Spherical circulation type dual-channel high-pressure SCR reactor for marine high-power diesel engine

A high-power diesel engine, SCR reactor technology, applied in machines/engines, mechanical equipment, engine components, etc., can solve the problem of failure to effectively utilize the residual energy of exhaust gas, low cycle energy efficiency and utilization rate, and easy to be affected by dust content. and other problems, to achieve the effect of convenient disassembly and operation, reducing pressure loss and improving mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

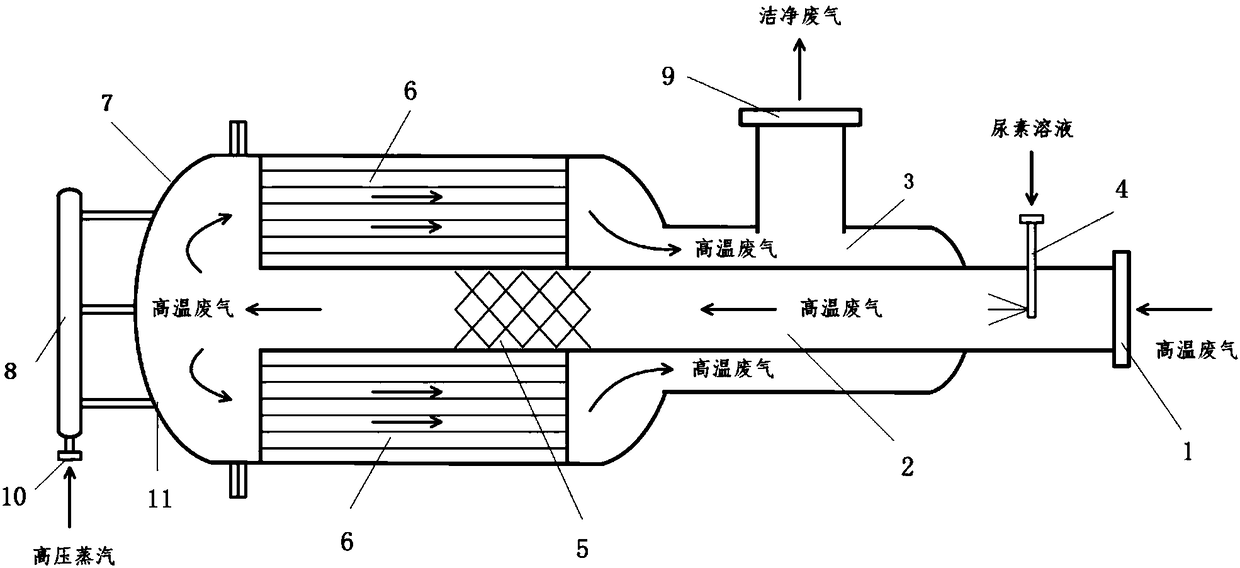

[0023] figure 1 It is an overall structural diagram of a spherical circulation double-channel high-pressure SCR reactor for a marine high-power diesel engine. It is mainly composed of exhaust gas inlet 1, inner channel 2, outer channel 3, urea nozzle 4, static mixer 5, denitrification catalyst 6, spherical circulation plate 7, soot blowing system 8, exhaust gas outlet 9 and high-pressure steam inlet 10. The inner channel 2 is installed at the center of the outer channel 3, the outer channel 3 adopts a large and small variable diameter structure, the spherical circulation plate 7 is connected to the outer channel by bolts, and the denitrification catalyst 6 is arranged in an annular shape at the entrance section of the outer channel 3.

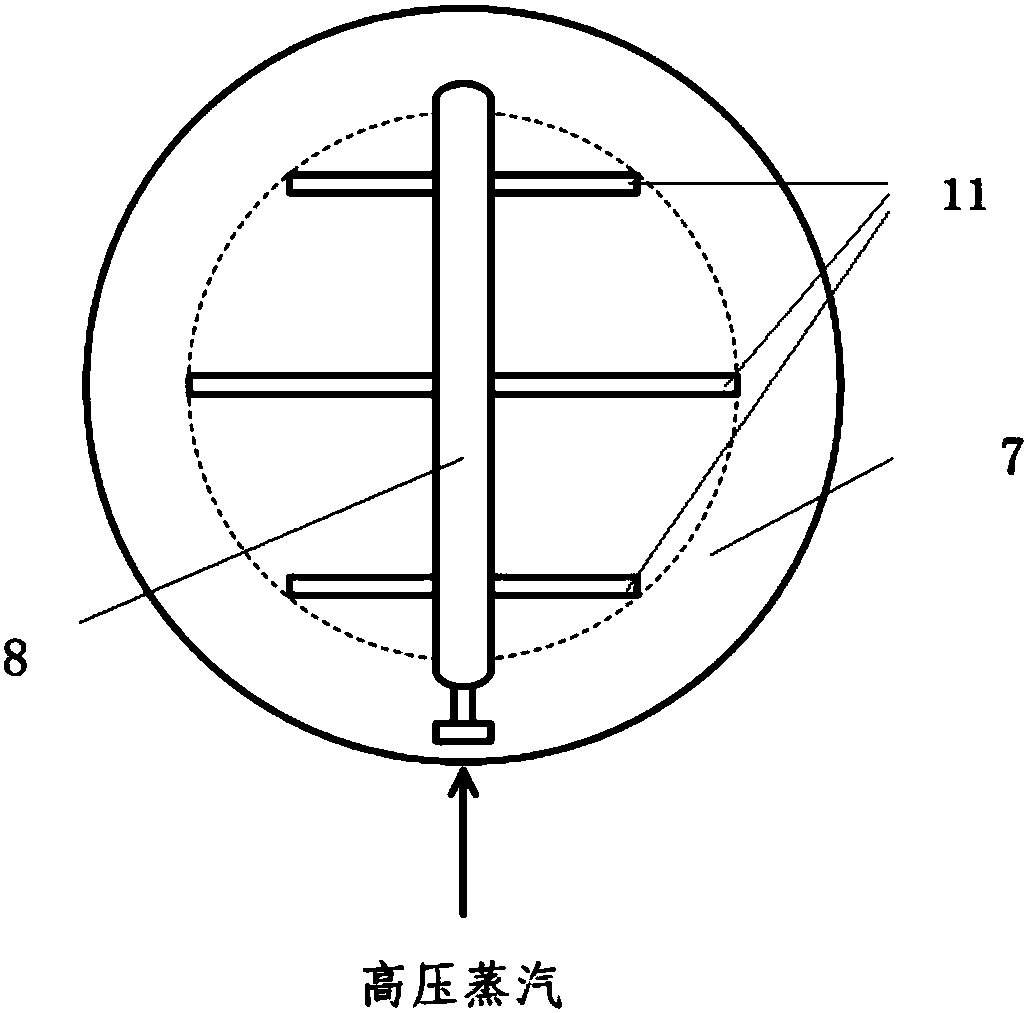

[0024] figure 2 It is a structural schematic diagram of the soot blowing system of the present invention, which is mainly composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com