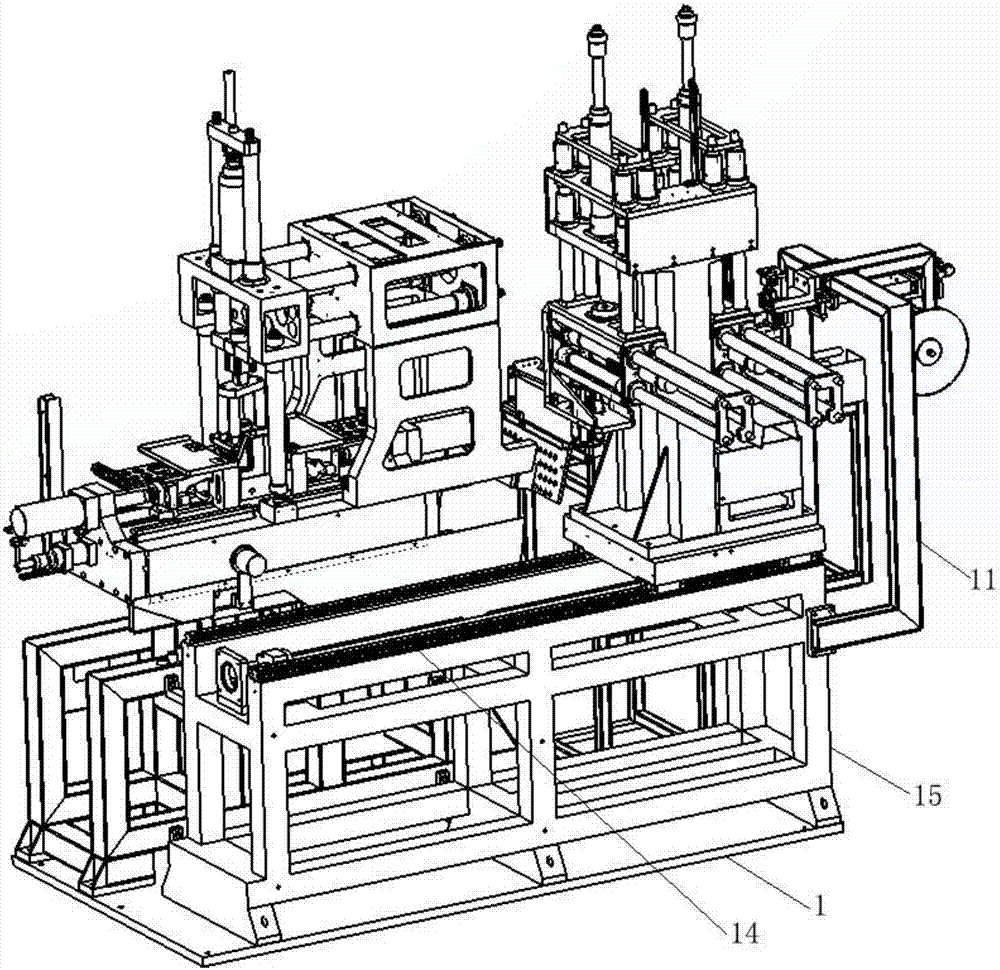

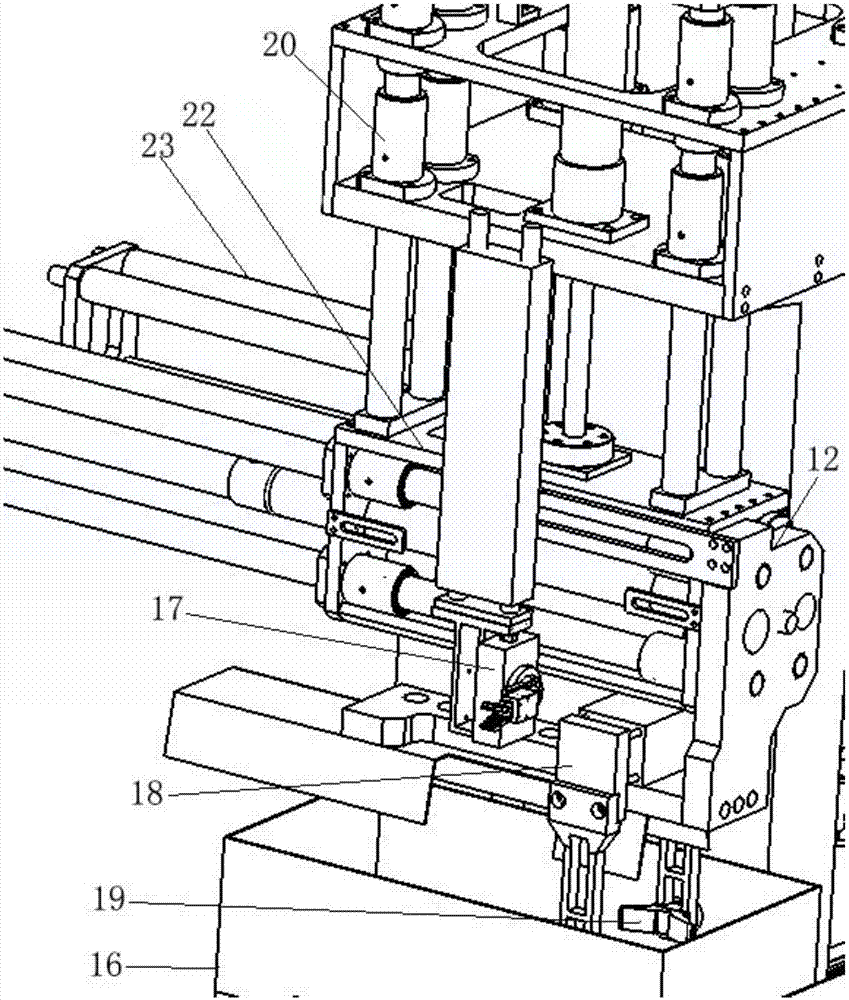

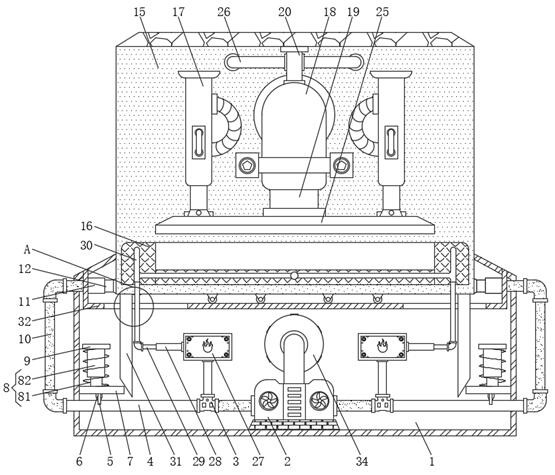

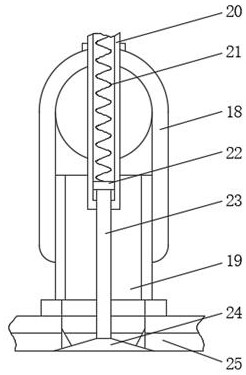

Automatic casting device

ActiveCN107297490AReduce dross contentReduce processing intensityCasting safety devicesCasting cleaning apparatusMaterials scienceCasting

The invention relates to the field of casting devices, and discloses an automatic casting device. The automatic casting device comprises a bottom plate, a casting machine rack, a material receiving rack and a base with a rail are arranged on the upper surface of the bottom plate, the casting machine rack and the material receiving rack are located on the front side, and the base is located on the rear side. The casing machine rack, the material rack and the base are provided with a casting mechanism, a material receiving box and a conveying unit respectively. In the automatic casting device, a filter screen is put on a screen feeding central shaft in a screen feeding box in a curled mode, and the one-storage-multiple-use effect is achieved; the filter screen is conveyed to a notch through a screen conveying air cylinder on a conveying support and a filter screen guide wheel on one side of the conveying support, compressed through a screen compressing air cylinder and then cut by using a cutter, and a cutting wire screen feeding rotary air cylinder and clamping jaw fingers grip a product, and convey the filter screen to a next casting machine rack for casting in the cooperation of a traveling rack and the screen feeding air cylinder after cutting. The device is high in intelligent level, short in production time, high in production efficiency, good in product quality and safe in production.

Owner:JINHUA BAOLIN TECH CORP LTD

Construction waste crushing device with dust collection function and method

ActiveCN108465528ASimplify the screening processEasy to sieveSievingElectrostatic separationDrive motorEngineering

The invention discloses a construction waste crushing device with a dust collection function and a method. The crushing device comprises a supporting base plate, a supporting frame, a crushing box, astanding box and a dust collector. A crushing assembly is movably connected with the interior of the crushing box, a driving motor is arranged on the outer wall of the crushing box and connected withthe crushing assembly, a material guiding slope plate and oscillation mechanisms are arranged inside the crushing box separately, the material guiding slope plate is located below the crushing assembly, a material separating sieve plate is arranged between the oscillation mechanisms, and the material separating sieve plate is located below the material guiding slope plate; the crushing method comprises the following steps of 1 material mixing and crushing, 2 oscillating and separating, 3 standing and dust removal and 4 maintaining. The crushing device is simple in structure, high in crushing efficiency and good in crushing effect, collected building waste granules are uniform, and follow-up utilization is convenient; the crushing method is reasonable and orderly, easy to control, automaticand efficient, the labor intensity of workers is lowered, and the service life of the device is prolonged.

Owner:嘉兴登云智联科技有限公司

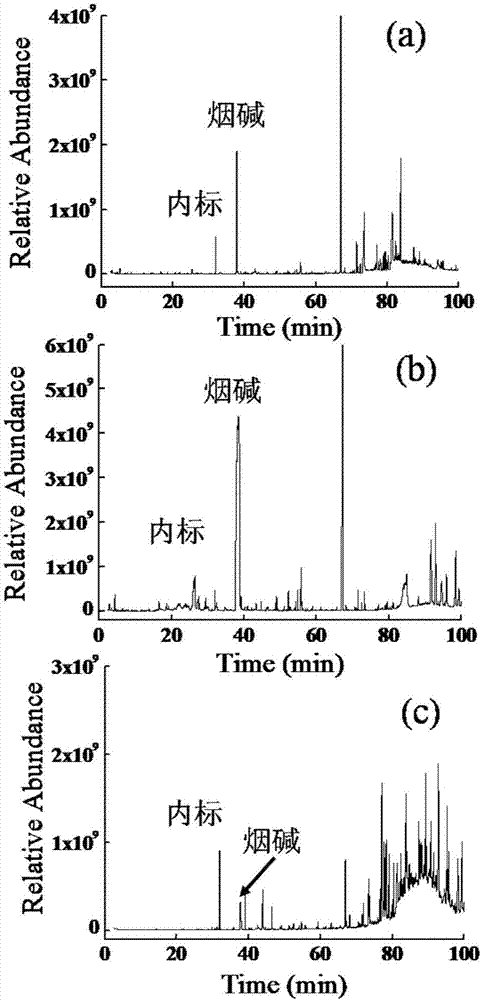

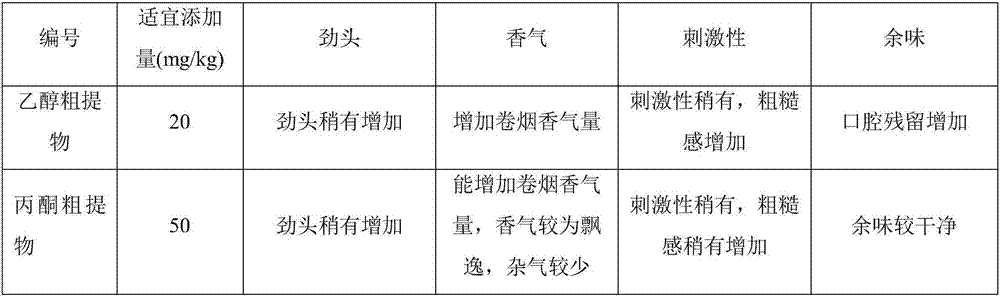

Low-nicotine tobacco extract and preparation method thereof

ActiveCN107149161AGood removal effectGood nicotine contentTobacco preparationTobacco treatmentFlavorKetone

The invention discloses a low-nicotine tobacco extract and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing tobacco extract liquid with relatively low nicotine content by extracting through a ketone or ester solvent; secondly, removing a certain amount of nicotine by water washing; thirdly, concentrating for removing the solvent; finally, completely removing the nicotine through molecular distilling to obtain a tobacco extract spice which is very low in nicotine content and higher in fragrance quality. By adopting the preparation method, the treated tobacco extract can be added into cigarettes in a larger amount, the cigarette fragrance can be improved more remarkably, the fragrance and concentration are enhanced, the strength and irritation are not increased basically, and the cigarette quality is improved well.

Owner:CHINA TOBACCO ANHUI IND CO LTD

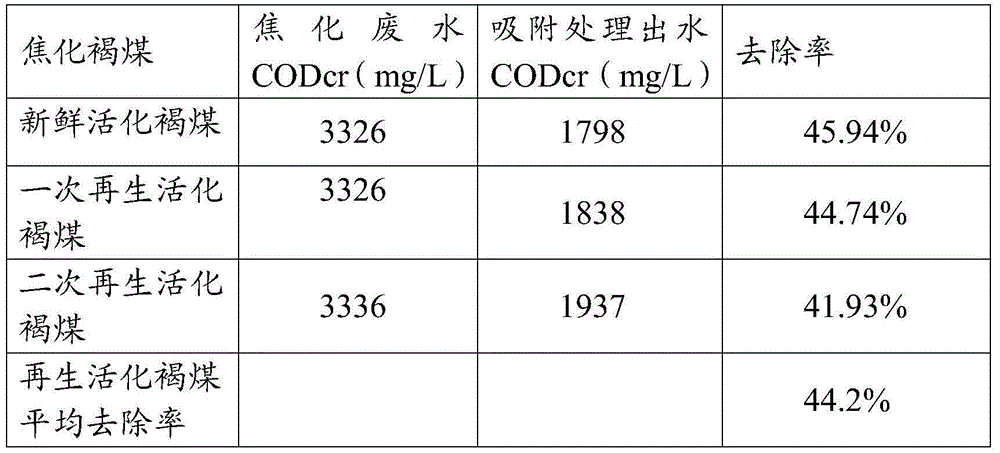

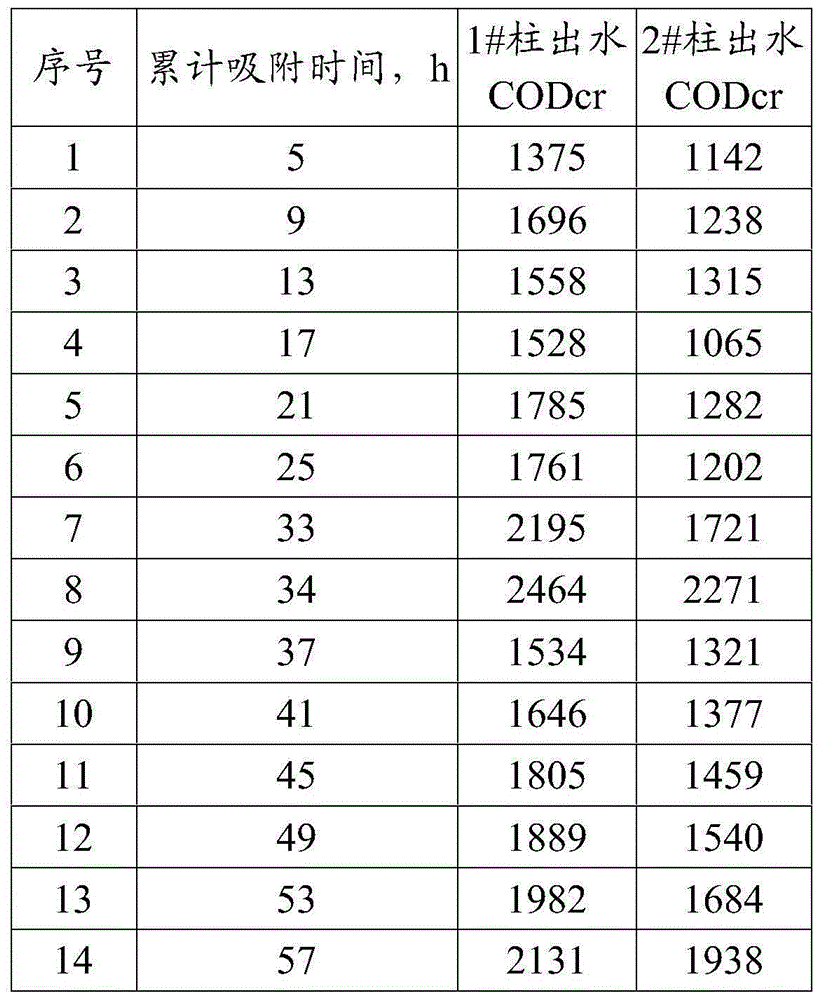

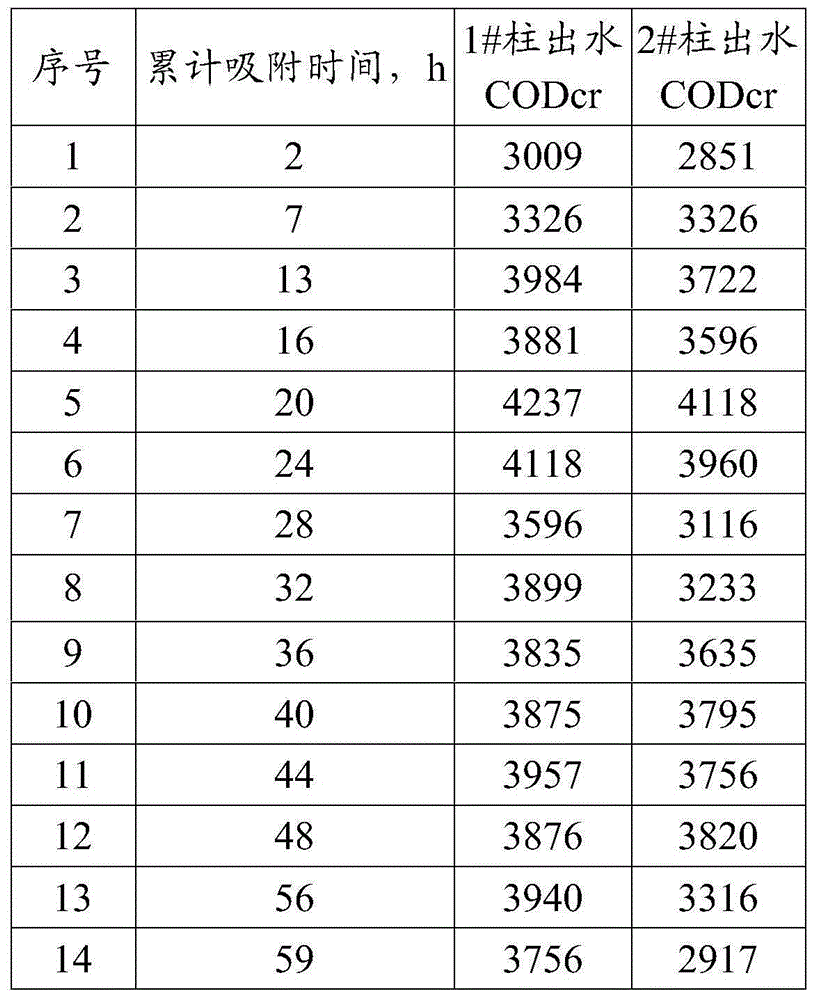

Activated brown coal and coking wastewater treatment process applying activated brown coal

InactiveCN105214625AGood adsorption effectLow costOther chemical processesMultistage water/sewage treatmentBrown coalActivated carbon

The invention relates to the field of environment friendliness and in particular relates to activated brown coal and a coking wastewater treatment process applying the activated brown coal. Specifically, the activated brown coal is used as an adsorbing material to perform pretreatment on coking wastewater, the treated coking wastewater is fed into an inner circulation anaerobic bioreactor to be treated and then is subjected to conventional anoxia and aerobiotic treatment and advanced treatment, and finally, standard discharging is achieved. Compared with the prior art, for the coking wastewater treatment process disclosed by the invention, the adopted activated brown coal can be recycled, absorbing amount is high, and is far lower in cost is fat lower than that of activated carbon; simultaneously, the inner circulation anaerobic bioreactor is used for treatment instead of a common underground anaerobic organism pool, the treatment efficiency of anaerobic organisms is greatly improved, the load of follow-up treatment processes is reduced, the standard discharging is achieved, and a blank of coking wastewater treatment in the prior art is made up.

Owner:SHANDONG SWAN WATER ENG

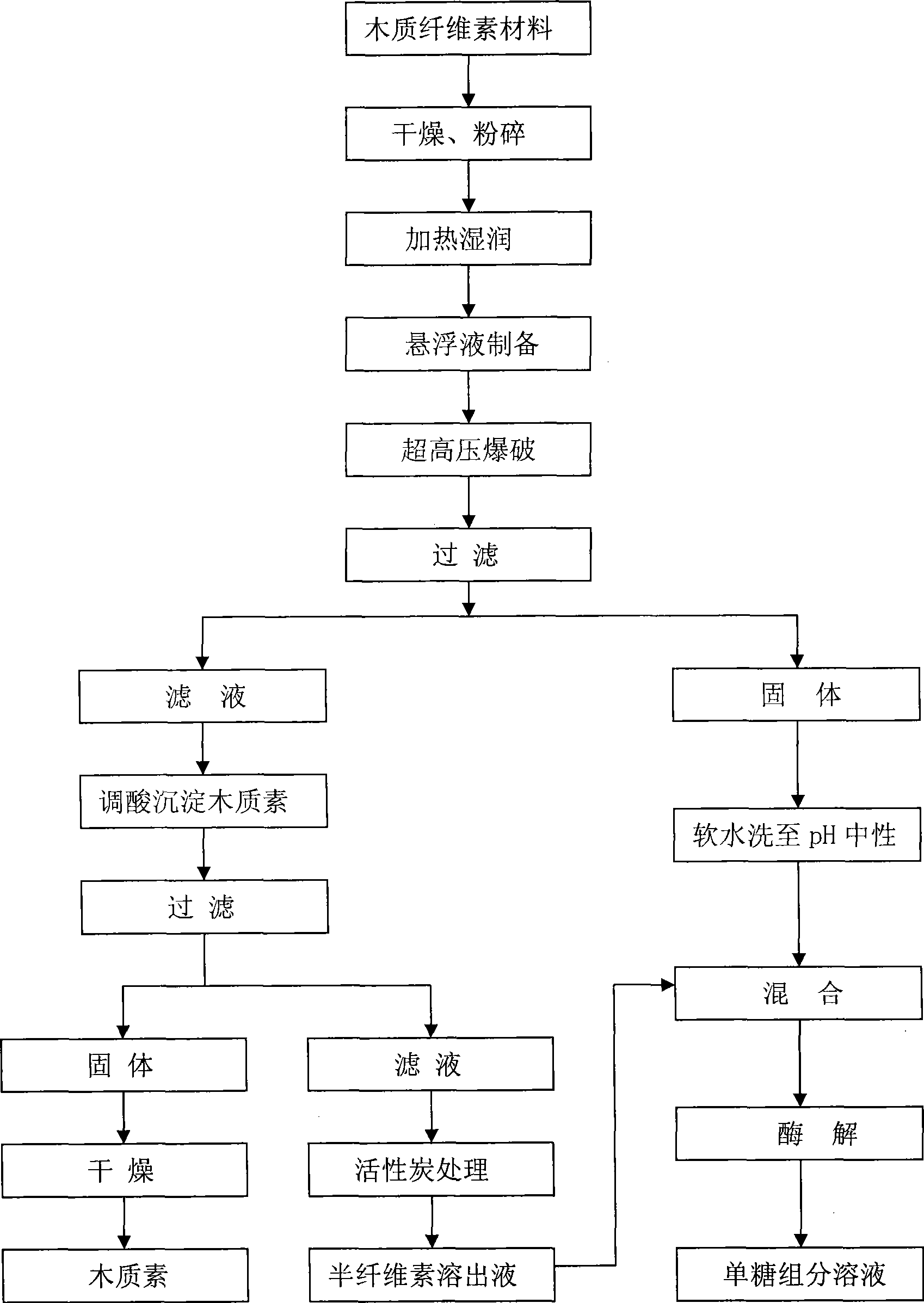

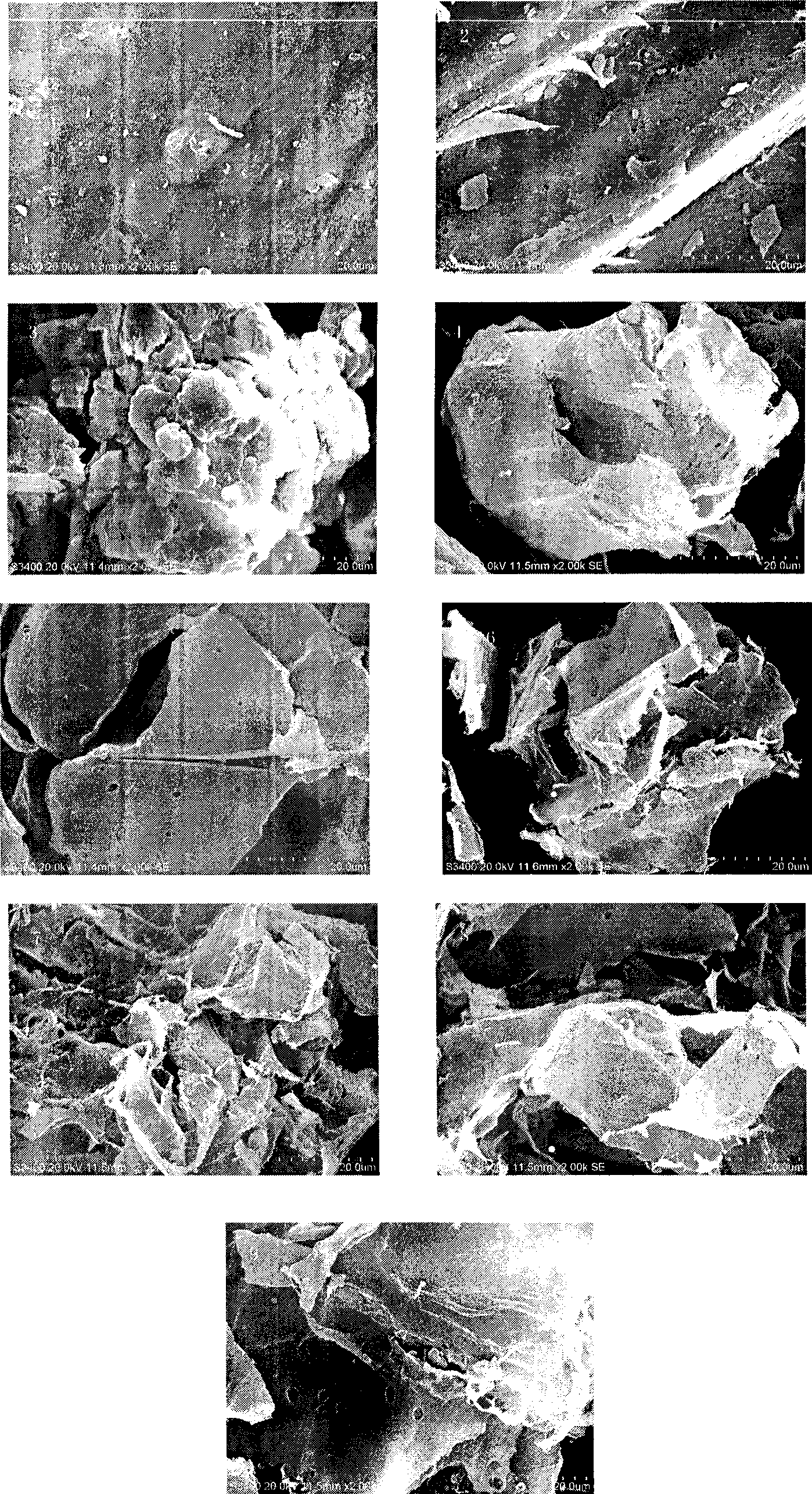

Pretreatment method for ultra-high pressure blasting wood fiber material

InactiveCN101463571AImprove enzymatic hydrolysis rateReduce processing intensityPulping with inorganic basesRaw material divisionCelluloseFiber

The invention discloses a pretreatment method for lignocellulosic materials. The method is as follows: a high-pressure homogenizer which is conventional but is currently only used for processing liquid state materials is taken as the treatment equipment, a stirring device is installed at the feed funnel of the homogenizer, the materials are exploded under ultrahigh pressure by means of transient pressure and pressure elimination in the homogenizing process. The method comprises the steps as follows: the pre-processes like drying, smashing and sieving, etc. of the lignocellulosic materials, the heating and moistening of the materials, the preparation of the suspending liquid, the ultrahigh pressure explosion and the material process after explosion, etc. Compared with various currently disclosed pretreatment methods for lignocellulosic materials, the method not only has the advantages of low requirement for equipment, mild process condition, no harmful substances which inhibit microorganism fermentation and low energy consumption, etc. but also can process the ultramicrostructure which totally changes the lignocellulosic materials and creatively realize the full hydrolyzation of the lignocellulosic materials by making use of the cellulolytic enzyme system of low beta-glucosidase activity.

Owner:GUANGXI ACAD OF SCI

Biological sheep membrane for ocular surface treatment and preparation method thereof

ActiveCN104825493APreserve natural active ingredientsLow content of natural active ingredientsAntipyreticAnalgesicsDamages tissueIrritation

The invention discloses a biological sheep membrane for ocular surface treatment and a preparation method thereof. The biological sheep membrane is prepared from sheep membrane through steps of rapid material obtaining, rapid material cutting, and radiation sterilization. The provided biological sheep membrane and preparation method have the following advantages: (1) various natural active components in sheep membrane can be effectively preserved; (2) the anti-inflammation and scar-resistant functions of natural active components in sheep membrane can be effectively preserved; (3) at the same time, the bacteria and viruses in the sheep membrane are completely killed, and thus the safety of the biological sheep membrane can be guaranteed; (4) the biological sheep membrane can be used to repair the damaged tissues, in the early period of treatment, the biological sheep membrane can promote the epithelization; and at the same time the biological sheep membrane can solve the problems that: (a) the material degrades too fast, and the curative effect cannot be achieved; (b) the material degrades too slowly, and the adverse irritation is generated on normal tissue.

Owner:广州瑞泰生物科技有限公司

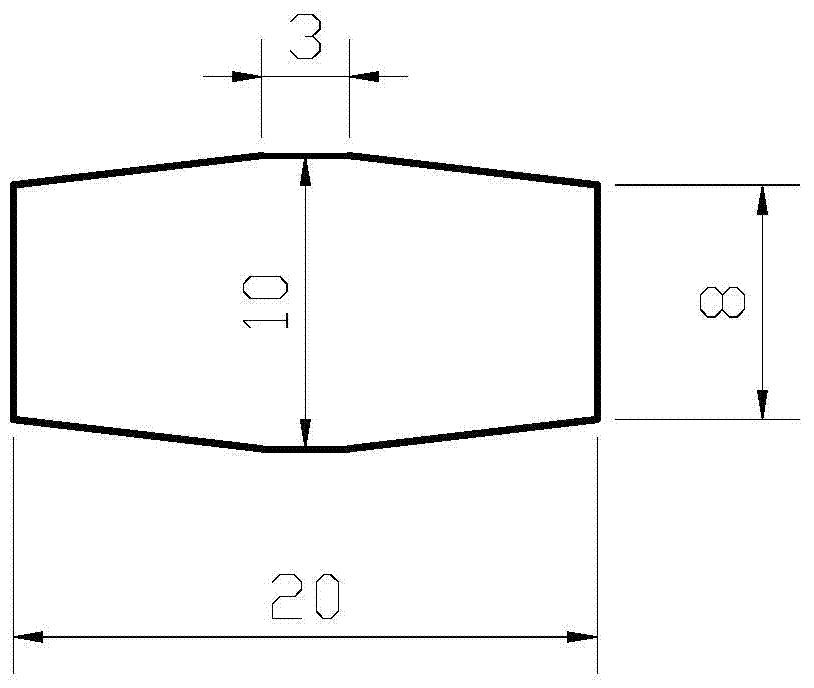

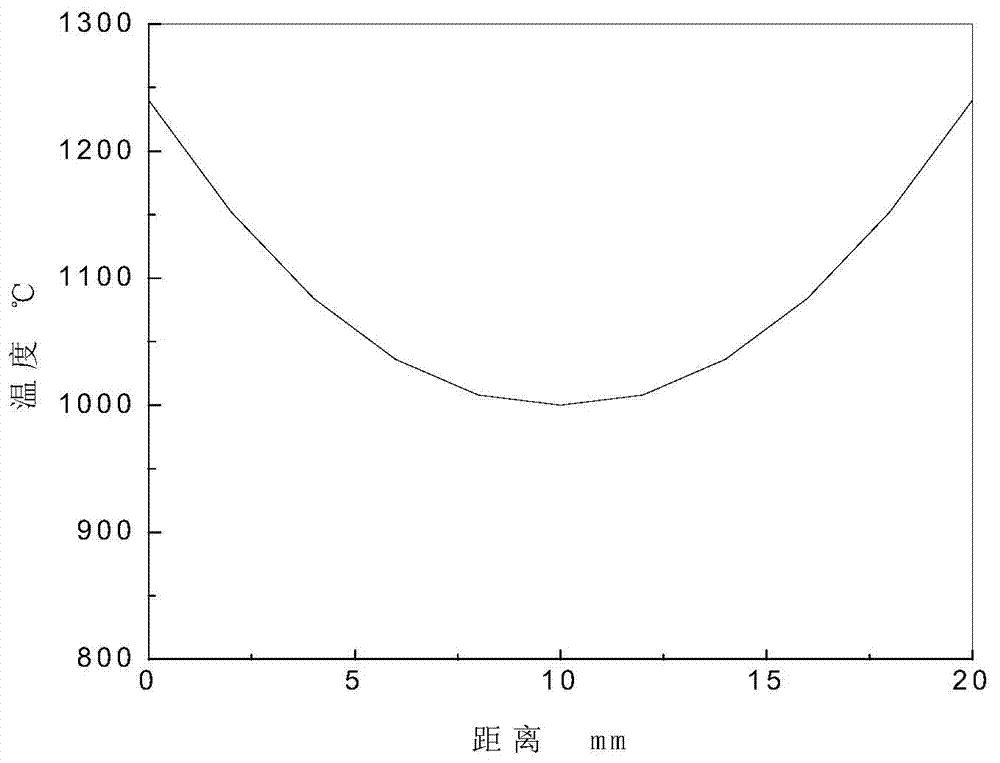

Manufacturing method of pressure head used on thermal force simulation testing machine

ActiveCN103752746AReduce deformation resistanceIncrease the compression ratioMetal-working apparatusManufacturing cost reductionThermal force

The invention provides a manufacturing method of a pressure head used on a thermal force simulation testing machine. The manufacturing method of the pressure head used on the thermal force simulation testing machine includes: processing a blank into an olive shape with two ends fine and the middle thick, determining temperature when shrinking rate of a cross section of the blank is large or the maximum stress value of the cross section of the blank is low to be heating or deformation temperature of the blank, placing the blank between two anvil heads which both have heating and hot pressing deformation functions after a thermoelectric couple is welded on the thickest middle position of the olive-shaped blank, adding a spacer between the blank and each anvil head, and performing 2-7 times of compression deformation on the blank after the blank is heated to the deformation temperature through voltage applied between the two anvil heads so as to combine the spacers and the blank into a whole, wherein deformation amount in each time of the compression deformation is larger than deformation amount in the last time of the compression deformation. The manufacturing method of the pressure head used on the thermal force simulation testing machine can reduce deformation resistance when the blank is compressed, decreases the number of defects of the blank, improves strength of the pressure head, prolongs service life of the pressure head, avoids adhesion between the blank and each anvil head, simplifies processing technology, shortens the production cycle, and reduces manufacturing cost.

Owner:ANGANG STEEL CO LTD

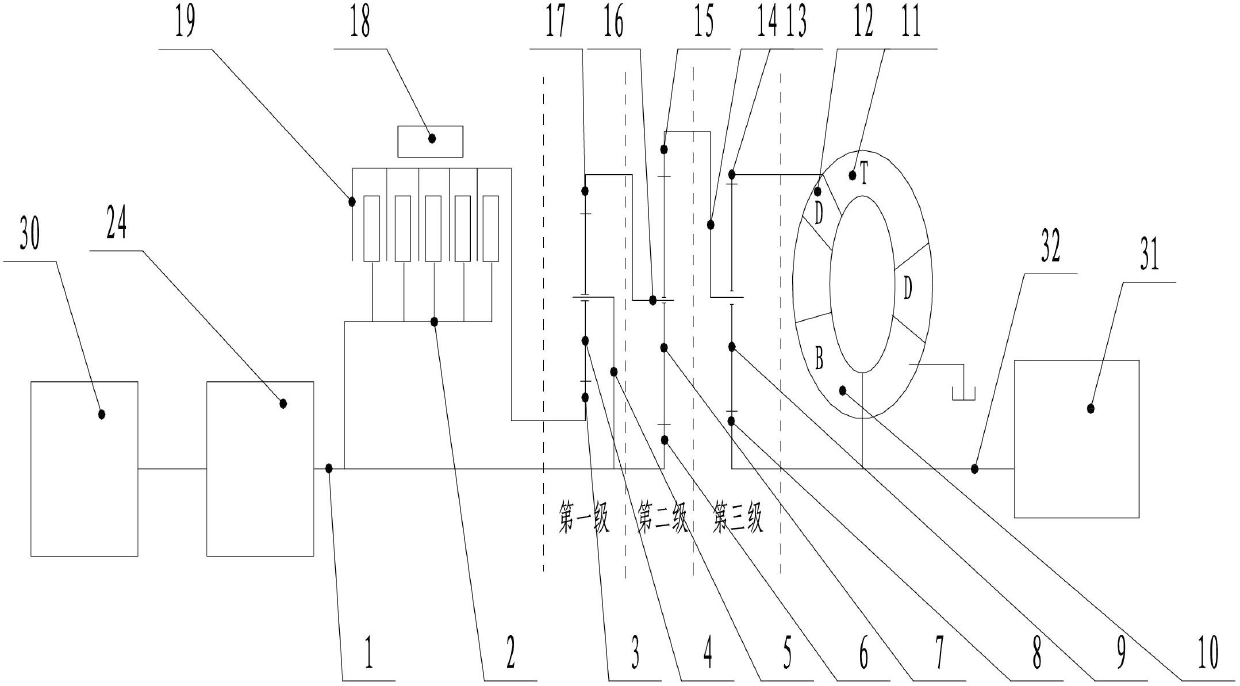

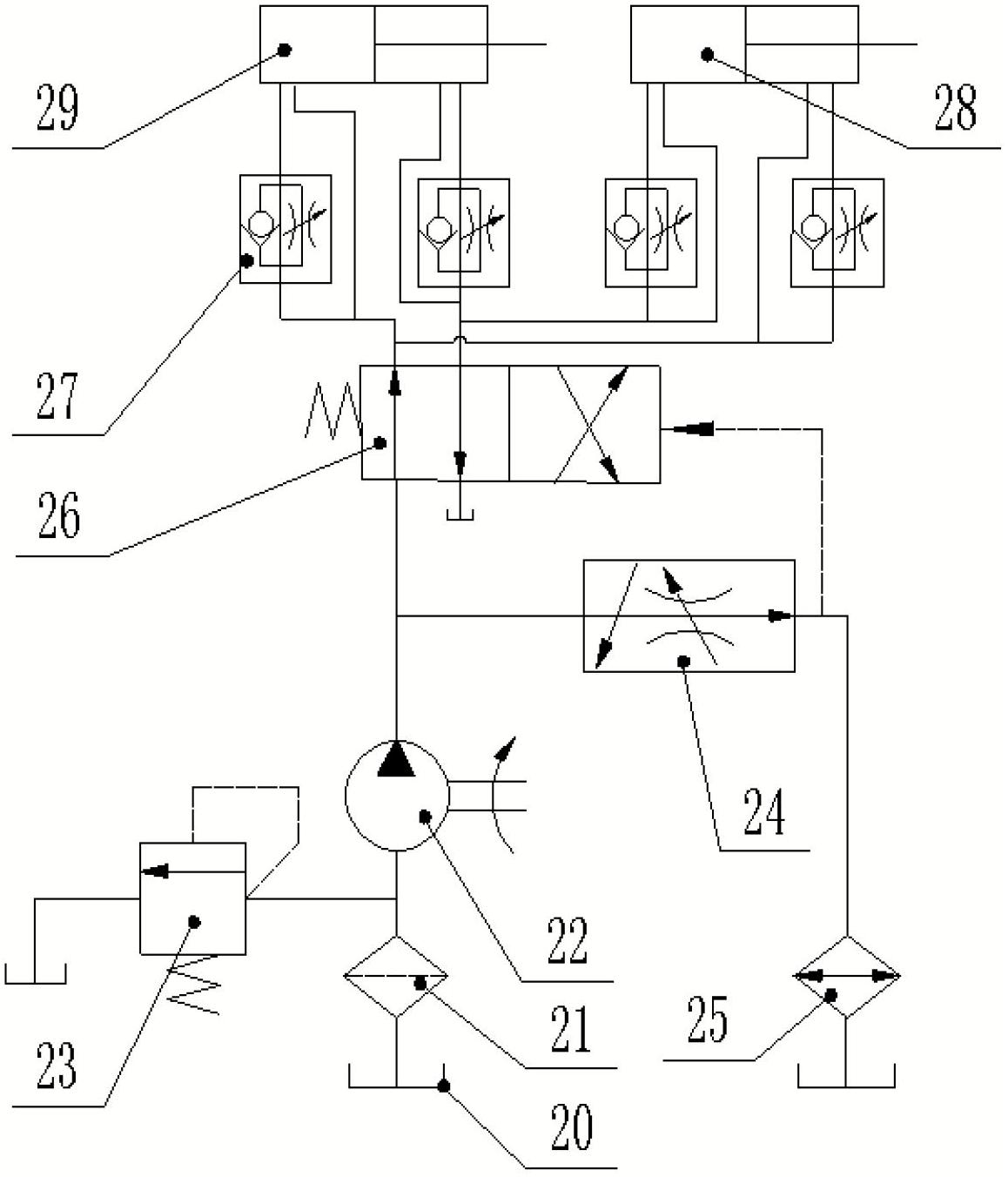

Wind power generation hydraulic control shifting voltage stabilizer

InactiveCN102678876AAdapt to increased wind speed rangeWith shift functionGear lubrication/coolingGearing controlThree levelControl theory

The invention belongs to the technical field of wind power generation and relates to a wind power generation hydraulic control shifting voltage stabilizer. According to the wind power generation hydraulic control shifting voltage stabilizer, automatic gearshift can be achieved, and the range of wind speed adaptation of a wind motor is remarkably improved. The wind power generation hydraulic control shifting voltage stabilizer comprises a three-level planet gear transmission mechanism, a gearshift actuating mechanism, a hydraulic control system, a speed increaser and an adjustable torque converter, a first level sun wheel is connected with a driving disc of a direct gear clutch, a first level gear ring is connected with a second level planetary frame, a second level gear ring is connected with a third level planetary frame, a first level planetary frame, a driven disc of the direct gear clutch and a second level sun wheel are respectively connected with an output shaft of the speed increaser, a centrifugal speed regulating valve is arranged on the output shaft of the speed increaser, a speed increasing gear brake is arranged on the side of the driving disc of the direct gear clutch, a third level gear ring is connected with a turbine of the torque converter, a third level sun wheel and a pump wheel of the torque converter are respectively connected with a generator input shaft, and each level of planet wheels is meshed with one corresponding sun wheel and one corresponding gear ring which are at the same level and is connected with one corresponding planetary frame at the same level through a bearing.

Owner:NORTHEASTERN UNIV

Bridge span reduction method and special-purposed bridge span reduction backfill material

InactiveCN105016770AFast hydrationRapid early strength developmentEmbankmentsCeramicwareFoaming agentMixed materials

The invention provides a bridge span reduction method and a special-purposed bridge span reduction backfill material. The material comprises the following components, by weight, 150-400 parts of cement, 20-120 parts of a mixed material, 50-200 parts of water, 15-50 parts of a regulator, 5-15 parts of a foaming agent, 2-10 parts of a micro-foaming agent, and 5-10 parts of a waterproofing agent. The lightweight foam soil provided by the invention is lightweight and has high strength. The material has a good overall performance. With the material, a soft soil area soil bearing capacity can be satisfied, and the bearing capacity of a backfilled foundation to the upper load can be satisfied. The load of a special subgrade is reduced, and subgrade settlement is reduced.

Owner:河南华泰新材科技股份有限公司

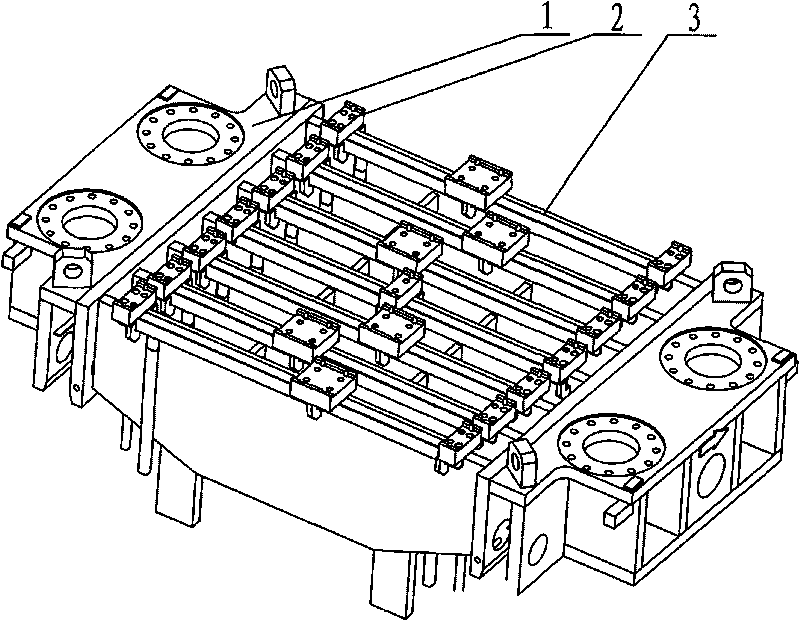

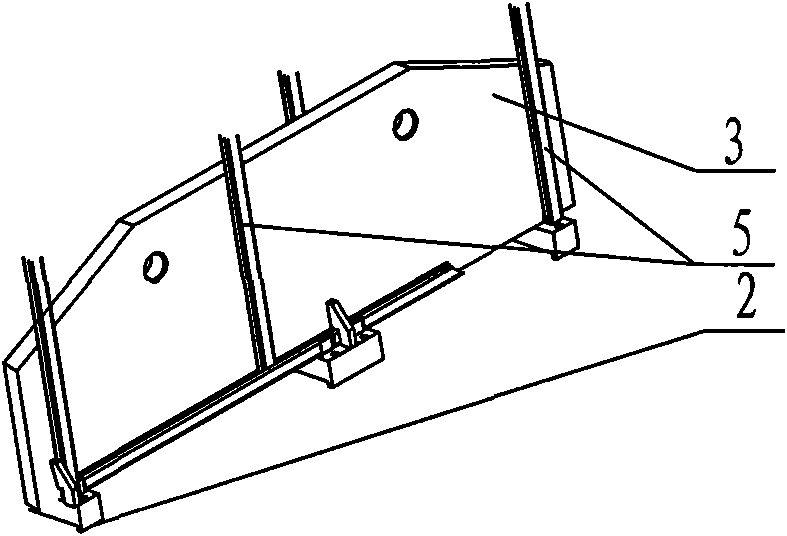

Method for assembling and welding curved-surface sector-segment frames

The invention discloses a method for assembling and welding curved-surface sector-segment frames, which relates to a method for welding complex frames. By adopting positioning blocks and special process modules, a plurality of working-equipment matching surfaces and bearing blocks of upstanding-plate welding components are positioned, assembled and fixed respectively. The method has the advantages of raising work speed, saving 17 hours of assembly, reducing work intensity, improving machining quality and reducing rework rate from 40 percent to 5 percent.

Owner:YICHANG JIANGXIA MARINE MACHINERY

Wear-resistant steel and smelting method

ActiveCN110004371AReduce harmful gas contentImprove the cleanliness of molten steelManufacturing convertersSteel platesWear resistant

The invention discloses wear-resistant steel which is prepared from, by mass, 0.20%-0.30% of C, 0.10%-0.35% of Si, 0.40%-1.50% of Mn, 0.010% or less of P, 0.0020% or less of S, 0.010%-0.030% of Nb, 0.050% or less of Cu, 0.10%-0.50% of Mo, 0.010%-0.030% of Ti, 0.10%-0.90% of Ni, 0.3%-0.9% of Cr, 0.001%-0.0050% of Ca, 0.01%-0.03% of V, 0.0010%-0.0030% of B, 0.020%-0.060% of Al and the balance Fe andimpurities. Influences of large-particle inclusions in a steel plate on the stress of the steel plate are reduced, and the phenomenon that a casting blank and the steel plate are likely to crack whenmachined is relieved.

Owner:NANJING IRON & STEEL CO LTD

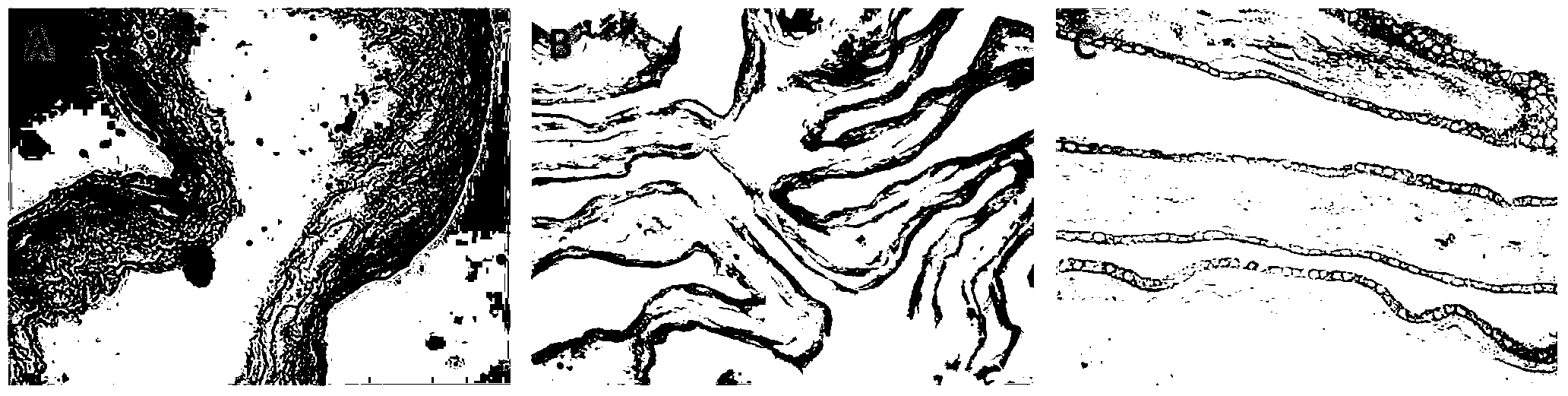

Preparation and preservation method of amniotic membrane biological agent

InactiveCN105497984AImprove featuresWide variety of sourcesDead animal preservationProsthesisDecellularizationUltimate tensile strength

The invention provides a preparation and preservation method of an amniotic membrane biological agent. The method includes the first step of raw material selection and pretreatment, the second step of inactivation treatment of viruses, the third step of preparation, the fourth step of dyeing and the fifth step of preservation. Compared with the prior art, the method has following advantages that the preparation method is simple, raw materials are wide in source, large-scale industrial production can be achieved, prepared decellularized amniotic membranes are low in treatment strength and good in decellularization effect, and dense collagenous structures of natural amniotic membranes can be fully maintained. Amniotic membrane features are optimized easily, and important technical support can be provided for tissue engineering amniotic membrane industrialization.

Owner:马玉玲

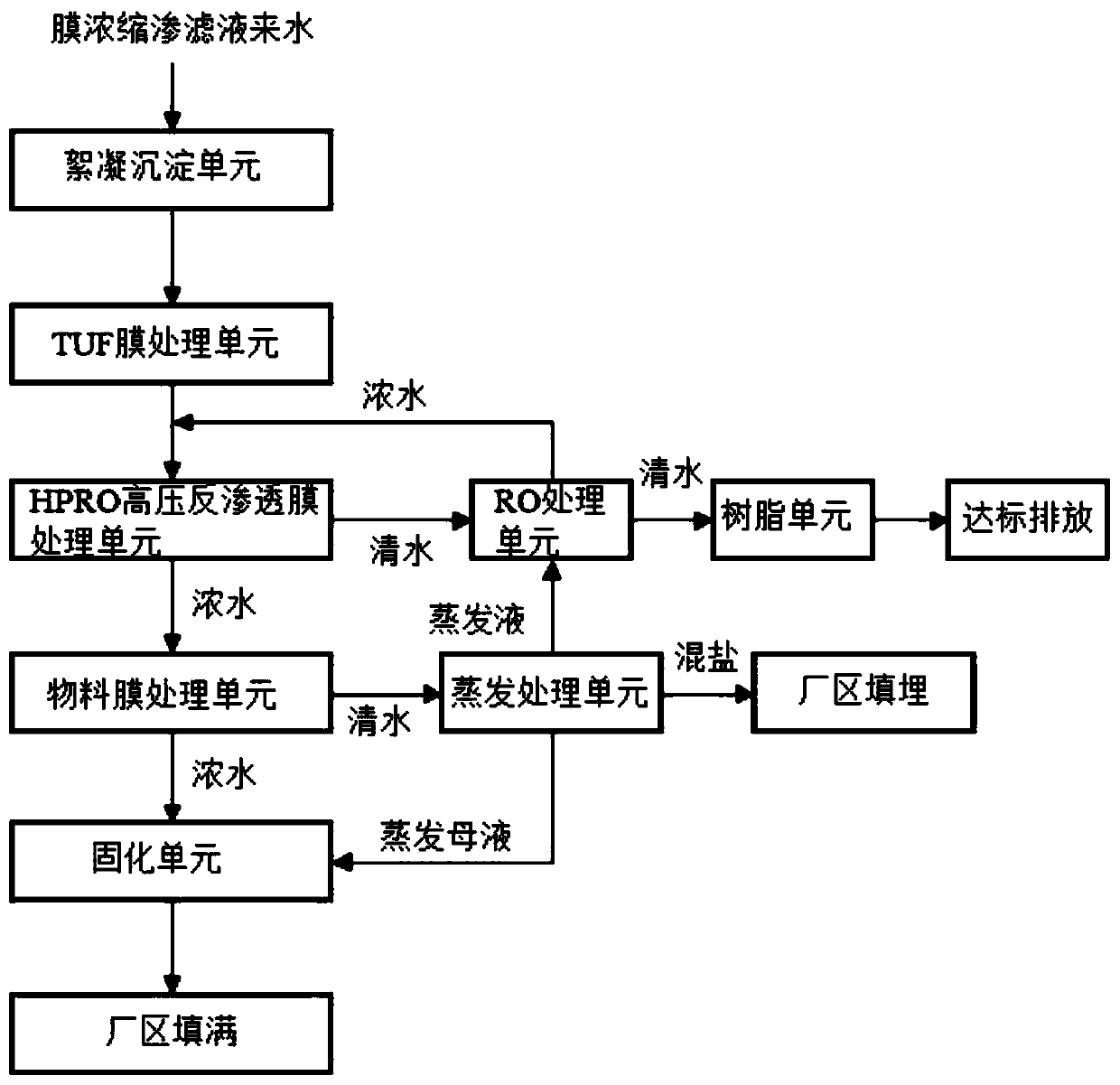

Refuse landfill membrane concentration leachate treatment method

InactiveCN111362494AHarmless treatmentResolve disposal issuesSpecific water treatment objectivesTreatment involving filtrationPollutantMother liquor

The invention provides a refuse landfill membrane concentration leachate treatment method. The method comprises the following steps: firstly, refuse landfill membrane concentration leachate sequentially enters a flocculation precipitation unit, a TUF membrane treatment unit and an HPRO high-pressure reverse osmosis membrane treatment unit, clear water generated by the HPRO high-pressure reverse osmosis membrane treatment unit is introduced into an RO treatment unit, clear water generated after treatment of the RO treatment unit enters a resin unit, and generated concentrated water is introduced into the HPRO high-pressure reverse osmosis membrane treatment unit again and is treated; and concentrated water generated by the HPRO high-pressure reverse osmosis membrane treatment unit is introduced into a material membrane treatment unit, clear water treated by the material membrane treatment unit is introduced into the evaporation treatment unit and is evaporated, and the concentrated water of the material membrane treatment unit and evaporation mother liquor are introduced into the solidification unit and are solidified. The problems of high sewage treatment difficulty caused by continuous recharging of the existing membrane concentrated leachate and continuous enrichment of pollutants and serious bubbles and scaling of an evaporation system are solved, and reduction and harmlesstreatment of the landfill leachate are realized.

Owner:武汉天源环保股份有限公司

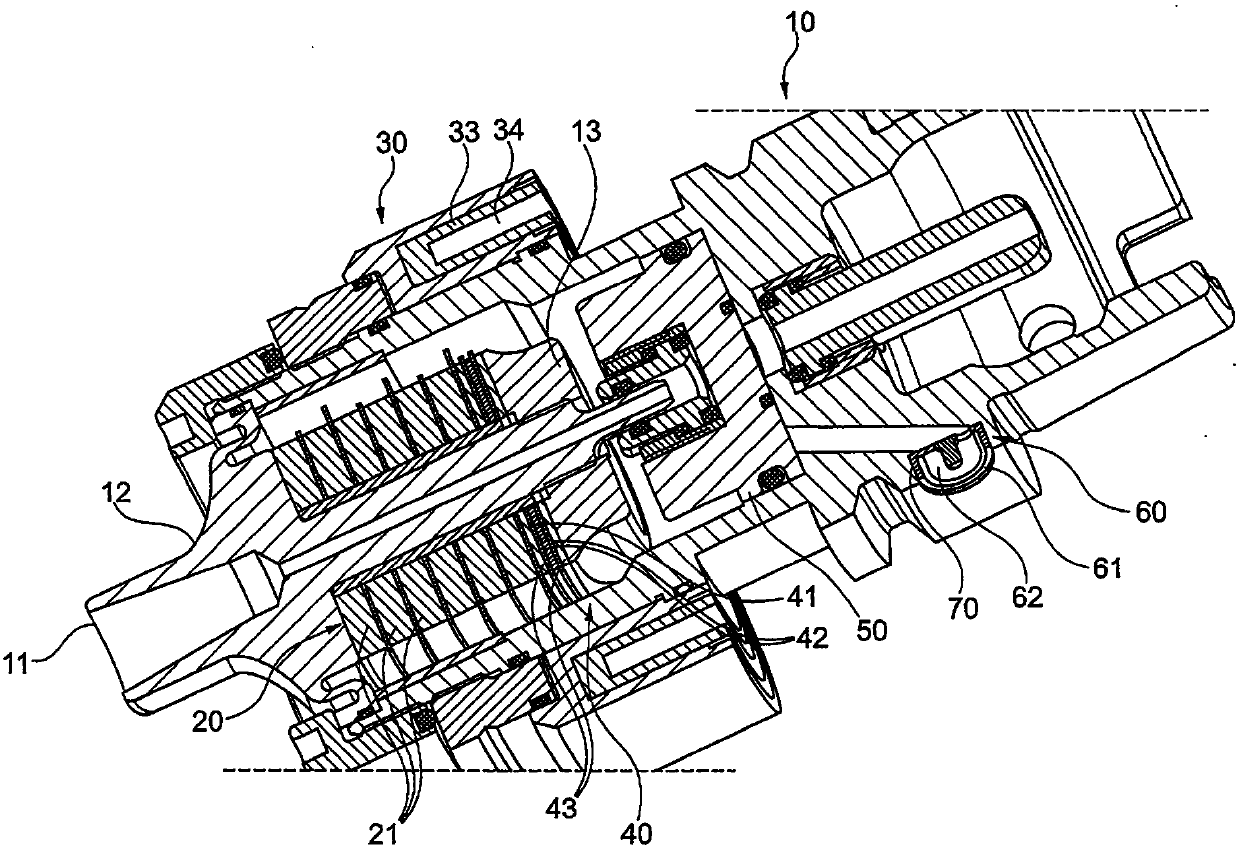

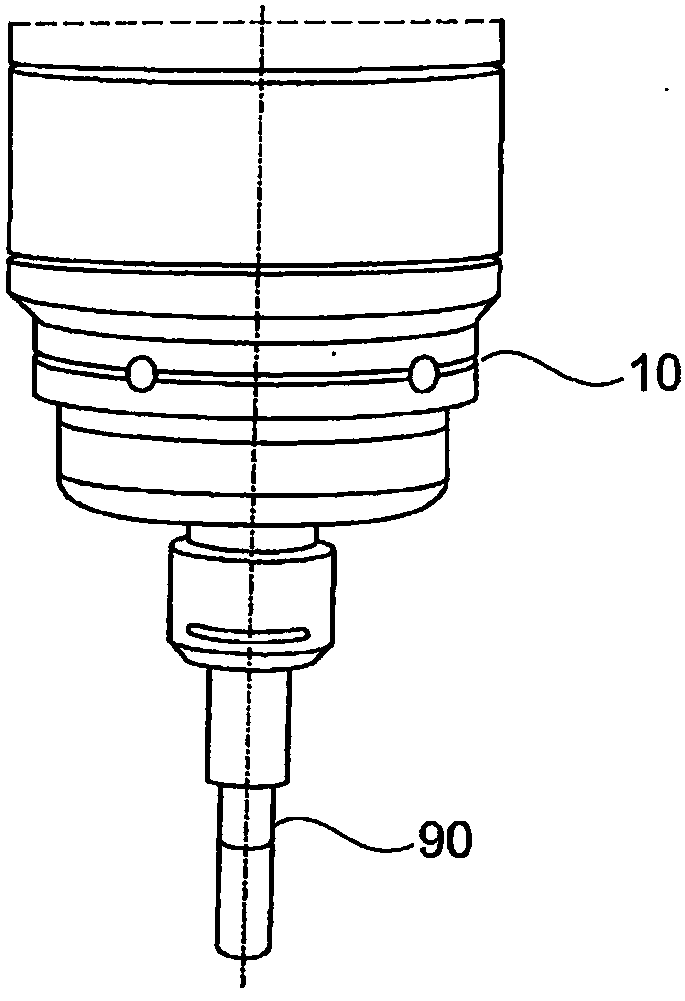

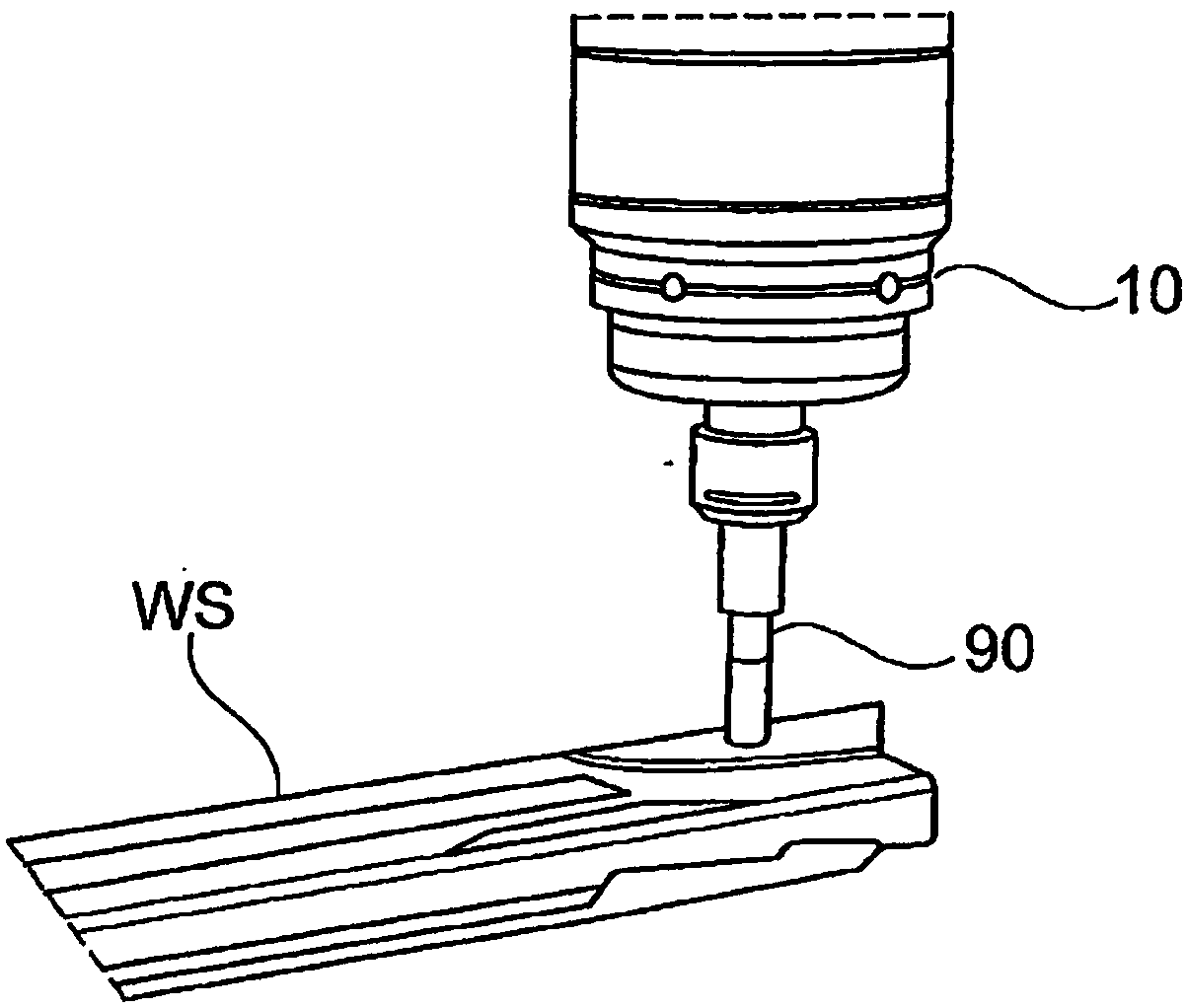

Method for processing a workpiece made of hard metal for producing a tool main body

InactiveCN107813192AIncrease productivityImprove production efficiencyAutomatic grinding controlGrinding machinesHard metalEngineering

A method for processing a workpiece WS made of hard metal for producing a tool main body on a numerically controlled machine tool 1000 with a tool-carrying work spindle 1040, comprising: accommodatinga tool holder 10 that holds a tool 90 on a tool support 1041 of the work spindle 1040 of the machine tool 1000, wherein the tool holder 10 comprises a vibration generator 20 for generating a vibration of the tool 90, and processing the workpiece WS which is clamped on the machine tool 1000 and is made of hard metal by the vibrating tool 90 held on the tool holder 10 for working out one or more recesses at the workpiece for producing the tool main body.

Owner:萨奥有限公司

Smoke block pre-loose processing device and method

The invention discloses a smoke block pre-loose processing device and method. The smoke block pre-loose processing device comprises a curved roller conveying mechanism is arranged above a belt conveyor, rollers in the roller conveying mechanism are connected with a power mechanism, a rake nail is arranged on each roller, linear speed of the rear roller is greater than that of the former roller and / or elongation length of the rake nails on the rollers is increased by degrees by adjusting rotating speed of the rollers gradually, and tearing of smoke blocks in the roller conveying mechanism is realized. By the arrangement of a roller shifting mechanism, the smoke blocks are enabled to produce cracks effectively and be inserted and divided, and pre-loose effect can be guaranteed; the entire loosening device is simple in structure, small in size and capable of effectively utilizing the upper space of the belt conveyor, basically, no effect is caused to original equipment, and processing strength and energy consumption of loosening and moisture regain processes can be reduced.

Owner:CHINA TOBACCO SHANDONG IND

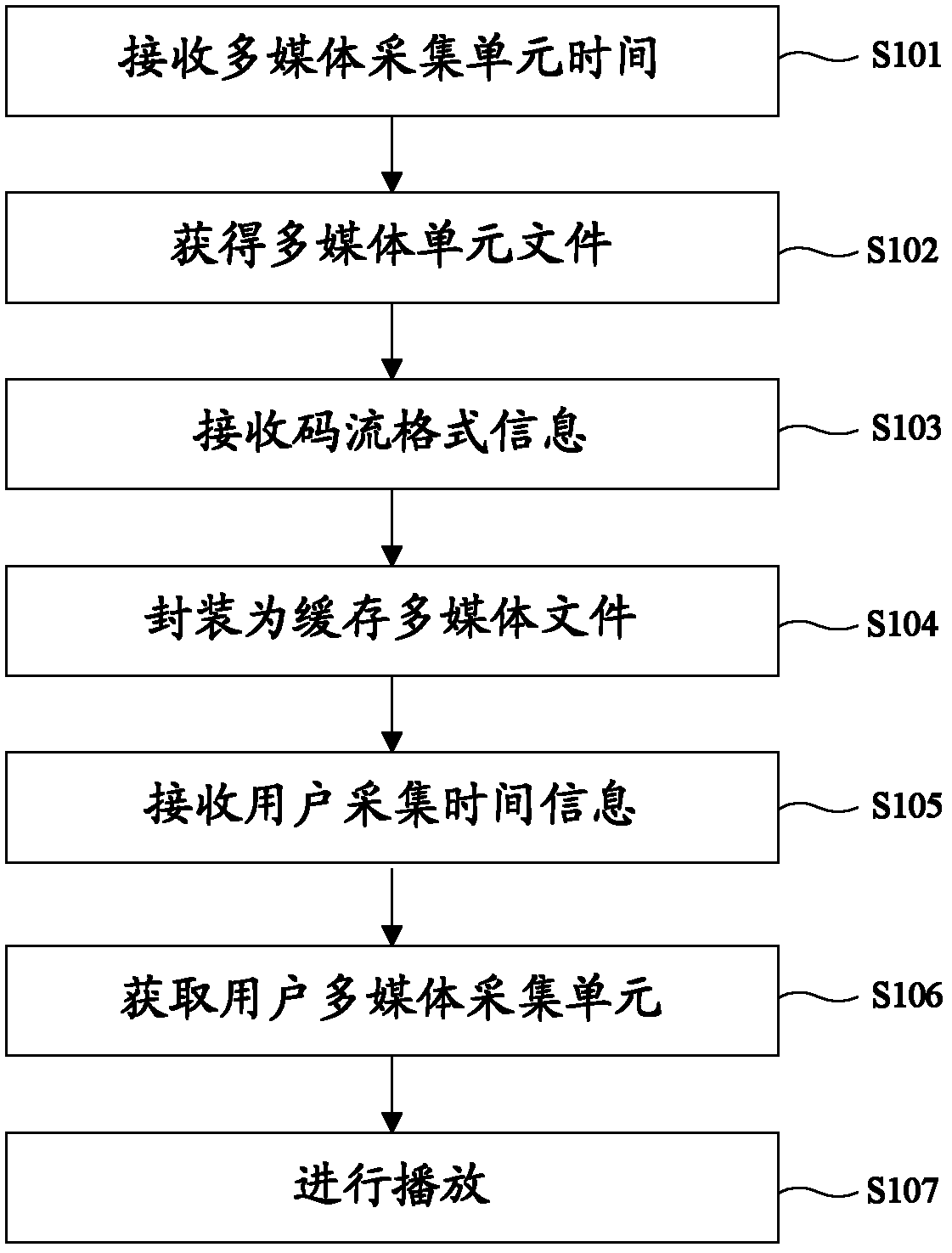

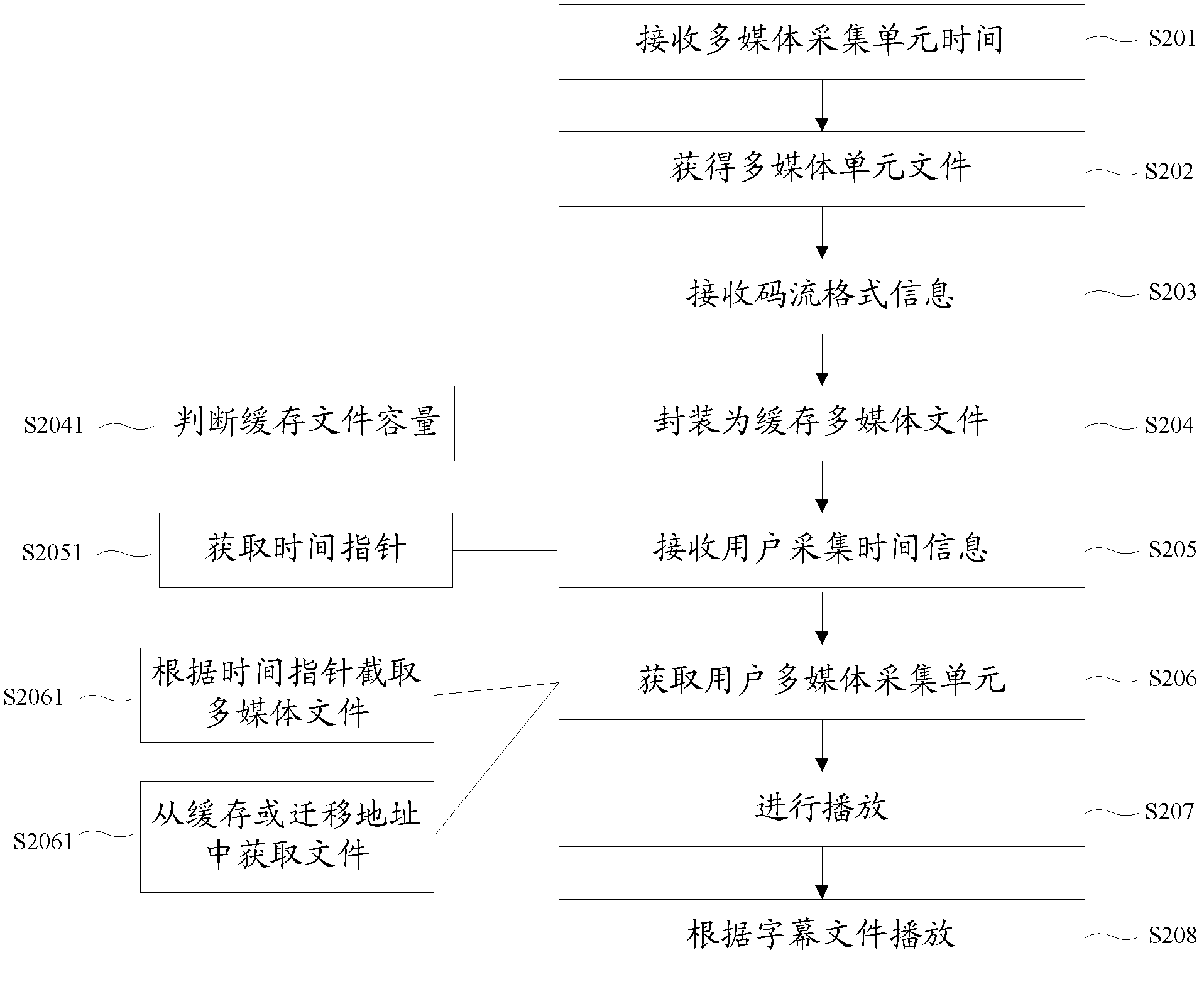

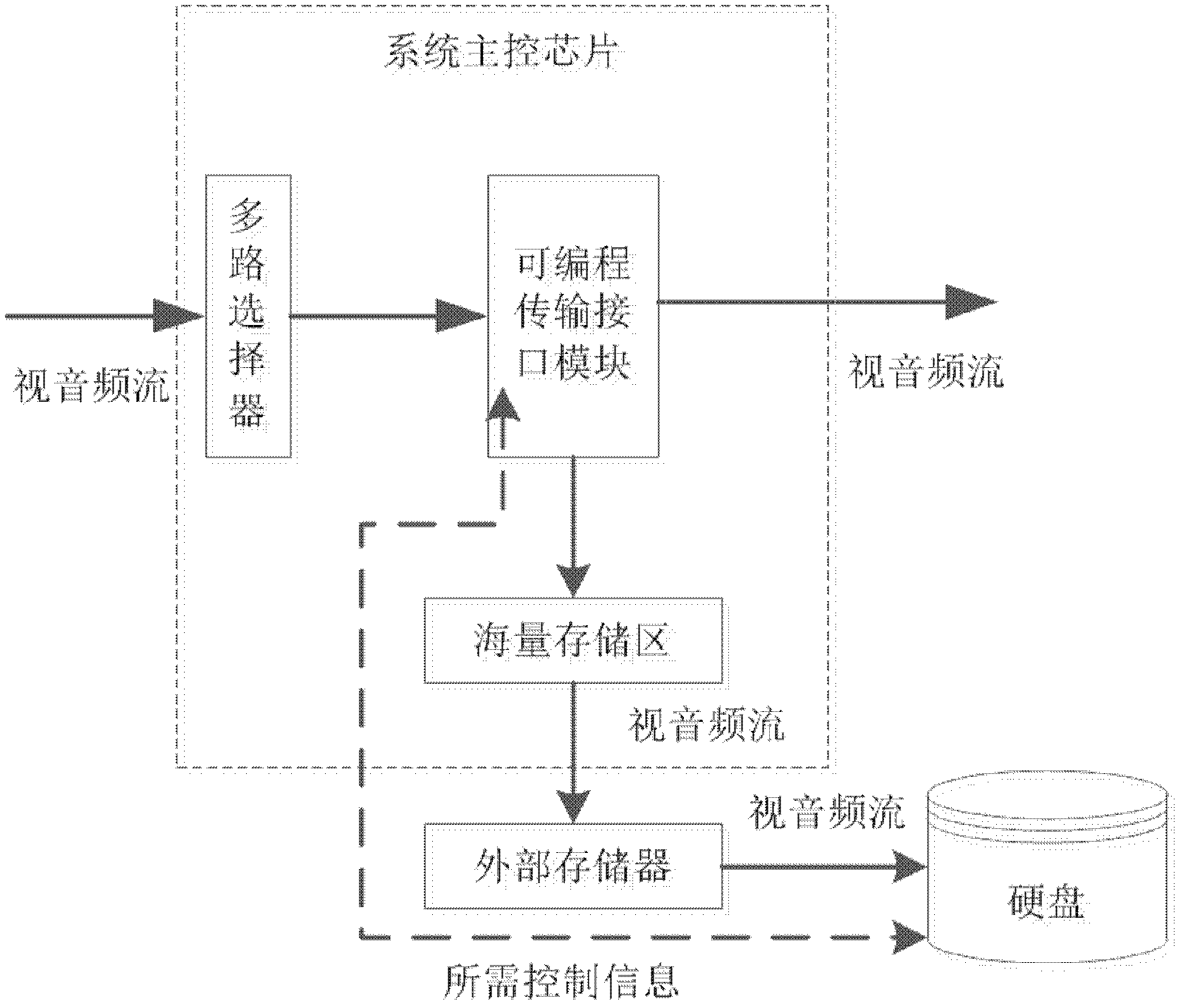

Cyclic recording method

InactiveCN102724429AEasy to collectRealize acquisitionTelevision system detailsColor television detailsComputer hardwareAcquisition time

The invention discloses a cyclic recording method. The method comprises the following steps: according to a multimedia acquisition time unit, receiving a multimedia file and acquiring a multimedia file unit; according to code stream format information, packaging the multimedia file into a cache multimedia file; receiving user acquisition time information; according to the user acquisition time information, intercepting the cache multimedia file and acquiring a user multimedia acquisition unit; according to the user multimedia acquisition unit, acquiring a user multimedia file; carrying out playing according to the user multimedia file. By using the method of the invention, user interception can be performed on a multimedia material at any time. A system resource can be fully used. A stable working state of a system is maintained and stability of the system is enhanced. Actual file recording is not performed on historical data and the multimedia file is actually generated after the user intercepts the file. Therefore, user can collect the historical data, a system storage resource is saved and system operation cost is saved too.

Owner:NEWAUTO SILICON VALLEY VIDEO TECH

Preparation equipment of energy-saving and environment-friendly ecological composite wallboard

InactiveCN112476724AReduce congestionReduce processing intensityFeeding arrangmentsAuxillary shaping apparatusMachiningIndustrial engineering

The invention discloses preparation equipment of an energy-saving and environment-friendly ecological composite wallboard, and particularly relates to the technical field of wallboard machining. The preparation equipment comprises a mounting shell; a draught fan is fixedly connected to the lower surface of the inner wall of the mounting shell; air outlets in the left side and the right side of thedraught fan communicate with one ends of opposite faces of two tee joints correspondingly; the ends, away from each other, of the two tee joints communicate with the ends of opposite faces of two first guide pipes correspondingly; blocking plates are clamped to the upper surfaces of the first guide pipes; and sealing blocks are fixedly connected to the outer surfaces of the blocking plates. By arranging the draught fan, connecting plates and extrusion rods, when the preparation equipment is used for machining raw materials, the machining processing steps can be completed only by injecting theraw materials into a mold and then starting the draught fan, so the machining strength of workers is reduced; and after the raw materials enter the mold, the draught fan can push a mounting plate tomove leftwards and rightwards, so that the raw materials in the mold are flatly spread in the mold, and the quality of a wallboard machined by the preparation equipment is guaranteed.

Owner:宿迁永泰邦辰知识产权运营管理有限公司

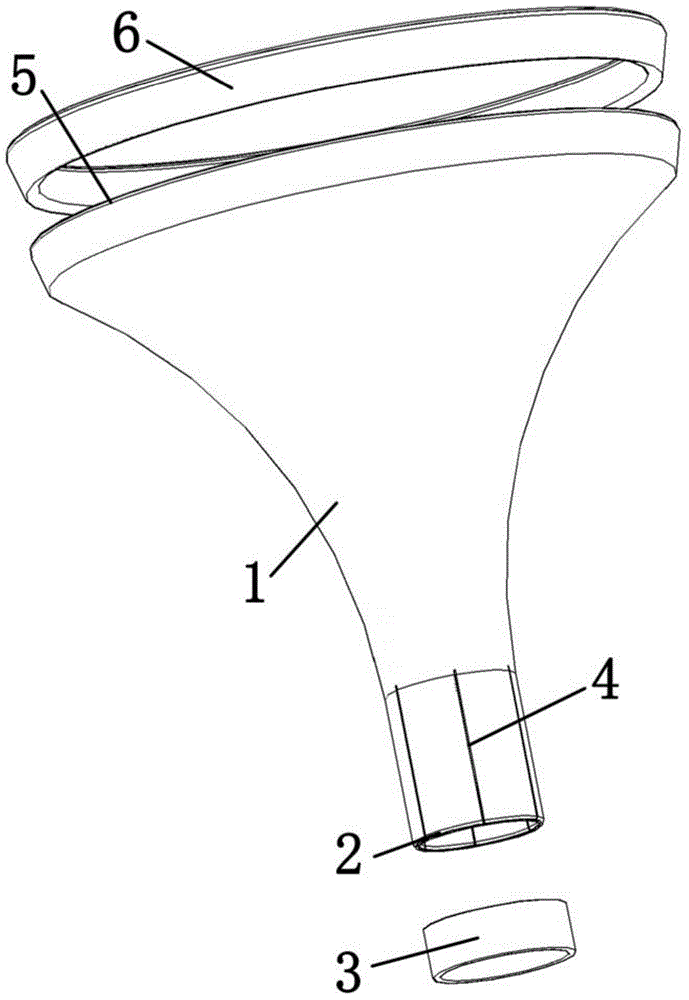

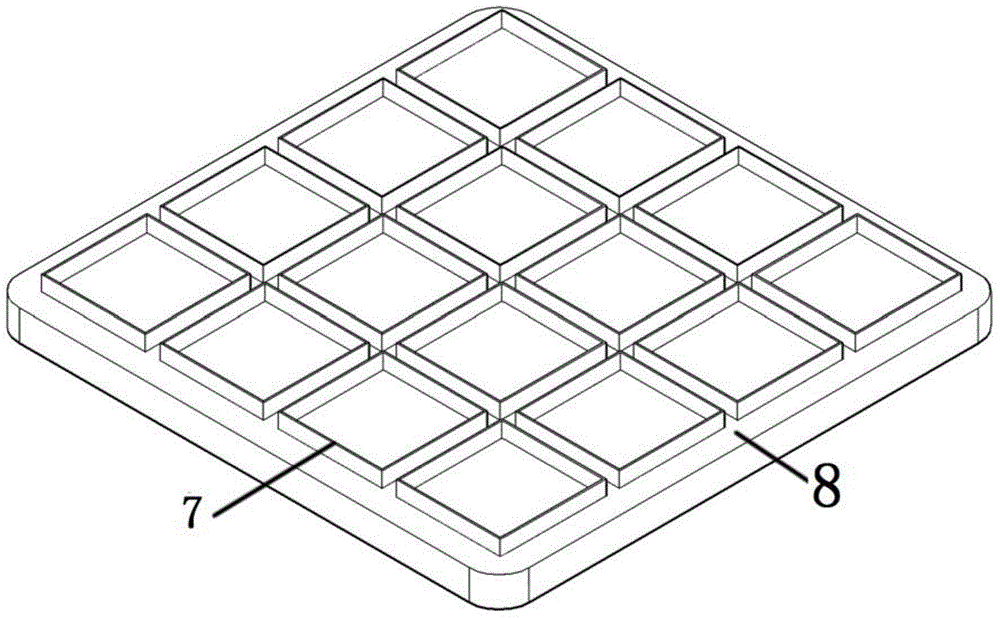

Microporous RTM (regenerative tissue matrix) as well as preparation and application thereof

The invention provides a microporous RTM (regenerative tissue matrix) as well as preparation and application thereof. The microporous RTM is a flaky material of a porous structure, micropores are uniformly distributed in the material, the pore diameter of the micropores is 0.15-0.20 mm, the distance between micropores is 0.8-1.2 mm, and collagen fiber extending into the pores is arranged on the inner surfaces of the micropores. The microporouse RTM provided by the invention removes cells completely and has no immunogenicity or cytotoxicity factors, collagen fiber, reticular fiber, elastic fiber of the RTM and a three-dimensional structure consisting of the fibers are slightly damaged, the RTM is better attached to wounds, multiple collagen fibers extending into the pores are arranged on the inner surfaces of the mciropores, and more immigrated cell attachment sites can be provided.

Owner:石卫华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com