Multifunctional sludge, sewage and dirt treatment machine of septic tank

A septic tank and multi-functional technology, applied in the direction of water/sludge/sewage treatment, sludge treatment, water/sewage multi-stage treatment, etc., can solve the problem of organic fertilizer and water loss, reduce equipment life, and increase equipment failure rate and other problems, to achieve clear water filtration, reduce equipment investment, and improve self-priming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

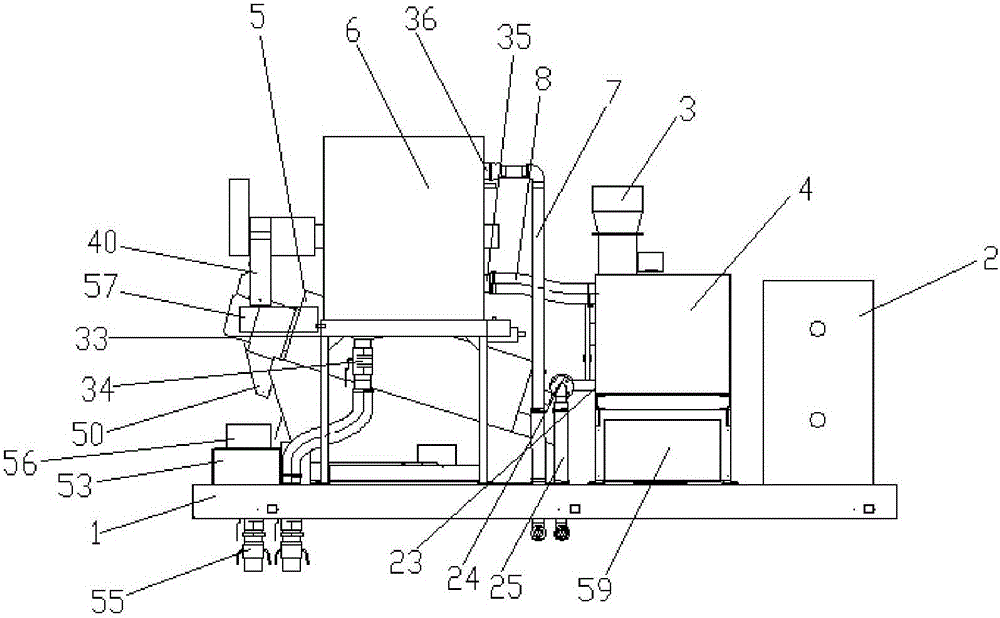

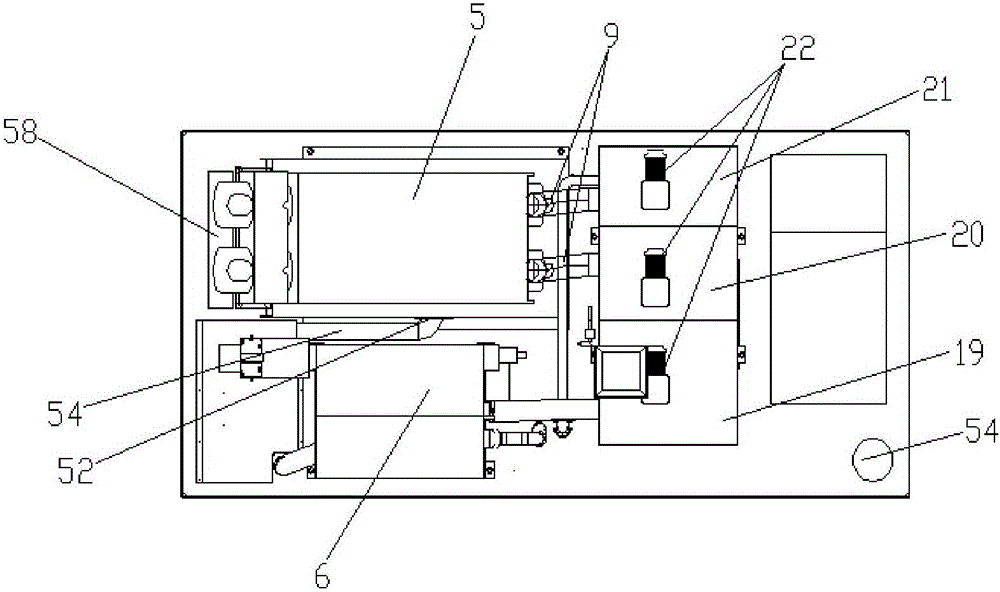

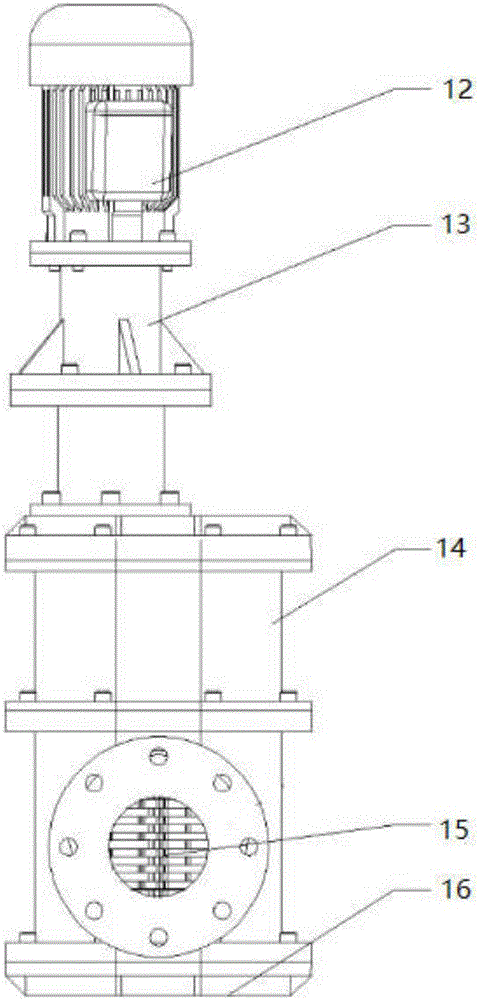

[0019] As shown in the figure: a multifunctional septic tank sludge, sewage, and sewage treatment machine includes a suction system, a dosing system group, a solid-liquid separation system, a base I1, several connecting pipes, and several valves; the suction system It includes a movable self-priming pump combination 2 and a steel coil hose I; the dosing system group is composed of a dry powder dosing machine 3 and a three-compartment reaction tank 4; the solid-liquid separation system includes a stacked screw extrusion dehydrator 5, a rough Filter extruder 6; the movable self-priming pump assembly 2 is installed on the base, and connected to the coarse filter extruder 6 by using steel ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com