Patents

Literature

165results about How to "Reduce line speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

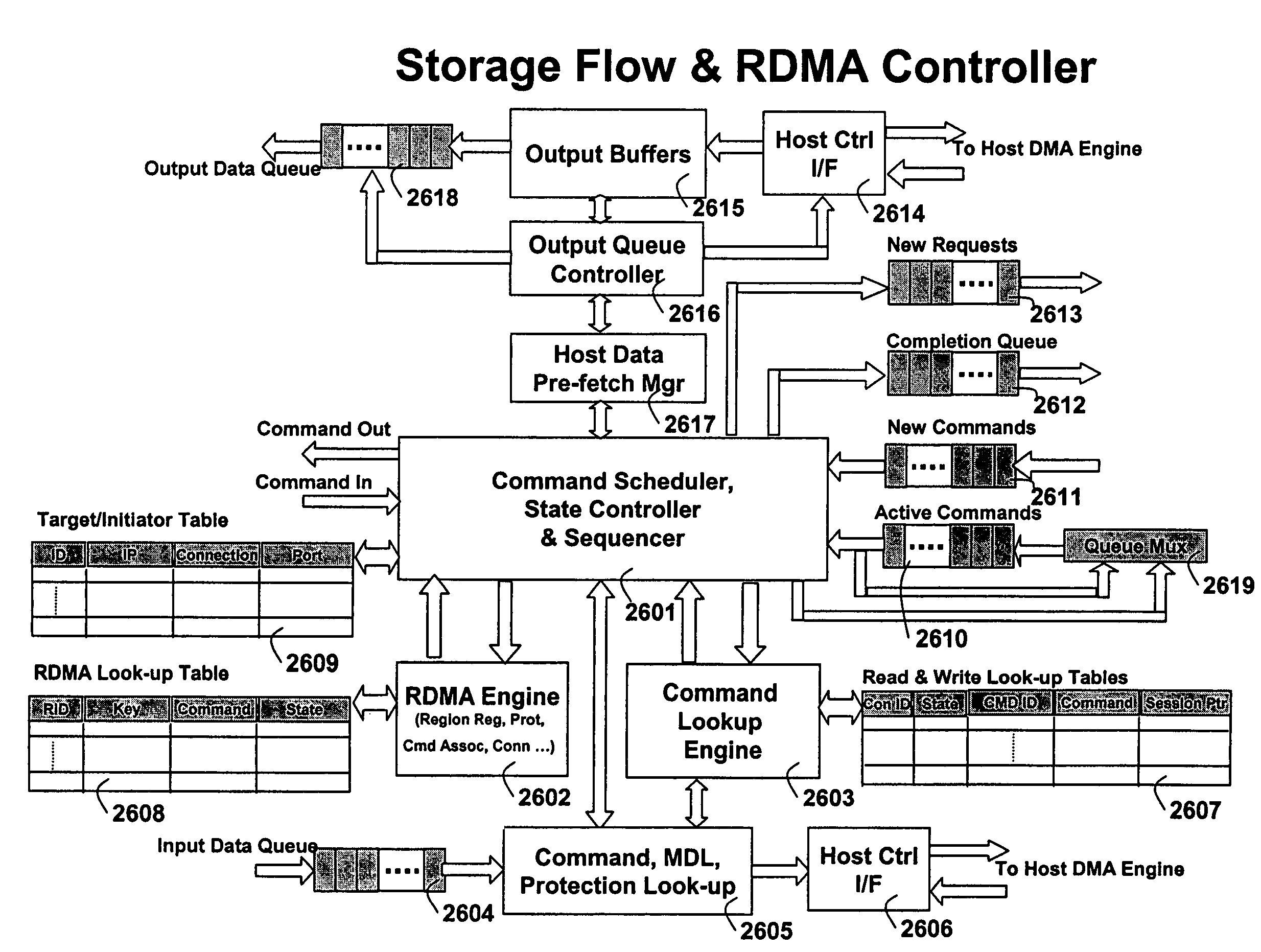

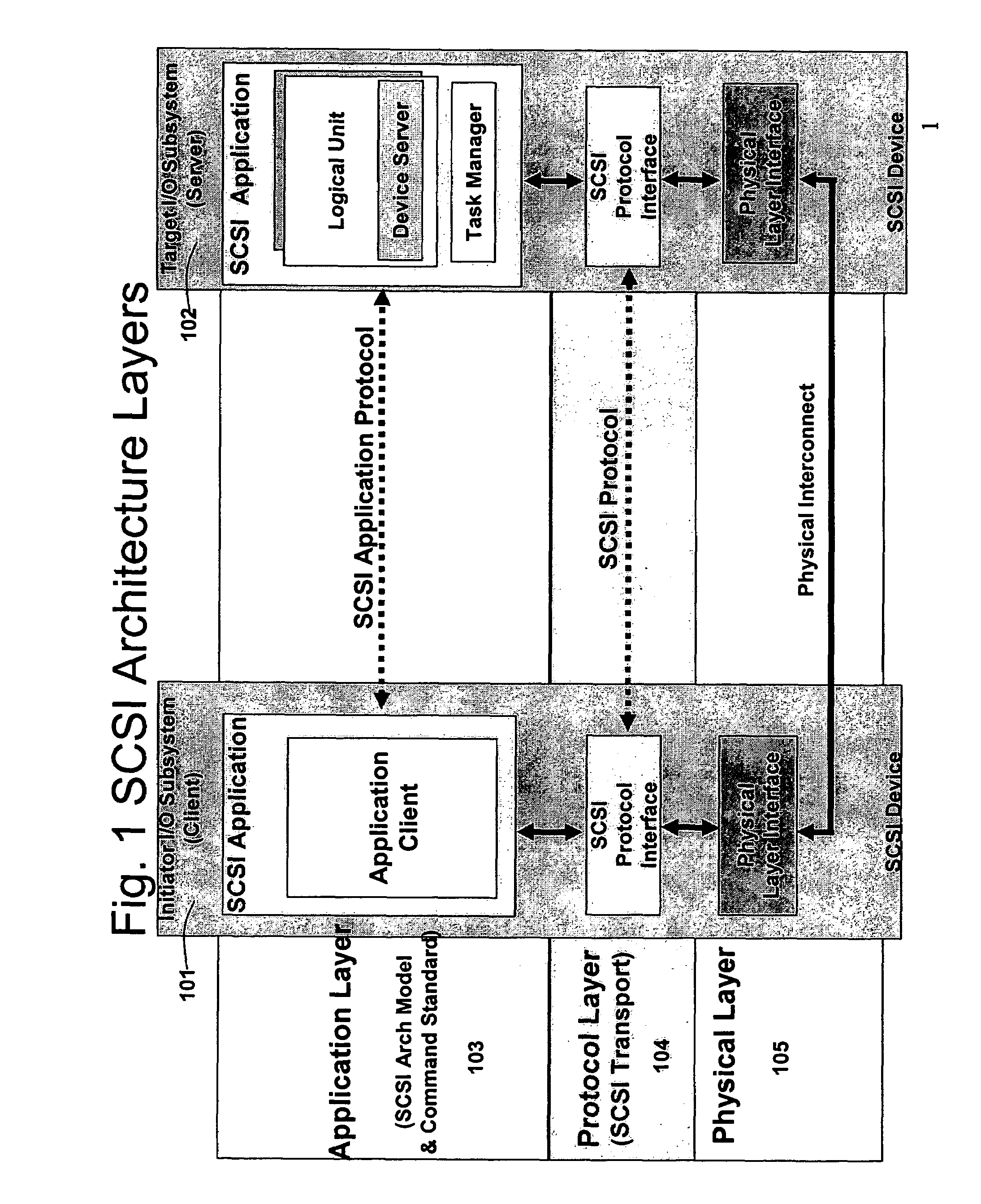

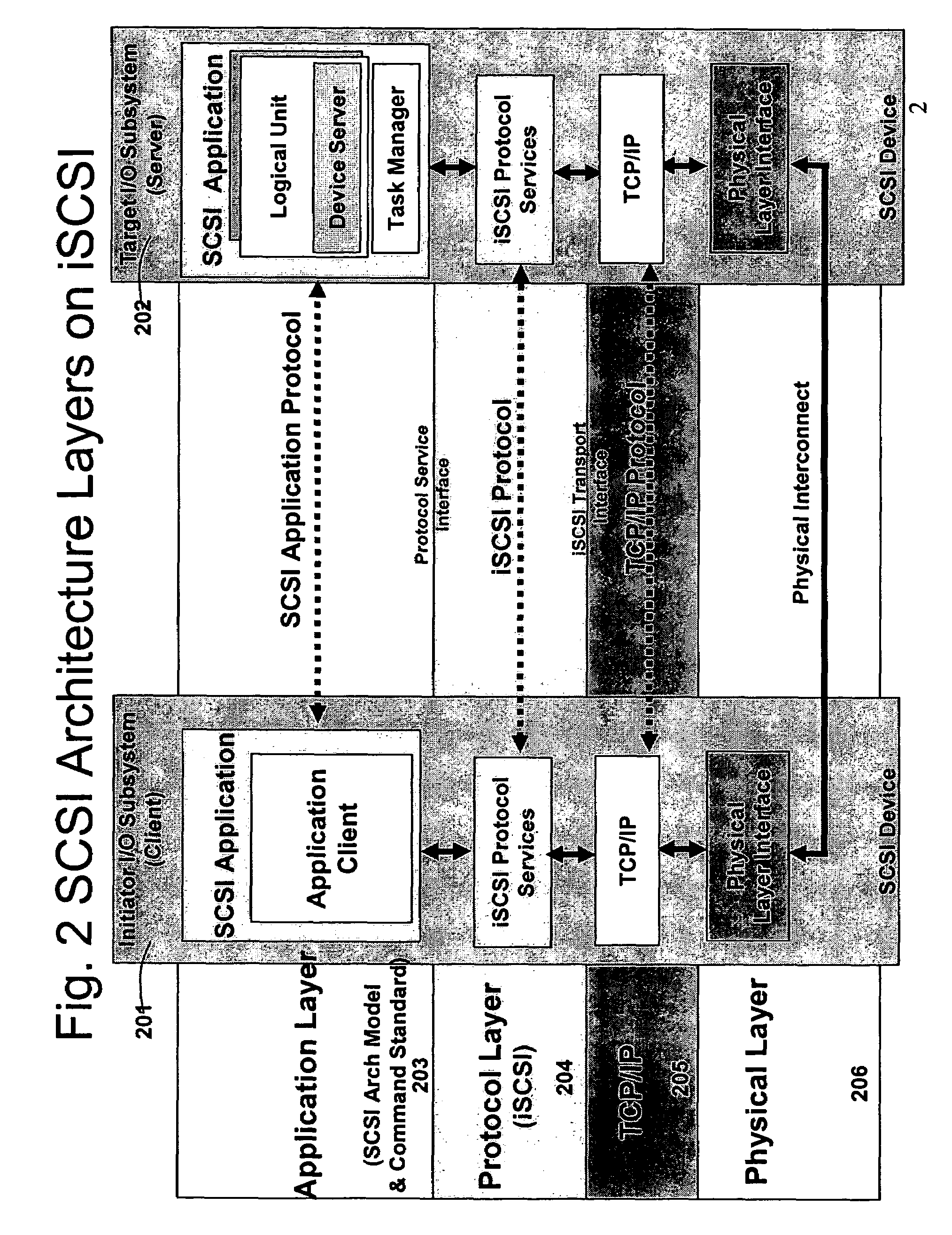

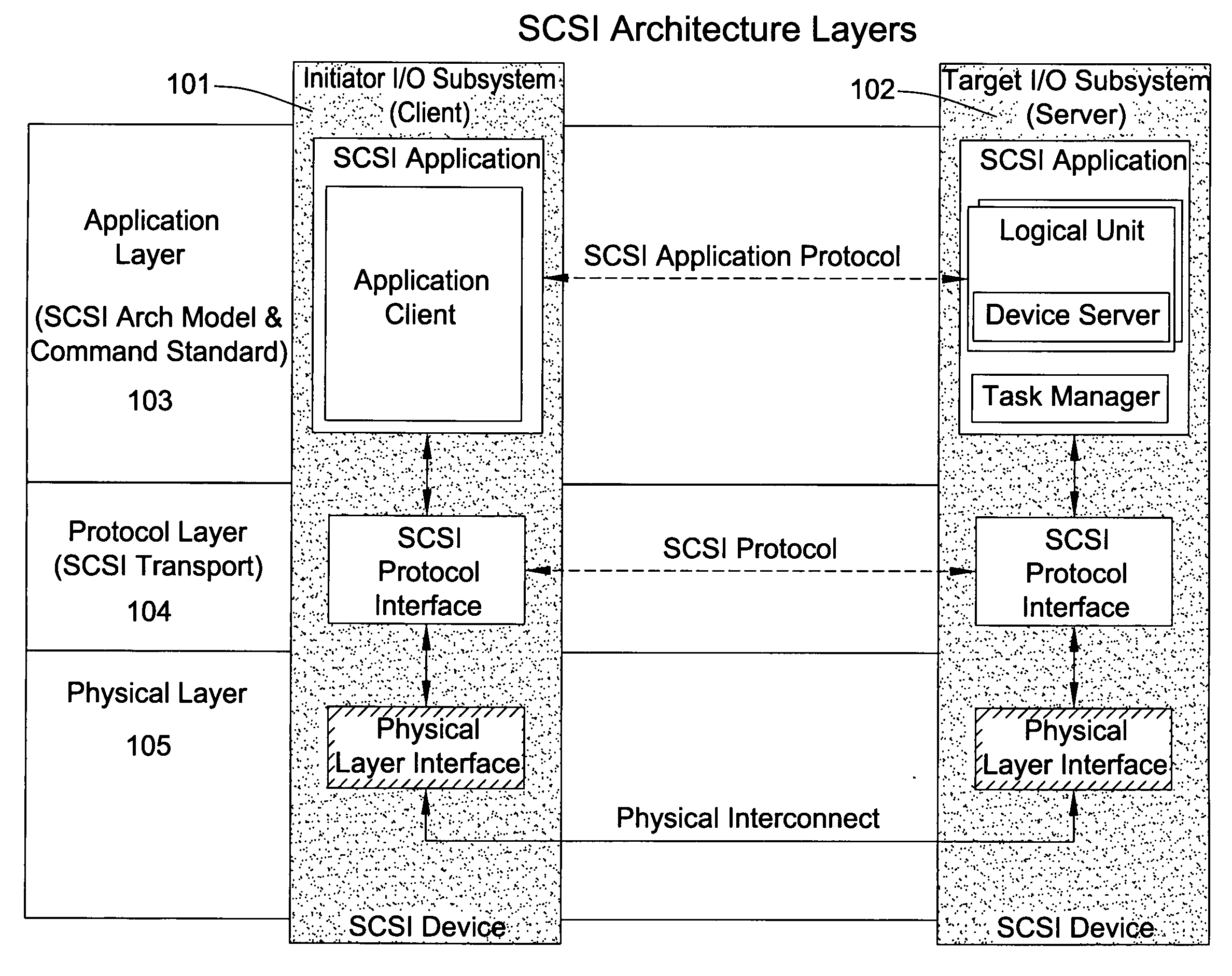

TCP/IP processor and engine using RDMA

ActiveUS7376755B2Sharply reduces TCP/IP protocol stack overheadImprove performanceMultiplex system selection arrangementsMemory adressing/allocation/relocationTransmission protocolInternal memory

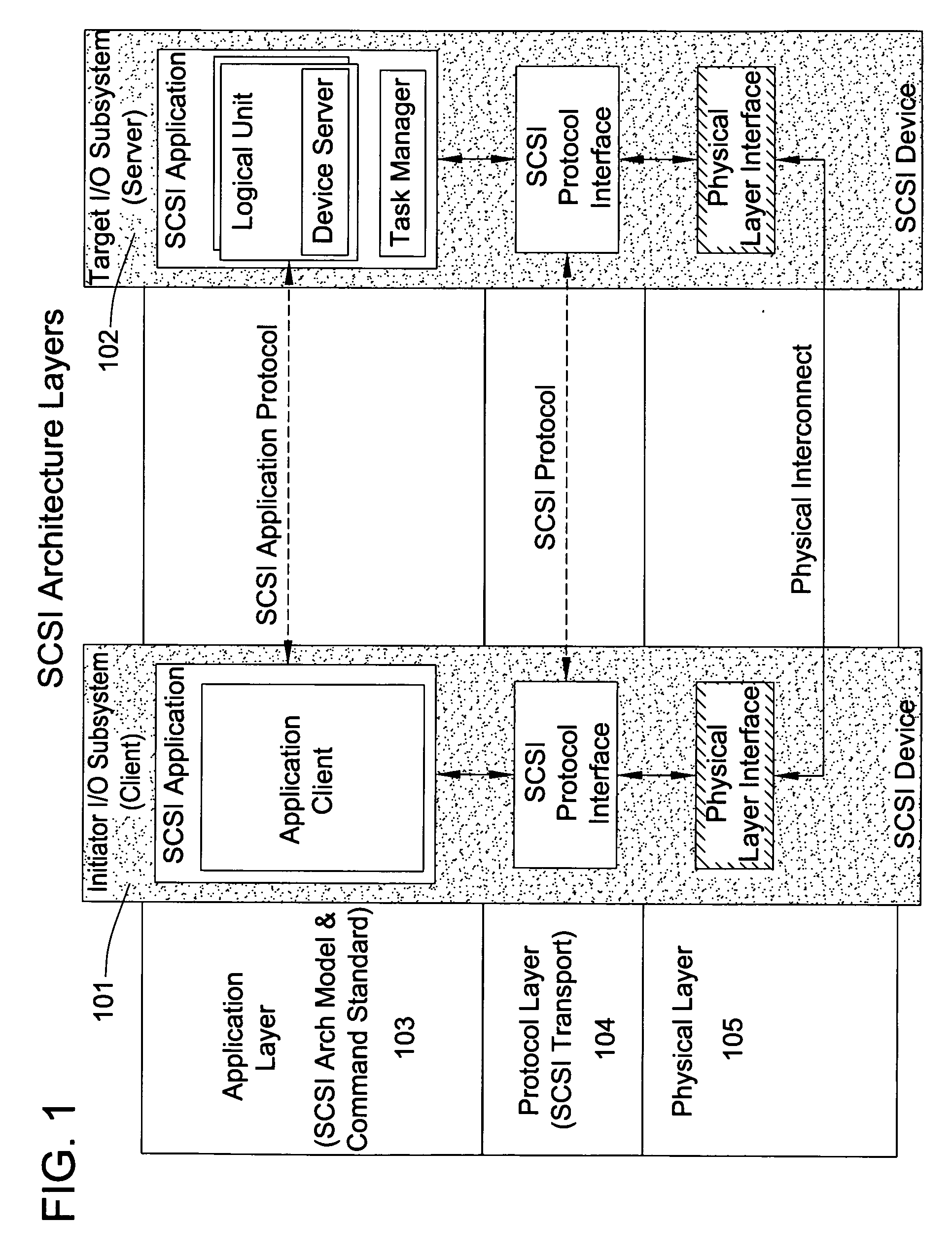

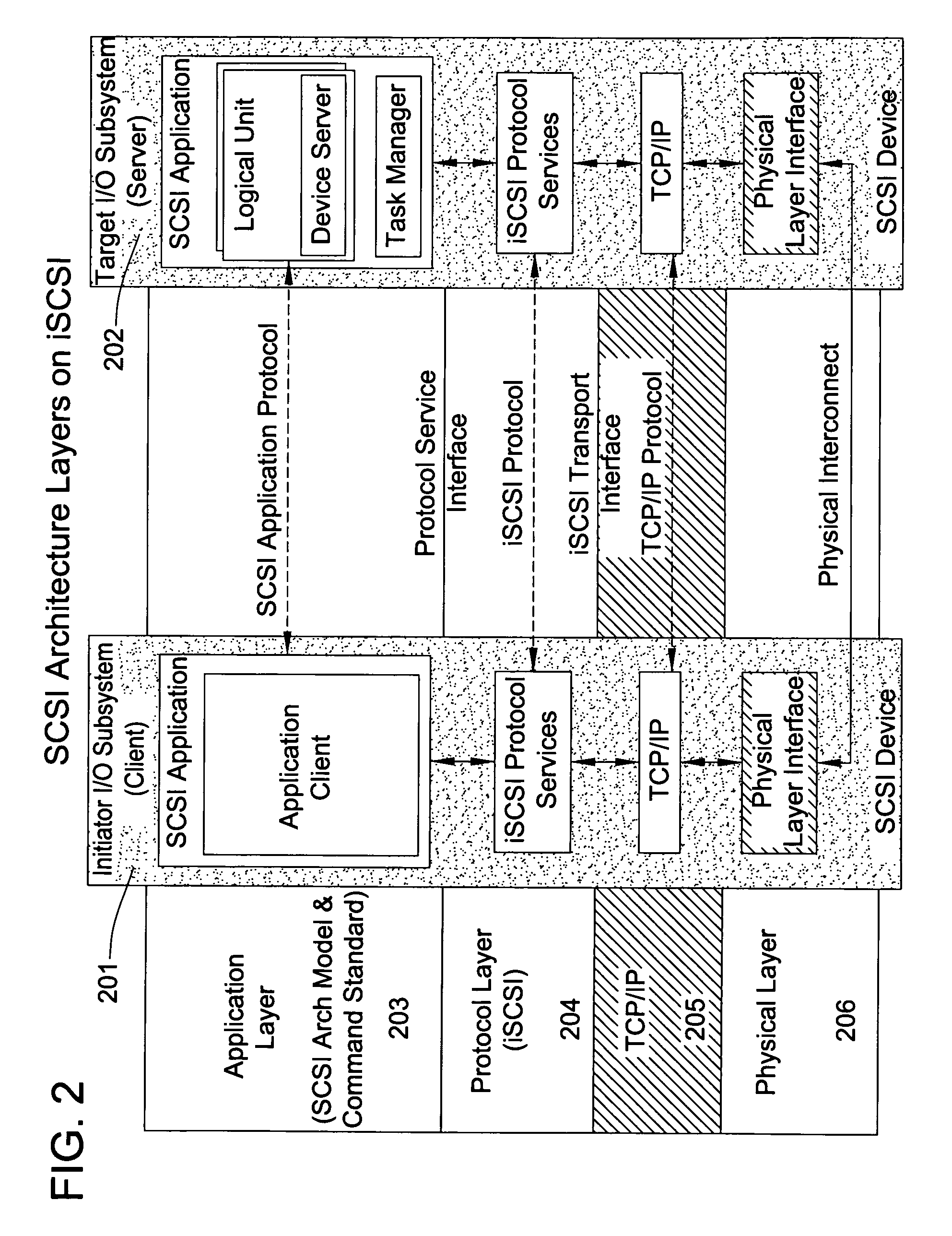

A TCP / IP processor and data processing engines for use in the TCP / IP processor is disclosed. The TCP / IP processor can transport data payloads of Internet Protocol (IP) data packets using an architecture that provides capabilities to transport and process Internet Protocol (IP) packets from Layer 2 through transport protocol layer and may also provide packet inspection through Layer 7. The engines may perform pass-through packet classification, policy processing and / or security processing enabling packet streaming through the architecture at nearly the full line rate. A scheduler schedules packets to packet processors for processing. An internal memory or local session database cache stores a TCP / IP session information database and may also store a storage information session database for a certain number of active sessions. The session information that is not in the internal memory is stored and retrieved to / from an additional memory. An application running on an initiator or target can in certain instantiations register a region of memory, which is made available to its peer(s) for access directly without substantial host intervention through RDMA data transfer.

Owner:MEMORY ACCESS TECH LLC

Tcp/ip processor and engine using rdma

InactiveUS20080253395A1Sharply reduces TCP/IP protocol stack overheadImprove performanceDigital computer detailsTime-division multiplexInternal memoryTransmission protocol

A TCP / IP processor and data processing engines for use in the TCP / IP processor is disclosed. The TCP / IP processor can transport data payloads of Internet Protocol (IP) data packets using an architecture that provides capabilities to transport and process Internet Protocol (IP) packets from Layer 2 through transport protocol layer and may also provide packet inspection through Layer 7. The engines may perform pass-through packet classification, policy processing and / or security processing enabling packet streaming through the architecture at nearly the full line rate. A scheduler schedules packets to packet processors for processing. An internal memory or local session database cache stores a TCP / IP session information database and may also store a storage information session database for a certain number of active sessions. The session information that is not in the internal memory is stored and retrieved to / from an additional memory. An application running on an initiator or target can in certain instantiations register a region of memory, which is made available to its peer(s) for access directly without substantial host intervention through RDMA data transfer.

Owner:MEMORY ACCESS TECH LLC

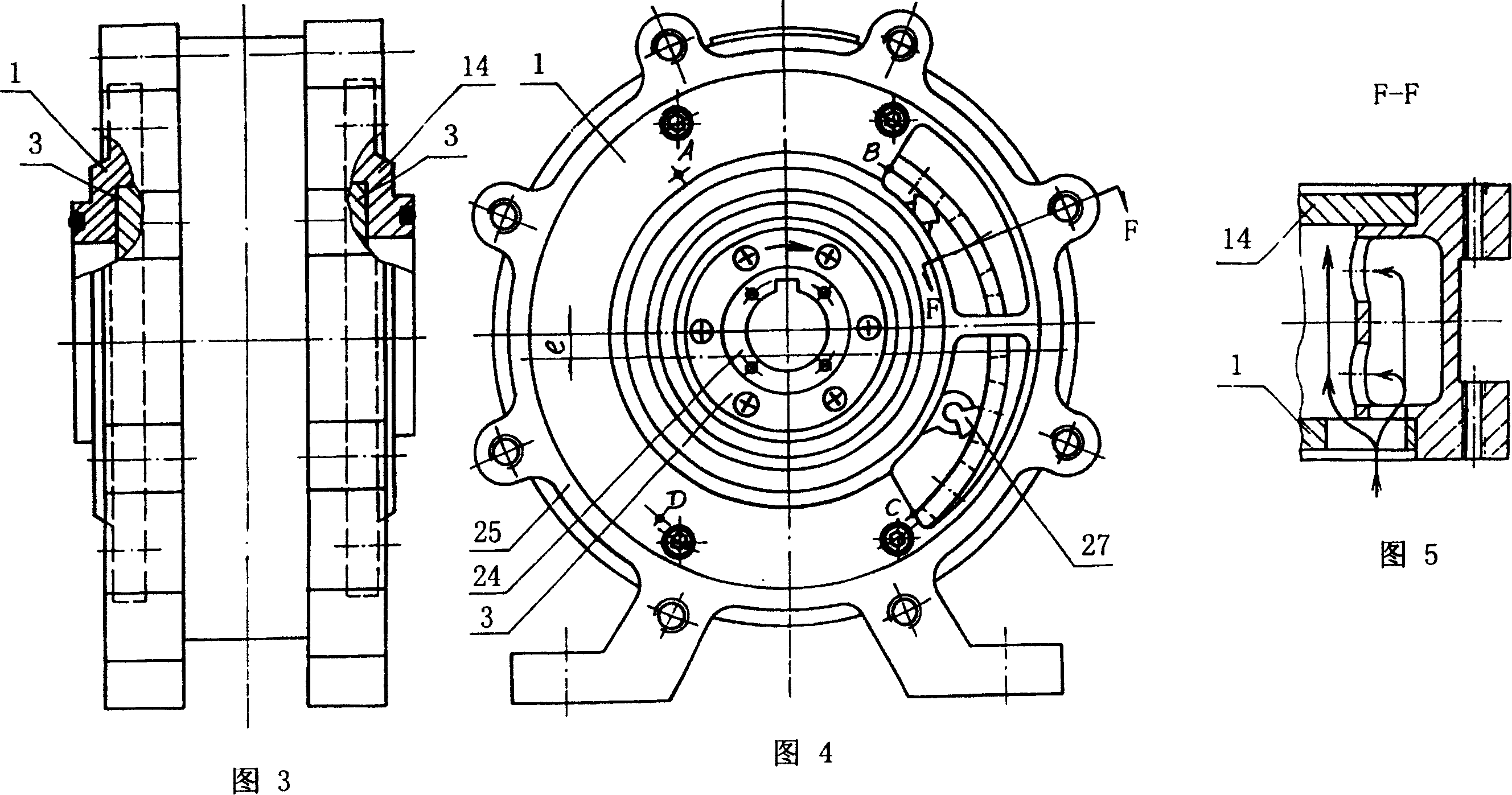

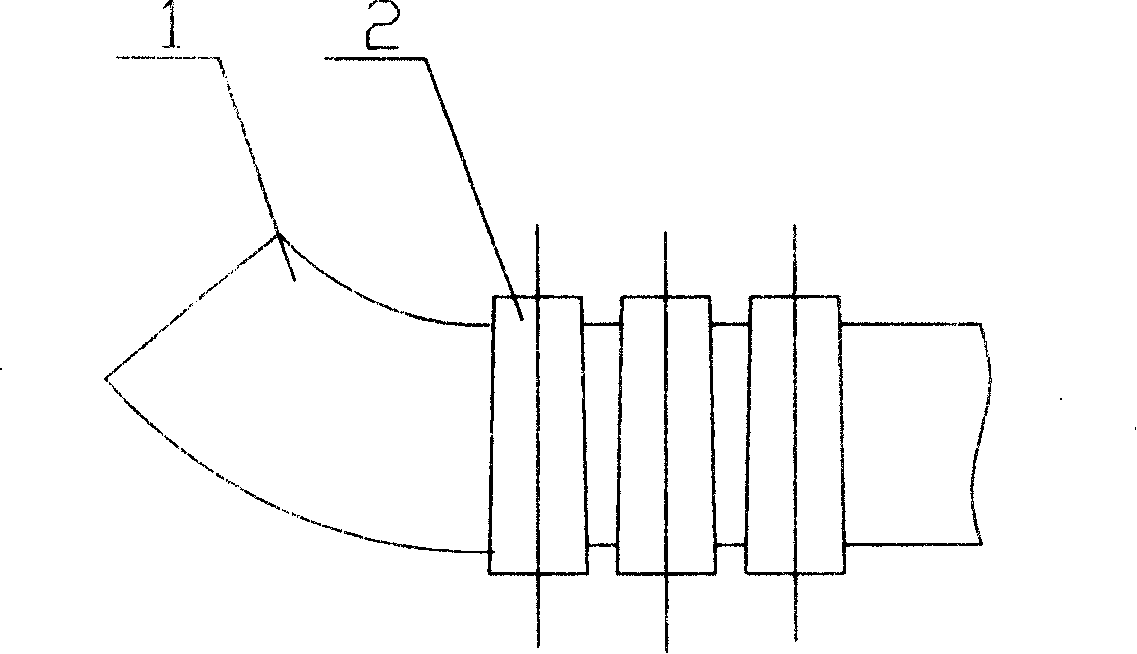

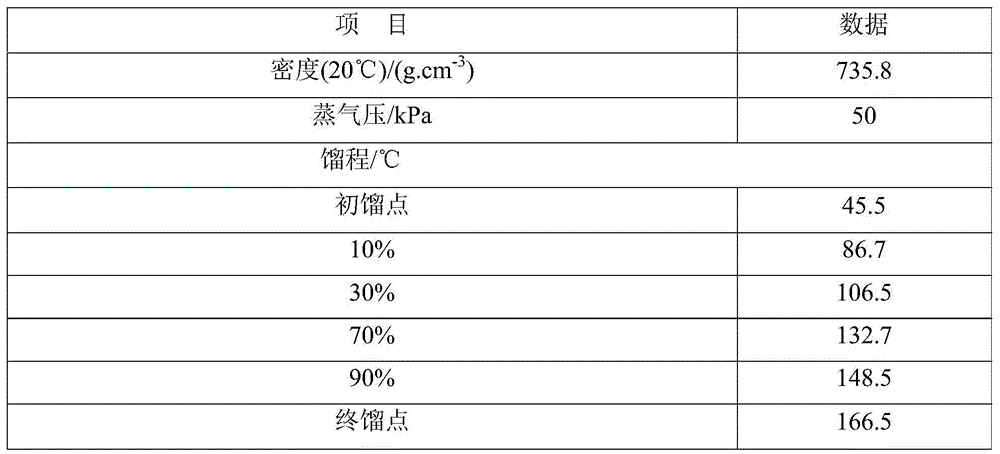

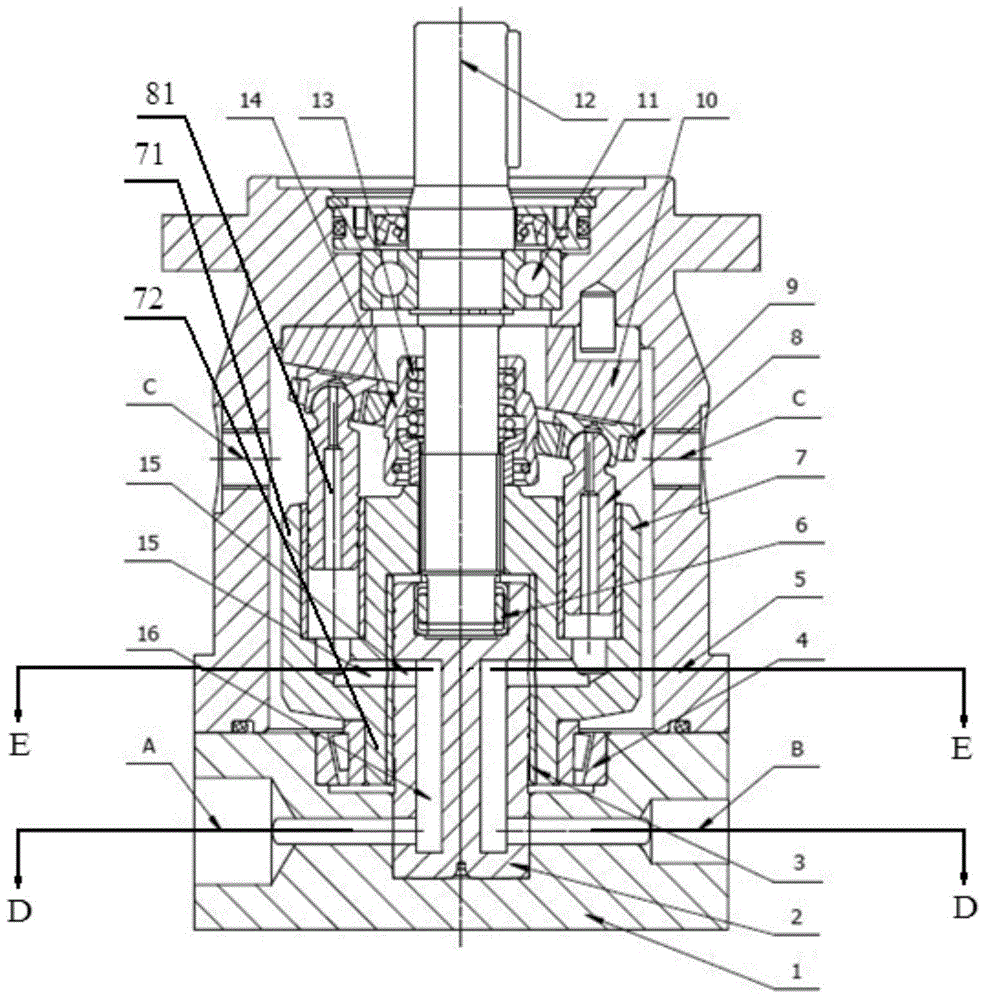

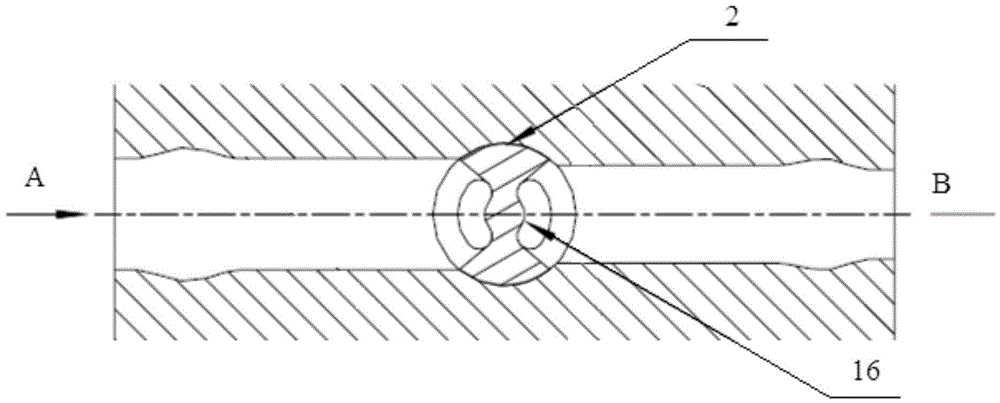

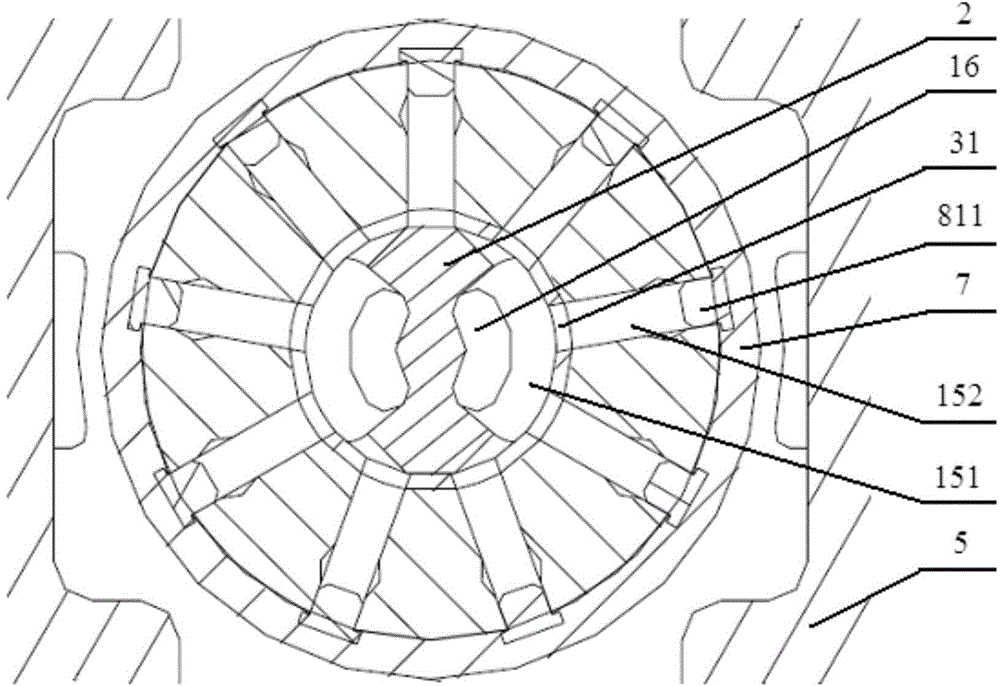

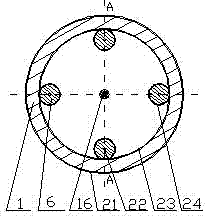

Rotary blade pump

InactiveCN100374725CReduce line speedEliminate cavitationRotary piston pumpsRotary piston liquid enginesClassical mechanicsEngineering

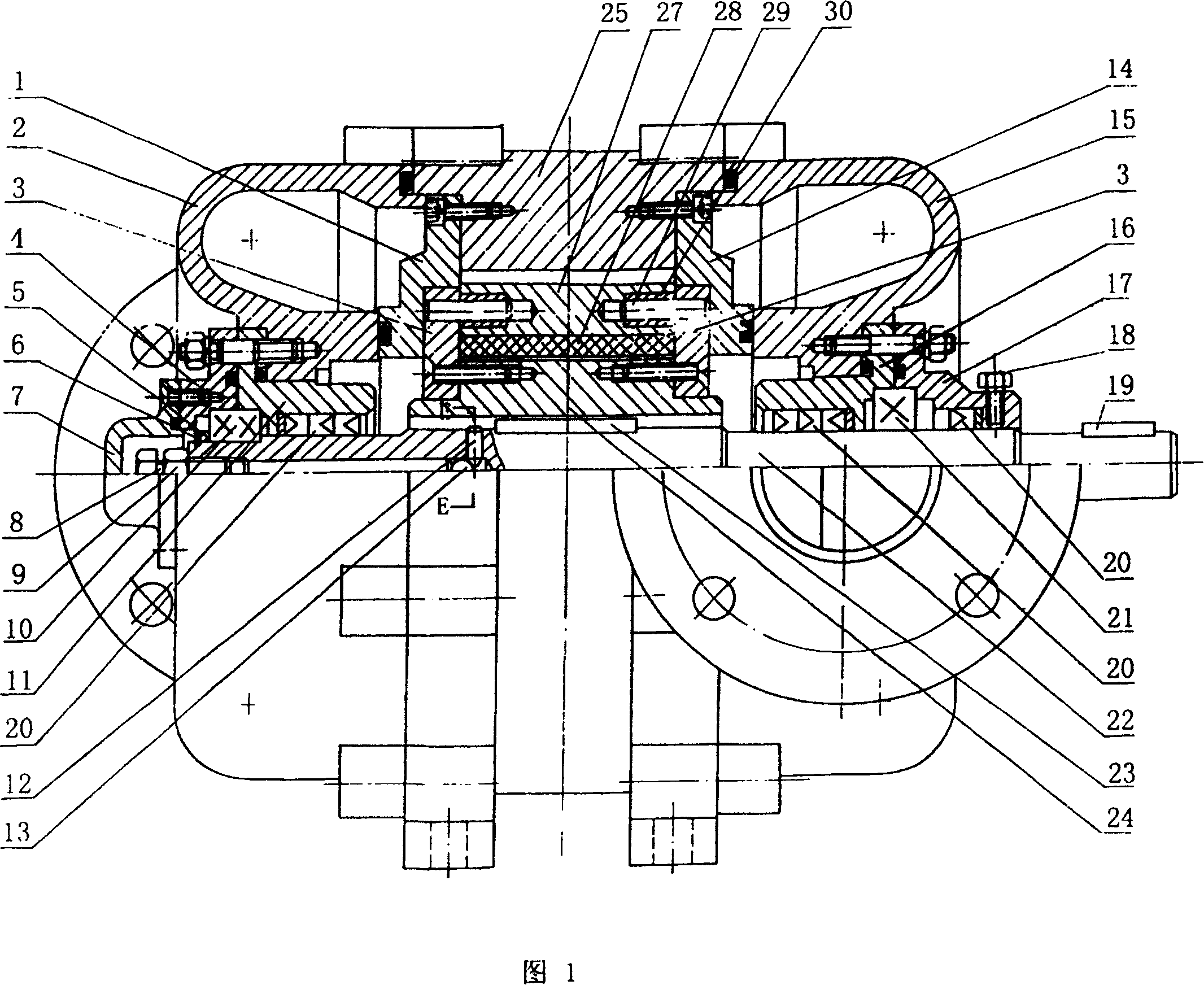

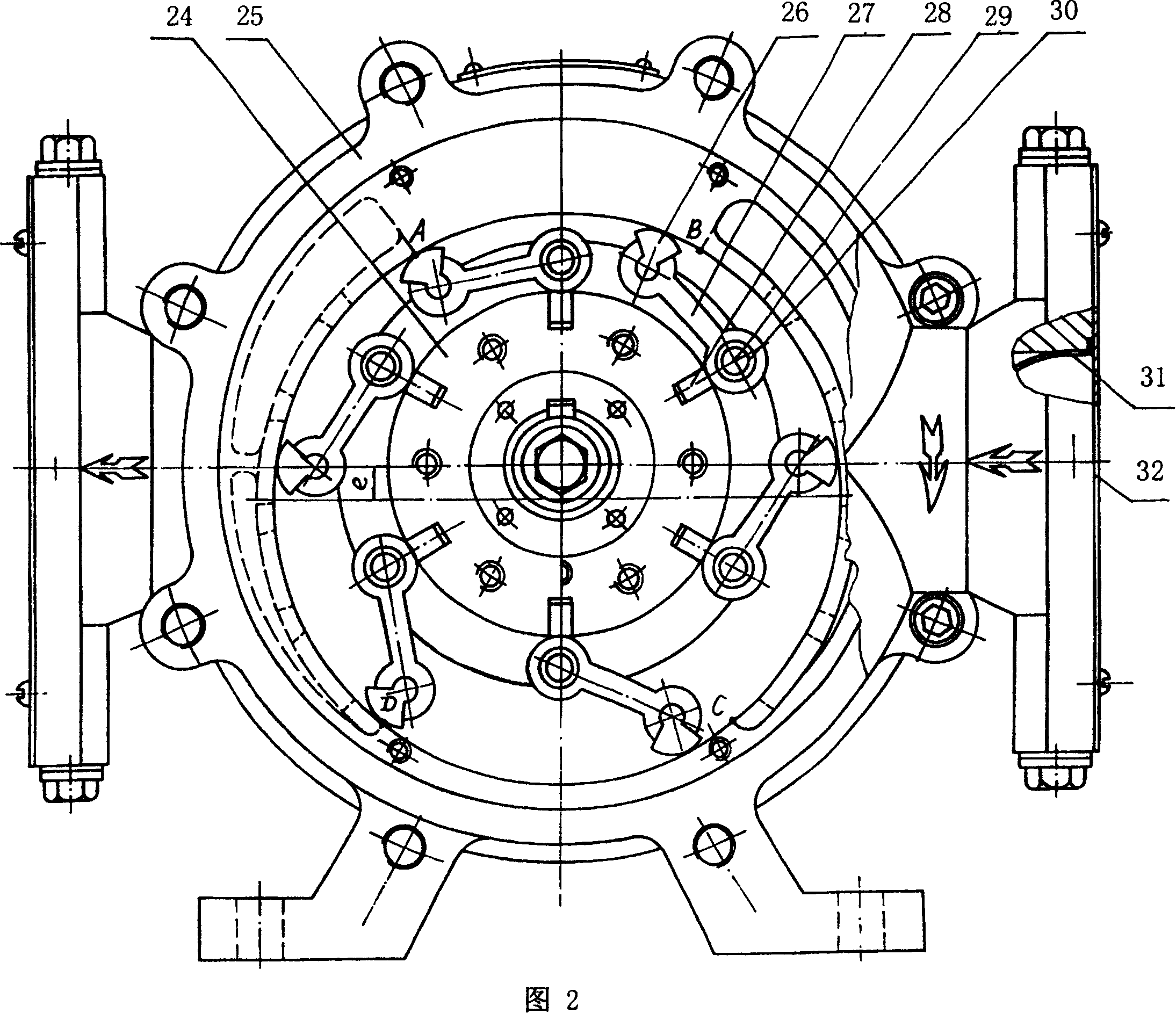

In the invention, an inlet-outlet oil flow plate is fixed at two ends of a pump case stator. A radial inlet-outlet runner is built-up on the pump case stator to realize axial and radial inlet and outlet oil at the same time. A rotor is mounted in the internal cavity of the pump case stator and there is an offsetting e between the rotor and the ID of the pump case stator. Rotary vanes are mounted on a rotating board fixed on the two end faces of the rotor. The rotor is mounted on the pump spindle via a rotor key. A rotor locking device is assembled on the front part of the pump spindle. The inlet-outlet oil pump covers are fixed at two ends of the pump stator separately. A ring inlet-outlet oil passageway is disposed in inlet-outlet oil pump. A bearing support and sealing device is assembled on the central of the inlet-outlet oil pump cover.

Owner:王振忠 +1

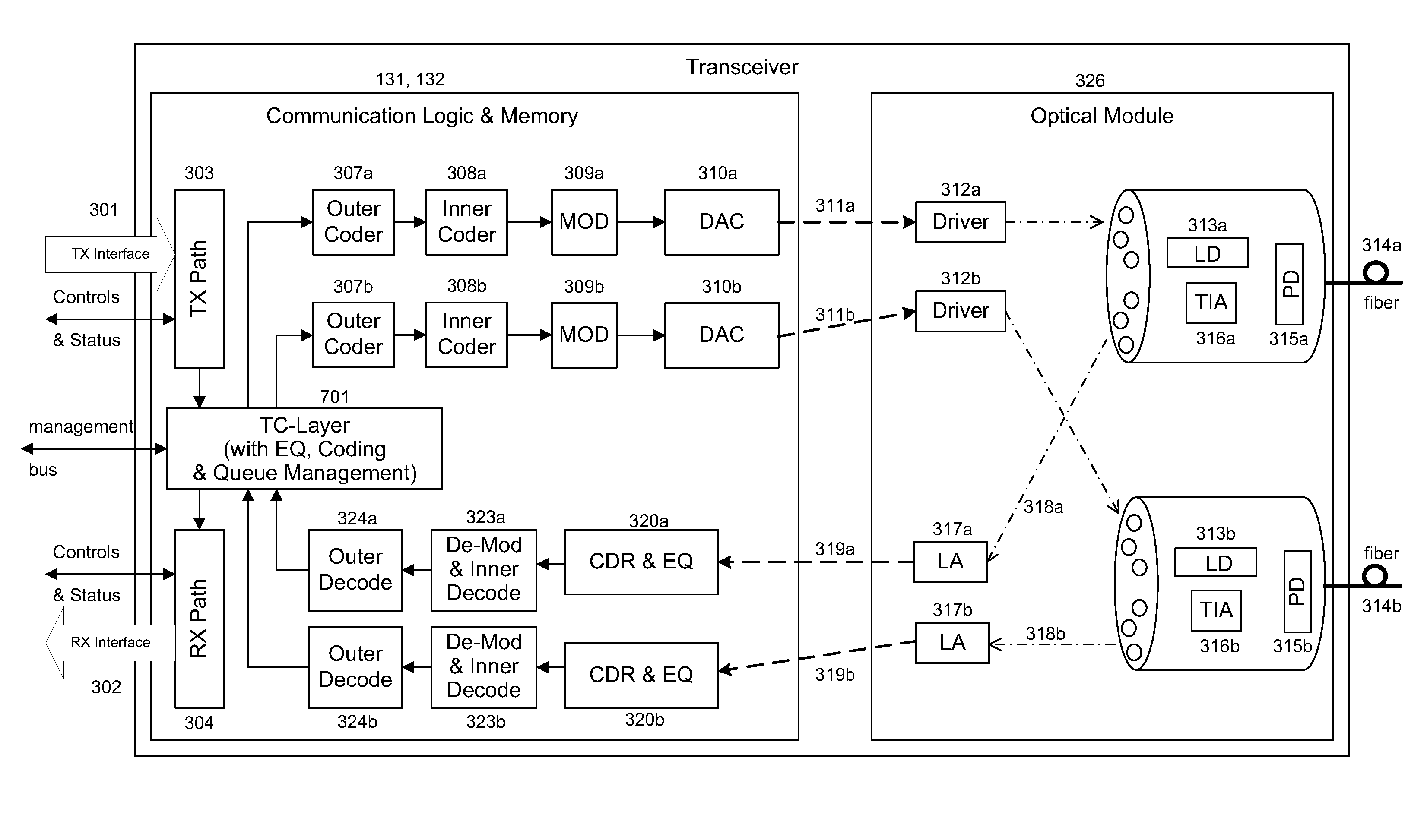

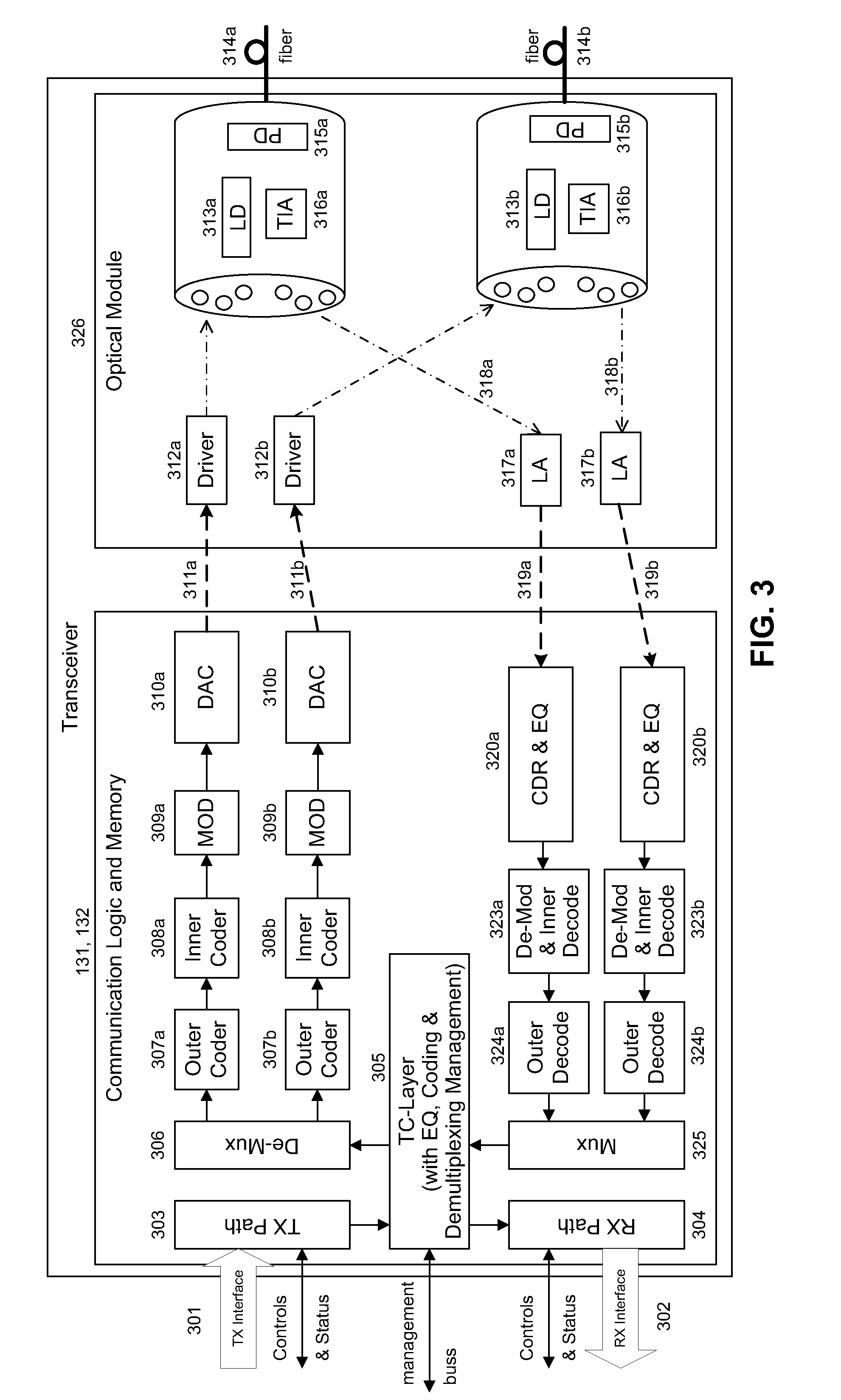

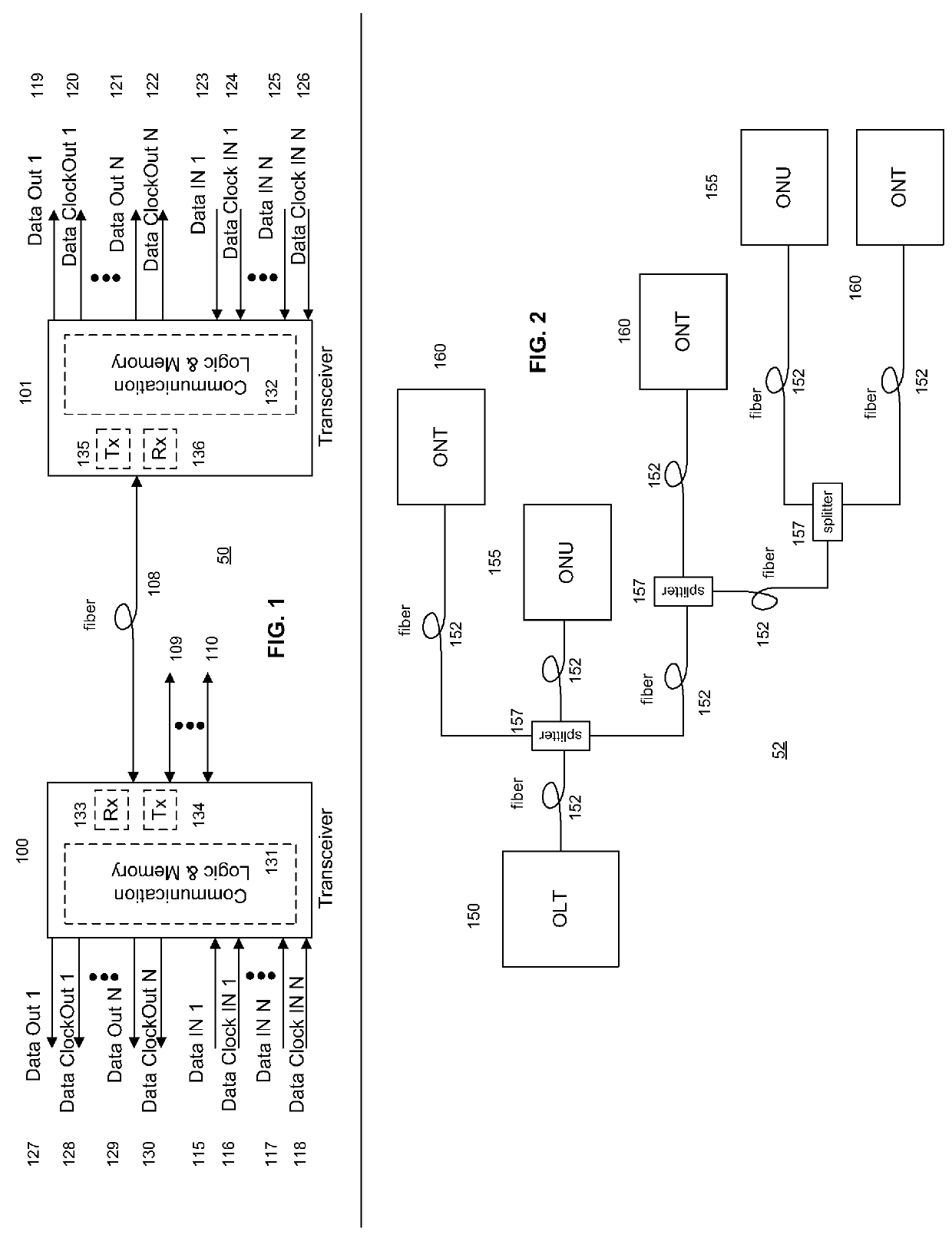

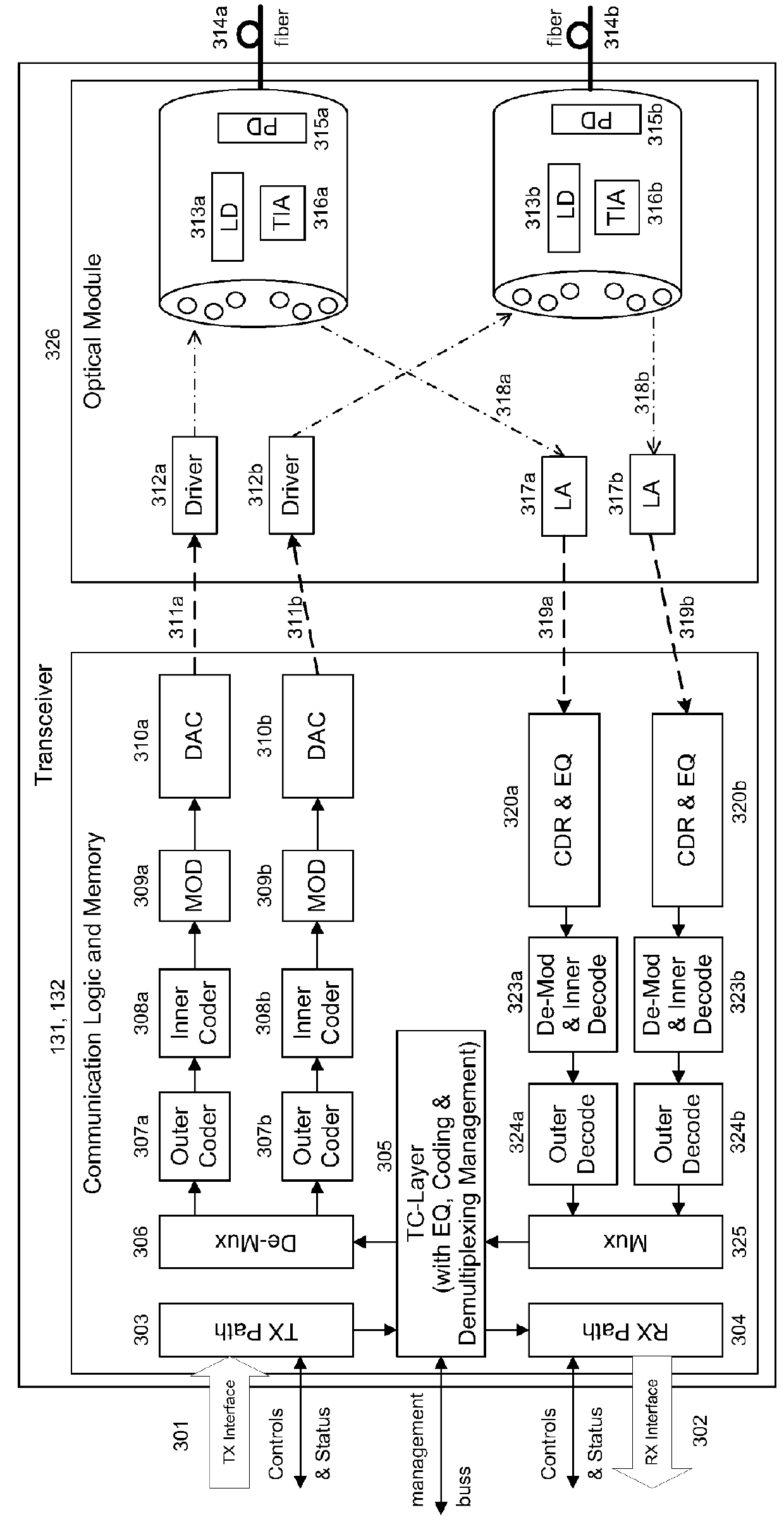

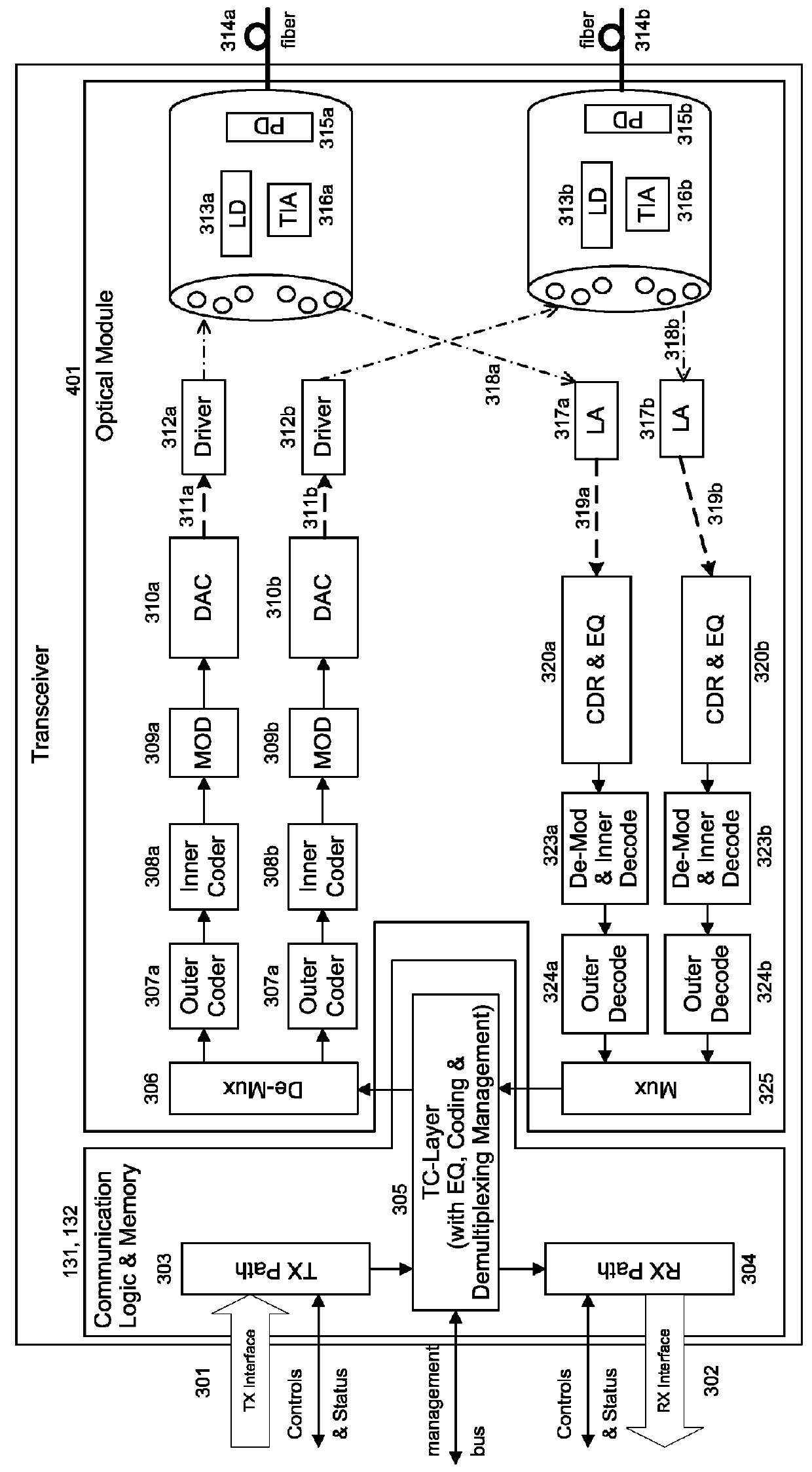

System and method for performing high-speed communications over fiber optical networks

ActiveUS20100158530A1Low line rateIncrease data throughputWavelength-division multiplex systemsDistortion/dispersion eliminationFiberWaiting period

Processing a received optical signal in an optical communication network includes equalizing a received optical signal to provide an equalized signal, demodulating the equalized signal according to an m-ary modulation format to provide a demodulated signal, decoding the demodulated signal according to an inner code to provide an inner-decoded signal, and decoding the inner-decoded signal according to an outer code. Other aspects include other features such as equalizing an optical channel including storing channel characteristics for the optical channel associated with a client, loading the stored channel characteristics during a waiting period between bursts on the channel, and equalizing a received burst from the client using the loaded channel characteristics.

Owner:SOTO ALEXANDER I +1

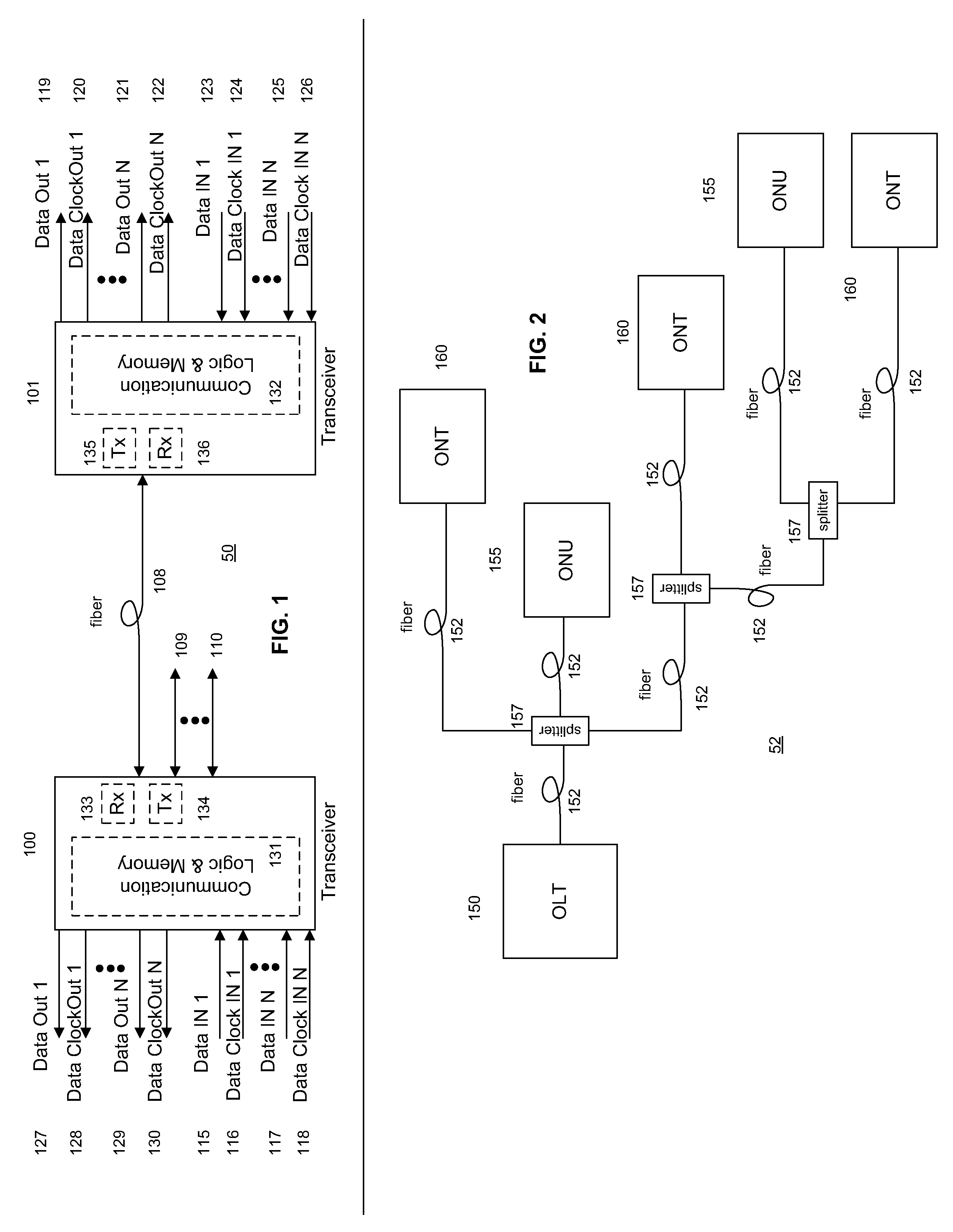

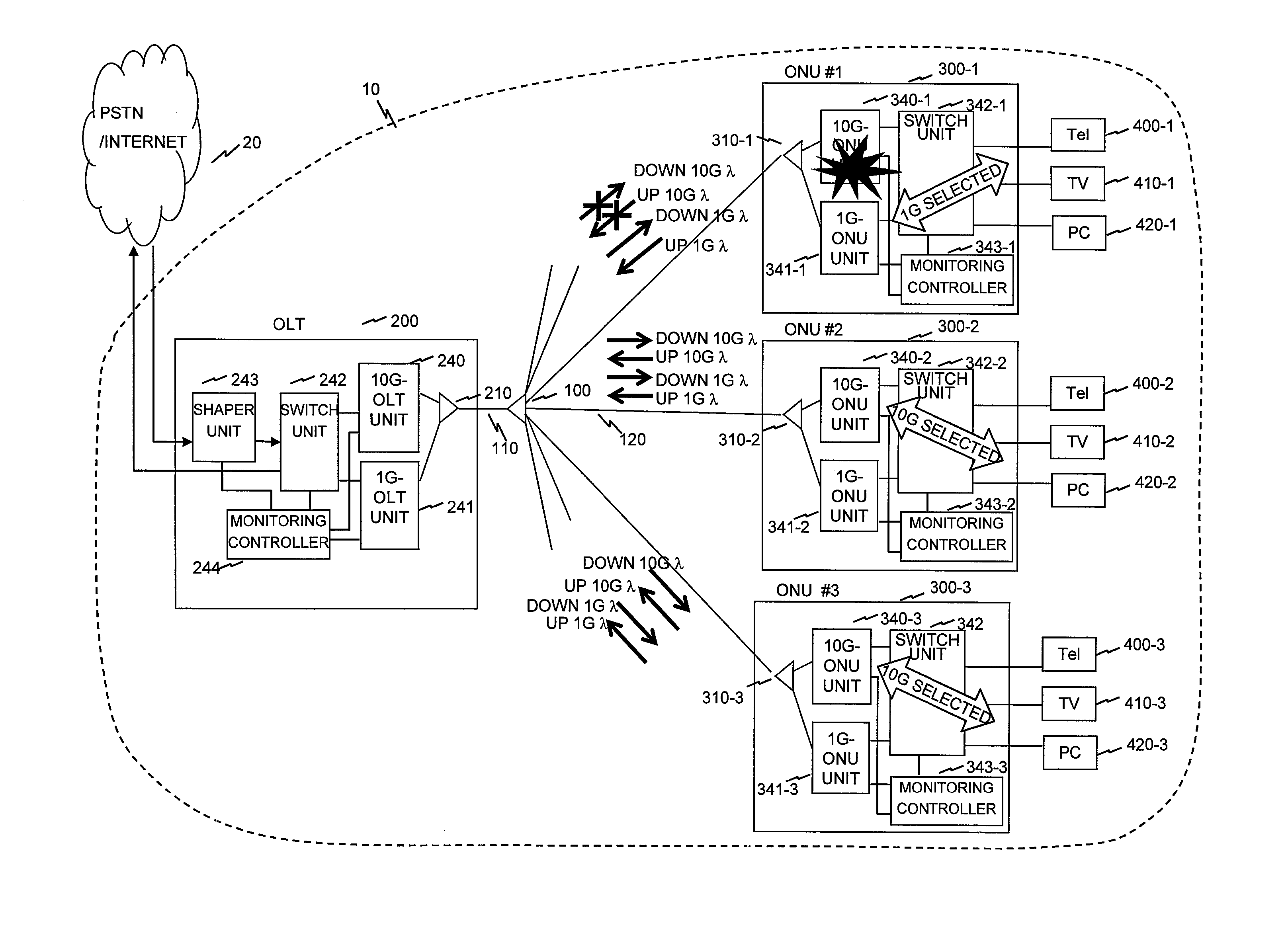

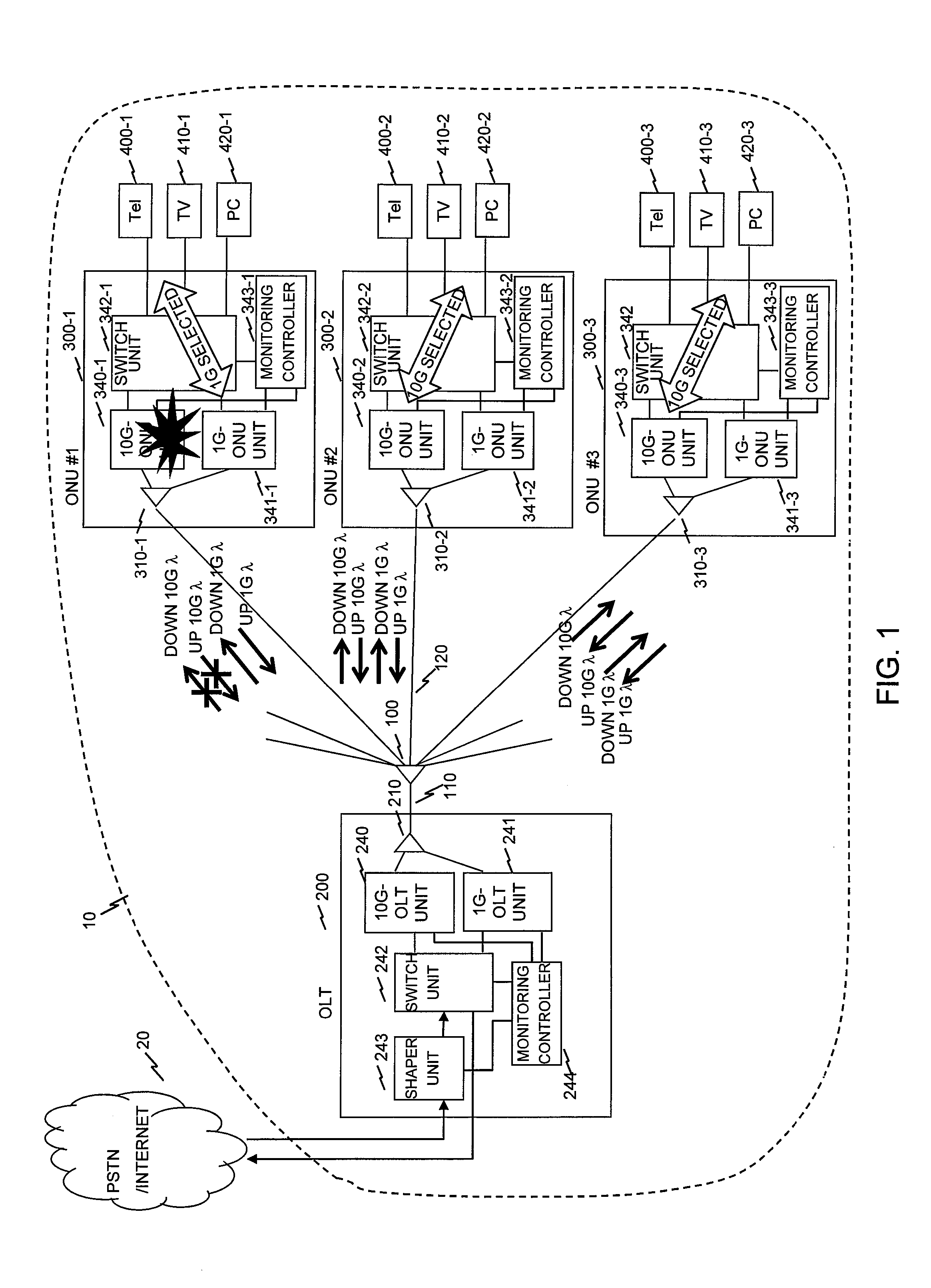

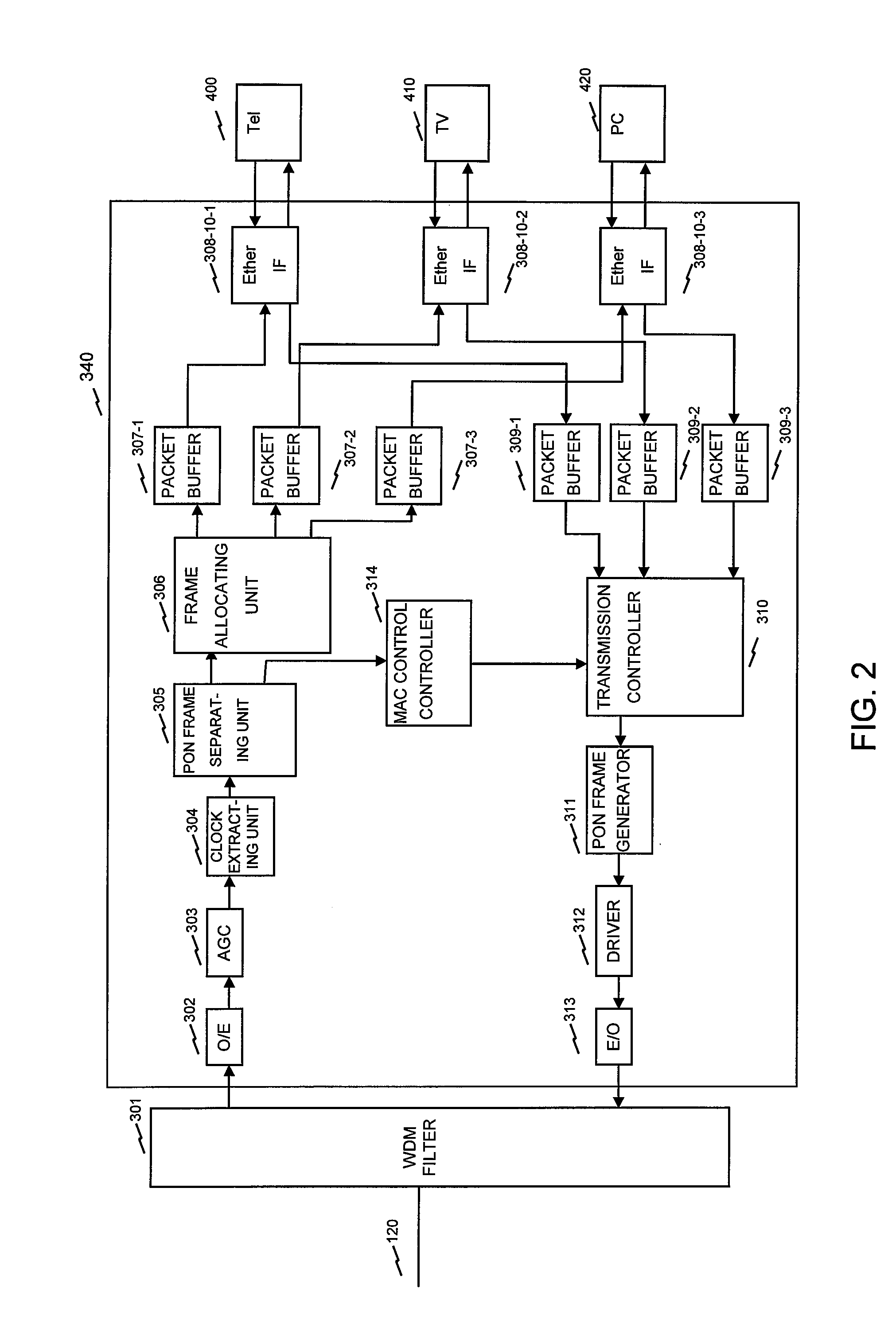

Passive optical network system and optical line terminal

InactiveUS20110103792A1Reduce power consumptionReduce line speedMultiplex system selection arrangementsLaser detailsEngineeringBackup

A transmission speed of a protection (backup) line using 1G-OLT unit and 1G-ONU unit is set to be lower than a transmission speed of a working (primary) line using 10G-OLT unit and 10G-ONU unit. A priority and band of each communication service in ONU are preset individually and separately every LLID for a working (primary) line and a protection (backup) line. When bands are allocated to the protection (backup) line, the band allocation is performed so as to secure a minimum number of bands of each communication service. A monitoring controller refers to a predetermined band information table according to an operation state of the working (primary) line or the protection (backup) line with respect to a downstream signal packet.

Owner:HITACHI LTD

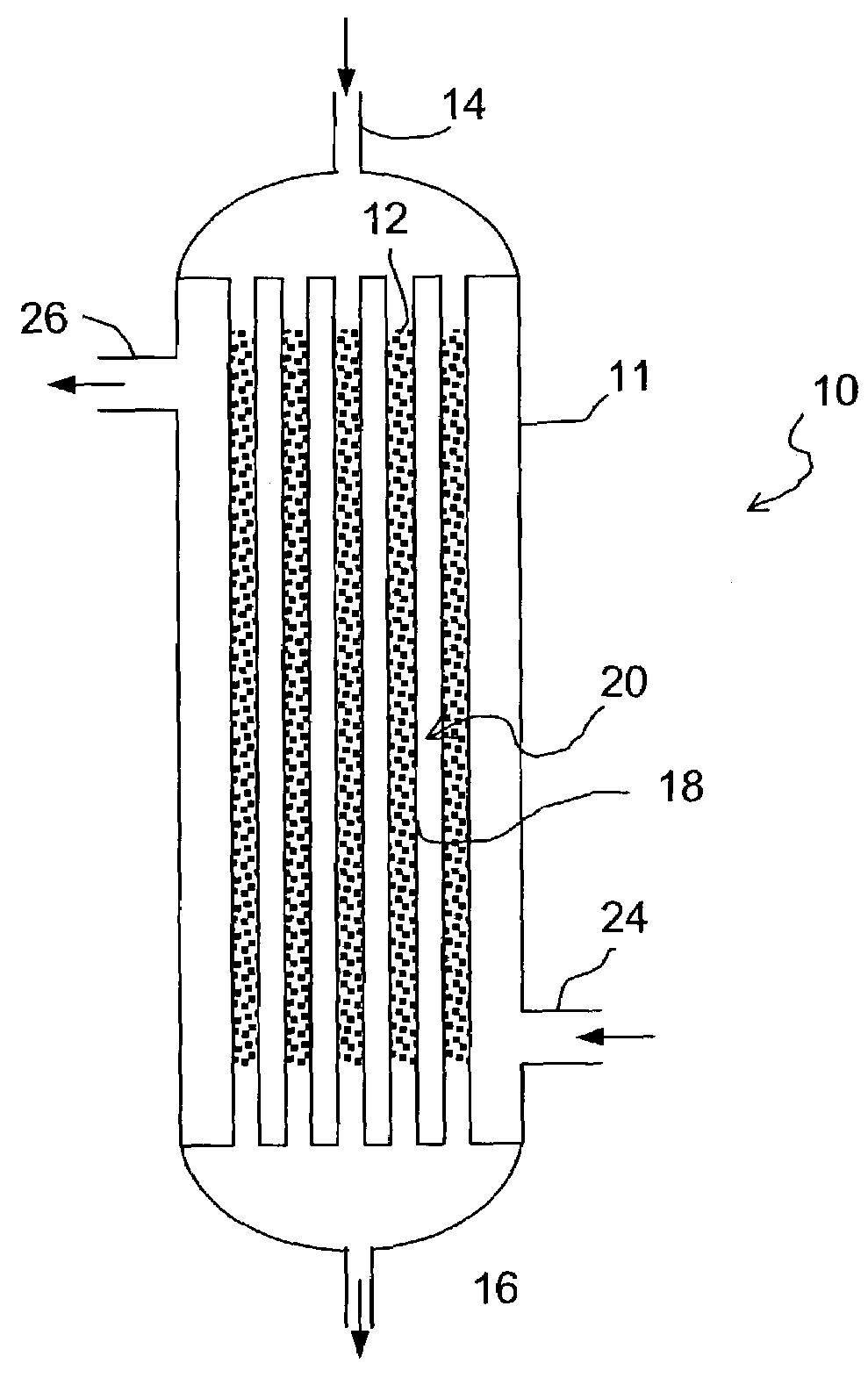

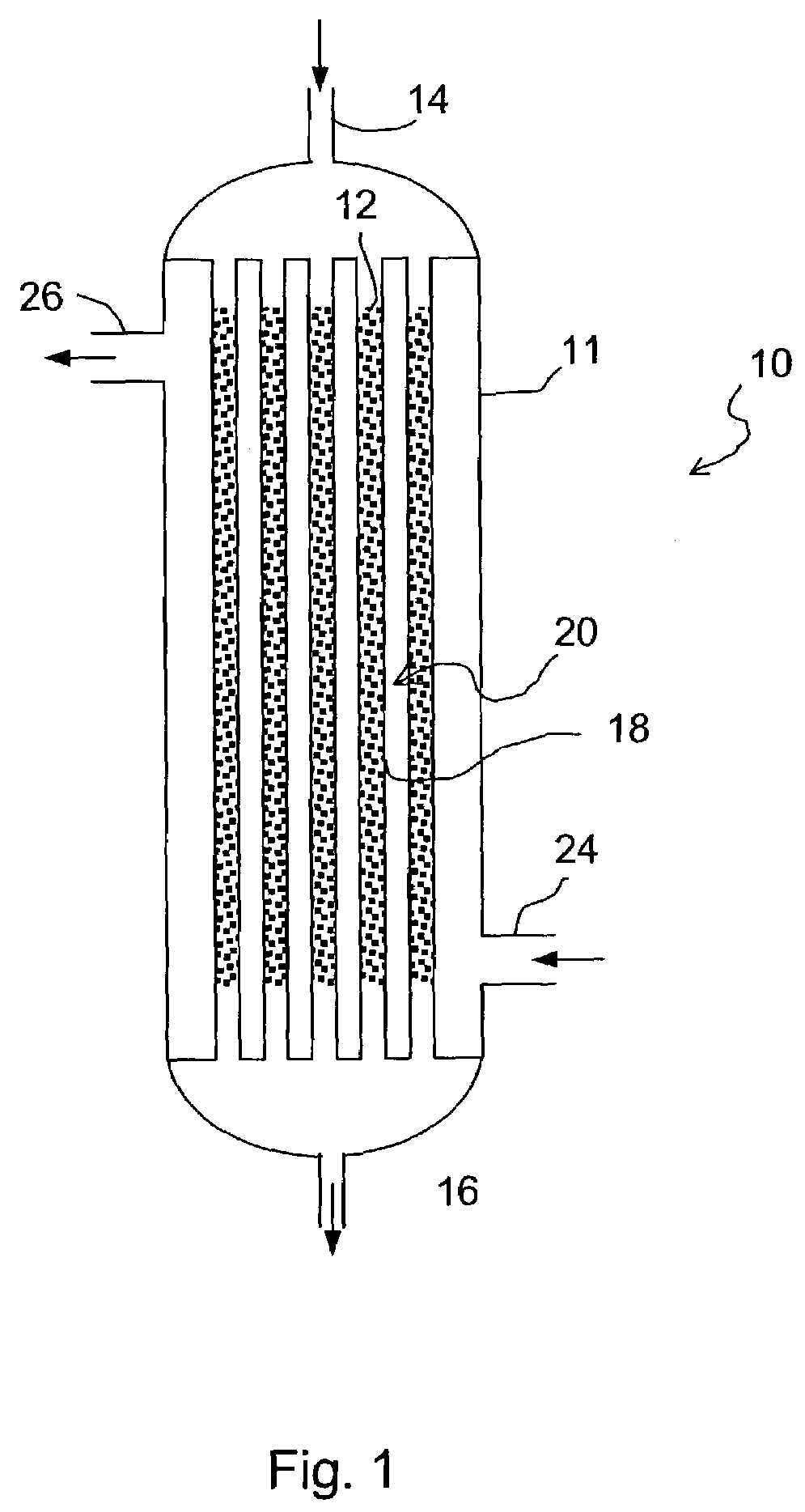

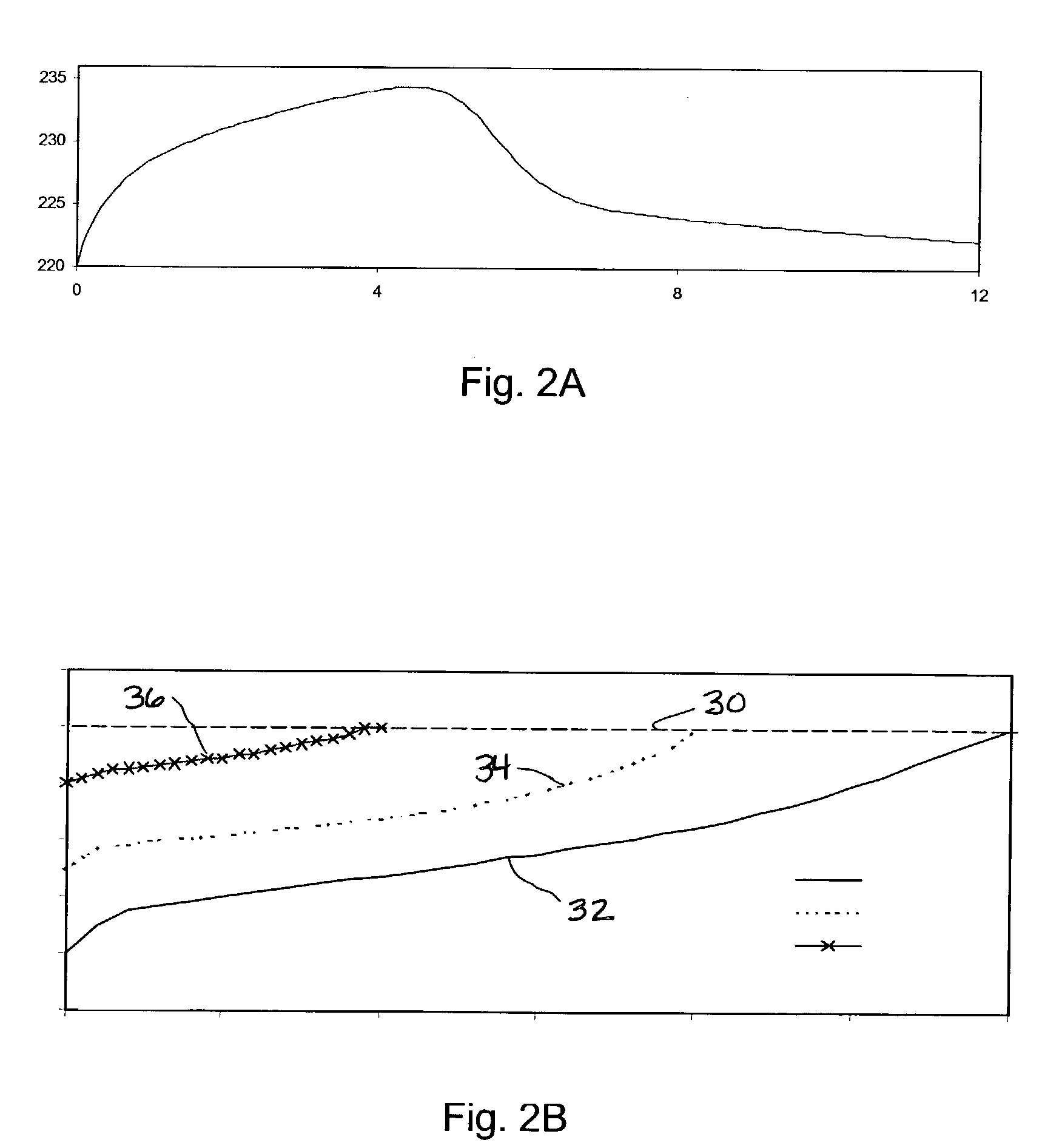

Commercial fischer-tropsch reactor

InactiveUS7012103B2Improve efficiencyIncrease conversionsOrganic compound preparationOxygen compounds preparation by reductionHydrogenIntrinsic activity

A process for producing hydrocarbons comprises providing a multi-tubular reactor having at least 100 tubes units containing a catalyst, each tube being between 2 and 5 meters tall and in thermal contact with a cooling fluid; feeding hydrogen and carbon monoxide to each tube at a linear gas superficial velocity less than about 60 cm / s; and converting the gas feedstream to hydrocarbons on the catalyst, wherein the yield of hydrocarbons in each tube is greater than 100 (kg hydrocarbons) / hr / (m3 reaction zone). Each tube may have an internal diameter greater than 2 centimeters. The catalyst may be active for Fischer Tropsch synthesis and may comprise cobalt or iron. The maximum difference in the radially-averaged temperature between two points that are axially spaced along the reactor is less than 15° C., preferably less than 10° C. The catalyst loading or intrinsic activity may vary along the length of the reactor.

Owner:CONOCOPHILLIPS CO

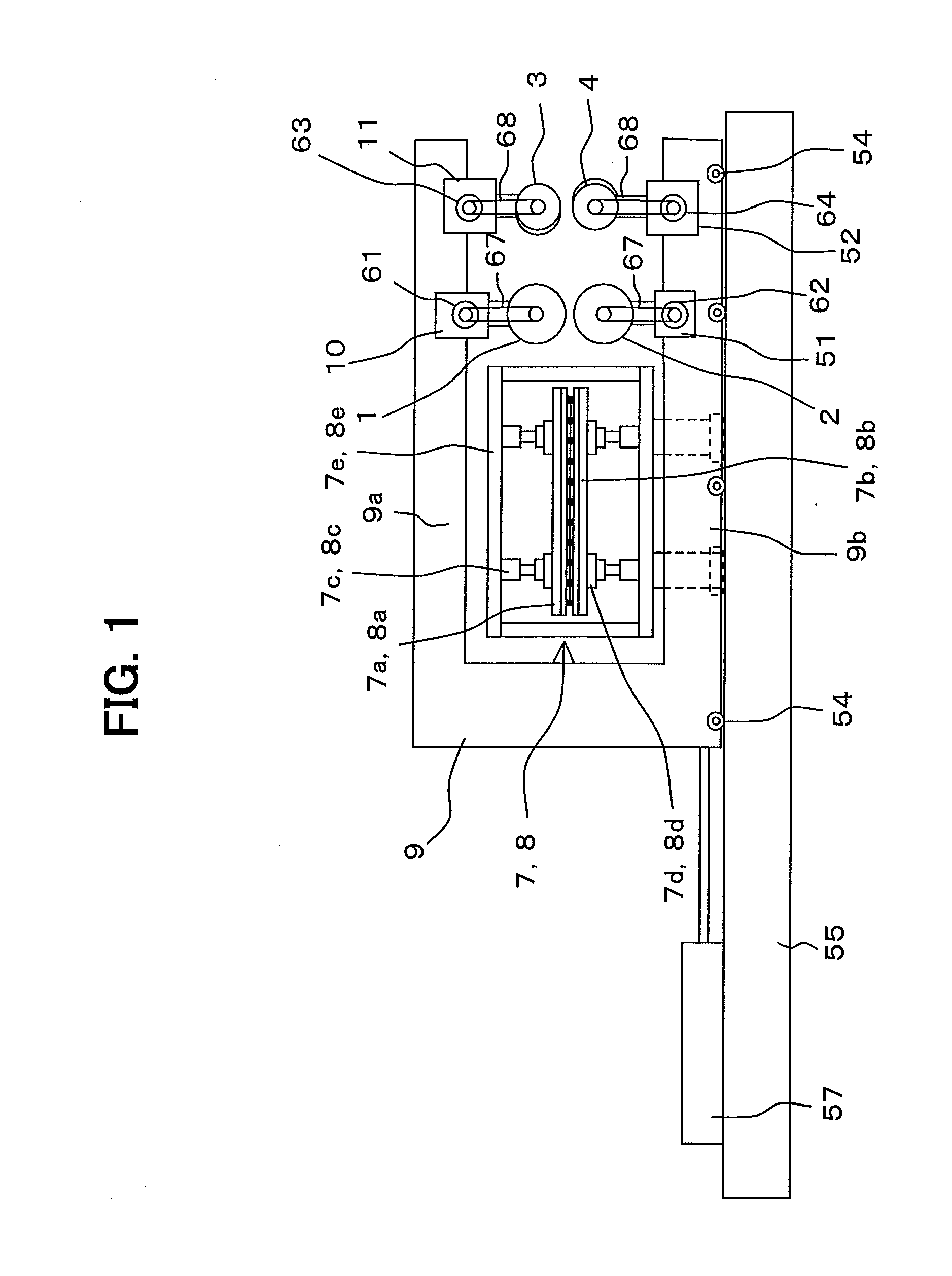

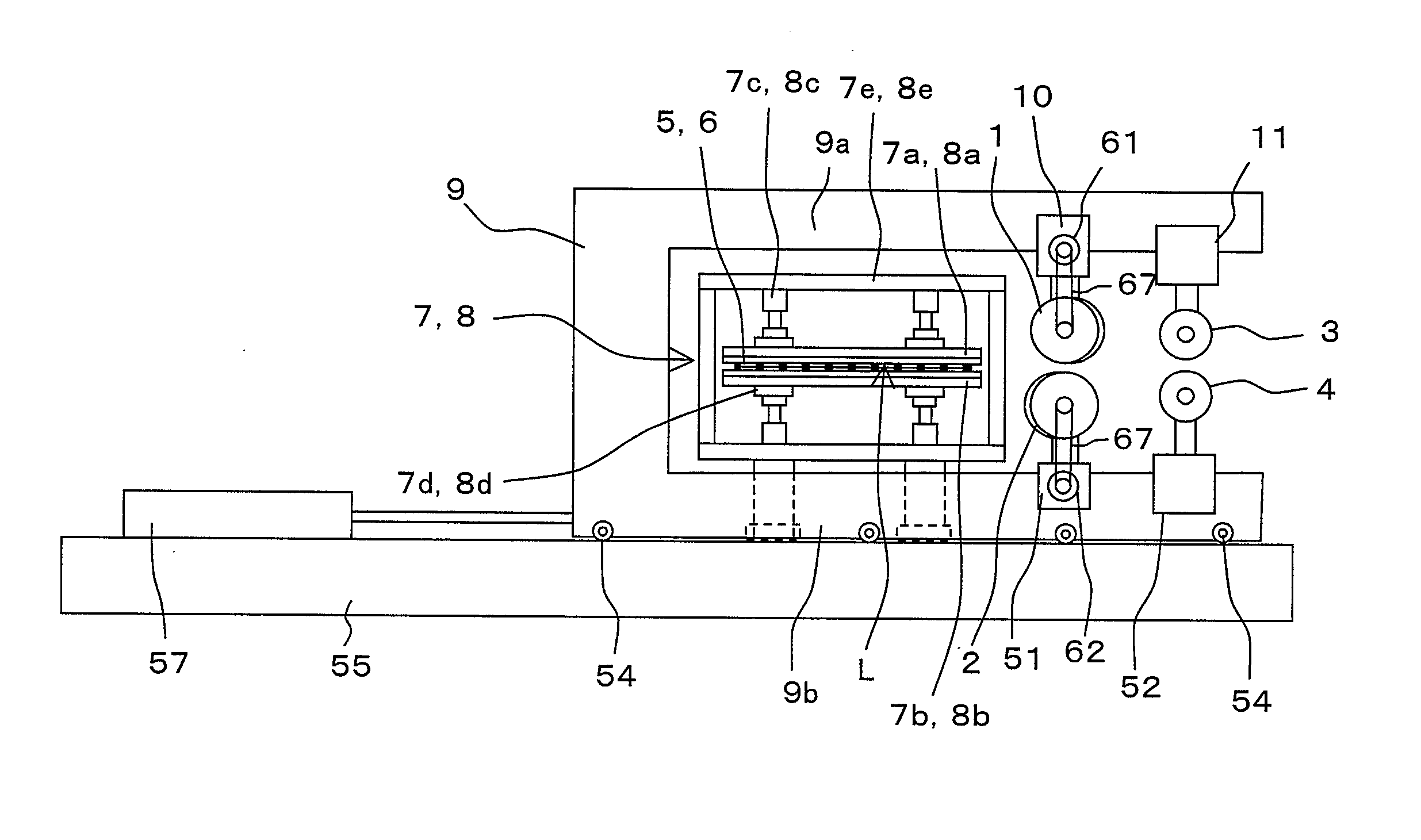

Metal plate joining method and apparatus

ActiveUS20110163074A1High degreeIncrease the amount of cuttingWelding/cutting auxillary devicesRectilinear seam weldingEngineeringMetal

A pair of upper and lower pressure rollers 3, 4 is disposed so that their axes 15, 16 are tilted in a horizontal plane in respective directions opposite to each other with respect to a straight line perpendicular to a welding line of a joint portion J. The pressure rollers 3, 4 are positively driven by corresponding electric motors 63, 64 to thereby roll the joint portion. Thus, steps defined at the joint portion can be smoothed and a step gradient can be reduced to ensure a high degree of joint strength.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

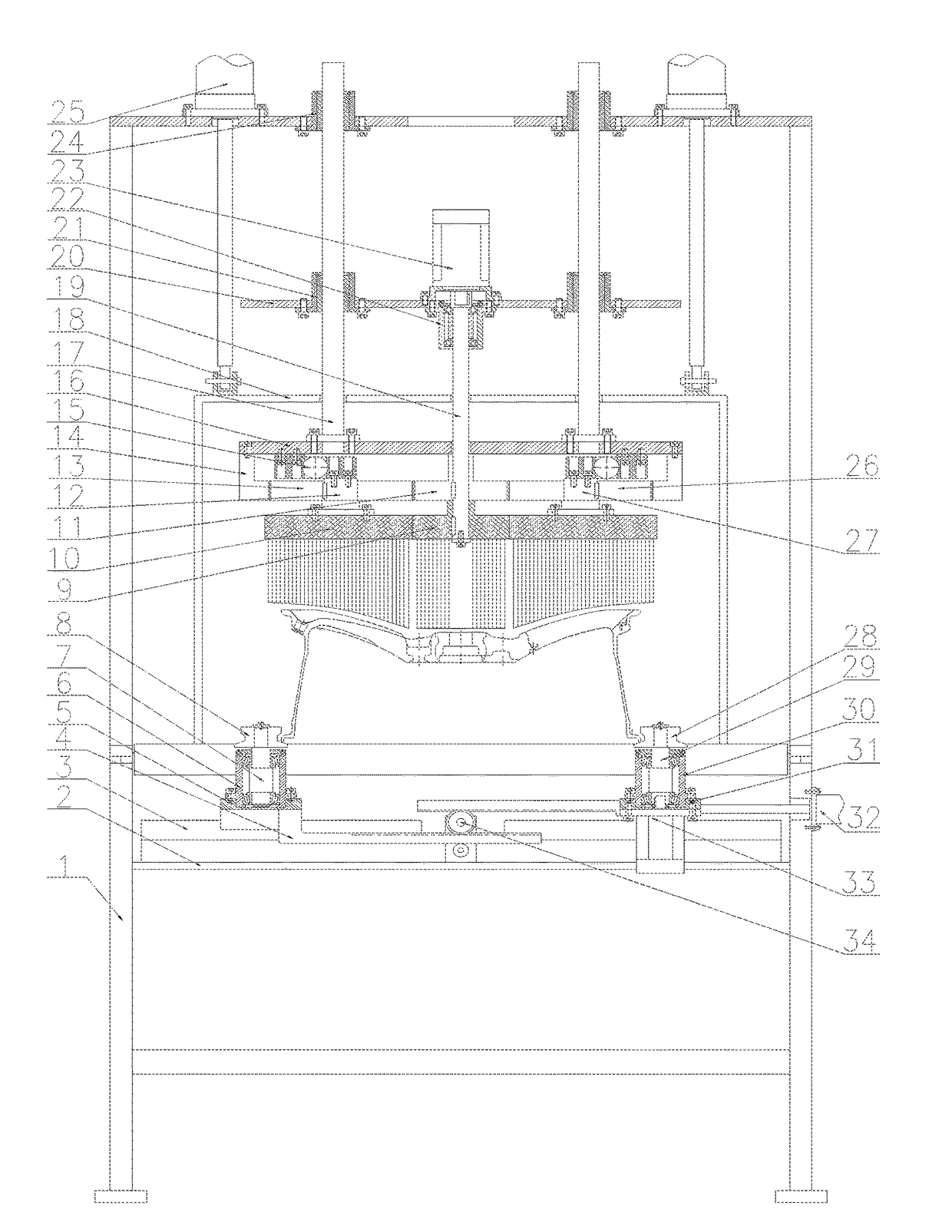

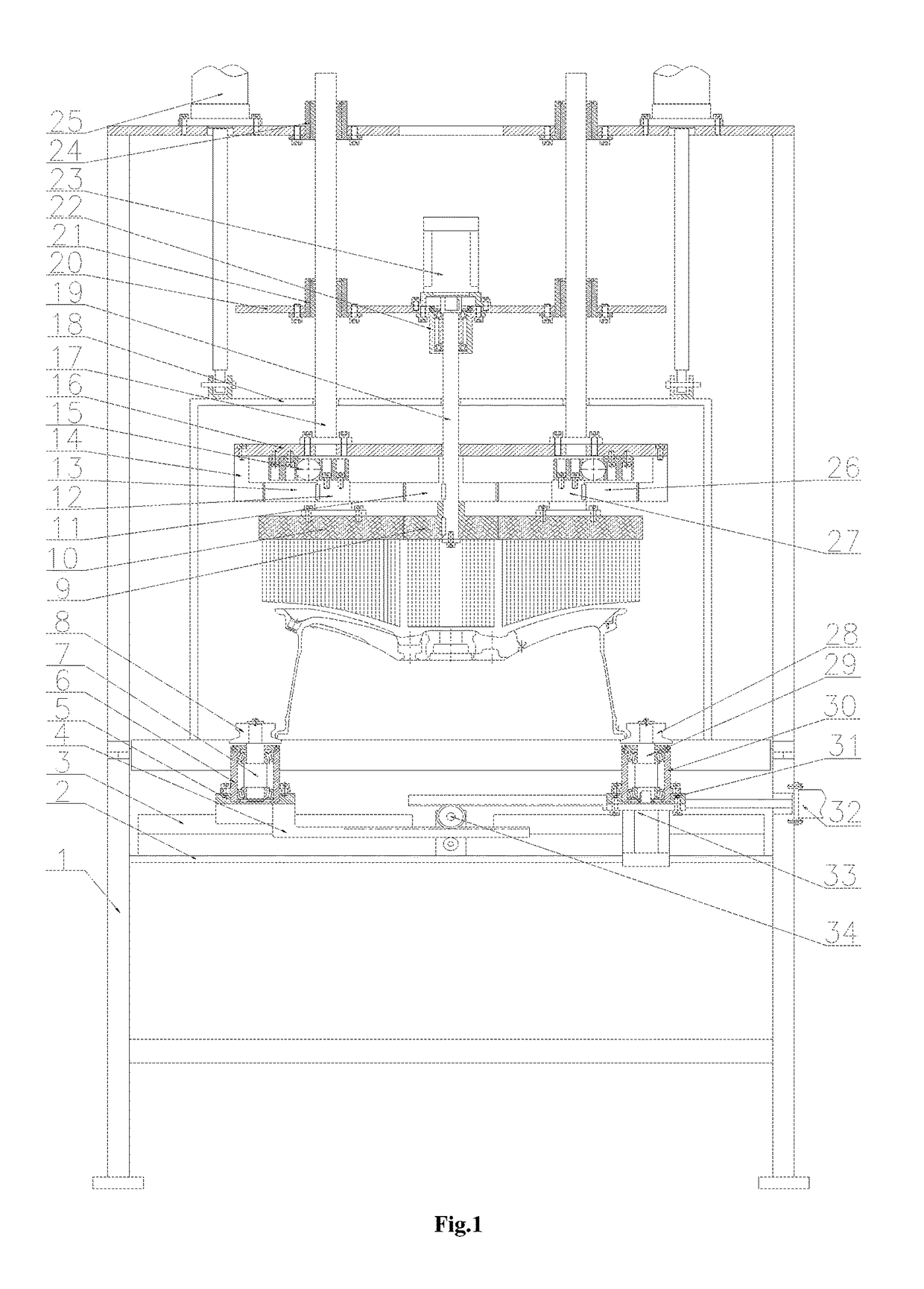

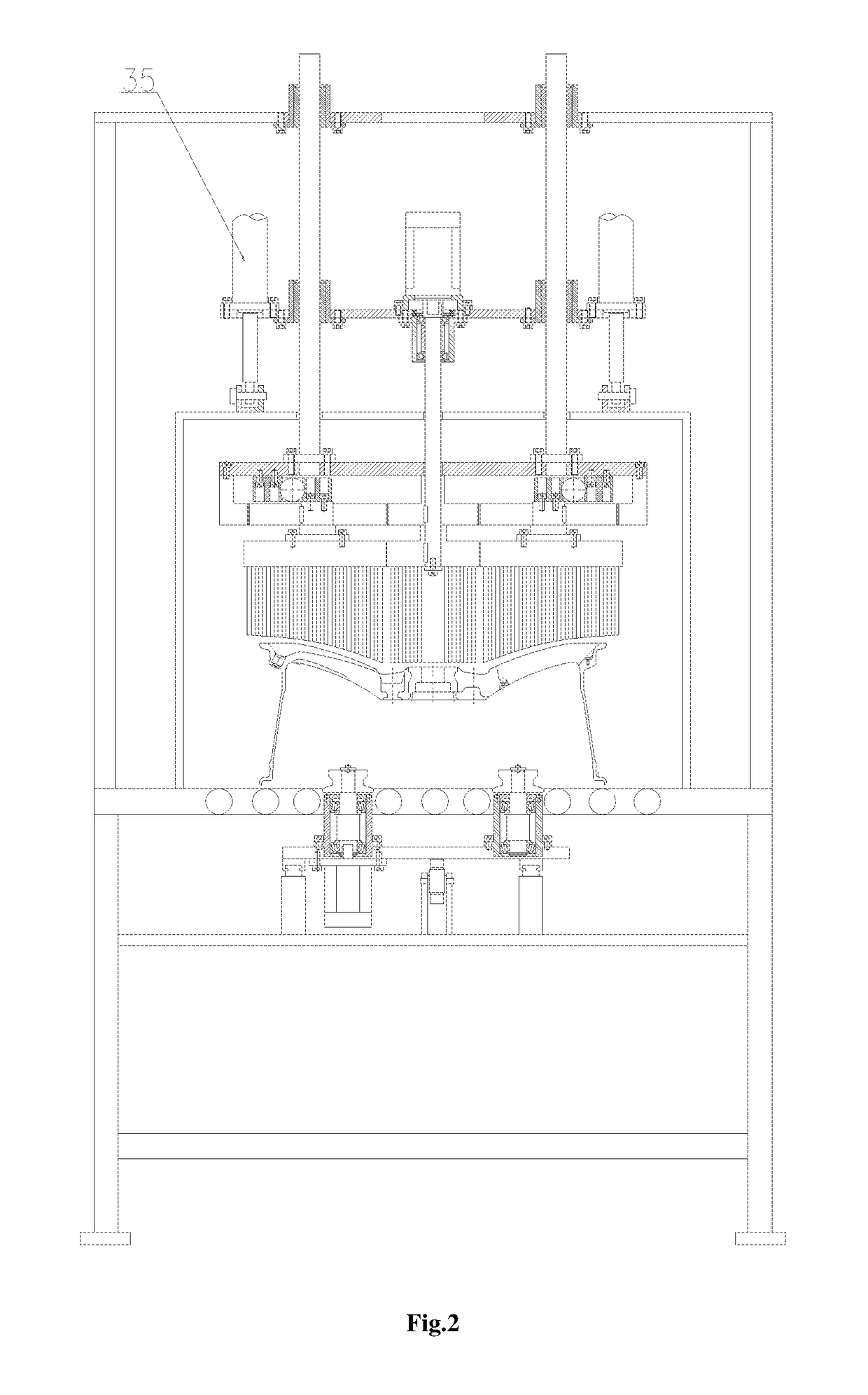

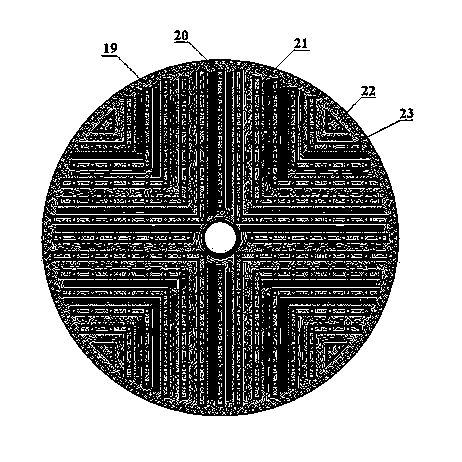

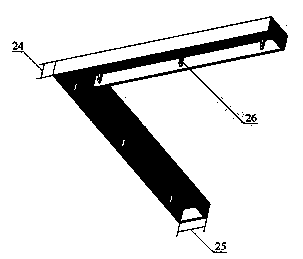

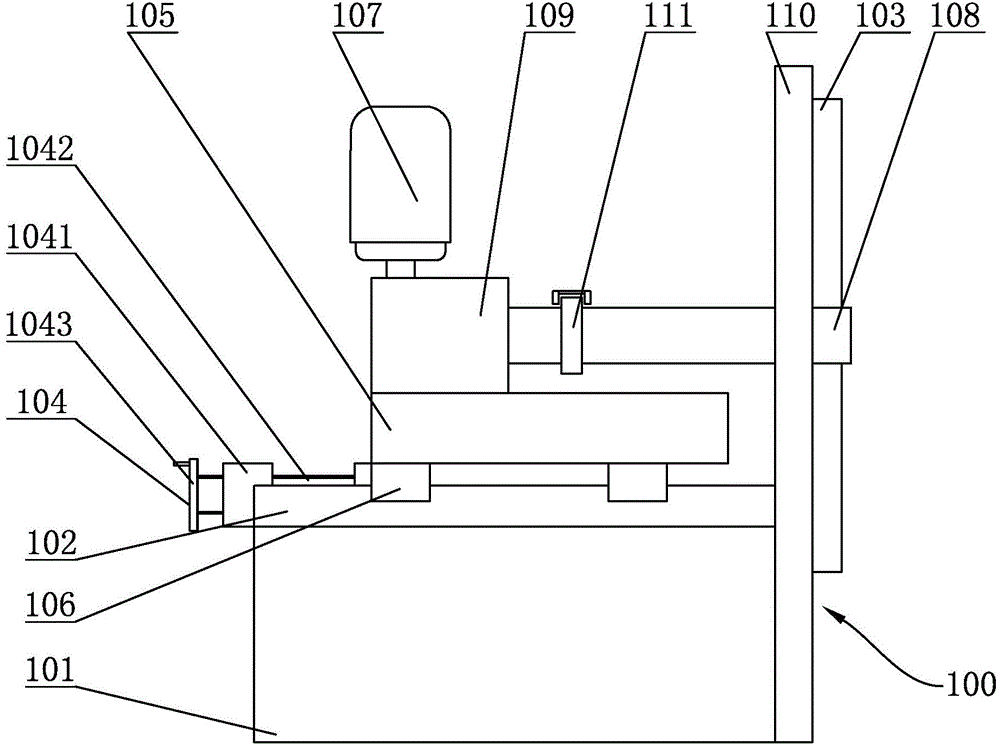

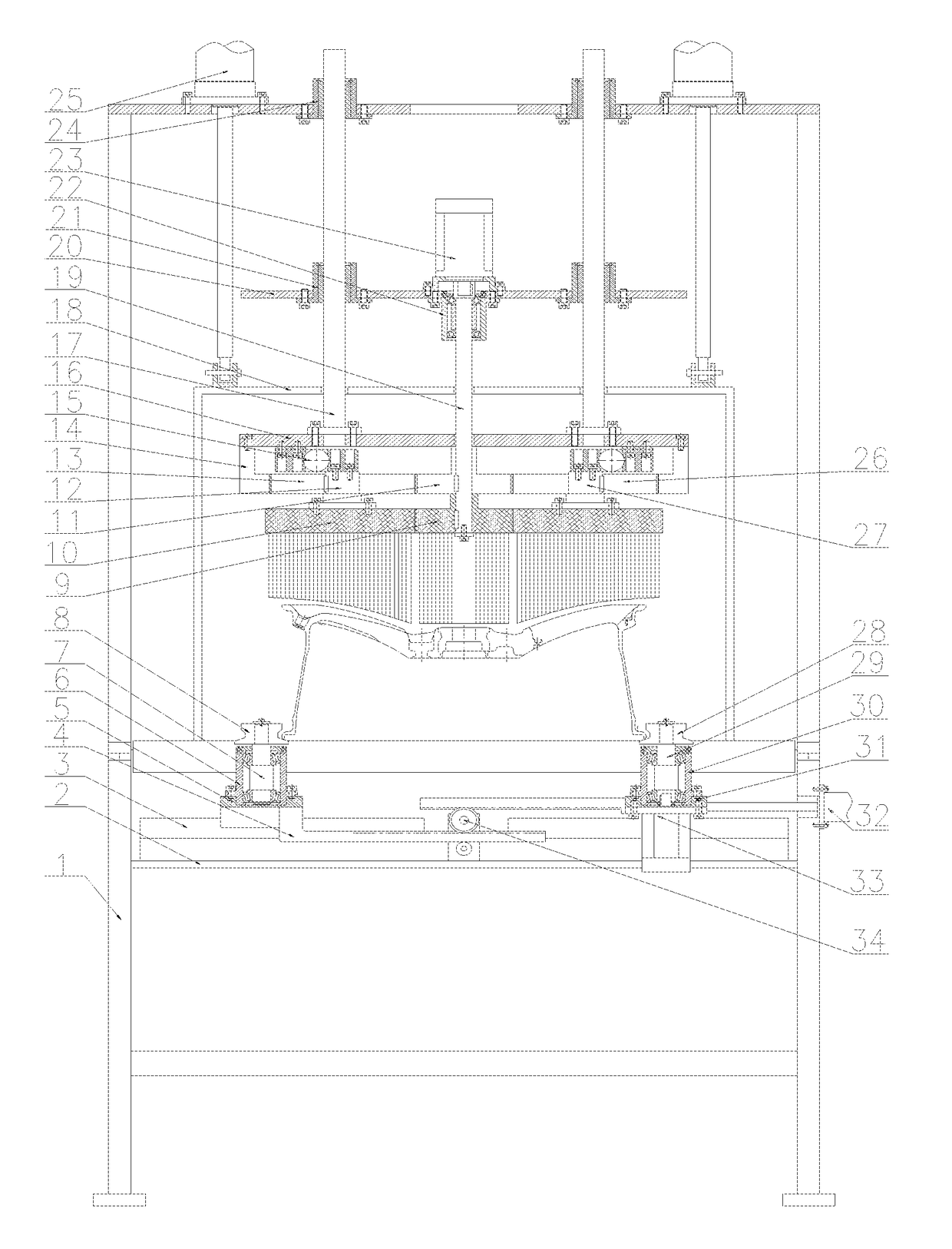

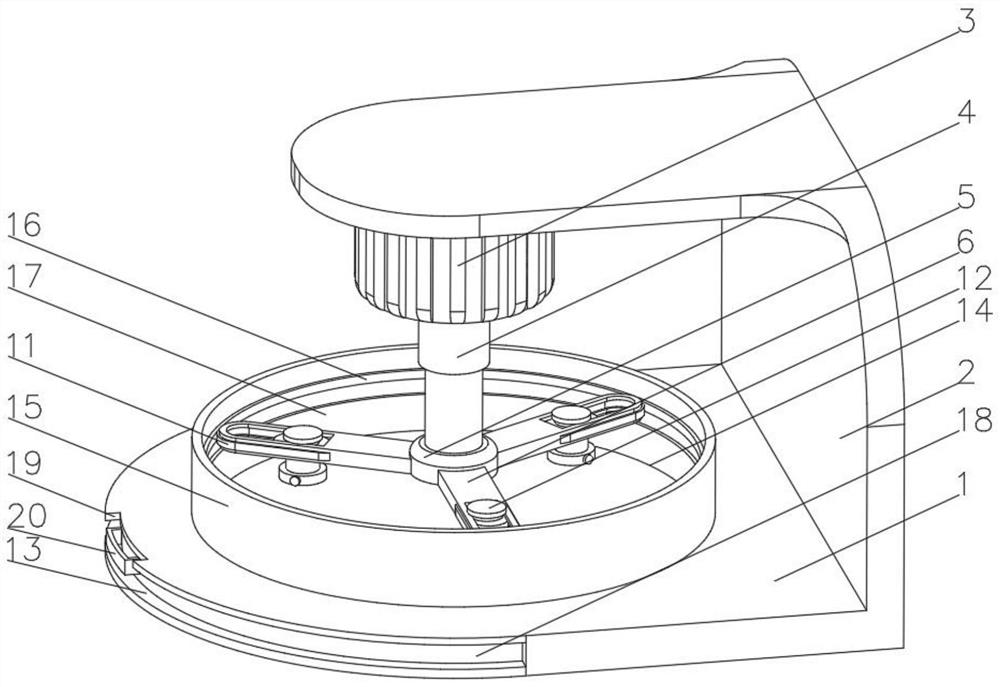

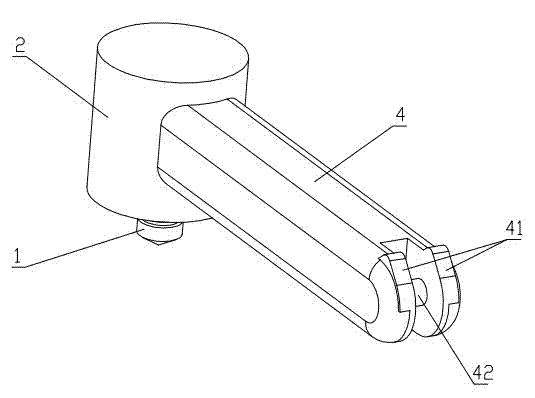

Device for Burring Front Face of Wheel

ActiveUS20170182617A1High degree of automationSafe and stable performanceEdge grinding machinesPolishing machinesCircular discMotor drive

The present invention relates to a device for burring a front face of a wheel. The device is composed of a rack, a motor, a guide rail, air cylinders, brushes and the like. A sensor enables the wheel to be positioned on a roller way, a clamping air cylinder drives left rolls and right rolls via synchronous gears and gear racks to clamp the wheel, a servo motor drives the wheel to rotate at relatively low speed under the clamped condition, and the rotation direction of the wheel is opposite to that of the brushes; the air cylinders I enable a dust cover to go down, and the motor drives a gear I and a central brush via a shaft II to rotate at relatively high speed; the gear I drives a gear II and a gear III to rotate simultaneously at slightly slow speed, so as to drive an outer ring brush to also rotate at relatively slow speed; and the air cylinders II drive the central brush and outer ring brush to go down, and burring can be performed once the central brush and outer ring brush contact the front face of the wheel. When in use, the device provided by the present invention can burr the central part and the spoke of the wheel at different rotation speeds, and the problem that the traditional big disc brush has low linear speed at the central position when rotating at fixed angular speed is avoided.

Owner:CITIC DICASTAL

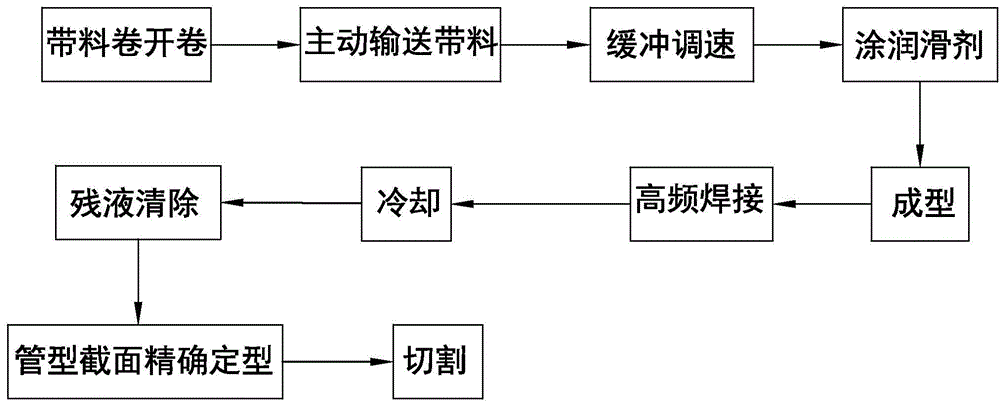

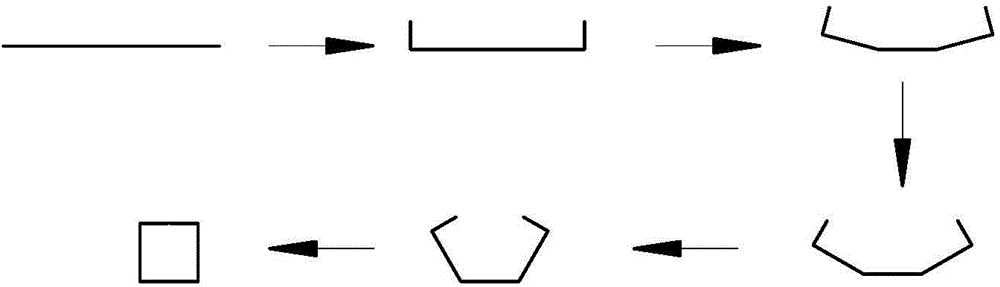

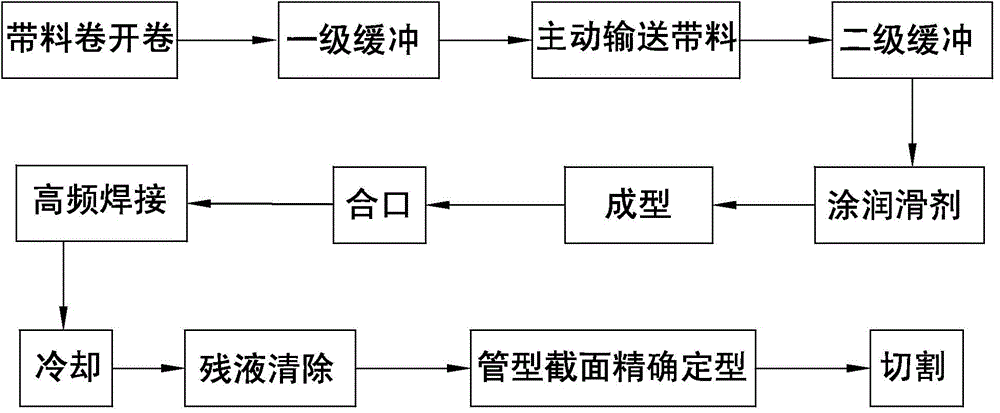

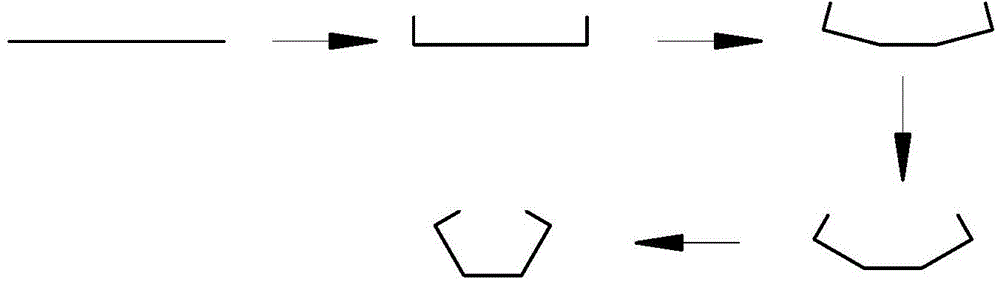

Machining method for thin-wall squared tube

The invention discloses a machining method for a thin-wall squared tube and belongs to the technical field of square tube forming processes. The machining method for the thin-wall squared tube mainly includes the following steps that 1 a strip roll is decoiled, wherein the strip roll is unfolded and a strip is discharged; 2 the strip is conveyed actively, wherein the strip is discharged downstream under the action of traction force; 3 buffering speed governing is conducted, wherein the strip is discharged at a constant speed without the action of tensile force, and the active conveying frequency of the strip is controlled; 4 lubricant coating is conducted, wherein the two surfaces of the strip are coated with lubricants; 5 forming is conducted, wherein the strip is gradually bent in a cold mode, so that the strip forms a tube blank with a weld joint and a square section, and the weld joint is located on the upper surface of the tube blank; 6 high-frequency welding is conducted; 7 cooling is conducted; 8 residual liquor is cleaned away; 9 the tube section is accurately shaped; 10 cutting is conducted. The machining method solves the technical problems that existing thin-wall squared tubes are poor in forming quality and low in production efficiency, and the machining method is widely applied to manufacturing thin-wall squared tubes.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL

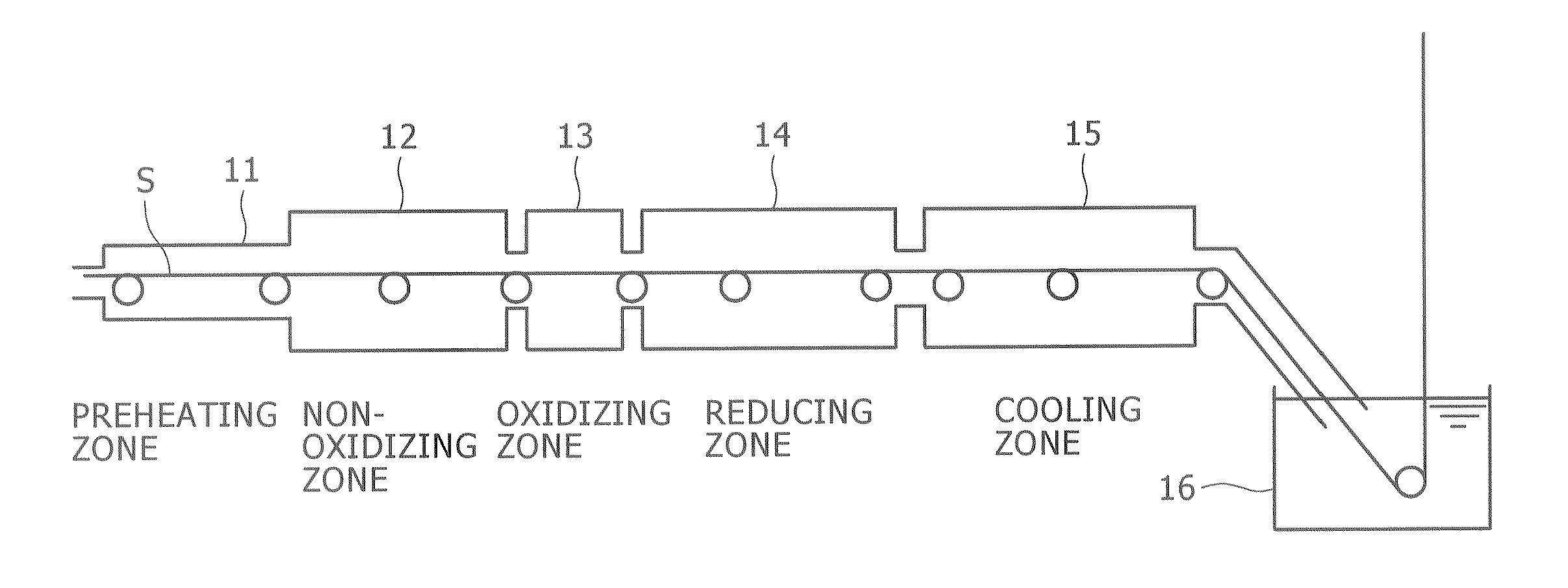

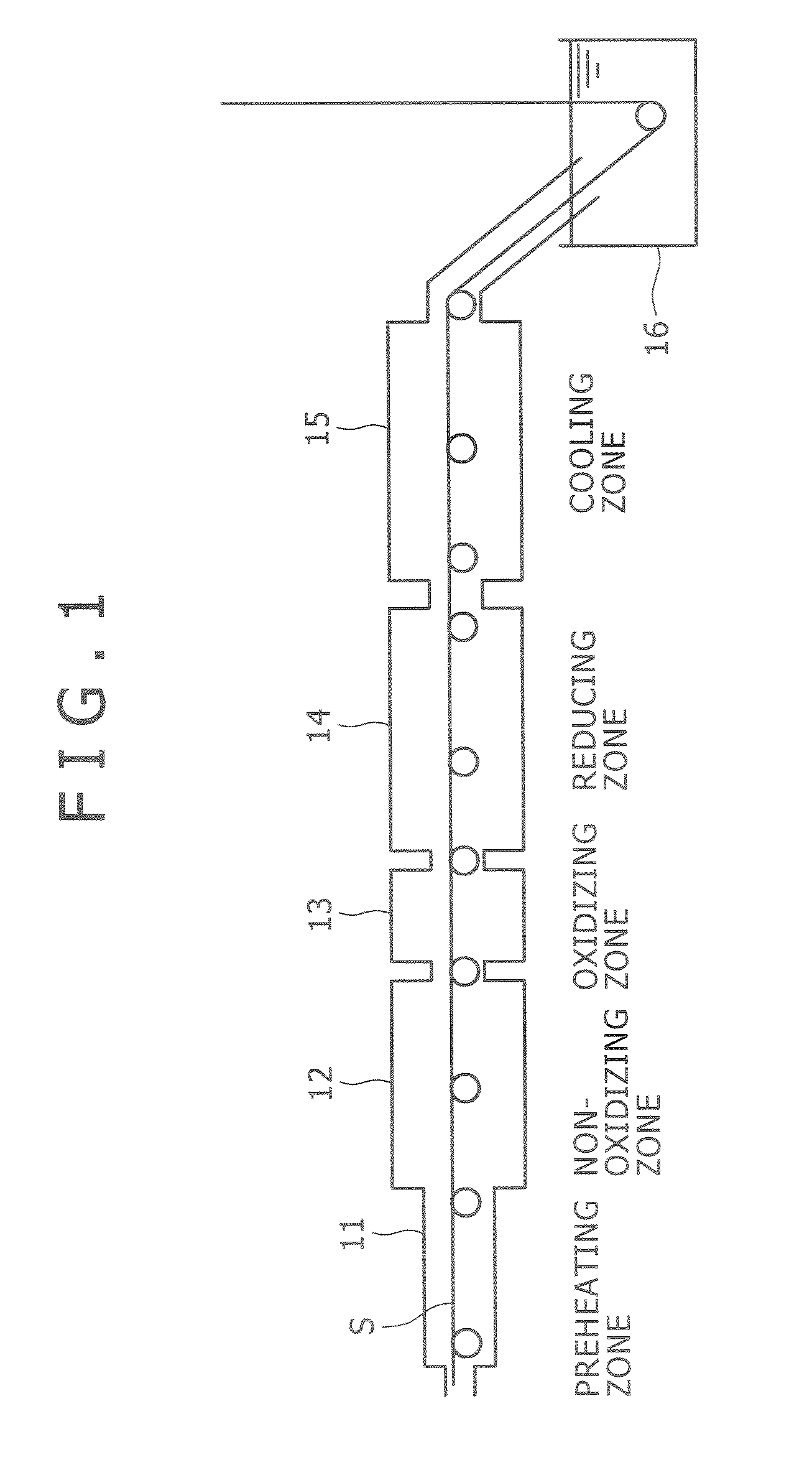

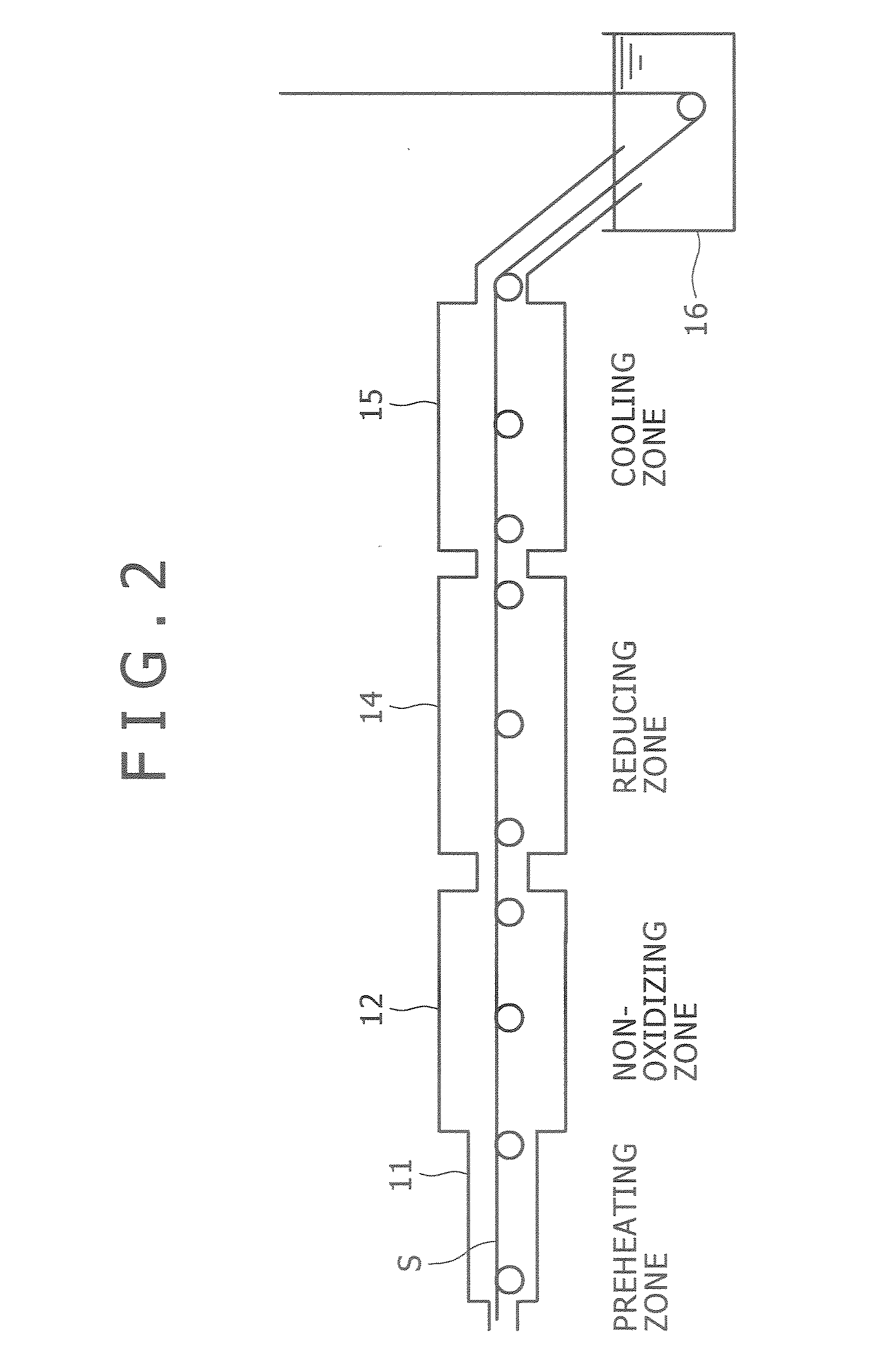

Method and Facility for Hot Dip Zinc Plating

ActiveUS20080023111A1Reduce line speedQuality improvementHot-dipping/immersion processesLiquid surface applicatorsOxidation zoneElectroplating

According to a process for hot-dip galvanization of the present invention, a steel sheet is treated by the oxidization / reduction method for better quality of galvanization and then hot-dip galvanized. An annealing line of equipment for hot-dip galvanization is composed of a non-oxidizing zone, an oxidizing zone, and a reducing zone, in his order. A steel sheet containing elements liable to oxidize more easily than iron is oxidized by blowing flames onto it in the oxidizing zone according to the oxidization / reduction method. Further, the steel sheet is reduced and annealed in the reducing zone.

Owner:KOBE STEEL LTD

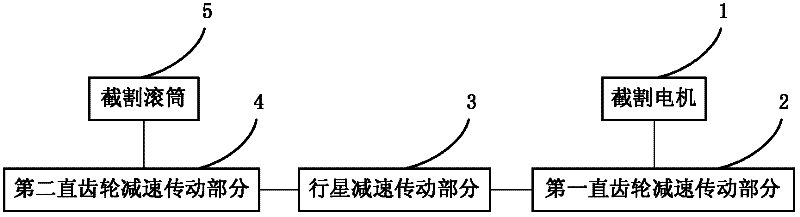

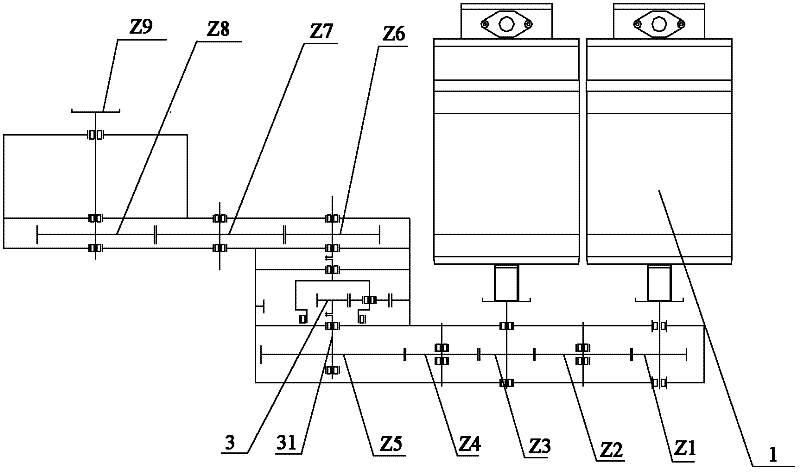

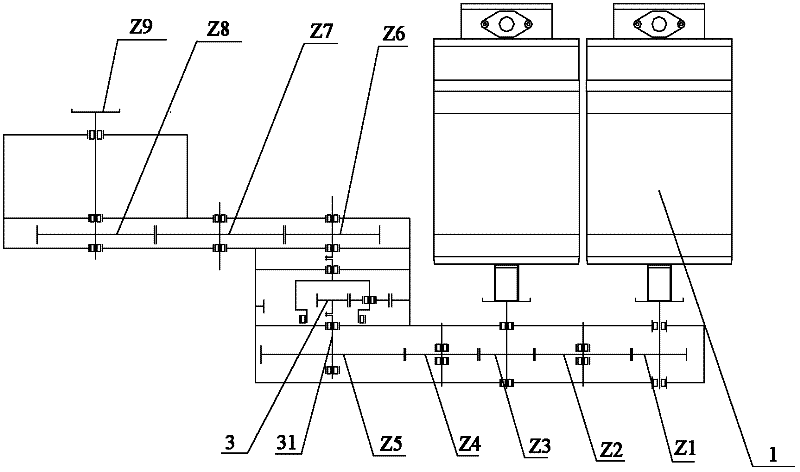

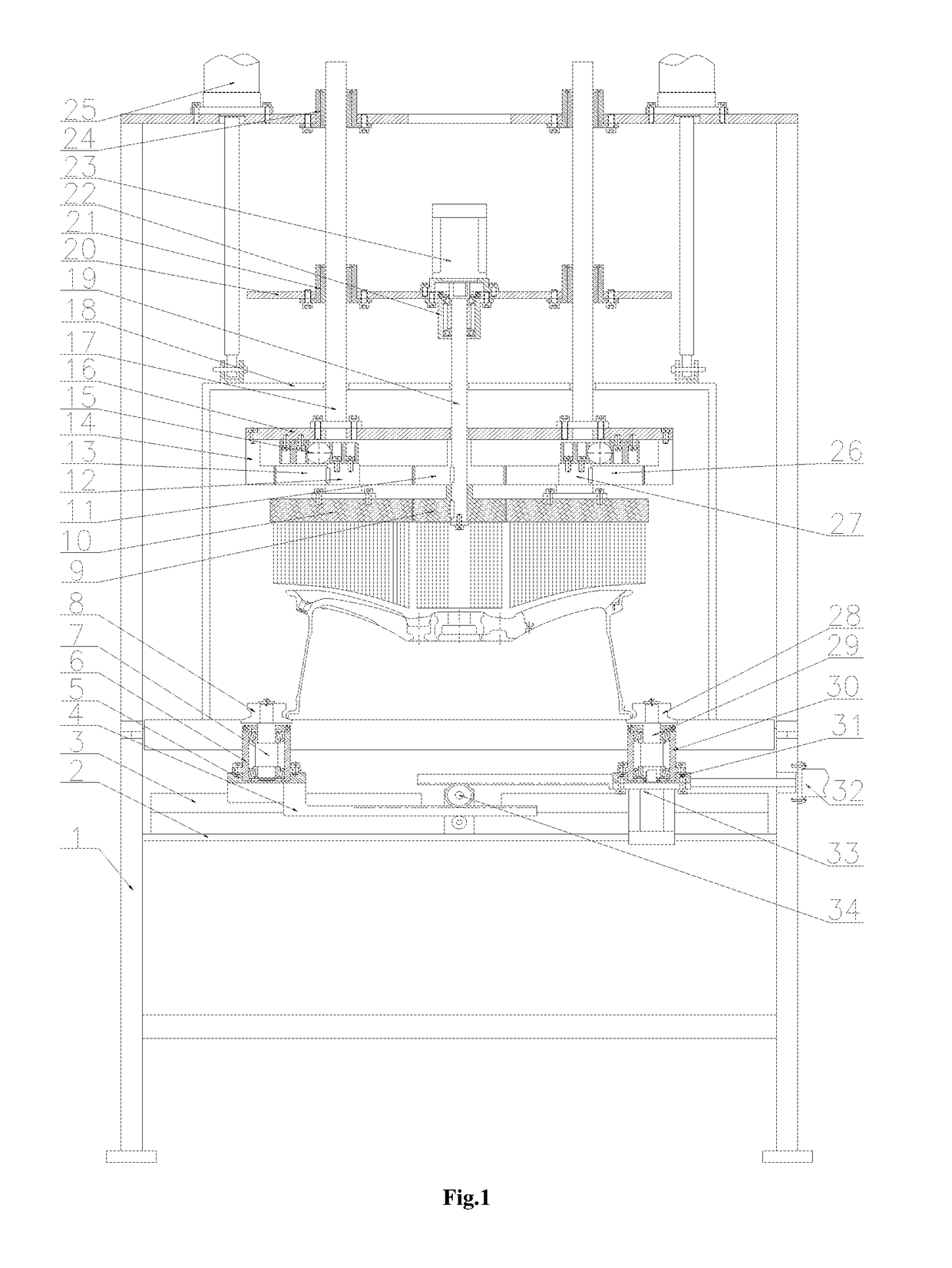

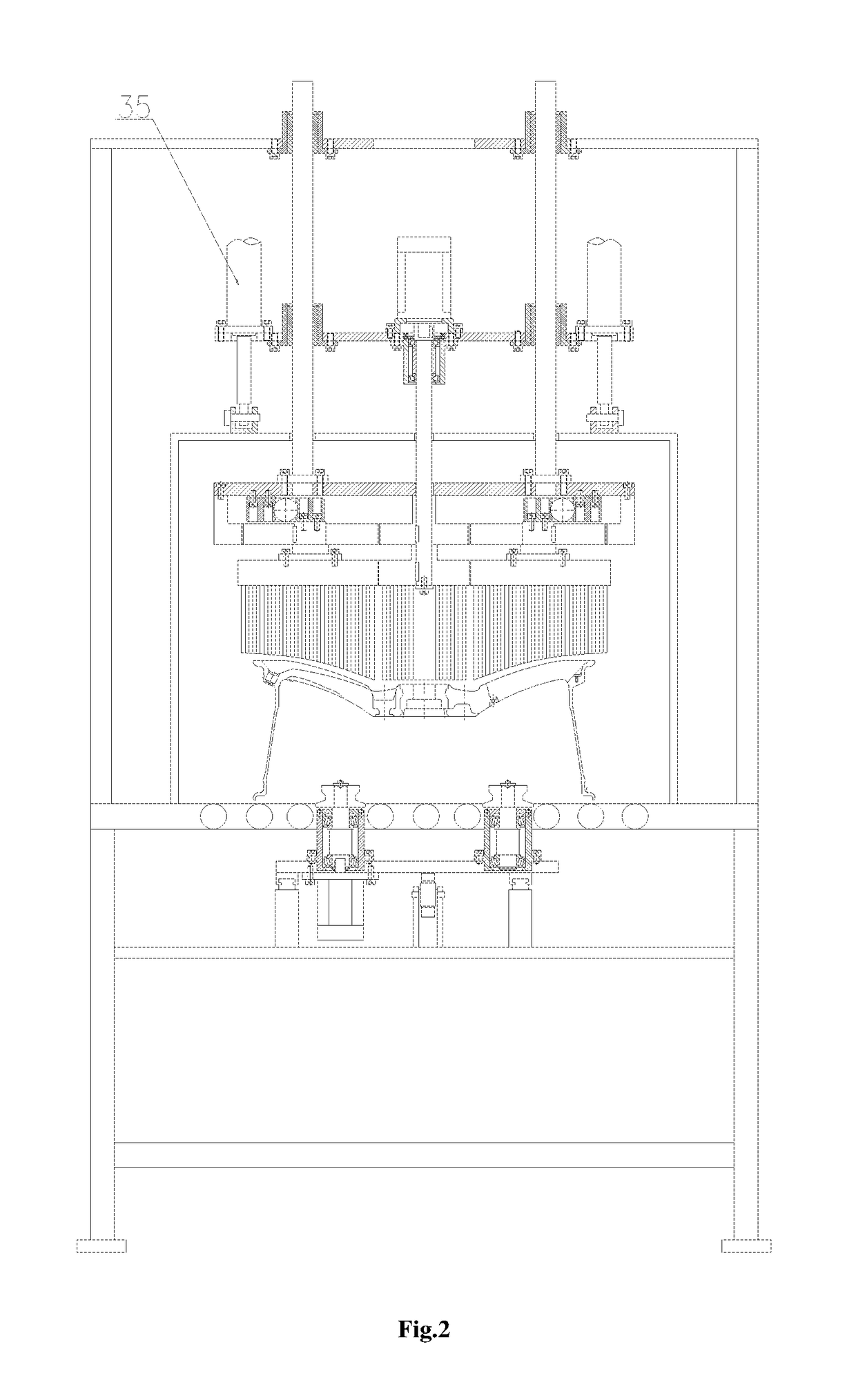

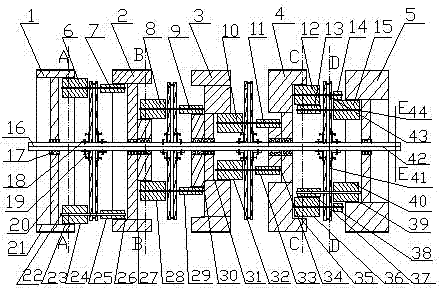

Coal cutter and rocker arm transmission system thereof

InactiveCN102434155ALarge transmission ratioReduce speedToothed gearingsDriving meansGear wheelEngineering

The invention relates to the field of mining machinery, and discloses a coal cutter and a rocker arm transmission system thereof. The rocker arm transmission system is arranged between a cutting roller and a cutting motor. The rocker arm transmission system comprises a first spur gear speed-reducing transmission part connected to the cutting motor, a second spur gear speed-reducing transmission part connected to the cutting roller, and a planet gear speed-reducing transmission part arranged between the first spur gear speed-reducing transmission part and the second spur gear speed-reducing transmission part. The rocker arm transmission system of the coal cutter has the advantage that the planet gear speed-reducing transmission part is arranged between the first spur gear speed-reducing transmission part and the second spur gear speed-reducing transmission part, and thus the rocker arm transmission system has a large transmission ratio; a rotating speed and a line speed of the cutting roller are reduced; a working face environment of the coal cutter is improved; a size of a structure cooperating with a cutting roller hub is reduced; the length of a cutting roller blade is increased; and coaling effects and coaling efficiency of a thin coal layer are improved.

Owner:SANY HEAVY EQUIP

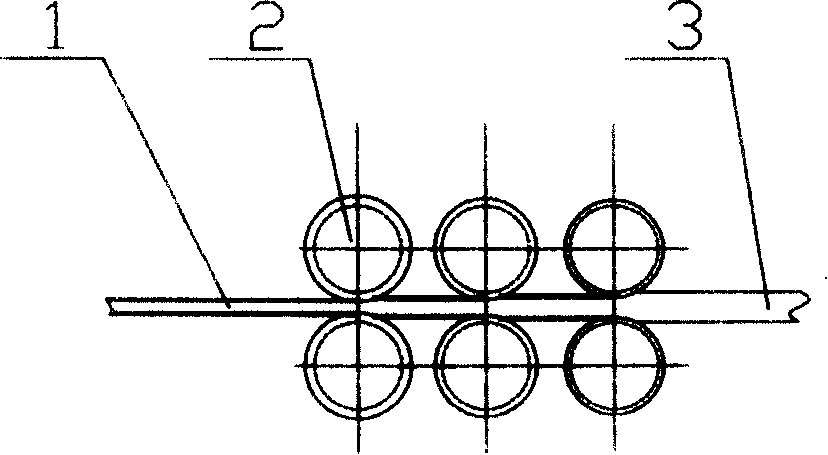

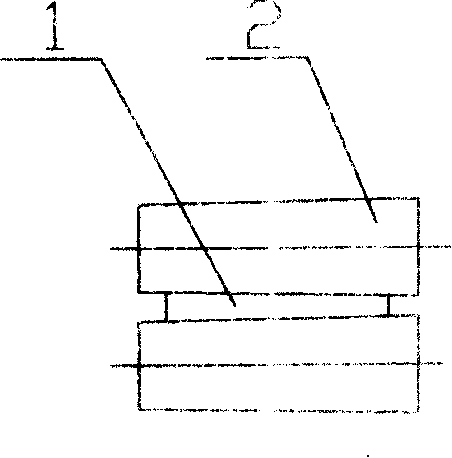

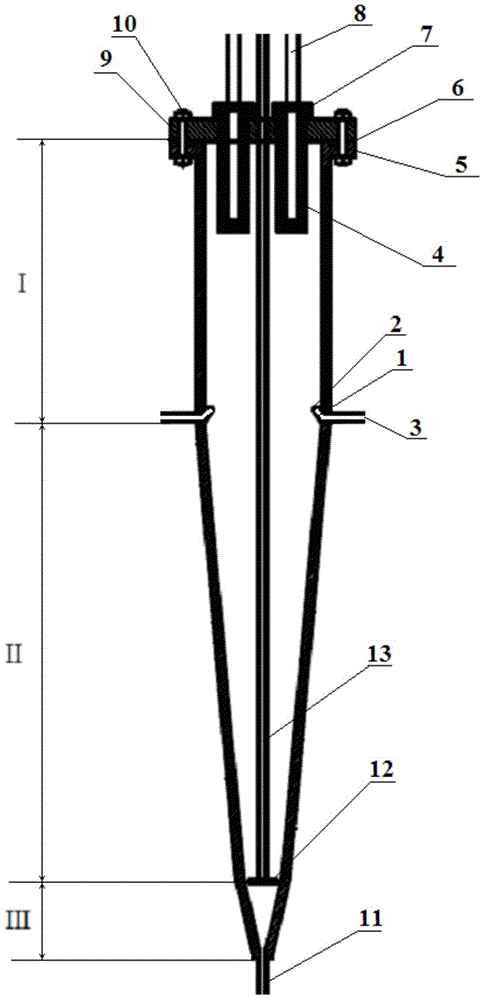

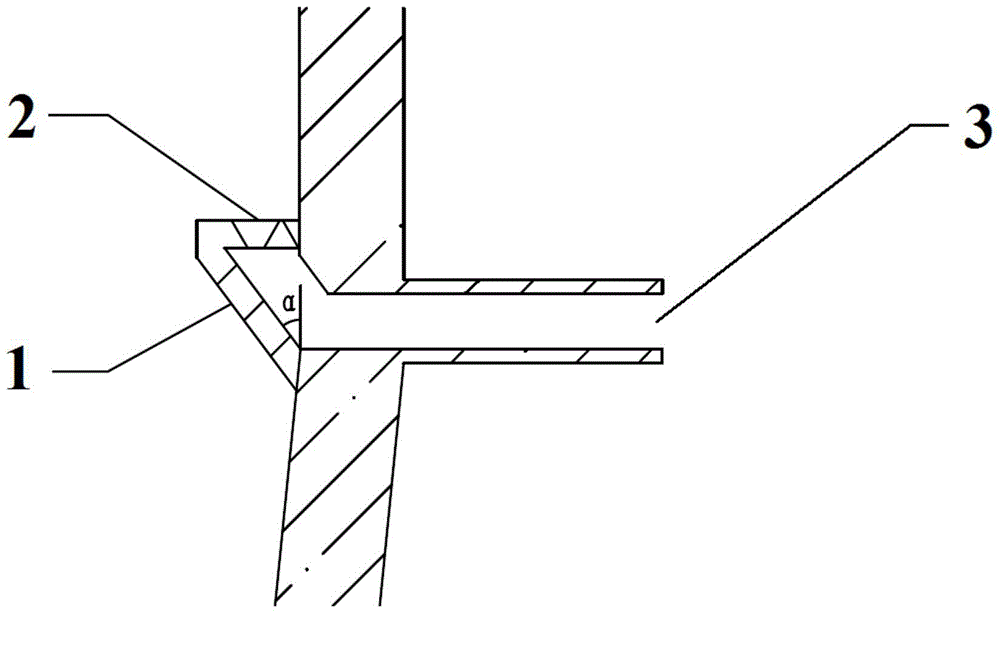

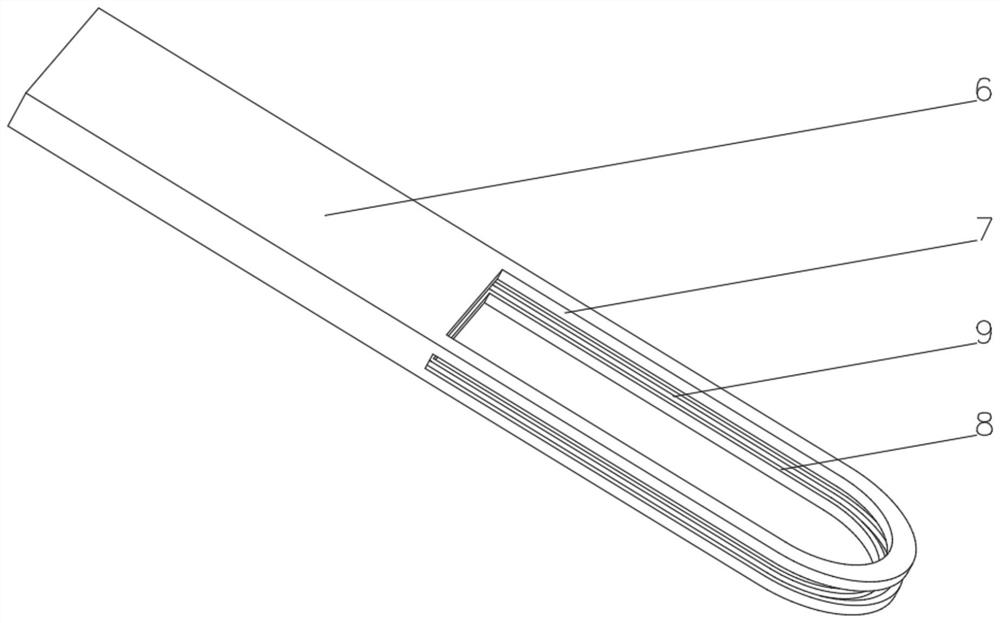

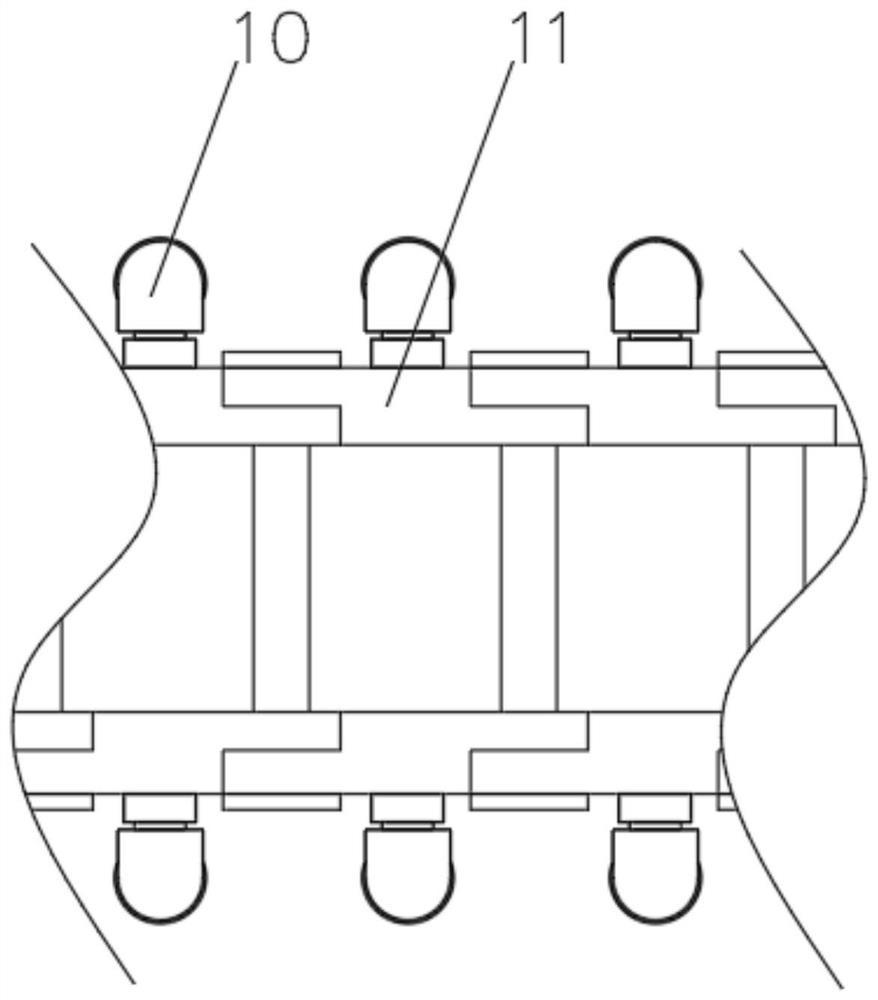

Process method and special device of helical blade

InactiveCN101204771AShorten processing timeImprove efficiencyShaping toolsExtrusion diesWinding machineHelical blade

The invention relates to a processing method and a specific device for a spiral blade. The processing method of the invention essentially adopts strip shaped materials to form through binding and enwinding. The specific device of the invention consists of a taper roller extruding press and a drag winding machine. An outlet of the taper roller extruding press is arranged correspondingly to an inlet of the drag winding machine. The taper roller extruding press comprises a frame, at least one pair of taper rollers ad a drive device. The conicity of the taper roller is 1 to 15 degrees. Two taper rollers are arranged in the same direction and the axes are in an included angle of 1 to 10 degrees. The bigger head parts of the rollers have a small gap and the drive device is connected with the rollers. The drag winding machine comprises a frame, a rotary shaft, three drag rollers uniformly arranged at the circumferential direction of the rotary shaft and a drive device. The drag rollers are provided with V-shaped slot. The axes of the three drag rollers are parallel to the rotary shaft and arranged in an equal distance on height. The rotating directions of the rotary shaft and the three drag rollers are opposite. The invention omits a plurality of working procedures, improving the efficiency and has a high product precision.

Owner:王琪

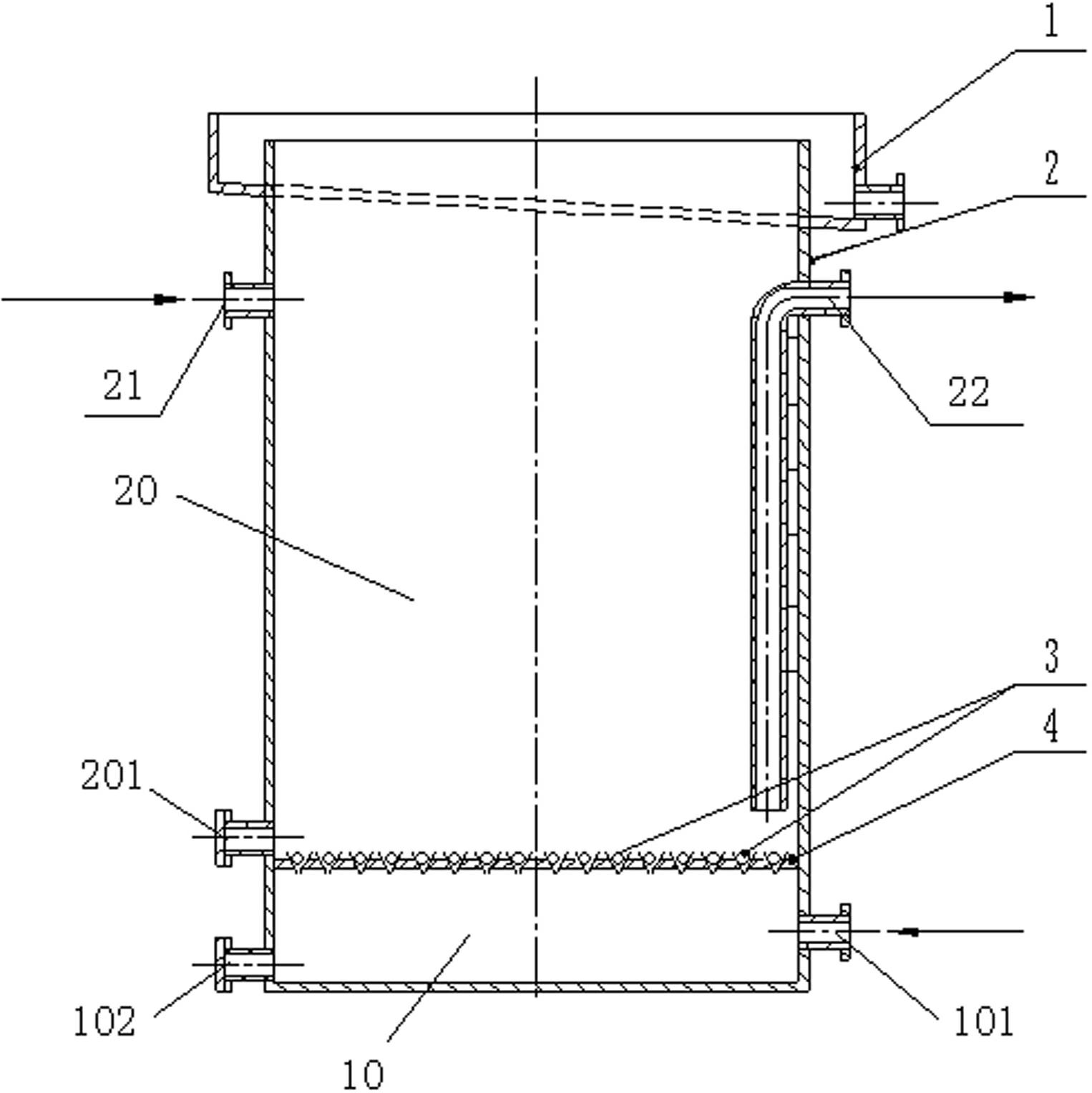

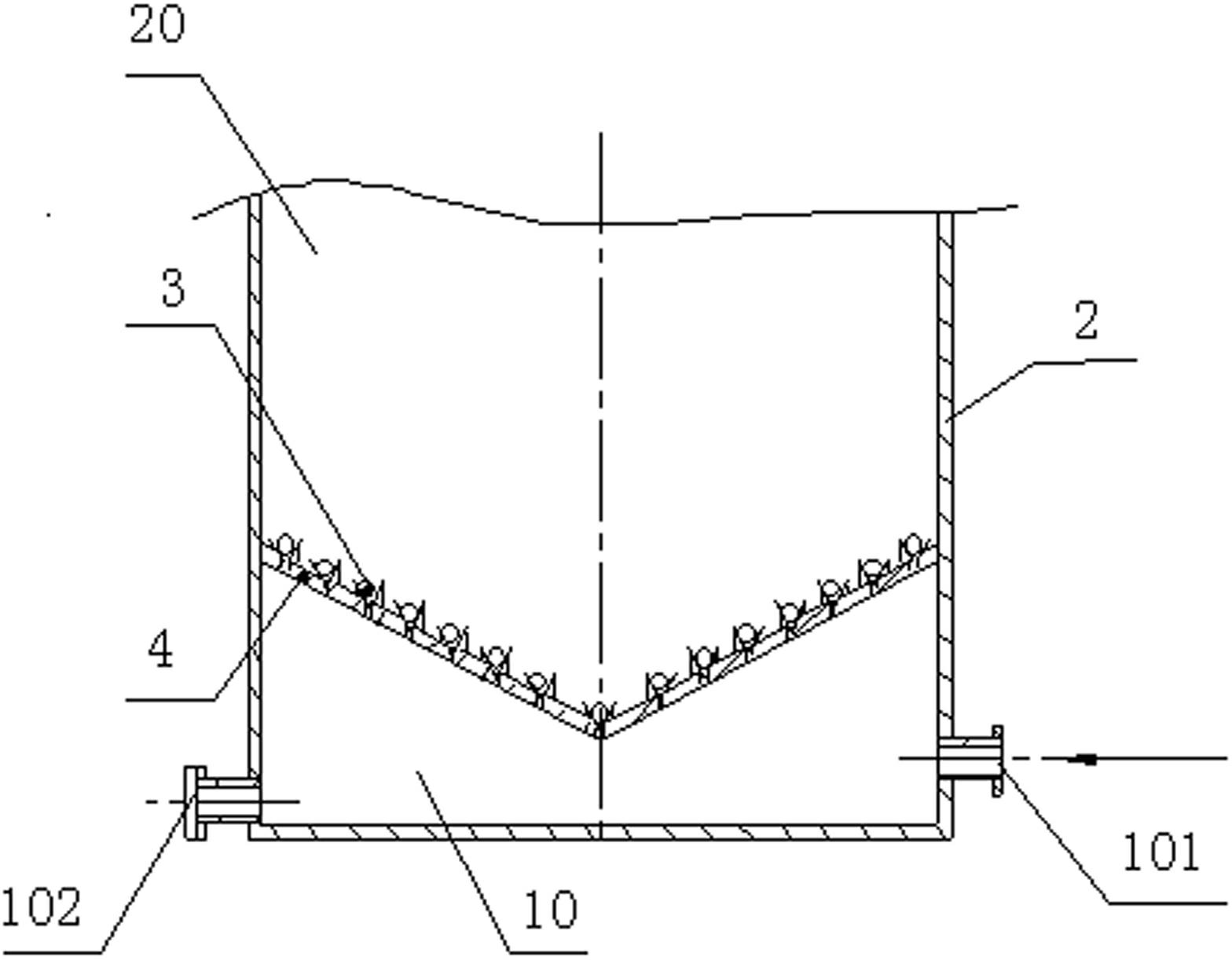

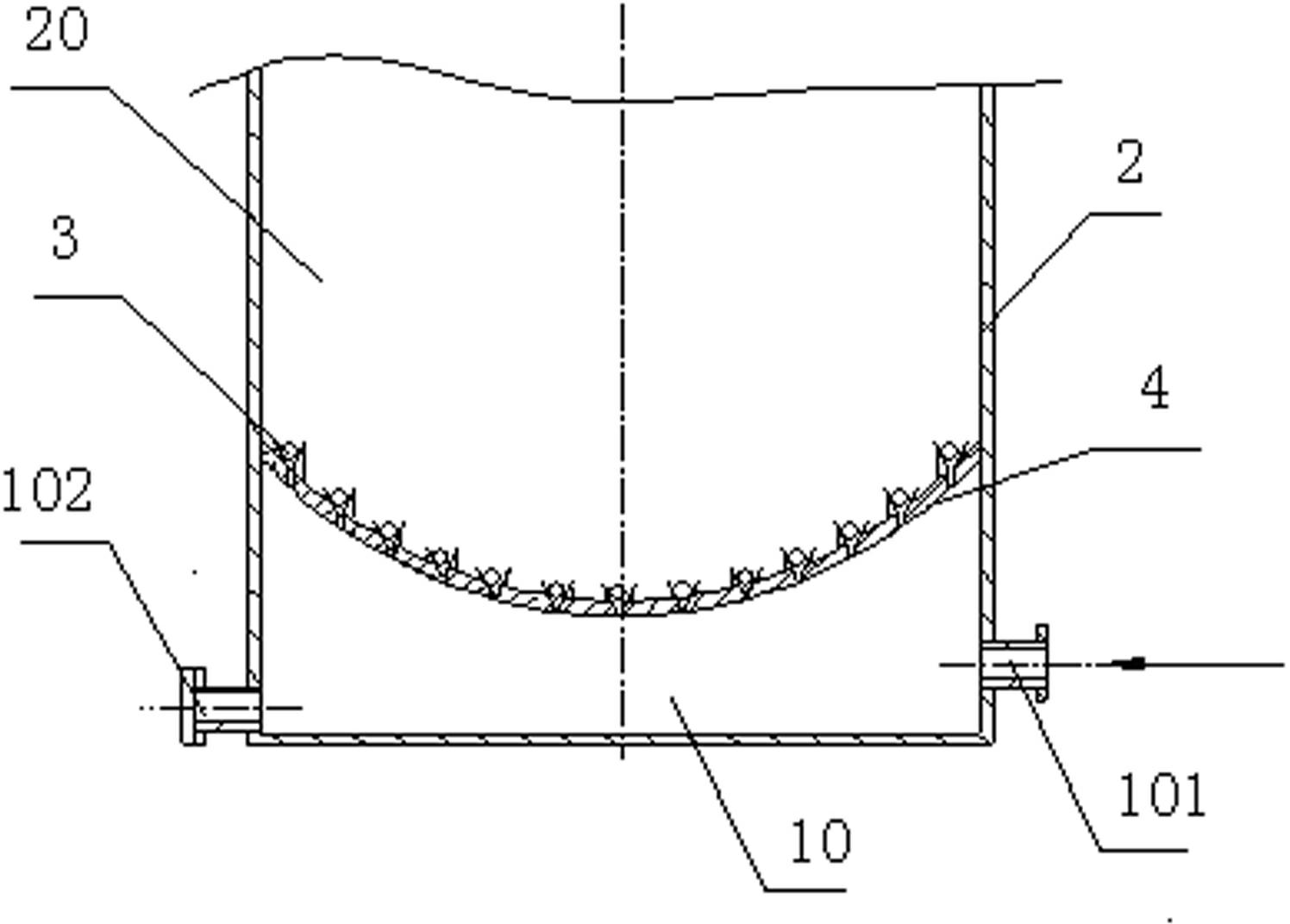

Fixed fluidized bed reactor and using method thereof

ActiveCN104549071AEnhanced inhibitory effectGood carburizing abilityChemical/physical processesNuclear engineeringFluidized bed

The invention discloses a fixed fluidized bed reactor and a using method thereof. The fixed fluidized bed reactor comprises a top sealing structure and a reactor main body, as well as an outlet pipe and a feeding pipe which are communicated with the reactor main body, wherein the reactor main body comprises a settling section, a reaction section and an oiling agent initial contact section from top to bottom, wherein a coking inhibitor injecting part is arranged at the bottom of the settling section, the coking inhibitor injecting part comprises a frustum-shaped baffle plate arranged in the circumferential direction of the inner wall of the bottom of the settling section, an annular filter plate for connecting the top of the frustum-shaped baffle plate with the inner wall of the reactor main body, and a coking inhibitor injecting hole, a cavity is formed among the frustum-shaped baffle plate, the annular filter plate and the inner wall of the reactor main body, and the coking inhibitor injecting hole is communicated with the cavity. By adopting the fixed fluidized bed reactor disclosed by the invention, a coking inhibitor is injected through the coking inhibitor injecting part, so that the yield of coke can be remarkably reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

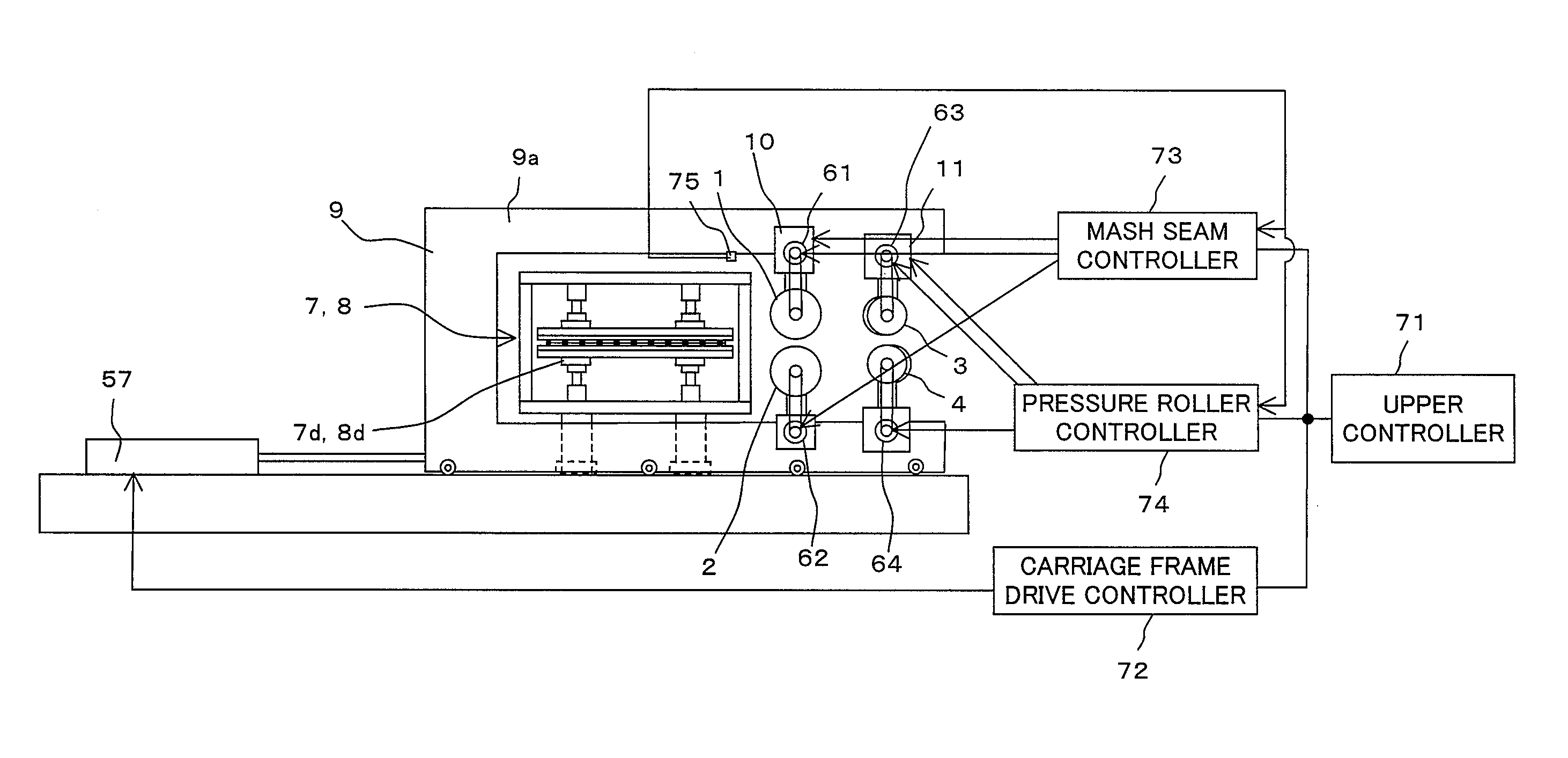

Mash seam welding method and apparatus

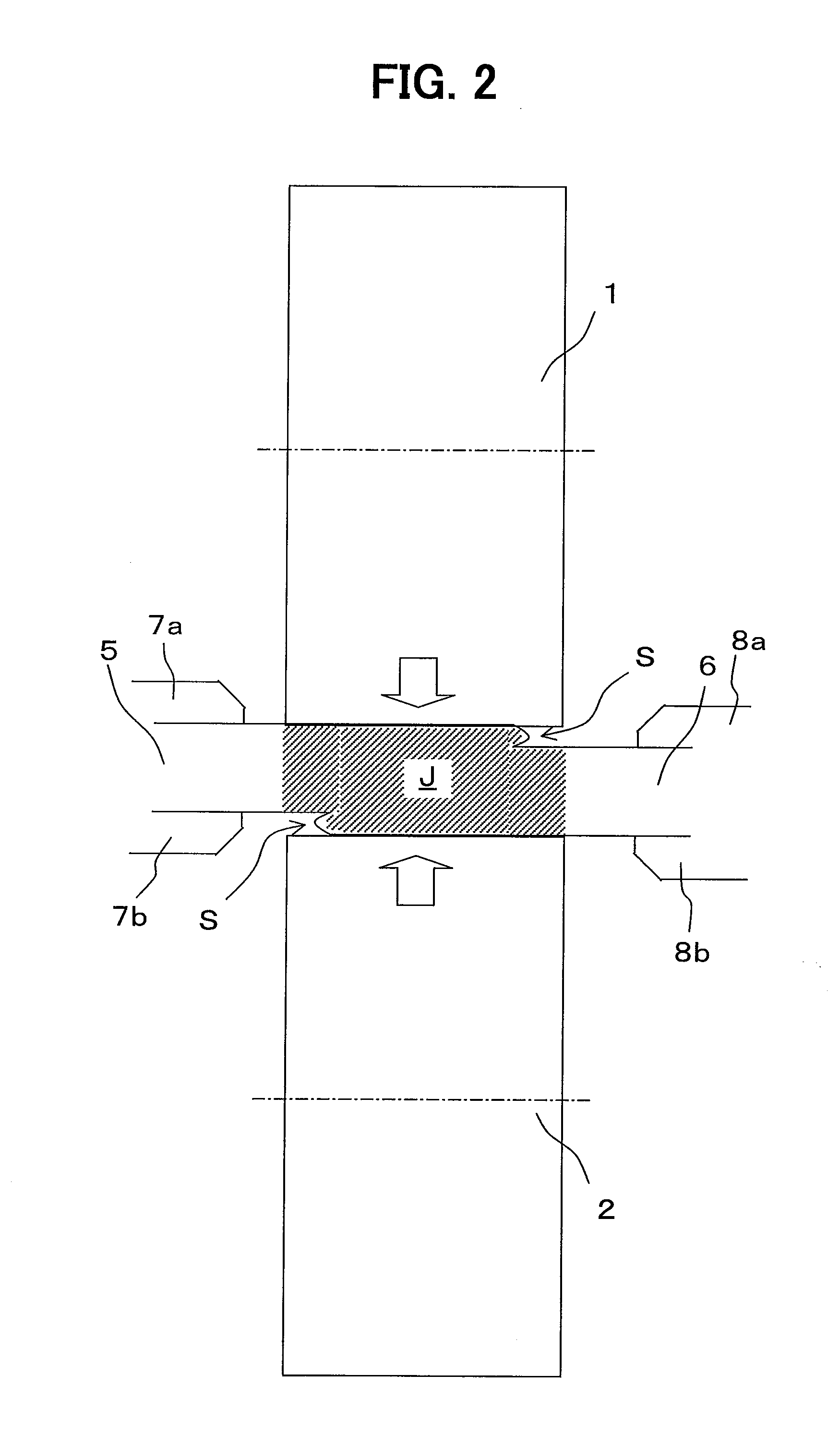

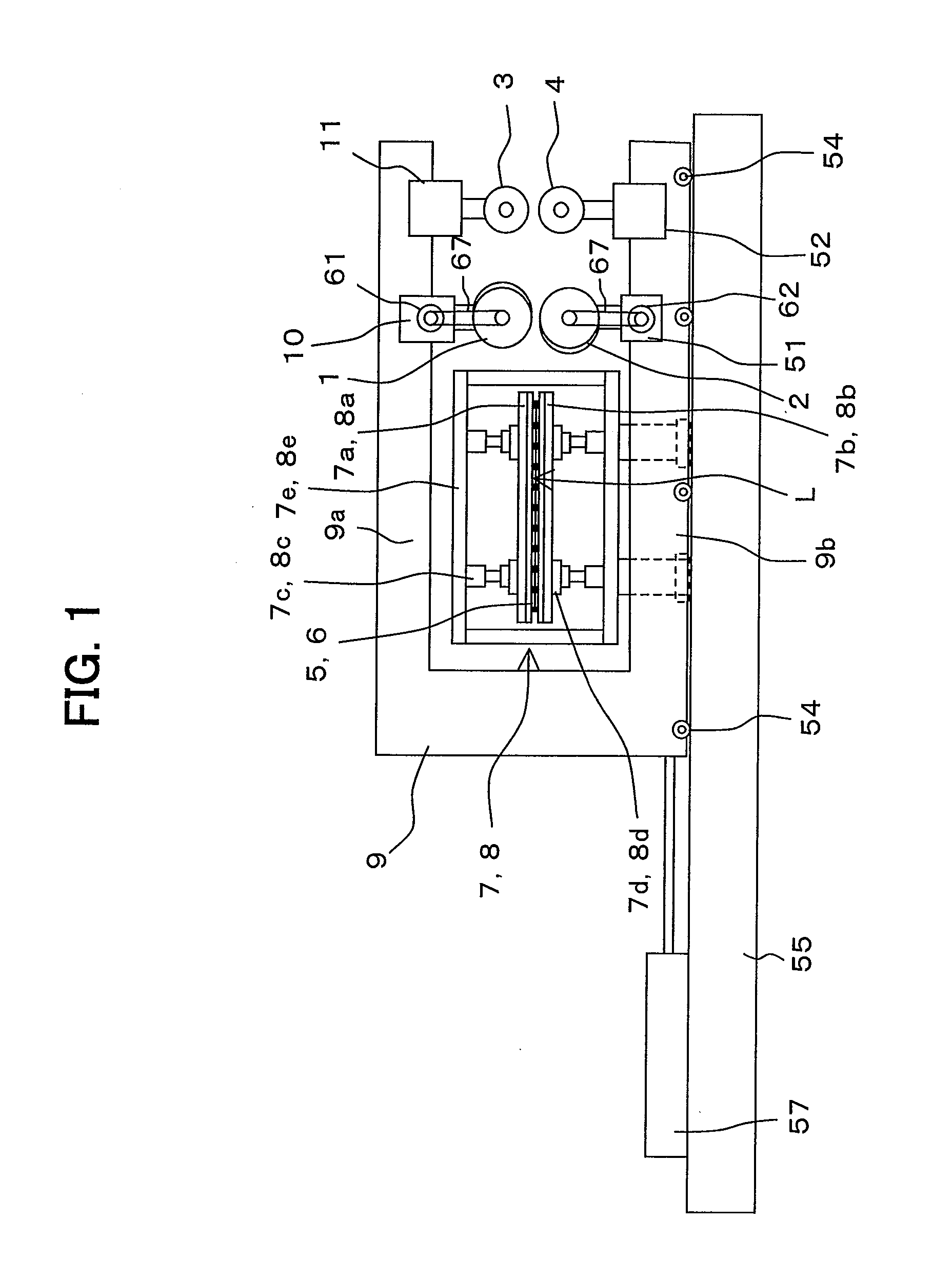

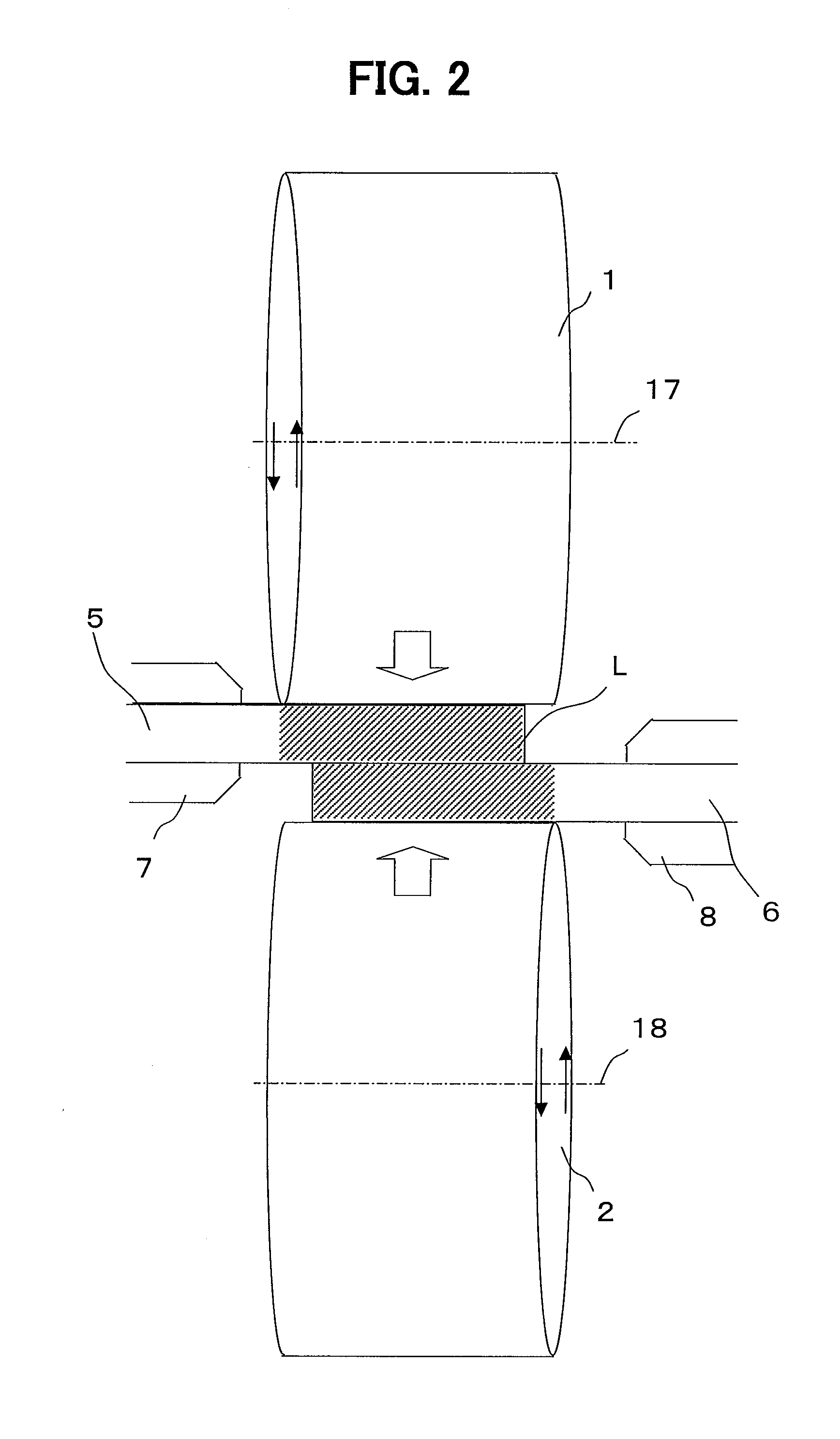

InactiveUS20110120979A1Reduce thicknessHigh degreeWelding/cutting auxillary devicesRectilinear seam weldingStress concentrationSeam welding

A pair of upper and lower electrode wheels 1, 2 are disposed so that their axes 17, 18 are tilted in a horizontal plane in respective directions opposite to each other with respect to a straight line Y perpendicular to a welding line X defined on overlapping portions (L) of two metal plates 5, 6, and mash seam welding is performed while positively driving electric motors 61, 62. This can reduce the increased amount of thickness and step gradient of a joint portion to reduce a stress concentration factor and ensure joint strength. The metal plates are joined to each other such that a nugget N is not deviated from a joint interface. Therefore, it is possible to prevent respective ends of the metal plates at the overlapping portions L from biting into and scratching the corresponding electrode wheels 1, 2 and to prevent spattering during the welding.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

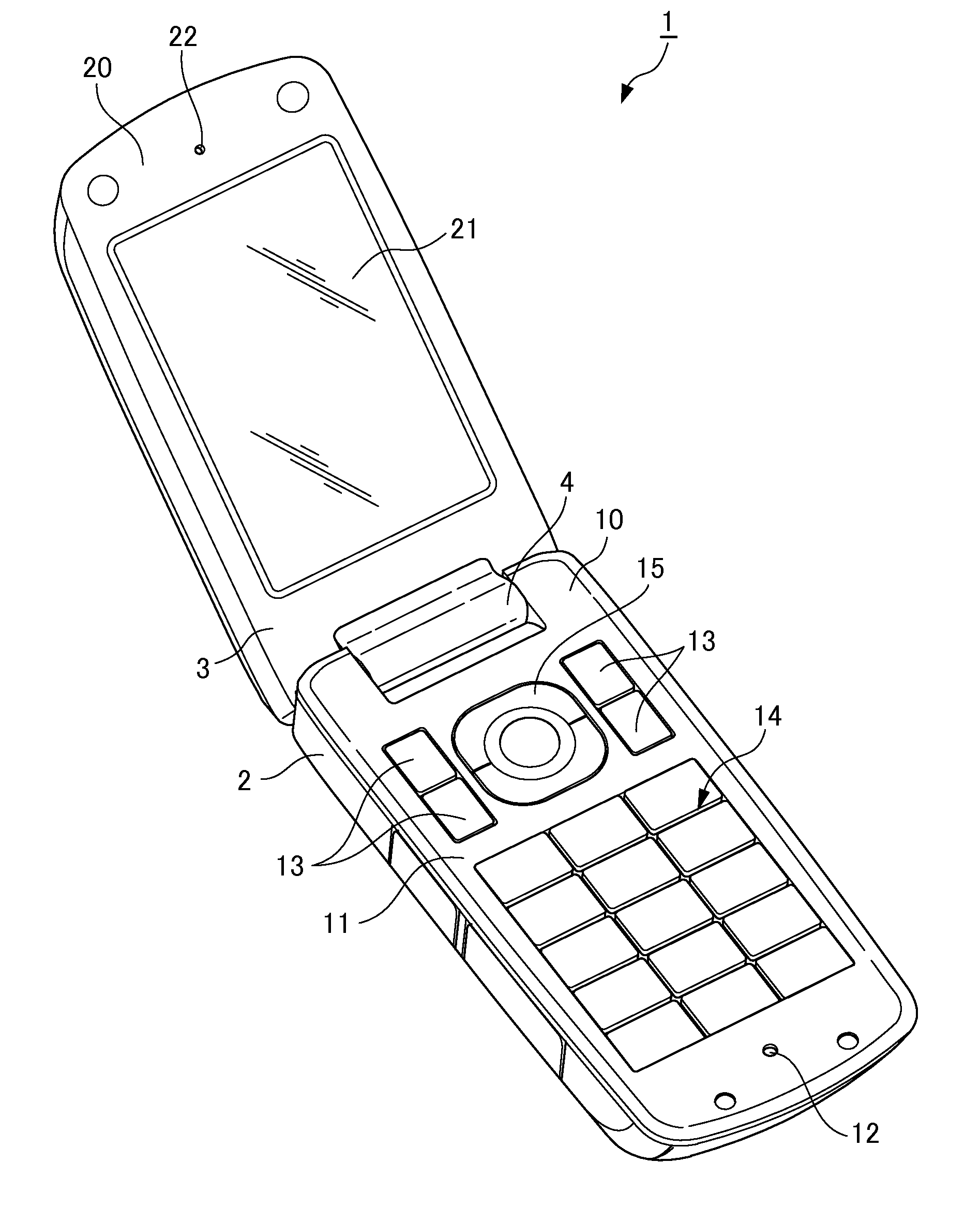

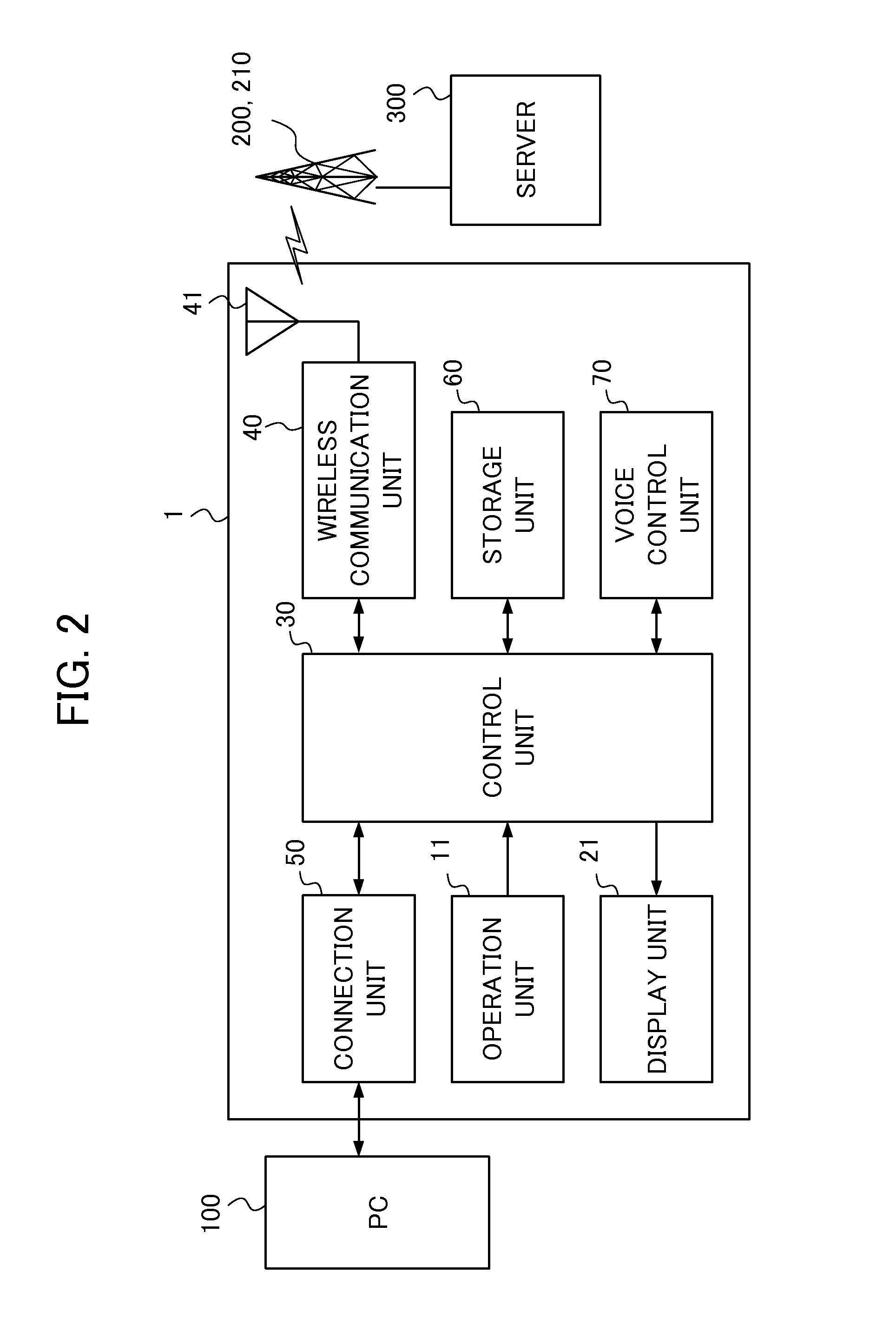

Wireless Communication Device and Control Method Thereof

InactiveUS20120320829A1Improve throughputLoss of dataNetwork traffic/resource managementWireless network protocolsLow speedTelecommunications

To provide a wireless communication device that can suppress data loss due to reduction in line speed in accordance with hand-down, to thereby improve throughput, and a control method thereof. A cellular telephone device 1 that is connected to a PC 100 and provides data packets received from a server 300 via wireless communication to the PC 100, includes: a wireless communication unit 40 that can establish data communication by connecting to the server 300 both in LTE and CDMA2000_1x that is of lower speed than LTE; and a control unit 30 that, in a case in which, during communication by the wireless communication unit 40 using LTE, communication is handed down to CDMA2000_1x due to reduction in communication quality to a first threshold, reduces an RWIN to be notified to the server 300 from the size before hand-down.

Owner:KYOCERA CORP

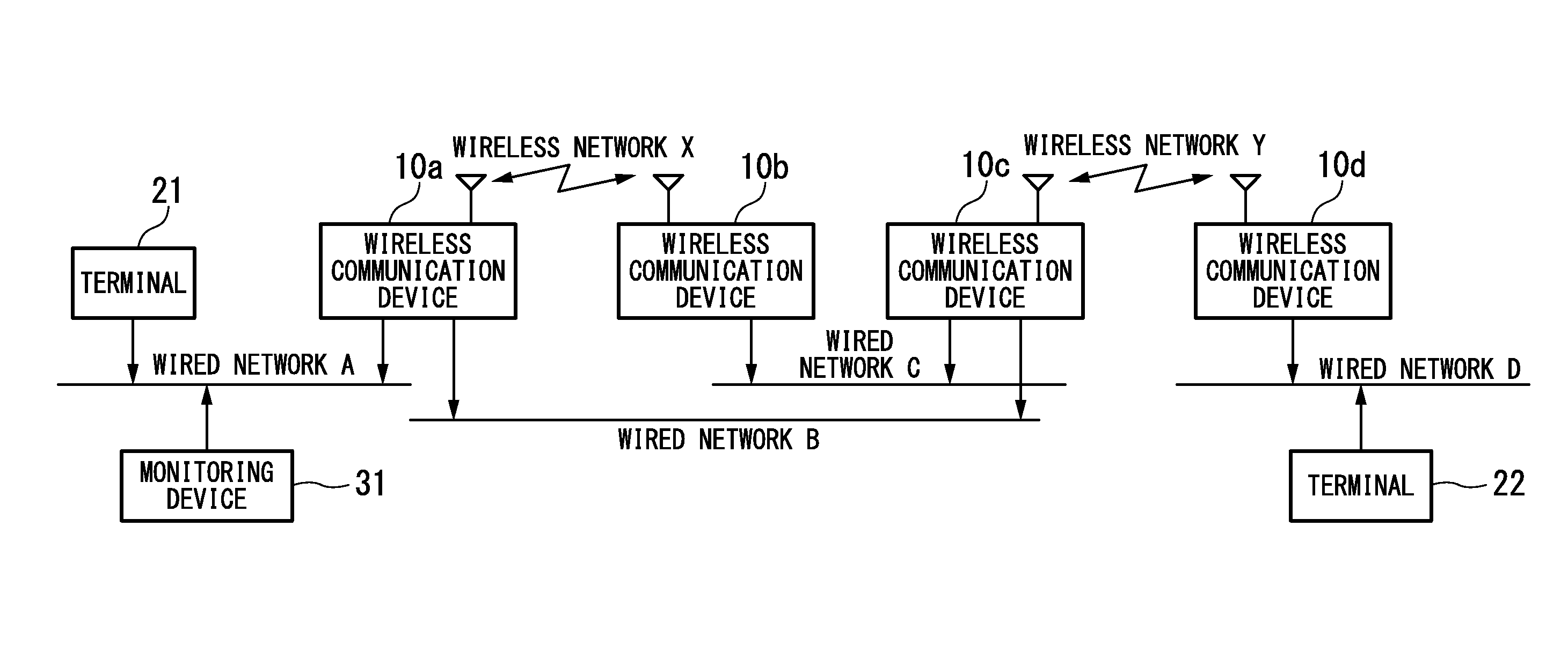

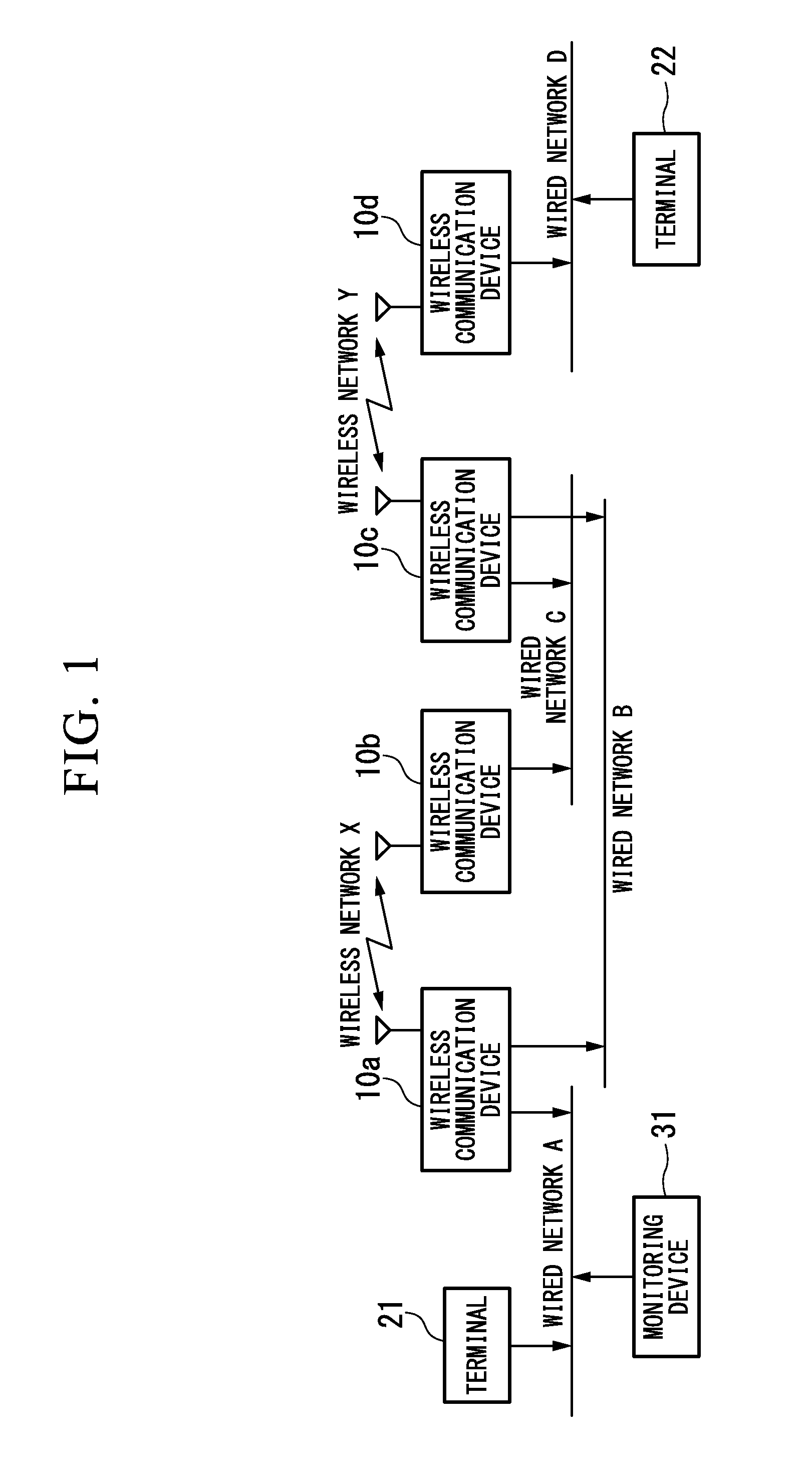

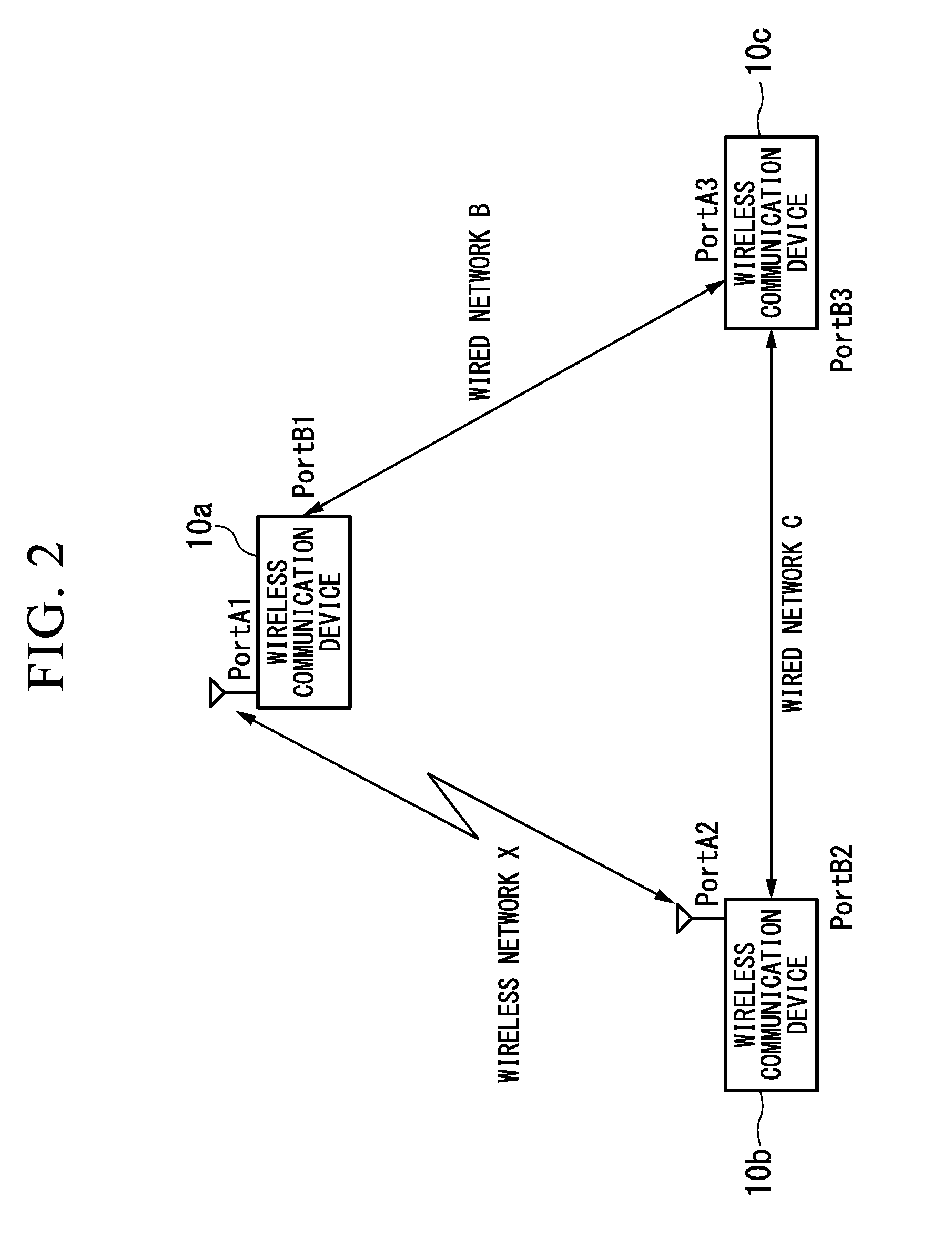

Stp pathway control system applied to wireless communication device having amr function

ActiveUS20130308437A1Solve insufficient capacityReduce line speedFrequency-division multiplex detailsTransmission systemsTelecommunicationsSelf adaptive

A pathway control system, implementing control and setting for a communication pathway between wireless communication devices each implementing wired communication and wireless communication and each equipped with an AMR function, detects communication speed with respect to uplink wireless communication and downlink wireless communication in each wireless communication device, thus determining which one of uplink wireless communication and downlink wireless communication undergoes communication failure. It carries out adaptive modulation control on uplink wireless communication or downlink wireless communication, which undergoes communication failure, calculates new communication speed, and carries out STP pathway control based on new communication speed. Irrespective of a reduction of line speed due to activation of an AMR function, it is possible to automatically switch to redundant pathways by way of STP pathway control; it is possible to prevent momentary disconnection of wireless communication; and it is possible to maintain an adequate capacity for communication pathways.

Owner:NEC CORP

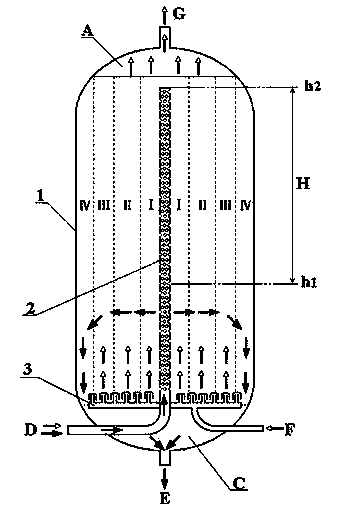

Radial flow-type residual oil hydrotreating reactor

ActiveCN103805234ASolve the problem that the radial flow residual oil hydrogenation reaction process cannot be realizedThe reaction space velocity is constantHydrocarbon oil crackingHydrocarbon oils refiningHydrogenation reactionFixed bed

The invention discloses a radial flow-type fixed bed residual oil hydrotreating reactor. The reactor of the present invention mainly comprises members of a housing, a central shaft oil inlet pipe, and a bottom hydrogen distribution disc; in a residual oil hydrogenation reaction process, raw oil mainly flows in a reaction diameter direction in a catalyst bed layer, and reaction supplemented hydrogen flows from bottom to top. The residual oil hydrogenation device of the invention has good operation flexibility, can realize synchronous inactivation of various catalysts, effectively prolongs the running period of the device, and makes full use of the active resources of residual oil hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

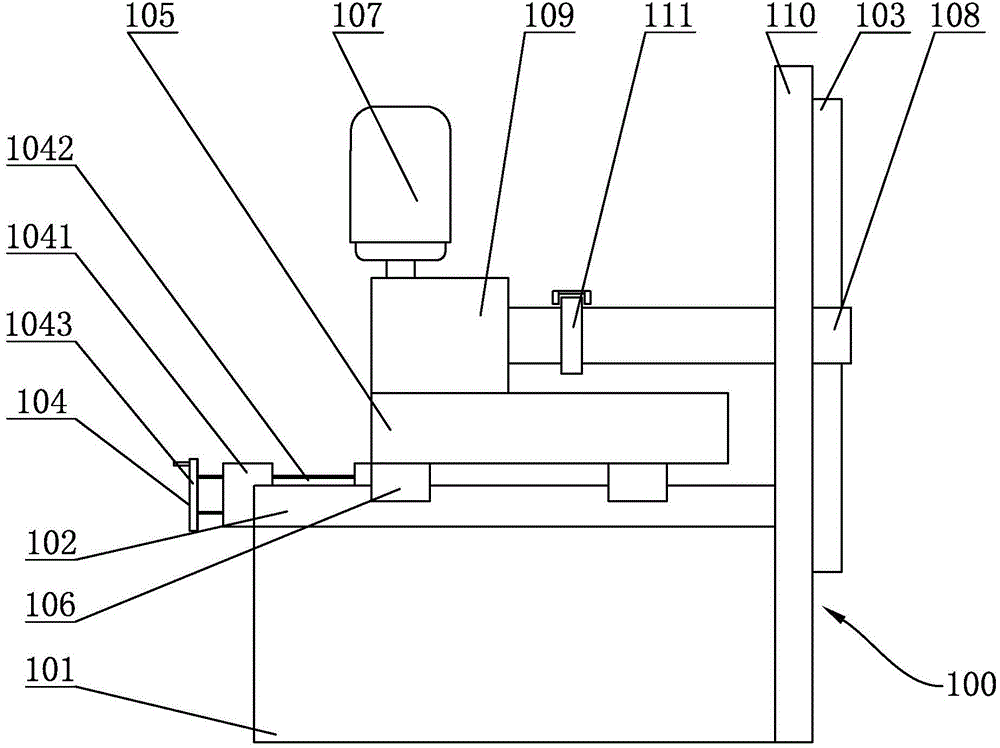

Machining device of square tubes made of thin-wall strips

InactiveCN104625753AEasy to weldEasy to weld and formOther manufacturing equipments/toolsEngineeringLubricant

The invention discloses a machining device of square tubes made of thin-wall strips and belongs to the technical field of square tube forming equipment. According to the strip conveying direction, the machining device mainly comprises a strip decoiling device, a primary buffering device, an active strip conveying device, a secondary buffering device, a strip surface lubricant coating device, a forming device, a tube blank shaping device, a high-frequency welding device, a post-welding cooling device, a surface residual liquid removing device, a square tube shaping device and a cutting device which are arranged in sequence. The machining device solves the technical problems that existing thin-wall square tubes are poor in forming quality and low in production efficiency, and the machining device is widely applied to manufacturing the thin-wall square tubes.

Owner:佛山市九钢制管有限公司

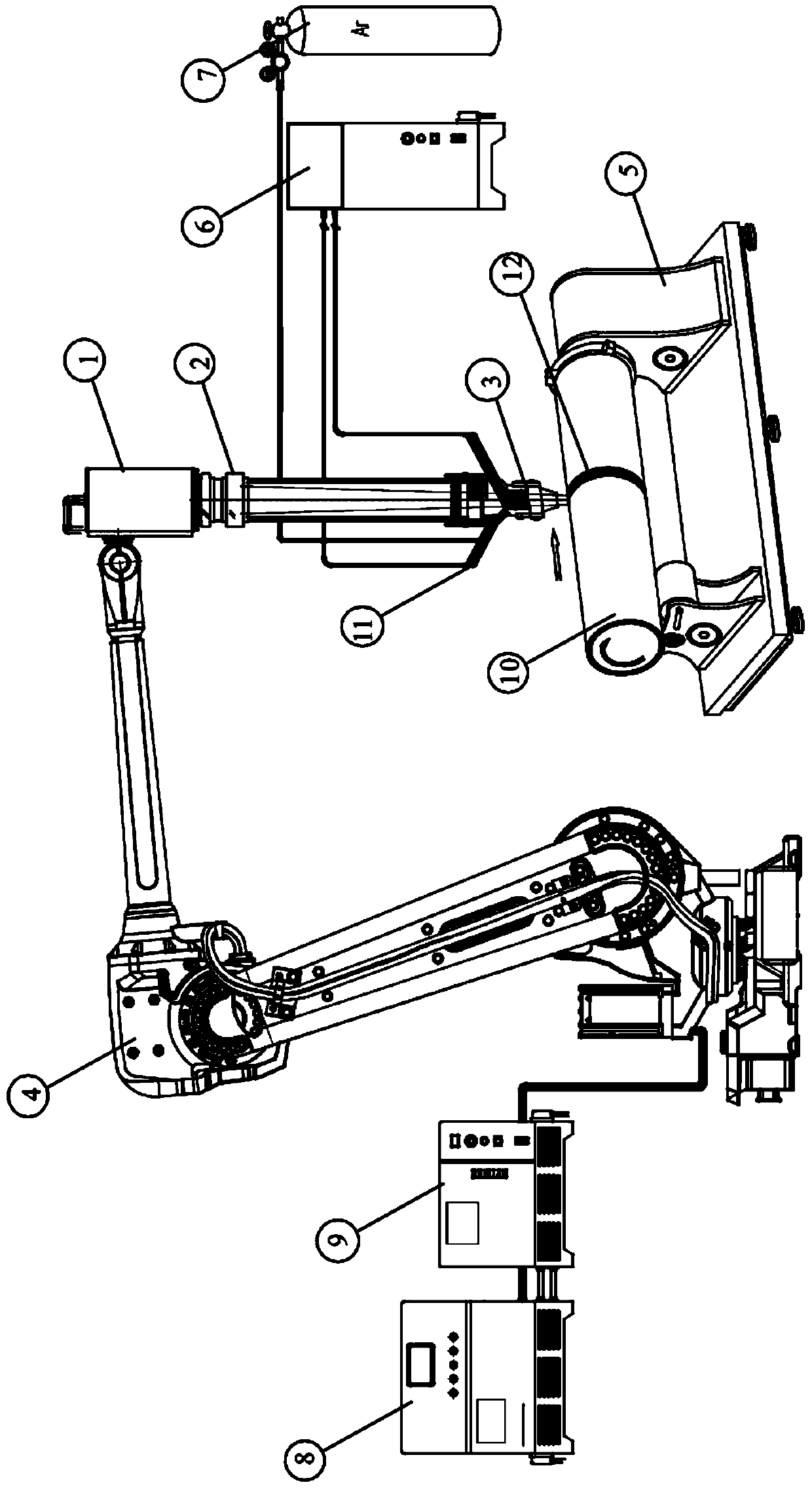

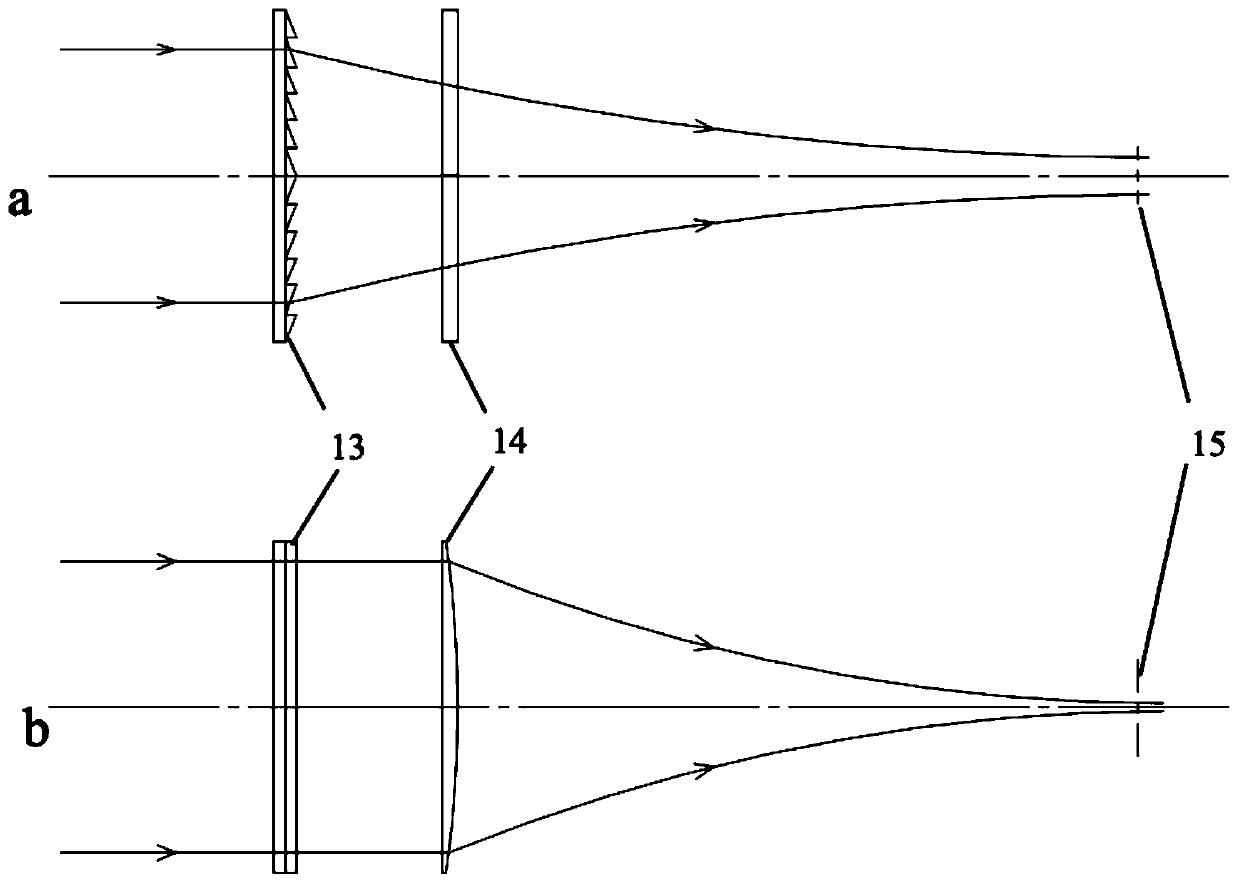

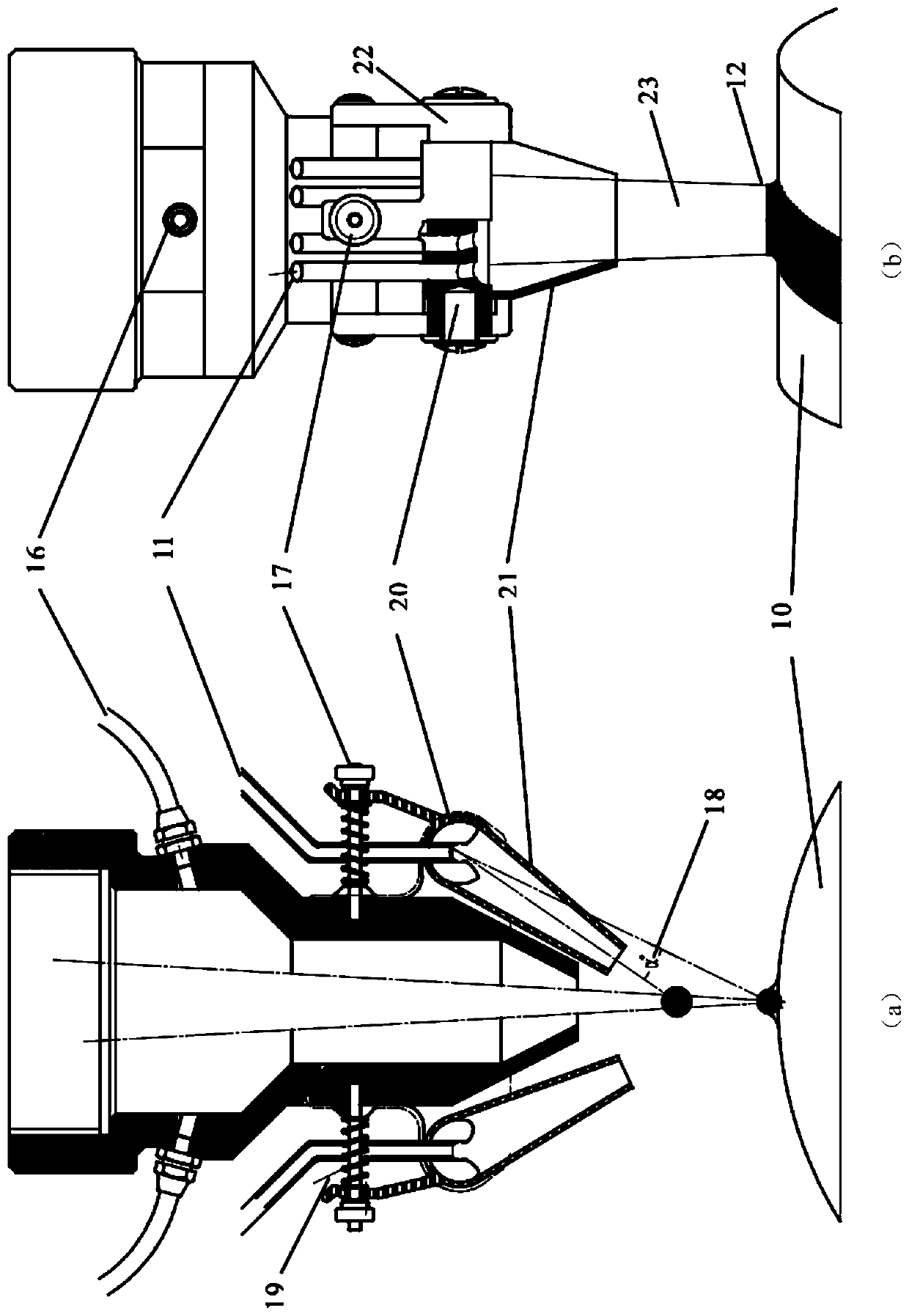

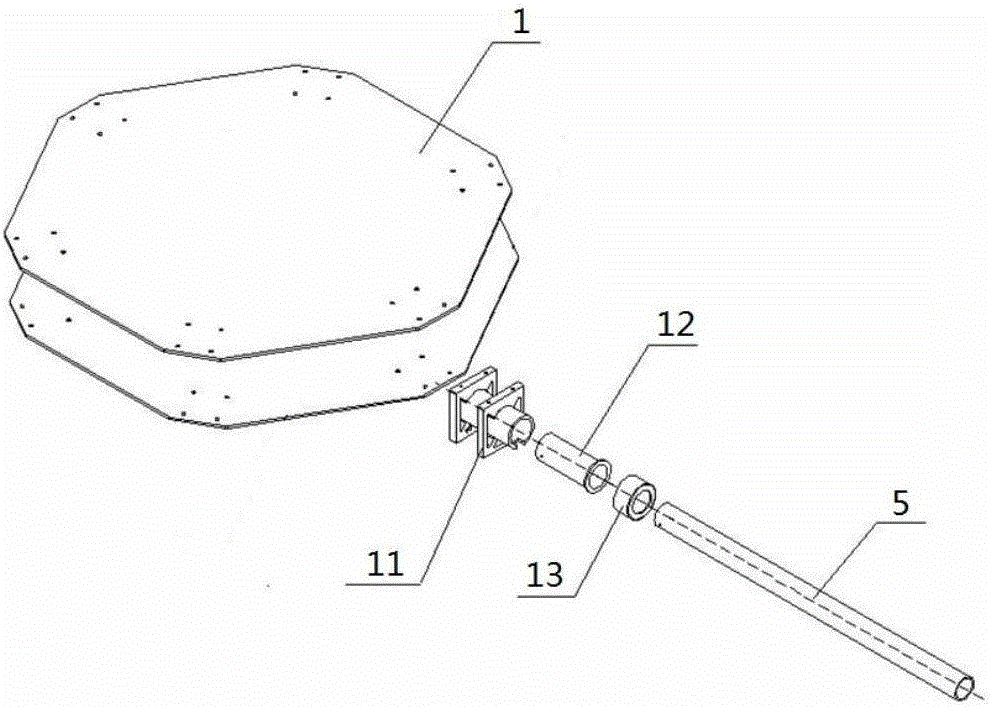

Fast and efficient semiconductor laser cladding device with wide light beam and adjustable powder feeding angle

ActiveCN110144583AIncrease single pass cladding areaReduce the burden of rotationMetallic material coating processesLaser lightSurface modification

The invention belongs to the technical field of laser surface modification, and discloses a fast and efficient semiconductor laser cladding device with a wide light beam and an adjustable powder feeding angle. The fast and efficient semiconductor laser cladding device with the wide light beam and the adjustable powder feeding angle comprises a semiconductor laser (1), a light beam shaping and Fresnel focusing system (2), an adjustable wide light band powder feeding head (3), a powder feeder (6), a high-speed machine tool (5), a six-axis linkage robot (4) and a central control system (9), wherein the light beam shaping and Fresnel focusing system (2) is used for shaping a laser light and focusing to form a wide-light-band laser light; the adjustable wide light band powder feeding head (3) is used for conveying powder and the wide-light-band laser light on the surface of a large-scale shaft type workpiece to be processed; and the diameter of a workpiece is larger than 1000mm, and the length of the workpiece is not lower than 10m. According to the fast and efficient semiconductor laser cladding device with the wide light beam and the adjustable powder feeding angle provided by the invention, through improving structures and arrangement manners of key components, outer surface strengthening and surface repairing can be carried out aiming at the large-scale shaft type workpieces such as petroleum pipelines, ocean facilities, natural gas conveying, mining and tunnel piercing, so that the wear resistance and the corrosion resistance of the surface are improved, and the service life is greatly prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

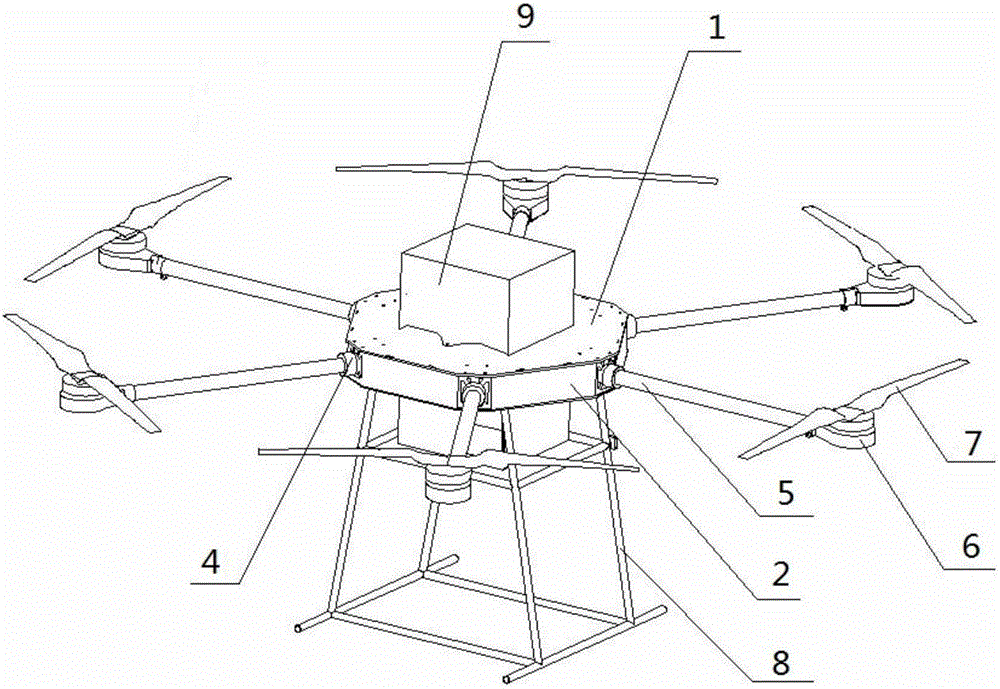

Six-rotor-wing unmanned aerial vehicle

PendingCN106741825AOptimize aircraft structureHeavy loadFuselage framesPropellersEngineeringMarine engineering

The invention provides a six-rotor-wing unmanned aerial vehicle. A fuselage cover plate is of a polygonal box type structure; a plurality of jib arm connecting parts are fixed in the fuselage cover plate and are located at all corners of the fuselage cover plate respectively. One end of each jib arm connecting rod is fixedly connected with the corresponding jib arm connecting part and a motor is mounted at the other end of each jib arm connecting rod. Batteries are arranged on a fuselage upper plate and a fuselage lower plate. According to the six-rotor-wing unmanned aerial vehicle, the effective load can reach 20kg or more every time; the six-rotor-wing unmanned aerial vehicle has the characteristics of long cruising duration, rapidness and convenience for dismounting and mounting a fuselage and a jib arm again, flexibility and convenience and wide environment adaptability.

Owner:西安三翼航空科技有限公司

System and method for performing high-speed communications over fiber optical networks

ActiveUS9337948B2Remove distortionImprove data throughputWavelength-division multiplex systemsDistortion/dispersion eliminationWaiting periodFiber network

Owner:SOTO ALEXANDER I +1

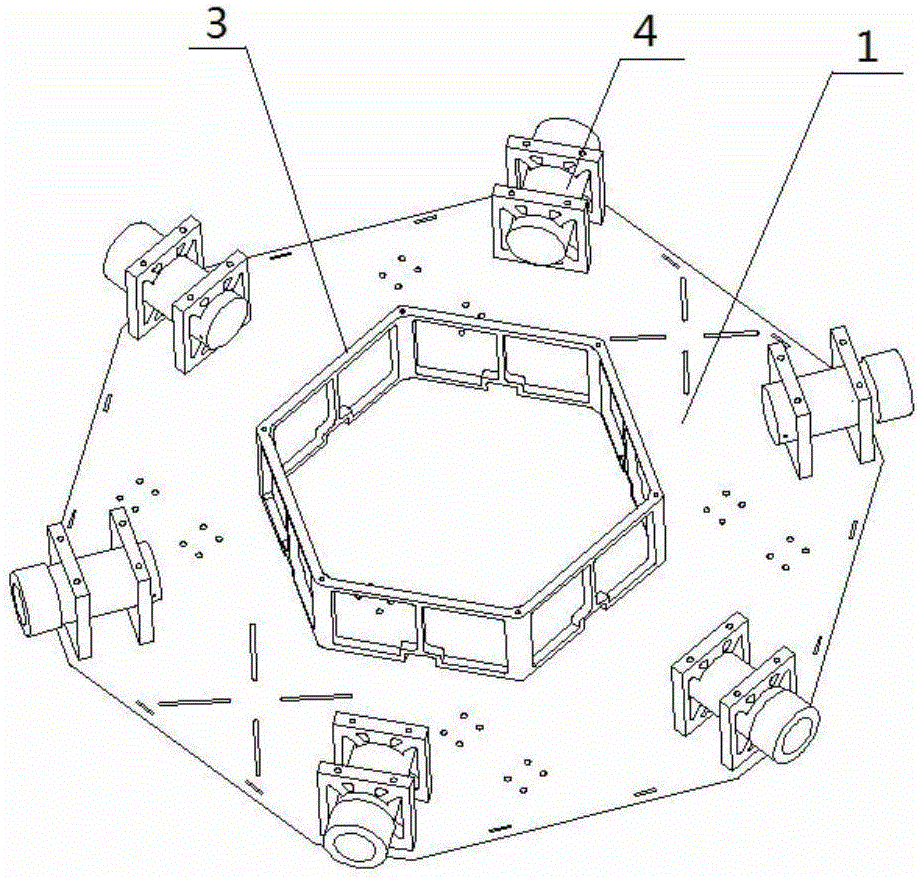

Device for burring front face of wheel

ActiveUS10022834B2High degree of automationSafe and stable performanceEdge grinding machinesPolishing machinesCircular discLow speed

The present invention relates to a device for burring a front face of a wheel. The device is composed of a rack, a motor, a guide rail, air cylinders, brushes and the like. A sensor enables the wheel to be positioned on a roller way, a clamping air cylinder drives left rolls and right rolls via synchronous gears and gear racks to clamp the wheel, a servo motor drives the wheel to rotate at relatively low speed under the clamped condition, and the rotation direction of the wheel is opposite to that of the brushes; the air cylinders I enable a dust cover to go down, and the motor drives a gear I and a central brush via a shaft II to rotate at relatively high speed; the gear I drives a gear II and a gear III to rotate simultaneously at slightly slow speed, so as to drive an outer ring brush to also rotate at relatively slow speed; and the air cylinders II drive the central brush and outer ring brush to go down, and burring can be performed once the central brush and outer ring brush contact the front face of the wheel. When in use, the device provided by the present invention can burr the central part and the spoke of the wheel at different rotation speeds, and the problem that the traditional big disc brush has low linear speed at the central position when rotating at fixed angular speed is avoided.

Owner:CITIC DICASTAL

Grinding and polishing device

PendingCN112405269AEasy to change the relative positionIncrease profitGrinding carriagesGrinding drivesDrive shaftElectric machinery

The invention discloses a grinding and polishing device. The device comprises a fixing base, wherein a support is fixedly connected to one side of the top of the fixing base, a driving motor is fixedly connected to the bottom of the support, a telescopic rod is fixedly connected to a driving shaft of the driving motor, a control panel is fixedly connected to the end, away from the driving motor, of the telescopic rod, a supporting rod is fixedly connected to the side face of the control panel, a sliding hole is formed in the top of the end, away from the control panel, of the supporting rod, asliding way is formed in the inner wall of the sliding hole, sliding grooves are formed in the two sides of the inner wall of the sliding way, and double-head slide wheels are slidably connected to the inner walls of the sliding grooves, one sides of the bottoms of the double-head slide wheels penetrate through the sliding grooves and extends into the sliding way, and the parts, located in the sliding way, of the double-head slide wheels are fixedly connected with toothed chains. The grinding and polishing device relates to the technical field of machining. The grinding and polishing device is high in polishing efficiency and safe and reliable to use, abrasive paper is firm in installation, not prone to falling off, high in utilization rate and is saved.

Owner:任峰

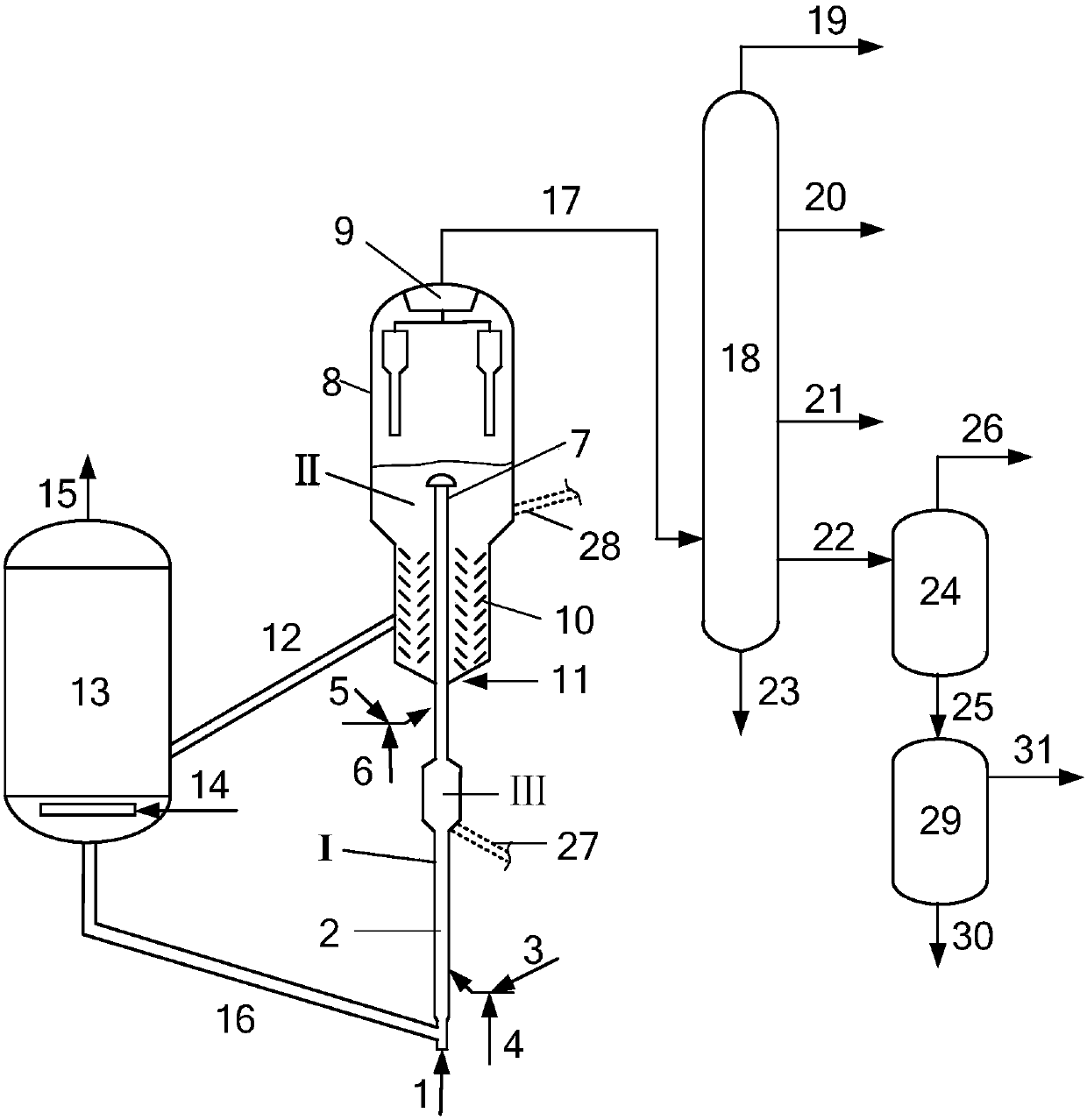

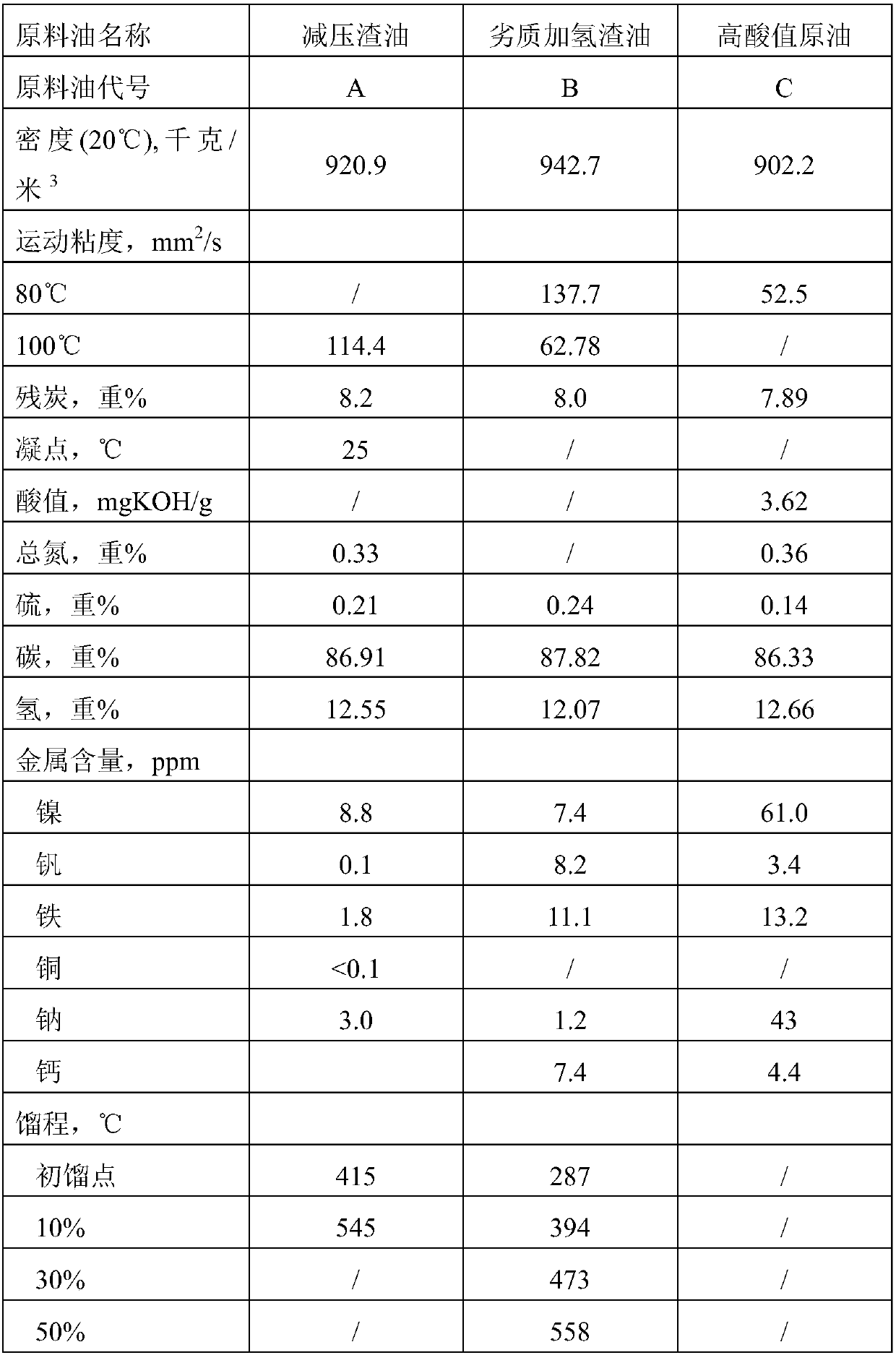

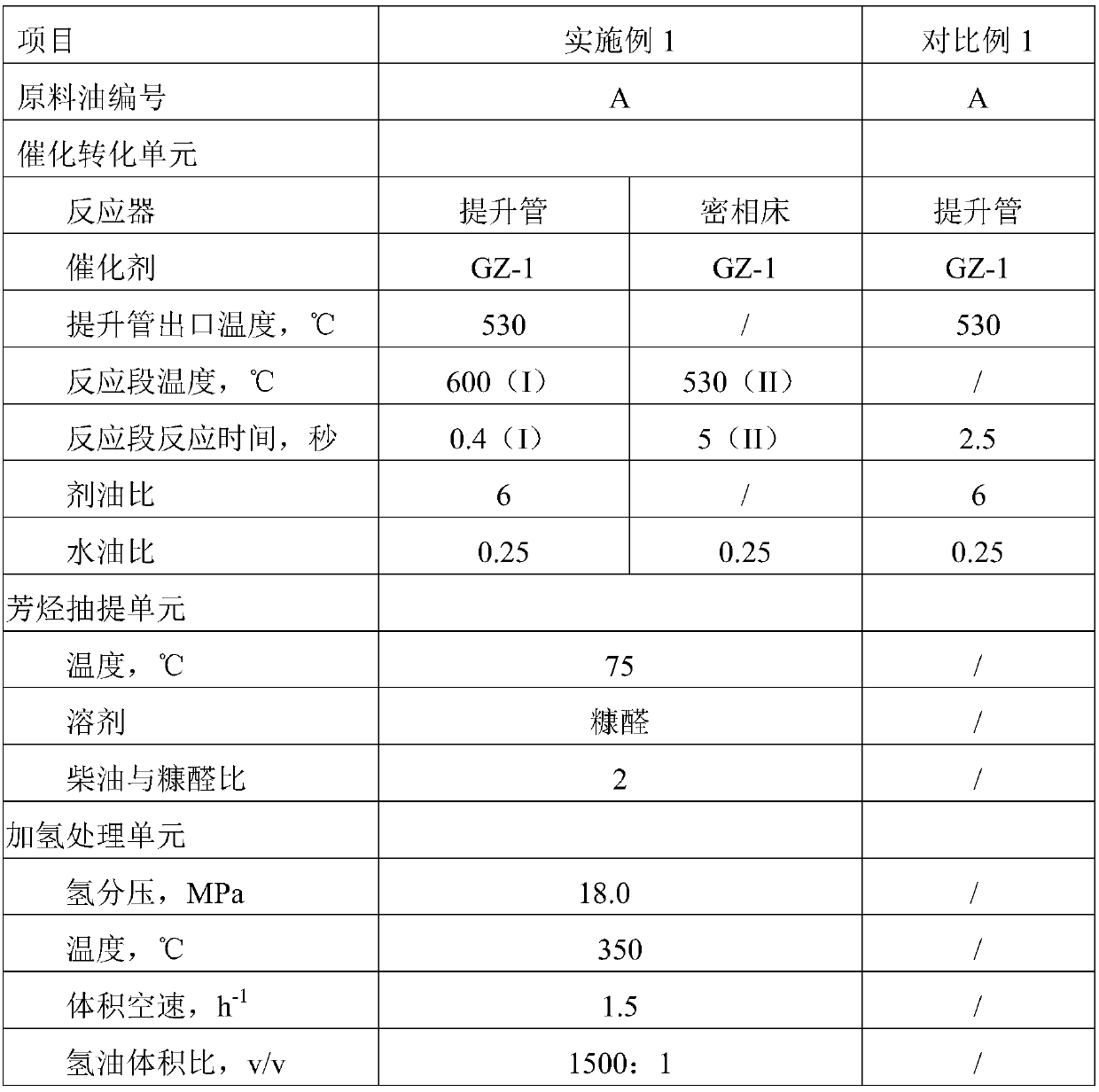

Method and system for catalytic conversion of poor quality raw material oil

ActiveCN107557067AHigh activityImprove conversion depthTreatment with hydrotreatment processesLighter fuelAromatic hydrocarbon

The invention discloses a method and a system for catalytic conversion of poor quality raw material oil. The method comprises: carrying out a catalytic conversion reaction on poor quality raw materialoil sequentially with a riser reactor and a settler, feeding the obtained reaction product into a product separation unit, separating, and sequentially carrying out aromatic hydrocarbon extraction and hydrogenation treatment on the obtained diesel oil, wherein the partial catalyst is taken out from the diameter expanding section at the middle portion of the riser reactor, and the partial regeneration catalyst is fed into the settler. According to the present invention, by organically combining the catalytic conversion, the aromatic hydrocarbon extraction, the hydrogenation treatment and otherprocesses and the process apparatuses, the low carbon olefins, the light fuel oil and the heavy aromatic hydrocarbons are produced from the poor quality raw material oil at a maximum so as to achievethe efficient utilization of petroleum resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

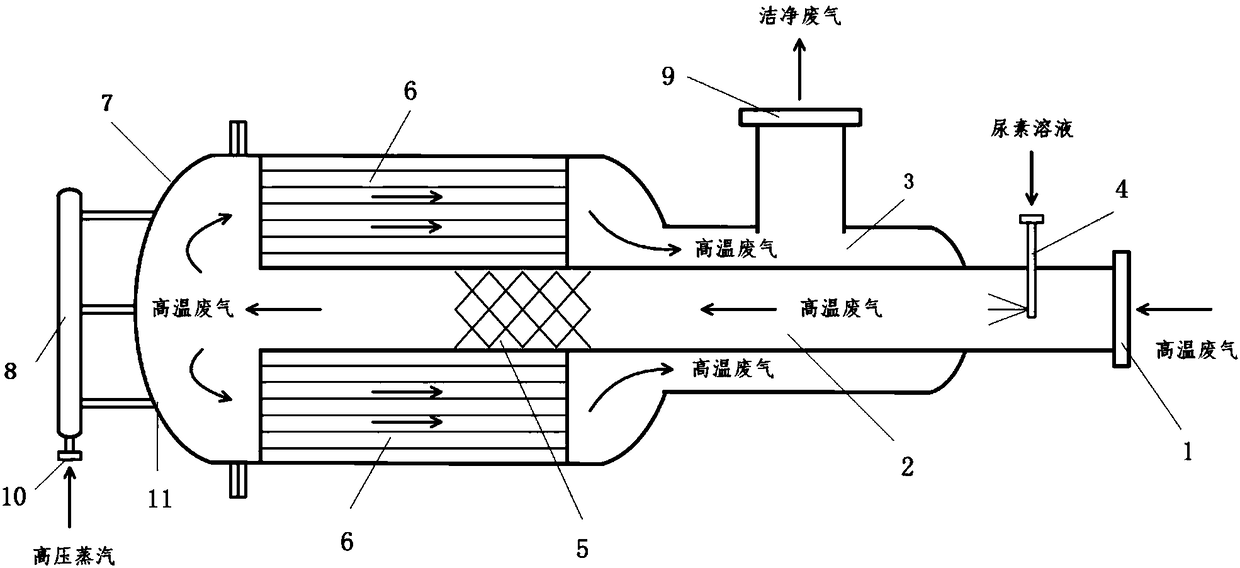

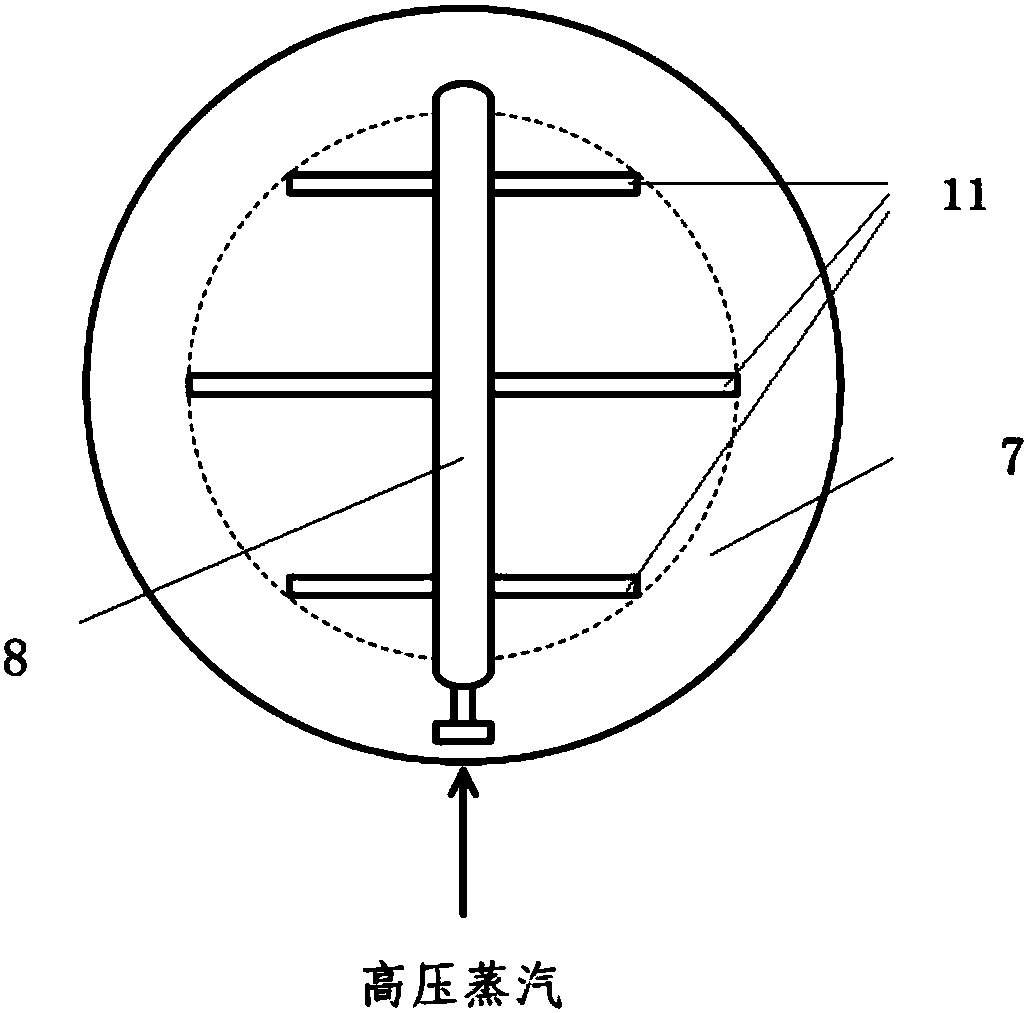

Spherical circulation type dual-channel high-pressure SCR reactor for marine high-power diesel engine

InactiveCN108487977AIncrease the cross-sectional areaReduce volumeInternal combustion piston enginesExhaust apparatusEngineeringHigh pressure

The invention relates to the technical field of marine diesel engine emission control, in particular to a spherical circulation type dual-channel high-pressure SCR reactor for a marine high-power diesel engine. The spherical circular current type dual-channel high-pressure SCR reactor comprises an internal passage, an external passage, an internal reaction system, an internal circulation system and a tail end soot blower system. The internal passage and the external passage are in a tube shape, the internal passage is installed in the center of the external passage, the internal reaction system is located in the passages, the internal circulation system is located at the joint of the internal passage and the external passage, and the tail end soot blower system is arranged on a spherical circulation plate of the internal circulation system. The spherical circulation type dual-channel high-pressure SCR reactor for the marine high-power diesel engine can reduce the size of the SCR reactor, improves the compactness, increases the sectional area of a denitration catalyst, realizes high efficiency denitration in a small size SCR reactor by utilizing the residual energy of turbine exhaust, can be periodically purged to reduce the sediment on the surface of the denitration catalyst and in the passages, and guarantees the safety of the turbine operation. In general, the energy cycle efficiency of the spherical circular current type dual-channel high-pressure SCR reactor for the marine high-power diesel engine is high in energy cycle utilization rate, the overall denitration efficiency is high, and the safety performance is good.

Owner:HARBIN ENG UNIV

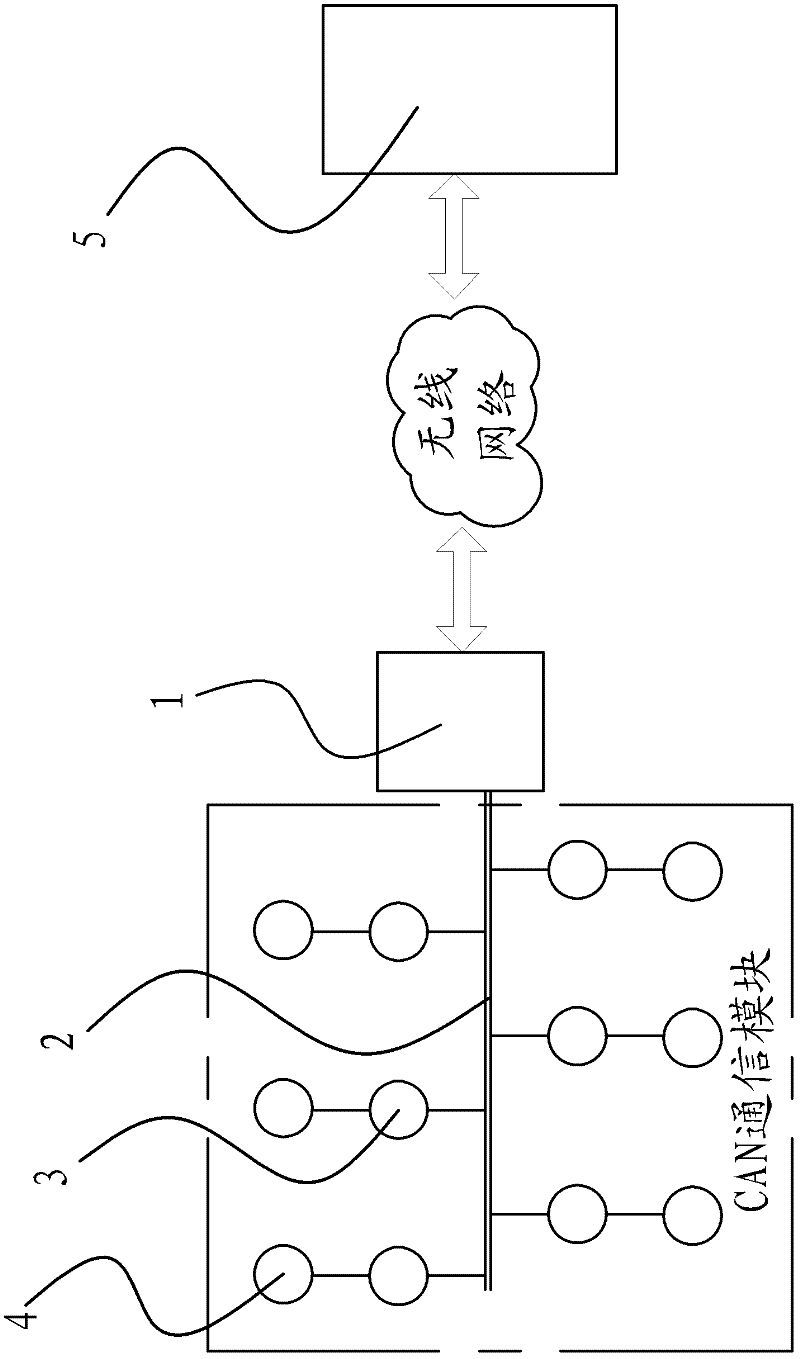

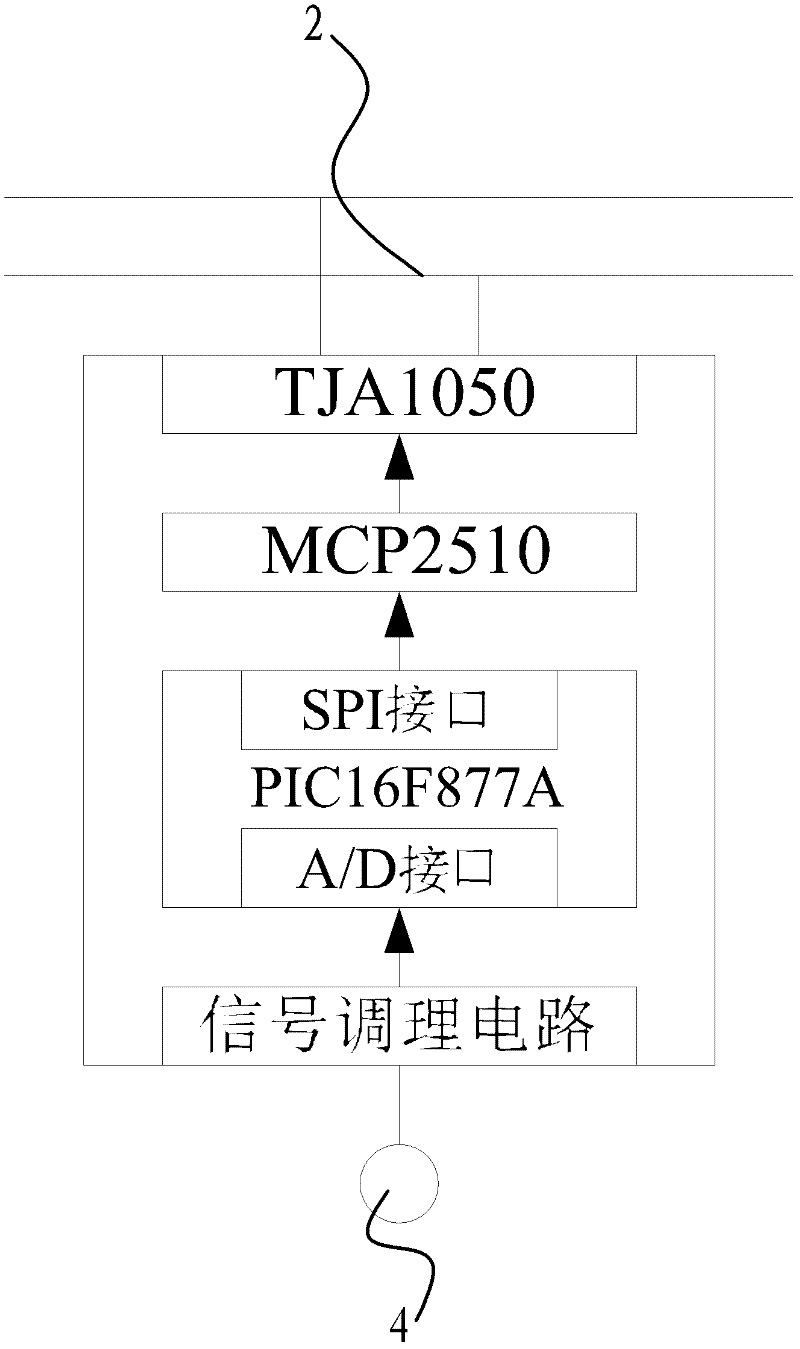

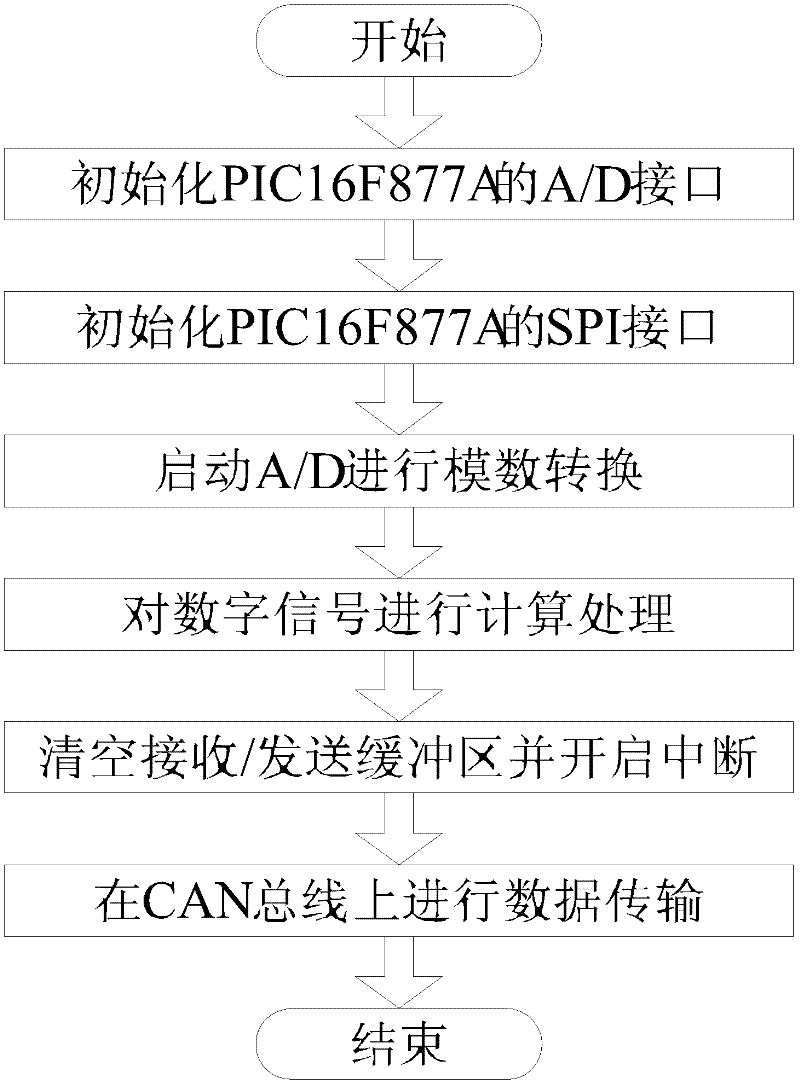

Building device for vehicular sensor network platform

InactiveCN102508464AReduce line speedSolve unmanageable problemsProgramme total factory controlSignal conditioning circuitsArea network

The invention provides a building device for a vehicular sensor network platform, which belongs to the technical field of automobiles and solves the problem of difficulty in management of sensor platforms in the prior art. The device comprises a plurality of sensors, a plurality of CAN (controller area network) bus communication modules of sensor nodes, a sensor gateway node and a monitoring service center host. The sensors are arranged in vehicles, the CAN bus communication modules of the sensor nodes are correspondingly connected with the sensors, the sensor gateway node is connected with the CAN bus communication modules of the sensor nodes by a CAN bus, each CAN bus communication module of the sensor node consists of a signal conditioning circuit, a node controller, a CAN controller and a CAN transceiver, each signal conditioning circuit is connected with the corresponding sensor, each node controller is connected with the corresponding signal conditioning circuit, each CAN controller is connected with an SPI (serial peripheral interface) of the corresponding node controller, each CAN transceiver is connected with the corresponding CAN controller, the sensor nodes can collect parameter signals detected by the sensors when the vehicles run, and the sensor gateway node can organize and coordinate data exchange between the internal CAN network of each vehicle and the external. The building device for the vehicular sensor network platform brings convenience for managing the networked sensor platform.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Quantified and axial plunger pump

ActiveCN104948409AImprove volumetric efficiencyReduce volumePositive-displacement liquid enginesMulti-cylinder pumpsRadial piston pumpWorking pressure

The invention provides a quantified and axial plunger pump. The plunger pump is a radial flow distribution pump and comprises a transmission shaft, a cylinder, a flow distribution sleeve, a flow distribution shaft and an inclined disc, wherein the transmission shaft is driven by external force to rotate, the cylinder, the flow distribution sleeve and the flow distribution shaft are connected with the transmission shaft, and the inclined disc enables the plunger pump to output fluid in a quantified mode. The cylinder, the flow distribution sleeve, the flow distribution shaft and the transmission shaft are coaxially arranged. Compared with a traditional radial plunger pump, the plunger pump has the main advantages of being simple in structure, small in size and light in weight; compared with a traditional axial plunger pump, the plunger pump has the main advantages that the rotation speed of the pump can be substantially increased, working pressure can be substantially increased, the nominal flow rate can be multiplied, or at equal working pressure, the volume efficiency of the pump is remarkably improved, and noise can be lowered by more than10 db.

Owner:湖南力威液压设备股份有限公司

Total cross-section inflatable floatation machine

InactiveCN102211061AIncrease exposureMaximize total specific surface areaFlotationEngineeringProduct gas

The invention relates to a total cross-section inflatable floatation machine, comprising a flotation tank and a foam overflow mechanism arranged at the top of the flotation tank, wherein the tank body of the flotation tank is provided with an ore pulp inlet and an ore pulp outlet, the bottom of the tank body of the flotation tank is provided with a check valve mounting plate, and the shape of the check valve mounting plate is matched with that of the cross section of the bottom of the tank body of the flotation tank, thus the tank body of the flotation tank is divided into a pulp bearing chamber and an air chamber arranged below the pulp bearing chamber, one side of the bottom of the pulp bearing chamber is provided with an ore discharge port, one side of the air chamber is provided with an air inlet, and multiple check valves are uniformly distributed on the check valve mounting plate. The total cross-section inflatable flotation machine provided by the invention has a simple structure and is convenient to maintain, the ore dressing recovery percentage is improved, the energy consumption is reduced, gas is fully utilized, the chemical usage is reduced, the life of a quick-wear part is prolonged, the flotation process stage is shortened, and the equipment cost and investment of capital construction are reduced.

Owner:YANTAI XINHAI MINING MACHINERY

Coaxial and co-cylindrical multistage positive and negative rotation transmission method and transmission utilizing same

InactiveCN102494084AReduce line speedReduce angular velocityToothed gearingsPortable liftingDrive wheelEngineering

A coaxial and co-cylindrical multistage positive and negative rotation transmission method comprises multistage gear engagement rotation transmission consisting of a driving wheel, a plurality of driven wheels and multistage auxiliary gear banks, the driving wheel is provided with two side gears, each driven wheel is provided with two side gears, the driven wheels are coaxially serially connected with the driving wheel, and the multistage auxiliary gear banks are uniformly distributed between the driving wheel and each driven wheel and between each two driven wheels, are respectively engaged with the side gears of the driving wheel and the driven wheels, and are provided with input auxiliary gears and output auxiliary gears. The coaxial and co-cylindrical multistage positive and negative rotation transmission method is characterized in that the side inner gear or the side outer gear of the driving wheel is engaged with the power input auxiliary gears so that rotation power is transmitted to the power input auxiliary gears, the power input auxiliary gears transmit the rotation power to the power output auxiliary gears via connecting shafts, and the power output auxiliary gears are engaged with the side inner gears or the side outer gears of the driven wheels so that the rotation power is transmitted to the driven wheels. The invention further provides a coaxial and co-cylindrical multistage positive and negative rotation transmission.

Owner:魏伯卿

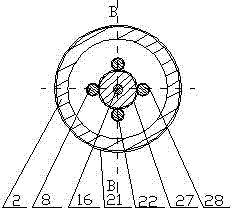

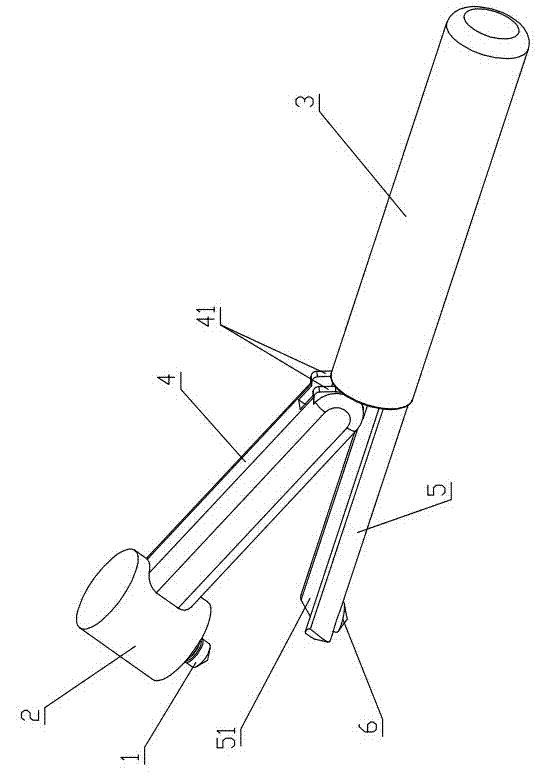

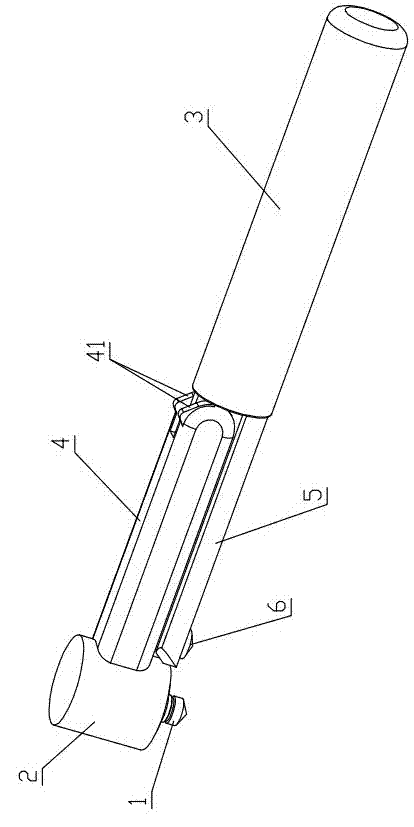

Emergency hammer

InactiveCN102774344ABreakableBig impactPedestrian/occupant safety arrangementHand hammersEngineeringEmergency situations

The invention discloses an emergency hammer. The emergency hammer comprises a first hammer head (1), a hammer body (2) and a handle (3). The first hammer head (1) is arranged at one end of the hammer body (2). A connecting rod (4) is arranged between the hammer body (2) and the handle (3). One end of the connecting rod (4) is fixed with the hammer body (2), and the other end of the connecting rod (4) is hinged with the handle (4). The handle (3) is further provided with a rigid pre-striking piece (5). The end of the rigid pre-striking piece (5), which is far from the hammer body (2), is connected with the handle (3). Accoring to the emergency hammer, users with small power can break the window glass easily.

Owner:广东多子熊家居生活用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com