Method for assembling and welding curved-surface sector-segment frames

A fan-shaped segment and frame technology, applied in the welding field of complex frames, can solve the problems of low product quality and production efficiency, heavy workload, etc., and achieve the effect of easy operation, reduced labor intensity, and uniform processing allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

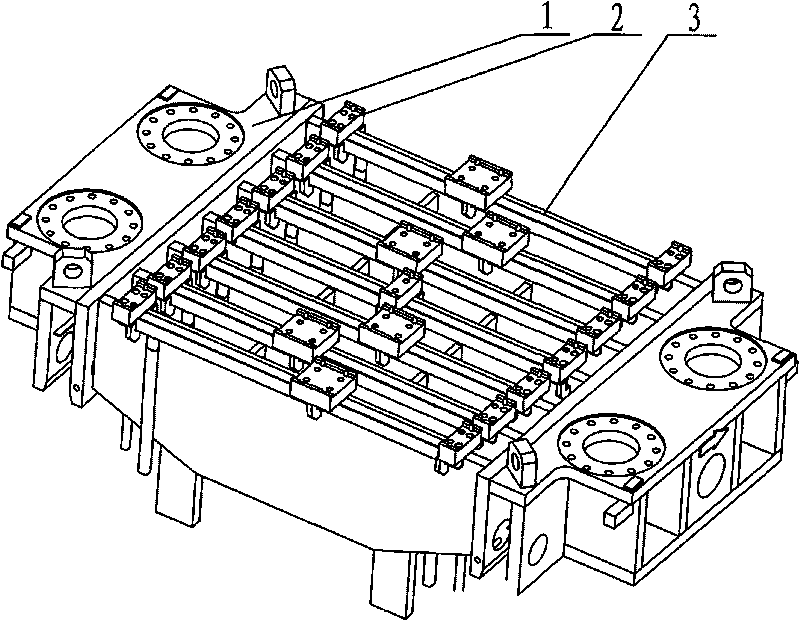

[0023] A method for assembling and welding a curved segment frame, comprising the following steps:

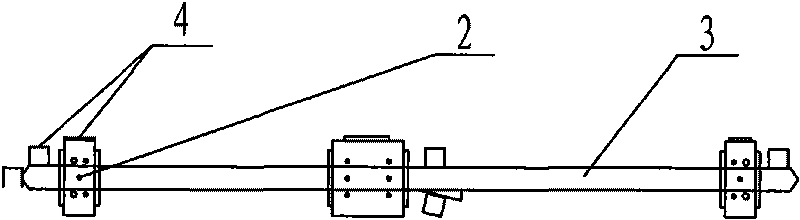

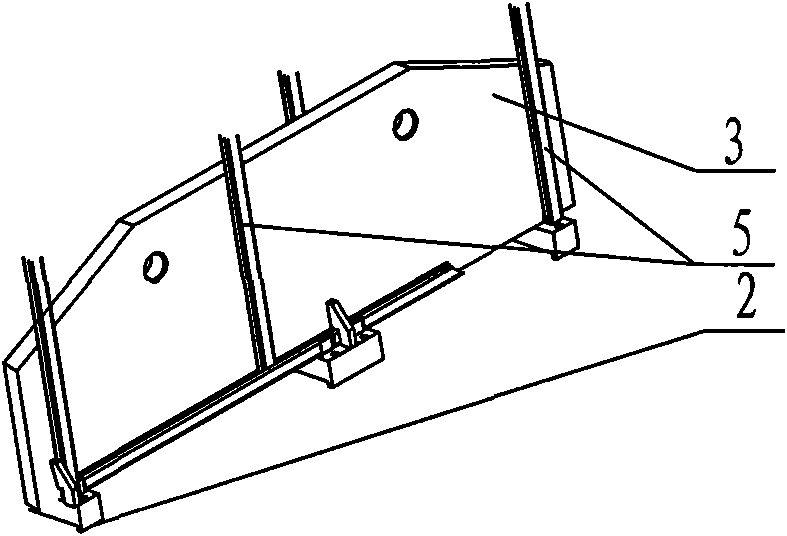

[0024] 1) if figure 2 In the process, the ground sample line is first drawn on the steel platform, positioned by the positioning block 4, and the vertical plate 3, the bearing seat 2 and the pipe assembly 5 are welded to obtain the following image 3 In the vertical plate welding assembly, the positioning block 4 includes a reference block, which is used to determine the assembly datum of the workpiece;

[0025] 2) if Figure 4 In the process, two assembling process modules 6 are processed on a 15mm thick steel plate with a CNC cutting machine, and the tooling mating surface 7 is ground according to the process requirements, even if the spatial position and inclination angle of the tooling mating surface 7 are consistent with the six vertical plate welding components After rotating 180°, the spatial position and inclination angle of the bearing seat on it are consistent;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com