A method for improving the performance of a high-speed heavy-duty plunger pump and a new tapered cylinder device

A plunger pump and cylinder technology, applied in the field of methods and new tapered cylinder devices, can solve the problems of increasing the overall size and increasing the pump weight, and achieve the goal of reducing the line speed, reducing the weight of the cylinder, and reducing the diameter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

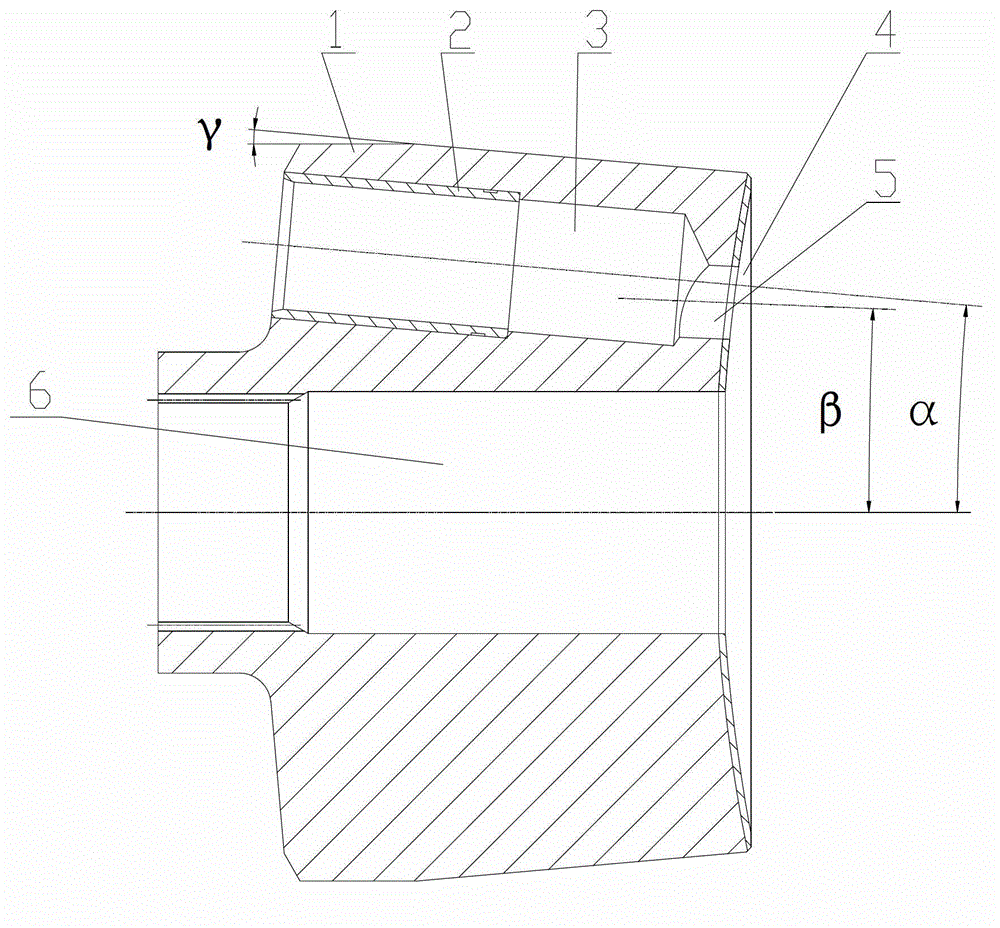

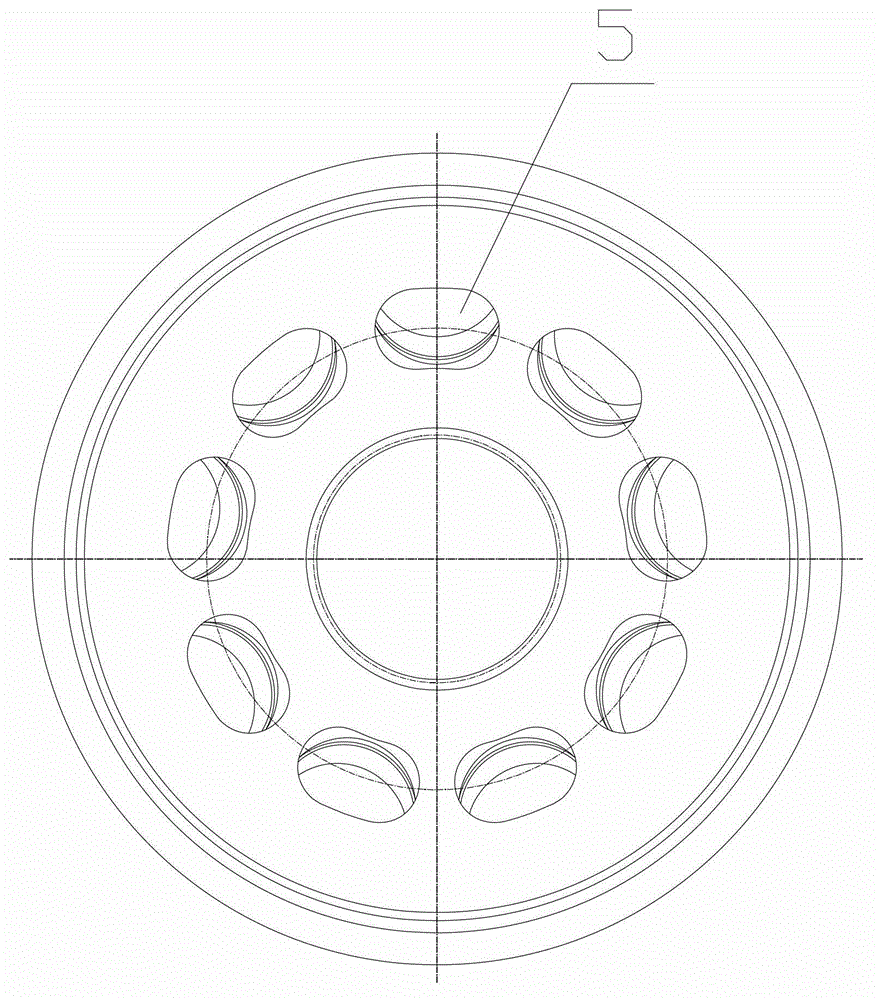

[0024] Example. A method for improving the performance of a high-speed heavy-duty plunger pump, which is characterized in that: the axis of the main shaft of the cylinder and the axis of the plunger are set at an angle α, and the centerline of the oil suction and discharge holes on the cylinder is interposed with the axis of the main shaft. The angle β is set to increase the working speed and displacement of the plunger pump; the range of the included angle α is controlled at 3-8°, and the range of the included angle β is controlled at 2-5°; and the included angle β is smaller than the included angle α; The outer wall of the cylinder is tapered to reduce the diameter of the oil distribution plate, reduce the linear velocity of the movement of the distribution surface of the cylinder, make the ρν val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com