Coaxial and co-cylindrical multistage positive and negative rotation transmission method and transmission utilizing same

A forward and reverse, cylindrical technology, applied in the field of transmission technology and gear transmission, can solve the problems of high production cost, large volume, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

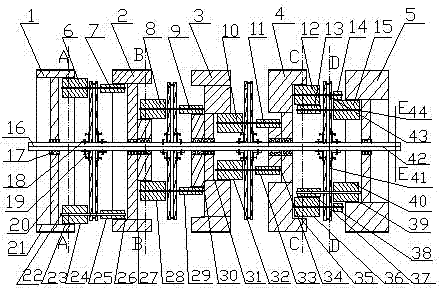

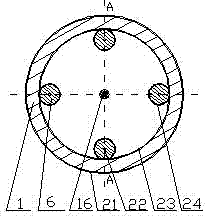

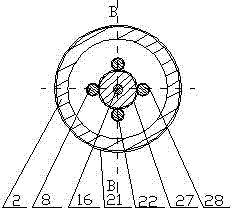

[0082] exist figure 1 In the embodiment shown in -6: coaxial and cylindrical multi-stage forward and reverse speed changer, including driving wheel 1, a plurality of driven wheels and evenly distributed between driving wheel 1 and primary driven wheel 2 and evenly distributed on A plurality of secondary gears between the driven wheels of each stage, the side internal gear 23 on the power output side of the driving wheel meshes with the primary power input secondary gear 6, and transmits the rotational power of the driving wheel 1 to the primary power input secondary gear 6, and then The primary power input pinion 6 transmits the rotational power to the primary power output pinion 7 at the same angular velocity through the power input pinion and the power output pinion connecting shaft 22, and the primary power output pinion 7 is connected to the primary driven wheel The side internal gear 26 on the power input side meshes to transmit the rotational power to the primary driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com