External radial plunger pump of sealing mechanism

A sealing mechanism and radial column technology, applied in the field of positive displacement pumps, can solve the problems of wear and heating of the joint surface of the rotor and the distribution shaft, and achieve the effects of increasing the discharge pressure, enhancing the sealing effect, and improving the volumetric efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

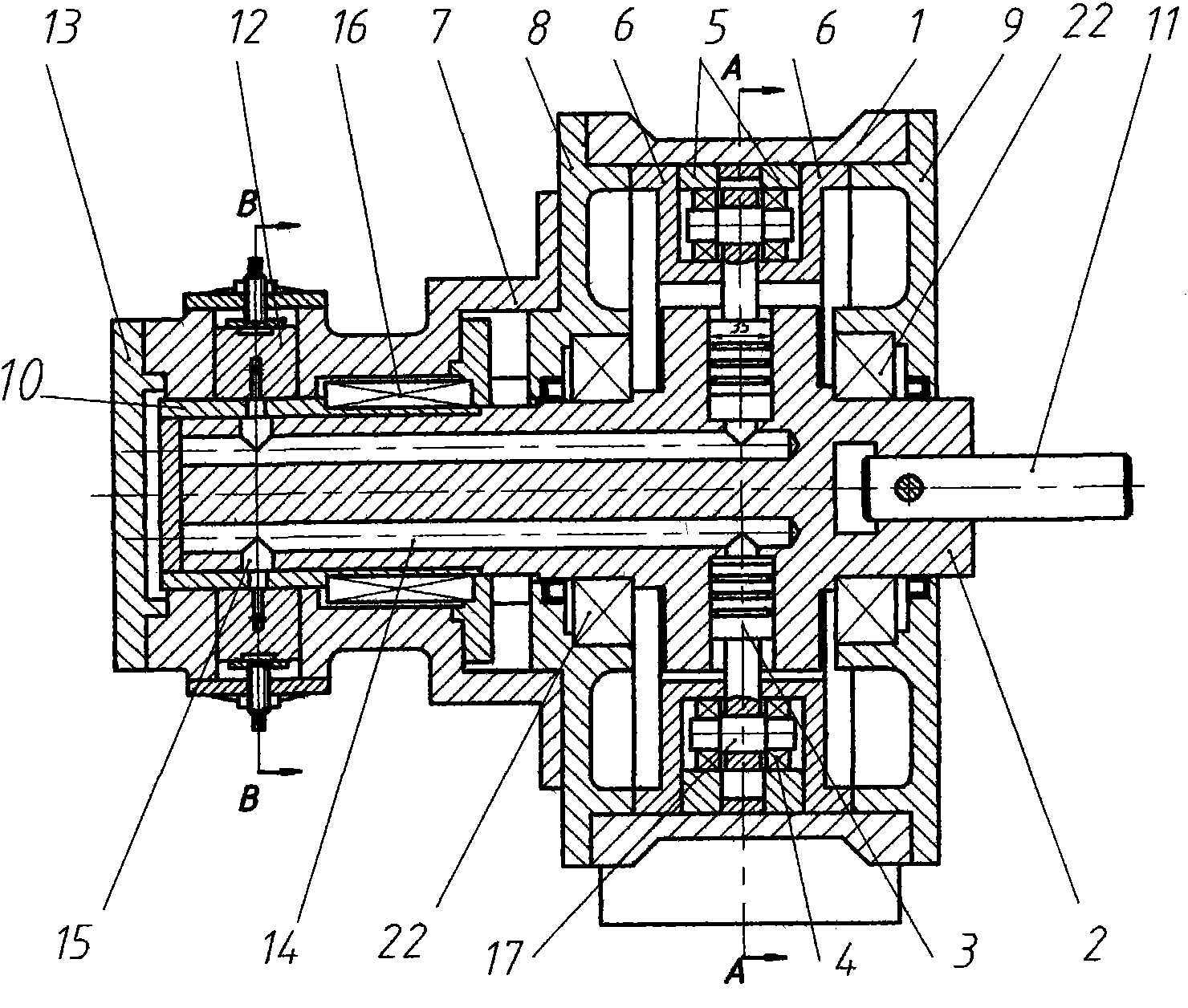

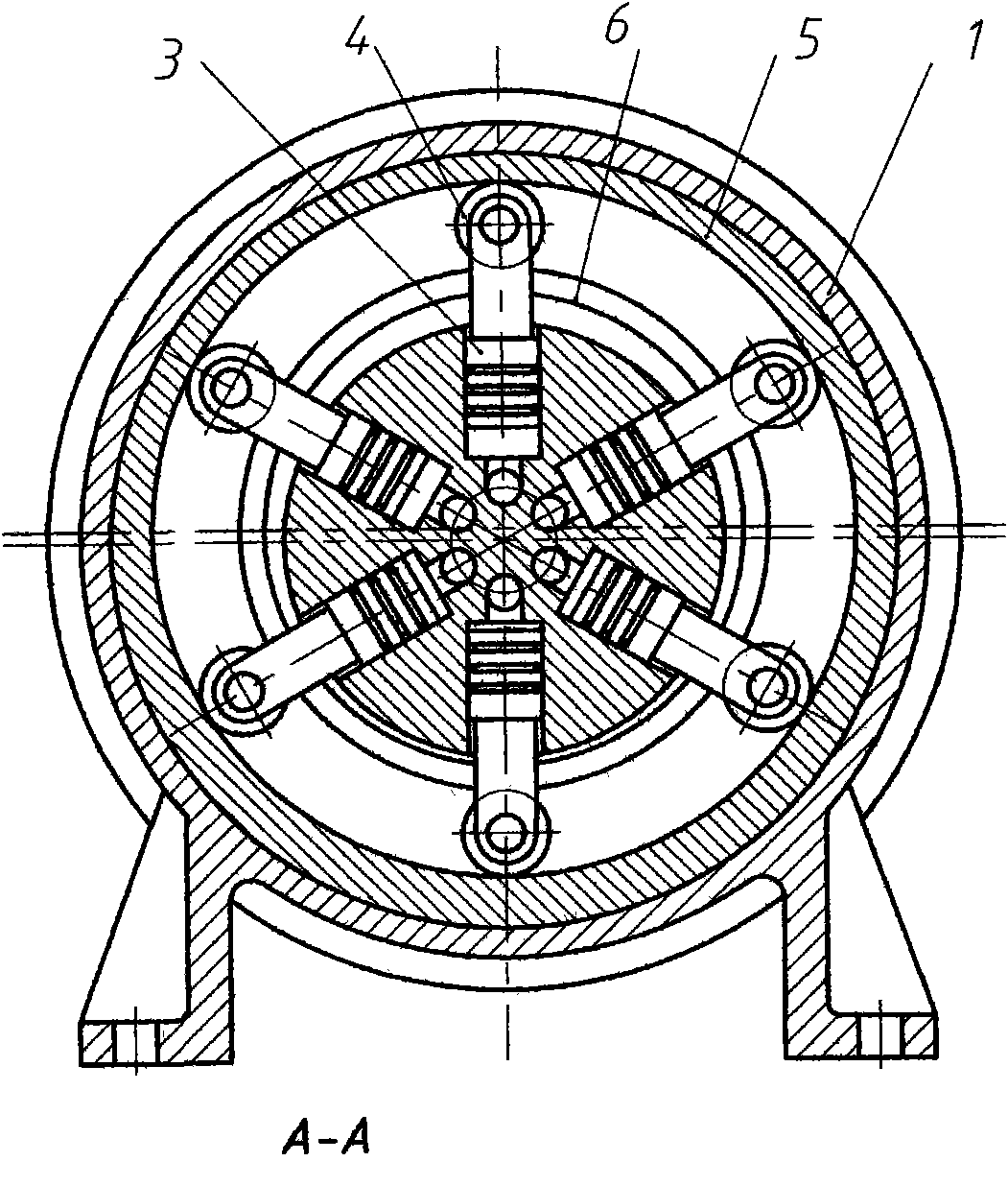

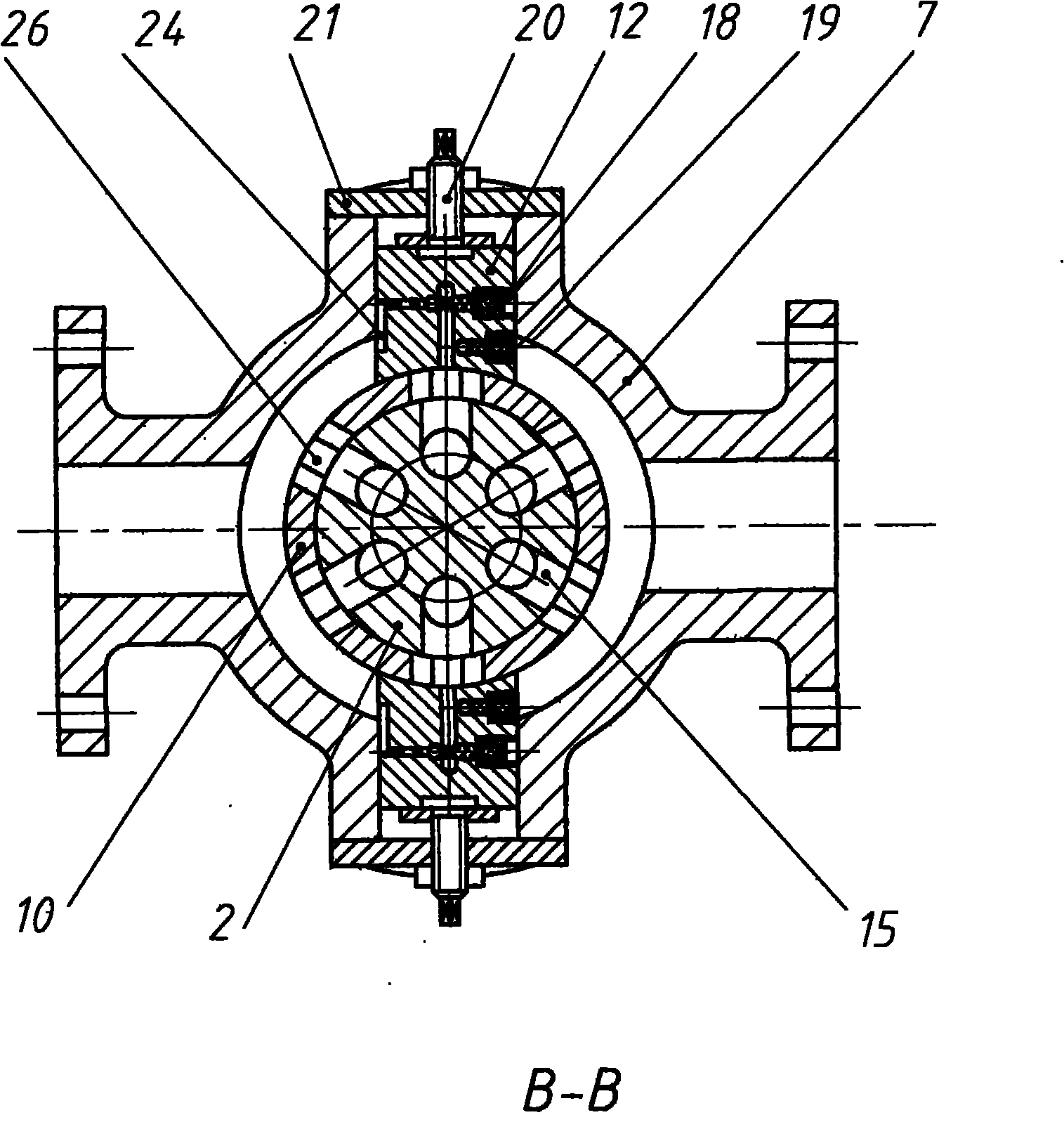

[0025] image 3 is a structural diagram of an embodiment of the present invention, Figure 4 is the A-A sectional view, Figure 5 It is a B-B sectional view.

[0026] The figure includes pump body 1, rotor 2, plunger 3, roller 4, annular stator 5, return ring 6, pump chamber 7, front cover 8, rear cover 9, rotor sleeve 10, drive shaft 11, floating spacer 12. Pump cover 13, central flow channel 14, radial through hole 15, shaft seal device 16, roller shaft 17, suction check valve 18, discharge check valve 19, adjusting screw 20, upper cover plate 21, bearing 22, Small groove 24, radial hole 26, narrow groove 27.

[0027] The rotor 2 is supported on the bearings 22 in the front cover plate 8 and the rear cover plate 9, each plunger hole communicates with a central channel 14, and the central channel 14 communicates with a radial through hole 15 at the pump chamber 7, the rotor 2 of this section The outer garden of the rotor sleeve 10 is fixed, and the rotor sleeve 10 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com