Patents

Literature

273 results about "Radial piston pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A radial piston pump is a form of hydraulic pump. The working pistons extend in a radial direction symmetrically around the drive shaft, in contrast to the axial piston pump.

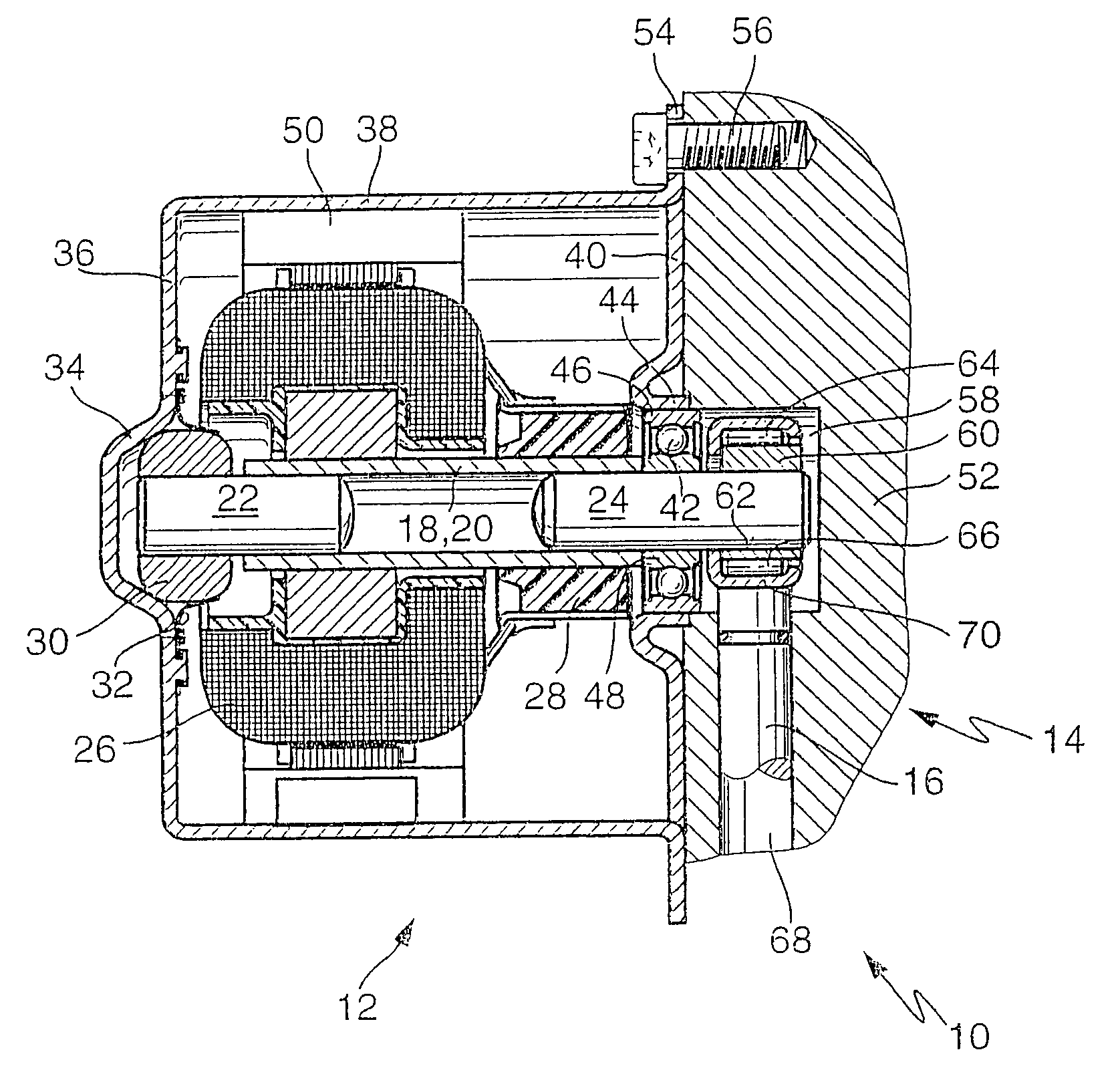

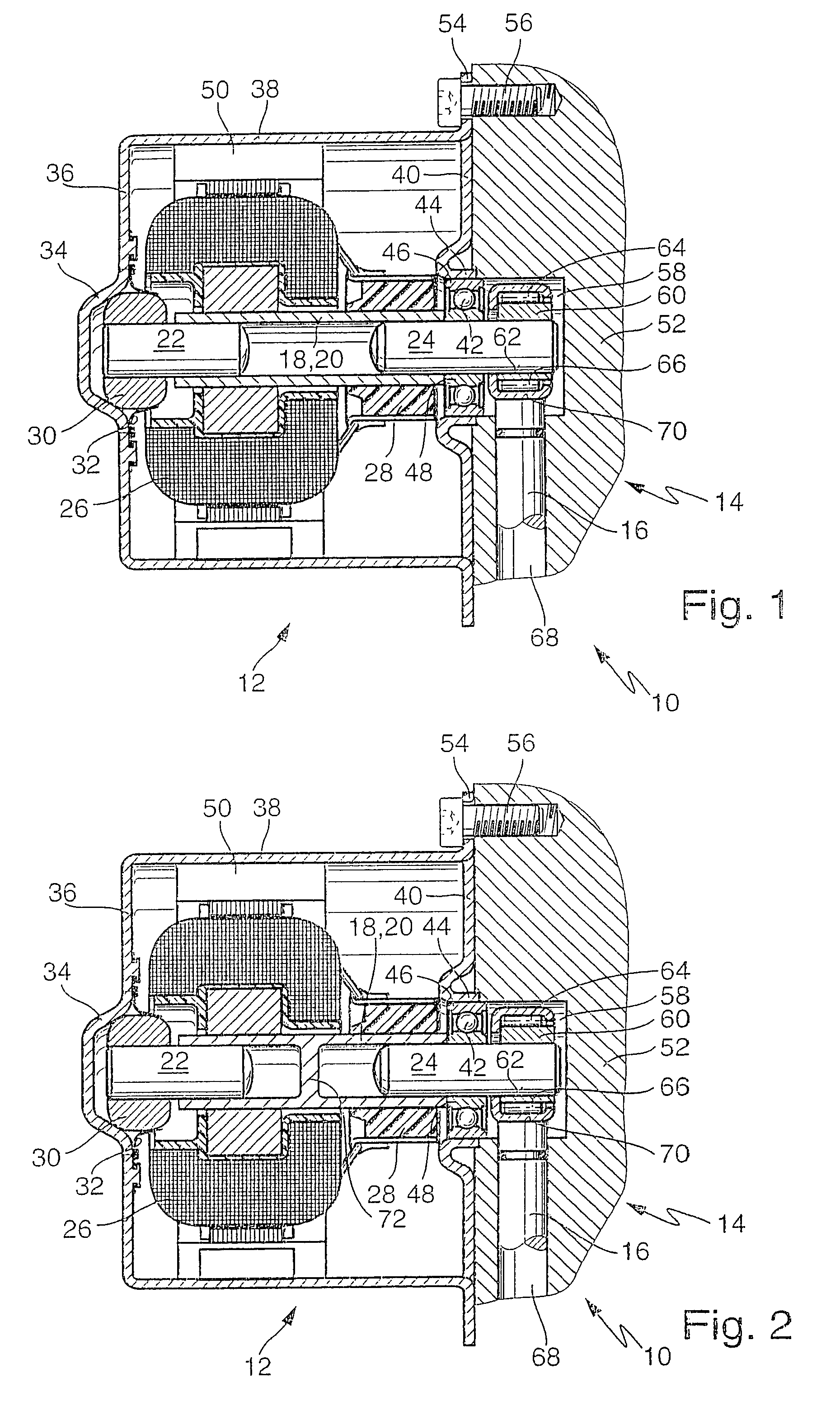

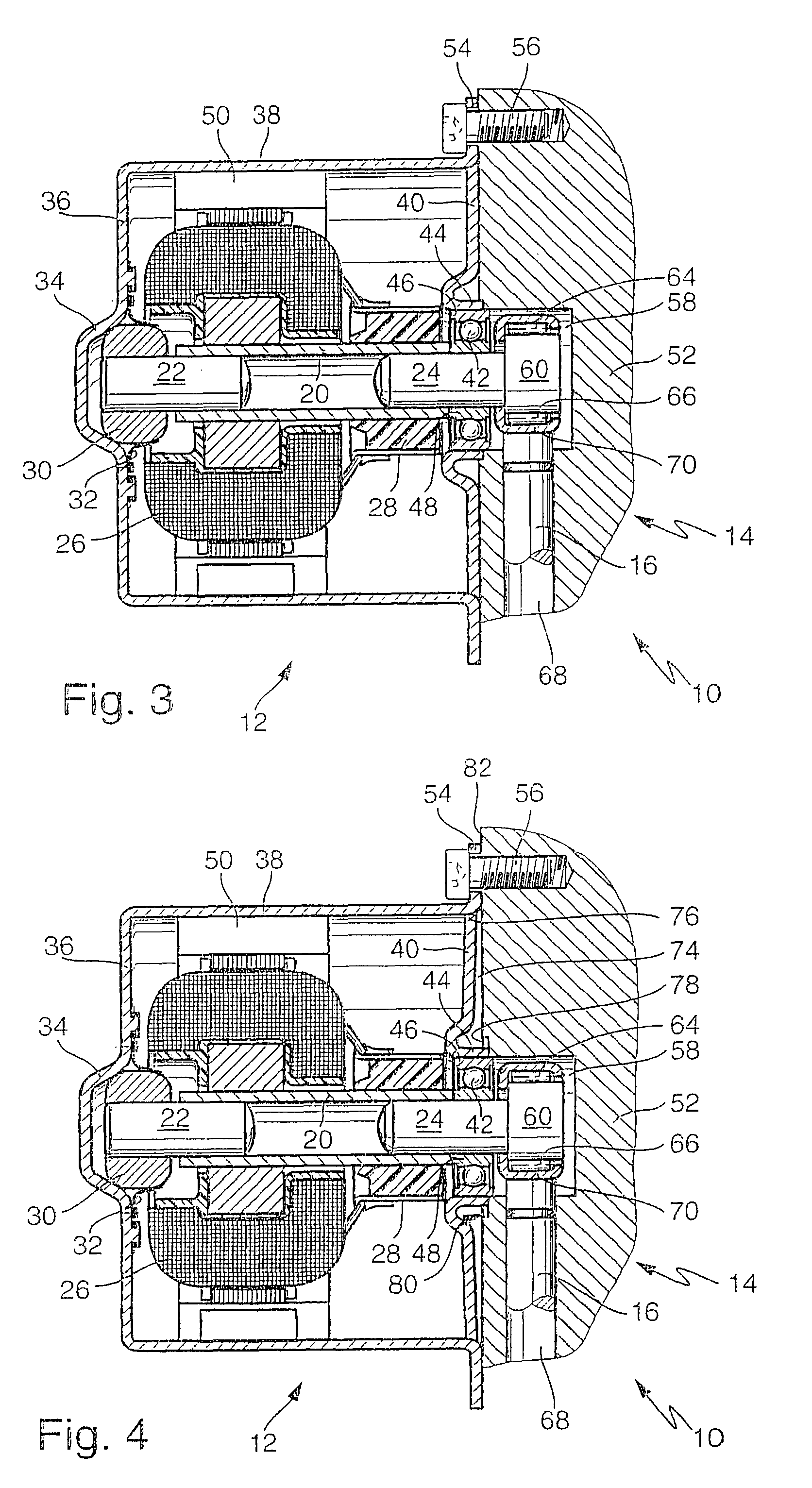

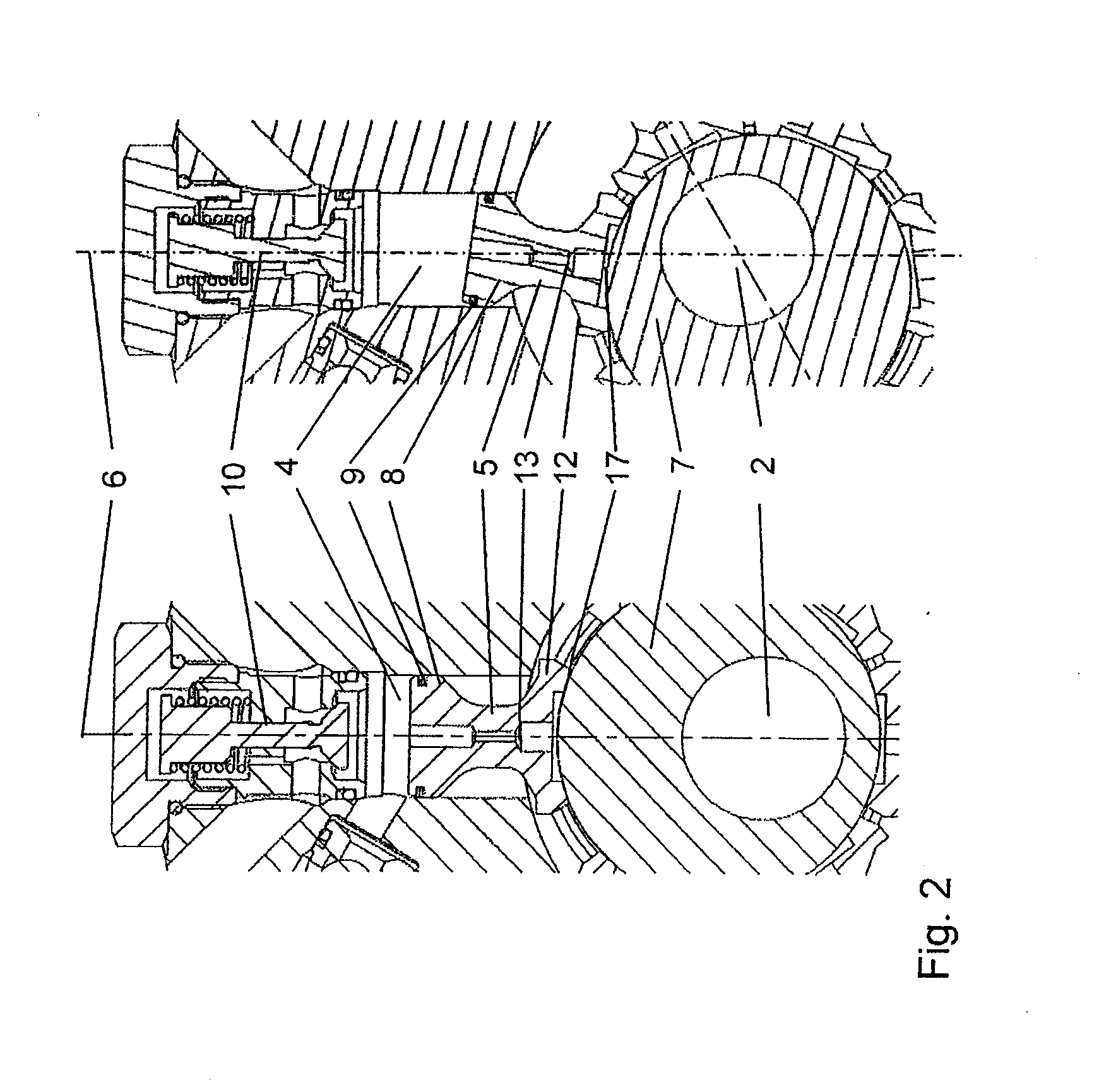

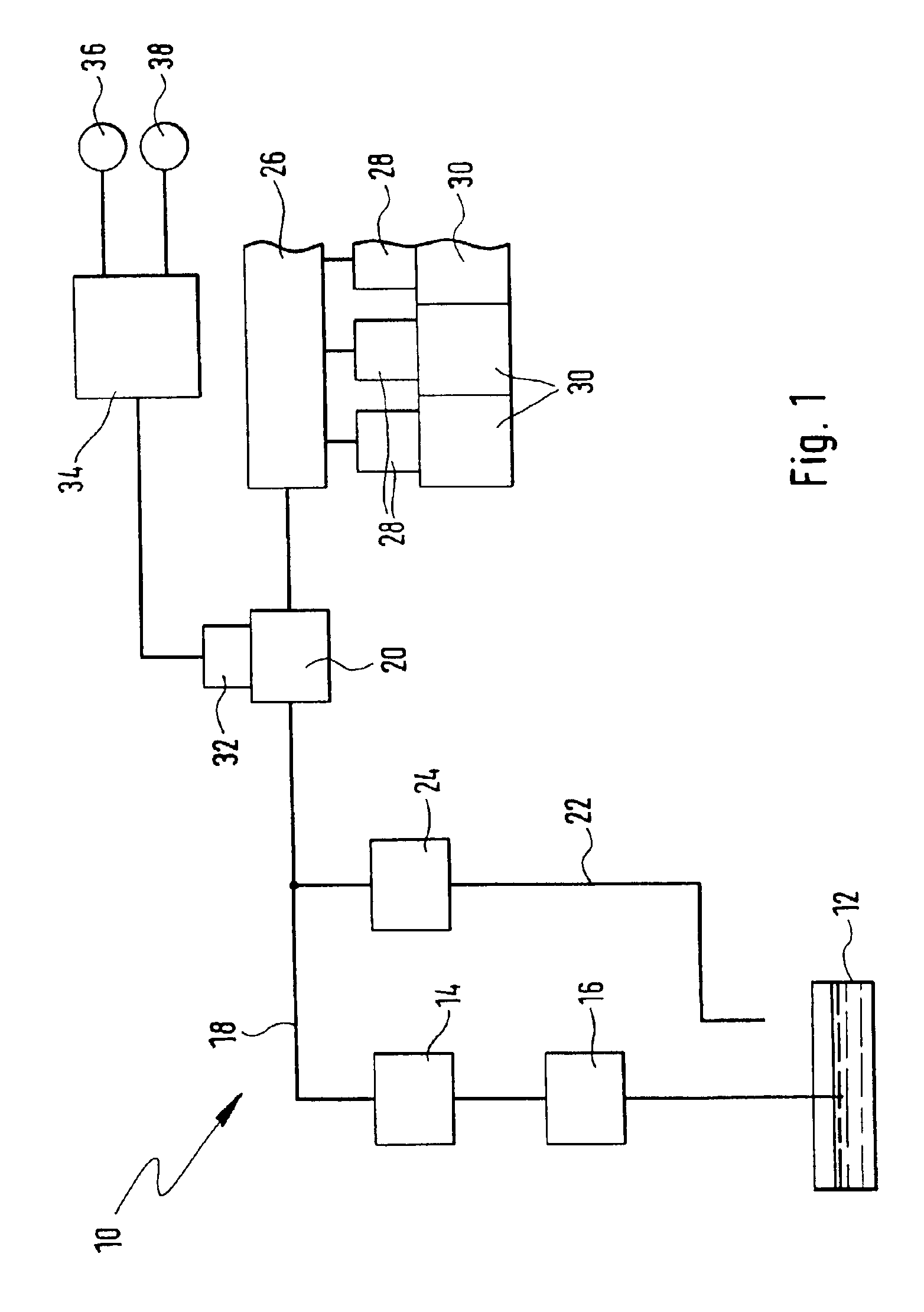

Pump aggregate for a hydraulic vehicle braking system

InactiveUS7168929B2Easy to bendImprove rigidityPositive displacement pump componentsBraking componentsRadial piston pumpTorsional strength

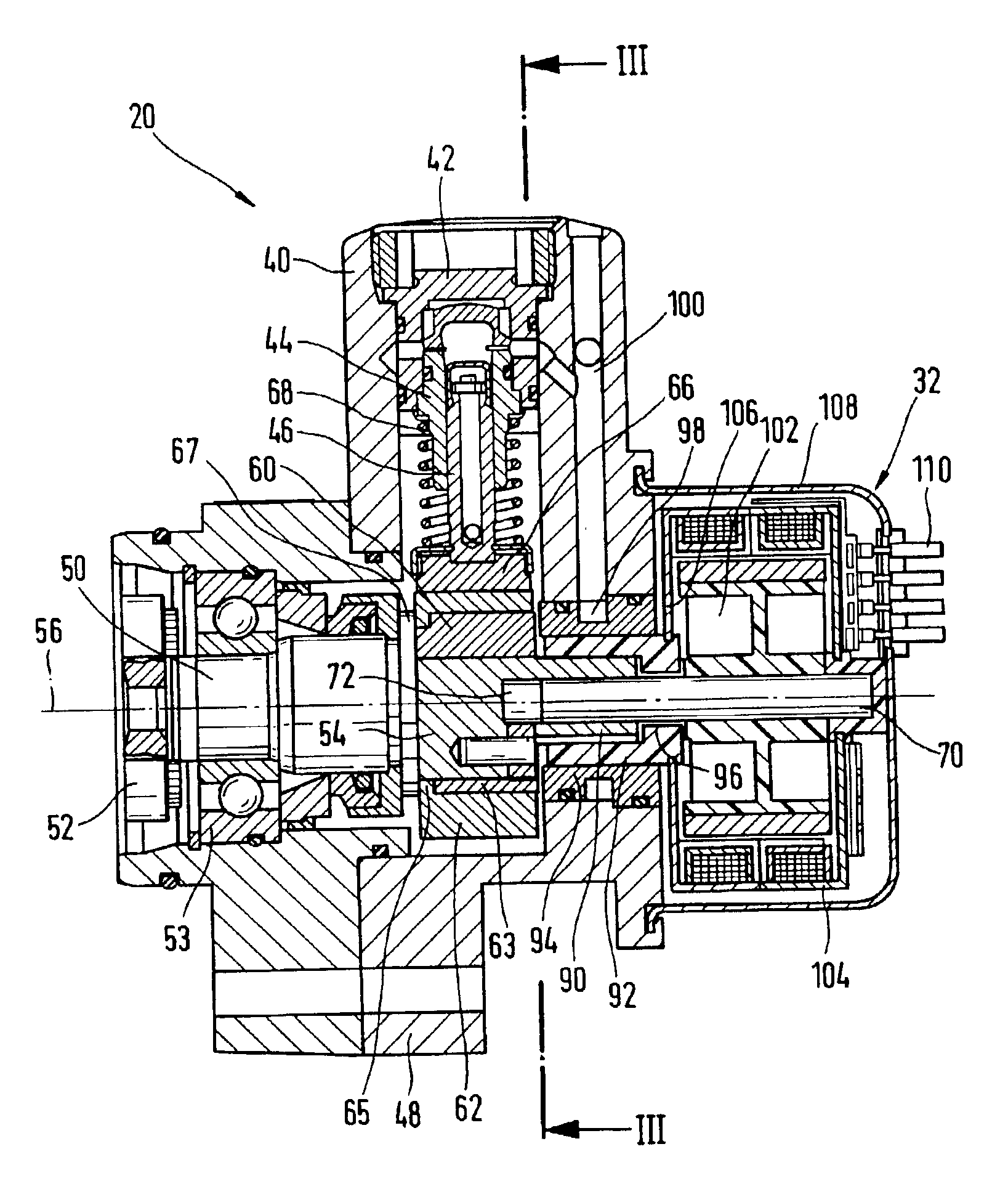

A pump unit for a hydraulic vehicle brake system with traction control has an electric motor driving a radial piston pump. A rotor shaft of the pump unit has a hollow shaft with two standardized, hardened cylindrical pins that are press-fitted into the ends of the hollow shaft. The rotor shaft can be produced simply, economically, and without metal-cutting machining. The hollow shaft has high bending and torsional strength. The rotor shaft has a small diameter at the bearing points, which makes a small bearing diameter and thus a small installation space for the pump unit possible.

Owner:ROBERT BOSCH GMBH

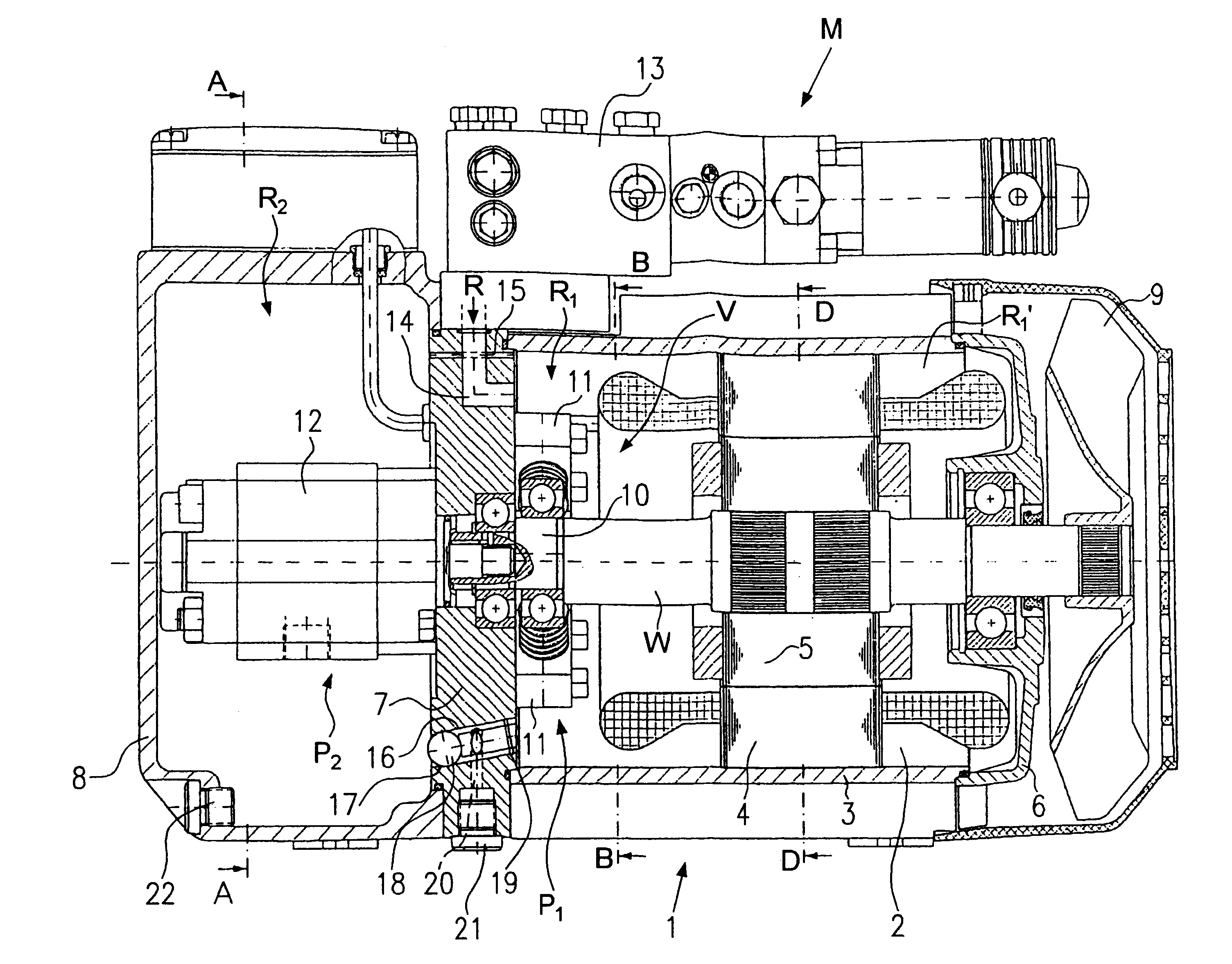

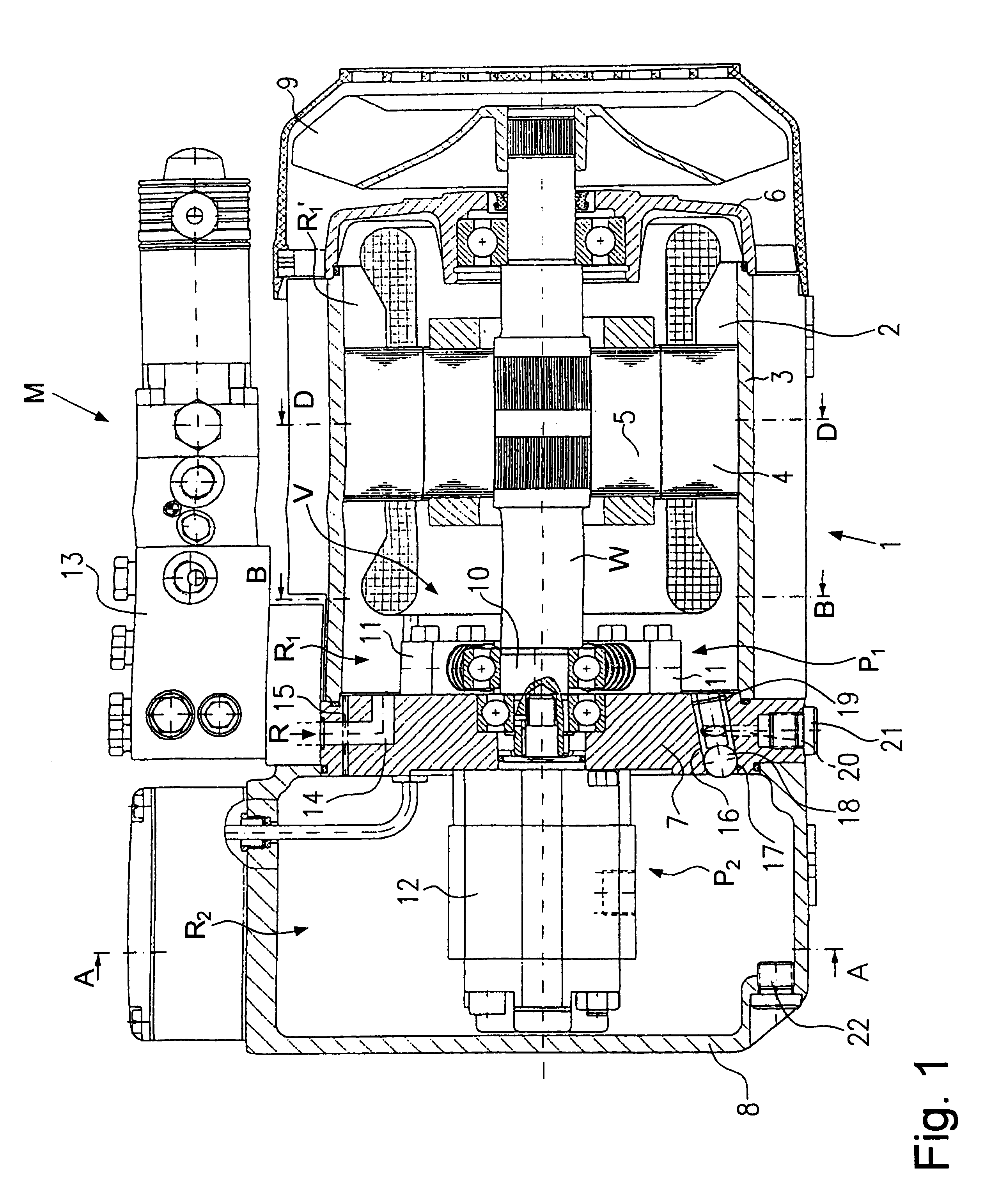

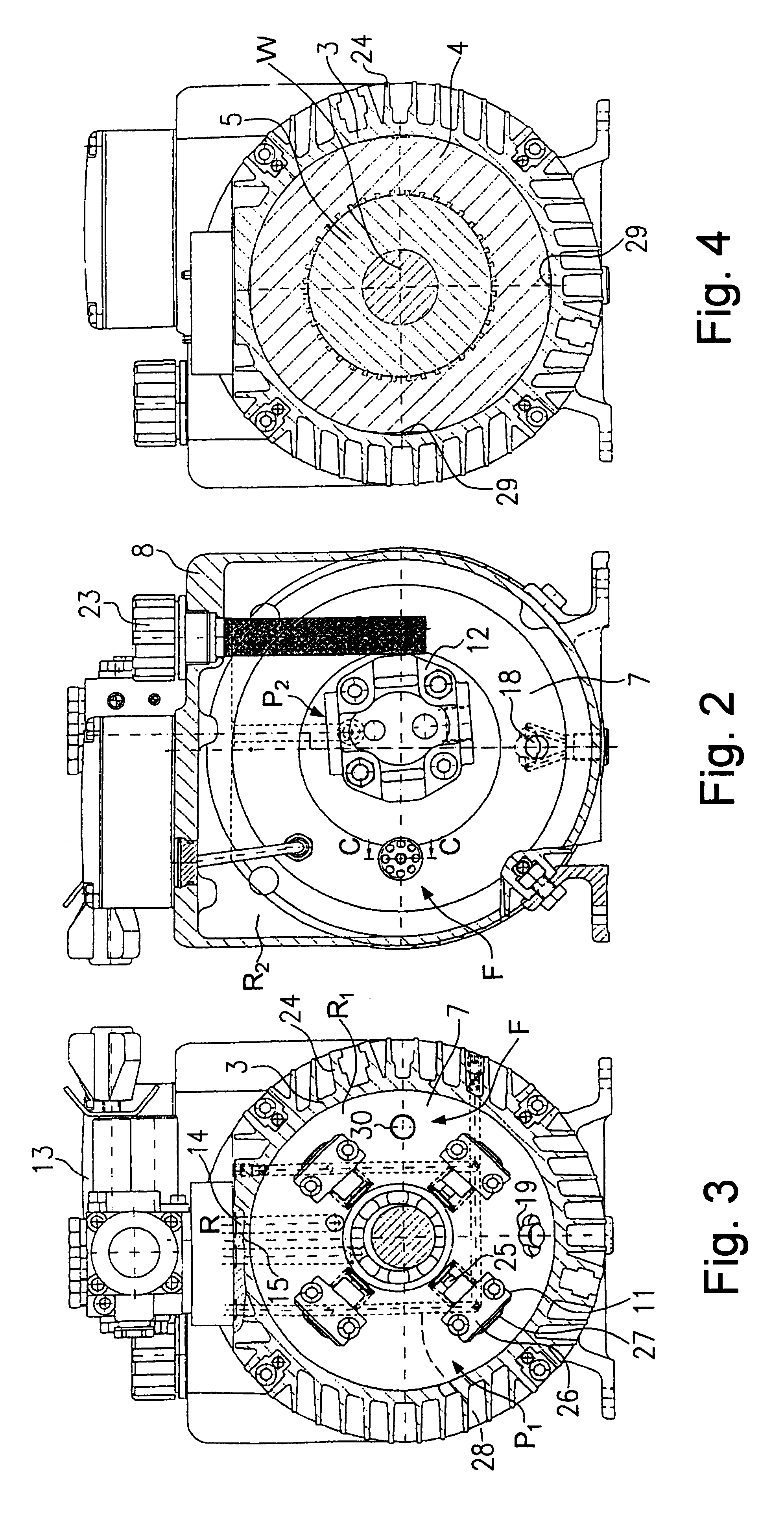

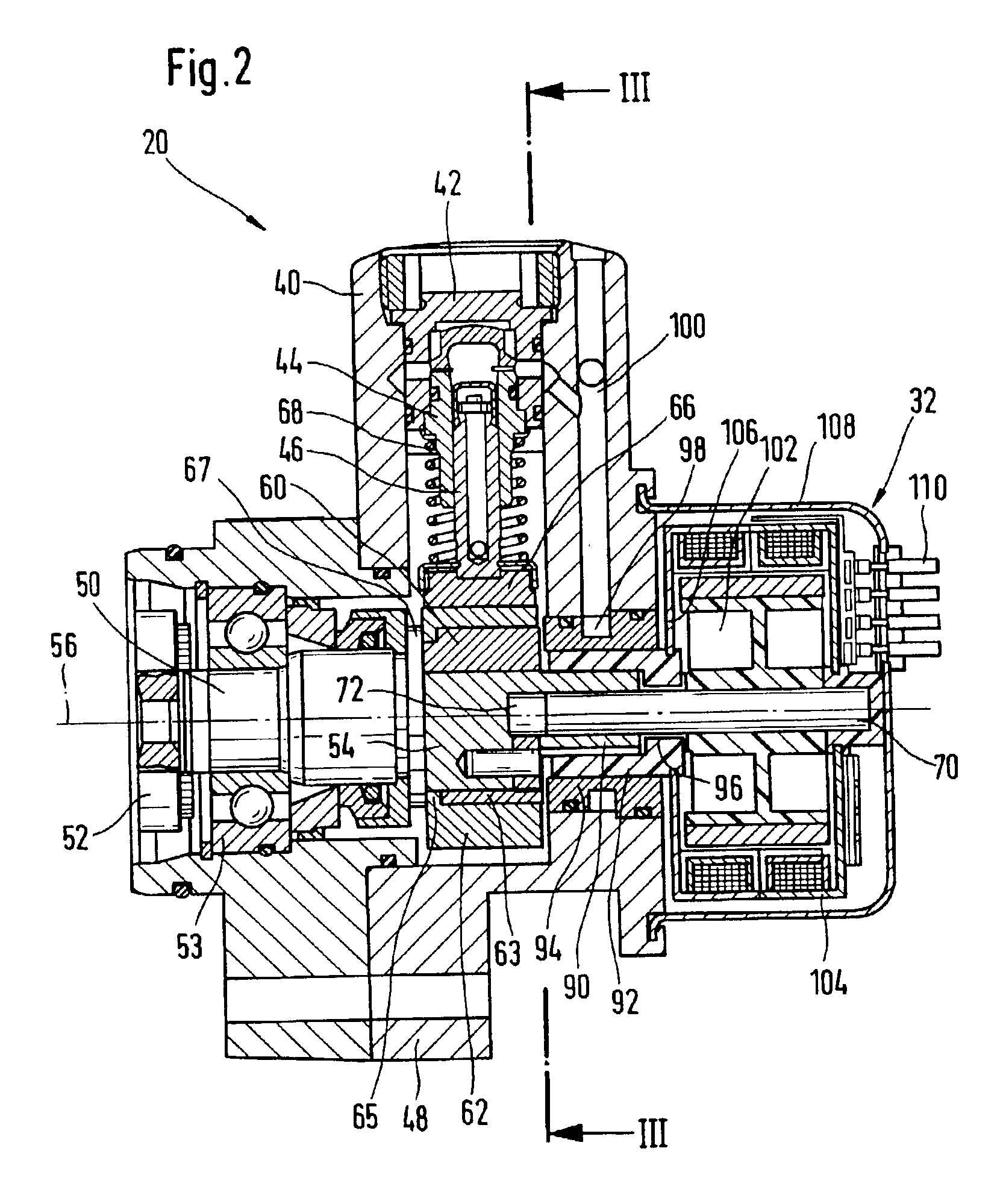

Motor pump unit

InactiveUS6524084B2Improve supply efficiencyAvoids getting trappedPositive displacement pump componentsPiston pumpsRadial piston pumpEngineering

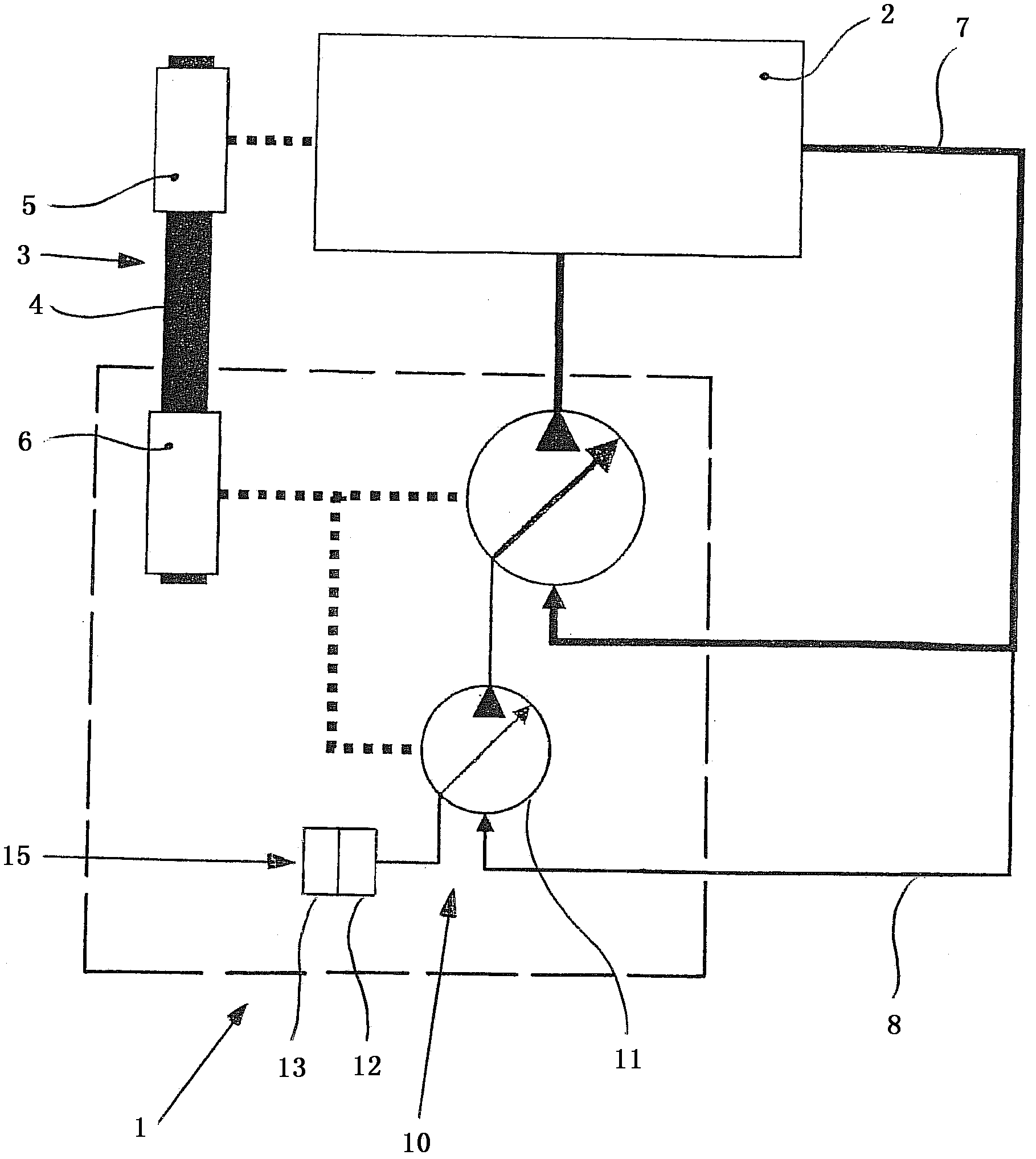

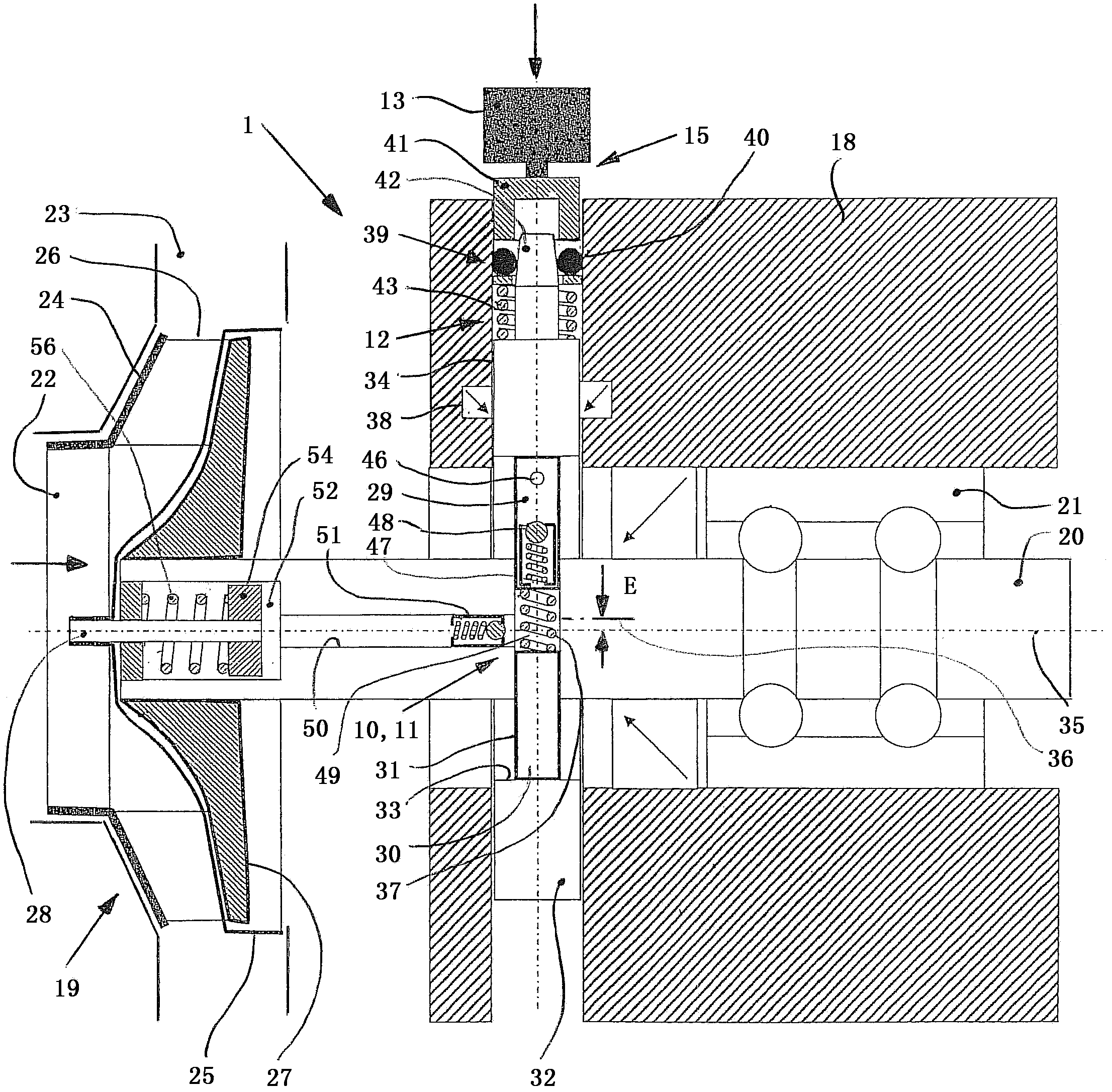

A motor pump aggregate M has a housing 1 defining an oil reservoir with first and second chambers R1, R2. An electromotor 2 is driving via its motor shaft W at least one radial piston pump arrangement P1 provided within said first chamber R2. Both chambers R1, R2 are separated by a separation wall 7. A filling and pressure biasing system V is provided for said first chamber R1 in order to adjust within said first chamber R1 a predetermined oil filling level and a pre-selected oil pressure pre-biasing for said radial piston pump arrangement P1.

Owner:HEILMEIER & WEINLEIN FAB FUR OEL HYDRAULIK

Radial piston pump

ActiveUS20090155095A1Sufficient degree of sealingReduce overall outer diameterPump controlPressure lubricationRadial piston pumpCylinder block

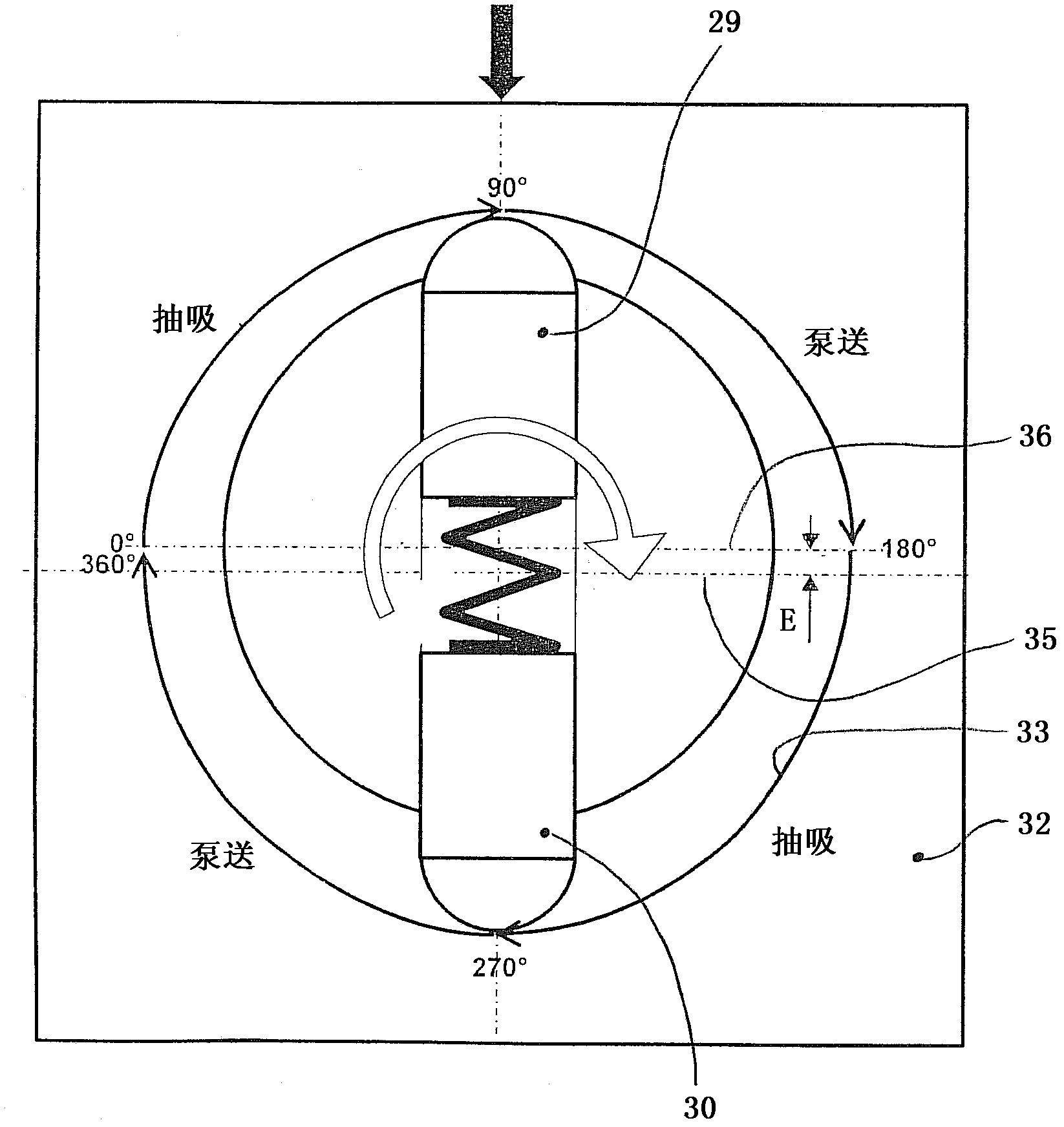

The invention relates to a radial piston pump having external loading. Said radial piston pump has an inner eccentric which is attached to a rotatable driveshaft, a cylinder block which has positionally fixed cylinder bores aligned radially with respect to the driveshaft, and displacement pistons which are mounted in a longitudinally movable manner in the cylinder bores, with the displacement pistons having a piston head with a short casing height, and being mounted with their piston base on the eccentric, in such a way that the piston head, during its longitudinal movement, pivots in a predetermined angle range &r about the longitudinal central axis of the associated cylinder bore.

Owner:DANFOSS POWER SOLUTIONS INC

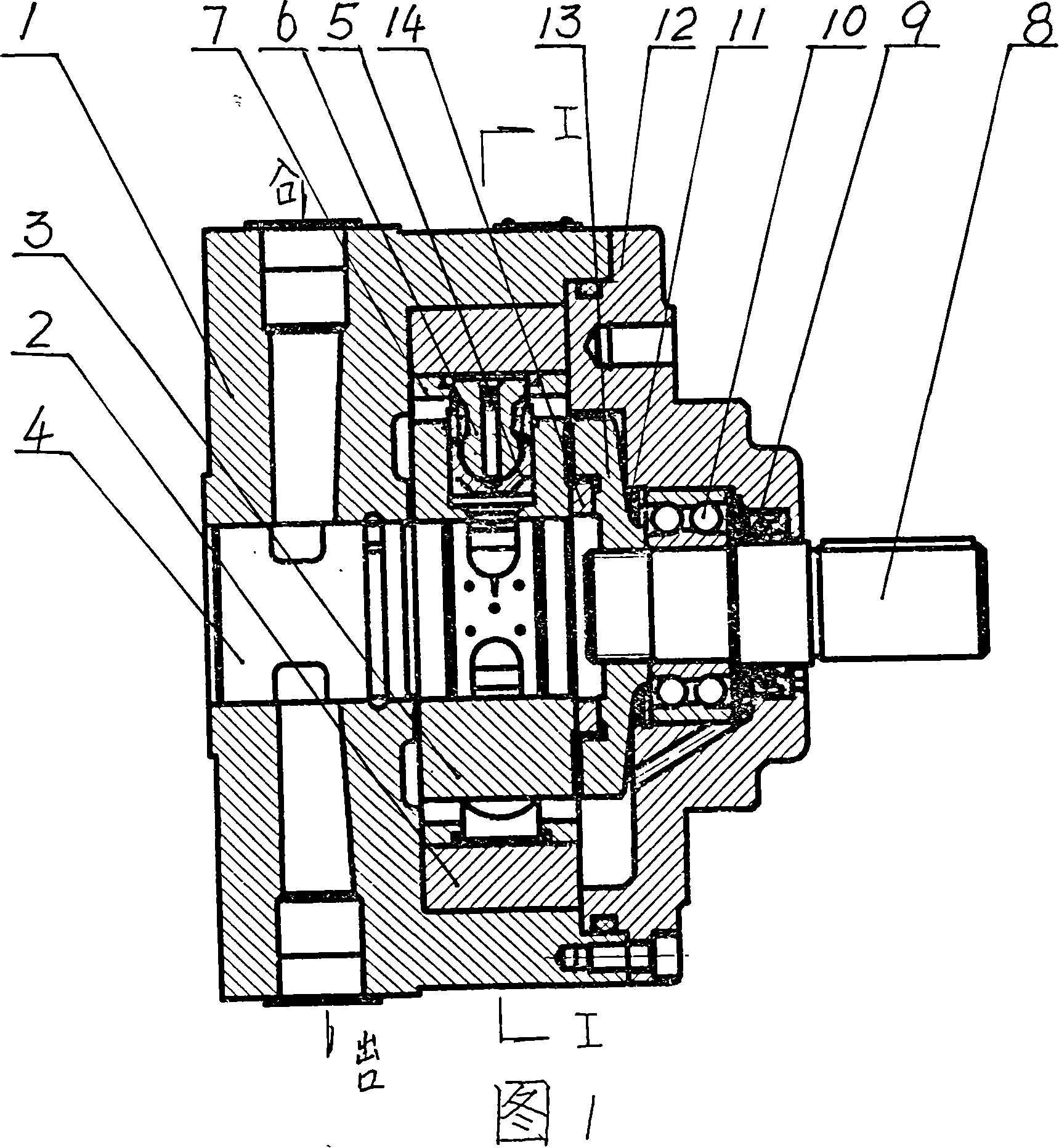

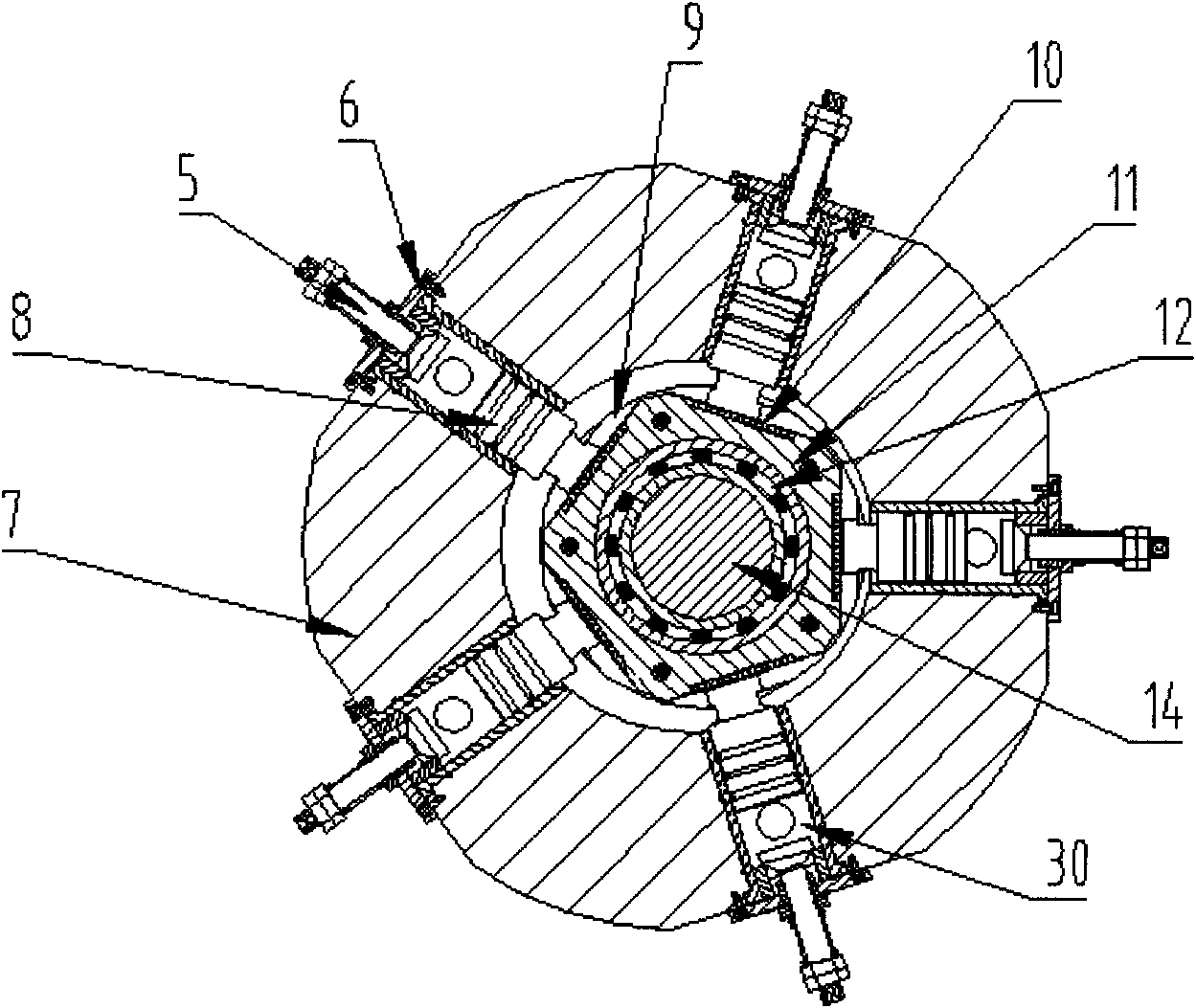

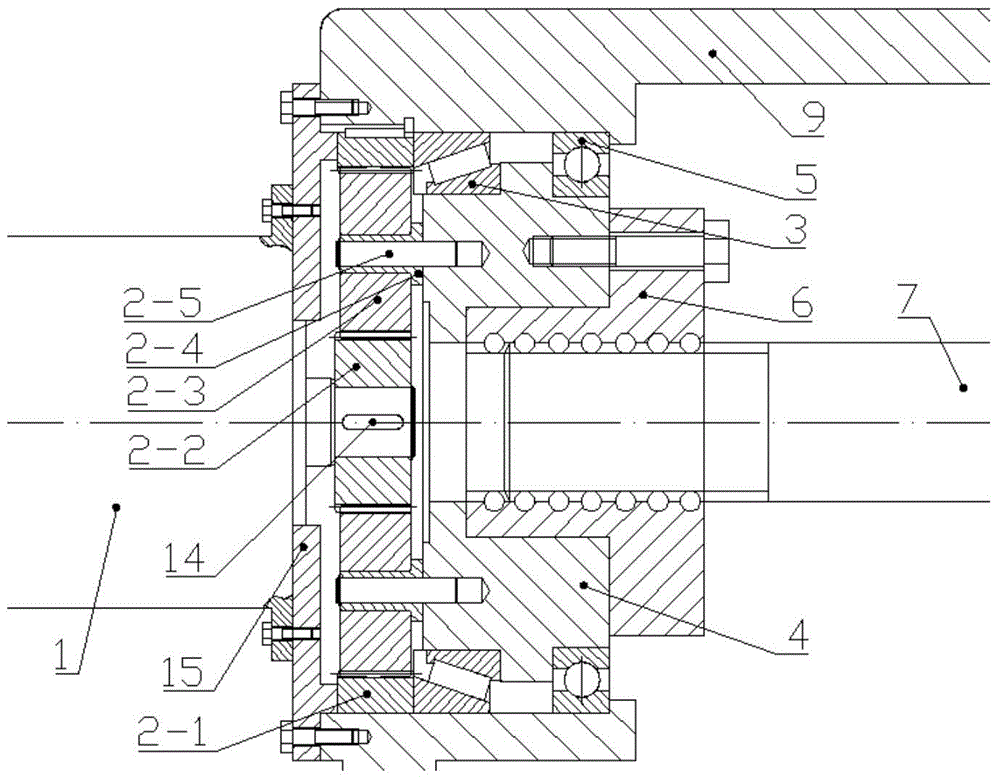

Constant-pressure variable radial-plunger pump

InactiveCN101131152ASimple structureSimple variable manipulationPositive-displacement liquid enginesMulti-cylinder pumpsLow noiseRadial piston pump

The present invention relates to one kind of constant pressure and variable displacement radial plunger pump, which has an elliptic pump shell; a stator sliding inside the shell and slide fitting to the back ring; a rotor on the flow distributing shaft and with plungers inside radial plunger holes and link rods inside the plungers; a driving shaft connected through coupling to the rotor; a flow distributing shaft with four blind holes; a large and a small control plungers pushing the stator through sliding blocks; a hand driven constant pressure and variable displacement valve to regulate oil pressure with an inner valve core to control the large control plunger and a screw bolt to control the small control plunger so as to control the eccentric distance between the stator and the rotor and determine the oil displacement. Rotating the rotor by one cycle completes once oil sucking and oil discharging. The present invention has simple structure, small size, low noise and other advantages.

Owner:董桂敏

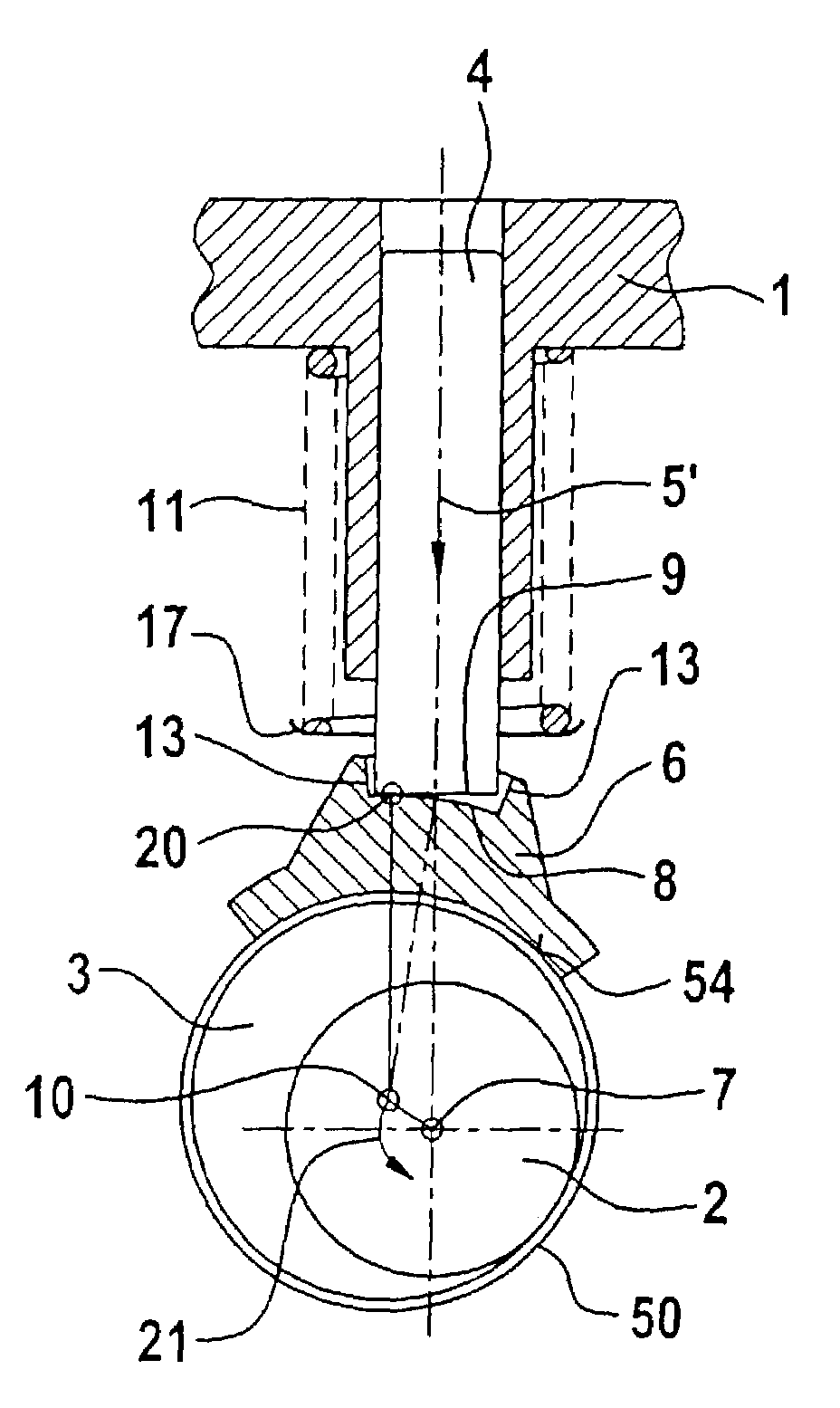

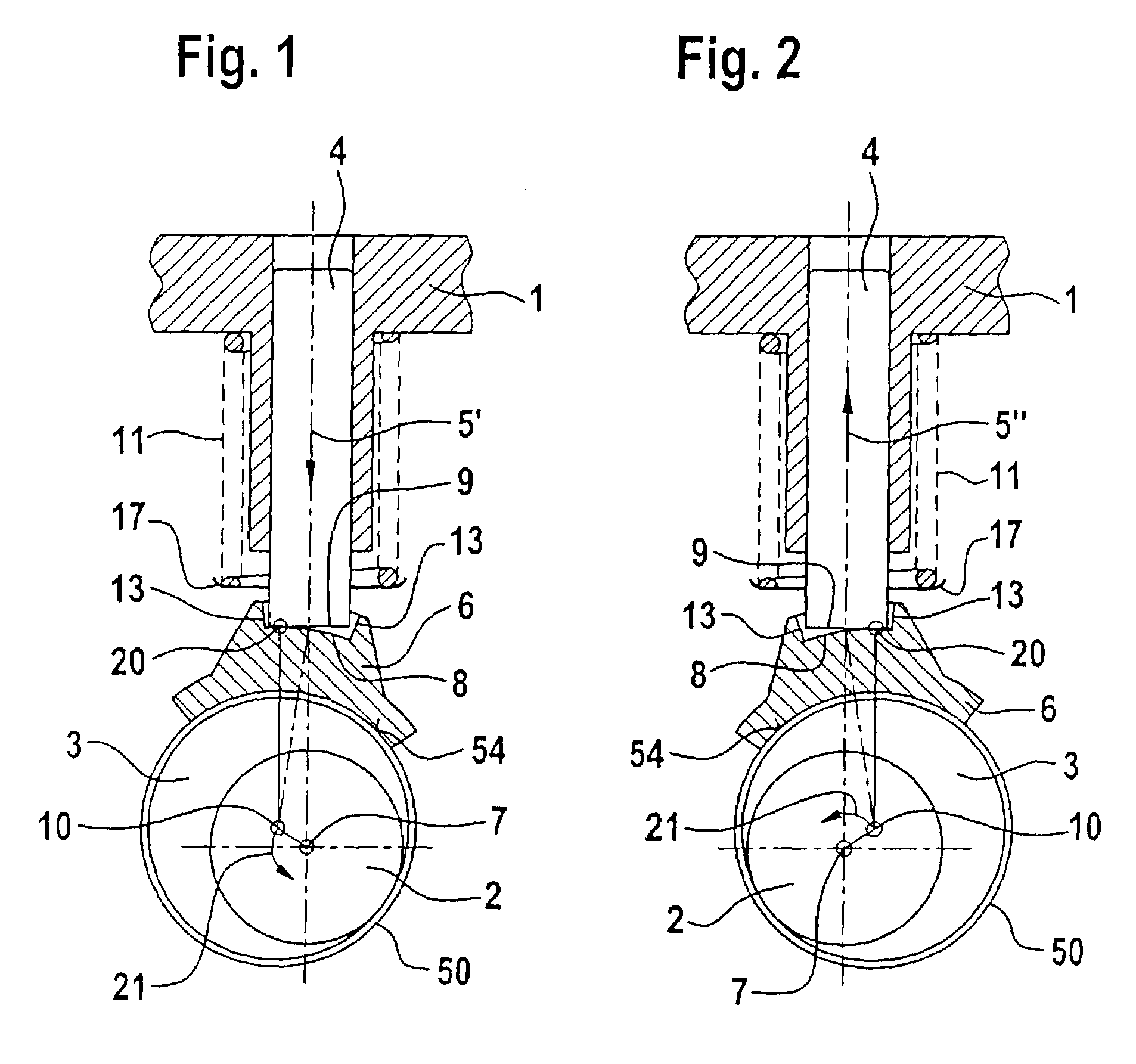

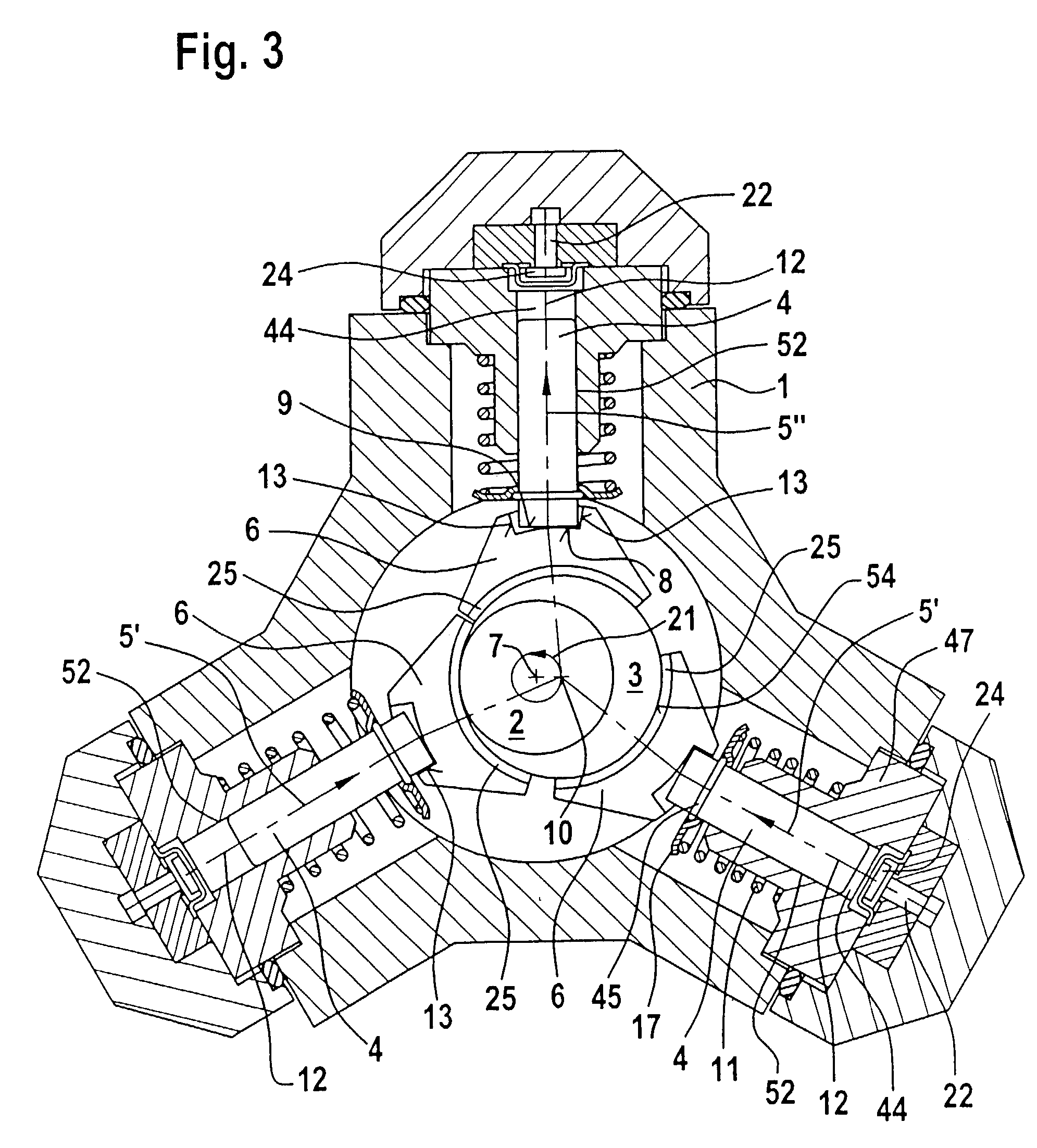

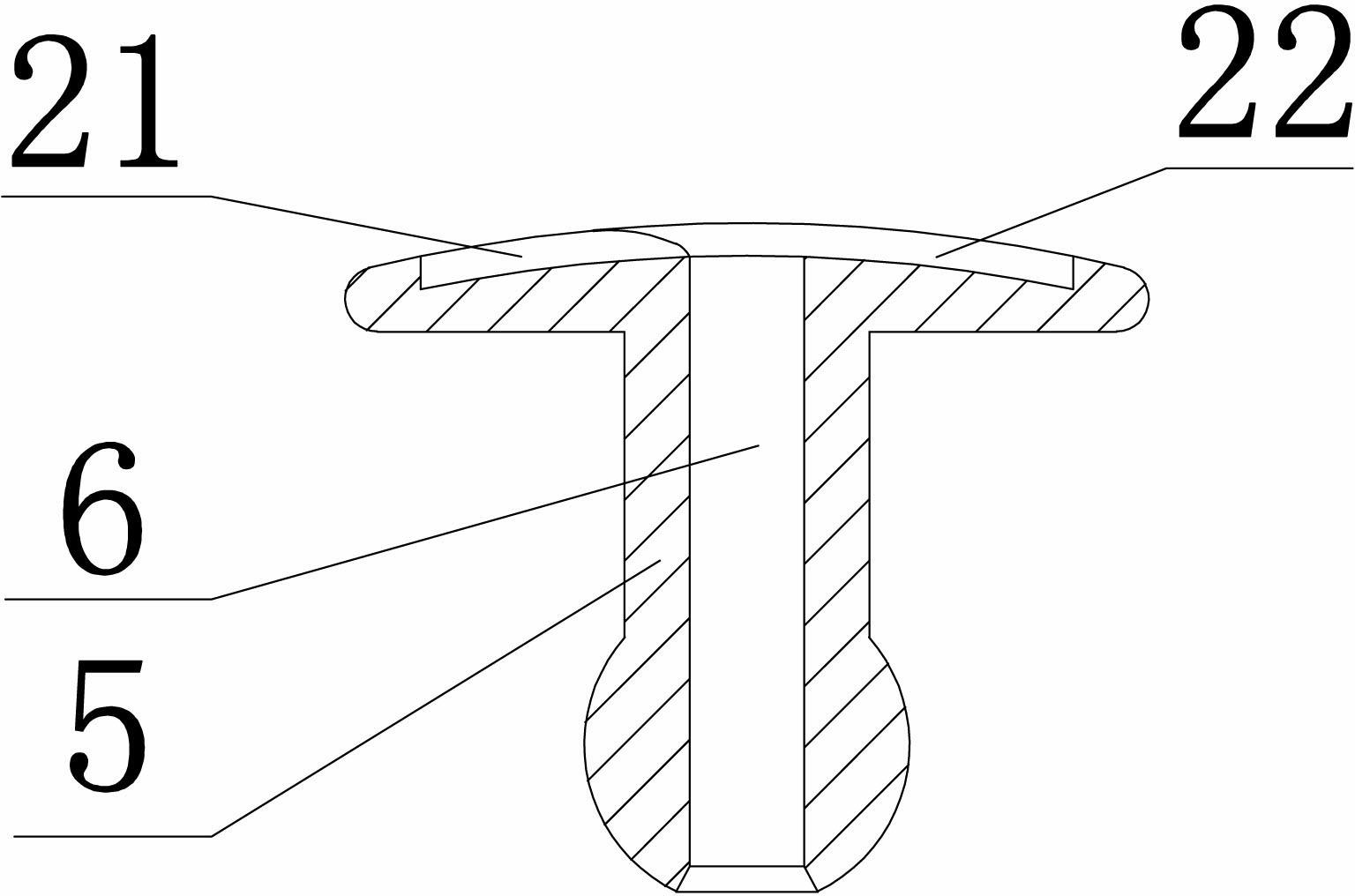

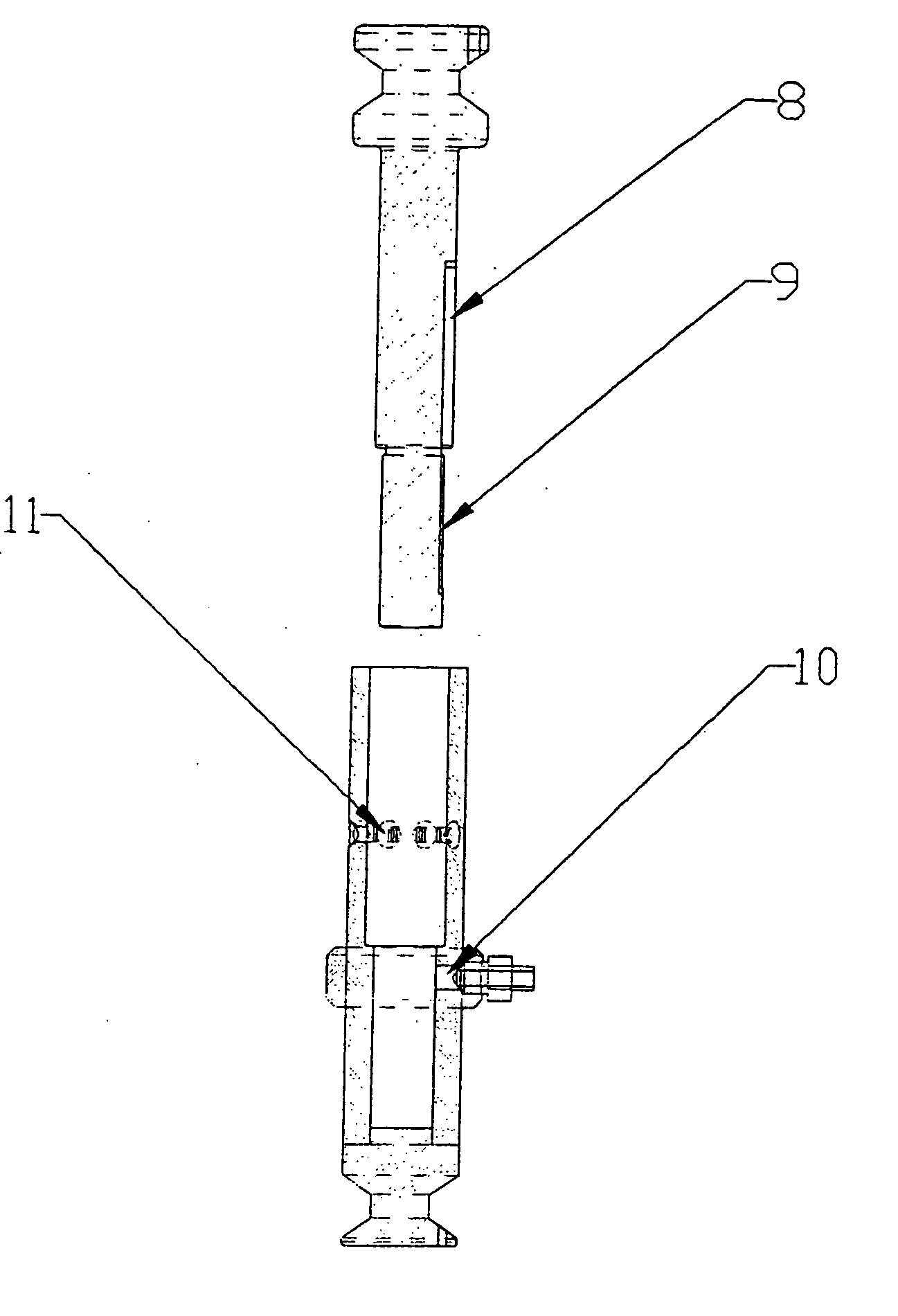

Radial piston pump with piston rod elements in rolling contact with the pump pistons

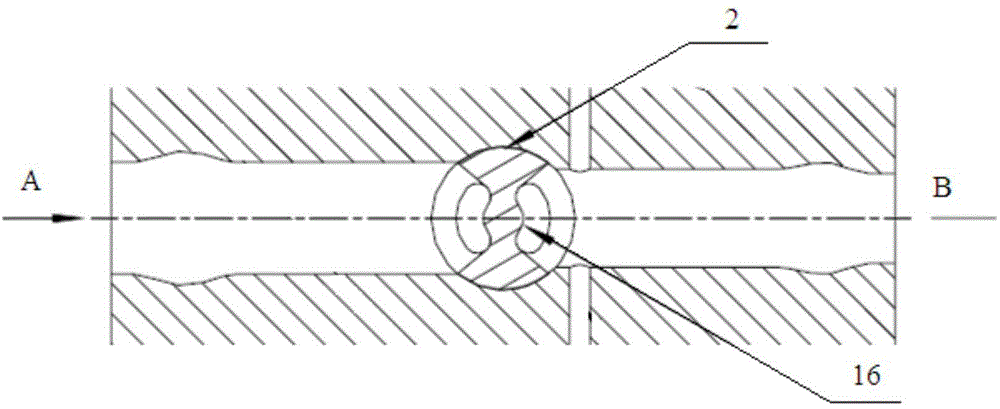

In a piston pump for providing high-pressure fuel in a common-rail fuel injection system including a camshaft (2), which is mounted rotatably in a pump housing (1) and which has at least one eccentric cam 93) for operating a pump piston (4, 14) in an approximately radial direction with respect to the camshaft (2), in order to reduce the wear of the piston pump, a piston-rod element (6, 16, 26, 36, 46) is arranged between each pump piston (4, 14) and the eccentric cam (3) so as to transmit the stroke movement (5) and the force from the eccentric cam of the camshaft (2) to the pump piston (4, 14) by a rolling movement.

Owner:DAIMLER AG

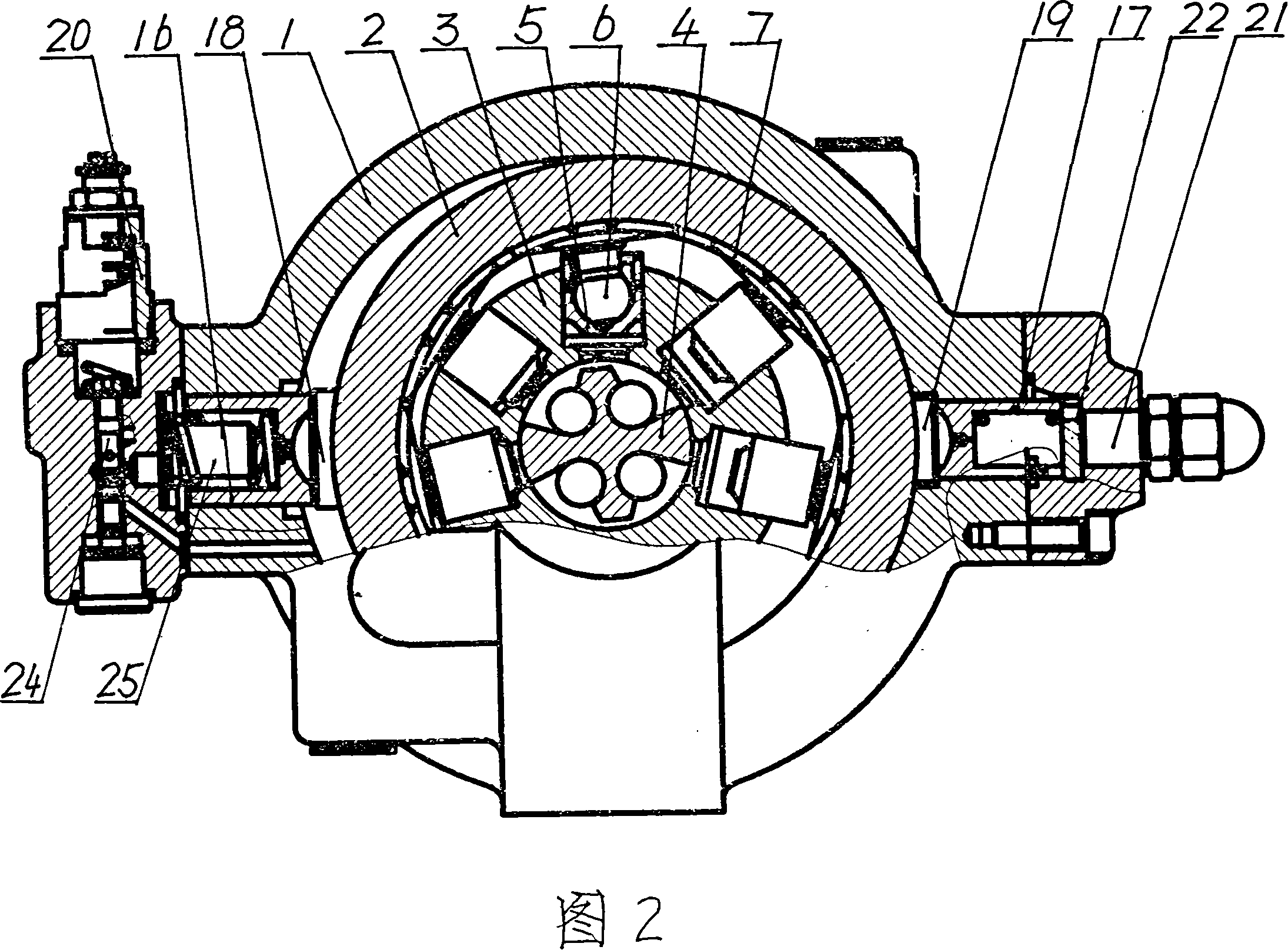

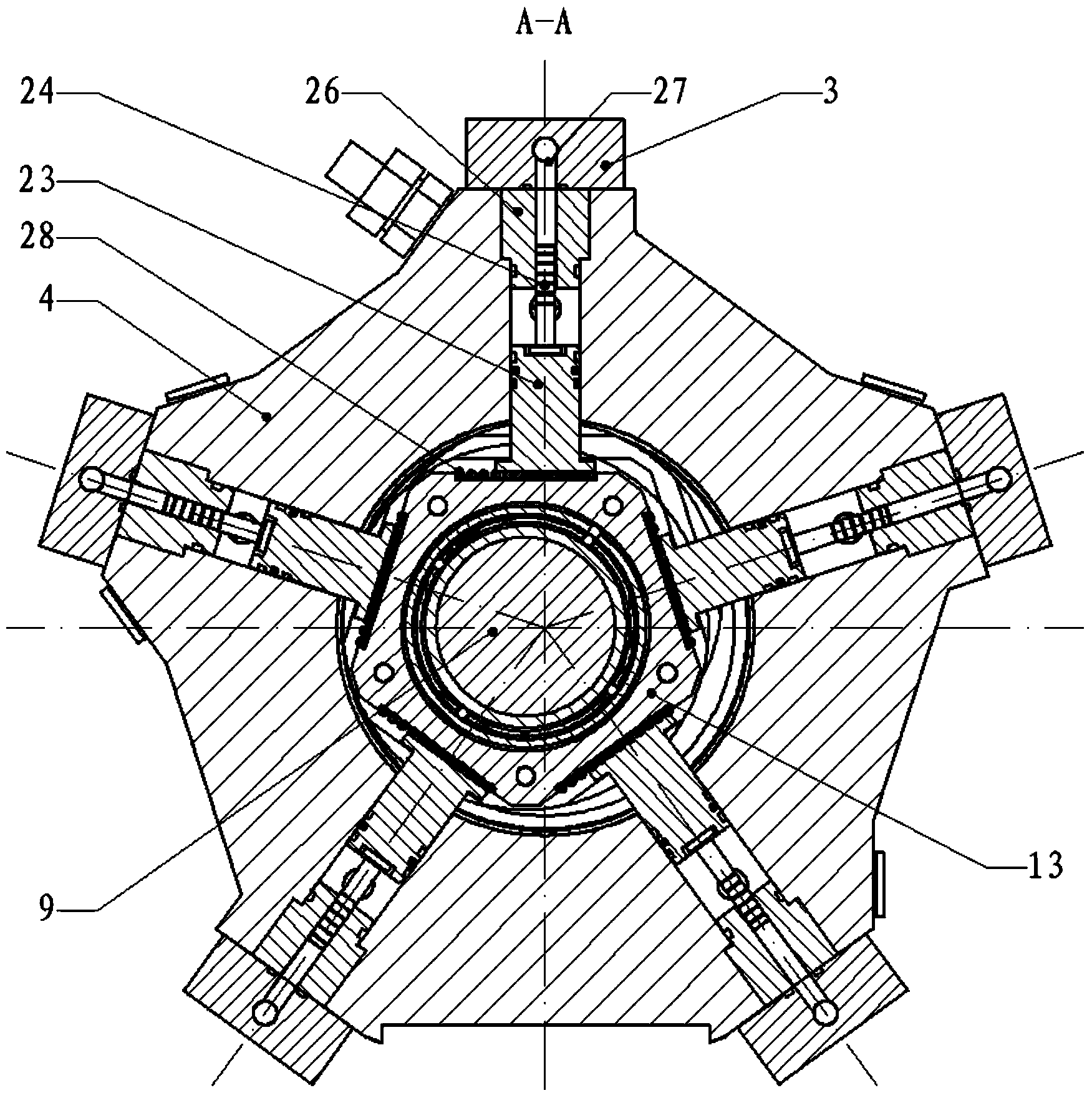

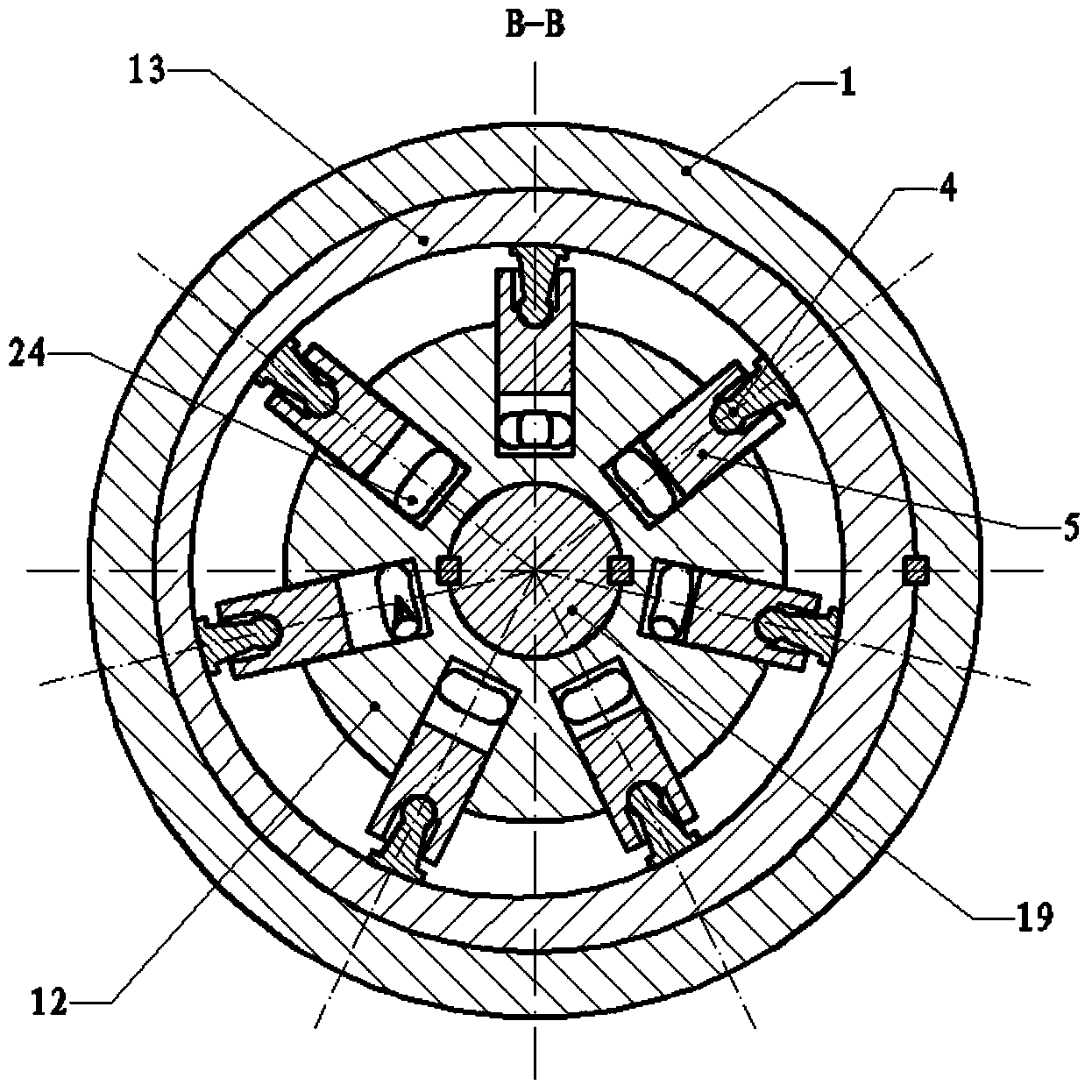

Fully-balanced type double-row radial plunger pump

InactiveCN102155367AImprove output performanceReduce volumePositive-displacement liquid enginesMulti-cylinder pumpsRadial piston pumpWear resistant

The invention discloses a fully-balanced type double-row radial plunger pump. A rolling bearing is arranged on the outer part of an eccentric part of the plunger pump; a pentagonal wear resistant sleeve is arranged on an outer ring of the rolling bearing; a groove is formed on the side face of the pentagonal wear resistant sleeve; a cylindrical roller is arranged in the groove; the outer side of the roller is contacted with the end of a plunger; a plunger cavity is communicated with a suction valve and a discharge valve respectively; the suction valve is designed by an external structure of areturn spring, so that the internal space of the plunger pump is saved; suction cavities are communicated with one another and discharge cavities are communicated with one another through inclined straight holes respectively to form internal flow channels; the suction cavities and the discharge cavities are communicated with the outside through a single suction inlet and a single discharge outlet; an eccentric shaft is directly driven to rotate through an alternating current servo motor; and fluctuation-free adjustment of output pressure and flow are realized through the servo motor. By the plunger pump, clutches and speed variable gear mechanisms are reduced, the volume and the mass of the pump are reduced, the performance of equipment is improved, and the service life of the equipment is prolonged simultaneously.

Owner:XI AN JIAOTONG UNIV

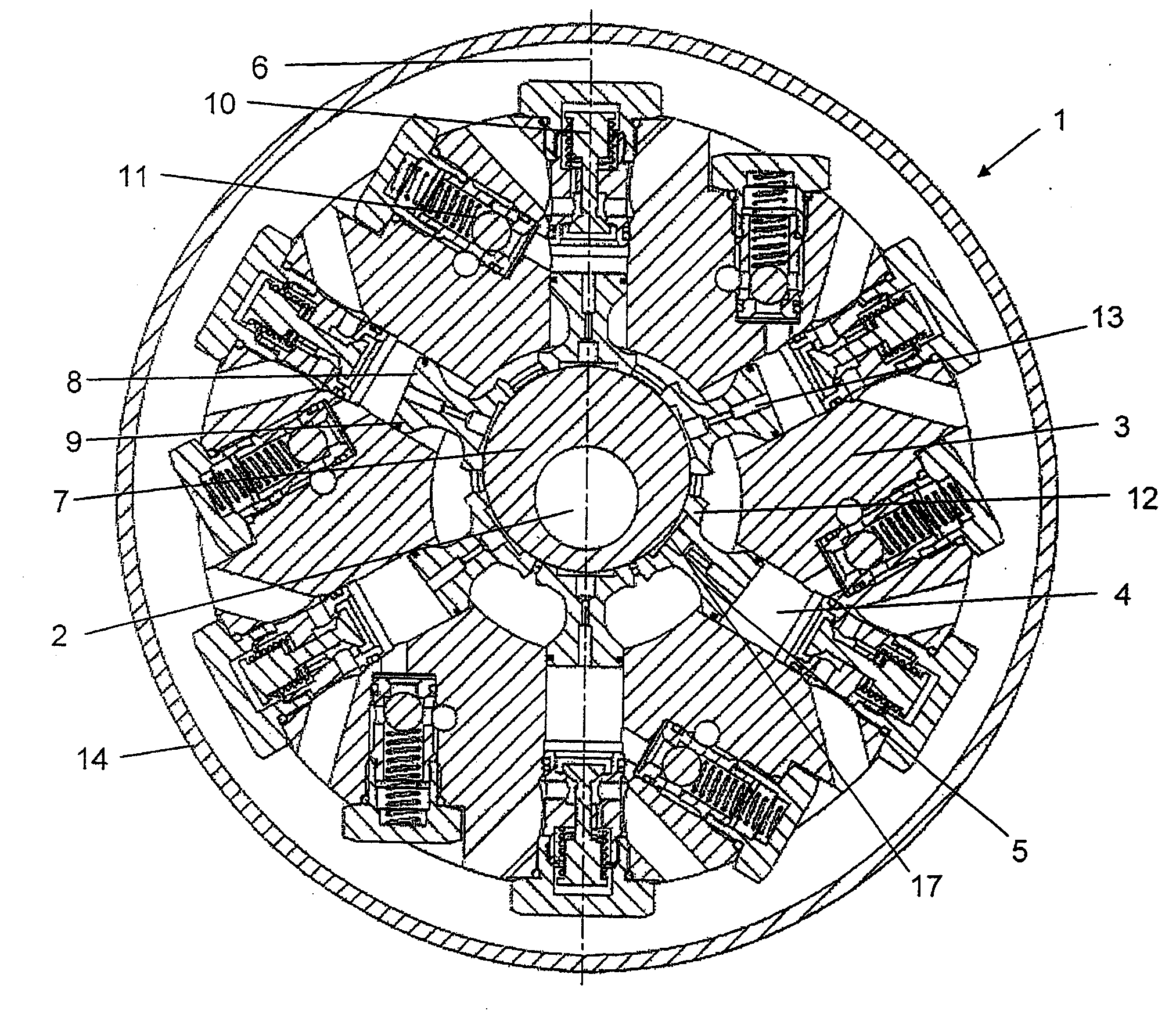

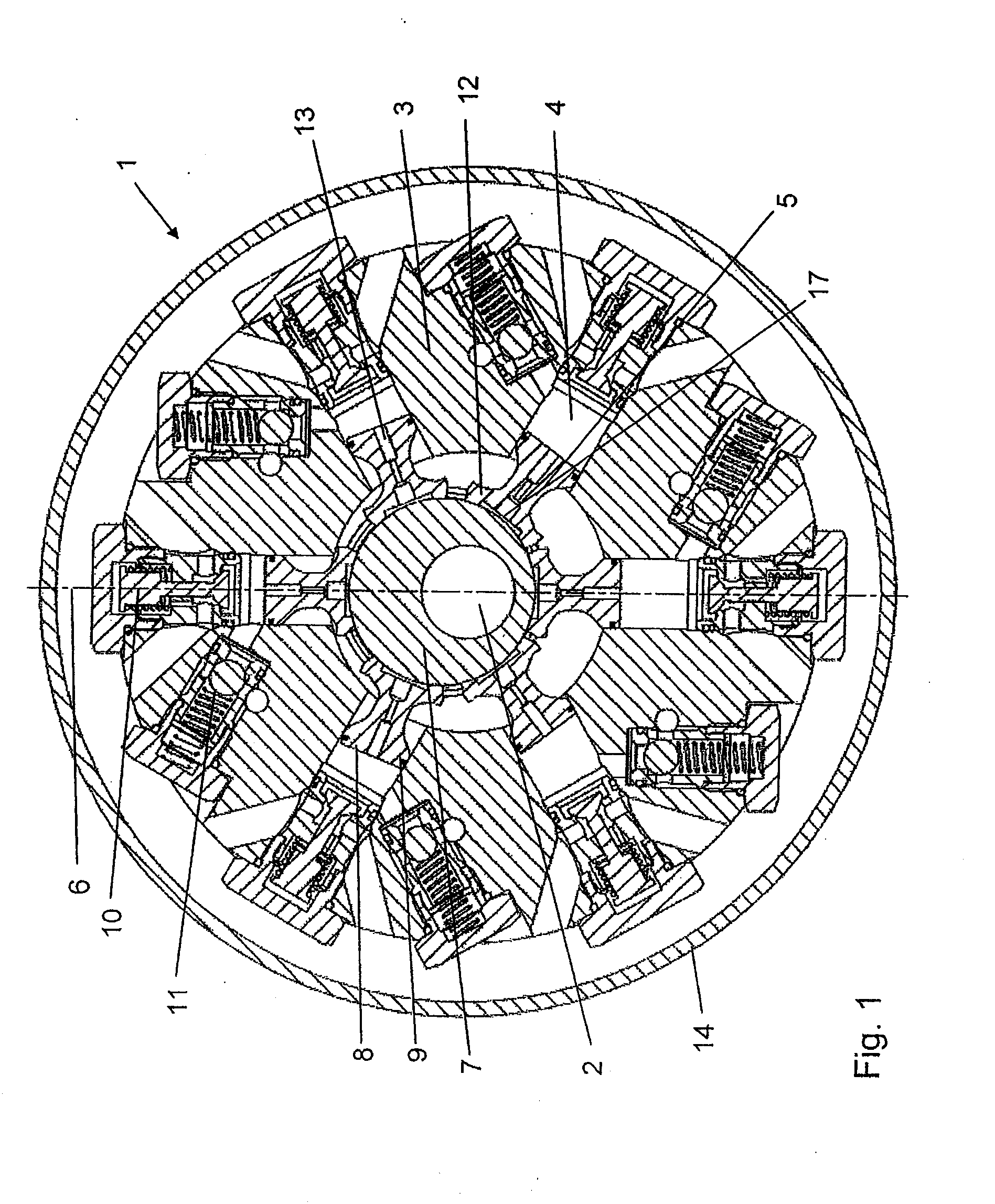

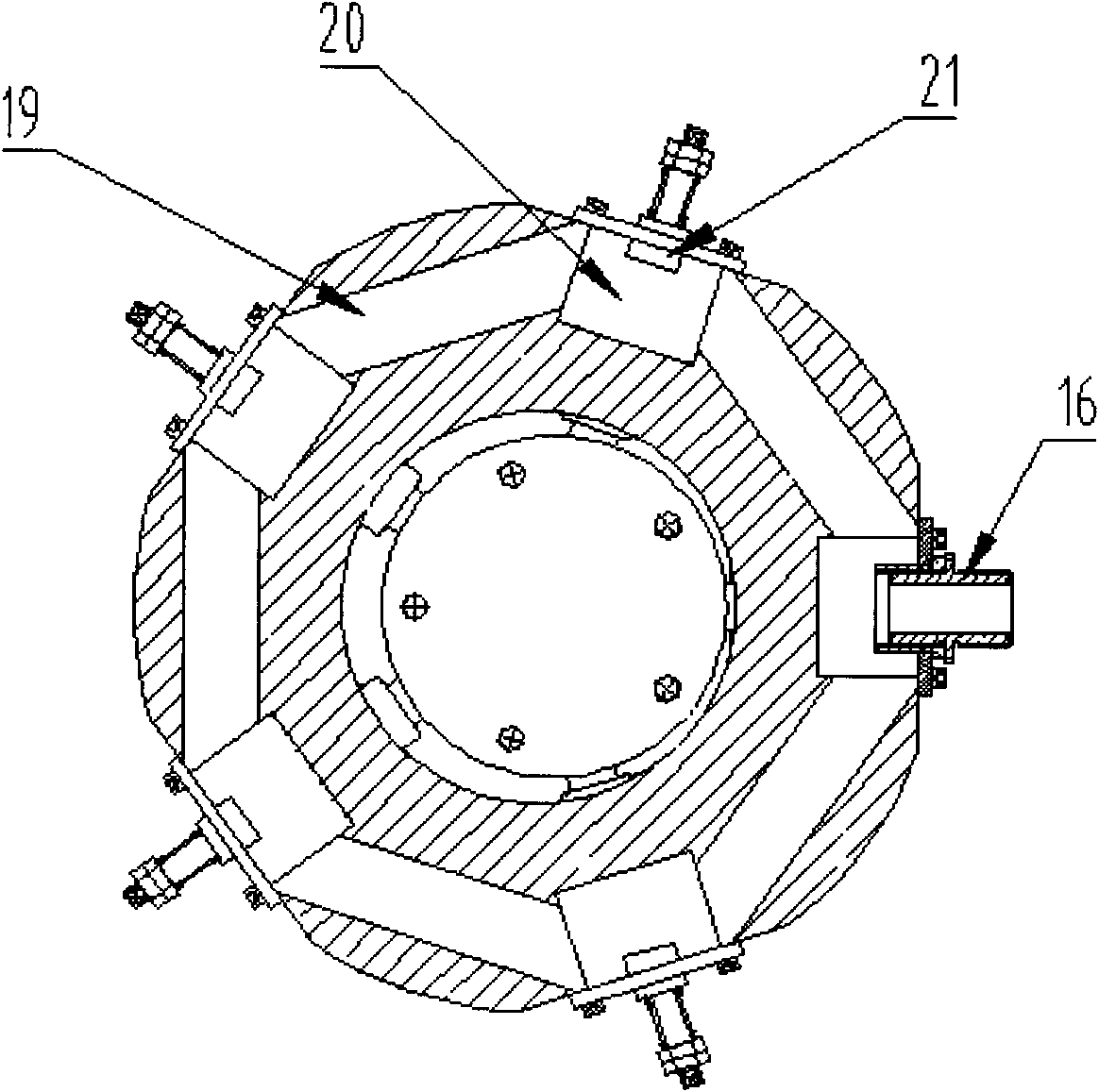

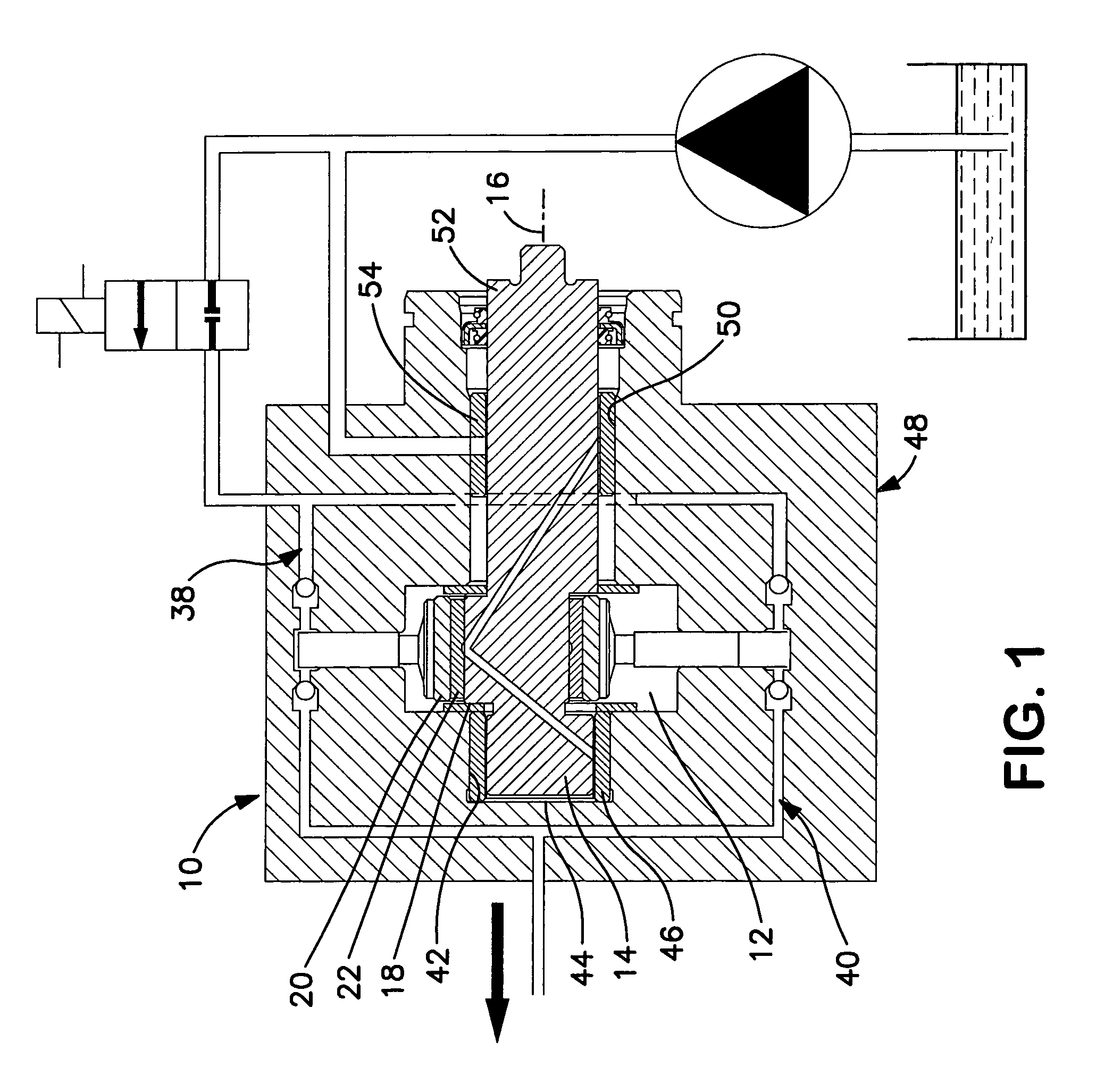

Variable displacement radial piston pump

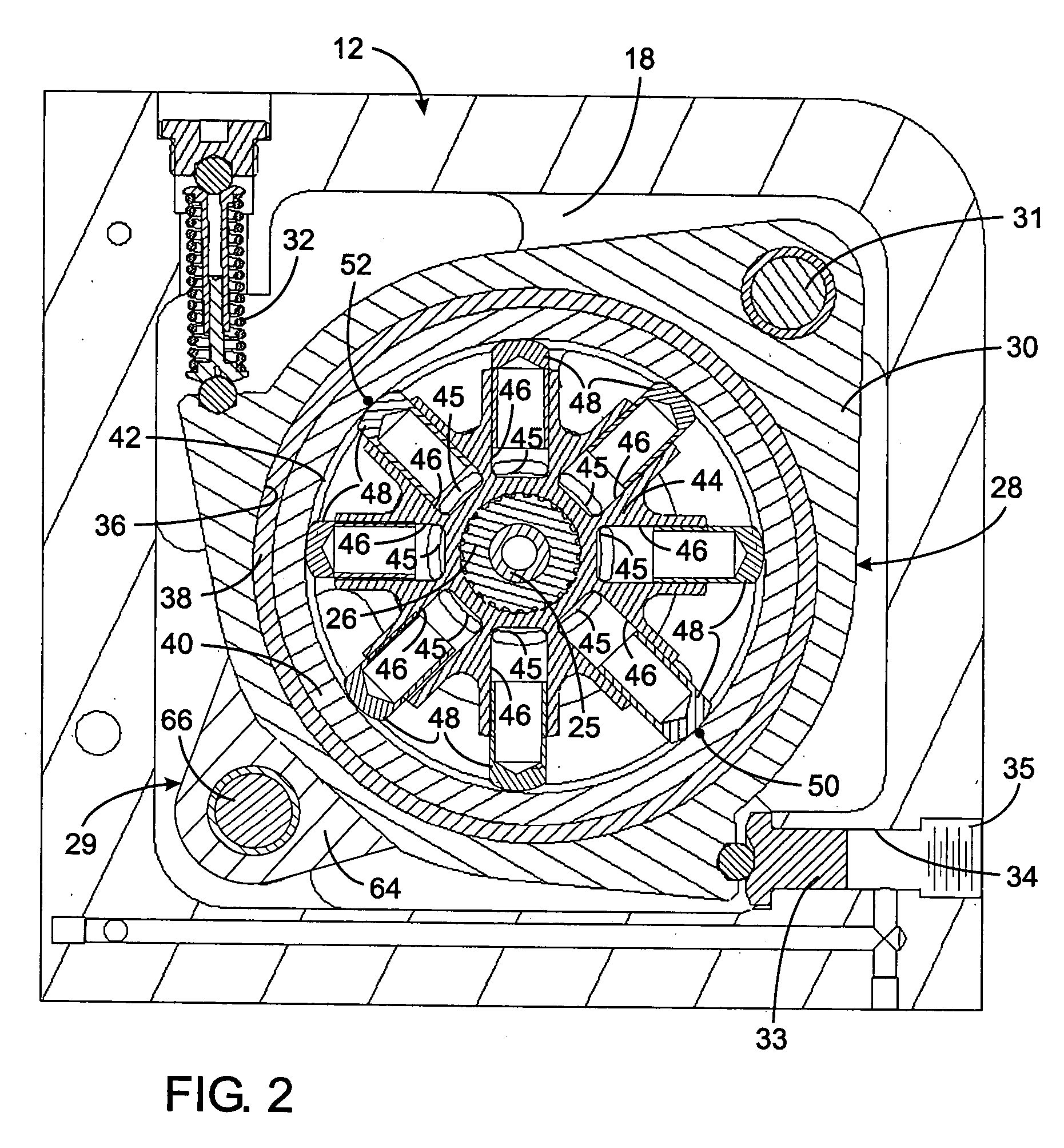

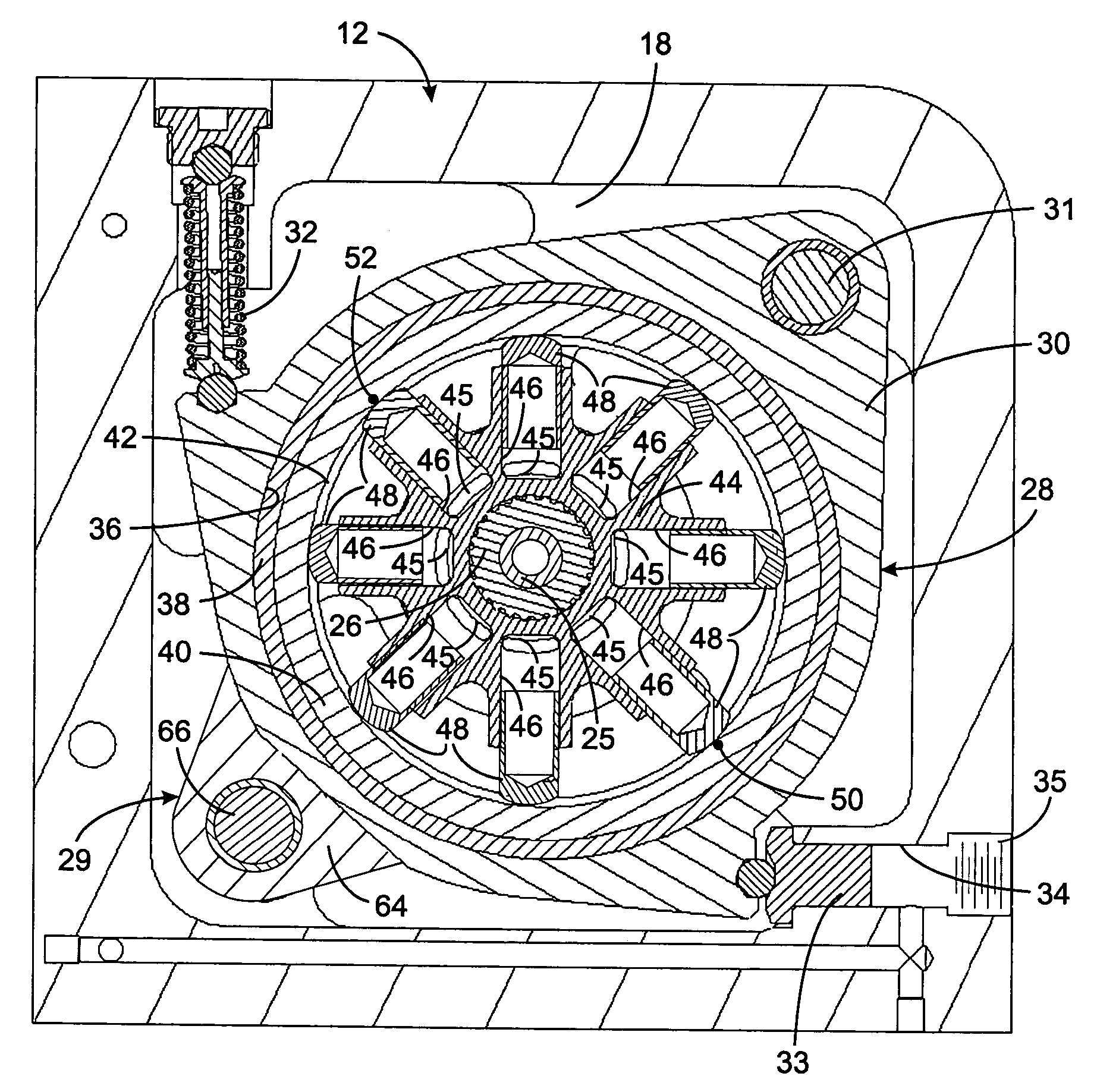

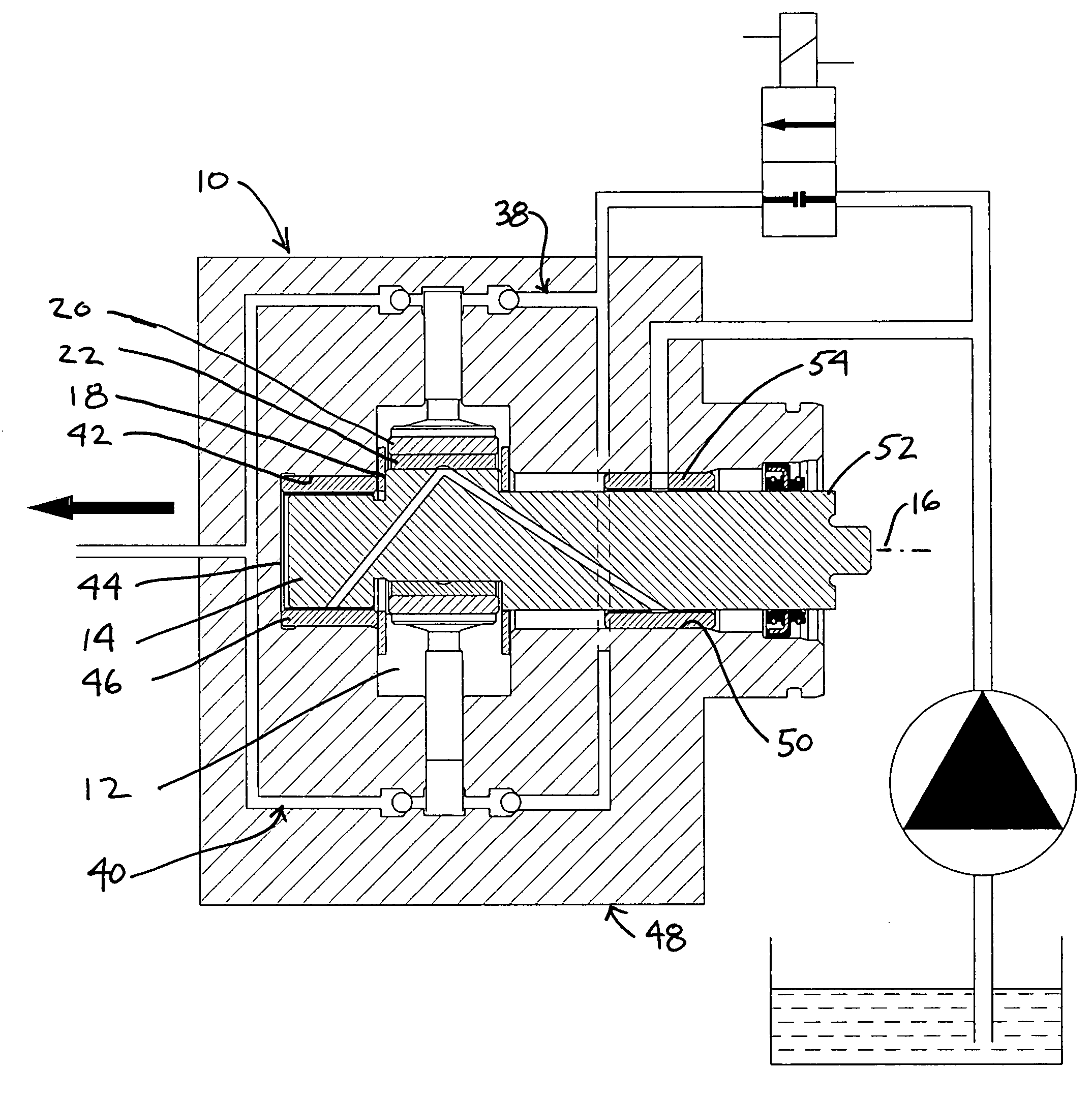

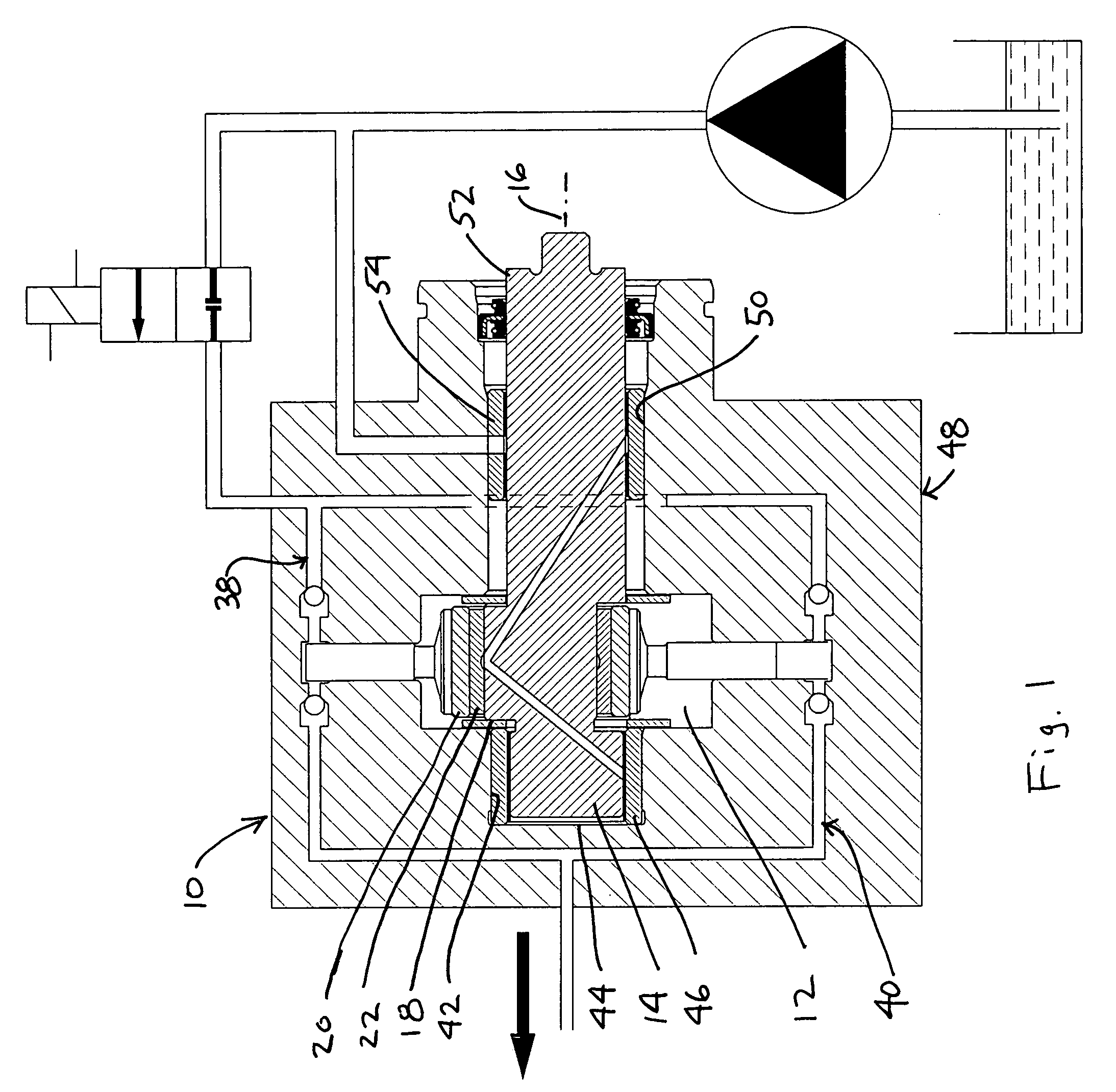

ActiveUS20060222512A1Alters spatial relationshipPump controlPositive-displacement liquid enginesRadial piston pumpCylinder block

A radial pump has a housing with a cylinder ring is pivotally mounted therein. The cylinder ring has a circular aperture within which a cam surface is formed. A cylinder block rotates within the cylinder ring aperture and has a plurality of radially extending cylinders each having port which selectively communicates with a fluid inlet and a fluid outlet as the cylinder block rotates. A plurality of pistons is slideably received within the plurality of cylinders and engages the cam surface. An actuator operably coupled to produce movement of the cylinder ring, which alters the spatial relationship between the cylinder ring and the cylinder block to vary the amount that the pistons move within the cylinders. The amount of movement of the pistons within the cylinders is directly related to the magnitude of fluid flow delivered by the pump and moving the cylinder ring thereby controls the fluid flow. Rotation of the bearing ring produces less torsional drag (parasitic horsepower loss) than the sliding motion of the pistons on a stationary ring, which allows for increasing speed of operation and less performance losses.

Owner:EATON INTELLIGENT POWER LIMITED

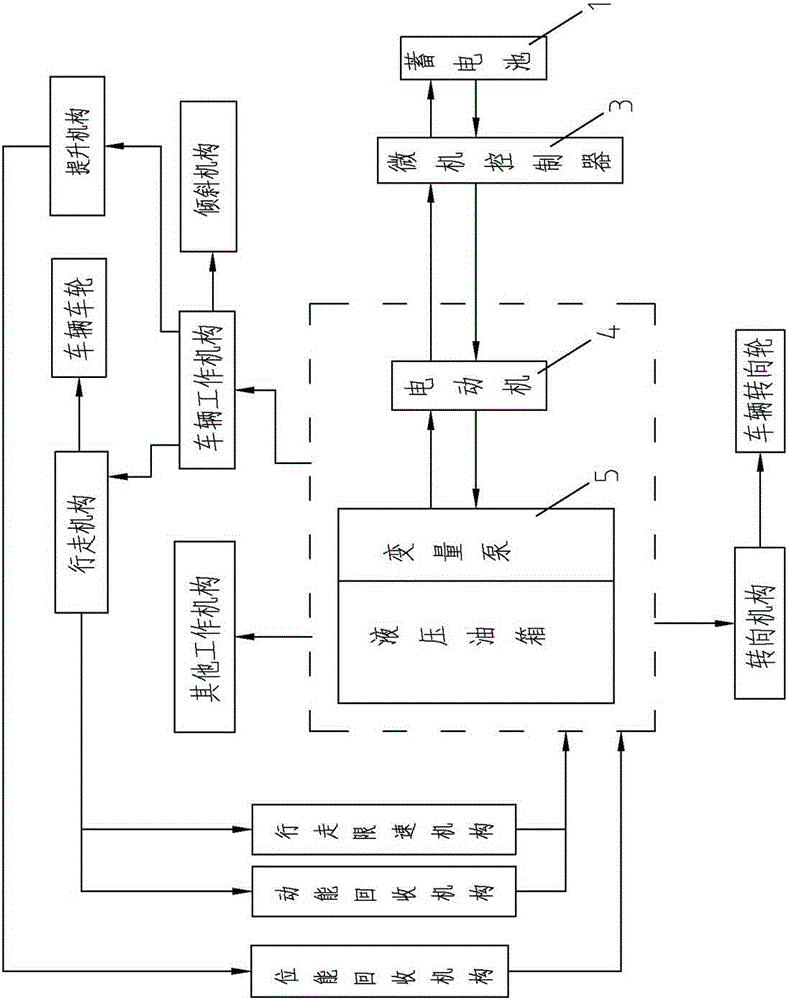

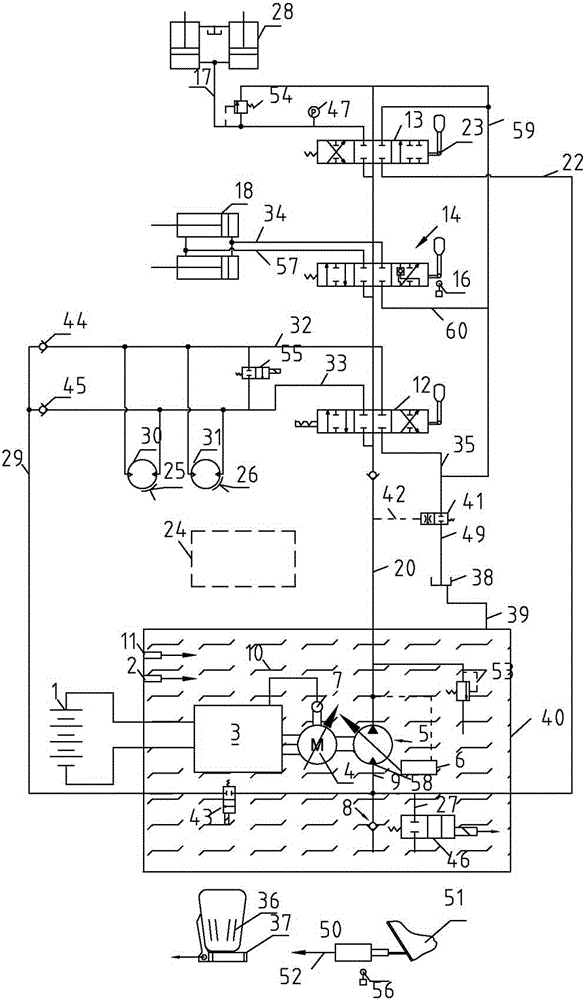

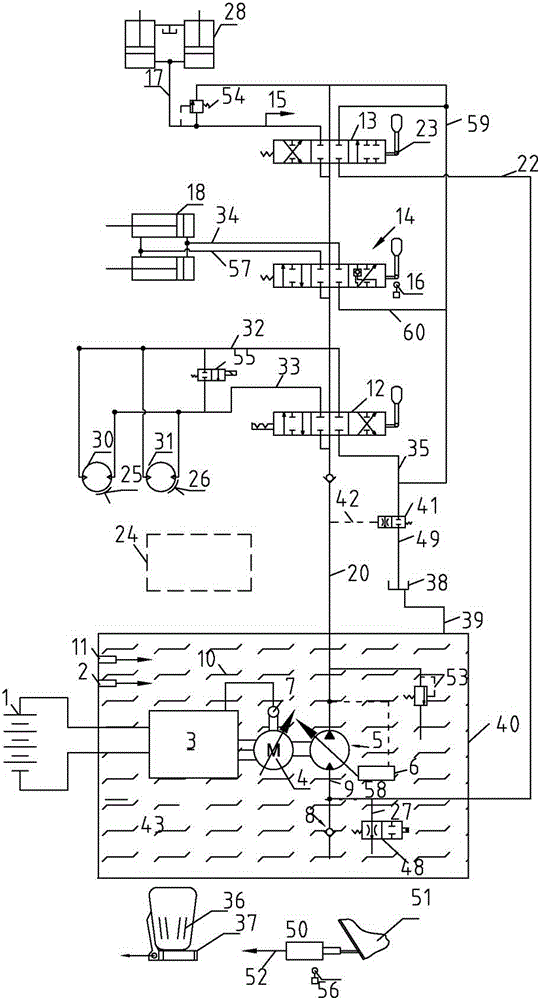

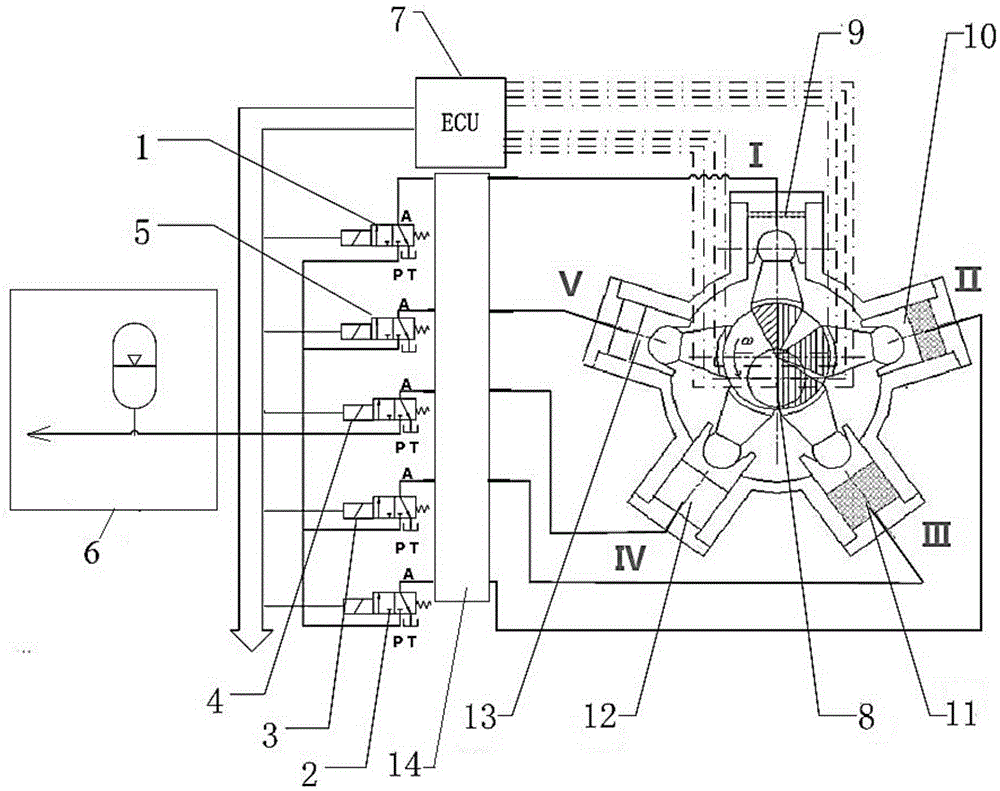

Electric control hydraulic driving system for industrial vehicle

ActiveCN105197840AAchieve recyclingSimple structureVehicle fittingsElectrodynamic brake systemsBrushless motorsRadial piston pump

The invention relates to an electric control hydraulic driving system for an industrial vehicle. Only one electromotor and one microcomputer controller are used for driving a variable pump to conduct frequency control so as to convey hydraulic oil in a hydraulic oil tank to a travelling mechanism, an inclining mechanism, a lifting mechanism, a steering mechanism, a kinetic energy recycling mechanism, a potential energy recycling mechanism and a travelling speed limiting mechanism; kinetic energy recycle, overload potential energy recycle, and no-load and light-load unloading can be realized while the vehicle realizes actions of travelling, inclining, lifting and steering; through the adoption of the travelling speed limiting mechanism, the vehicle speed can be limited, and the vehicle travelling can be stable; during slope sliding and braking, the hydraulic system can automatically supply oil; during slope climbing of the vehicle, the variable pump automatically varies according to the load pressure set value to achieve the low-speed large-torque slope climbing function, and the slope climbing current is low. The electromotor consists of a permanent-magnet brushless motor, an inverter controller and a variable piston pump; zero current start to a load current is realized, the starting time is within the millimeter-level range, large current starting can be avoided, and energy can be saved.

Owner:上海市闸北区物流工程技术研究所

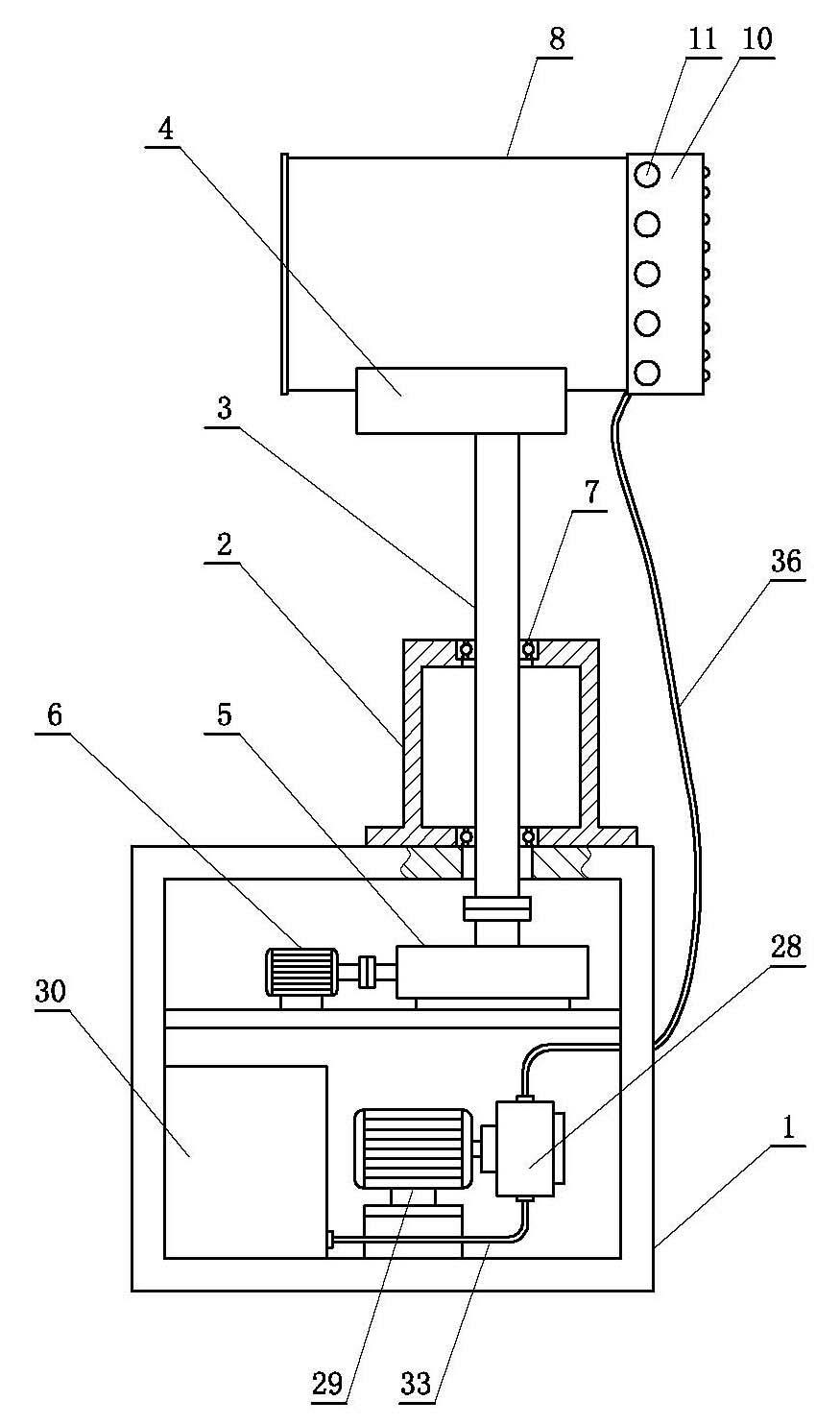

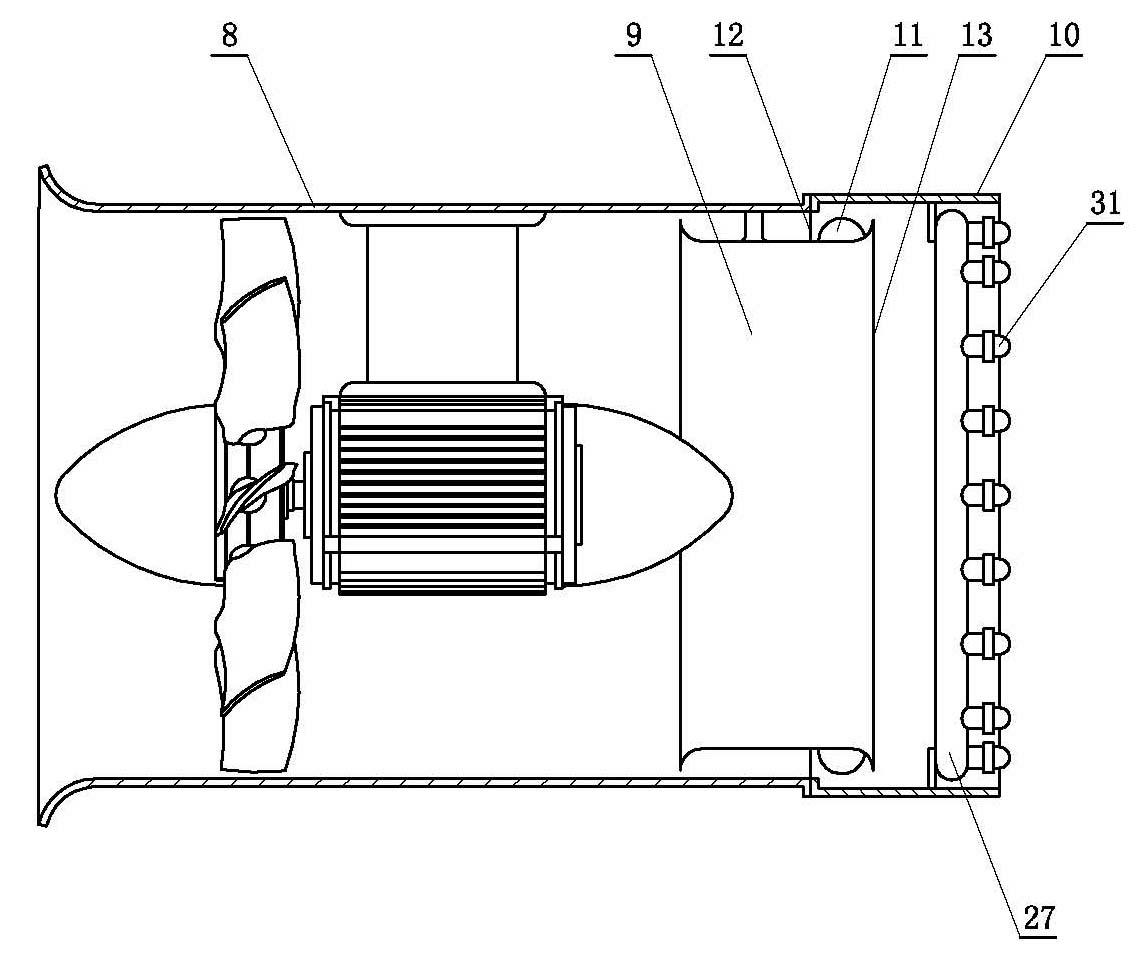

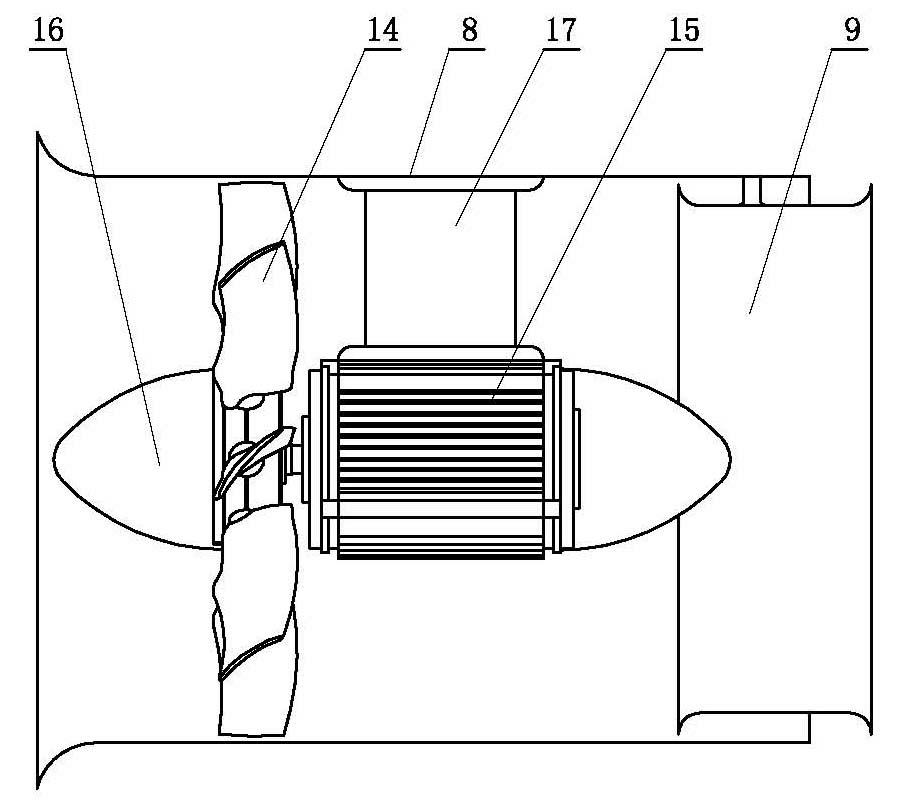

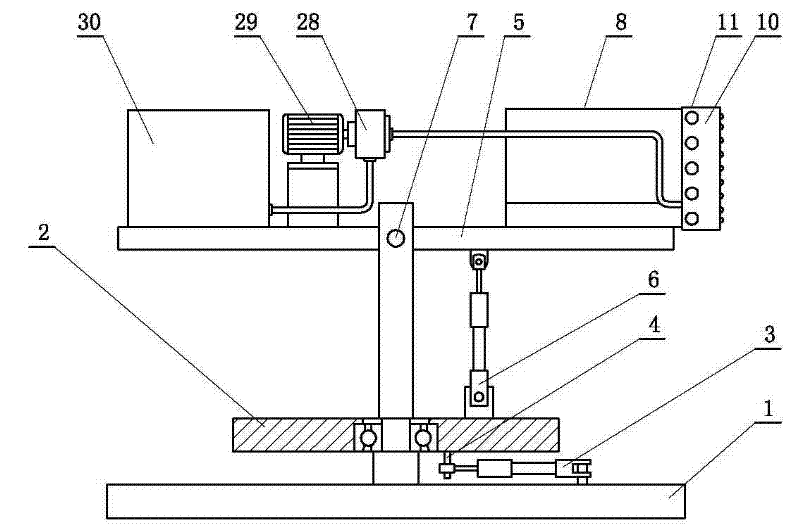

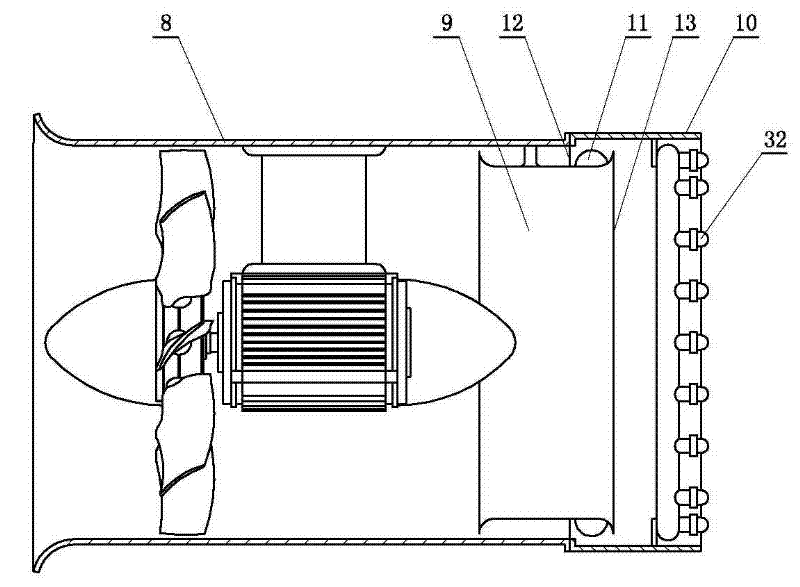

Far range air supply type mist spray purification device

InactiveCN102527548AReduce volumeReduce weightLiquid spraying apparatusRadial piston pumpHigh pressure

The invention relates to a far range air supply type mist spray purification device. The device comprises a machine seat and a main control platform, wherein an air supply device and a mist spray device are arranged on the machine seat; the air supply device is provided with a base; a rotating vertical column is arranged in the center of the base; a supporting plate is fixed at the upper end of the rotating vertical column; the lower end of the rotating vertical column is in power connection with a driving mechanism; an air cylinder is fixed on the supporting plate; a pressure diffusion throat pipe is arranged on the inner side of an air outlet of the air cylinder; the tail end of the air outlet of the air cylinder is connected with a backflow cover; a high-pressure axial flow fan is arranged in the center of the air cylinder; the mist spray device comprises an annular distribution pipe, a radial plunger pump, a motor and a water tank; an atomizing nozzle is arranged on the annular distribution pipe; a liquid absorption opening of the radial plunger pump is communicated with a water supply opening of the water tank through a liquid inflow pipeline; and a liquid outlet of the radial plunger pump is communicated with the annular distribution pipe through a liquid outflow pipeline. The device has a far mist spray range and low energy consumption, particularly can control the sizes of atomized fog drops effectively and has good dust removing and temperature reducing effects.

Owner:陈新

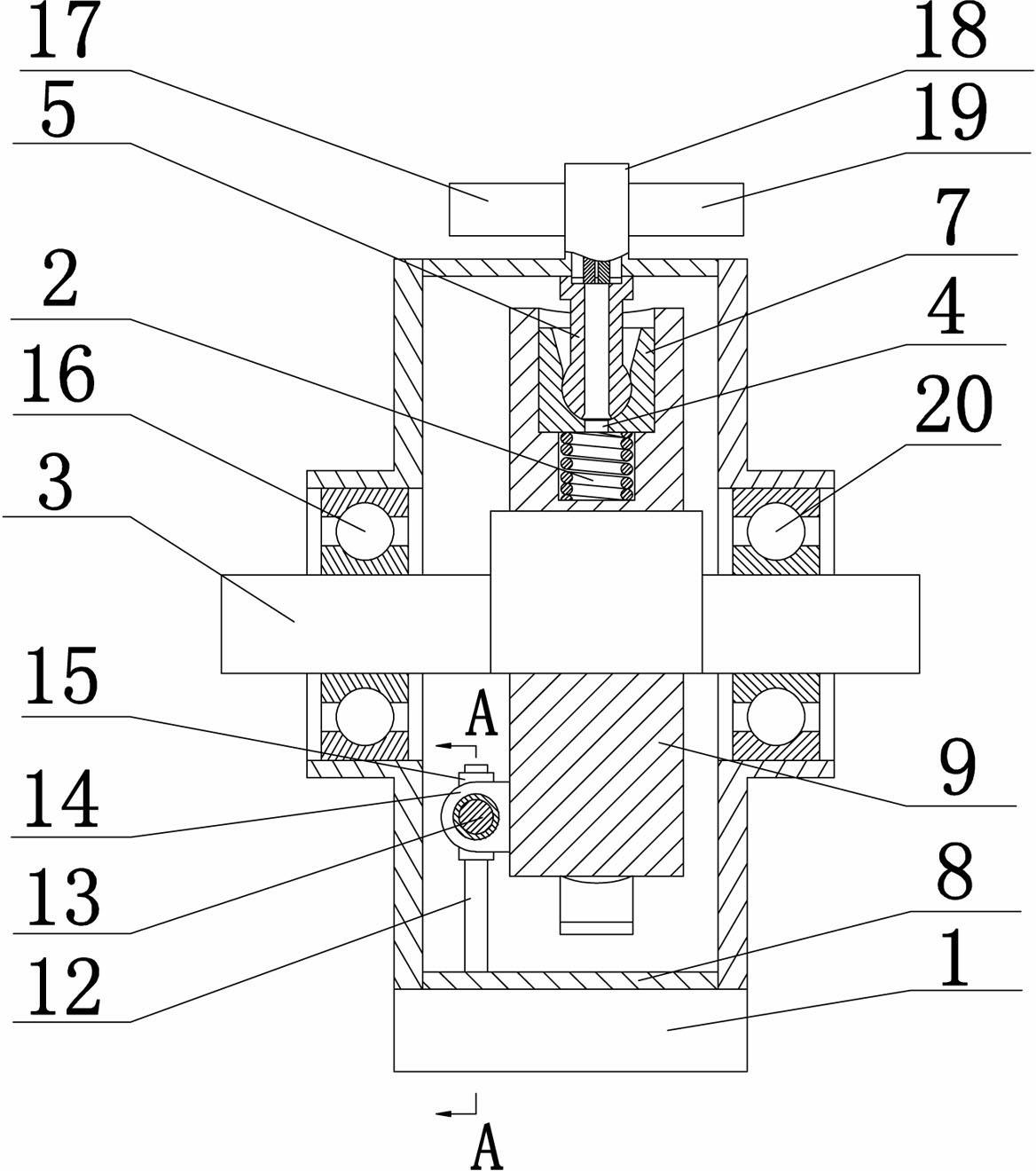

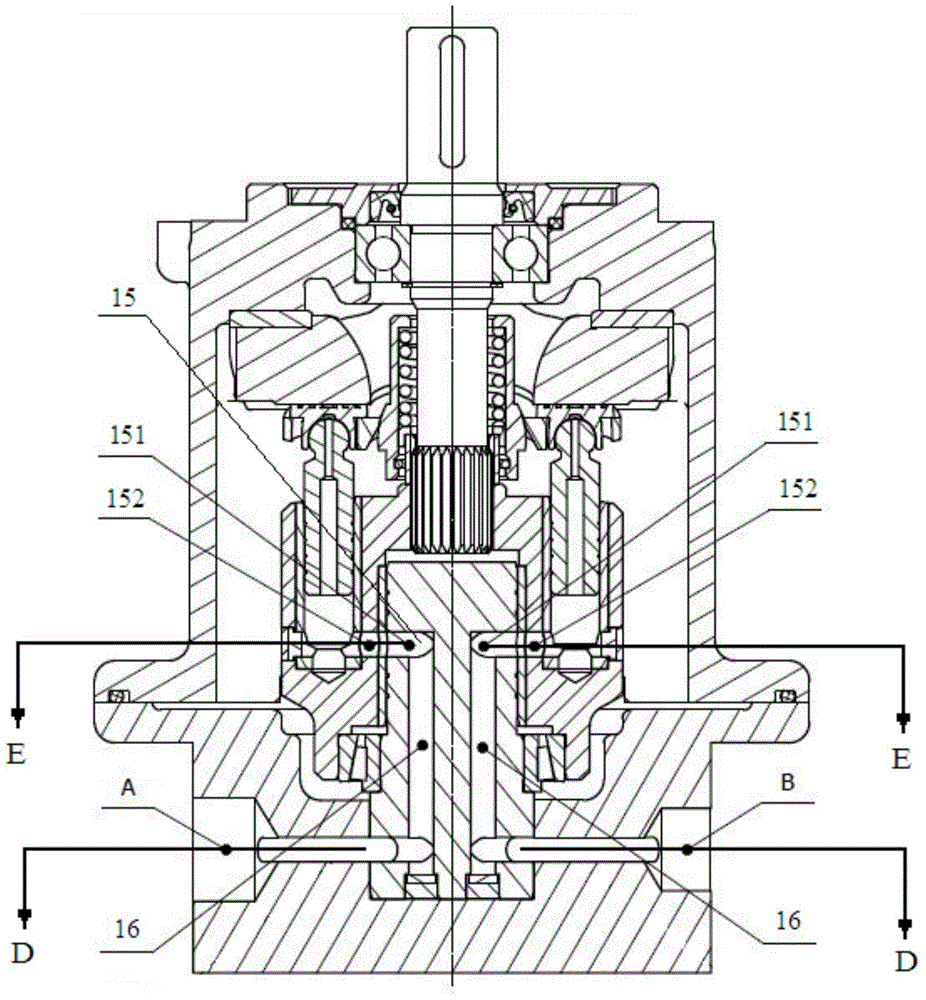

Alternating current servo motor driving device for discharge capacity adjustment of radial plunger pump

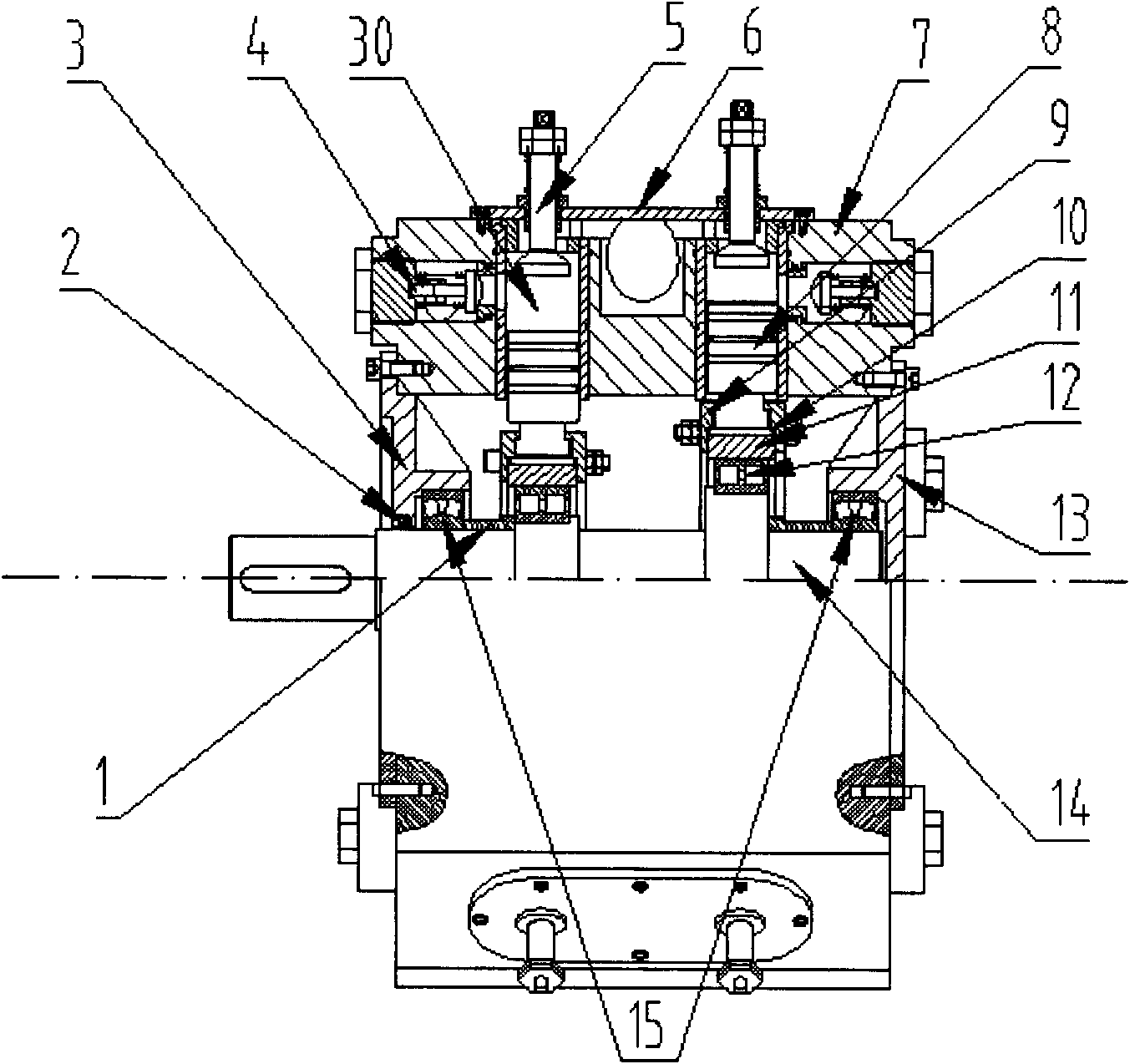

InactiveCN104153958AImprove dynamic performancePrecise flow controlPositive-displacement liquid enginesMulti-cylinder pumpsBall bearingMotor drive

An alternating current servo motor driving device for discharge capacity adjustment of a radial plunger pump comprises the shaft flow distribution radial plunger pump. A servo motor is fixed to a shell of the radial plunger pump through an end cover. An output shaft of the servo motor is in clearance fit with a sun wheel of a planetary reducer. A planet wheel of the planetary reducer is connected with a connecting block through a shaft sleeve and a hinge pin. The connecting block is connected with a screw nut. The outer portion of the connecting block is connected with the shell of the radial plunger pump in a matched mode through a conical roller bearing and a deep groove ball bearing. A ball screw is connected with a swing frame beam of the radial plunger pump. The swing frame beam is connected with a swing frame. The servo motor and the planetary reducer are both installed on the shell of the radial plunger pump. The screw nut rotationally drives the ball screw to move horizontally, so that the swing frame is driven to rotate around a swing shaft, and the offset of the radial plunger pump is adjusted. According to the alternating current servo motor driving device, adjustment is accurate and the response speed is high.

Owner:XI AN JIAOTONG UNIV

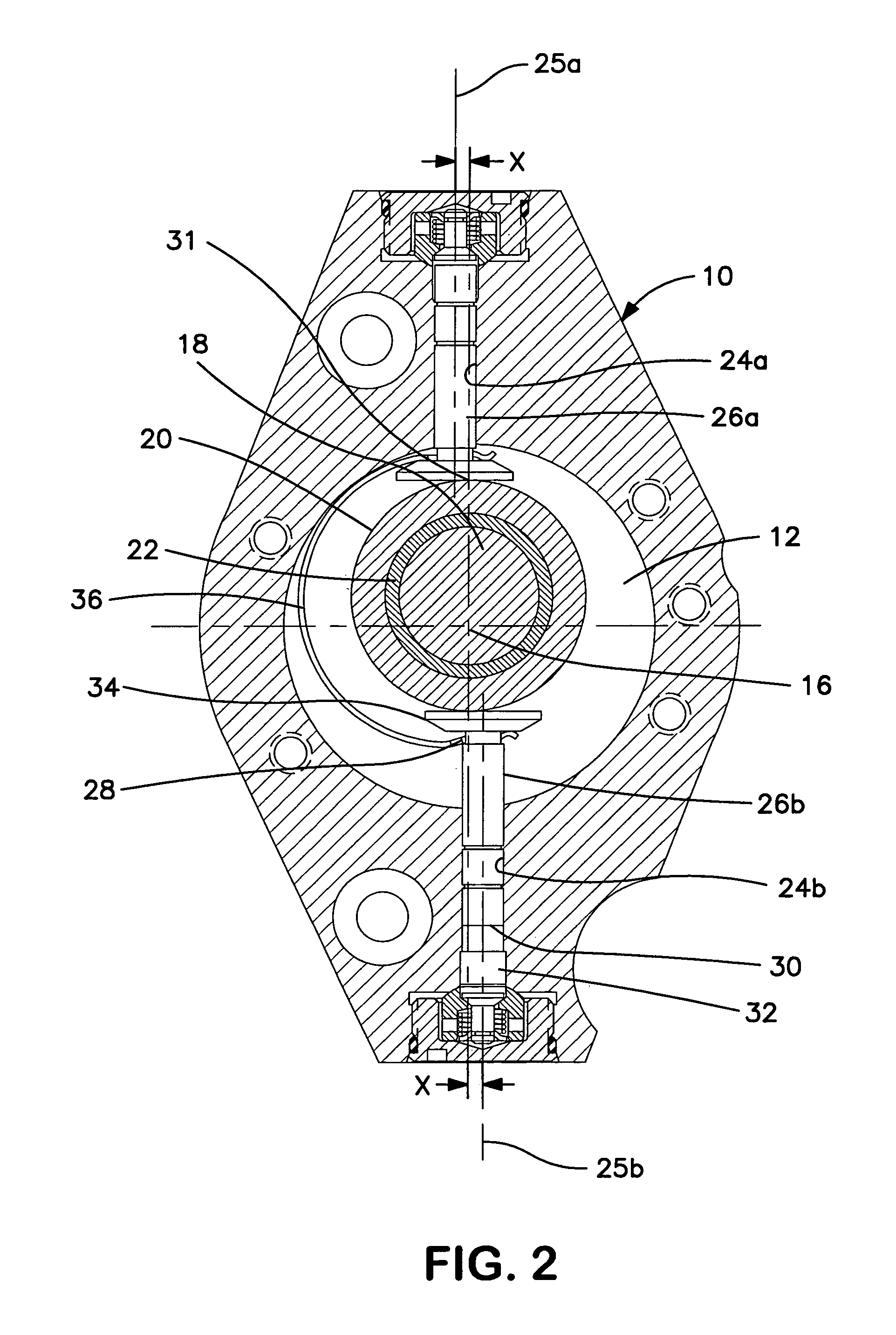

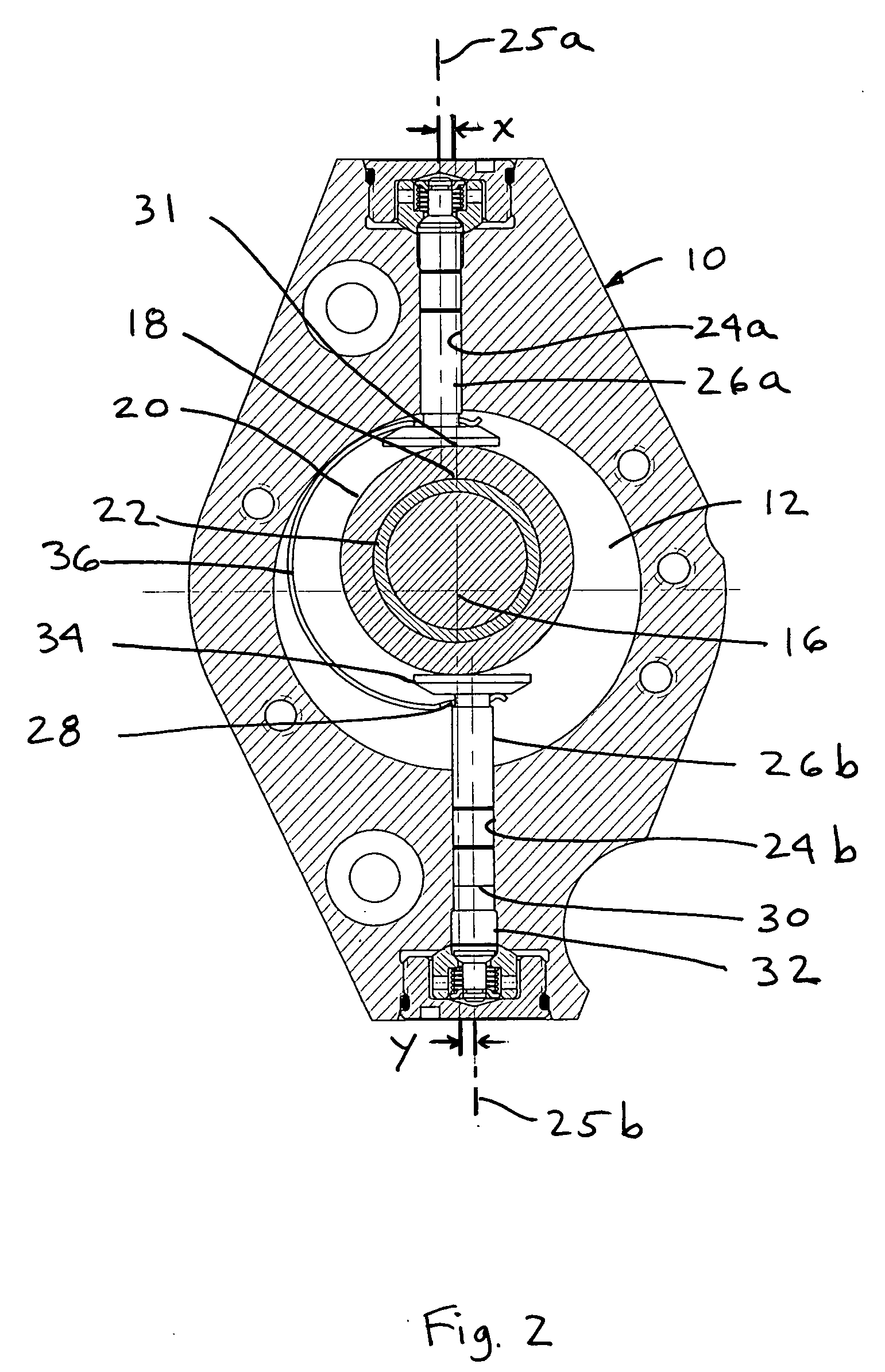

Variable displacement radial piston pump

A radial pump has a housing with a cylinder ring is pivotally mounted therein. The cylinder ring has a circular aperture within which a cam surface is formed. A cylinder block rotates within the cylinder ring aperture and has a plurality of radially extending cylinders each having port which selectively communicates with a fluid inlet and a fluid outlet as the cylinder block rotates. A plurality of pistons is slideably received within the cylinders and engages the cam surface. An actuator operably coupled to produce movement of the cylinder ring, which alters the spatial relationship between the cylinder ring and the cylinder block to vary the amount that the pistons move within the cylinders. The amount of movement of the pistons within the cylinders is directly related to the magnitude of fluid flow delivered by the pump and moving the cylinder ring thereby controls the fluid flow.

Owner:EATON INTELLIGENT POWER LTD

External radial plunger pump of sealing mechanism

InactiveCN101985921AThe advantages of the solution are: completely solve the structural defectsThe advantages of the solution are: completely solve the structural defect, that is, the phenomenon of "shaft holding"Positive displacement pump componentsPositive-displacement liquid enginesRadial piston pumpPump chamber

The invention discloses a cut-water external radial plunger pump of a sealing mechanism. The external radial plunger pump comprises a pump body, an annular stator, a rotor, a plunger, a roller, a return ring, a pump chamber, a rotor sleeve, a floating isolation tongue, a central flow passage, a shaft seal device, a suction and exhaust one-way valve, an adjusting screw and the like. The rotor and a distribution shaft are combined into a whole and supported on bearings at two ends; the rotor is provided with the central flow passage, the rotor sleeve is fixedly arranged on the external circle of one end of the rotor, and a radial flow passage is formed on the rotor sleeve; the sealing mechanism is externally placed in the pump chamber through the traditional radial plunger pump, the isolation tongue is floating, and the radial clearance between the junction surfaces of the floating isolation tongue and the rotor sleeve can be randomly adjusted; and the isolation tongue is wider than the radial flow passage on the rotor sleeve and is instantaneously dredged by the suction and exhaust one-way valve. The plunger pump thoroughly solves the problem of 'shaft holding', greatly enlarges the sealing area between a high pressure cavity and a low pressure cavity, and improves the sealing effect and the volume efficiency; and the service life of the pump is prolonged. The pump can convey oil, and also can convey water.

Owner:余文凌

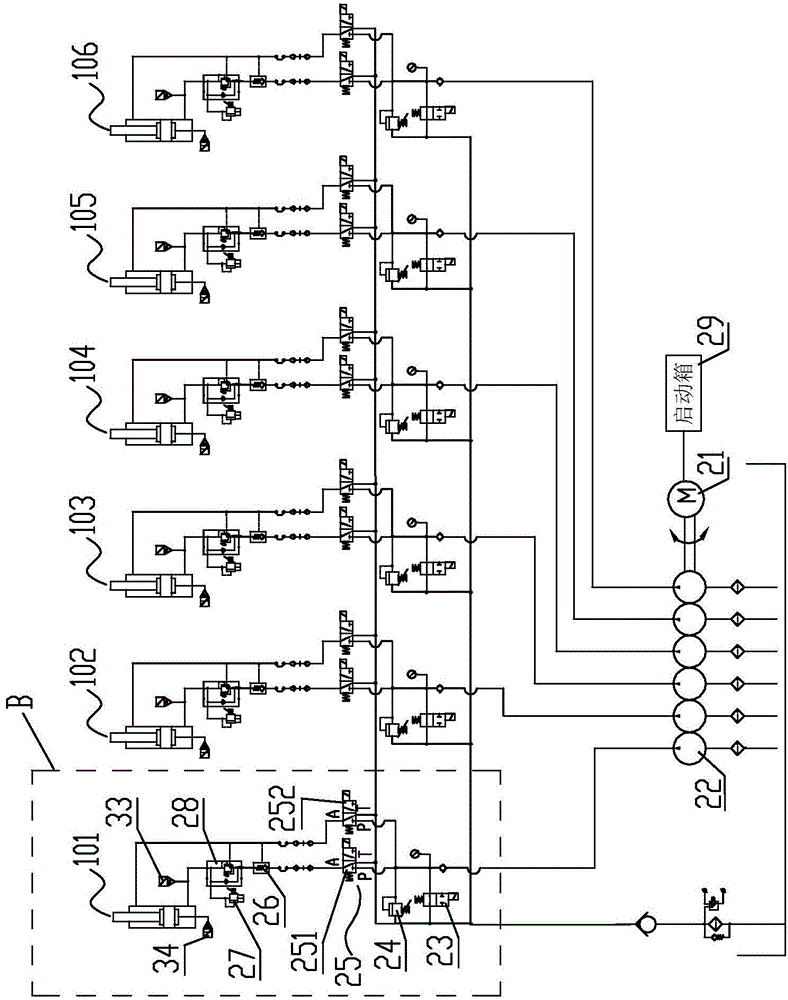

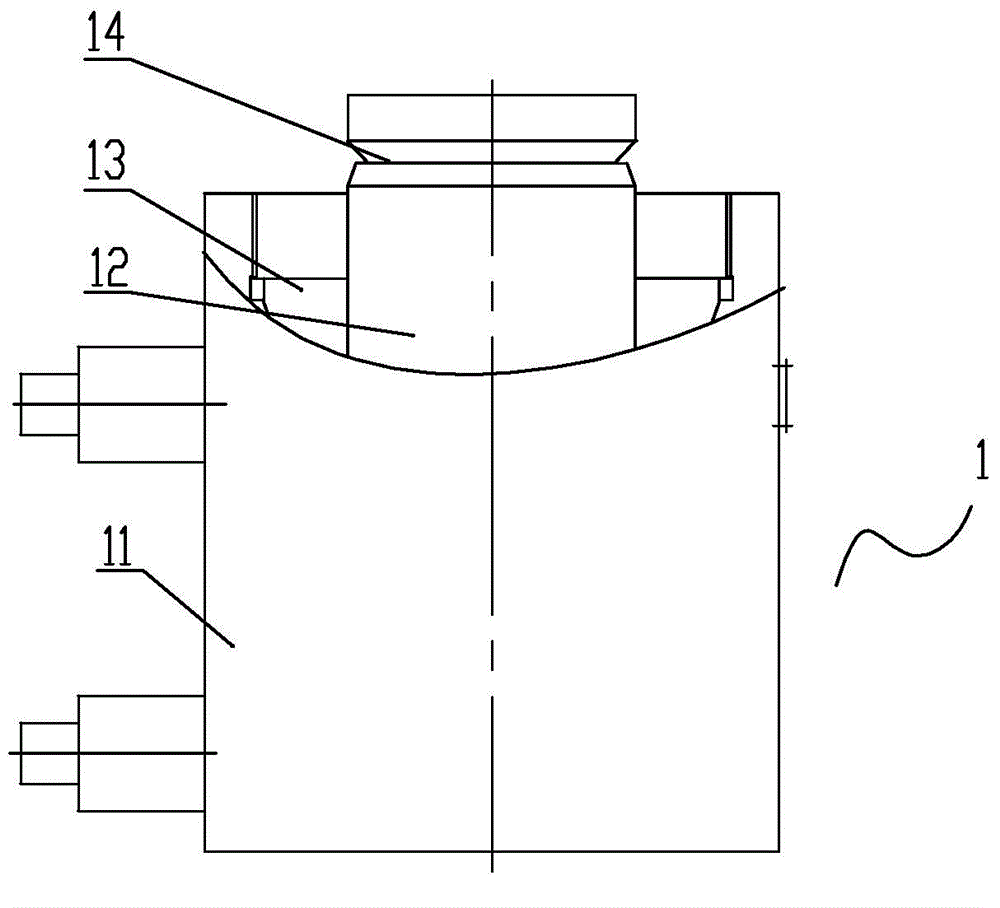

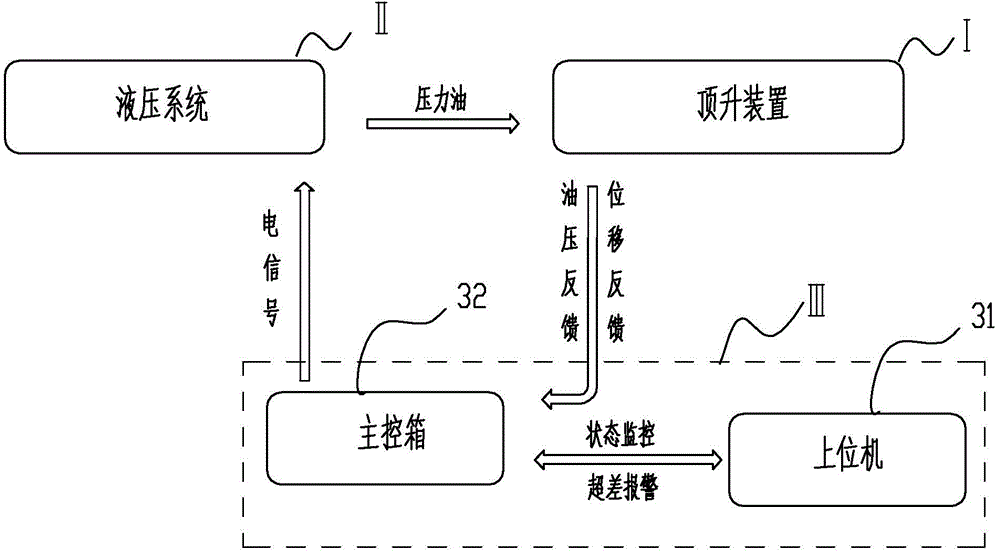

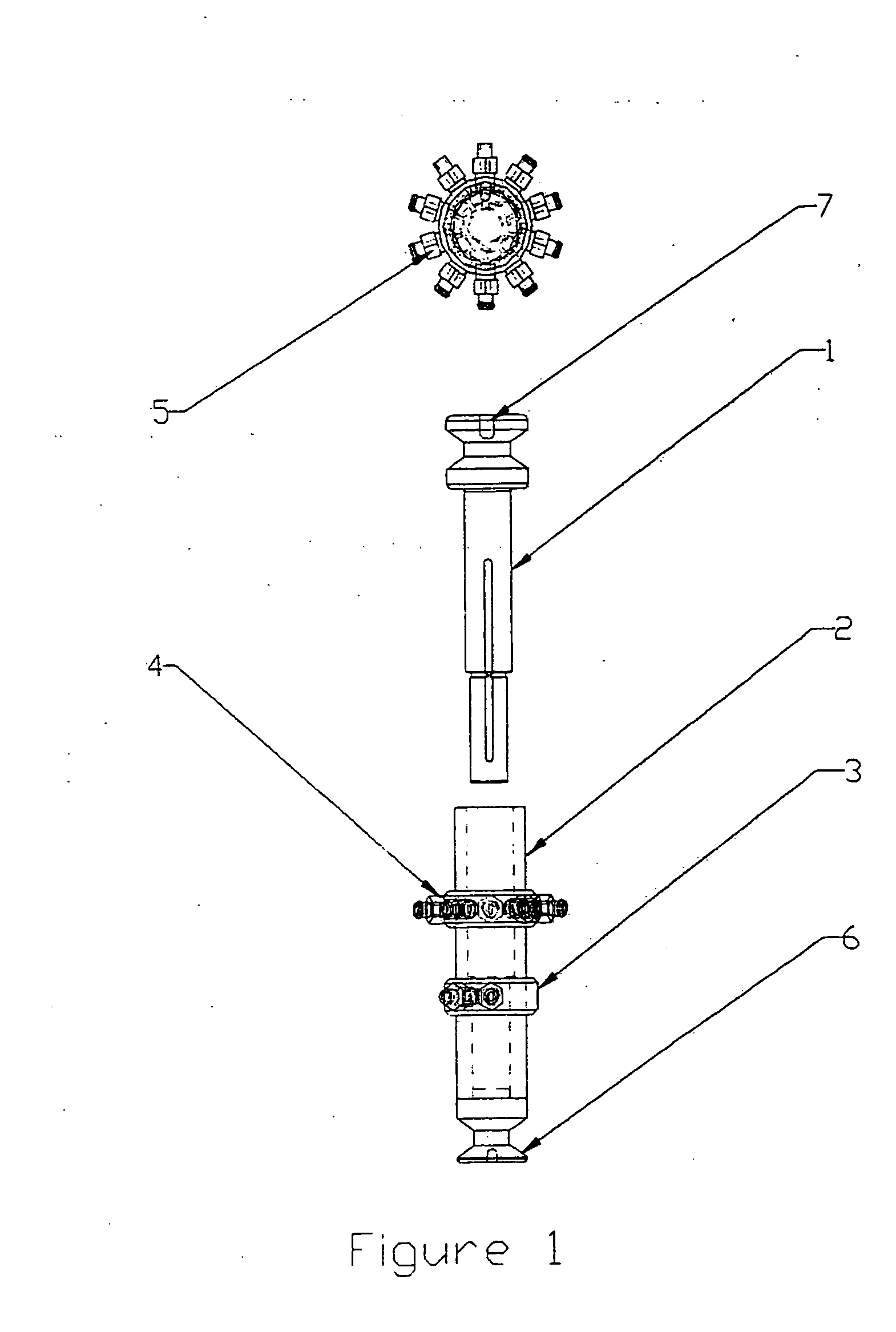

Intelligent separate control type hydraulic synchronous jacking system and method for replacing bridge support through same

InactiveCN104528582AAvoid deformationReduce riskServomotor componentsLifting devicesRadial piston pumpLoop control

An intelligent separate control type hydraulic synchronous jacking system comprises a jacking device, a hydraulic system and a control system. The jacking device comprises n lifting jacks. The hydraulic system comprises a frequency-variable motor, a starting box for controlling the frequency-variable motor to start and stop, n sets of multi-port and multi-pressure-output unit radial plunger pump heads and a valve set arranged between a lifting jack oil cylinder and the plunger pump heads. The valve set comprises an unloading electromagnetic valve, an overflow valve, an electromagnetic reversing valve, a hydraulic lock, a safety valve and a balancing valve. The n sets of unit radial plunger pump heads are driven by the same frequency-variable motor. Each set of unit radial plunger pump head corresponds to one lifting jack. The control system comprises an upper computer, a master control box, a pressure sensor and a displacement sensor, and 2<=n<=48. The intelligent separate control type hydraulic synchronous jacking system adopts a separate control and intelligent control mode, the unit radial plunger pump heads are used for independently controlling the lifting jacks and carry out double-closed-loop control over the stress and displacement of the lifting jacks, the stress and displacement of the lifting jacks are automatically controlled, and the synchronization performance is good.

Owner:LIUZHOU OVM MASCH CO LTD

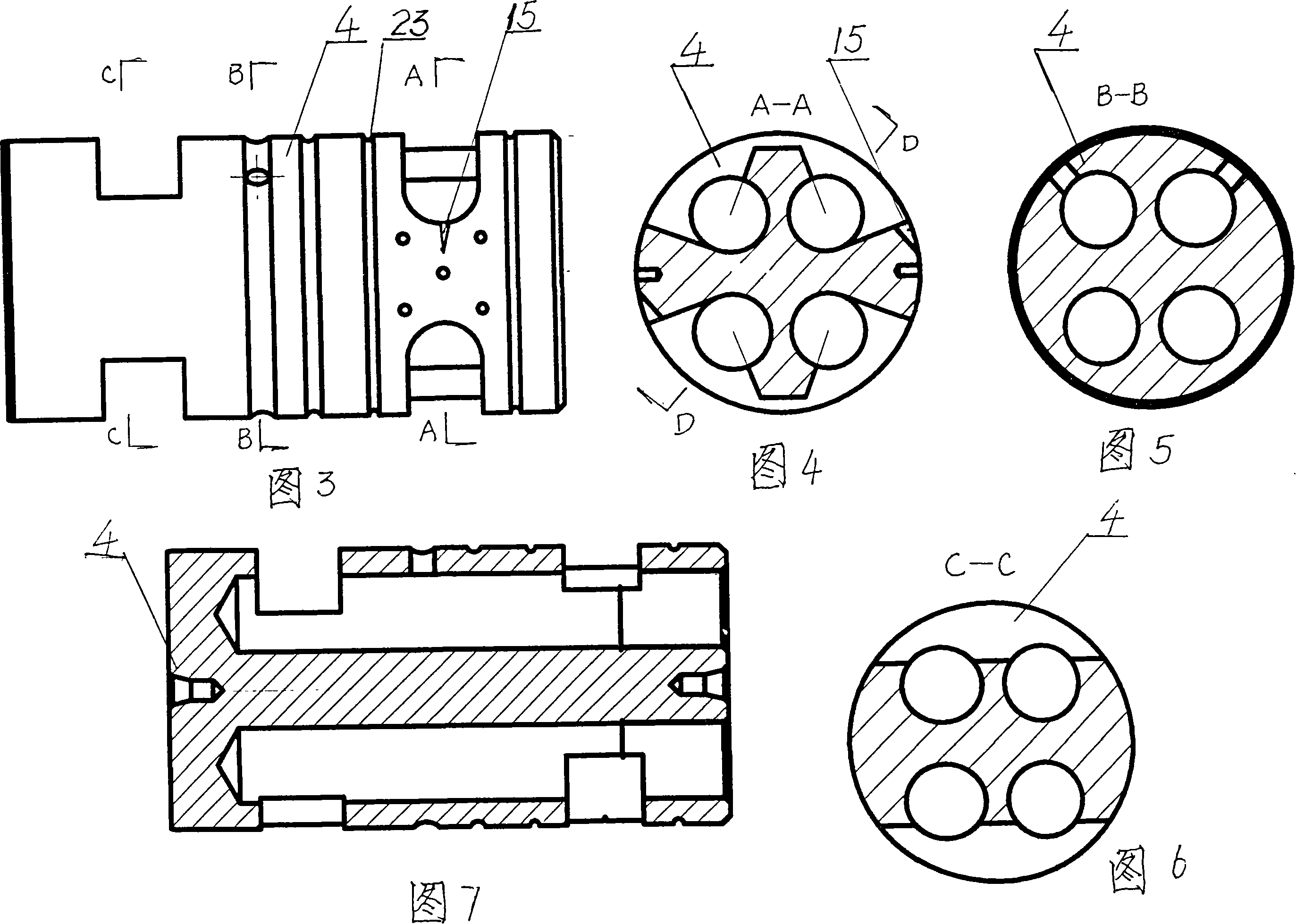

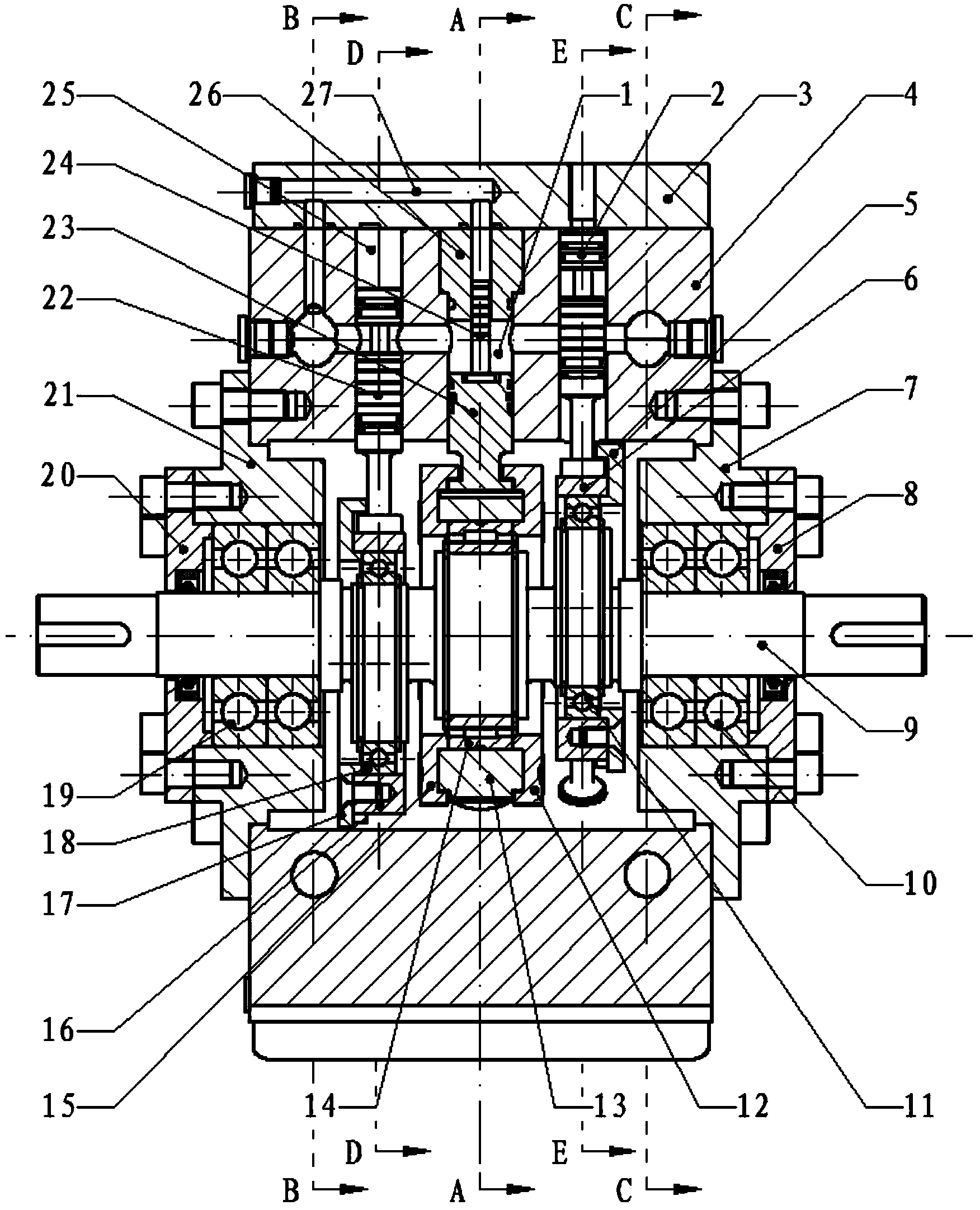

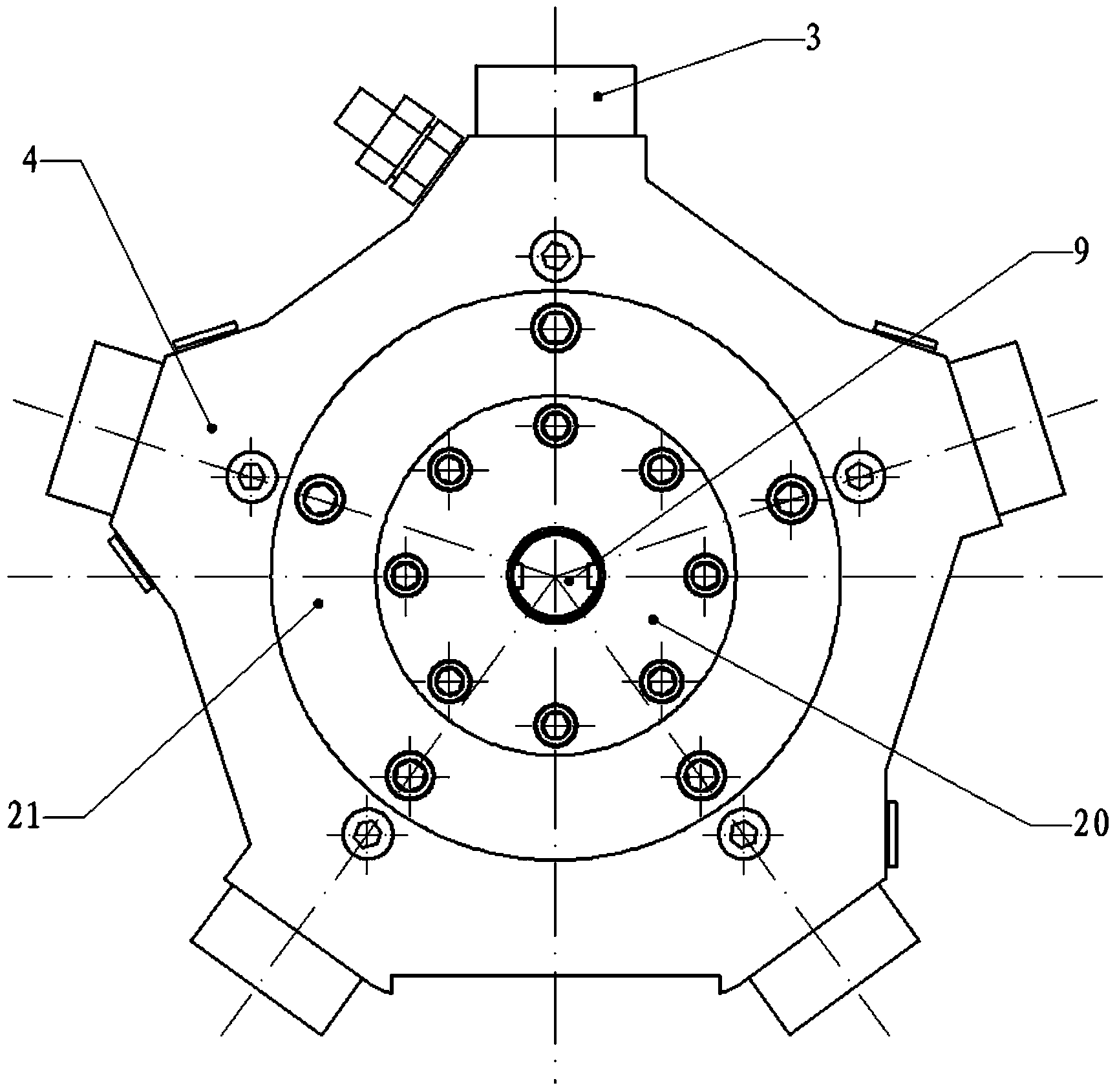

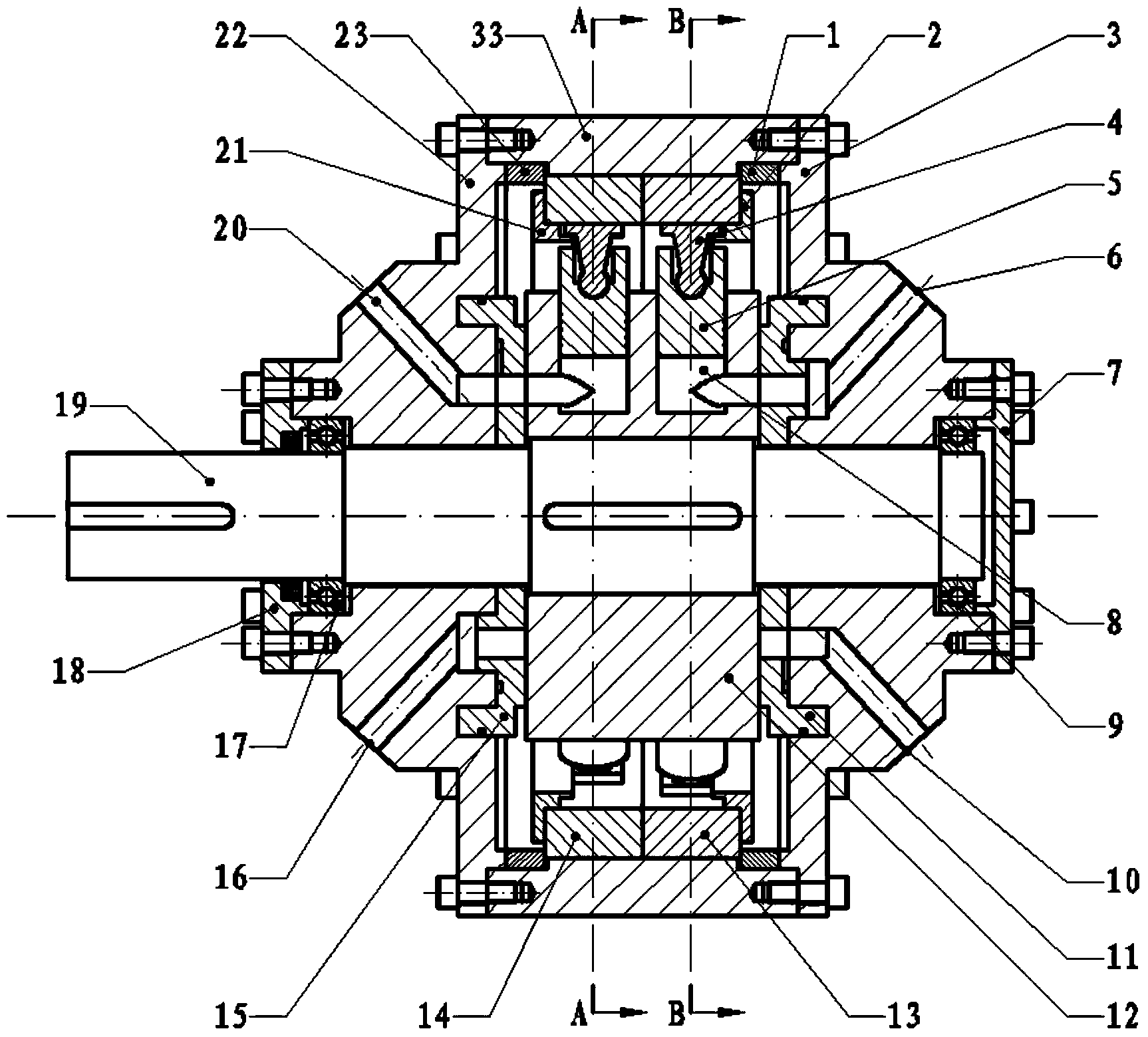

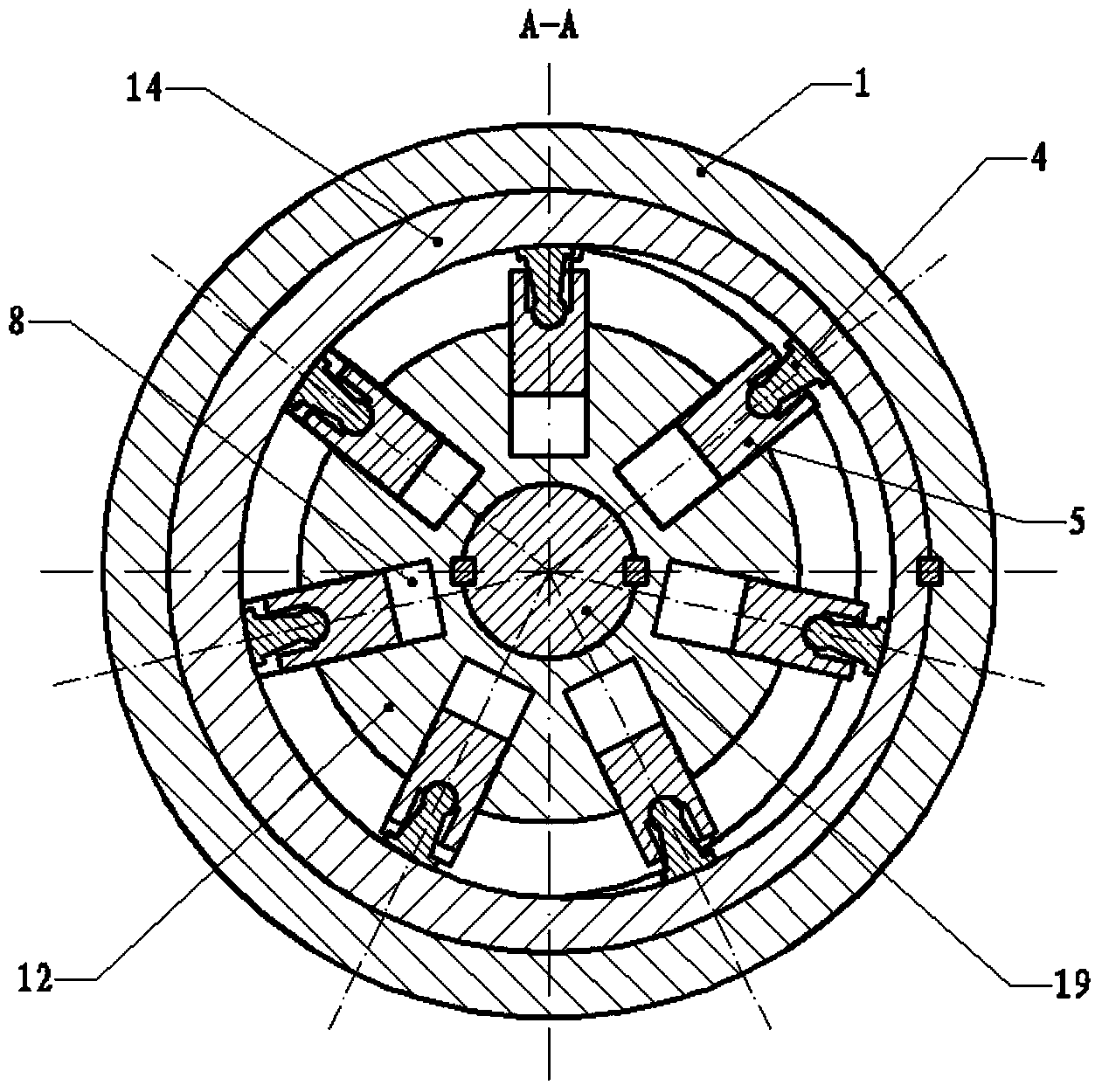

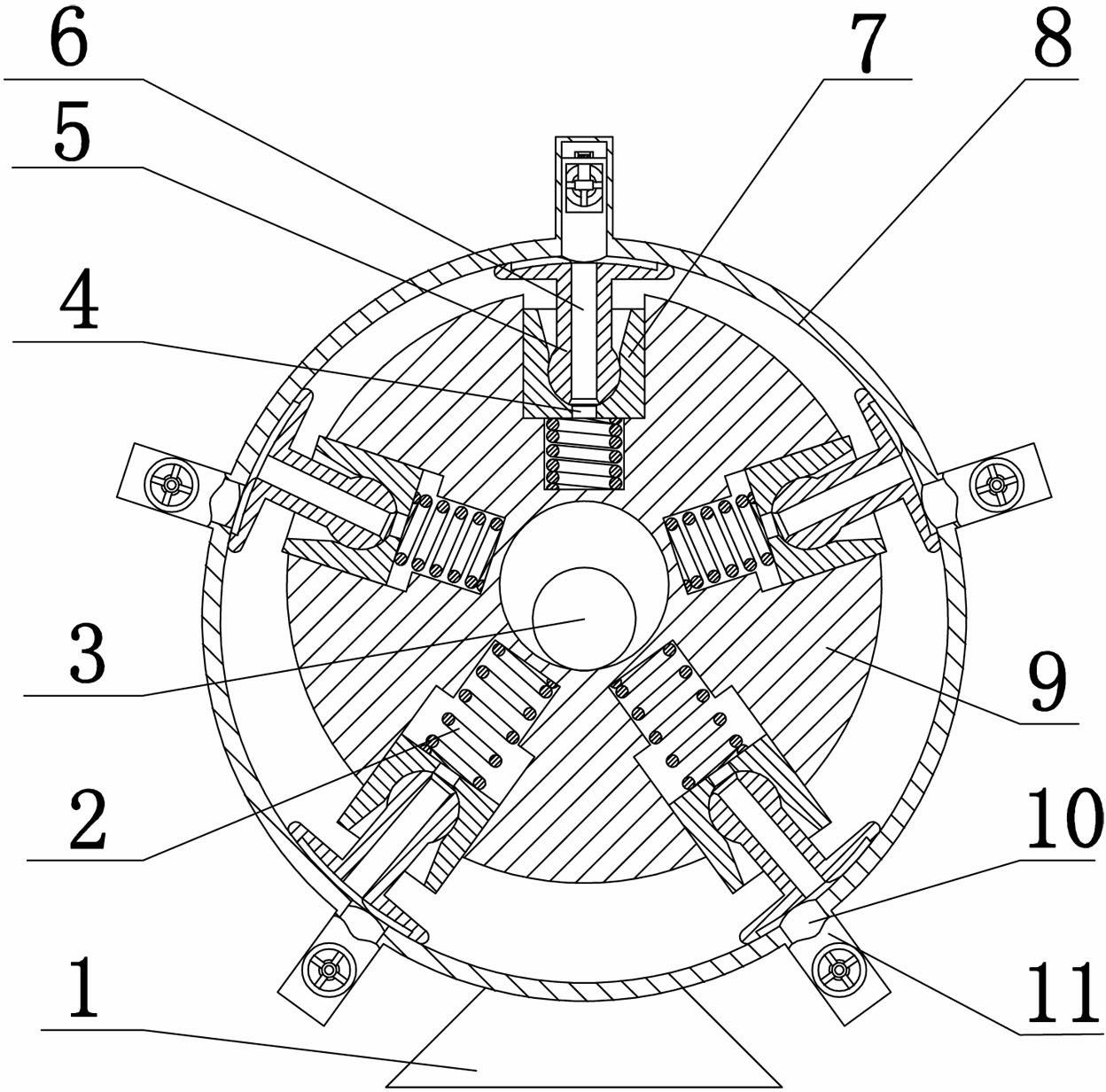

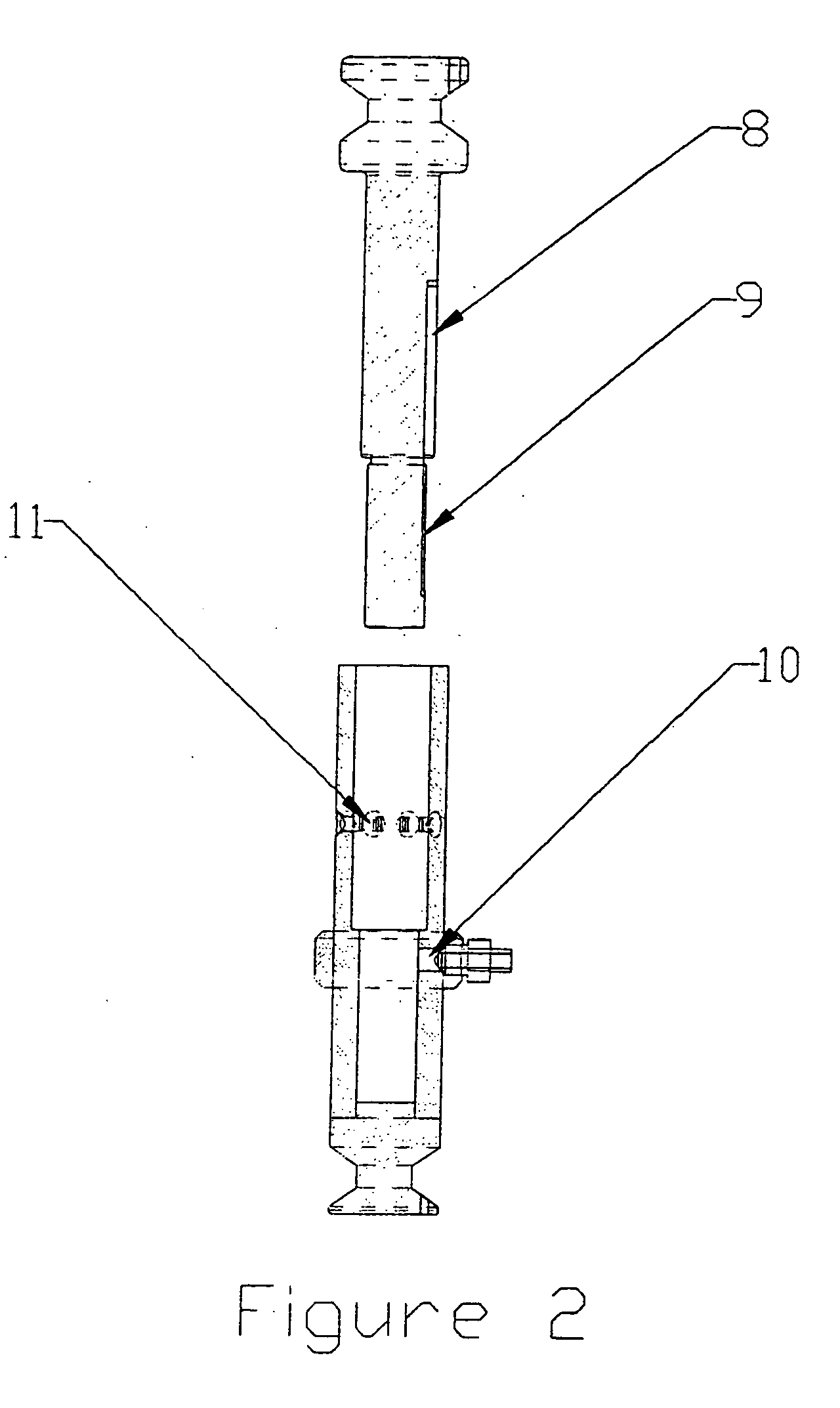

Hydraulic return travel radial plunger pump adopting double-column slide valves for oil distribution

InactiveCN103939311ACompact structureReliable transmissionPositive displacement pump componentsPositive-displacement liquid enginesRadial piston pumpDrive shaft

Provided is a hydraulic return travel radial plunger pump adopting double-column slide valves for oil distribution. Five plunger sets are arranged in the radial direction, the flow distribution slide valves matched with the plunger sets in work are arranged abreast on the two sides of plungers, the communication of oil feeding and oil discharging is achieved through an oil discharging and collecting flow channel and an oil feeding and collecting flow channel which are formed in a pump body, the space in the pump body is fully utilized, the rotation of a transmission shaft is converted into the needed rectilinear motion through a pentagon and corresponding bearings, transmission is reliable, and friction force is small. Due to the fact that hydraulic force is utilized in return travel, the return travel force is stable, noise is small, and the service life is long. Due to the fact that thrust is transmitted to the plungers through quill rollers, the friction force between relative moving surfaces is lowered. Due to the fact that the plunger sets are mounted on the pump body from the exterior through screws, fast demounting can be achieved, and mounting and maintaining are convenient.

Owner:XI AN JIAOTONG UNIV

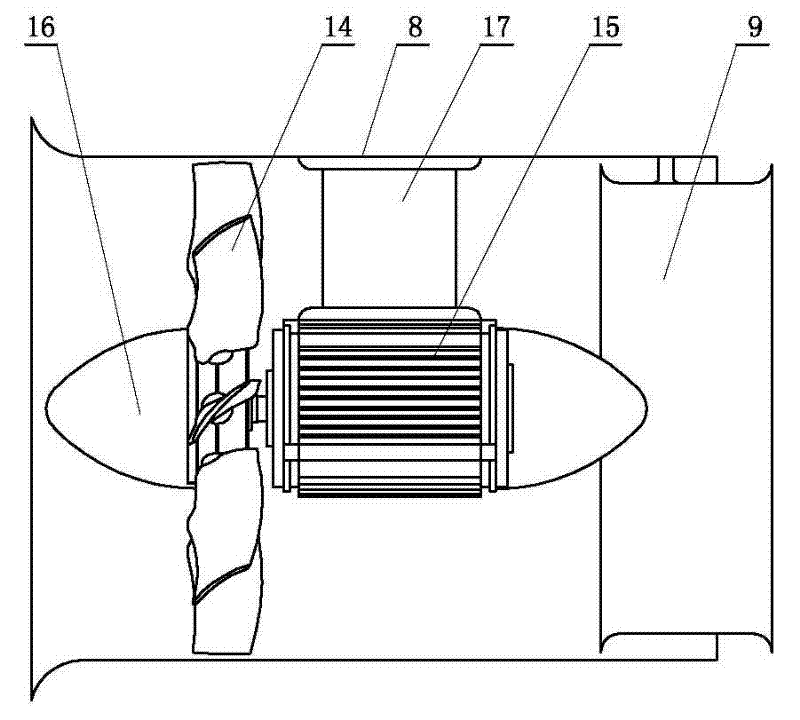

Far-range air-supply type spraying device

InactiveCN102524223AReduce volumeReduce weightInsect catchers and killersRadial piston pumpHigh pressure

The invention relates to a far-range air-supply type spraying device, which comprises an engine base and a main control station, wherein a cross rotating support and a rotating driving oil cylinder are arranged on the engine base, and the bottom of the cross rotating support is in power connection with the rotating driving oil cylinder. A revolving platform and a pitching driving oil cylinder arearranged on the cross rotating support, a revolving platform stand is erected on the cross rotating support, and the end head of a piston rod of the pitching driving oil cylinder is hinged with the bottom of the revolving platform. An air supply device and a spraying device are arranged on the revolving platform, and the air supply device is provided with an air funnel. The air outlet of the air funnel is provided with a diffusing pipe, and the center of the air funnel is provided with a high-pressure axial flow fan. The spraying device comprises an annular distributing pipe, a radial plungerpump, an electromotor, a liquid medicine box and a water box, and an atomizing nozzle is installed on the annular distributing pipe. A liquid absorbing port of the radial plunger pump is communicatedwith a liquid supply port of the liquid medicine box through a liquid inlet pipeline, and the liquid absorbing port of the radial plunger pump is communicated with a water supply port of the water box through a water delivery pipeline. A liquid discharging port of the radial plunger pump is communicated with the annular distributing pipe through a liquid outlet pipeline.

Owner:陈新

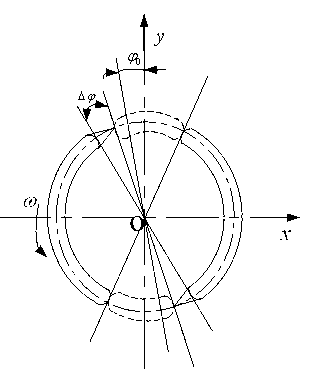

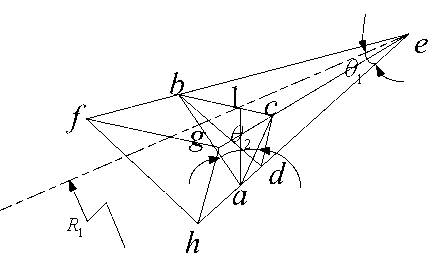

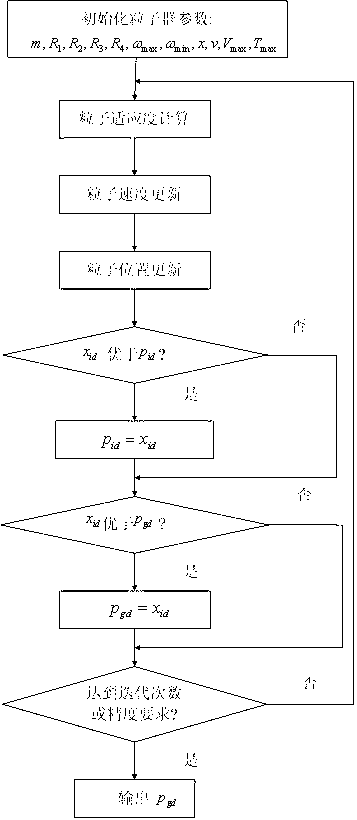

Optimized design method of axial piston pump valve plate based on particle swarm optimization method

InactiveCN103164583ALow efficiencyReasonable structureBiological modelsSpecial data processing applicationsRadial piston pumpEngineering

The invention discloses an intelligent optimized design method of an axial piston pump, in particular to an optimized design method of an axial piston pump valve plate based on a particle swarm optimization method. The minimum peak value of the pressure gradient serves as the objective function under the condition of no pressure difference transition, and the optimized design is conducted on the structural parameter of the valve plate. According to the optimized design method of the axial piston pump valve plate based on the particle swarm optimization method, the symmetric deflection type valve plate, whereina damping groove is opened to serve as the basis, and the axial piston pump is built. After oil is sucked by each piston cylinder bore, the axial piston pump enters a pre-boost area to boost the characteristic differential equation in advance. After the oil is discharged by each piston cylinder bore, the axial piston pump enters a pre-pressure-relief area to relieve the pressure of the characteristic differential equation in advance. An updating mechanism which is searched by multiparticles in parallel applies the acceleration adaptive particle swarm optimization algorithm, and the optimal matching of the structural parameter of the valve plate is obtained. The optimized design method of the axial piston pump valve plate based on the particle swarm optimization method provides a high-efficient solution for how to reduce the pressure shock in the pump and how to suppress the noise.

Owner:ZHONGBEI UNIV

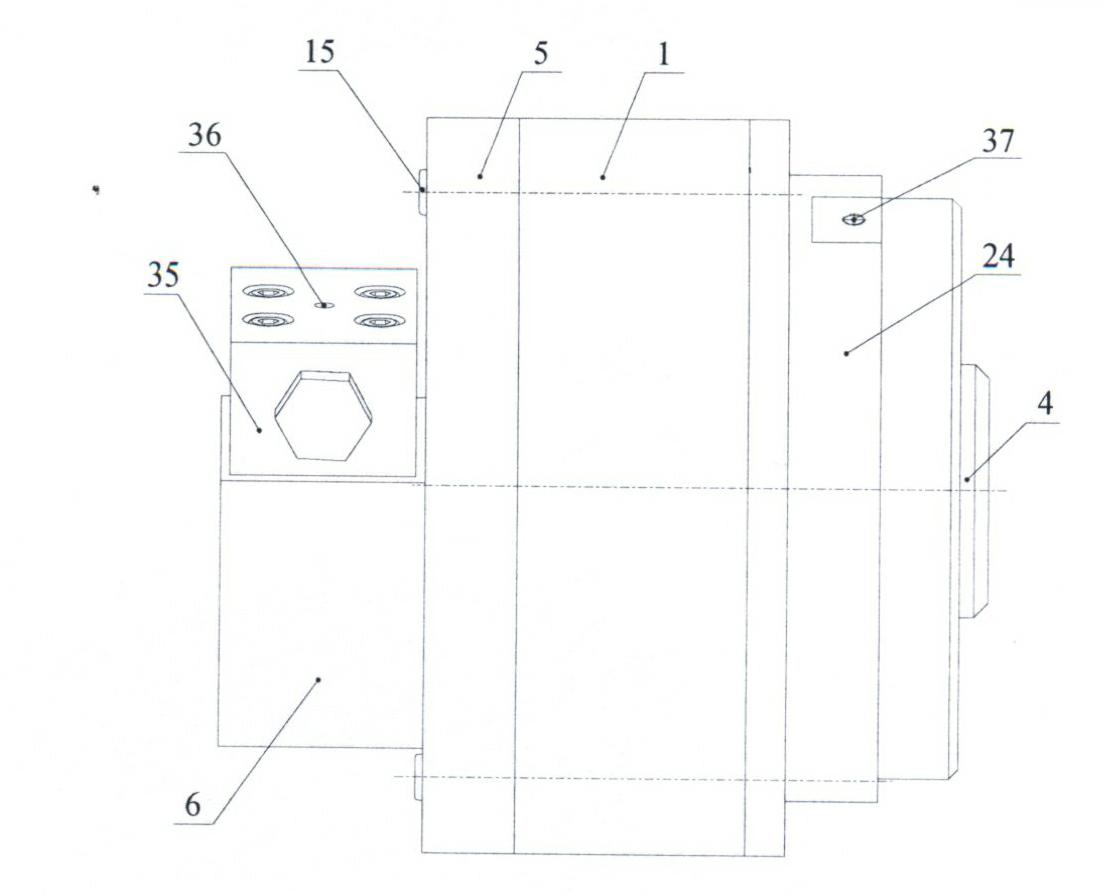

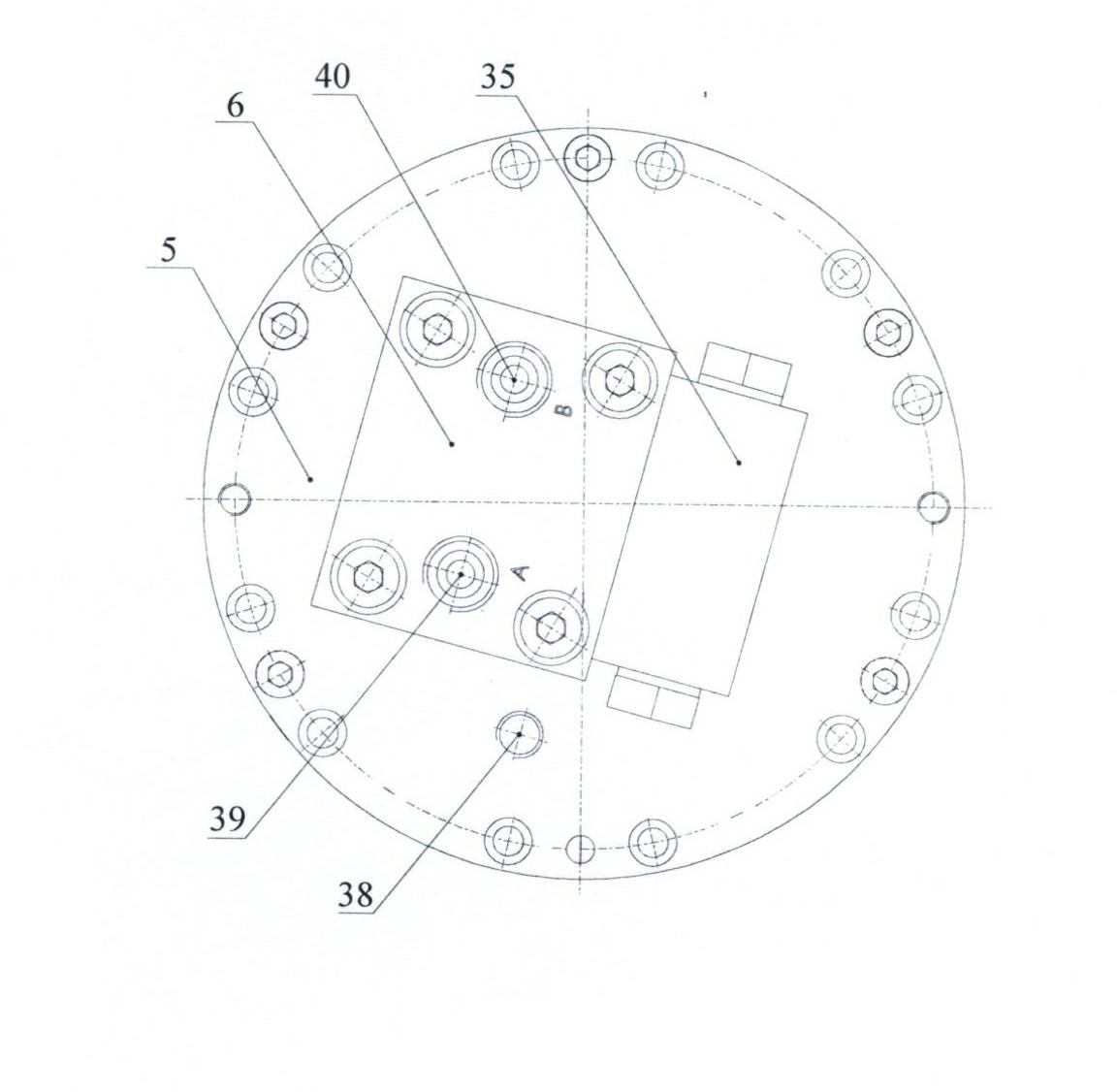

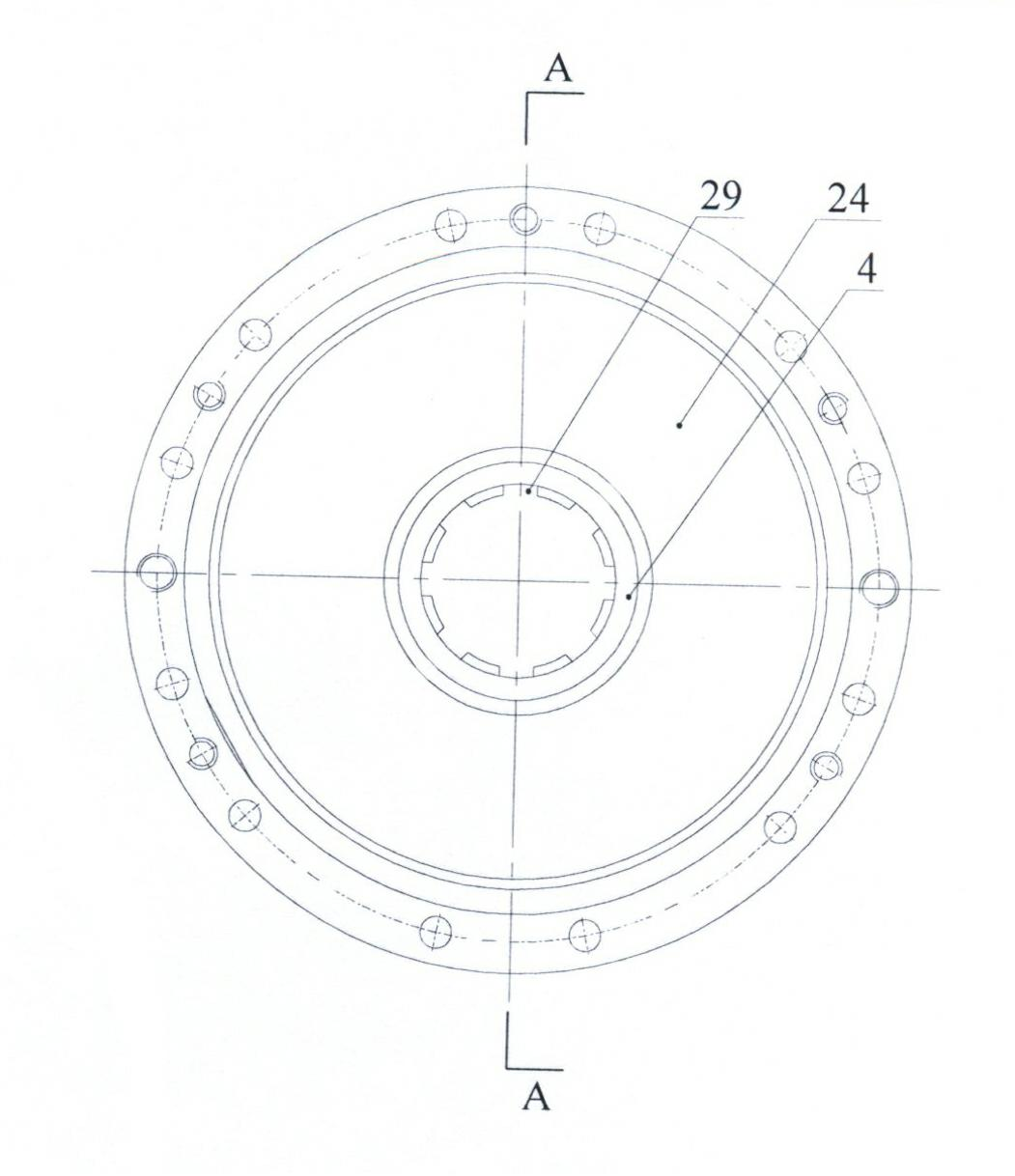

Radial piston rolling ball type end face valve low-speed high-torque hydraulic motor

InactiveCN102434382AReduce frictionReduce wearRotary piston enginesHydraulic motorRadial piston pump

The invention relates to a radial piston rolling ball type hydraulic motor in an end face valve pair. The hydraulic motor comprises a waterway block 6, a shuttle valve 35, a valve plate 5, a rotor 4, a stator 1, a piston 3, a rolling ball 2, a thrust ring 22, a lip-shaped sealing ring 26 and a right end cover 24, wherein the shuttle valve 35 is arranged on the waterway block 6; the waterway block 6 is arranged on the valve plate 5; the rotor 4 is arranged on an extending shaft of the valve plate 5; the thrust ring 22 is arranged between the rotor 4 and the right end cover 24; the valve plate 5, the stator 1 and the right end cover 24 are assembled into a whole; and an inner curved surface 18 of the stator 1 has a compound curve structure which is combined with Archimedes spiral according to constant acceleration, constant deceleration. Due to the adoption of the end face valve, the invention has the characteristics that: the hydraulic motor has a compact structure, fewer friction pairs, light weight, stable work, wide speed regulating range and balanced static force on a supporting shaft, easily realizes low speed and high torque, and the like, and the hydraulic motor is particularly suitable for water hydraulic transmission.

Owner:YANSHAN UNIV

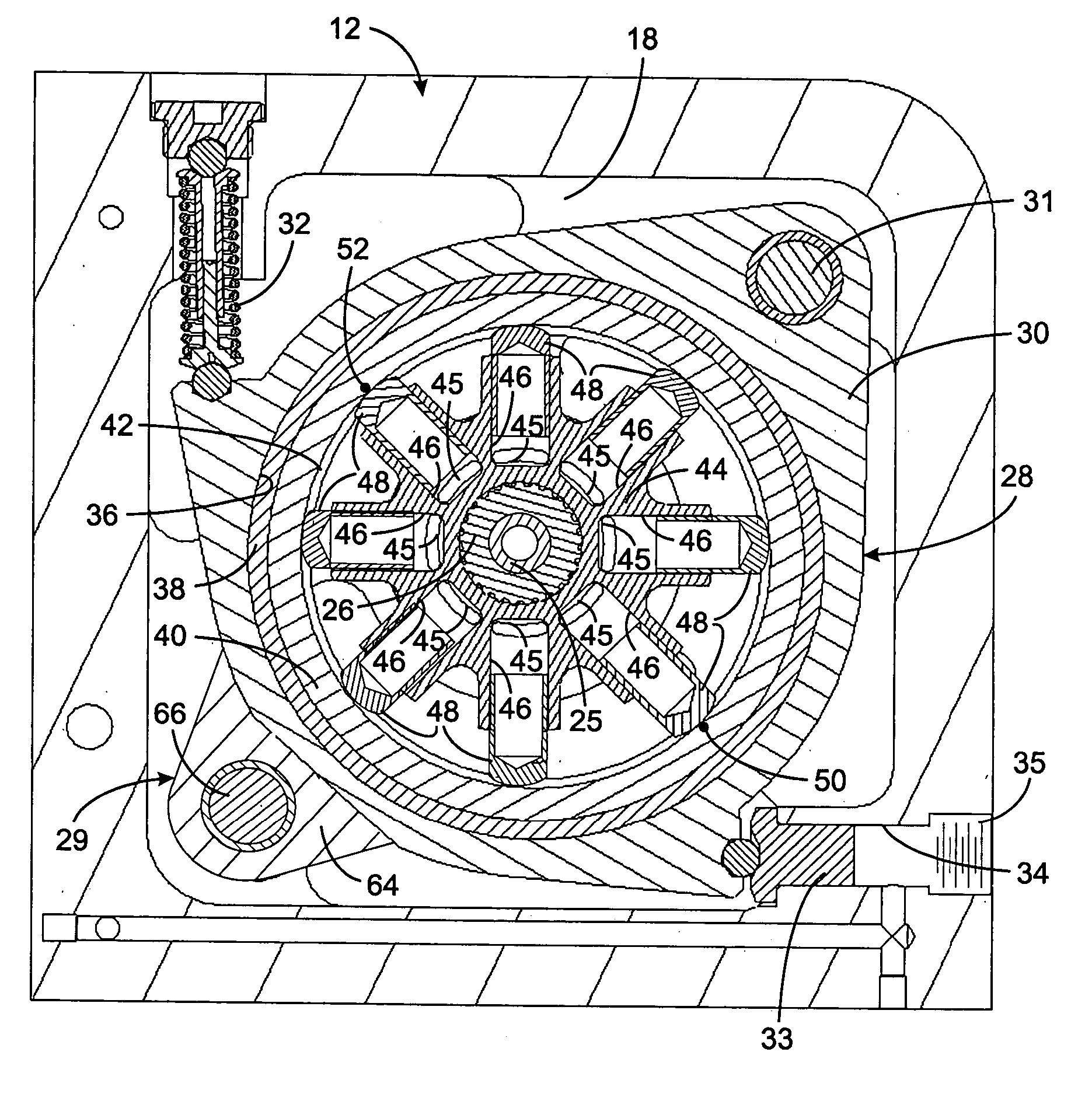

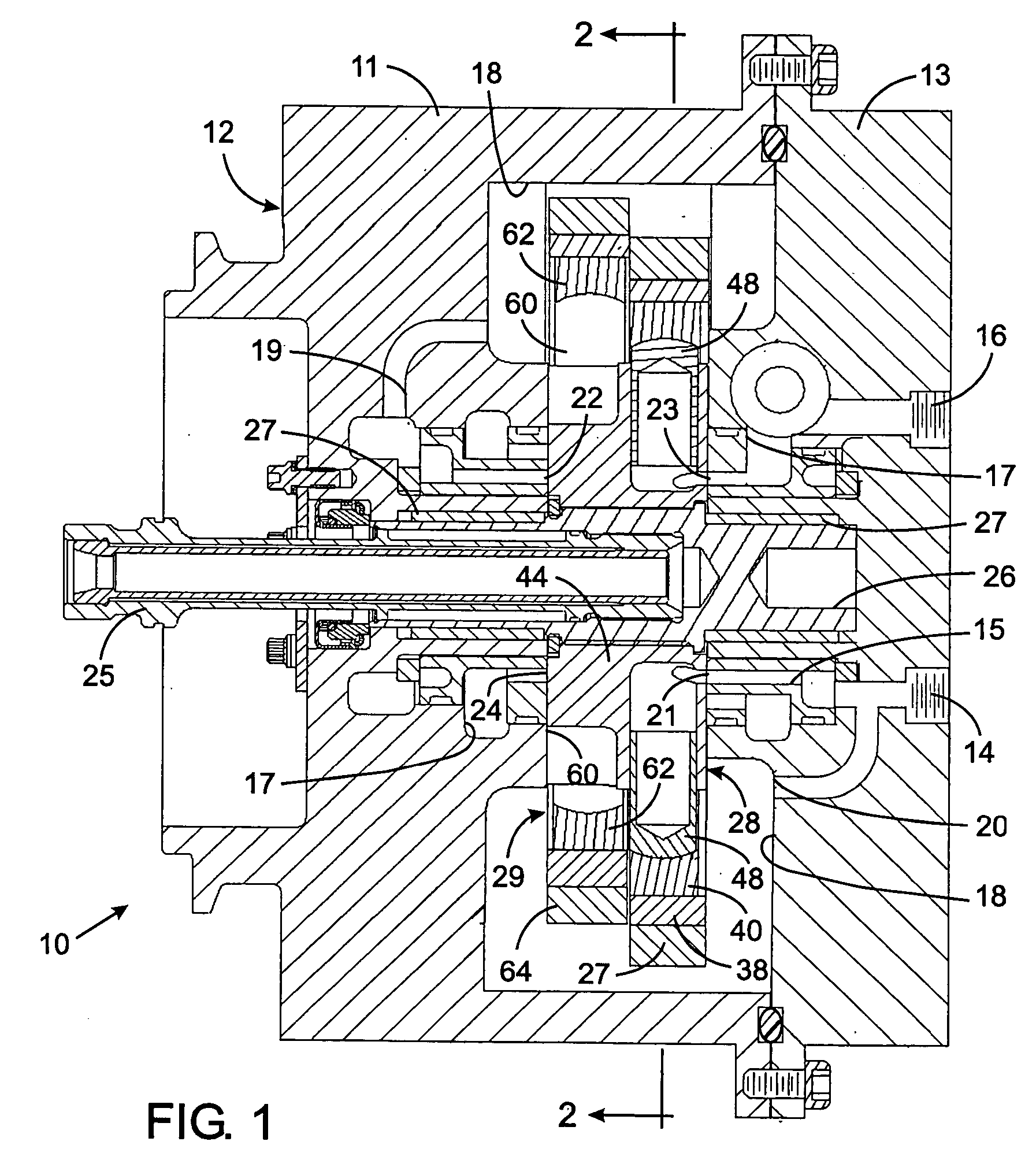

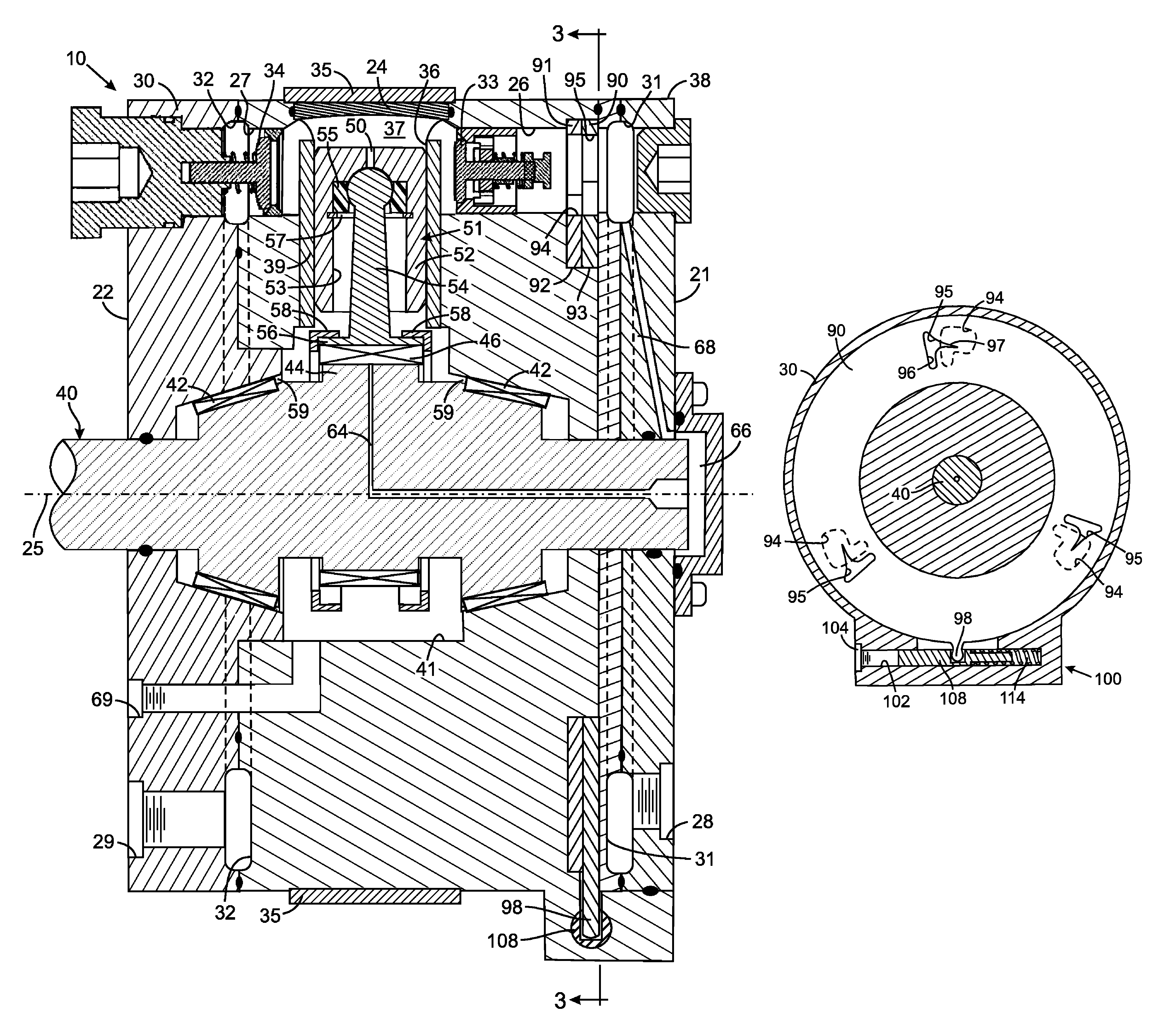

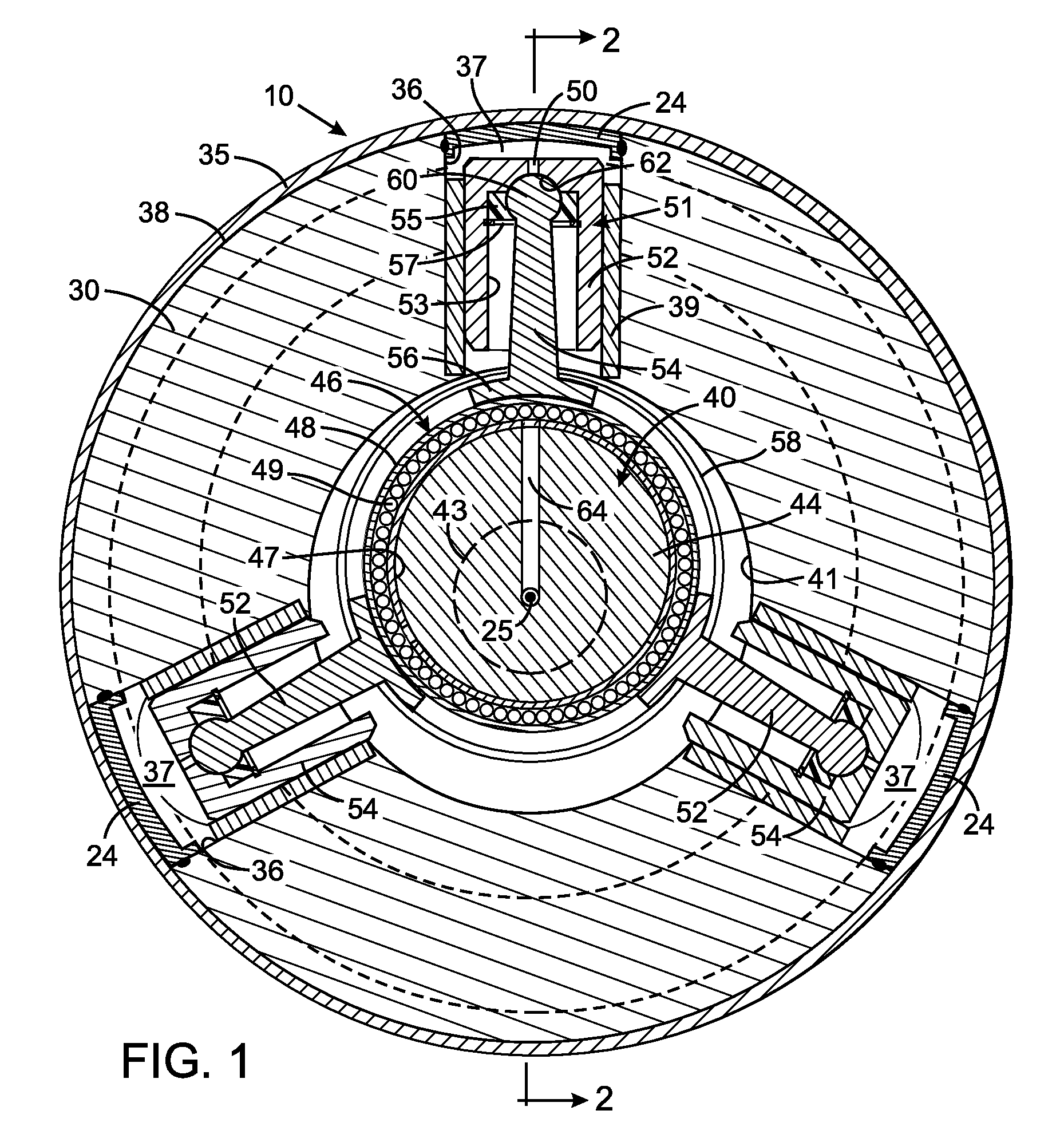

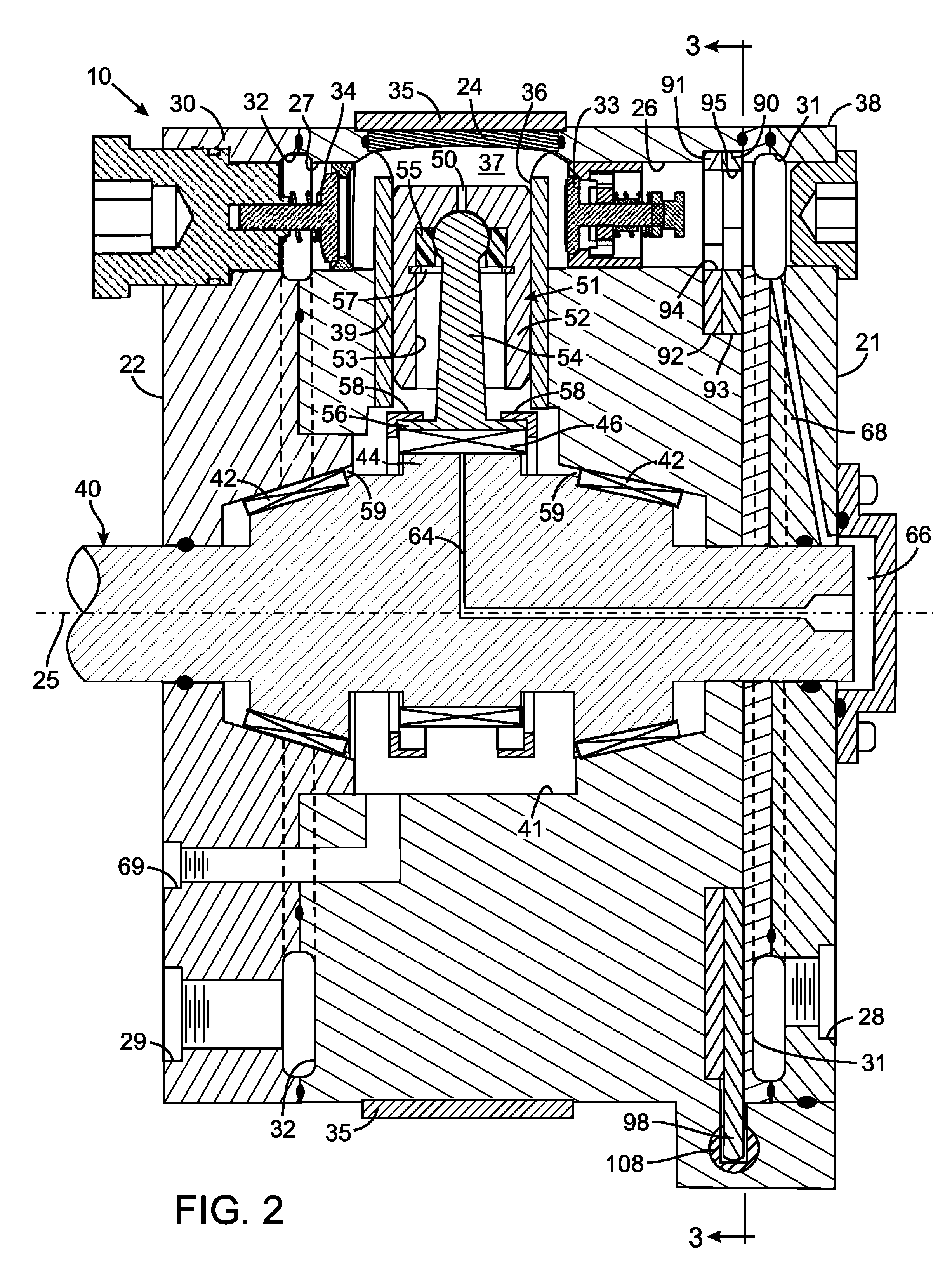

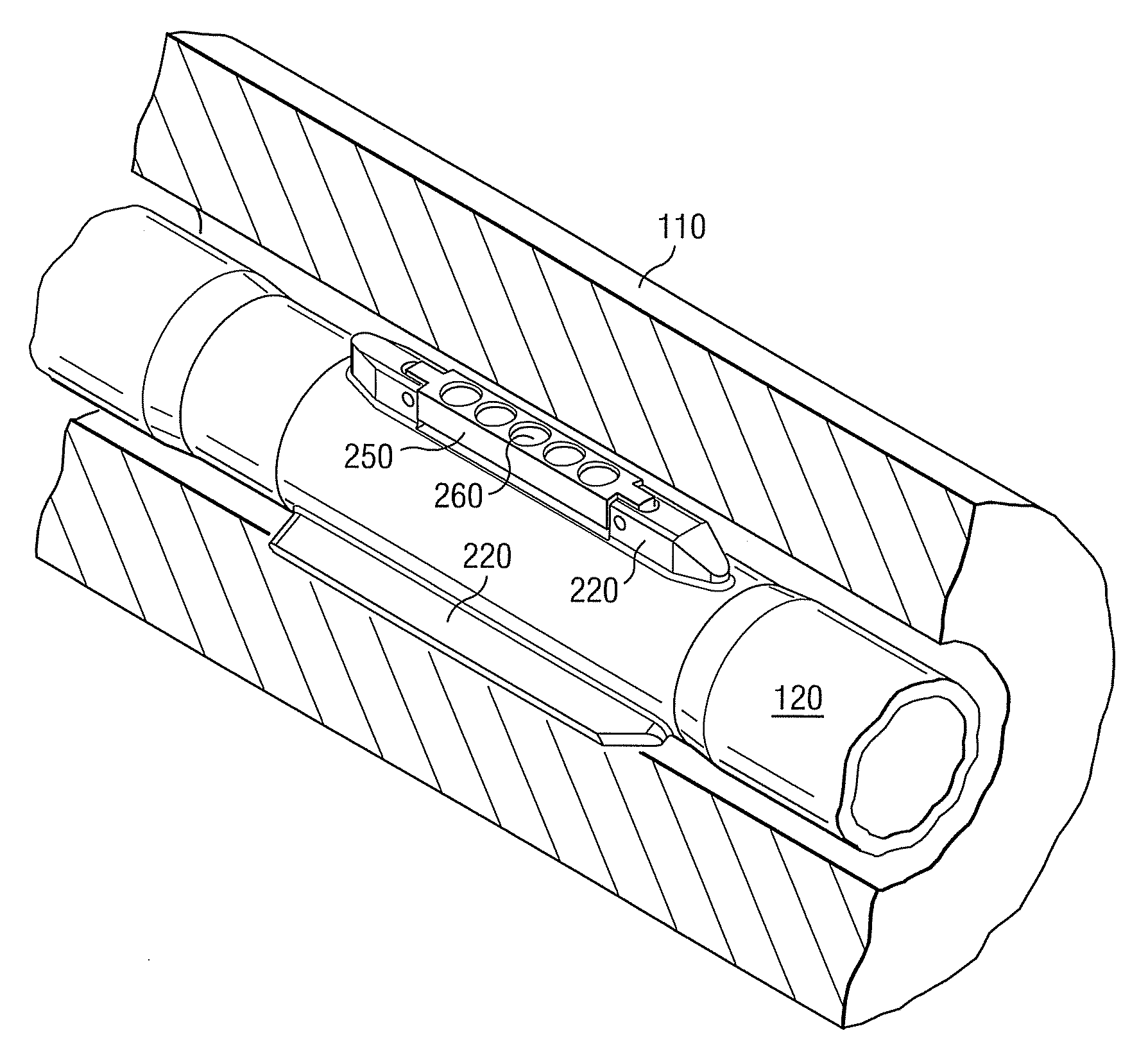

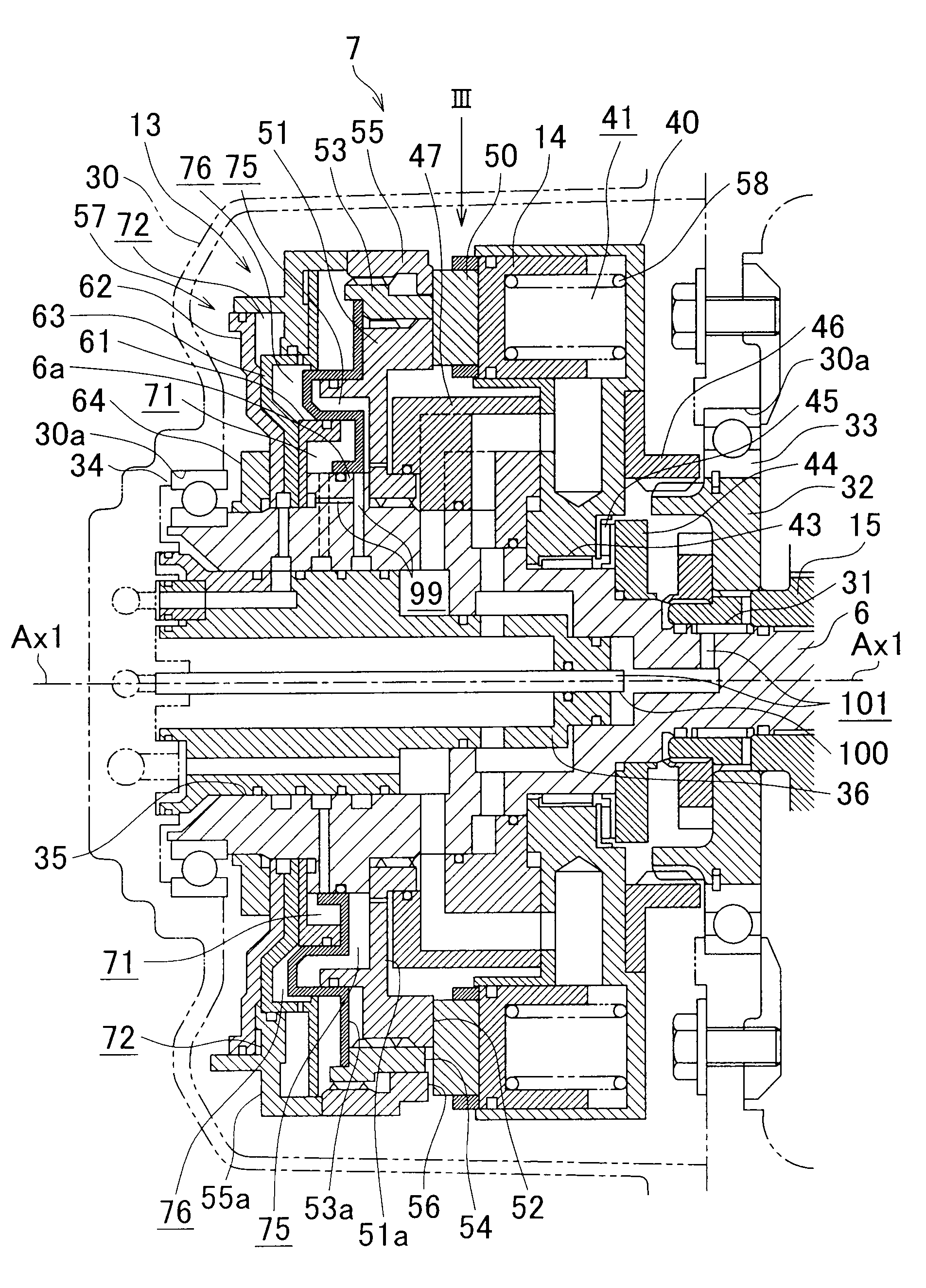

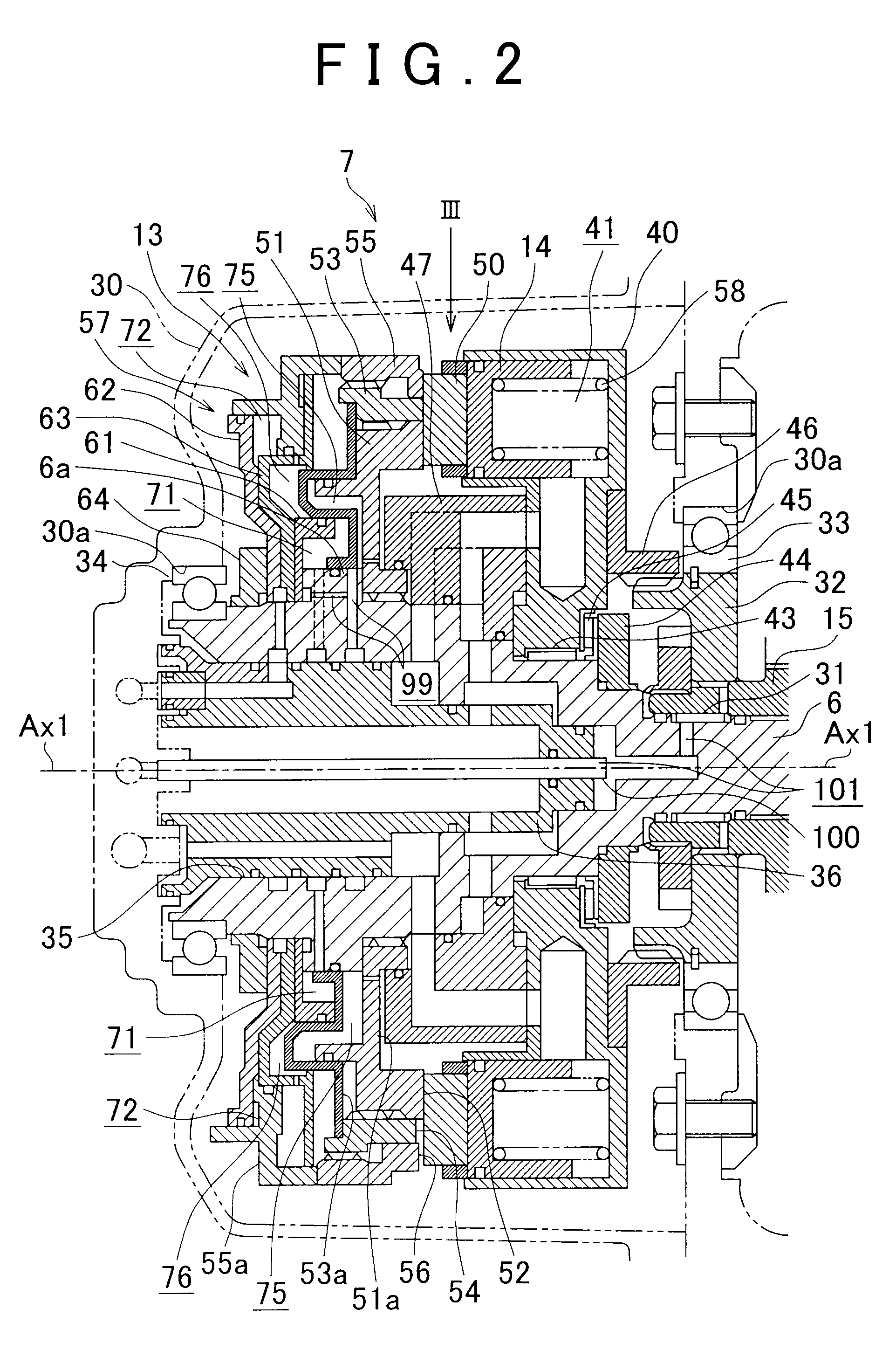

Radial piston pump with eccentrically driven rolling actuation ring

ActiveUS7134846B2Compensate for misalignmentMinimize deflectionFuel injecting pumpsPump controlRadial piston pumpDrive shaft

Owner:STANADYNE OPERATING CO LLC

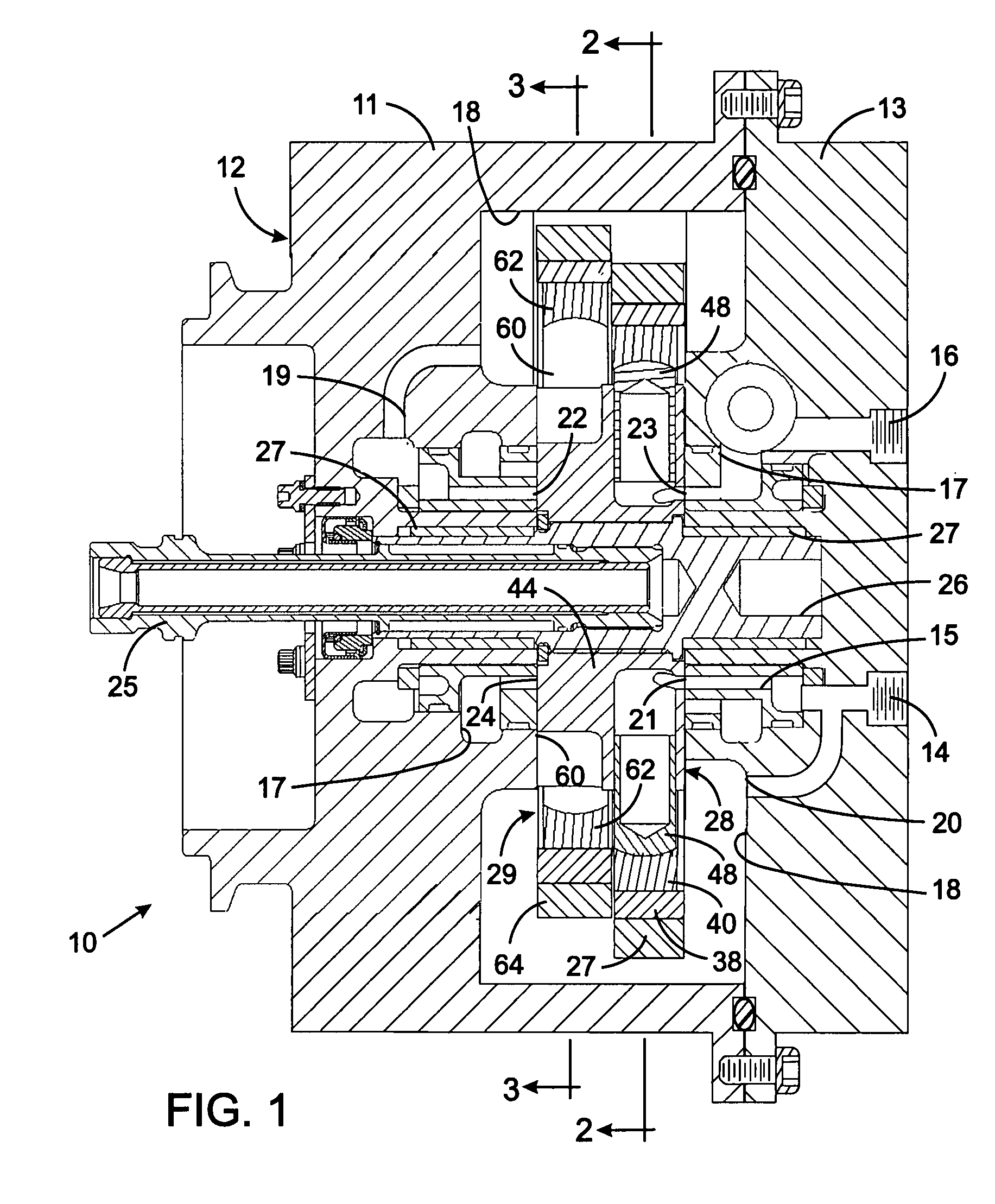

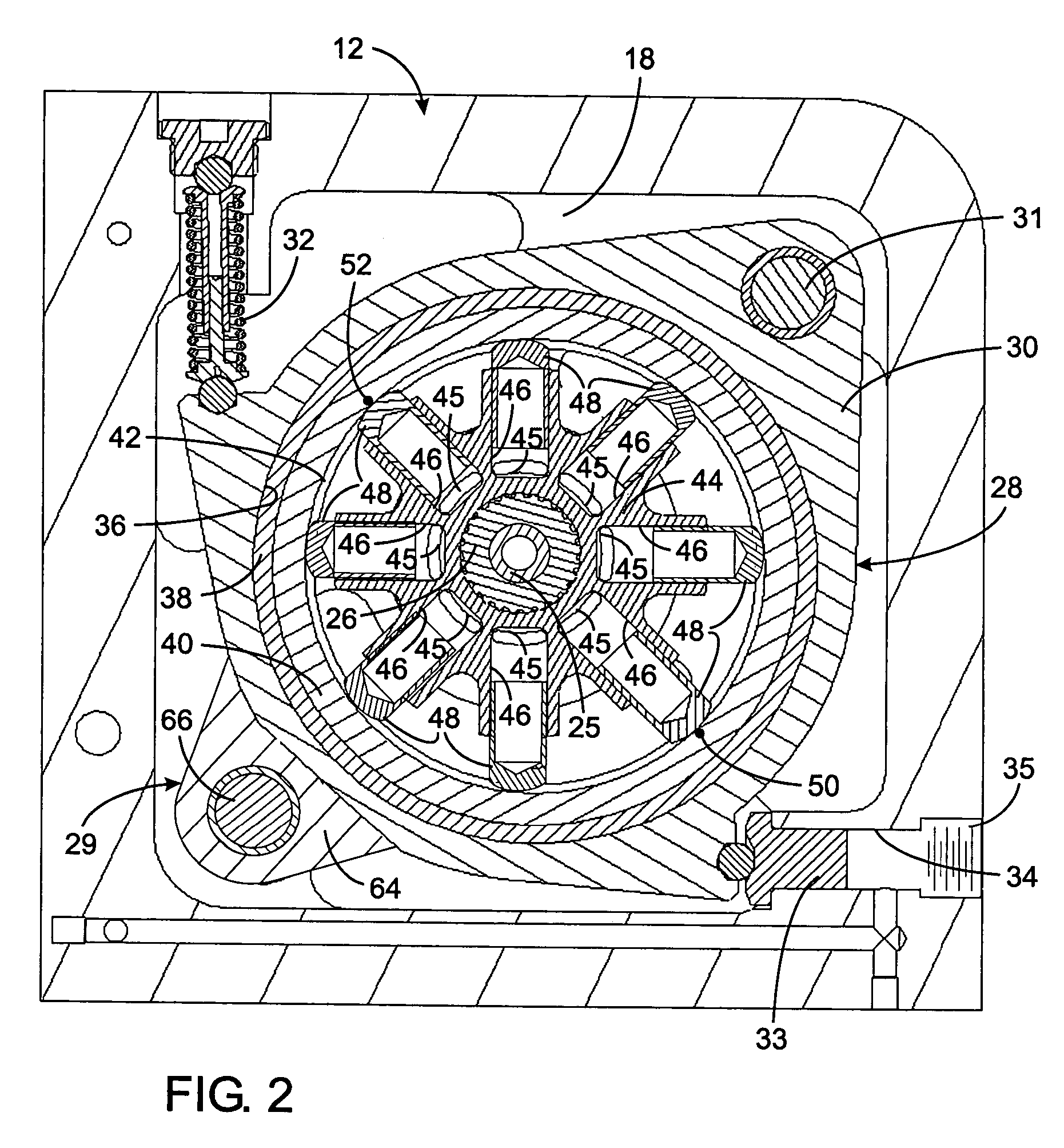

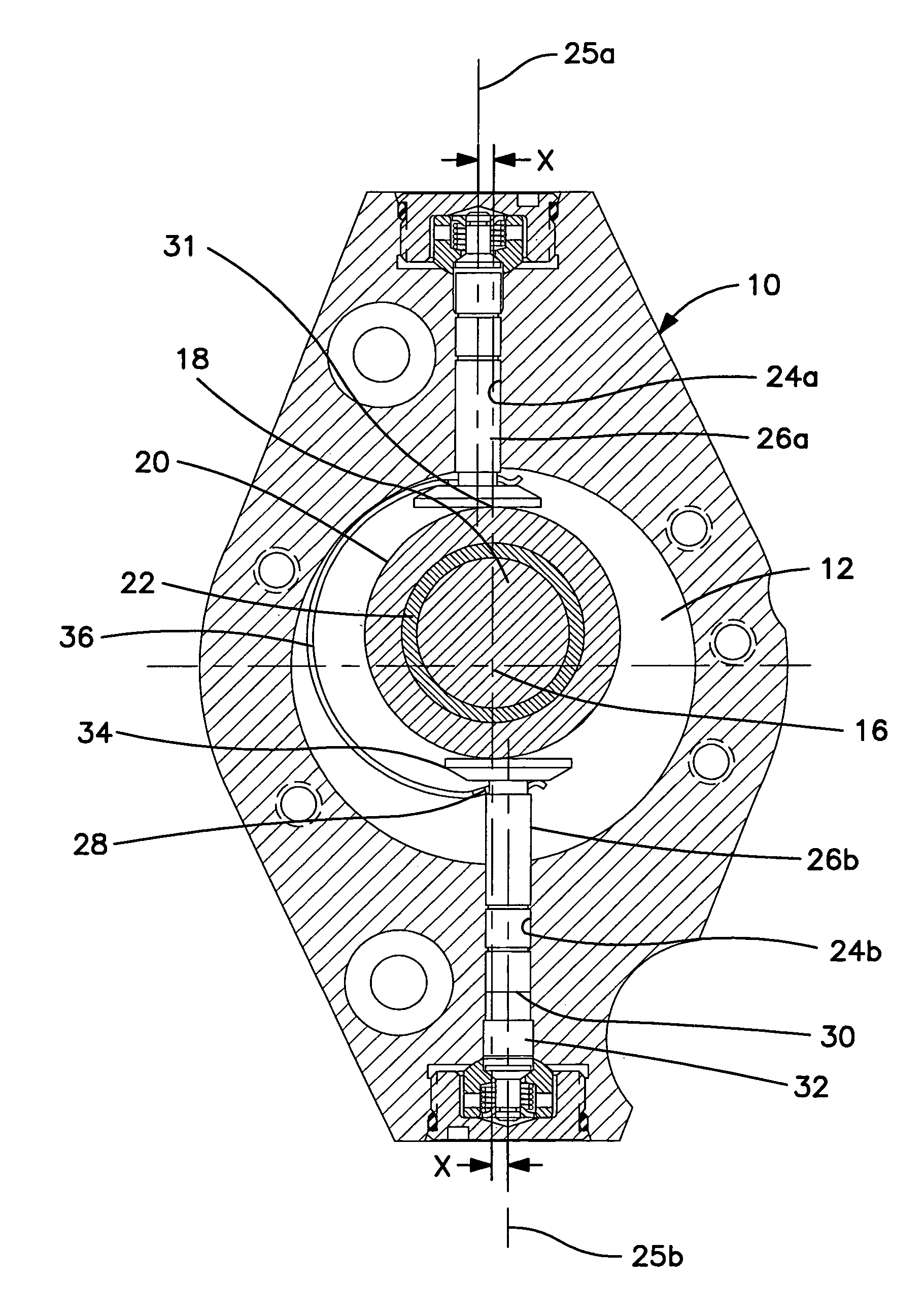

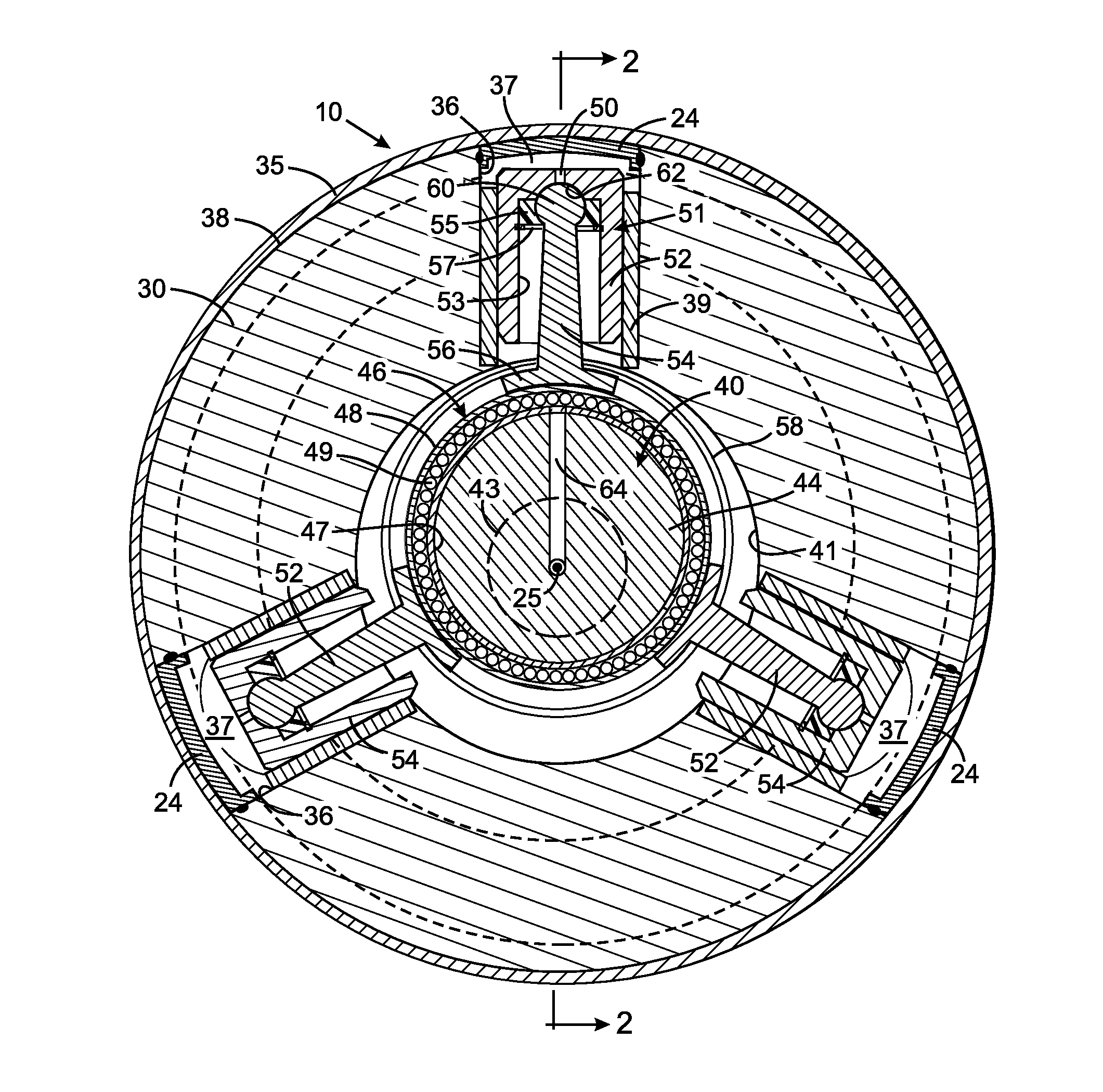

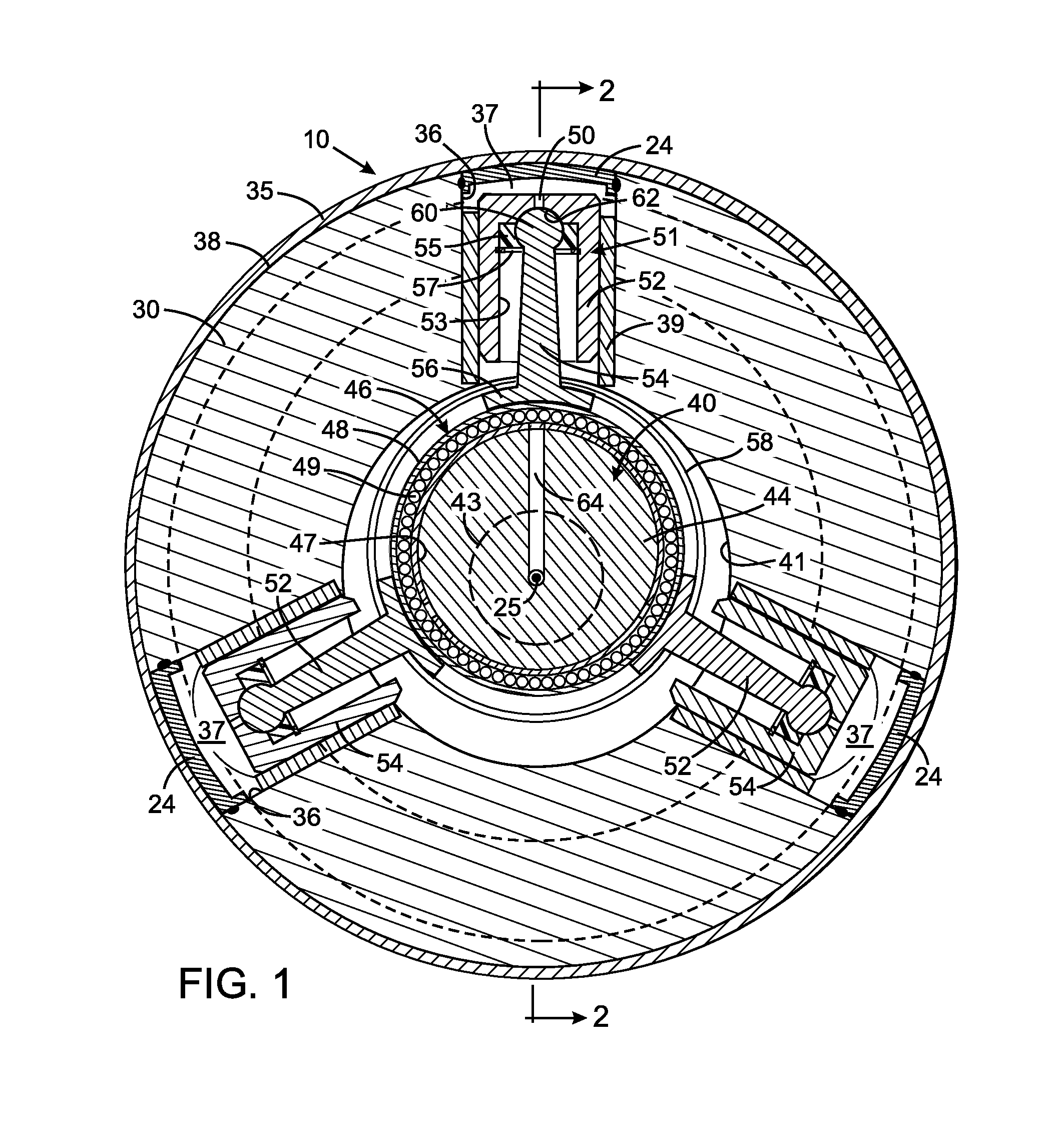

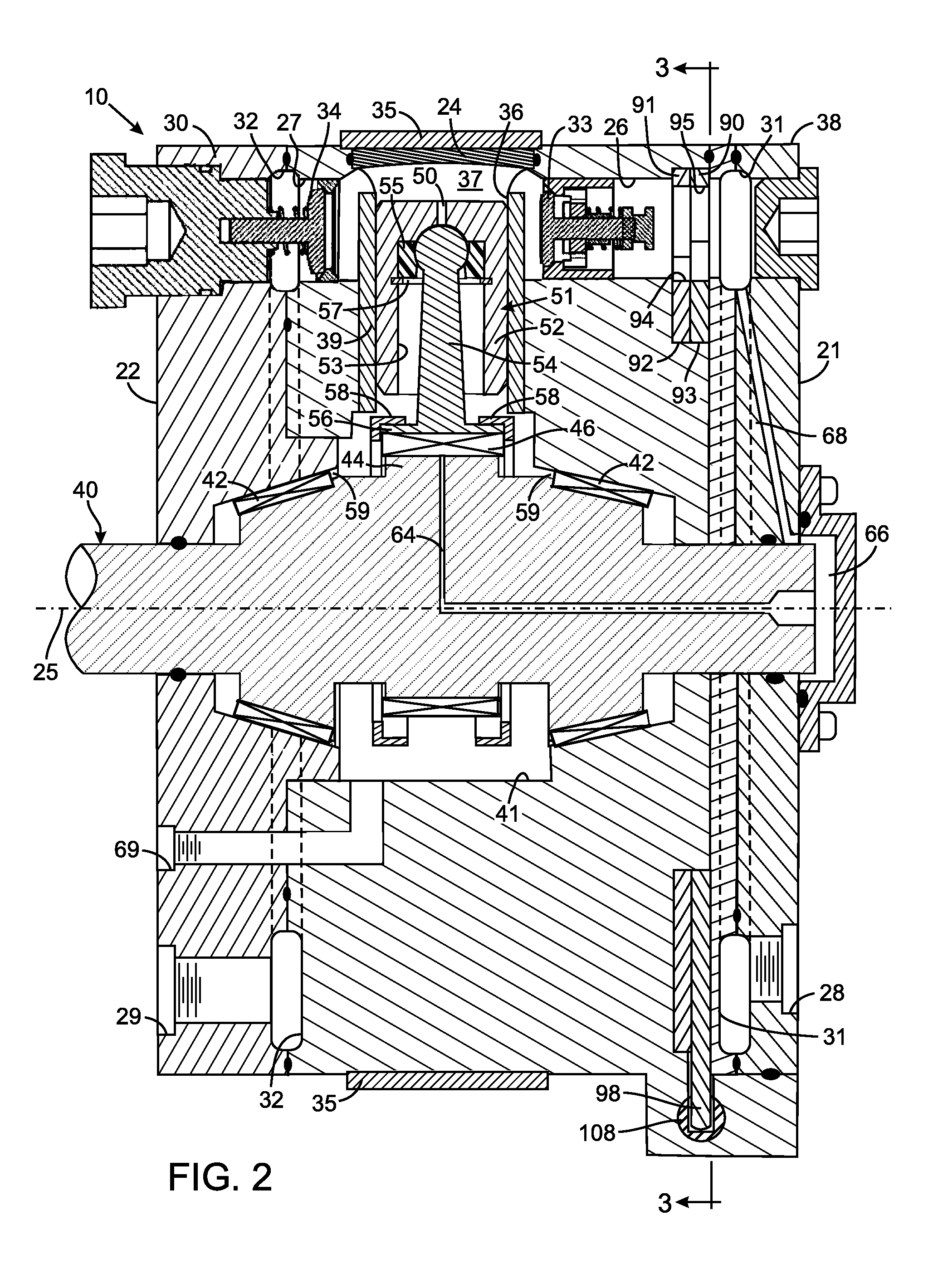

Radial piston pump with eccentrically driven rolling actuation ring

ActiveUS20050265867A1Minimize deflectionMinimizing heatFuel injecting pumpsPump controlRadial piston pumpDrive shaft

An hydraulic head features two or three individual radial pumping pistons and associated pumping chambers, annularly spaced around a cavity in the head where an eccentric drive member with associated outer rolling actuation ring are situated, whereby a rolling interaction is provided between the actuating ring and the inner ends of the pistons for intermittent actuation, and a sliding interaction is provided between the actuation ring and the drive member. The respective inlet and outlet valve trains are also situated in the head, and the head is attachable to an application and / or customer specific mounting plate. The outside diameter of the rolling element is barrel shaped, to compensate for any misalignment of the pistons relative to the drive shaft due, for example, to either tolerance stack up or deflection.

Owner:STANADYNE OPERATING CO LLC (

Actuator for a controlled coolant pump

InactiveCN103423170AAdjustable Space CostAdjustable construction costEngine controlPump controlImpellerFreewheel

A coolant pump of an internal combustion engine, with a pump housing and a hollow shaft rotatably mounted therein. Coolant is delivered via an impeller wheel from a suction connection. The flow is controlled by a guide plate on the impeller wheel that is variably displaceable axially between two end positions. The guide plate is adjustable by a push rod actuator guided in the pump shaft. The actuator has a radial piston pump integrated within the coolant pump with an intake piston and a counterpiston guided in the pump shaft, that are inserted lying opposite one another and delimit a pressure space. The pistons are enclosed outside by a linearly displaceable control element guided in the pump housing. Adjustment of the control element takes place as a function of a rotary angle of the pump shaft via an actuator unit having an electrically operated actuating element and a linear freewheel.

Owner:SCHAEFFLER TECH AG & CO KG

Radial piston pump for producing high fuel pressure, as well as method for operating an internal combustion engine, computer program, and control and/or regulating unit

InactiveUS6872056B2Simply and inexpensively producedHigh precisionElectrical controlFuel injecting pumpsRadial piston pumpCombustion

A radial piston pump used for producing high fuel pressure in fuel systems of internal combustion engines, in particular in a common rail injection system includes a housing with at least one cylinder and a drive shaft is supported in the housing and having at least one cam section. A stroke ring is disposed encompassing the cam section a piston contained in each cylinder is supported against the stroke ring. A possibility for adjusting the delivery quantity of the radial piston pump is achieved in that an adjusting ring is disposed between the cam section and the stroke ring and the internal opening of this adjusting ring is eccentric in relation to the outer contour and can be rotated around the central axis of the internal opening into a desired angular position in relation to the cam section.

Owner:ROBERT BOSCH GMBH

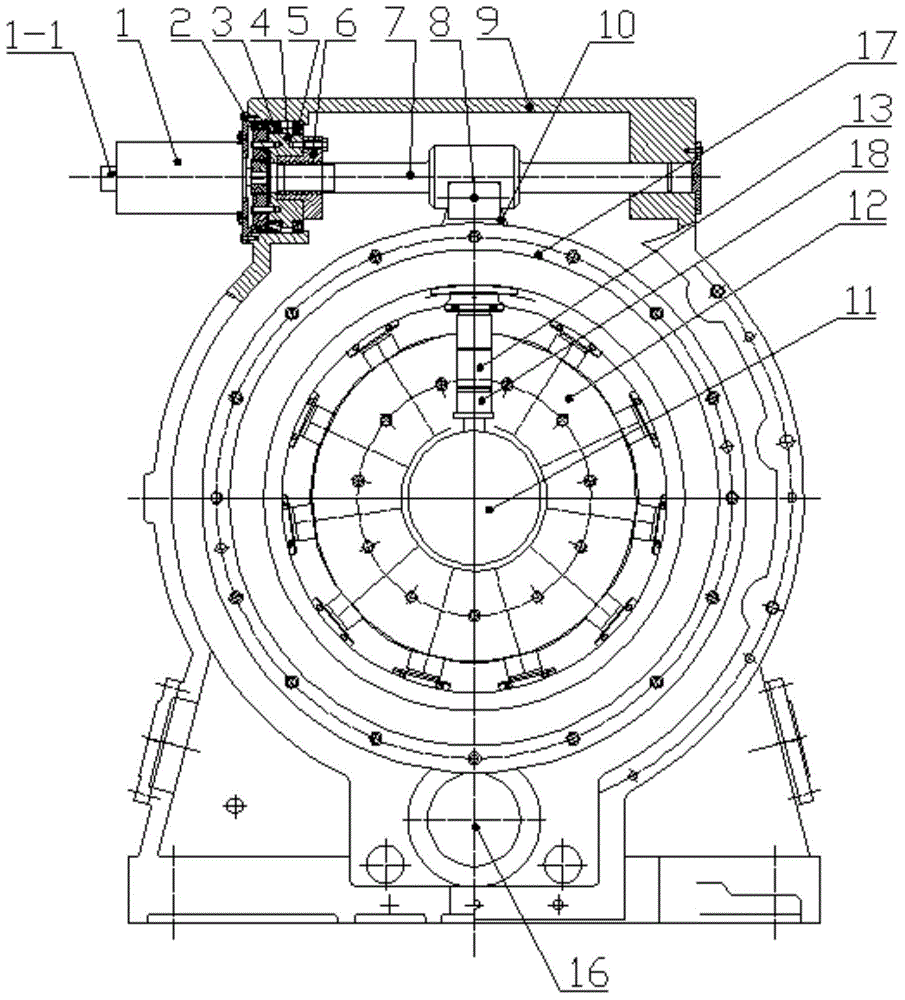

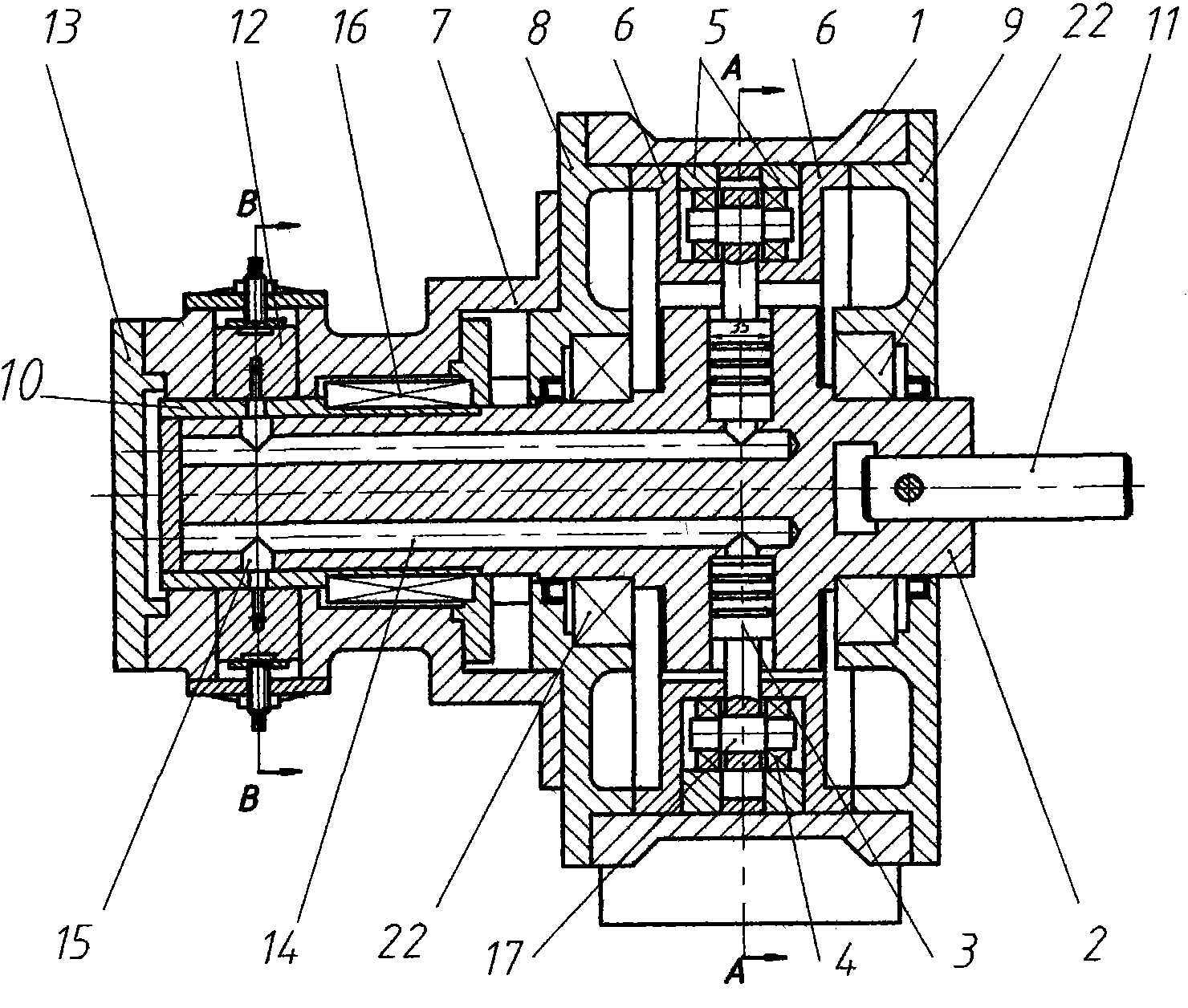

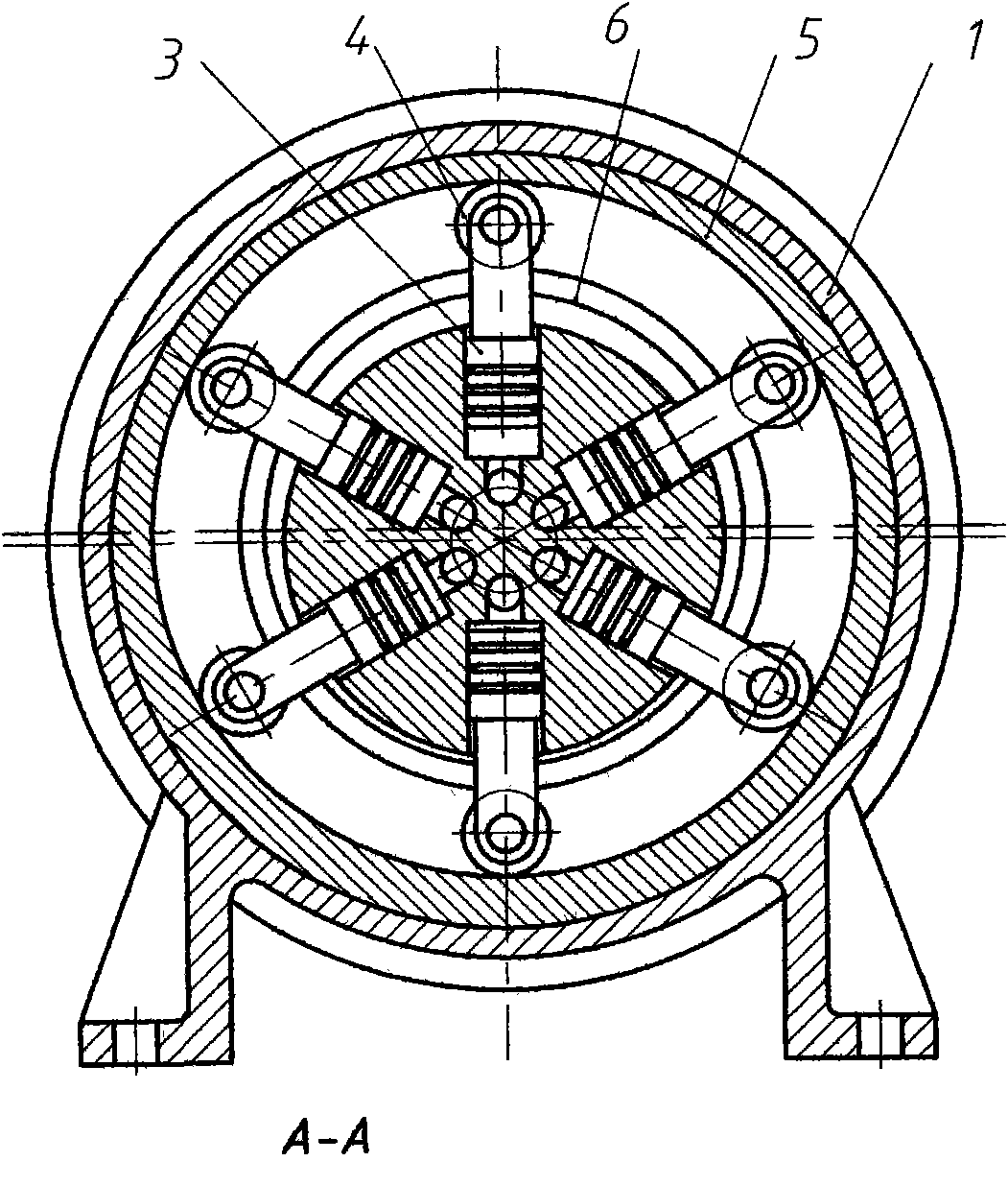

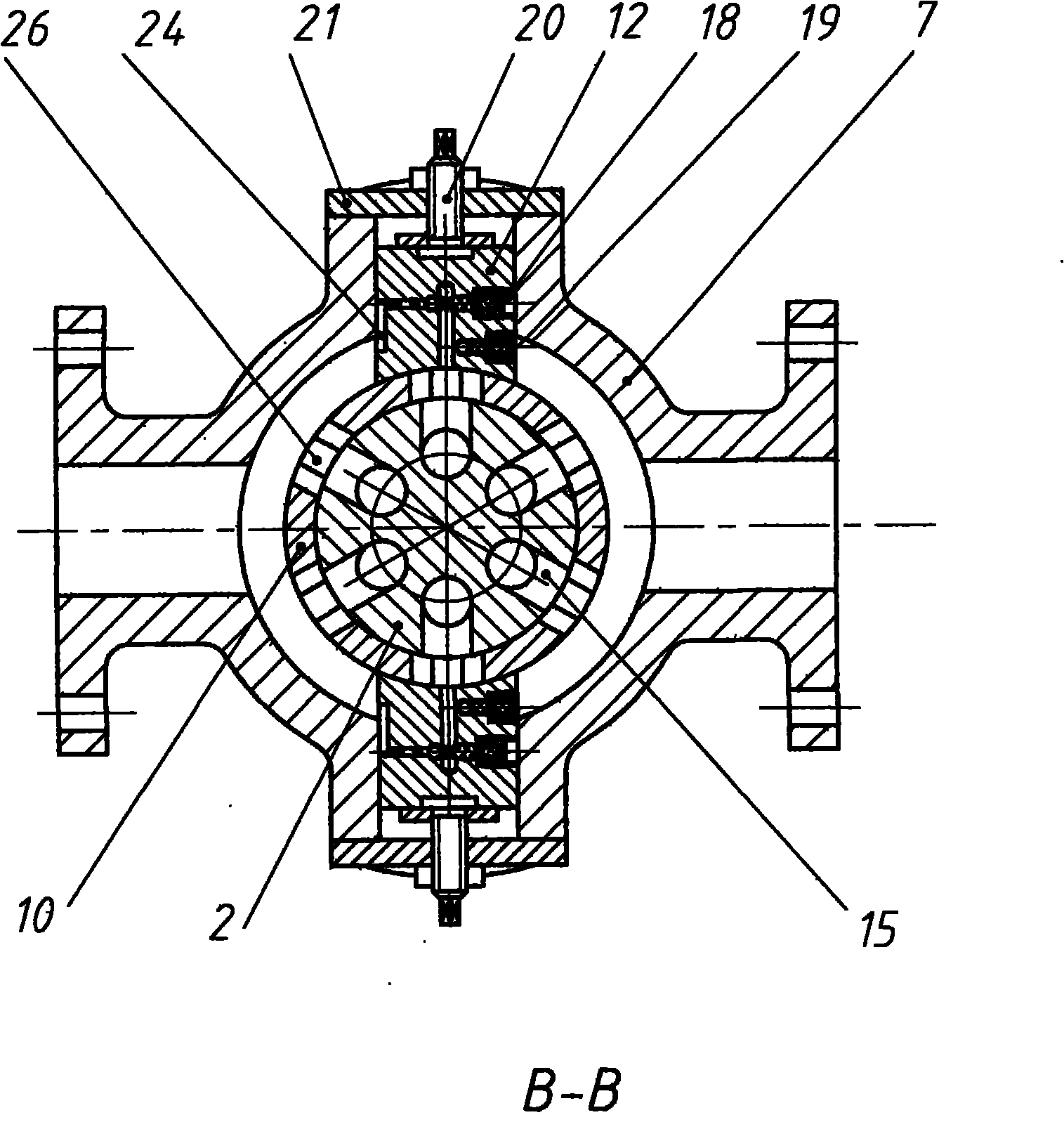

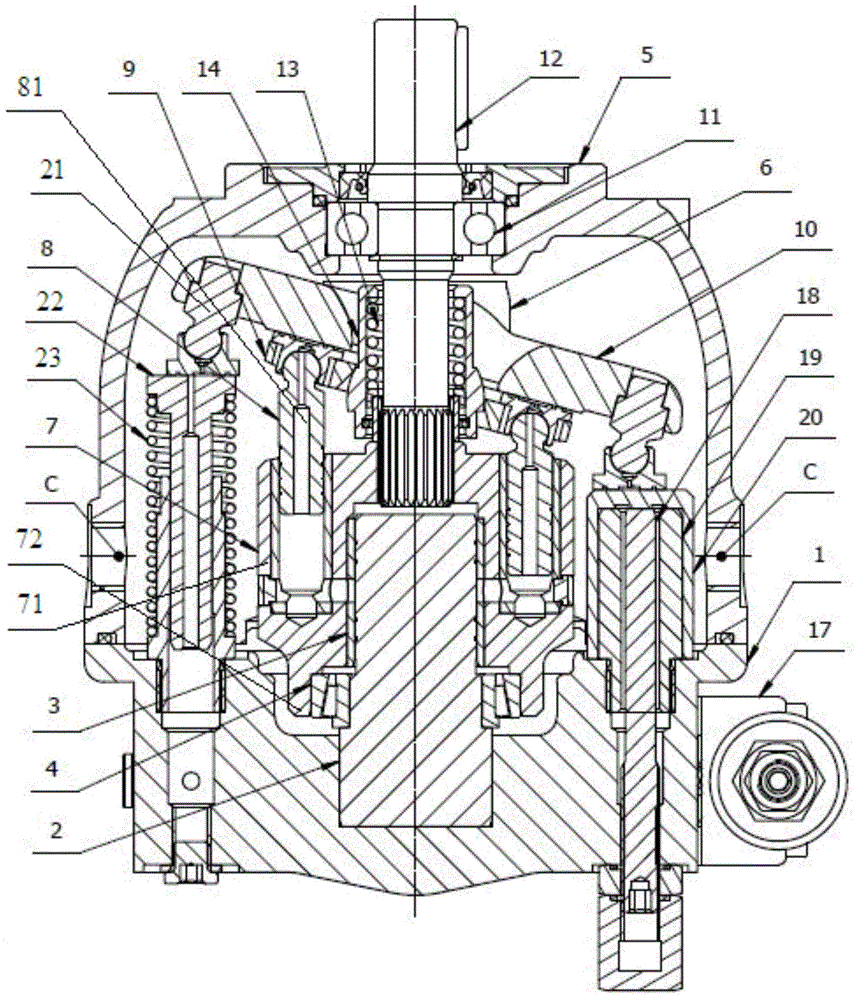

Non-axial force biserial radial piston pump distributing oil on end surface

InactiveCN104358664AReduce in quantityTake advantage ofPositive displacement pump componentsPositive-displacement liquid enginesRadial piston pumpDrive shaft

The invention discloses a non-axial force biserial radial piston pump distributing oil on an end surface. The biserial radial piston pump comprises a pump housing body; a first cam and a second cam are mounted in the pump housing body; the angle formed between the eccentric directions of the first cam and the second cam is 180 degrees; the two ends of a transmission shaft are supported by pump end covers; a rotor is mounted on the transmission shaft; the two sides of the rotor are propped against a first flow distributing plate and a second flow distributing plate respectively; two rows of radial piston holes are formed in the outer cylinder wall of the rotor in parallel; a piston is mounted in each piston hole; connecting rod skid shoes are mounted on the pistons, and are connected through spherical hinges; the first flow distributing plate and the second flow distributing plate are mounted on the pump end covers respectively; the angle formed between the mounting directions of the first flow distributing plate and the second flow distributing plate is 180 degrees; oil absorption arc grooves and oil pressing arc grooves which are isolated mutually are formed in the first flow distributing plate and the second flow distributing plate; oil inlet holes and oil outlet holes in the pump end covers are communicated with the oil absorption arc grooves and the oil pressing arc grooves respectively. According to the invention, distribution is realized through the first flow distributing plate and the second flow distributing plate; the piston pump has the advantages that the piston pump is compact in structure, simple in transmission, low in flow fluctuation, free from axial force, and reliable in support, conducts automatic hydraulic compensation, and is stable in operation, and long in service life.

Owner:XI AN JIAOTONG UNIV

Hydraulic piston pump with a variable displacement throttle mechanism

ActiveUS8926298B2Slow changeReduced flow areaPositive displacement pump componentsPump controlRadial piston pumpClosure rate

Owner:HUSCO INT INC

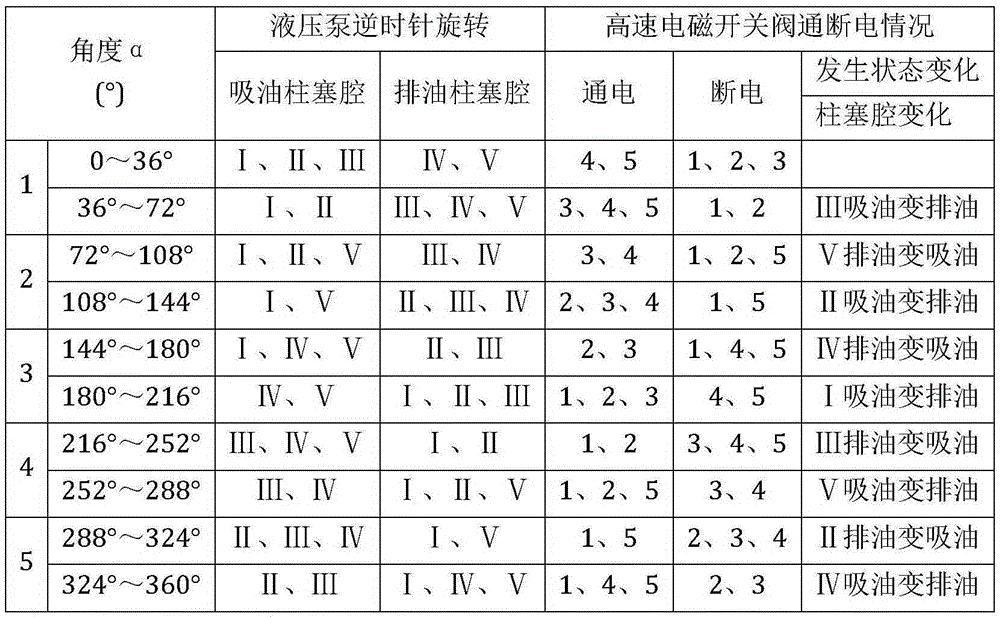

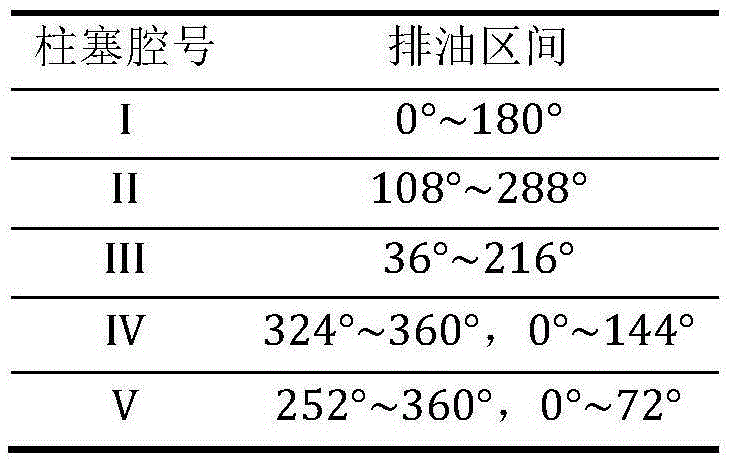

Digital flow-distribution constant-flow radial plunger pump

InactiveCN105386953ASmall pulsationGood for long time operationPositive-displacement liquid enginesMulti-cylinder pumpsRadial piston pumpControl signal

Provided is a digital flow-distribution constant-flow radial plunger pump. The digital flow-distribution constant-flow radial plunger pump comprises plunger chambers arranged in a pump body, two-position three-way high-speed switching valves connected with an oil tank and a load, an absolute value angle encoder connected with crank shafts of the plunger chambers, a flow-distribution body and a controller, wherein the two-position three-way high-speed switching valves are connected with the plunger chambers through the flow-distribution body, the controller is connected with the absolute value angle encoder and the two-position three-way high-speed switching valves, the controller receives a corner signal measured through the absolute value angle encoder, a PWM signal and a stroke control signal are output to the two-position three-way high-speed switching valves through a duty ratio control algorithm and a stroke ratio control algorithm, and therefore constant flow of the pump is achieved. According to the digital flow-distribution constant-flow radial plunger pump, the valves are controlled through the duty ratio and the stroke ratio, pulsation of the output flow of a hydraulic pump is reduced, pump vibration is relieved, long-time running of the pump is facilitated, random rotating speed working condition can be adapted, and constant-flow output is achieved.

Owner:SHANGHAI JIAO TONG UNIV

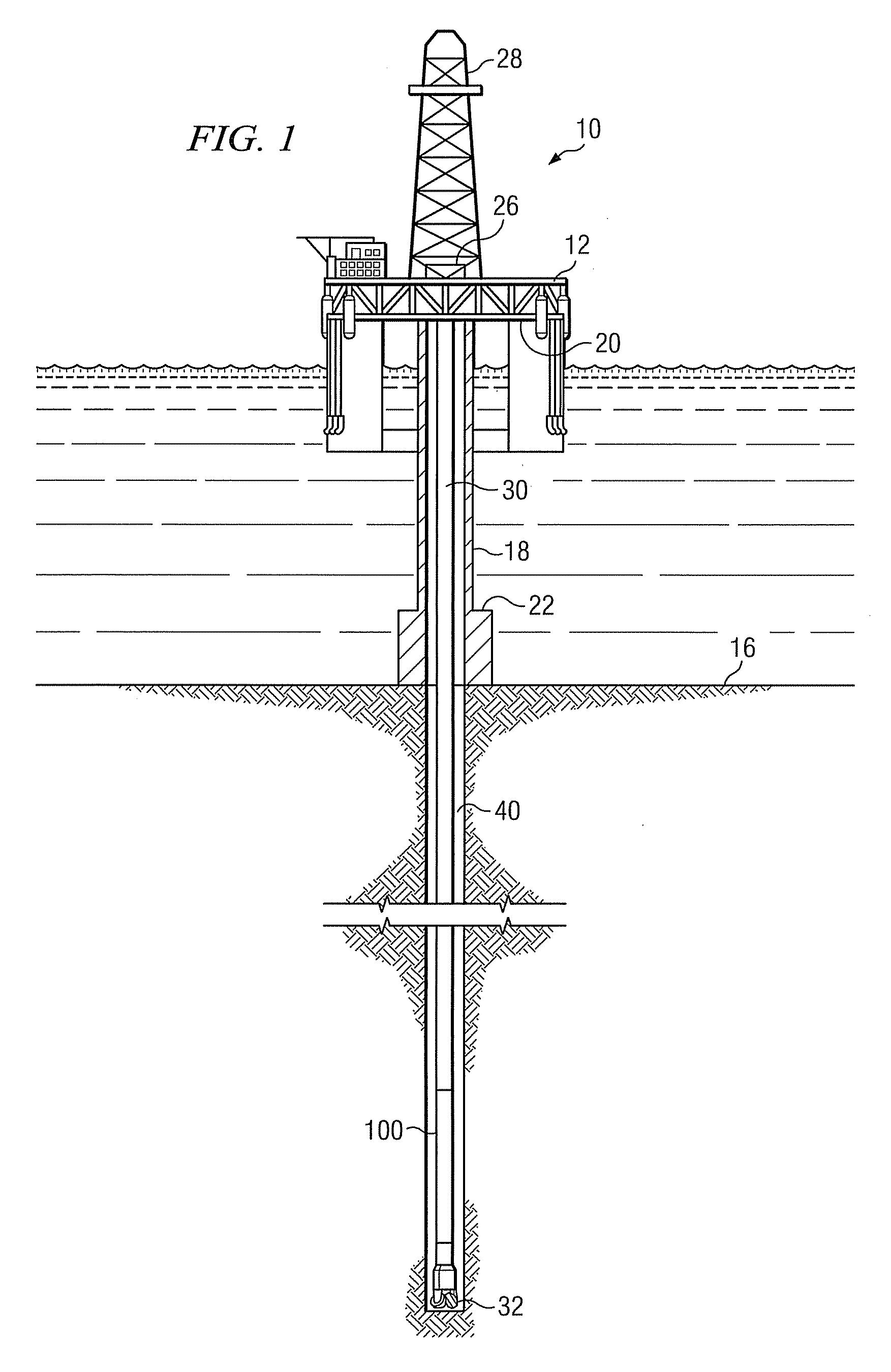

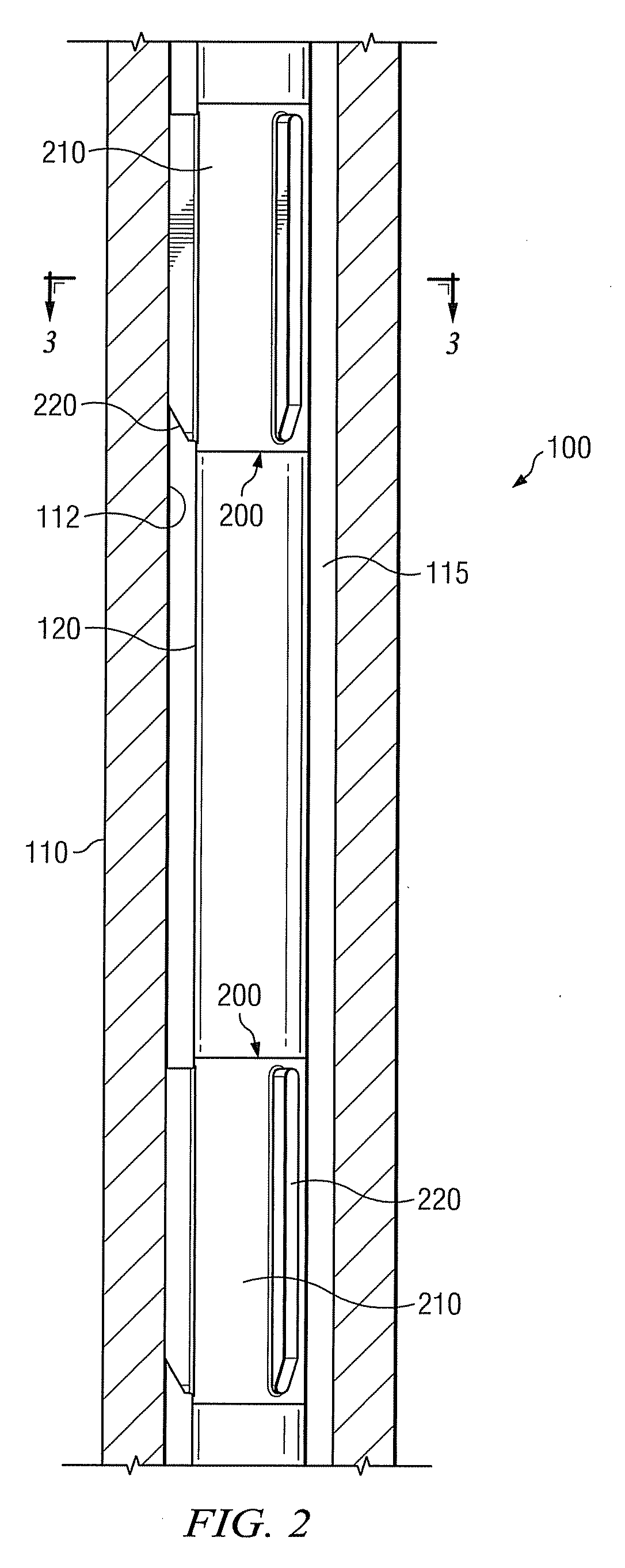

Hydraulically Locking Stabilizer

InactiveUS20110000665A1Improve stabilityMinimize frictional lossSurveyDrilling rodsRadial piston pumpHydrostatic pressure

A downhole tool includes a pressure housing deployed in the bore of a drill collar. At least three fins are deployed on the housing and in the tool annulus. At least one of the fins includes a floating blade deployed thereon. The blade includes a plurality of radial pistons deployed therein. The pistons are configured such that the surface area of the radially outward facing piston surfaces is greater than the surface area of the radially inward facing piston surfaces. This piston configuration causes the surface area of the radially outward facing blade surface to be less than the radially inward facing blade surface. In operation, hydrostatic pressure exerts a differential force on the pistons and the floating blade thereby urging the pistons radially inward towards the housing and the blade radially outward towards the drill collar.

Owner:SCHLUMBERGER TECH CORP

Connecting rod sliding shoe type flow distribution radial plunger pump

InactiveCN102644575ASensitive and reliable oil controlAvoid oil spillsPositive displacement pump componentsPositive-displacement liquid enginesRadial piston pumpEngineering

The invention discloses a connecting rod sliding shoe type flow distribution radial plunger pump, which comprises an eccentric shaft, a stator, a rotor, plungers, connecting rod sliding shoes and oil control valves and is characterized in that the bottom of the stator is fixedly connected with a base. A group of stator oil holes are evenly distributed on the inner wall of the stator along the radial direction, the group of stator oil holes are correspondingly connected with a group of oil control valves, the eccentric shaft is arranged in the stator, the rotor is arranged in the stator and connected to the outer side of the eccentric shaft in sleeved mode, a rotor anti-rotation mechanism is arranged at the bottom of the rotor, a group of plunger holes are evenly distributed on the rotor along the radial direction, a group of plungers are respectively arranged in the group of plunger holes, plunger return springs are arranged between the bottoms of the plunger holes and the plungers, the tops of a group of connecting rod sliding shoes are respectively arranged in the group of plungers and hinged to a group of plunger balls, and the bottoms of the group of connecting rod sliding shoes are slidingly connected with the inner wall of the stator and corresponds to the group of stator oil holes. The connecting rod sliding shoe type flow distribution radial plunger pump is sensitive and reliable in oil distribution, small in hydraulic oil leakage, low in fault rate and capable of effectively overcoming defects of a flow distribution mode of an existing radial plunger pump.

Owner:吕慧彬

Hydraulic piston pump with a variable displacement throttle mechanism

ActiveUS20130167957A1Alters alignmentSlow changePositive displacement pump componentsPump controlRadial piston pumpClosure rate

A radial piston pump has a plurality of cylinders within which pistons reciprocally move. Each cylinder is connected to a first port by an inlet passage that has an inlet check valve, and is connected to a second port by an outlet passage that has an outlet check valve. A throttling plate extends across the inlet passages and has a separate aperture associated with each inlet passage. Rotation of the throttling plate varies the degree of alignment of each aperture with the associated inlet passage, thereby forming variable orifices for altering displacement of the pump. Uniquely shaped apertures specifically affect the rate at which the variable orifices close with throttle plate movement, so that the closure rate decreases with increased closure of the variable orifices.

Owner:HUSCO INT INC

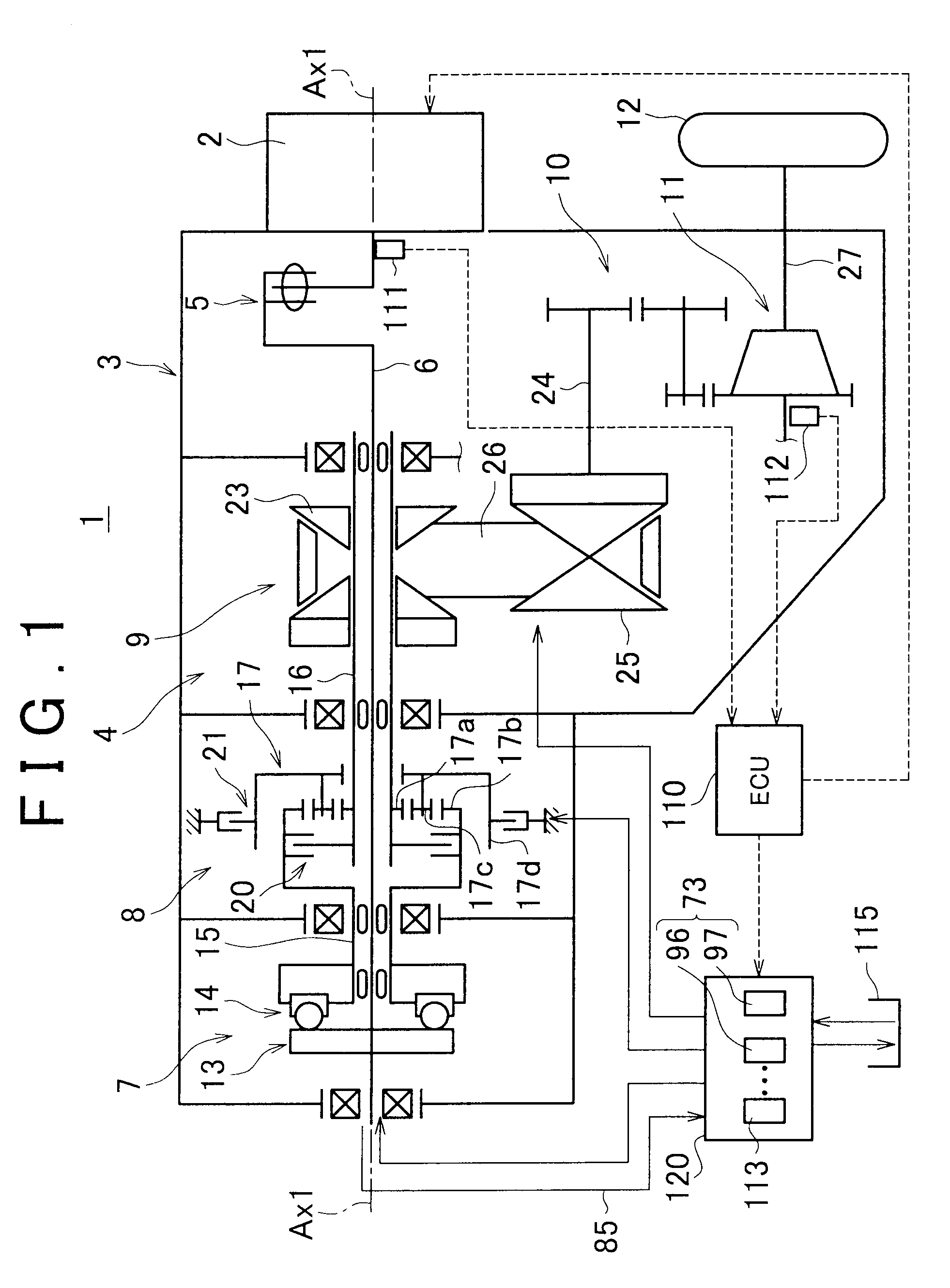

Axial piston pump, and power transmission device with axial piston pump

InactiveUS20090060765A1Avoid energy lossRotational differenceGearingPump controlRadial piston pumpDrive shaft

An axial piston pump has: a cylinder body that forms therein a cylinder chamber extending in an axial direction of a drive shaft and rotates integrally with a driven shaft; a piston that reciprocates in the axial direction of the drive shaft; and a cam device that rotates integrally with the drive shaft and has: a fixed cam member that has a cam surface capable of coming into contact with a cam follower coupled to the piston and is capable of rotating integrally with the drive shaft, with movement of the fixed cam member in the axial direction being restricted; and a movable cam member that has a cam surface capable of coming into contact with the cam follower and is capable of rotating integrally with the drive shaft, with movement of the movable cam member in the axial direction being allowed, irregularity differences in the axial direction of the cam surface of the fixed cam member and the movable cam member being different from each other.

Owner:TOYOTA JIDOSHA KK

Precision fluid dispensing system

InactiveUS20050006410A1Easy to controlMaintain accuracyContracting/expanding measuring chambersFlow mixersMicrocontrollerRadial piston pump

A precision fluid dispensing system containing at least one two-piece pump and a precision closed loop controller drive system to address the small volume precision dispensing requirements of bioscience applications. A multiple diameter pump can be combined with a pump having multiple inlet and outlet ports to allow for precision multiple outlet dispenses in a single pump that finds use with microtiter plate pipetting and other precision dispensing. Inlet ports can be located on the smaller diameter of the cylinder with outlet ports on the larger diameter of the cylinder. A microcontroller with closed loop feedback provides exact linear positioning and motion of the pump piston as well as optional control of a nozzle to provide exact micro-dispensing of fluids. A dual piston pump can be used to provide greater accuracy.

Owner:BACH DAVID +3

Variable axial plunger pump

ActiveCN104948408AImprove volumetric efficiencyReduce volumePositive-displacement liquid enginesMulti-cylinder pumpsRadial piston pumpDrive shaft

The invention provides a variable axial plunger pump. The variable axial plunger pump is a radial fluid distribution pump and comprises a drive shaft driven to rotate by an external force, a cylinder body connected with the drive shaft, a fluid distribution sleeve, a fluid distribution shaft and a variable control part enabling the plunger pump to variably output a fluid. The cylinder body, the fluid distribution sleeve and the fluid distribution shaft are coaxial with the drive shaft. Compared with a traditional radial plunger pump, the variable axial plunger pump mainly has the advantages of being simple in structure, small in size and light in weight. Compared with a traditional axial plunger pump, the variable axial plunger pump mainly has the advantages that the rotation speed of the pump can be remarkably improved, working pressure can be remarkably increased, nominal flow rate can be improved in a multiplied mode, or the volume efficiency of the pump can be remarkably improved under the condition of the same working pressure, and noise can be reduced by more than 10 decibels.

Owner:湖南润田水工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com