Smoke block pre-loose processing device and method

A technology for processing devices and cigarette blocks, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of small available space, large steam consumption, and large changes, and achieve reduced processing intensity and energy consumption, simple structure, and reduced volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

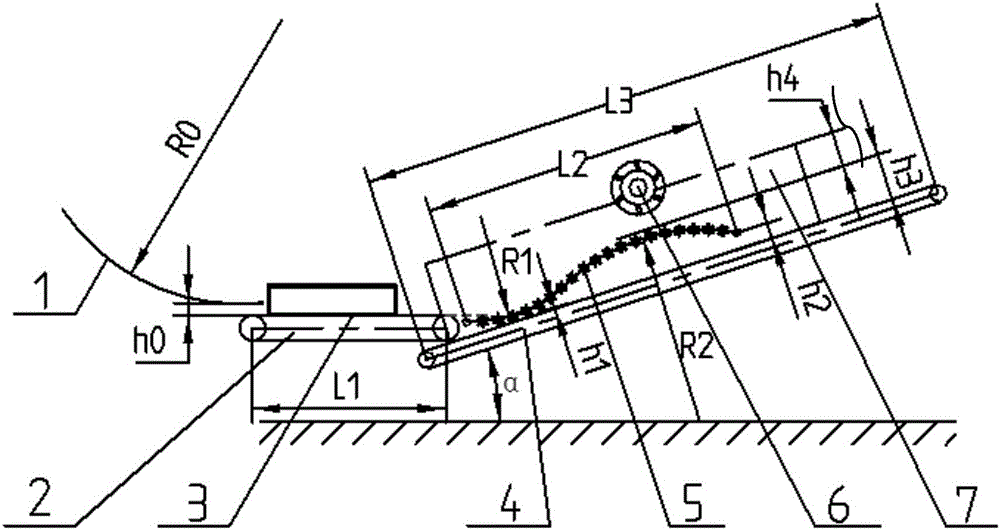

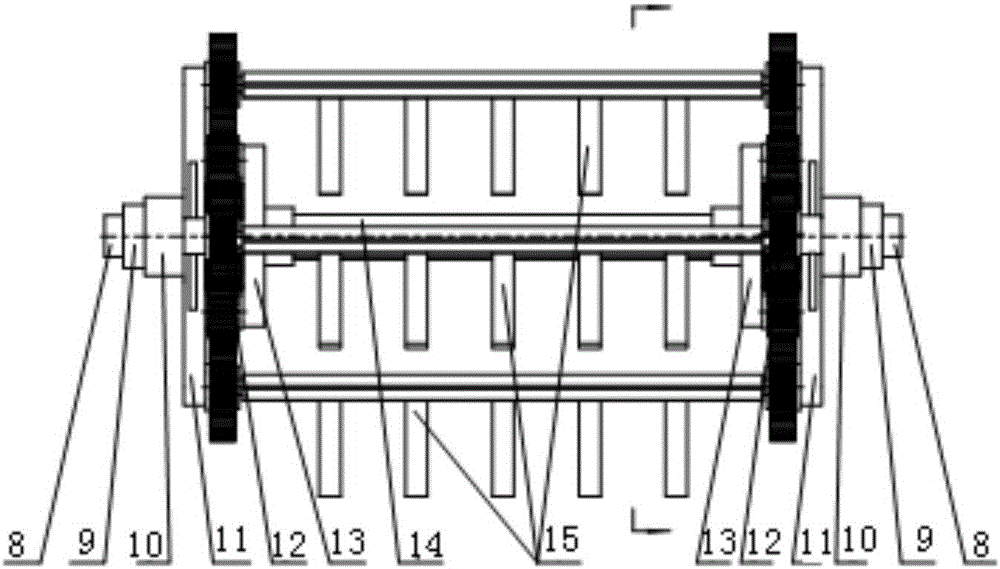

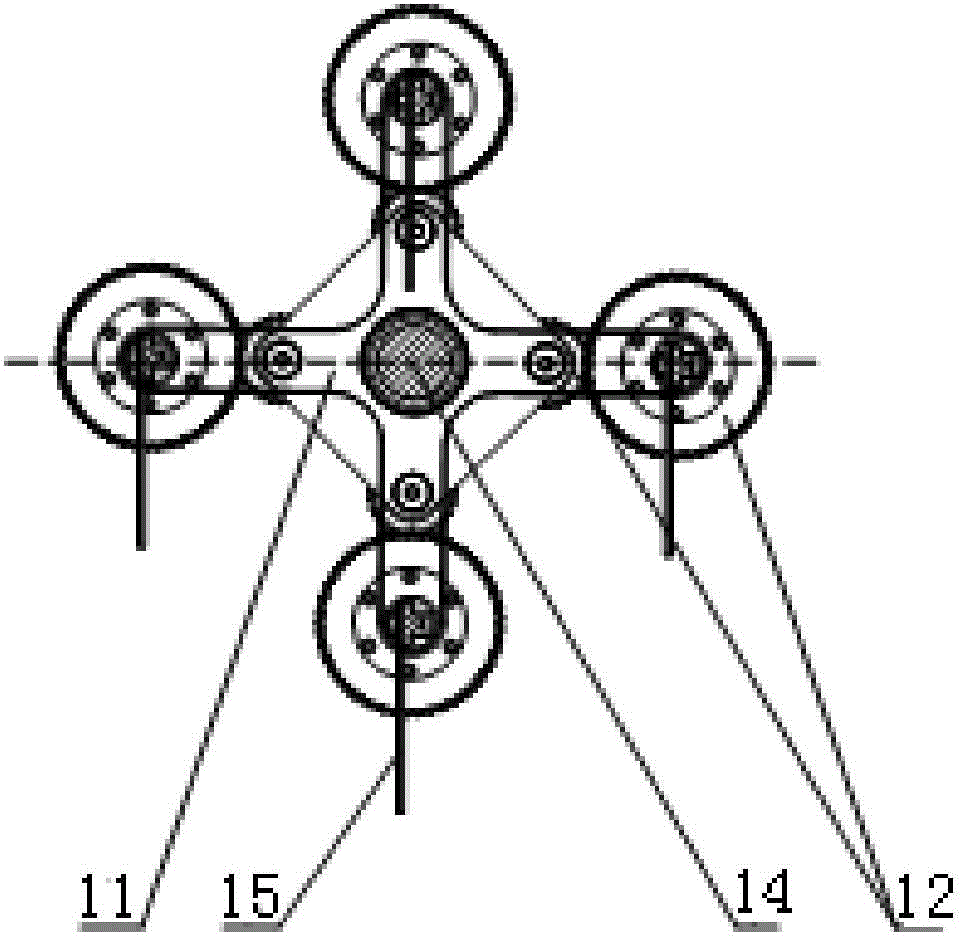

[0040] A kind of cigarette block pre-loose treatment device, such as figure 1 shown, including:

[0041] The arc-shaped roller conveying mechanism 5 is set above the belt conveyor. Each roller in the roller conveying mechanism 5 is connected with the power mechanism. By adjusting the speed of the rollers step by step, the linear speed of the latter roller is greater than that of the previous roller. The linear speed of the stage rollers, and / or increasing the elongation length of the nails on the adjacent rollers step by step, realizes the tearing of the cigarette block 3 on the roller table conveying mechanism 5.

[0042] The above-mentioned cigarette block pre-loosening treatment device, by setting the arc-shaped roller table conveying mechanism 5, can realize the stretching and compression of the upper and lower sides of the cigarette block through the arc-shaped curve formed by the roller table, and the adjacent rollers have different heights. , it is beneficial to genera...

Embodiment 2

[0057] A method for pre-loosening the cigarette block. The uniform thickness of the cigarette block formed after the slicing process is passed through at least two reverse arc-shaped roller conveying mechanisms, and a roller mechanism is arranged above the arc-shaped roller conveying mechanism to adjust the cigarette block. Interpolation is carried out so that the cigarette block can be effectively cracked before entering the moisture regaining process.

[0058] In addition, the rake nails are set on the rollers of the roller conveyor mechanism, and by adjusting the rotation speed of the rollers step by step, the linear speed of the latter stage of rollers is greater than that of the previous stage of rollers, and / or the rake nails on the rollers are gradually increased Extend the length to realize the tearing of the cigarette block on the roller conveying mechanism.

[0059] The roller mechanism is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com