Patents

Literature

286results about How to "Increase the sealing area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

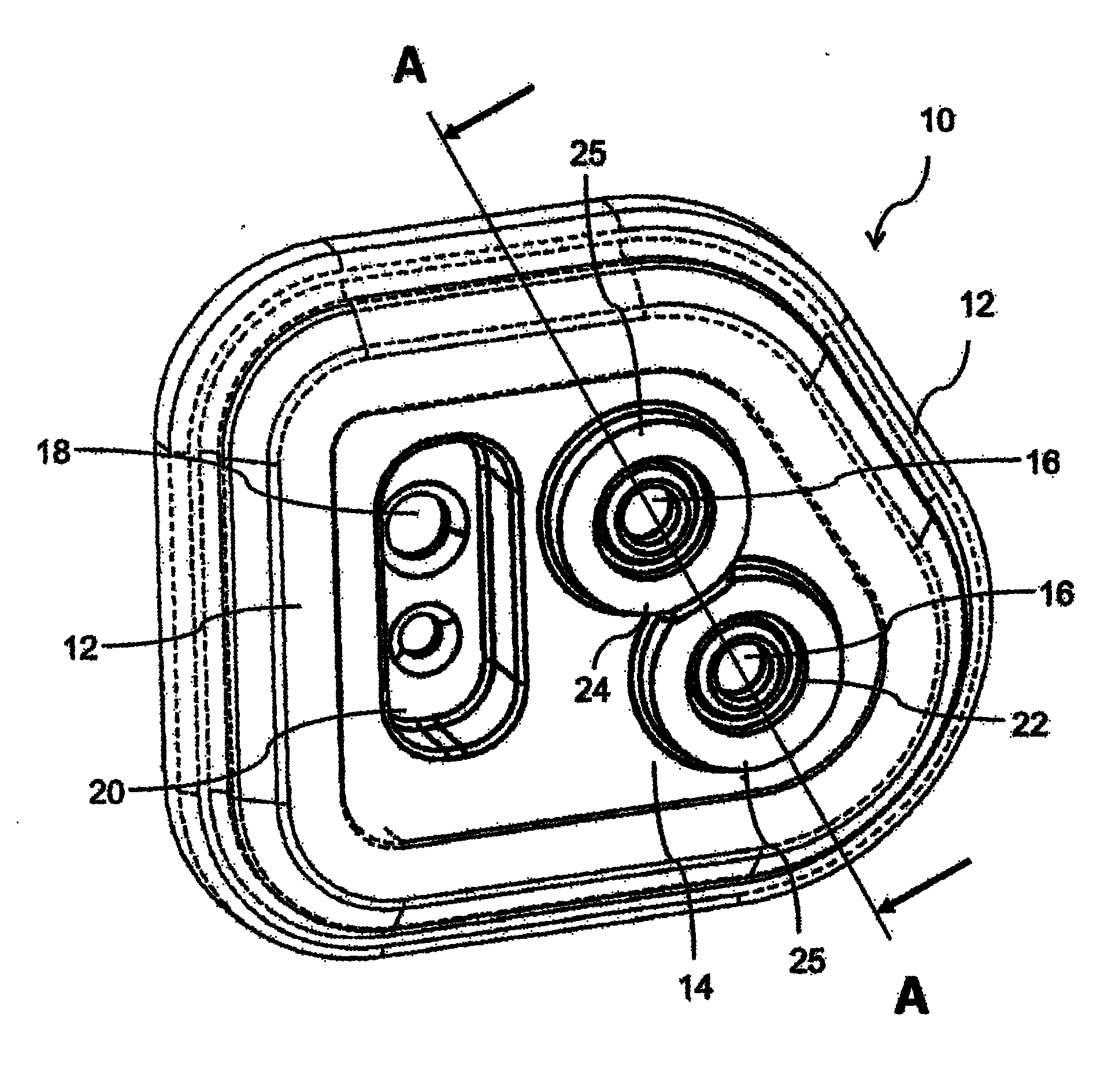

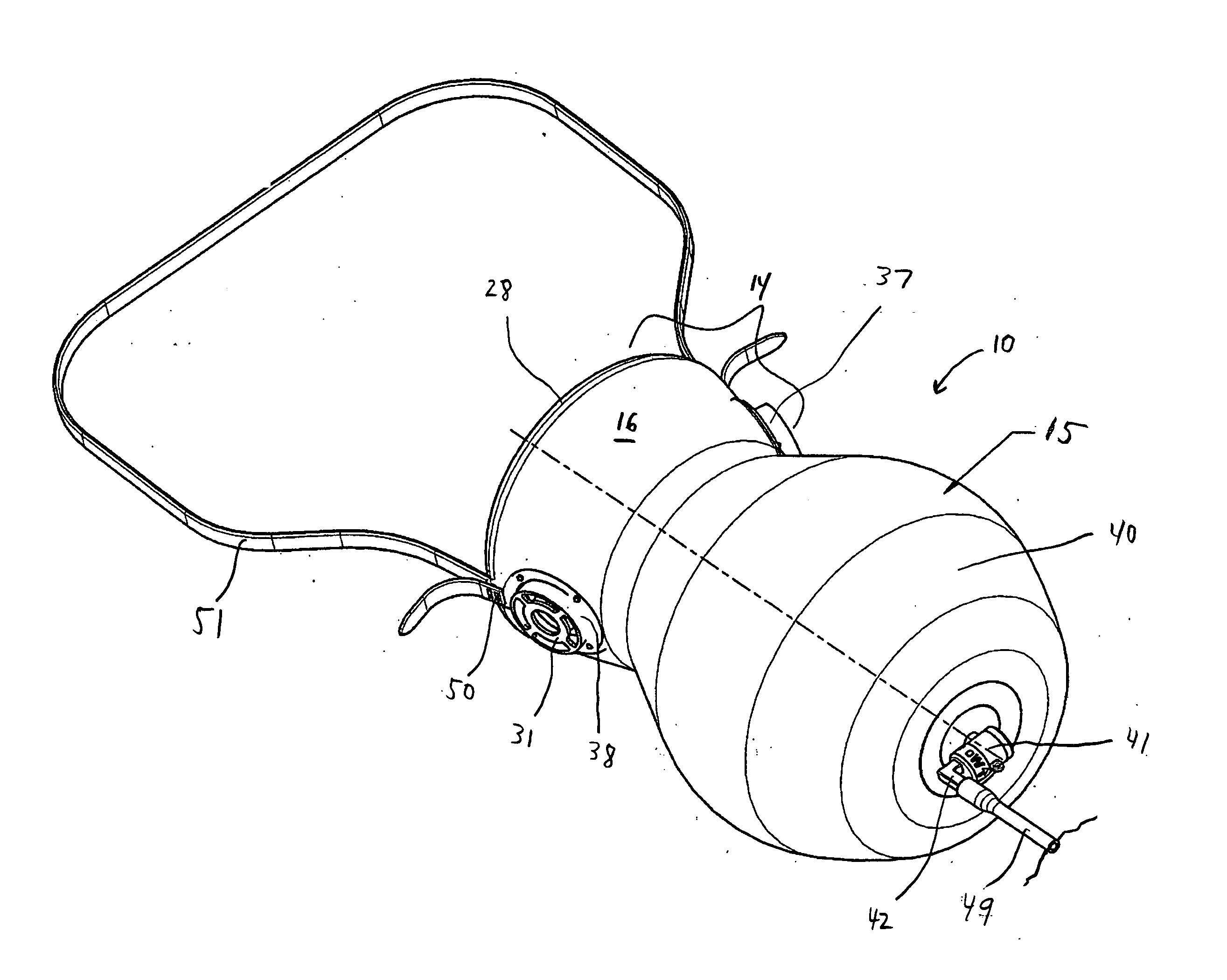

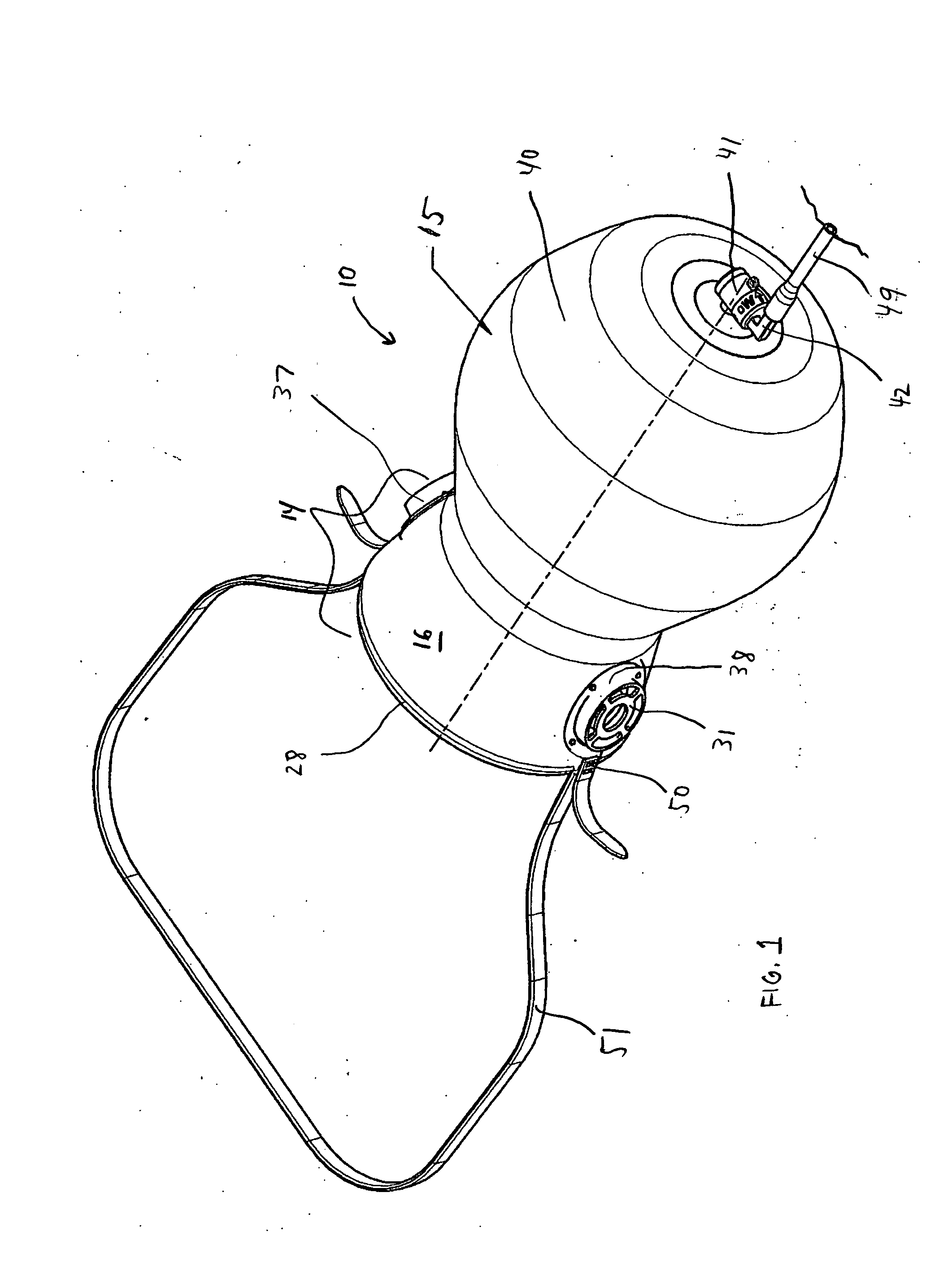

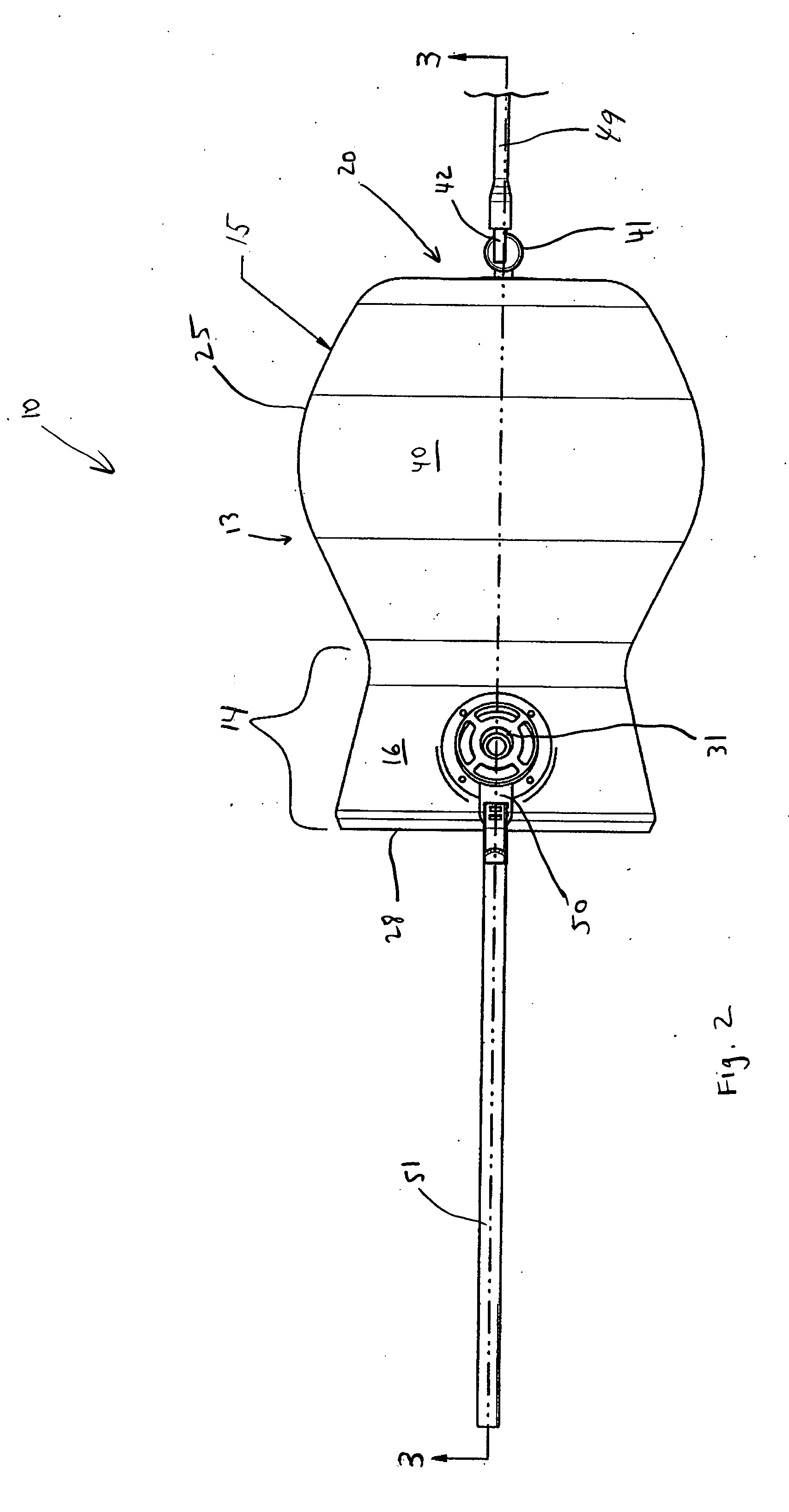

Mask System with Improved Sealing Properties for Administering Nasal Positive Airway Pressure Therapy

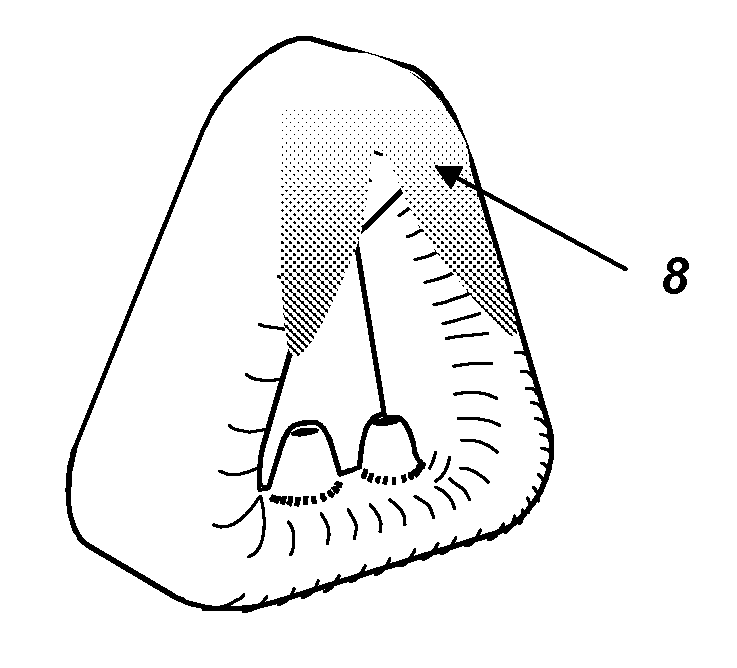

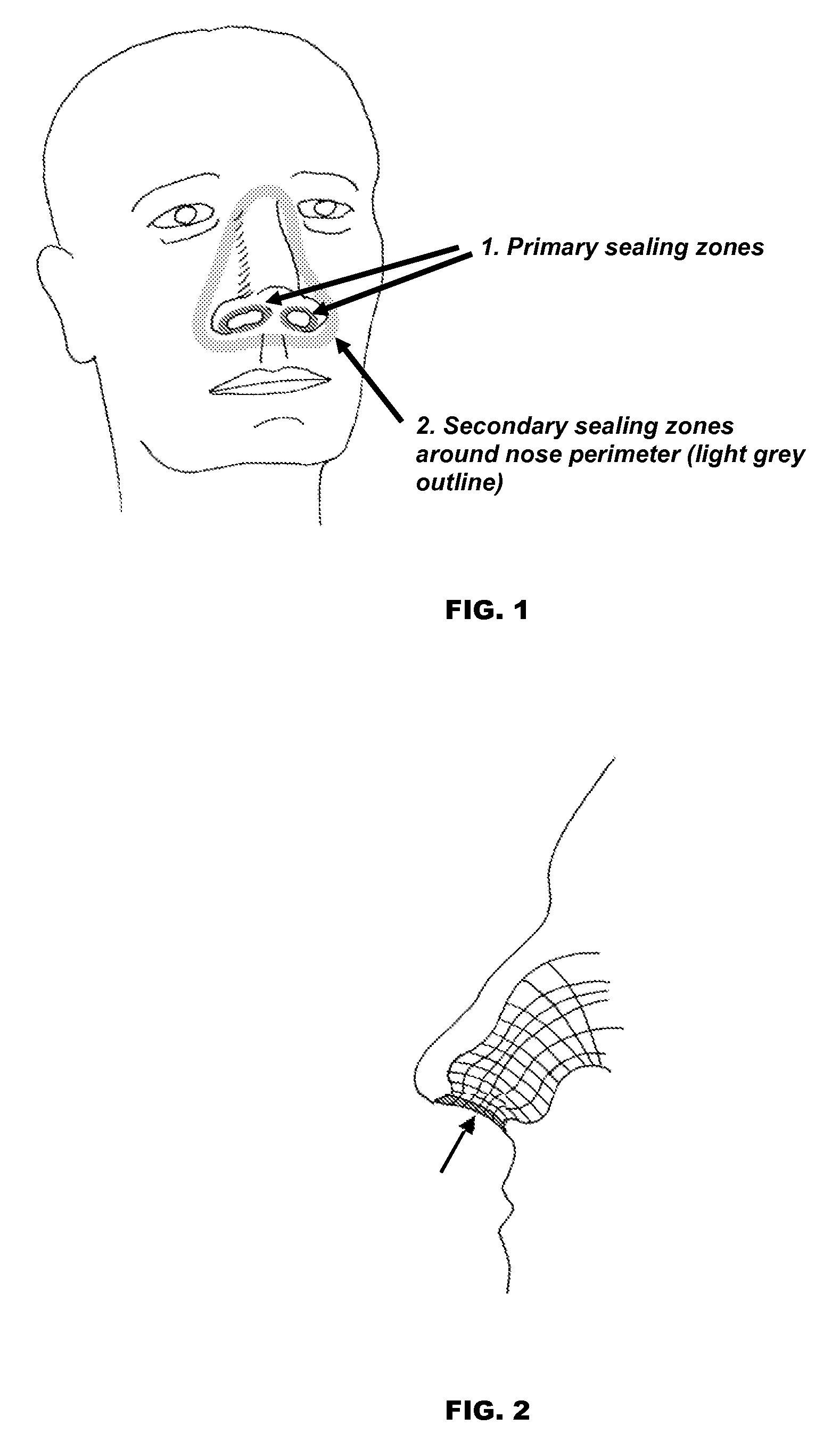

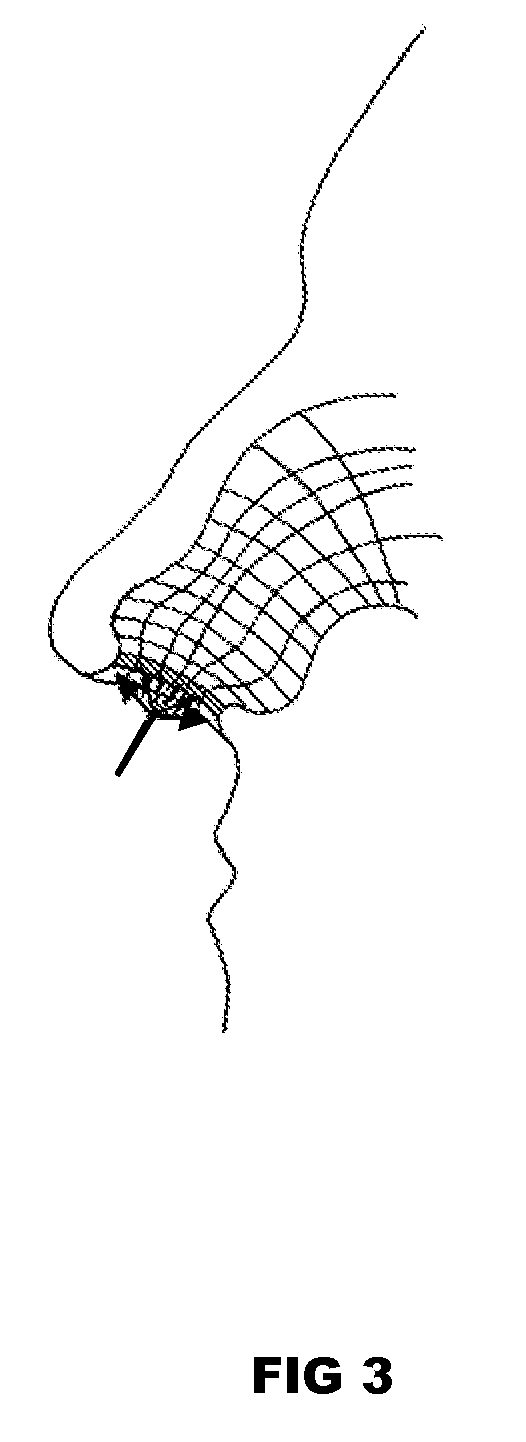

An improved mask sealing apparatus is described for use in nasal positive pressure therapies such as nasal CPAP (continuous positive airway pressure) and nasal ventilation for treatment of such disorders as sleep apnea, ventilatory insufficiency and complex sleep apnea. The device most importantly provides a means for formation of 2 sealing zones when fitted to a user's face. The first is formed at or within the nares of a user, while a second sealing zone is formed around a user's nose. The cushion so formed may be constructed as a thick walled profile or a thin walled profile using a materials of appropriate durometer. Various configurations of the nares and peri-nasal sealing components are further described.

Owner:HALLETT MICHAEL DAVID +1

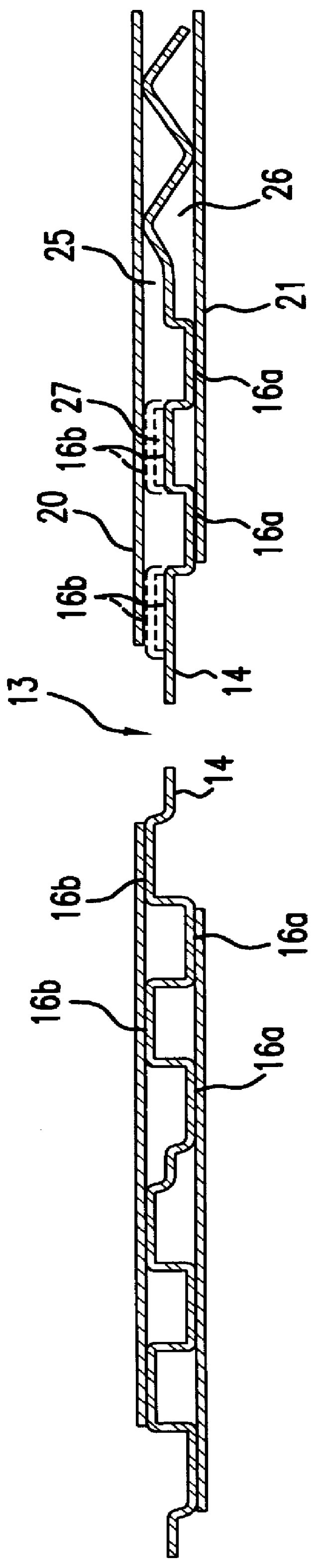

One piece fuel cell separator plate

InactiveUS6040076AShorten assembly timeImprove sealingFuel cells groupingFused electrolyte fuel cellsFuel cellsGuide tube

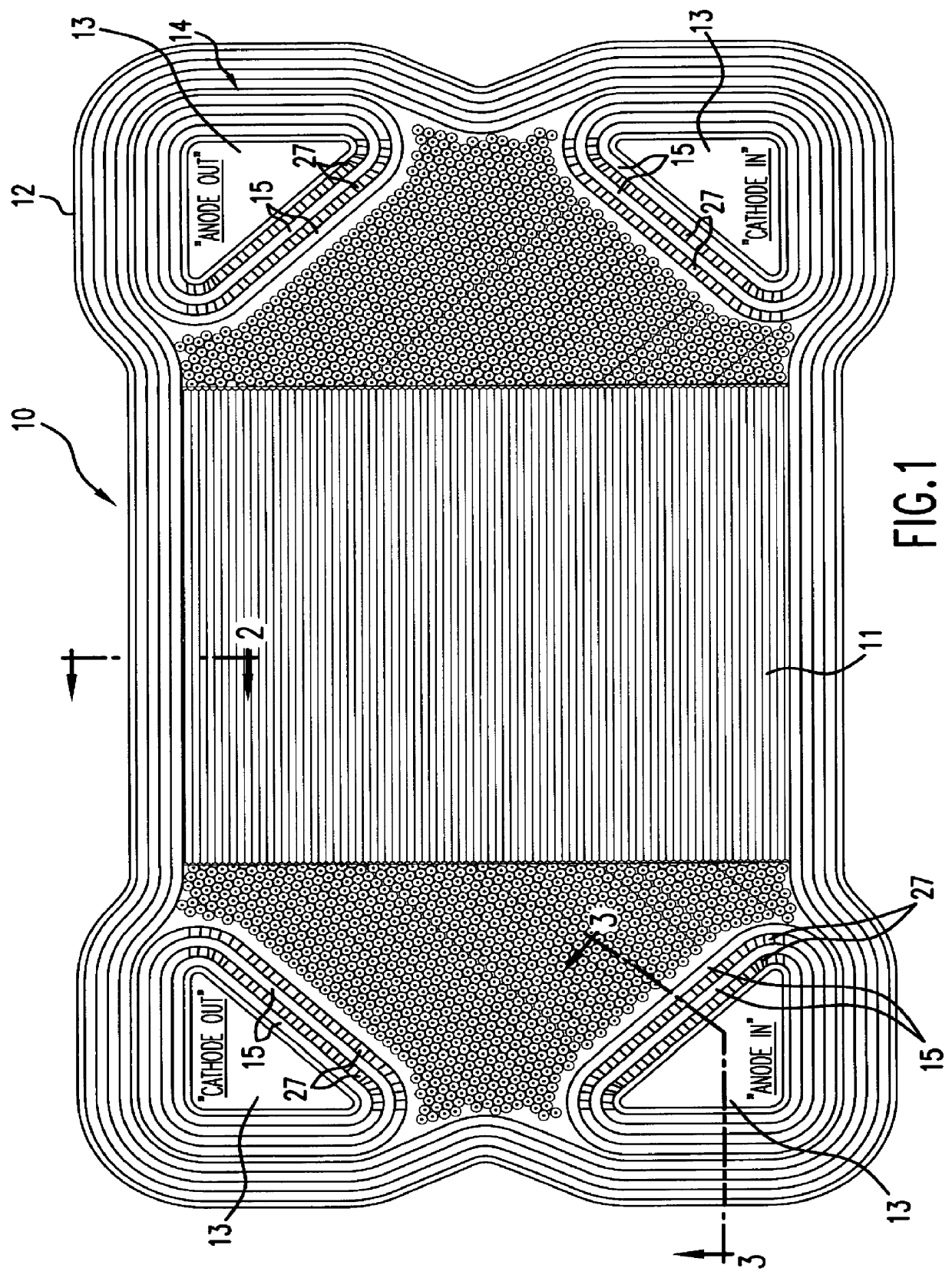

A separator plate for an internally manifolded fuel cell stack comprising a centrally disposed active region, a peripheral seal region, and forming at least one pair of perforations substantially geometrically disposed on opposite sides of the centrally disposed active region. The peripheral seal region comprises a peripheral seal structure on each face of the separator plate completely around the periphery of each said face. A manifold seal region in each face completely encloses each perforations, the manifold seal region comprising conduits on one of said faces for communication of a gas between the centrally disposed active region and at least the one pair of perforations. The separator plate is comprised of one sheet of a material suitable for use as a separator plate, preferably a pressed sheet metal.

Owner:INST OF GAS TECH

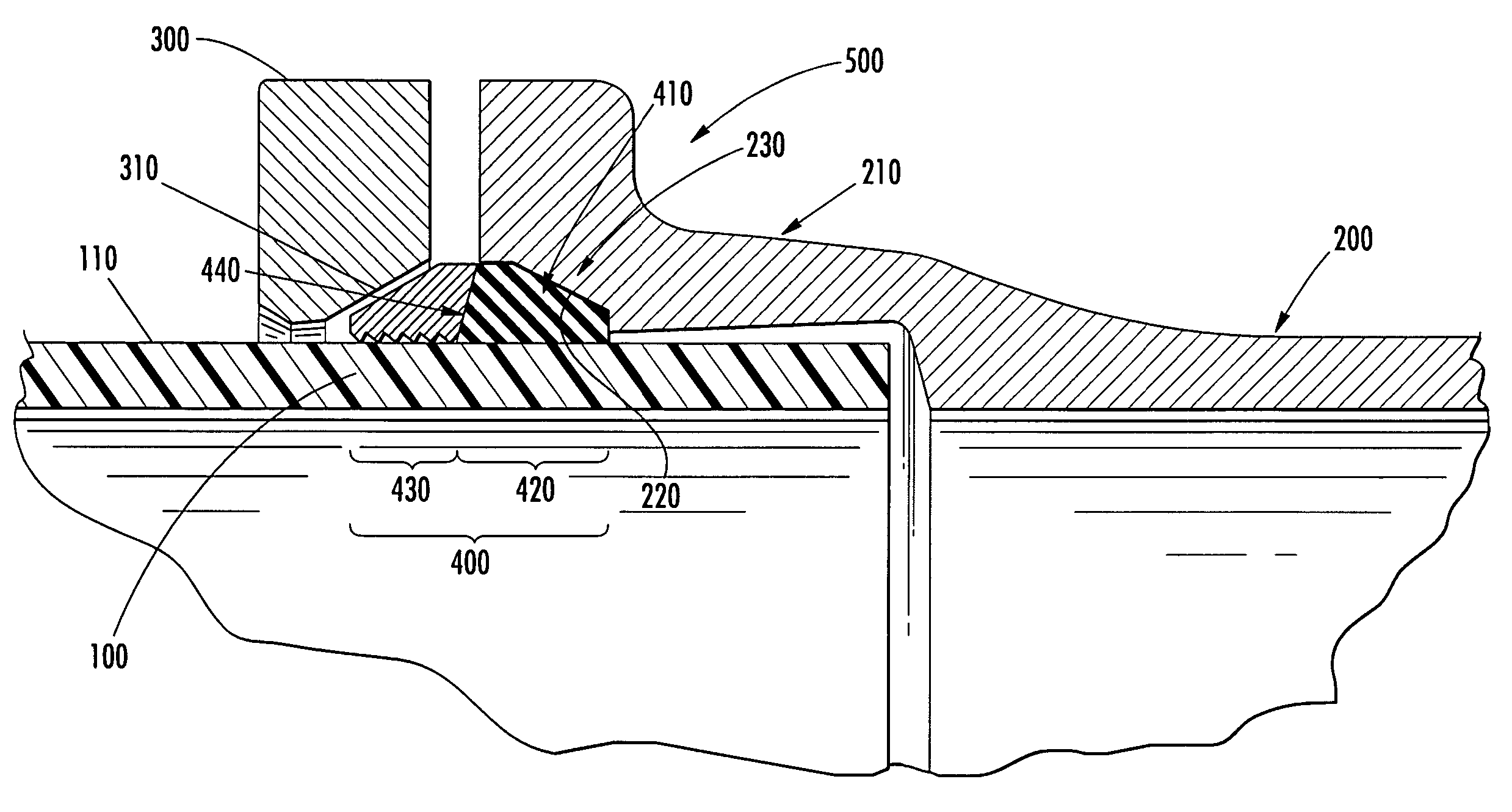

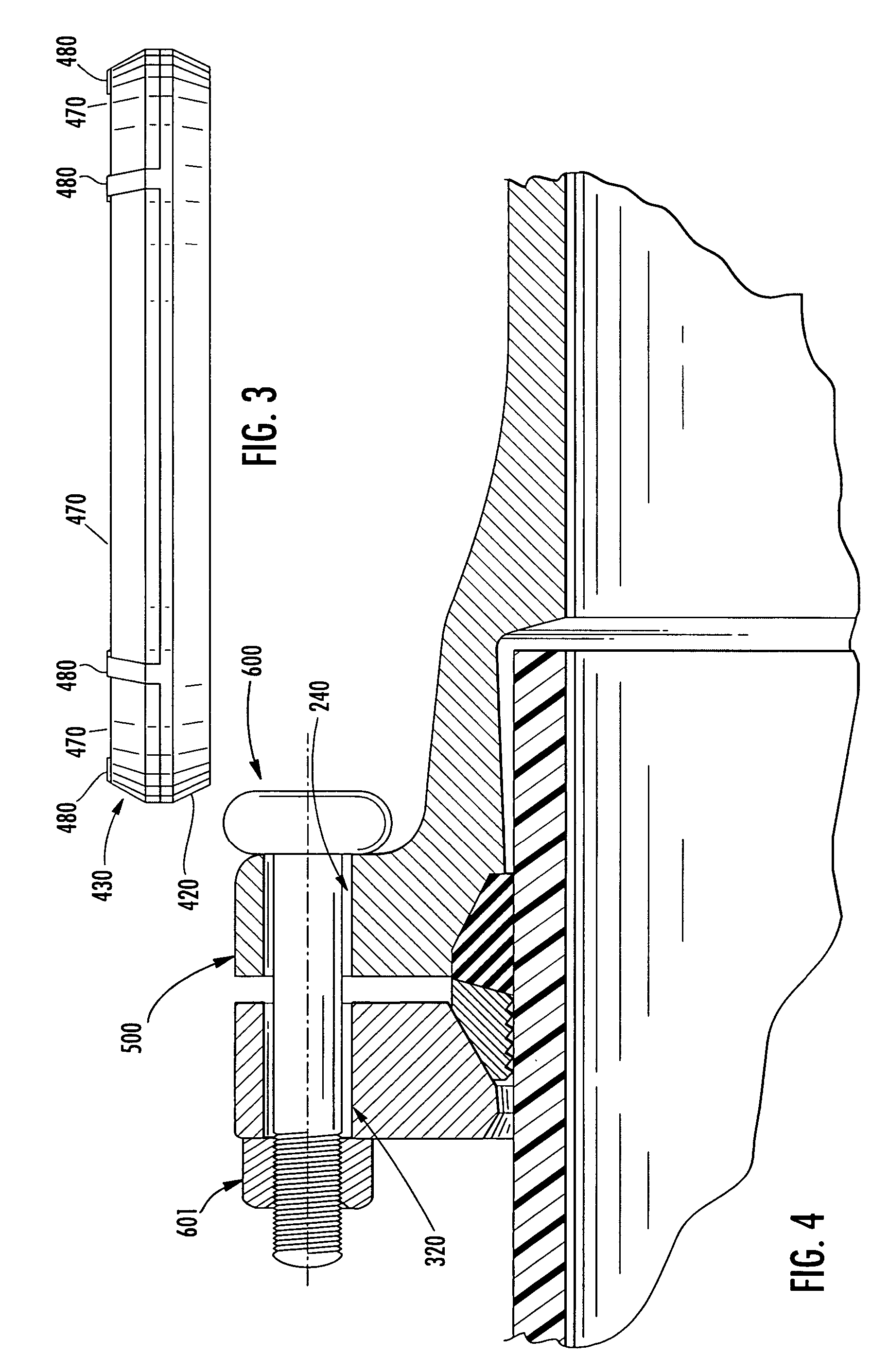

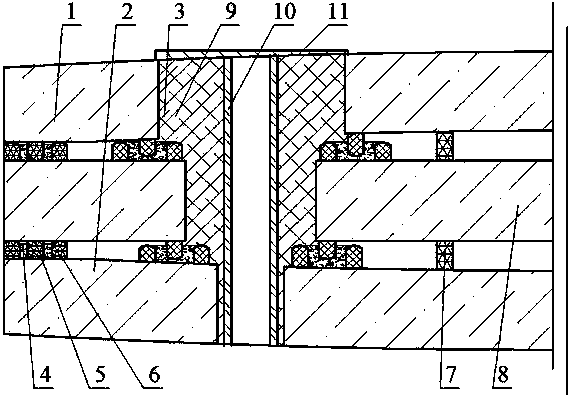

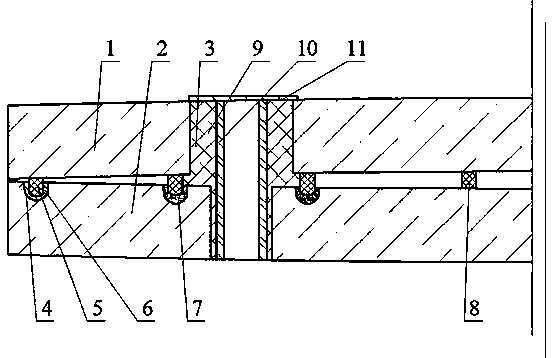

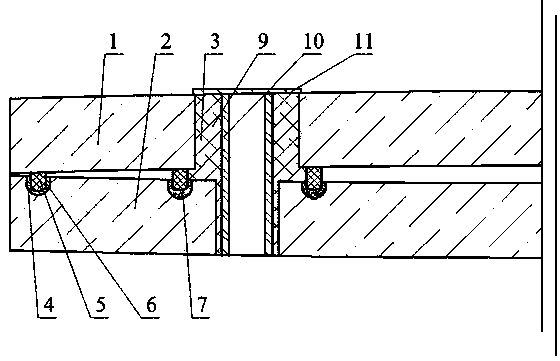

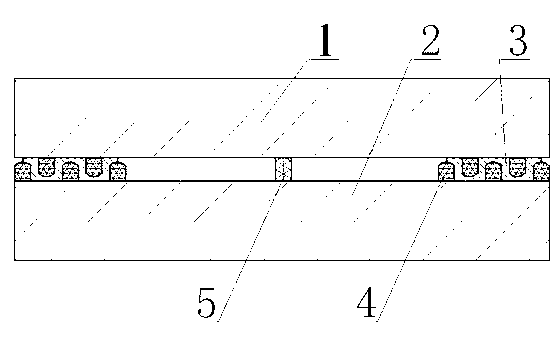

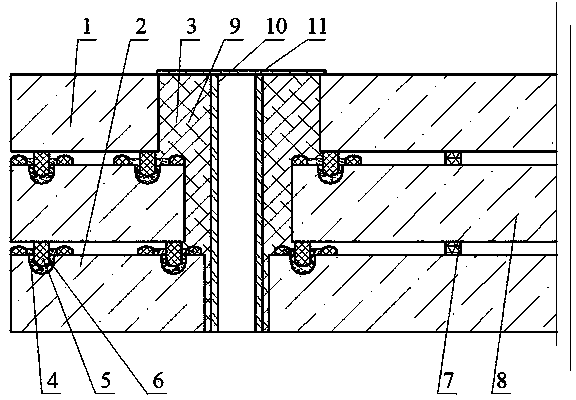

Mechanical pipe joint, gasket, and method for restraining pipe spigots in mechanical pipe joint bell sockets

ActiveUS20050230972A1Equally distributedLight weightSleeve/socket jointsFluid pressure sealed jointsEngineeringGasket

A mechanical pipe joint, restraining gasket, and method for restraining pipe spigots within adjacent bell sockets. The restraining gasket is composed of two axially-separate components: a sealing portion and a restraining portion made of a plurality of arcuate locking members. The restraining gasket and a gland surround an outer surface of the pipe spigot. The mechanical pipe joint is formed as the pipe spigot is inserted into the bell socket and the gland is axially attached to the bell socket so that the restraining gasket is held between: the gland, an inner surface of the bell socket, and the outer surface of the pipe spigot, so as to provide a fluid seal in the joint and urge the locking members into contact with the outer surface of the pipe spigot, axially restraining the pipe spigot within the bell socket.

Owner:US PIPE & FOUNDRY

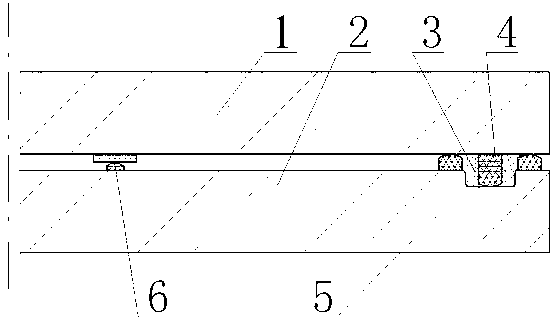

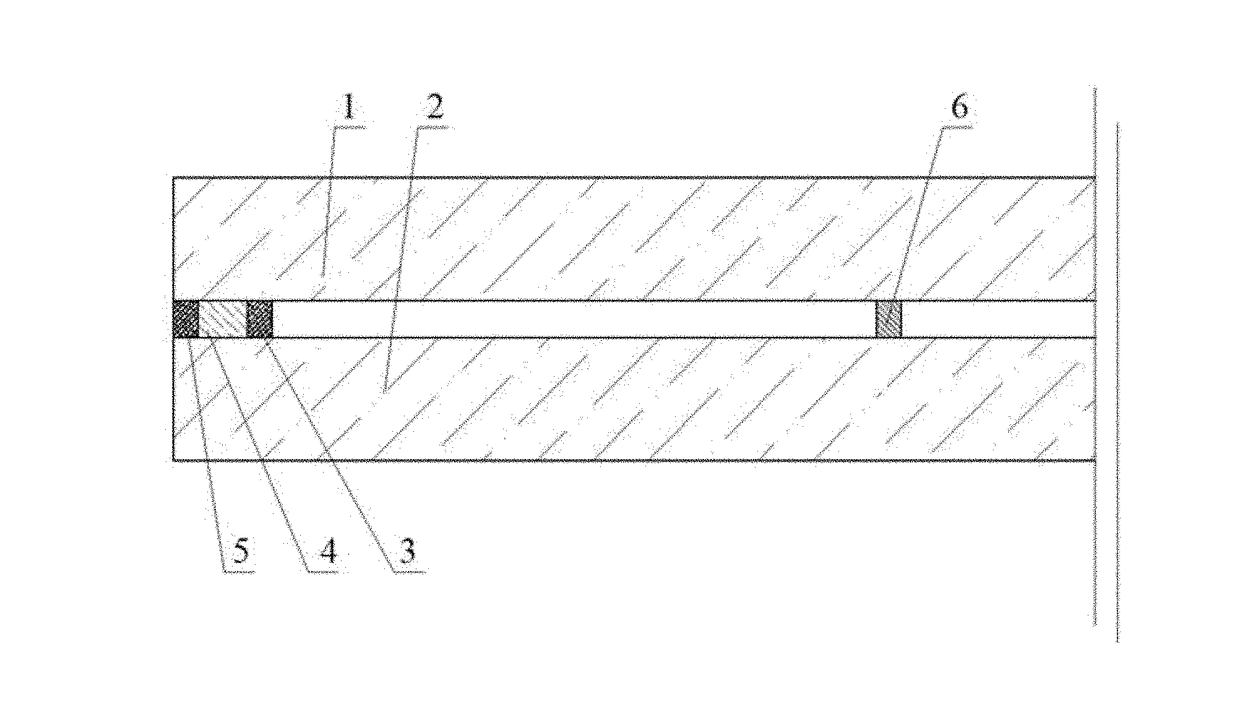

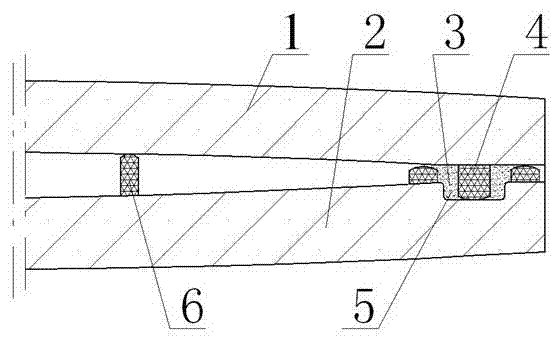

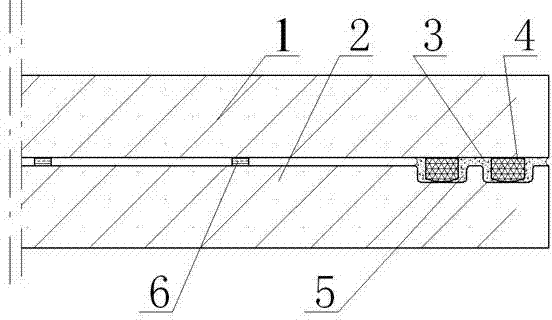

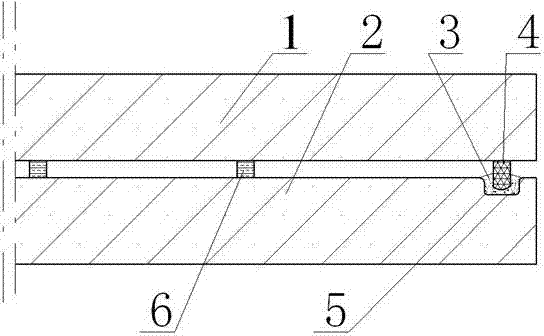

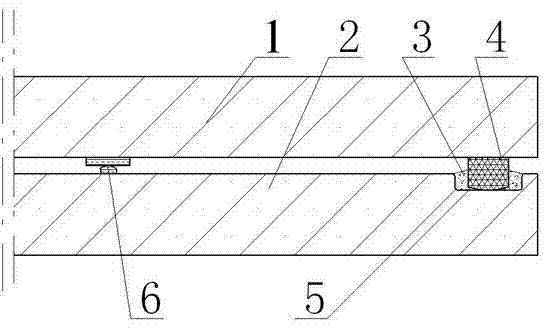

Convex low-altitude glass welded by metal solders and subjected to edge sealing by strip frame and groove, and manufacturing method of glass

InactiveCN102951814AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionConvex sideAlloy

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding peripheries of the upper glass and the lower glass are respectively provided with an edge sealing strip frame and an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a high-temperature edge sealing furnace, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

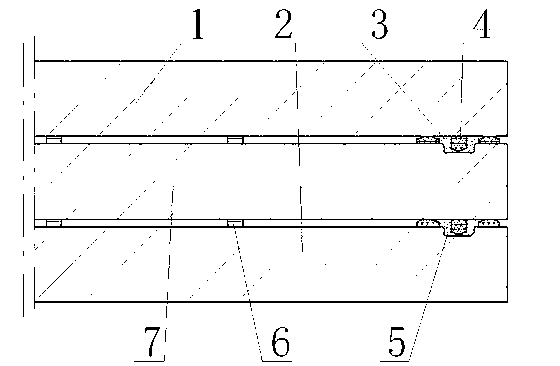

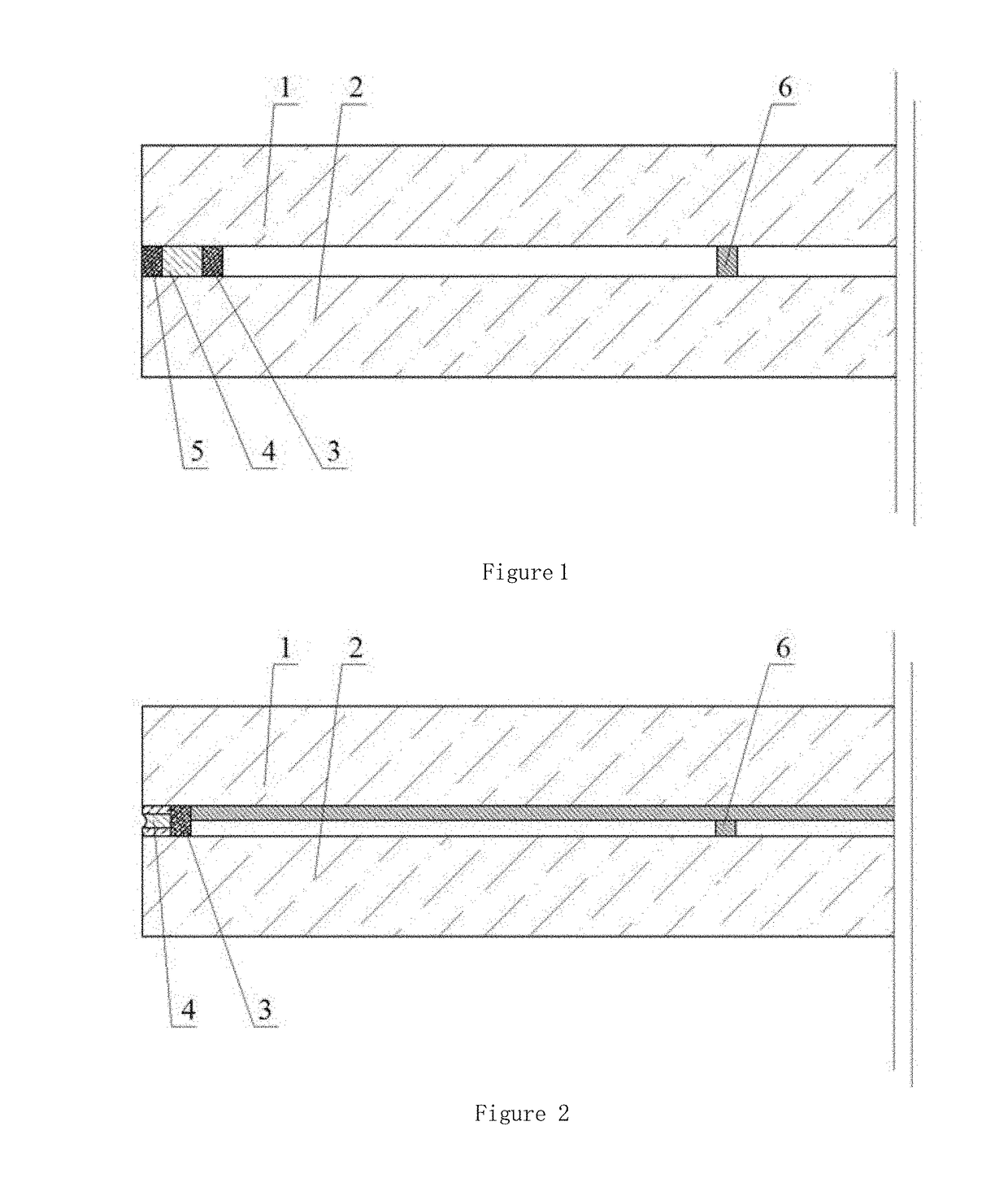

Double-vacuum layer convex glass with sealing strips and mounting holes through metal welding

A piece of double-vacuum layer convex glass with sealing strips and mounting holes through metal welding comprises an upper piece of glass, a lower piece of glass and a middle piece of glass, and is characterized in that the mounting holes are comprised; the upper and the lower piece of glass are convex glass; at least one is respectively arranged at the peripheries of the lower surfaces of the upper glass and the middle glass and of the mounting hole; at least two sealing strips are respectively arranged at the peripheries of the upper surfaces of the lower glass and the middle glass and of the mounting hole; the peripheries of the three pieces of glass are automatically welded together in a vacuum furnace through metal solder; the mounting hole is also automatically sealed through the metal solder. The vacuum glass and the manufacturing method thereof are simple in process. According to the vacuum glass and the toughened vacuum glass prepared, not only are mounting and using convenient, but also the airtightness of the vacuum glass is ensured, and the strength, and heat insulation and acoustic insulation performance are also increased.

Owner:戴长虹

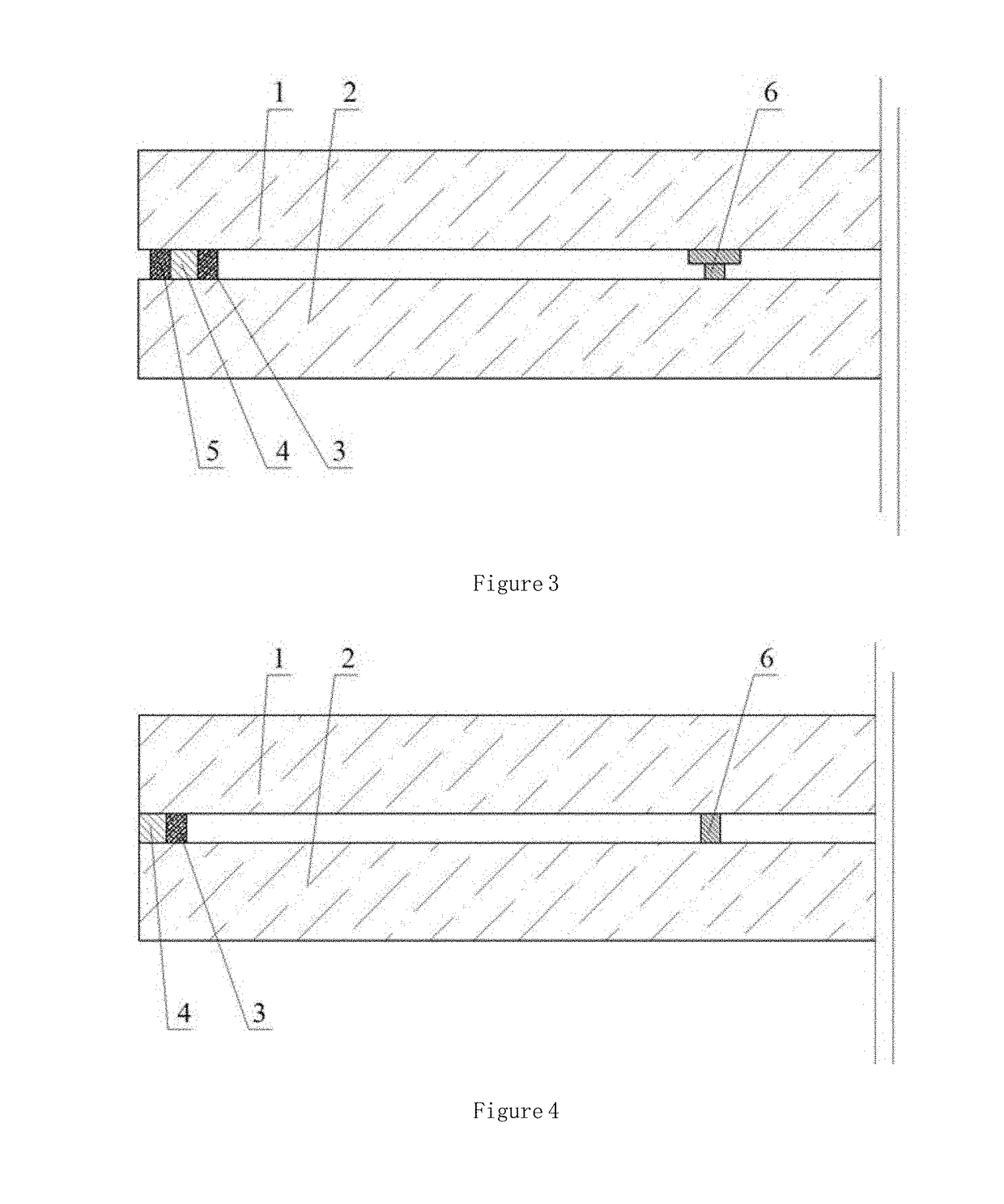

Vacuum convex glass welded with seal grooves and mounting holes

InactiveCN103420587AGuaranteed tightnessHigh strengthGlass reforming apparatusGlass productionEngineeringUltimate tensile strength

A piece of vacuum convex glass welded with seal grooves and mounting holes includes a piece of upper glass and a piece of lower glass, and is characterized in that the mounting holes and extraction openings are integrated; the upper glass and the lower glass are convex glass; seal strips are arranged on the peripheries of the upper glass and the extraction openings; the seal grooves are formed in the peripheries of the lower glass and the extraction openings; the peripheries of the upper glass and the lower glass are welded in an ordinary pressure lower edge sealing furnace through low temperature glass solder; the extraction openings are automatically sealed in a vacuum furnace through metal solder; a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and the manufacture method, provided by the invention, have the advantages that the technology is simple, the manufactured vacuum glass and the toughened vacuum glass facilitate mounting and use, the airtightness of the vacuum glass is guaranteed, and intensity as well as heat and sound insulation performance of the glass can be improved.

Owner:戴长虹

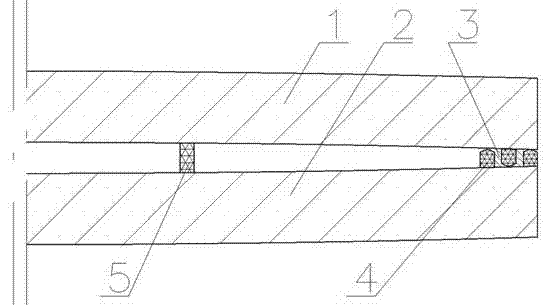

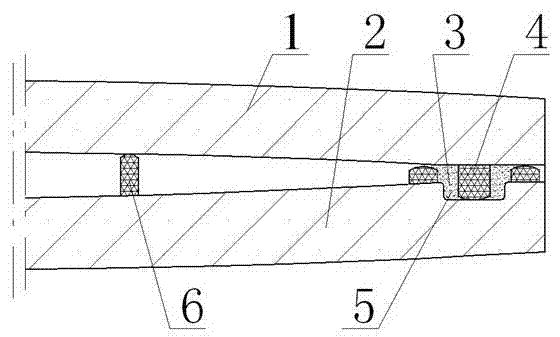

Flat vacuum glass welded by using metal welding material and provided with strip frame edge sealing, and manufacturing method thereof

InactiveCN102976592AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionAlloyGlass manufacturing

The present invention relates to a vacuum glass, which is characterized in that peripheries of an upper glass and a lower glass of the vacuum glass comprise edge sealing strip frames, and a metal welding material or an alloy welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the upper edge sealing strip frame and the lower edge sealing strip frame. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

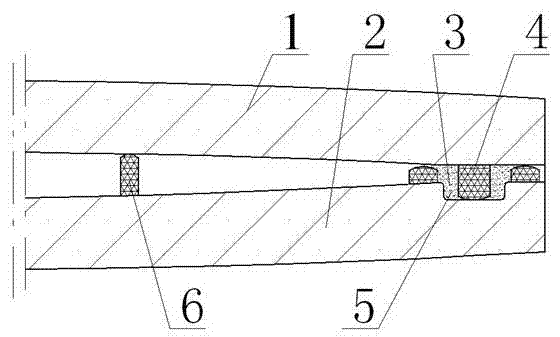

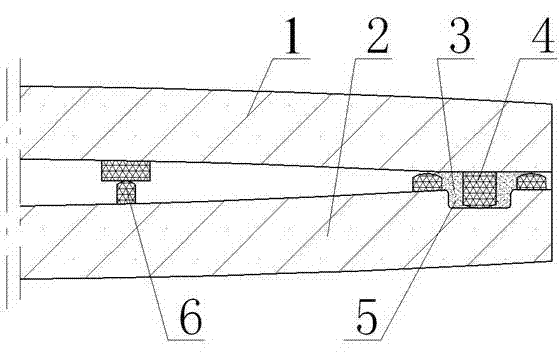

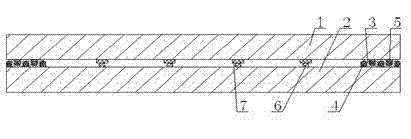

Plane double-vacuum-layer glass with sealing strips and grooves and mounting holes through metal welding

The invention provides plane double-vacuum-layer glass provided with sealing strips and grooves and mounting holes through metal welding. The plane vacuum glass comprises upper glass, lower glass and middle glass, and is characterized in that the plane double-vacuum-layer glass is provided with mounting holes; sealing strips are arranged at the peripheries of lower surfaces of the upper glass and the middle glass, and the mounting holes; sealing strips and sealing grooves are formed in the peripheries of the upper surfaces of the middle glass and the lower glass, and the mounting holes; the peripheries of three blocks of glass are automatically welded together through metal welding material in a vacuum furnace; the mounting holes are sealed automatically by adopting metal welding material; two closed vacuum layers are formed among three blocks of glass; supporting materials arranged in a dot matrix manner are arranged in the vacuum layers. The manufacturing method and technology of the vacuum glass provided by the invention are simple, the vacuum glass and tempered vacuum glass manufactured through the manufacturing method and technology has the advantages that the mounting and use are convenient, the air tightness of the vacuum glass can be guaranteed, and the strength, heat insulation performance and sound insulation performance of the vacuum glass are increased.

Owner:戴长虹

Metal solder-welded and strip frame-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951826AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMetalEdge banding

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex surface glass, edge sealing strip frames are arranged at the welded peripheries of the upper glass and the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the upper and the lower edge sealing strip frames can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

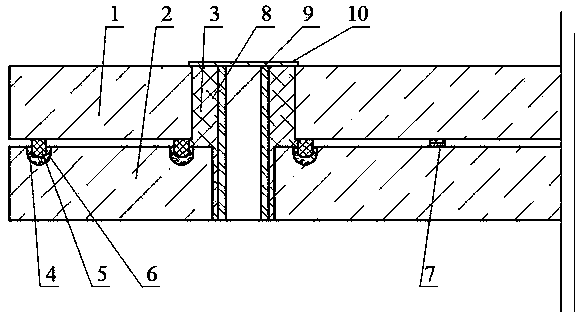

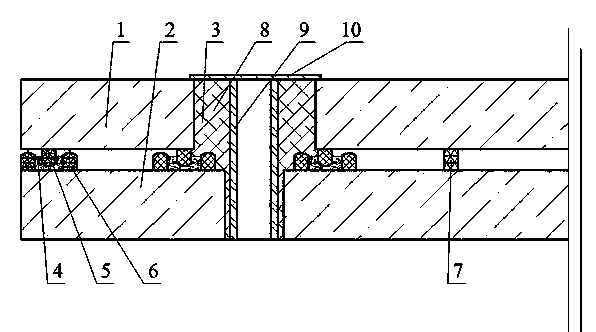

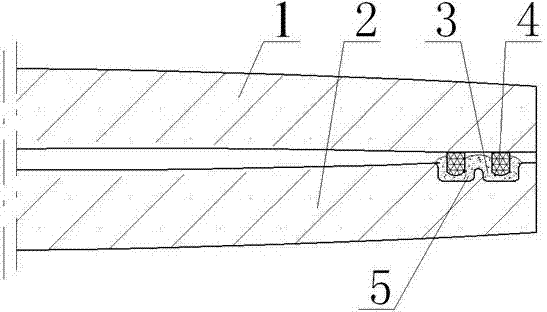

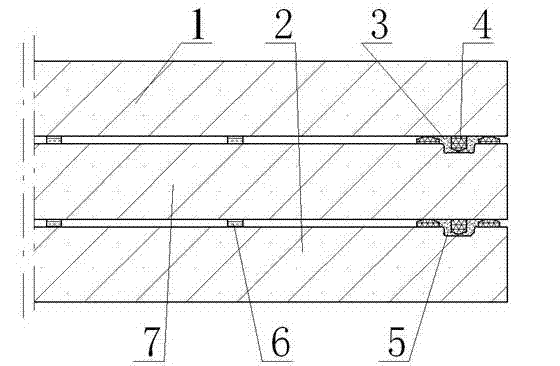

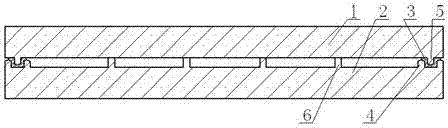

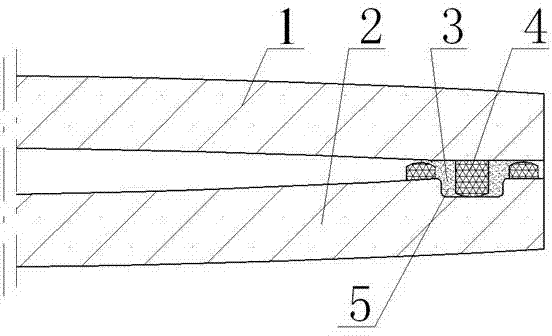

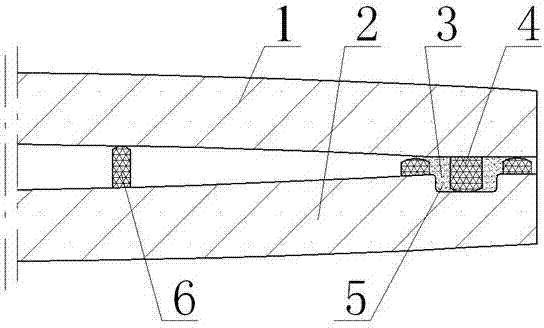

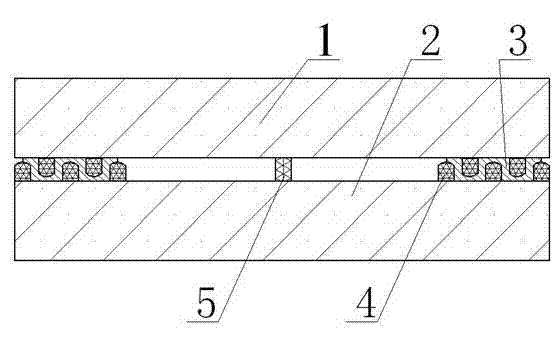

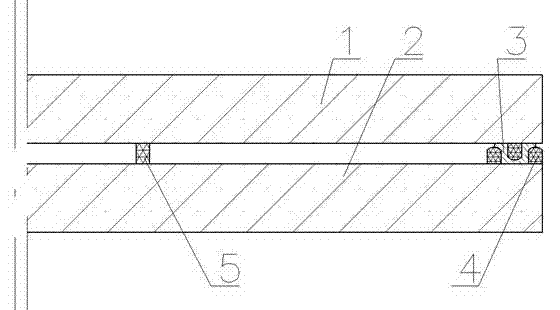

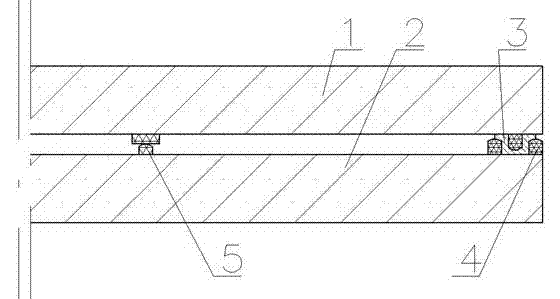

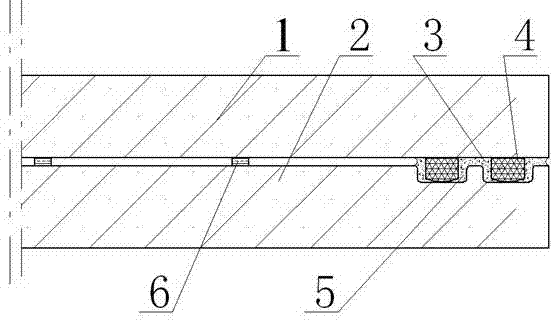

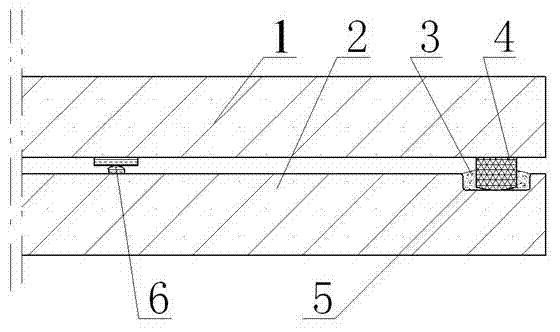

Plane vacuum glass with sealing grooves and mounting holes through metal welding

InactiveCN103420586AEasy edge banding and sealingHigh bonding strengthGlass reforming apparatusGlass productionVacuum furnaceGlass manufacture

The invention provides plane vacuum glass provided with sealing grooves and mounting holes through metal welding. The plane vacuum glass comprises upper glass and lower glass, and is characterized in that the plane vacuum glass is provided with mounting holes; wherein the upper glass and the lower glass are plane glass; sealing strips are arranged at the peripheries of the upper glass and the mounting holes; sealing grooves are formed in the peripheries of the lower glass and the mounting holes; the peripheries of the upper glass and the lower glass are automatically welded together through metal welding material in a vacuum furnace; an extract opening is automatically sealed in the vacuum furnace by adopting metal welding material; a closed vacuum layer is formed between the upper glass and the lower glass; supporting materials arranged in a dot matrix manner are arranged in the vacuum layer. The manufacturing method and technology of the vacuum glass provided by the invention are simple, the vacuum glass and tempered vacuum glass manufactured through the manufacturing method and technology has the advantages that the mounting and use are convenient, the air tightness of the vacuum glass can be guaranteed, and the strength, heat insulation performance and sound insulation performance of the vacuum glass are increased.

Owner:戴长虹

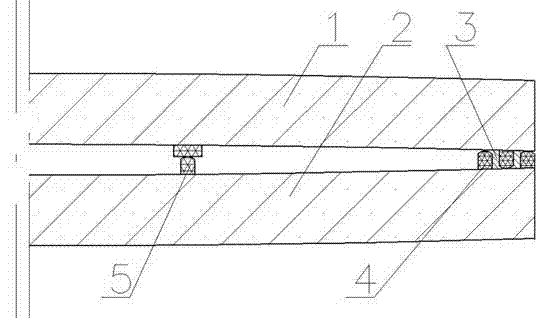

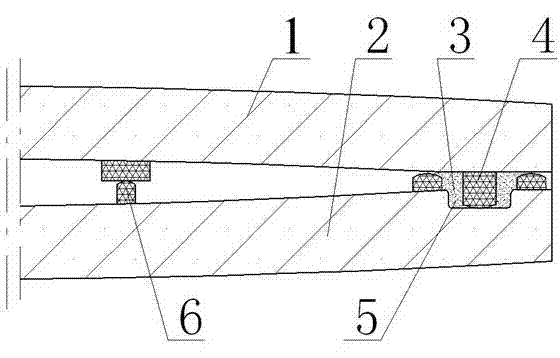

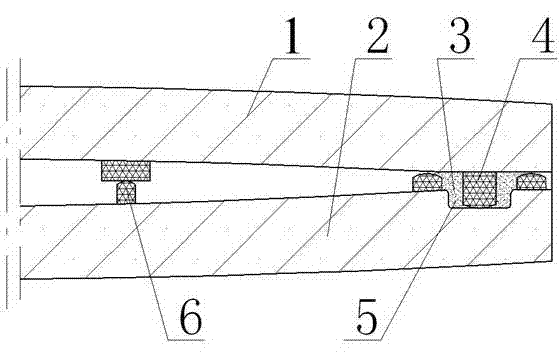

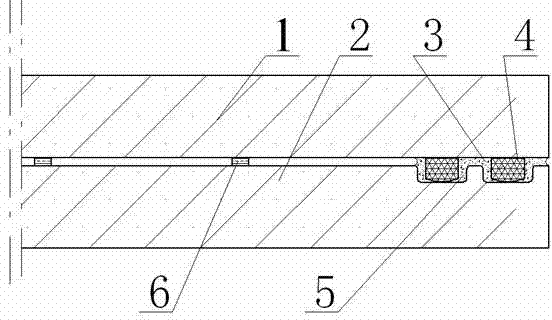

Flat vacuum glass welded by using glass welding material and provided with strip frame edge sealing and ditch groove edge sealing, and manufacturing method thereof

InactiveCN102976595AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionEngineeringGlass manufacturing

The invention relates to a vacuum glass, which comprises an upper glass and a lower glass, and is characterized in that the welding periphery of the upper glass is provided with an edge sealing strip frame, the welding periphery of the lower glass is provided with an edge sealing strip frame and an edge sealing ditch groove, and a glass welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the edge sealing strip frame and the edge sealing ditch groove. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

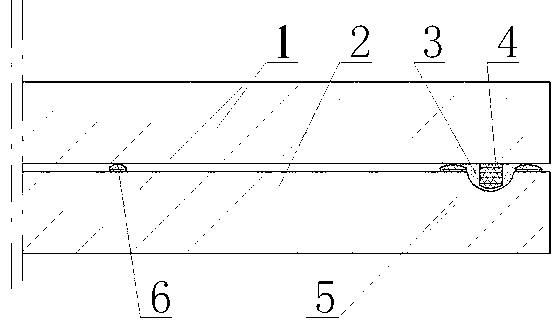

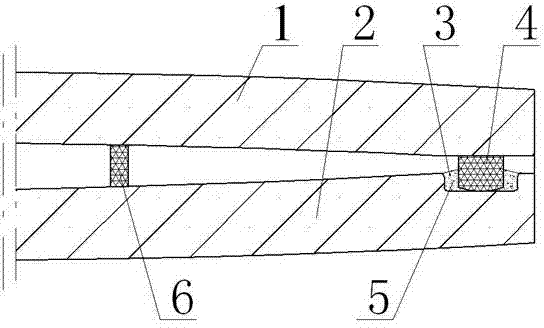

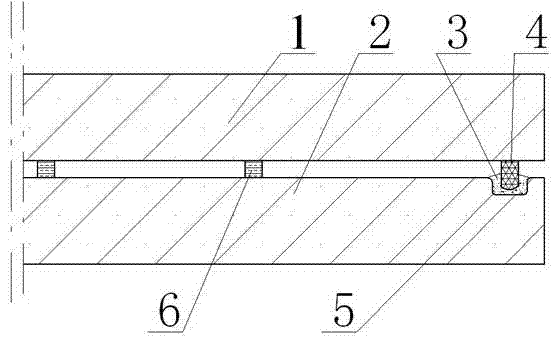

Vacuum plane glass provided with sealing strips and mounting hole through metal welding

A vacuum plane glass provided with sealing strips and a mounting hole through metal welding comprises an upper glass and a lower glass, and is characterized by further comprising the mounting hole, wherein both the upper and the lower glass are plane glasses; at least one sealing strip is respectively arranged at the peripheries of the mounting hole and the upper glass; at least two sealing strips are respectively arranged at the peripheries of the lower glass and the mounting hole; the sealing strips on the upper glass insert among the sealing strips on the lower glass; the peripheries of the lower and the upper glasses are automatically welded together in a vacuum furnace through metal solder; the mounting hole is also automatically sealed through the metal solder. The vacuum glass and the manufacturing method thereof are simple in process. According to the vacuum glass and the toughened vacuum glass prepared, not only are mounting and using convenient, but also the airtightness of the vacuum glass is ensured, and the strength, and heat insulation and acoustic insulation performance are also increased.

Owner:戴长虹

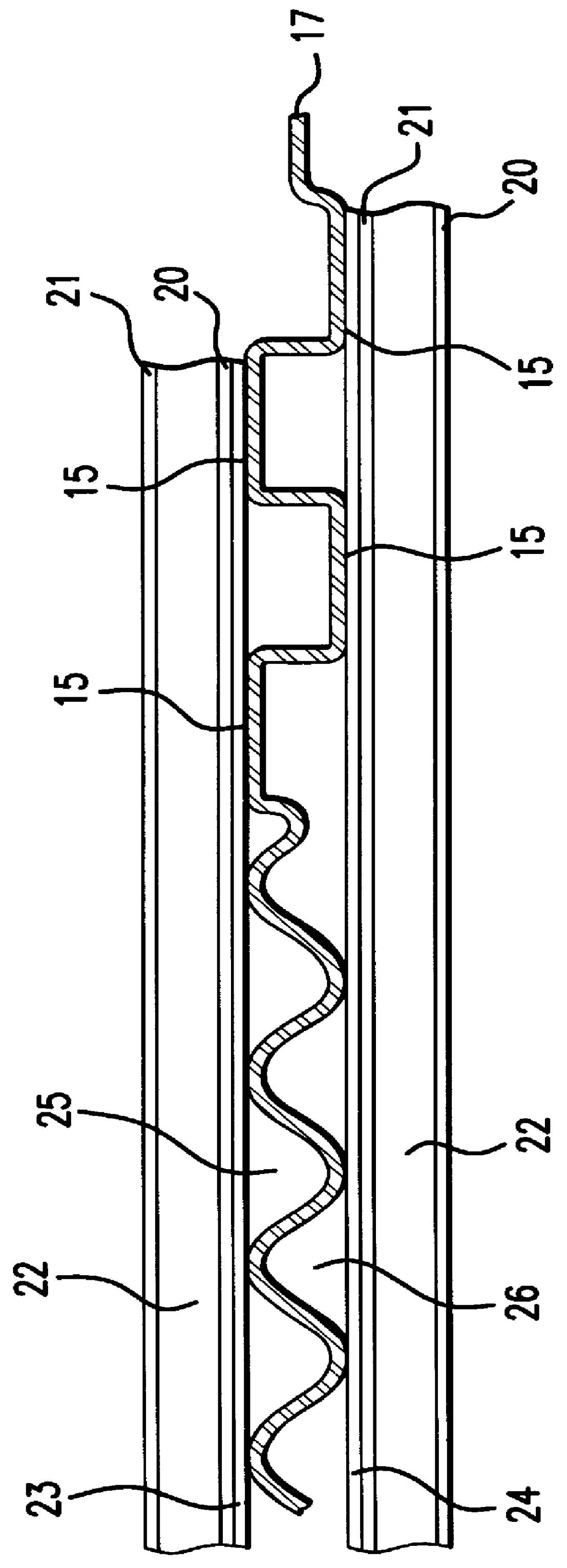

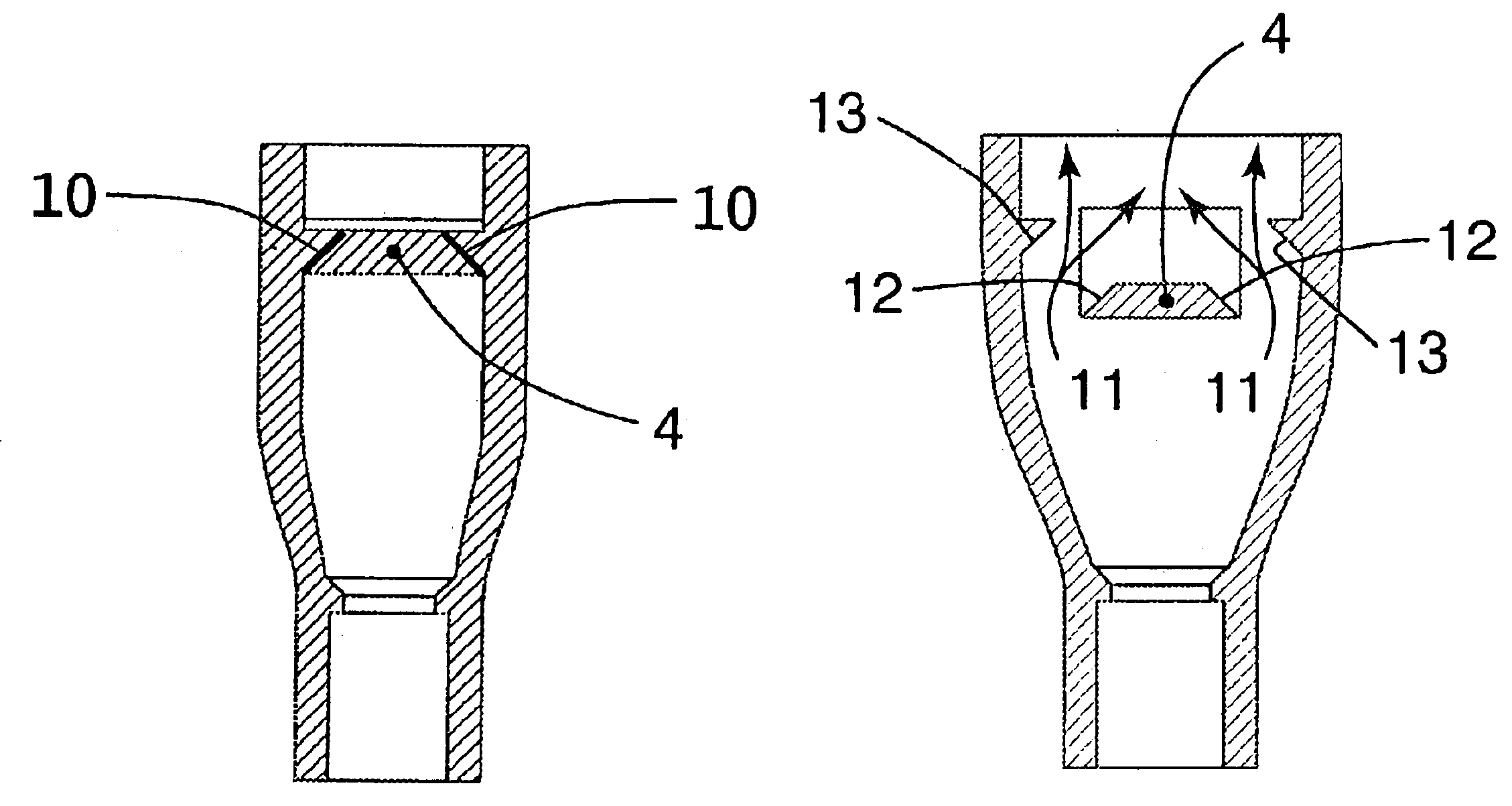

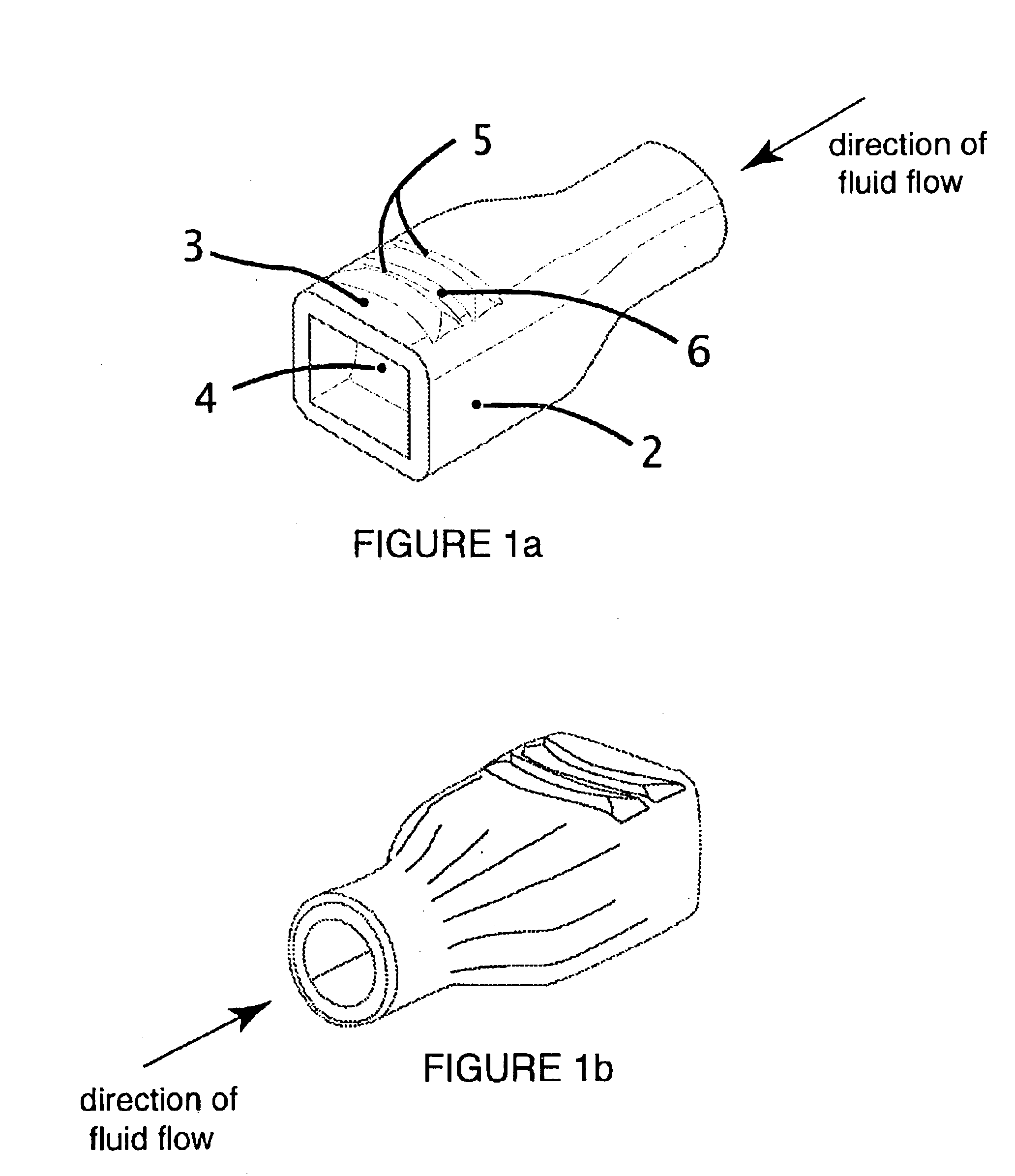

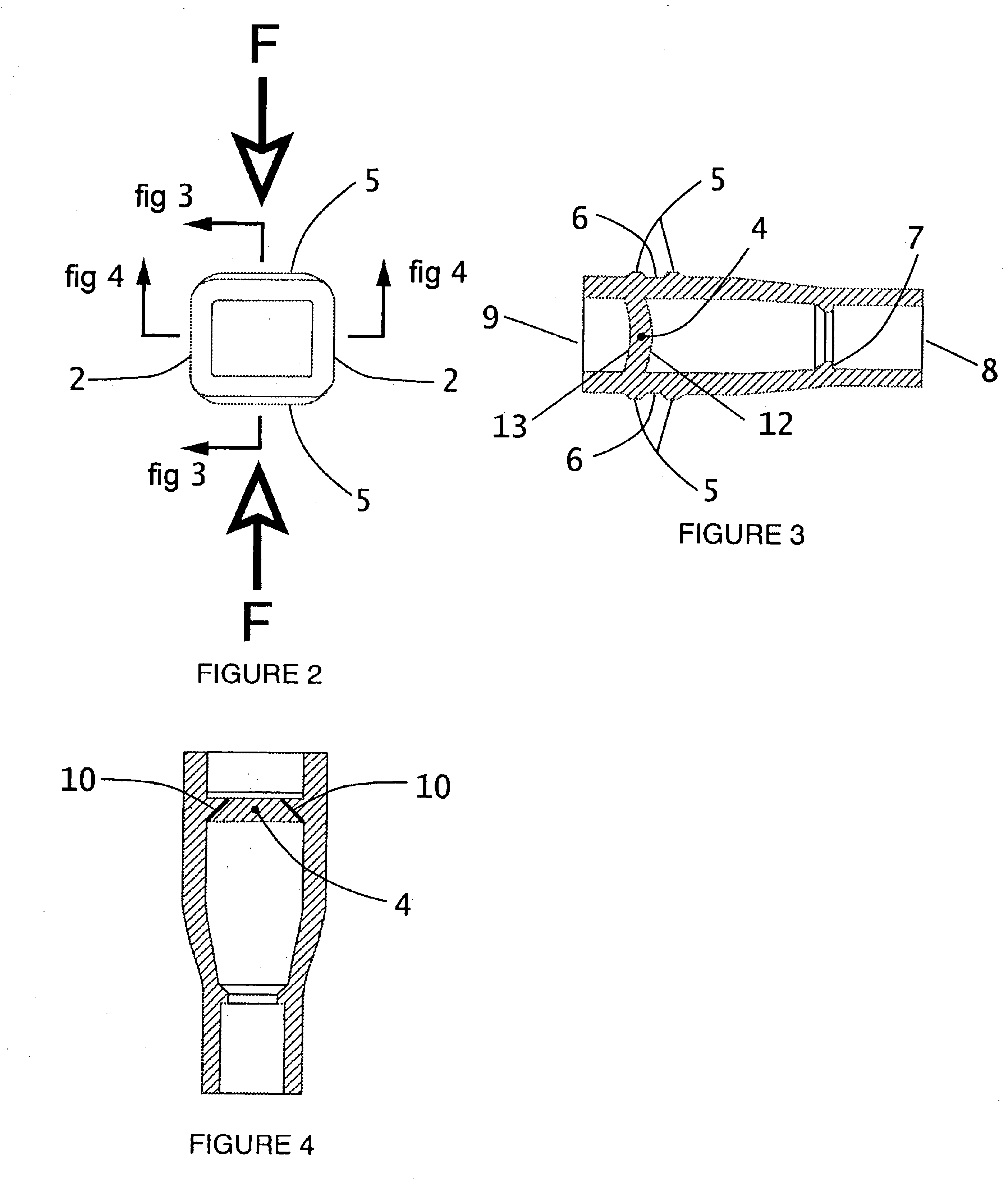

Angled-slit bite-valve

InactiveUS6874760B2Low costLow cost productionOperating means/releasing devices for valvesCheck valvesLine tubingKinematics

Bite-valves are synonymous with personal hydration systems. Their action is to provide regulation of fluid that is drawn from the hydration reservoir by supplying a vacuum or by sucking like on a straw. Bite valves are placed in line and usually at the end of the line with the tube or hose that communicates with the reservoir. Bite-valves are normally closed and are opened when the person performs a biting action on the valve itself. Bite valves should provide the user with a perfect seal, high flow characteristics, and be small in size. Slit-type valves today are kinematically inefficient and as a consequence their flow rates are relatively slow compared to the inventor's bite-valve. This valve made of elastomeric material incorporates two angled slits along opposing vertical edges that are perpendicular to the biting direction or action. The general shape of the cross section at the site of the slitted septum is rectangular. The rectangular geometric shape is important in the flow dynamics of this valve. The septum, set back from the orifice's edge, is concavely biased towards the exit and is slit vertically at an angle such that the aperture is narrower on the exit side than on the fluid side and its purpose is to promote sealing at positive fluid pressures. When the bite-valve is pinched as from a biting action the concavely biased septum folds on itself while the side walls bulge away from each other, and form two fluid paths of a semi-circular cross section, one on each side. In addition to the formation of two fluid paths they are smooth in transition from the tubular central path and allow for flow rates almost twice that of bite-valves with a single slit of similar size.

Owner:STECKEL ERIC S

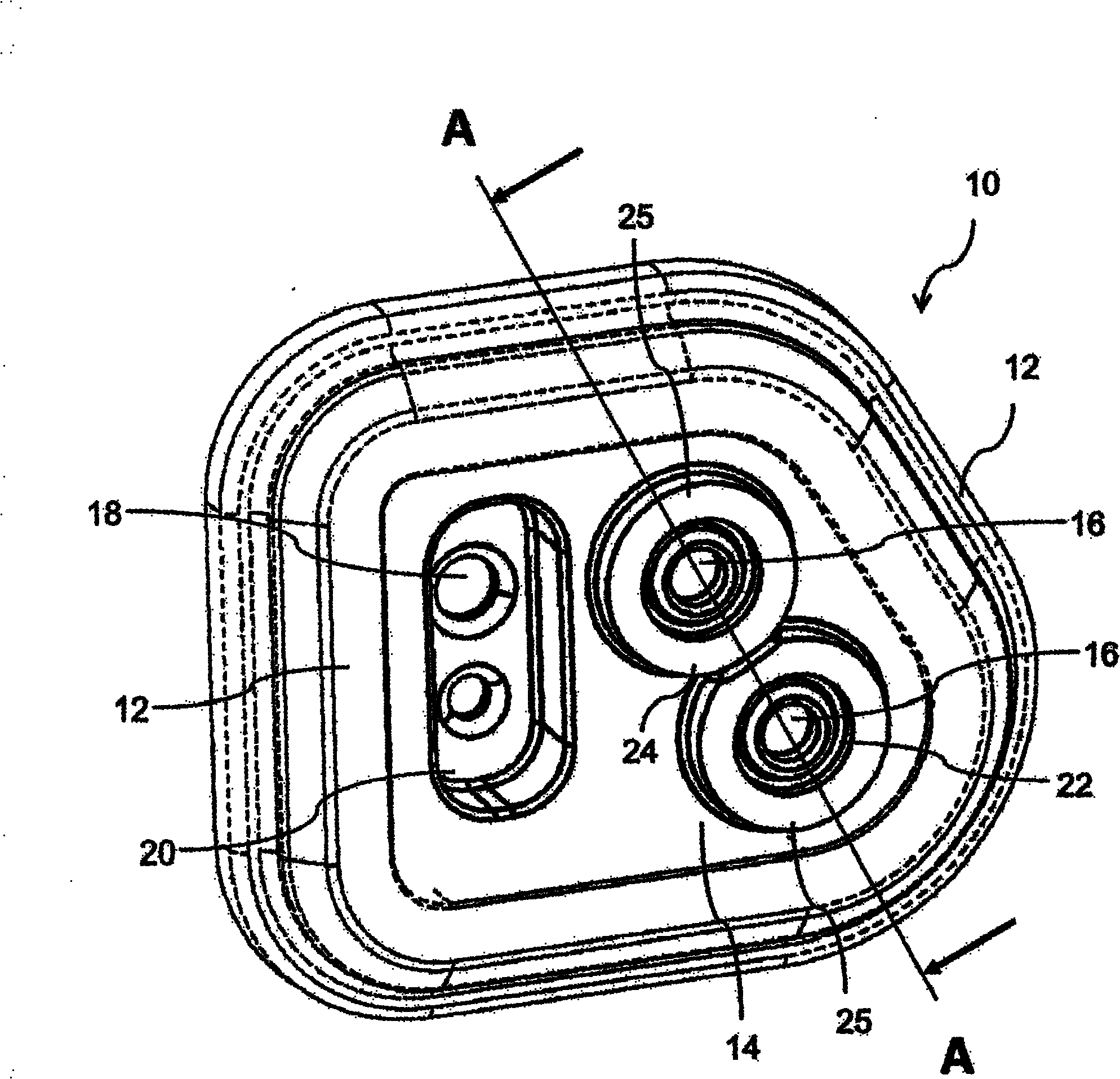

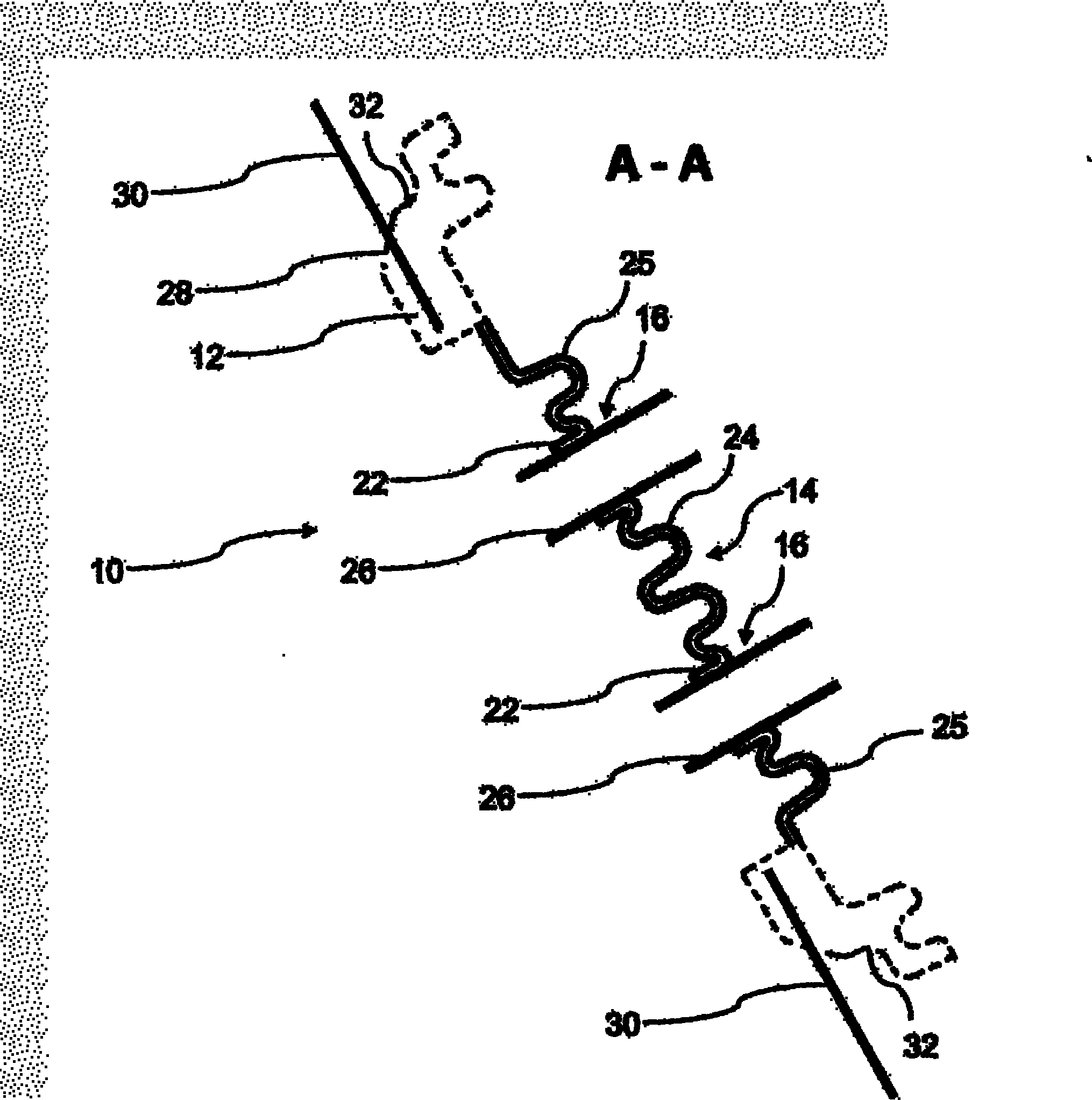

A seal configuration for a motor vehicle front wall

InactiveCN102080742AAchieve separationIncrease elasticityEngine sealsPipesEngineeringAir conditioning

A seal configuration is provided for sealing an opening of a motor vehicle front wall 30 provided for the passage of heating and / or air-conditioning pipes, such as heating and / or air-conditioning pipes, having a two-component seal body insertable into the opening, which has an outer peripheral edge component 12 made of a first seal material and an inner seal component made of a second seal material. The first and the second seal materials 12, 14 have different moduli of elasticity and / or different acoustic damping properties.

Owner:GM GLOBAL TECH OPERATIONS LLC

Convex vacuum glass welded by glass solders and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951803AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionConvex sideEngineering

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by glass solders in a vacuum edge sealing furnace, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and not only can be used for manufacturing common vacuum glass, but also is particularly suitable for manufacturing of tempered vacuum glass; and the vacuum glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

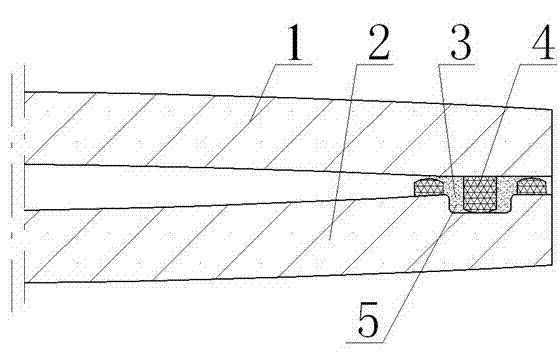

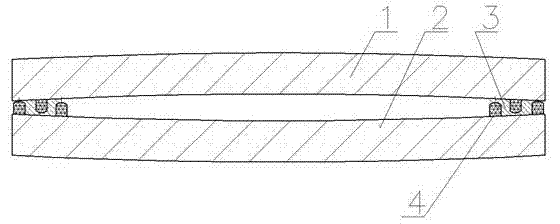

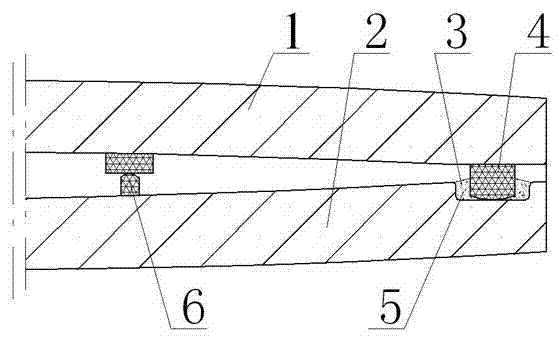

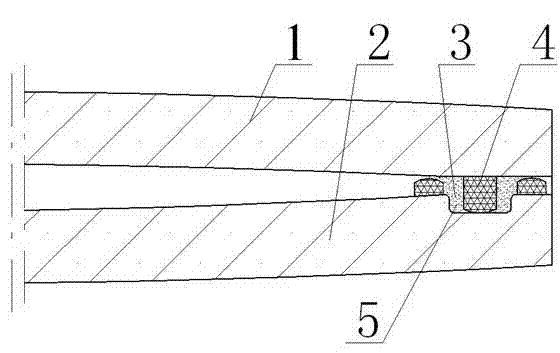

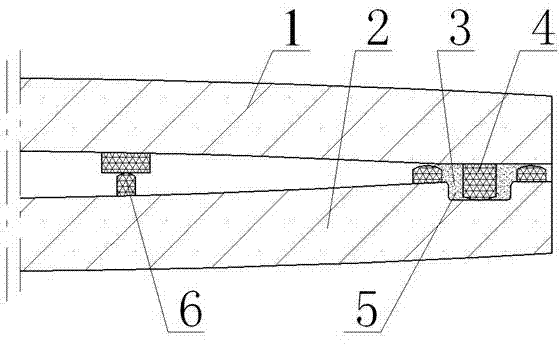

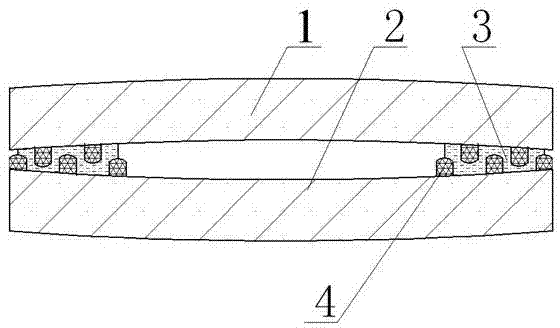

Vacuum glass and manufacturing method therefor

InactiveUS20180066470A1Low production costGood light transmissionDoors/windowsClimate change adaptationFlat glassEngineering

Vacuum glass includes a piece of upper glass, a piece of lower glass, and a closed vacuum layer sandwiched between the upper class and the lower glass, the peripheries of the upper glass and the lower glass are in seal connection using two or more layers of sealing material, the upper glass and the lower glass are convex glass or flat glass, convex surfaces of the convex glass face outward, and supports are disposed between two pieces of flat glass. The manufacturing method of the vacuum glass is simple, the prepared vacuum glass and tempered vacuum glass solve the defects in the prior art, can ensure the airtightness and service life of the vacuum glass, and are suitable for mechanization, automation, and mass production.

Owner:DAI CHANGHONG

Convex low-altitude glass welded by glass solders and subjected to edge sealing by strip frame and groove, and manufacturing method of glass

InactiveCN102951813AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionGlass manufactureLow altitude

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding peripheries of the upper and lower glass are provided with an edge sealing strip frame and an edge sealing groove; and the upper and lower glass are welded together by glass solders in a high-temperature edge sealing furnace, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

Glass solder-microwave welded and strip frame-groove-edge-sealed planar vacuum glass and manufacturing method thereof

InactiveCN102951828AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention relates to vacuum glass. The vacuum glass comprises upper glass and lower glass and is characterized in that an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing strip frame and an edge sealing groove are arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing glass solder in a microwave oven; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frames and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology; and the method can be used for manufacturing both the ordinary vacuum glass and tempered vacuum glass.

Owner:戴长虹

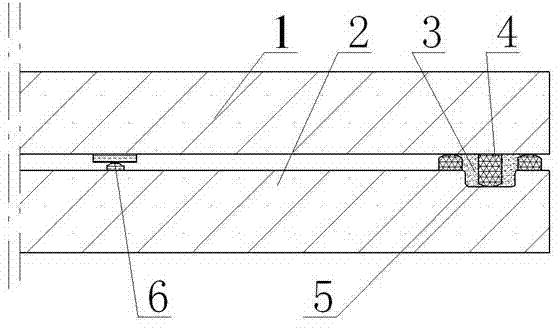

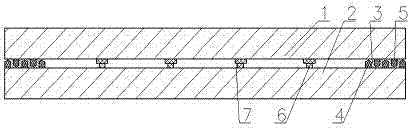

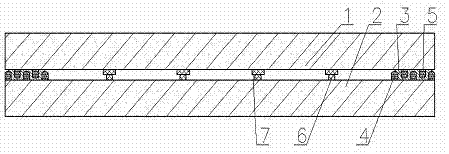

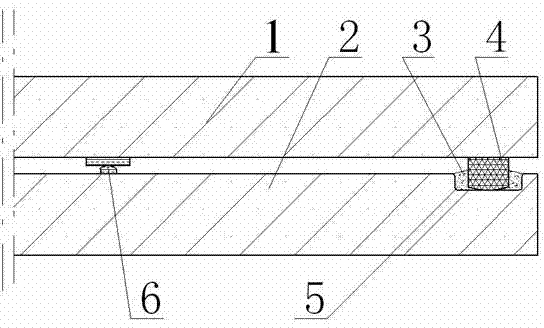

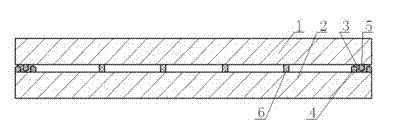

Flat tempered vacuum glass with glass welding and manufacturing method of glass

ActiveCN102951790AEasy edge bandingGuaranteed tightnessGlass reforming apparatusGlass productionEngineeringWelding

The invention provides flat tempered vacuum glass. The glass comprises upper glass and lower glass, which are flat tempered glass, wherein edge sealing strip frames are arranged on the peripheries of the welding surfaces of the upper and lower glass; the peripheries of the upper and lower glass are welded together through low-temperature glass solders; and a closed vacuum layer is formed between the upper glass and the lower glass and is internally provided with supports which are arranged in a lattice manner. A manufacturing method of the vacuum glass provided by the invention is simple in process; and the manufactured tempered vacuum glass can overcome defects in the prior art and can be subjected to mass production.

Owner:戴长虹

Metal solder-welded and strip frame-groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951829AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionAlloyMetal

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing strip frame and an edge sealing groove are arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frames and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

Vacuum ceramic thermal baffle welded by metal solders and manufacturing method of thermal baffle

InactiveCN102953509AGood heat insulationGood sound insulationCovering/liningsLaminationUltimate tensile strengthAir tightness

The invention provides a vacuum ceramic thermal baffle. The thermal baffle comprises an upper thermal baffle and a lower thermal baffle, wherein the peripheries of the upper and lower thermal baffles are welded together by metal or alloy solders; a closed vacuum layer is formed between the upper thermal baffle and the lower thermal baffle; and the upper and lower thermal baffles can be flat, flat externally and concave internally, or convex. A manufacturing method of the vacuum ceramic thermal baffle is simple in process. According to the invention, the manufactured vacuum ceramic thermal baffle can overcome defects of the conventional thermal baffle, the air tightness of the vacuum layer of the thermal baffle can be effectively ensured, the service life of the thermal baffle can be prolonged, the strength, sound insulation and fireproof performance of the thermal baffle can be improved, and the thermal baffle also can achieve a good decoration effect.

Owner:戴长虹

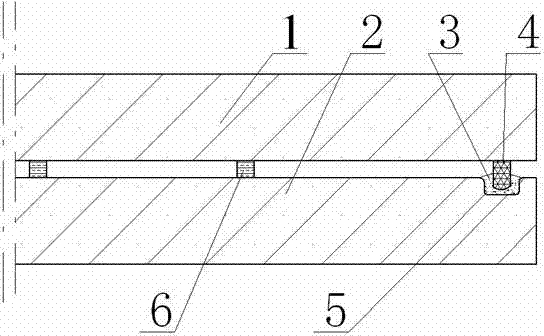

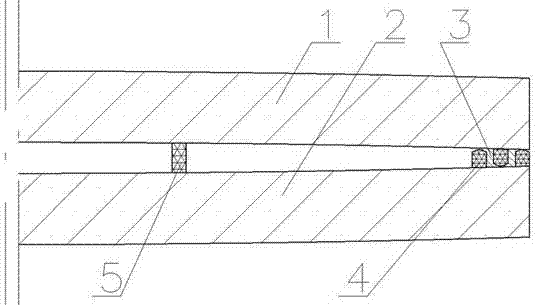

Metal solder-welded and groove-edge-sealed planar vacuum glass and manufacturing method thereof

InactiveCN102951825AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionAlloyMetal

The invention relates to vacuum glass. The vacuum glass comprises upper glass and lower glass and is characterized in that an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing groove is arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frame and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology; and the method can be used for manufacturing both the ordinary vacuum glass and tempered vacuum glass.

Owner:戴长虹

Planar vacuum glass welded by metal solders in microwave manner and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951809AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetal

The invention discloses vacuum glass. The vacuum glass consists of upper glass and lower glass and is characterized in that the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing not only common vacuum glass but also tempered vacuum glass.

Owner:戴长虹

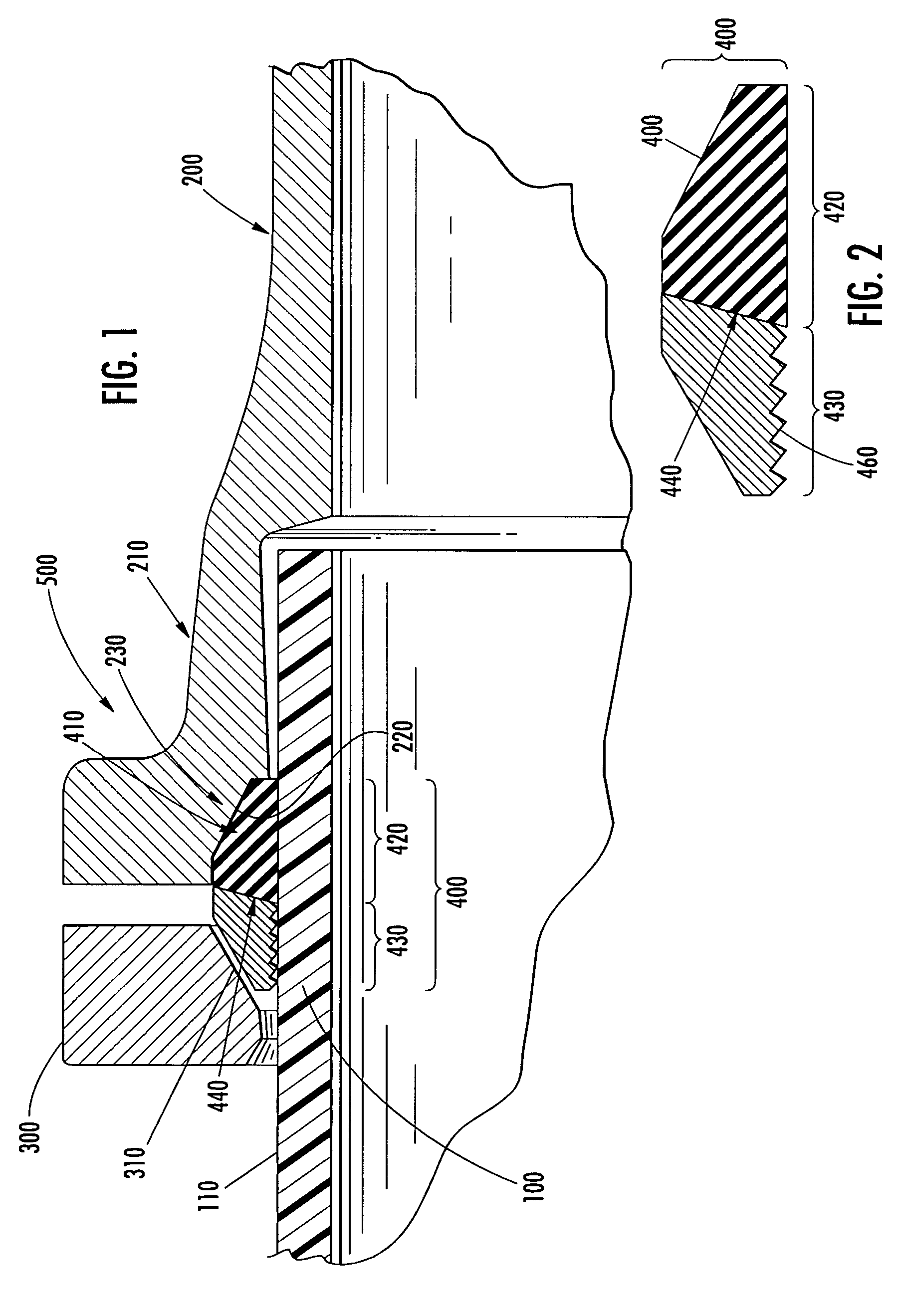

Supplemental passenger oxygen mask

InactiveUS20070240720A1Save spaceReduce in quantityBreathing filtersBreathing masksReservoir bagReservoir volume

A face piece / reservoir combination that is molded as one piece. By integrating the face piece and reservoir bag into one single piece, the mask conserves space and reduces the number of parts while maintaining adequate reservoir volume. The mask has an edge on the face cup that provides a larger sealing area for the users face and provides a more comfortable fit than existing masks. The mask may be configured as a simple constant flow mask or it may include valves, allowing it to function as a phase dilution mask. The mask may be equipped with a rebreather bag and valves to function as a rebreather / phase dilution mask

Owner:AVOX SYST

Glass solder-welded and strip frame-groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951821AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionEngineeringEdge banding

Owner:戴长虹

Convex vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951806AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the peripheries of the upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by low-temperature glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing common vacuum glass and tempered vacuum glass.

Owner:戴长虹

Planar vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951817AEasy edge bandingExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention discloses vacuum glass. The vacuum glass is characterized in that the peripheries of the upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by low-temperature glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without special extraction openings in mass by virtue of a one-step method, and can be used for manufacturing common vacuum glass and tempered vacuum glass.

Owner:戴长虹

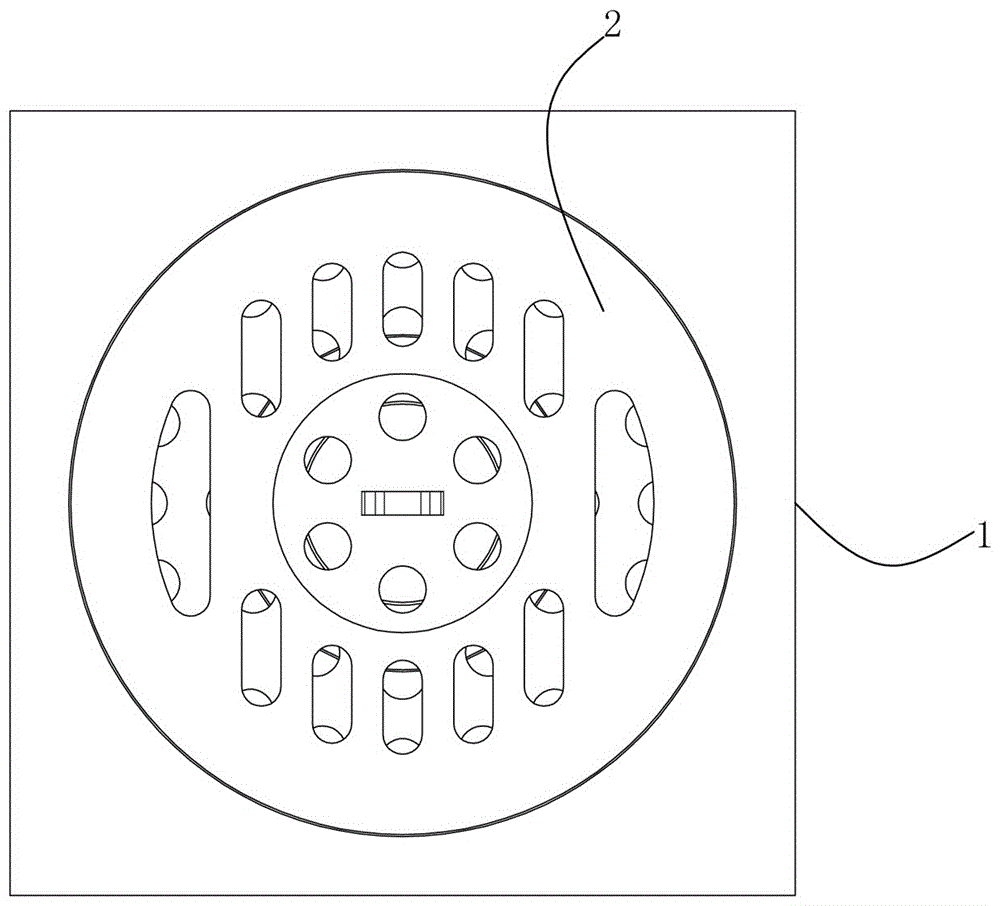

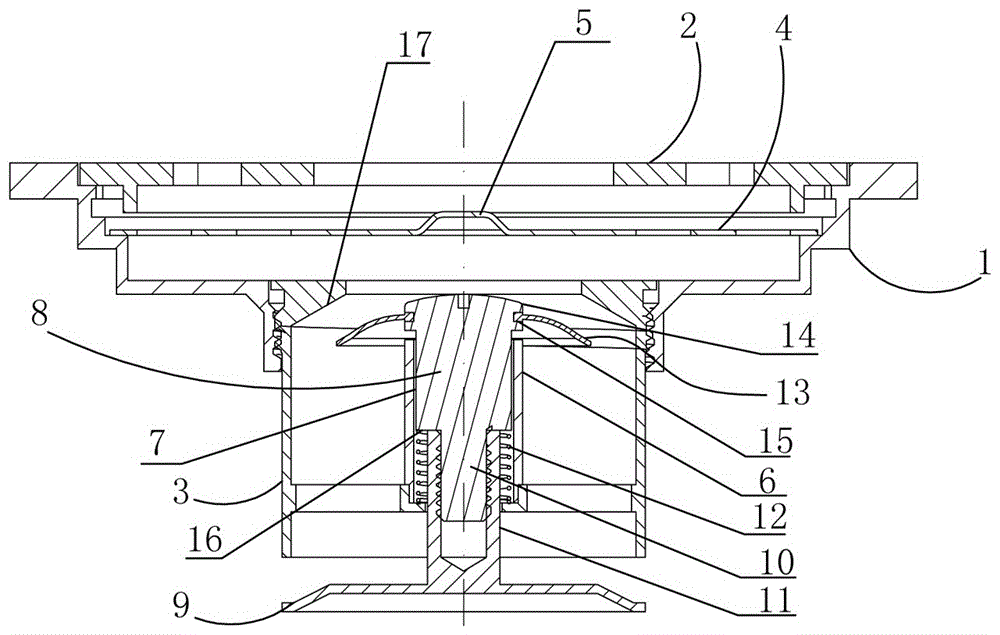

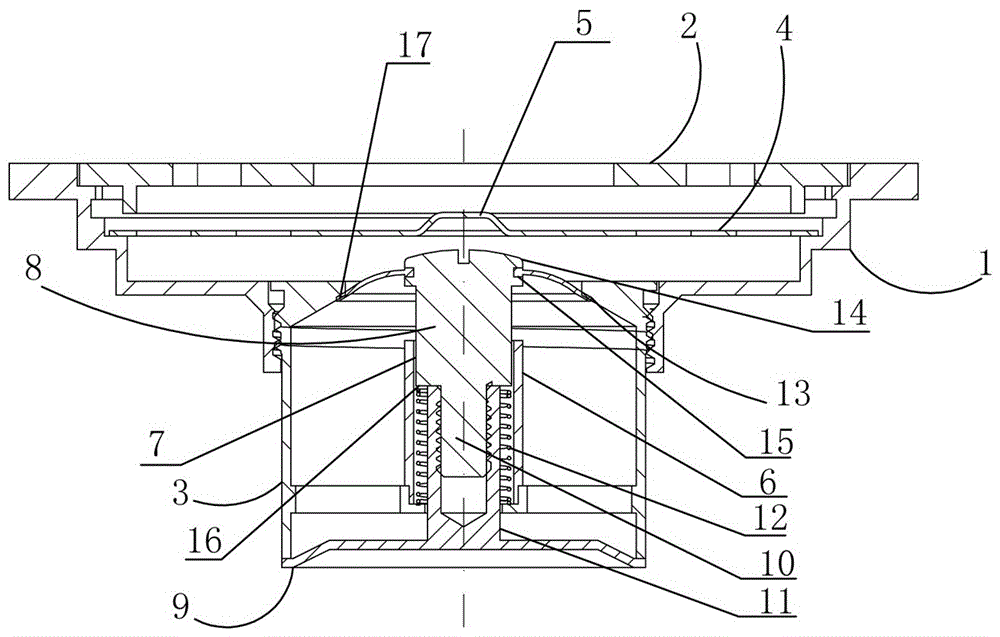

Odor-resistant floor drain

ActiveCN105839770AImprove sealingGood deodorizing functionSewerage structuresAcrylonitrileEngineering

The invention discloses an odor-resistant floor drain. The odor-resistant floor drain comprises an embedded box and a floor drain cover plate, wherein the lower part of the embedded box is detachably connected with a hollow floor drain main body, the upper part and the lower part of the floor drain main body are communicated, a hollow connecting seat is arranged in the floor drain main body, a guiding column is arranged in a center hole of the connecting seat in a sliding matching manner, the lower end of the guiding column is connected with a seal cover, and an elastic piece is arranged in the center hole of the connecting seat; the upper end of the guiding column is connected with an elastic sealing ring; the elastic sealing ring comprises an annular connecting part and an elastic sealing body; the annular connecting part is made from hydrogenated acrylonitrile butadiene rubber, the elastic sealing body comprises is prepared from the following components in parts by weight: 70 parts of styrene-butadiene-styrene block copolymer, 10-20 parts of aromatic hydrocarbon oil, 5-8 parts of polyethylene, 4-6 parts of alumina powder, 0.2-0.4 part of diphenylamine and 0.5-2 parts of nano silver. The odor-resistant floor drain has better sealing performance, high odor resistance and long service life.

Owner:NINGBO YINZHOU AG VAVLE

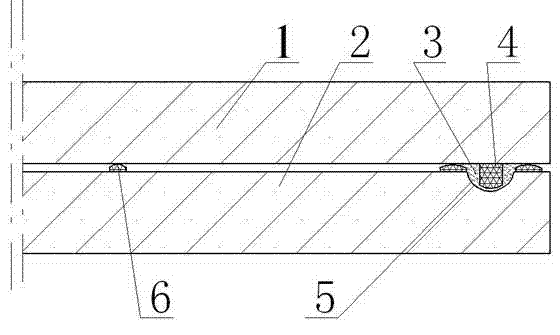

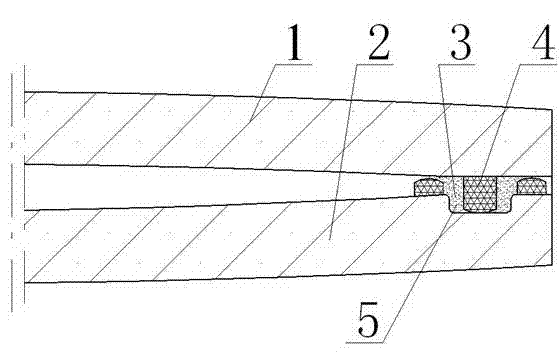

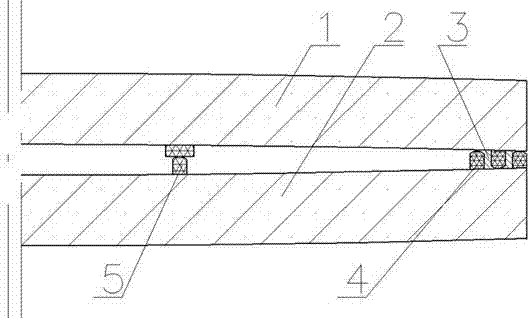

Planar vacuum glass welded by glass solders and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951802AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMetallurgyEdge banding

The invention discloses vacuum glass consisting of upper glass and lower glass. The vacuum glass is characterized in that the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by glass solders in a vacuum edge sealing furnace, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing not only common vacuum glass but also tempered vacuum glass.

Owner:戴长虹

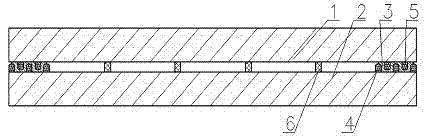

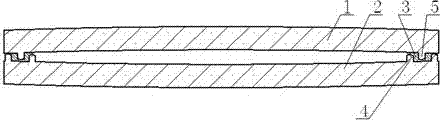

Flat tempered vacuum glass welded by metal and manufacturing method thereof

InactiveCN102951789AEasy edge bandingGuaranteed tightnessGlass reforming apparatusGlass productionMaterials scienceMetal

The invention provides flat tempered vacuum glass. The glass comprises upper glass and lower glass, wherein the upper and lower glass are flat tempered glass; edge sealing strip frames are arranged on the peripheries of the welding surfaces of the upper and lower glass; the peripheries of the upper and lower glass are welded together through low-temperature solders which are low-melting-point metal or alloy solders; and a closed vacuum layer is formed between the upper glass and the lower glass and is internally provided with supports which are arranged in a lattice manner. A manufacturing method of the vacuum glass provided by the invention is simple in process; and the manufactured tempered vacuum glass can overcome the defects in the prior art and can be subjected to mass production.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com