Quantified and axial plunger pump

An axial plunger pump and plunger pump technology, used in pumps, multi-cylinder pumps, liquid variable capacity machinery, etc. Large volume and other problems, to achieve the effect of compact structure, light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

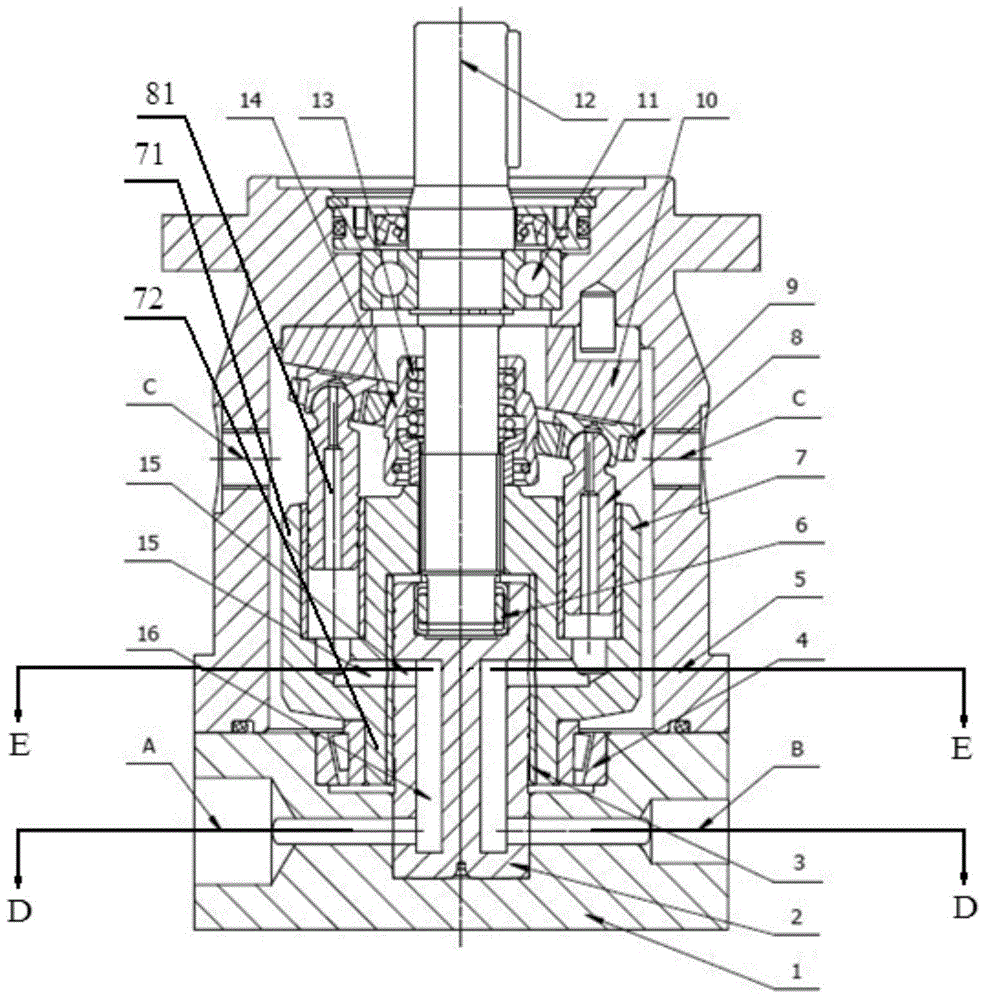

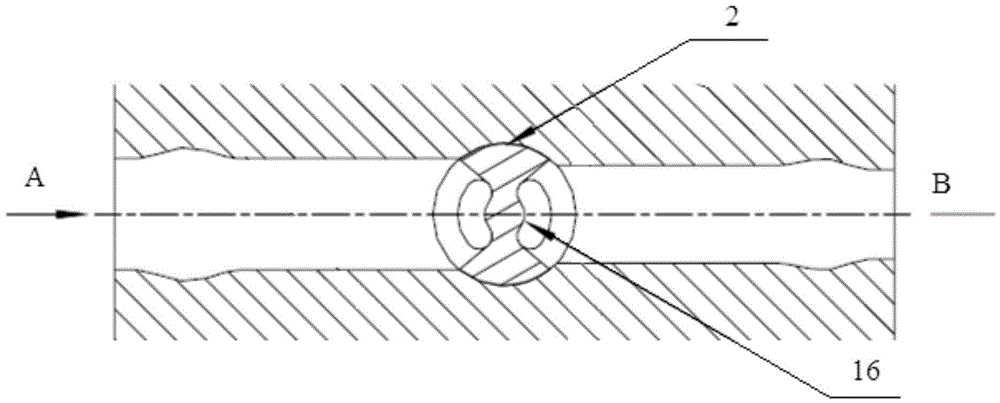

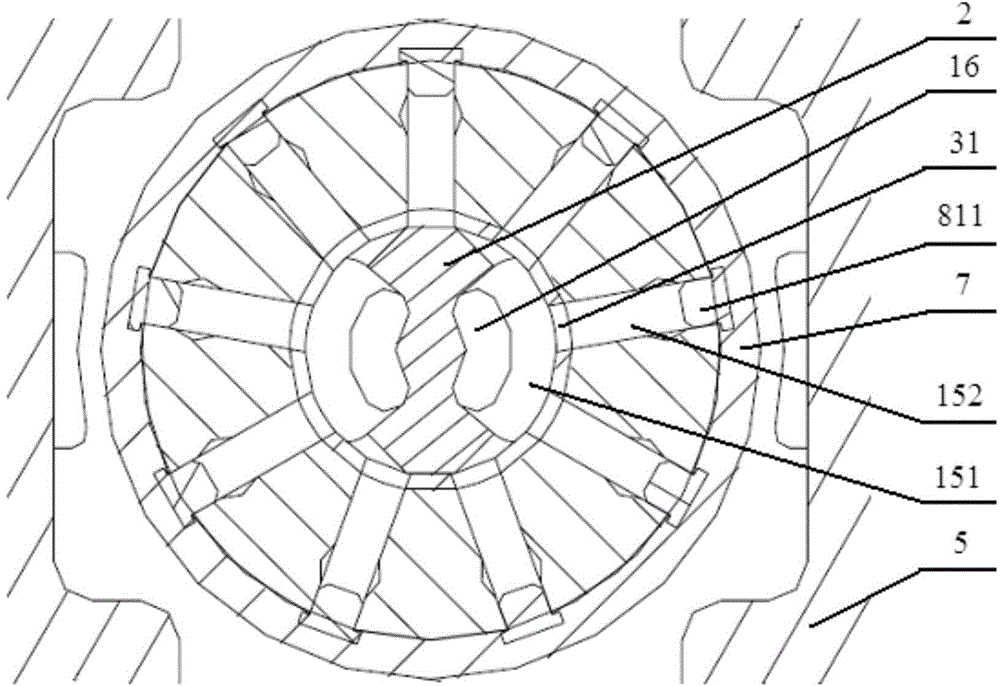

[0034] The invention provides a quantitative axial plunger pump, the plunger pump is a radial flow distribution pump, including a drive shaft 12 driven by external force to rotate, a cylinder 7 connected to the drive shaft, a flow distribution sleeve 3, and a flow distribution shaft 2 And the swash plate 10 that makes the plunger pump quantitatively output fluid; the cylinder body, the distribution sleeve and the distribution shaft are all coaxially arranged with the transmission shaft; the distribution sleeve is cylindrical, and the distribution sleeve is tightly connected to the cylinder In the cylindrical concave hole in the body; the rotation of the transmission shaft drives the cylinder body and the flow distribution sleeve to rotate around the flow di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com