Overflow no-damage multiphase mixed transmission pump

A mixed and flow-through technology, which is applied to radial flow pumps, pumps, components of pumping devices for elastic fluids, etc., can solve problems affecting the stable operation of the system, high vibration and noise during operation, and human health hazards. Achieve the effect of improving self-priming performance, good anti-cavitation performance and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

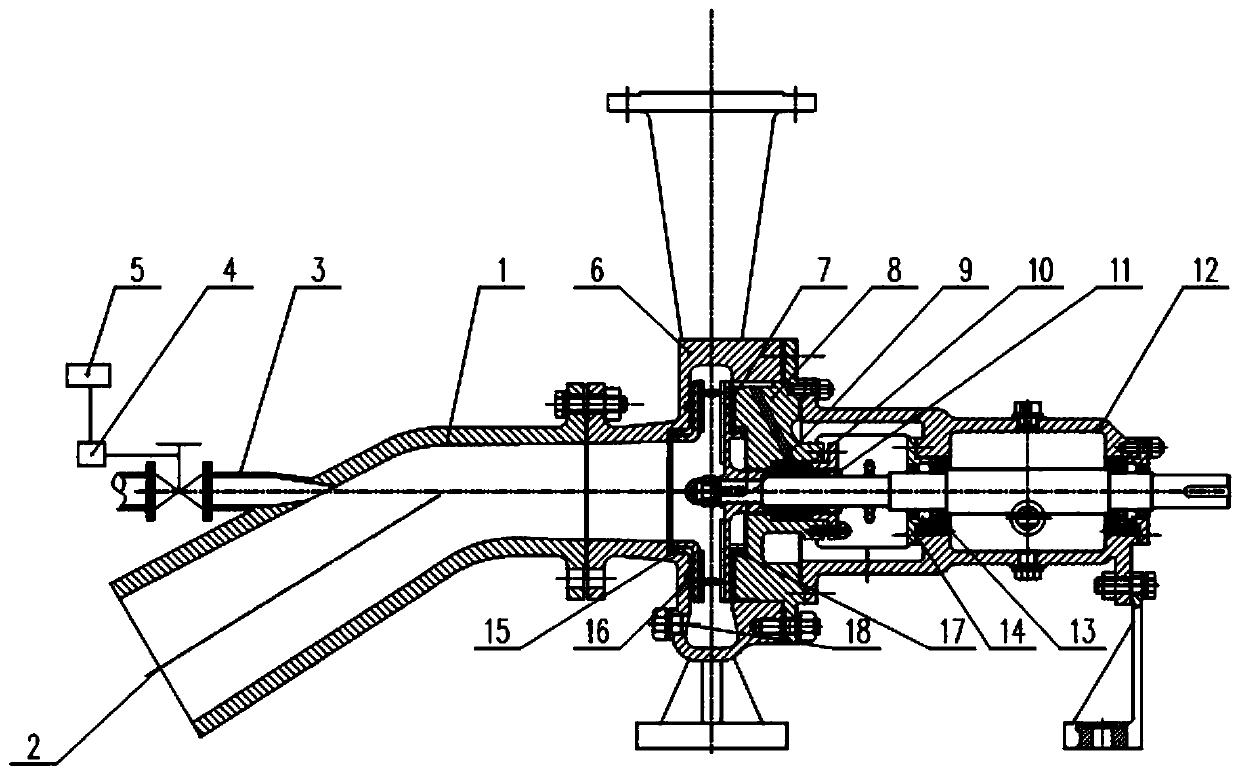

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

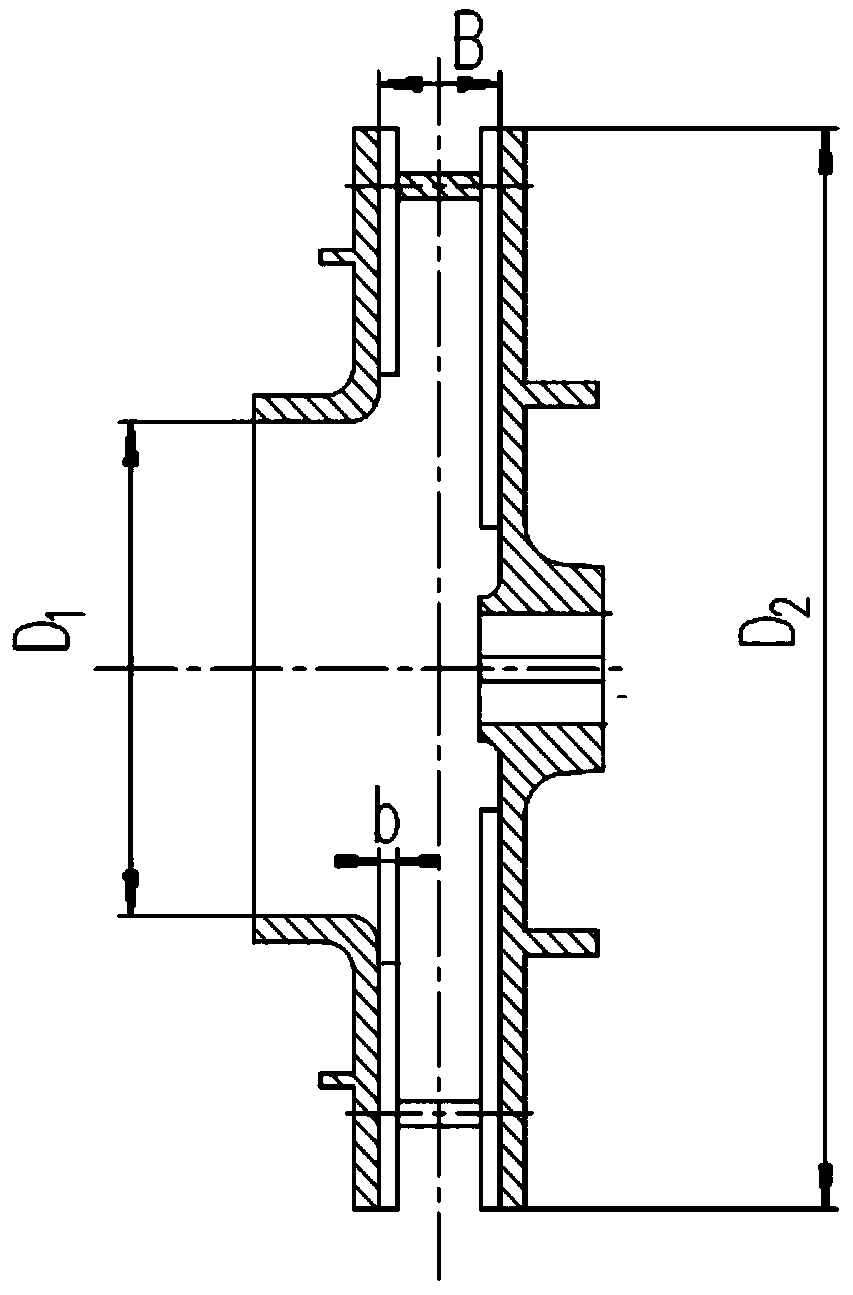

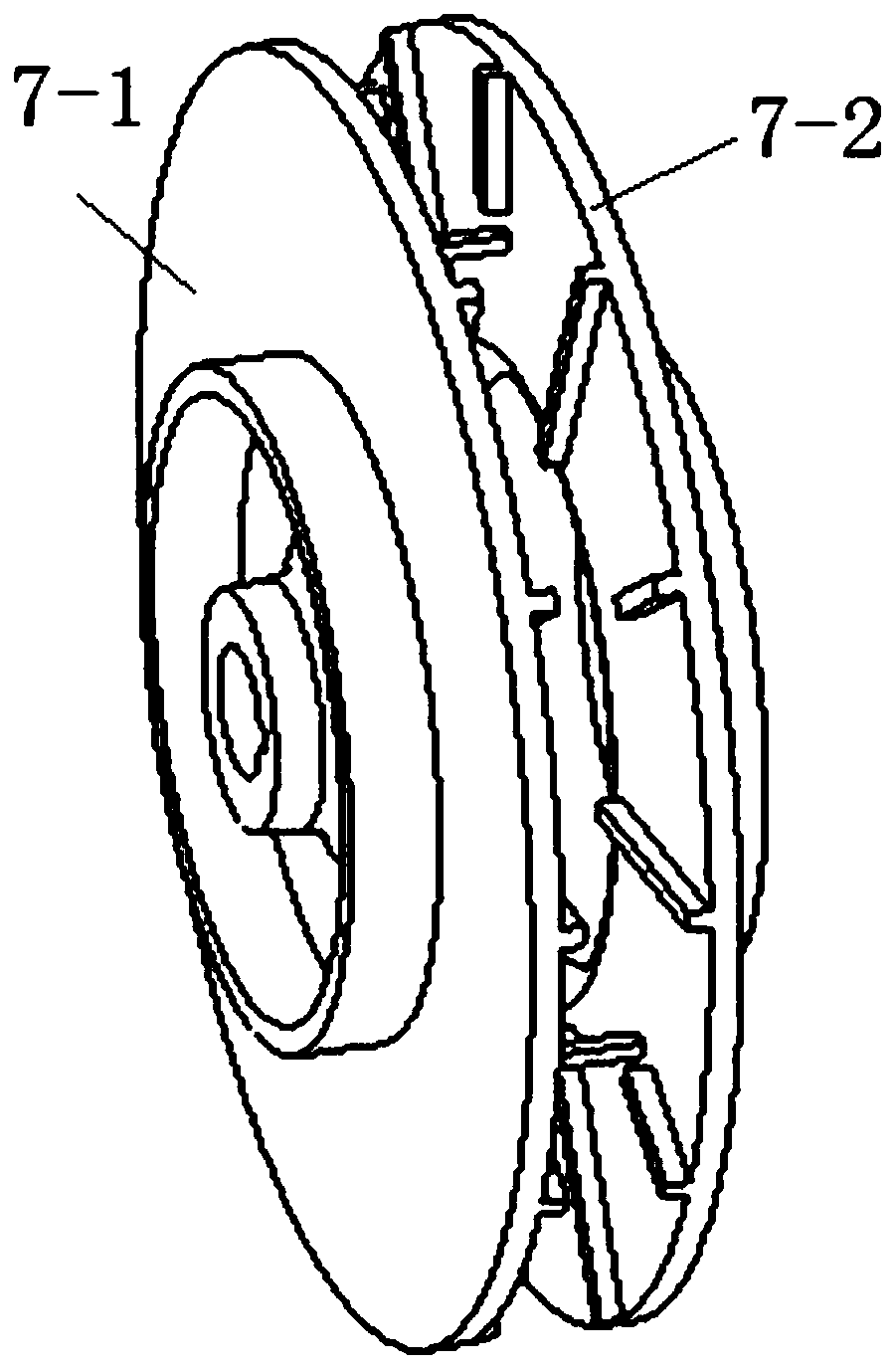

[0023] combine figure 1 and figure 2 , a flow-through lossless multi-phase mixed pump, comprising: suction pipe 1, interception net 2, conical shrinking nozzle 3, gas mass flow controller 4, controller 5, pump body 6, impeller 7, pump cover 8 , pump shaft 9, mechanical seal 10, sleeve 11, suspension 12, bearing 13, end cover 14, first front port ring 15, second front port ring 16 rear port ring 17, bottom valve 18, inlet of suction pipe 1 An interception net 2 is installed, and a conical constricting nozzle 3 is installed at the elbow of the suction pipe 1. The conical constricting nozzle 3 is connected to the gas mass flow controller 4. The conical constricting nozzle 3 communicates with high-pressure gas, and the gas mass flow rate The controller 4 is connected to the controller 5. The pump body 6 is provided with an impeller 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com