Plane vacuum glass with sealing grooves and mounting holes through metal welding

A vacuum glass and metal welding technology, applied in glass production, glass forming, glass reshaping, etc., to achieve the effect of improving quality and performance, high bonding strength, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

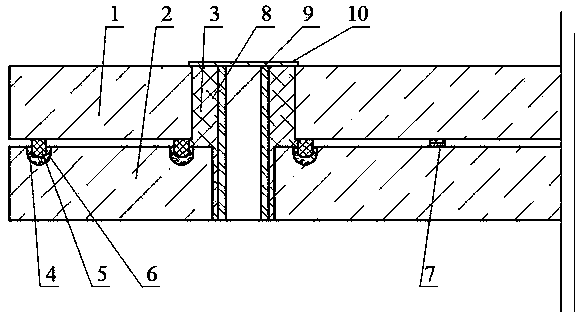

[0044]Embodiment: Referring to the accompanying drawings, the vacuum glass is composed of an upper glass 1 and a lower glass 2. The two glasses are tempered glass or semi-tempered glass, and one of them is low-emissivity glass. The manufacturing method is as follows: first, according to the shape of the vacuum glass produced Cut a piece of flat glass and a piece of low-emissivity glass to the required size, select the low-emissivity glass as the lower glass 2, drill a through hole at the corner of the upper and lower glass to form the installation hole 3, and install the installation hole 3 around the periphery of the lower glass 2 Set up a sealing groove 6 on the periphery of the upper glass 1, and perform edging, chamfering, cleaning, and drying. Use screen printing technology to print the sealing strip 5 and the support 7 at the periphery of the upper glass 1 and the periphery of the mounting hole 3. ; Next, send the two pieces of glass into the tempering furnace for air-coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com