Vacuum convex glass welded with seal grooves and mounting holes

A vacuum glass and sealing groove technology, which is applied in glass forming, glass reshaping, glass production, etc., to achieve the effects of convenient installation, increased productivity and pass rate, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

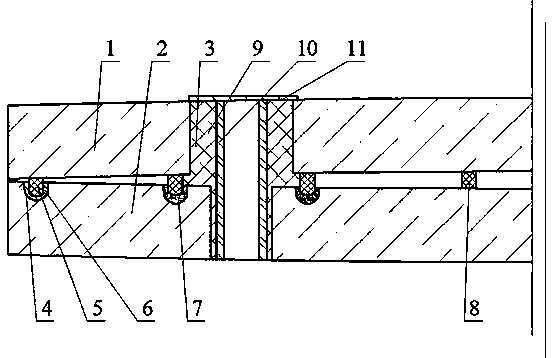

[0049] Embodiment 1: see figure 1 , The convex vacuum glass is composed of an upper glass 1 and a lower glass 2, the peripheries of the two pieces of glass are welded together by low-temperature glass solder 4, and the middle is a vacuum layer. Its production method is as follows: First, cut two pieces of flat glass of the required size according to the shape and size of the convex vacuum glass produced, drill a through hole at the corner of the upper and lower glass respectively to form an air inlet and a mounting hole 3, and place a hole around the lower glass 2. and the periphery of the air outlet 3 to provide a sealing groove 6, and carry out edging, chamfering, cleaning and drying, and use mechanical spraying technology to prepare the sealing strip 5 at the peripheral welding place of the upper glass 1 and the periphery of the air outlet 3, and use a glue dispenser Prepare the support 8 on the upper and lower glass; secondly, put the upper and lower pieces of glass into t...

Embodiment 2

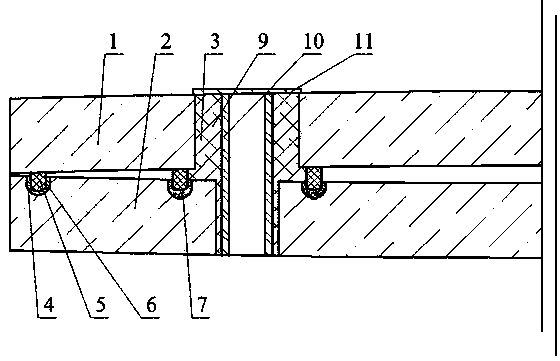

[0050] Example 2: see figure 2 The convex vacuum glass consists of an upper glass 1 and a lower glass 2. The two pieces of glass are tempered glass or semi-tempered glass, one of which is low-emissivity glass. The production method is as follows: firstly, cut the convex vacuum glass according to the shape and size of the convex vacuum glass. A piece of flat glass and a piece of low-emissivity glass of the required size, choose the low-emissivity glass as the lower glass 2, drill a through hole at the corner of the upper and lower glass respectively to form the air inlet and the installation hole 3, and place a hole around the lower glass 2 and the air outlet 3 Set up a sealing groove 6 on the periphery, and perform edging, chamfering, cleaning and drying, and use screen printing technology to print sealing strips on the peripheral welding part of the upper glass 1 and the periphery of the air inlet 3; secondly, put the two pieces of glass into the In two forming molds, the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com