Patents

Literature

109results about How to "Good deodorizing function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extra fine filament yarn containing deodorant functional agent and producing the same

InactiveUS20110142900A1Little deteriorationGood deodorizing functionBiocidePhysical/chemical process catalystsDeodorantEngineering

An extra fine multifilament obtained in the present invention contains a deodorant functional agent having a particle diameter equal to or more than the average diameter of extra fine single yarn fibers, and the deodorant functional agent is not completely covered with polymer and is partially exposed on the surface of the multifilament, whereby a dramatically improved deodorizing function can be achieved. Accordingly, a polyester cloth made of the multifilament has a durable deodorizing function, a high strength, and an excellent texture, and thereby is useful for apparel products (such as sports wears, casual wears, and mens and womens suits), medical applications, interior applications, etc.

Owner:TEJIN FIBERS LTD

Production method of fine-denier porous POY black yarn

InactiveCN102443859AImprove spinnabilityReduced stabilitySpinnerette packsMelt spinning methodsProduction rateYarn

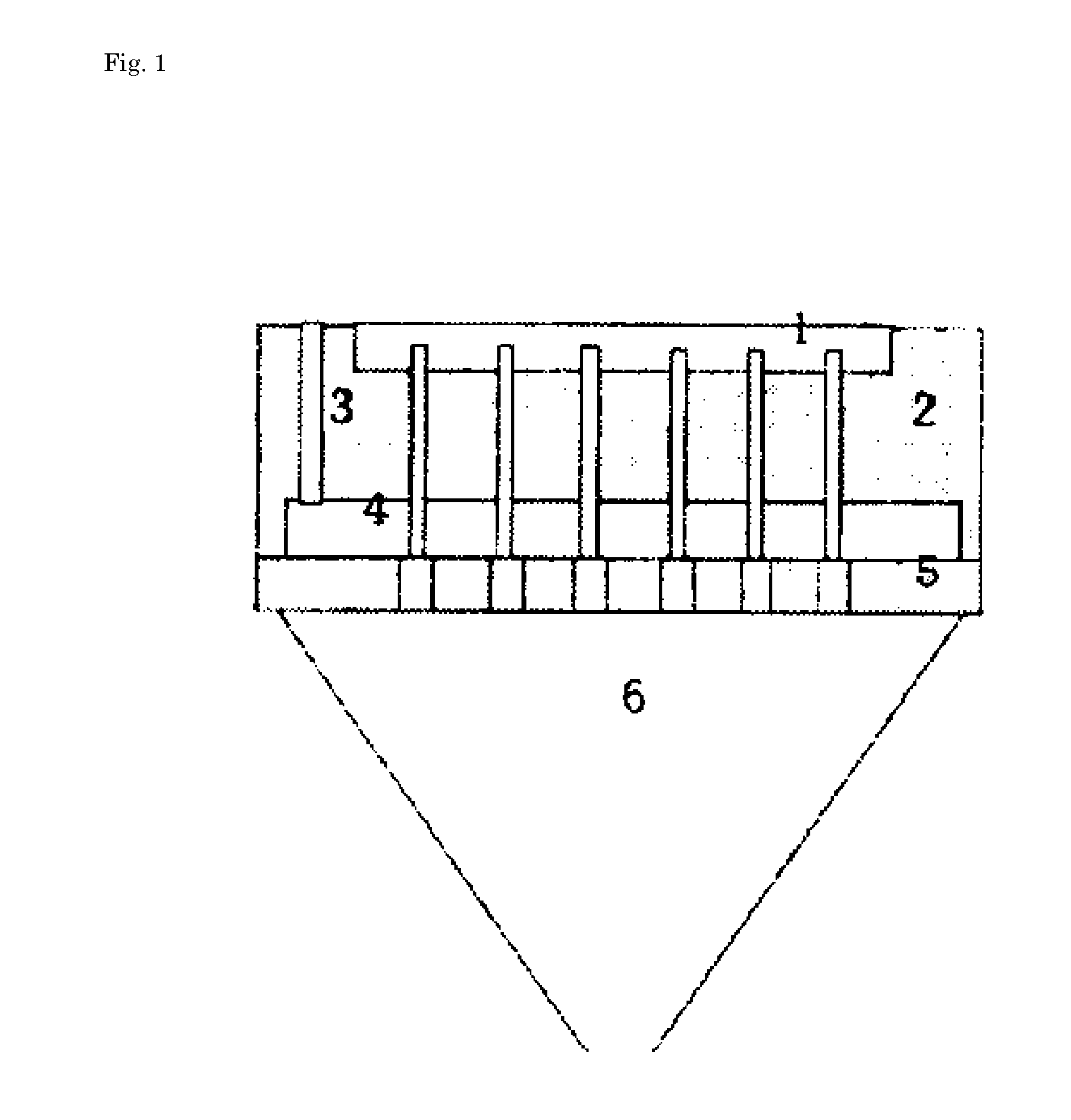

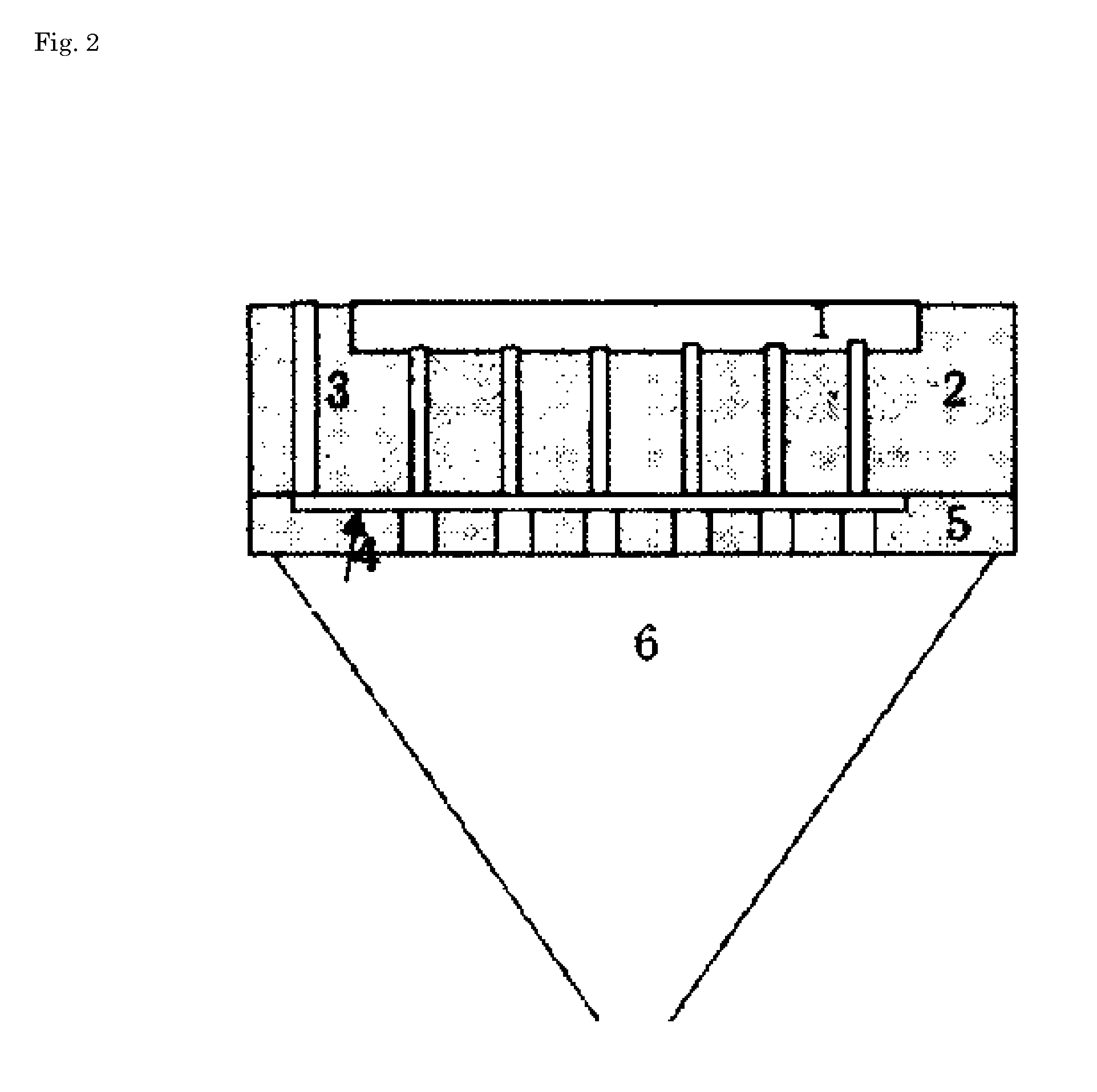

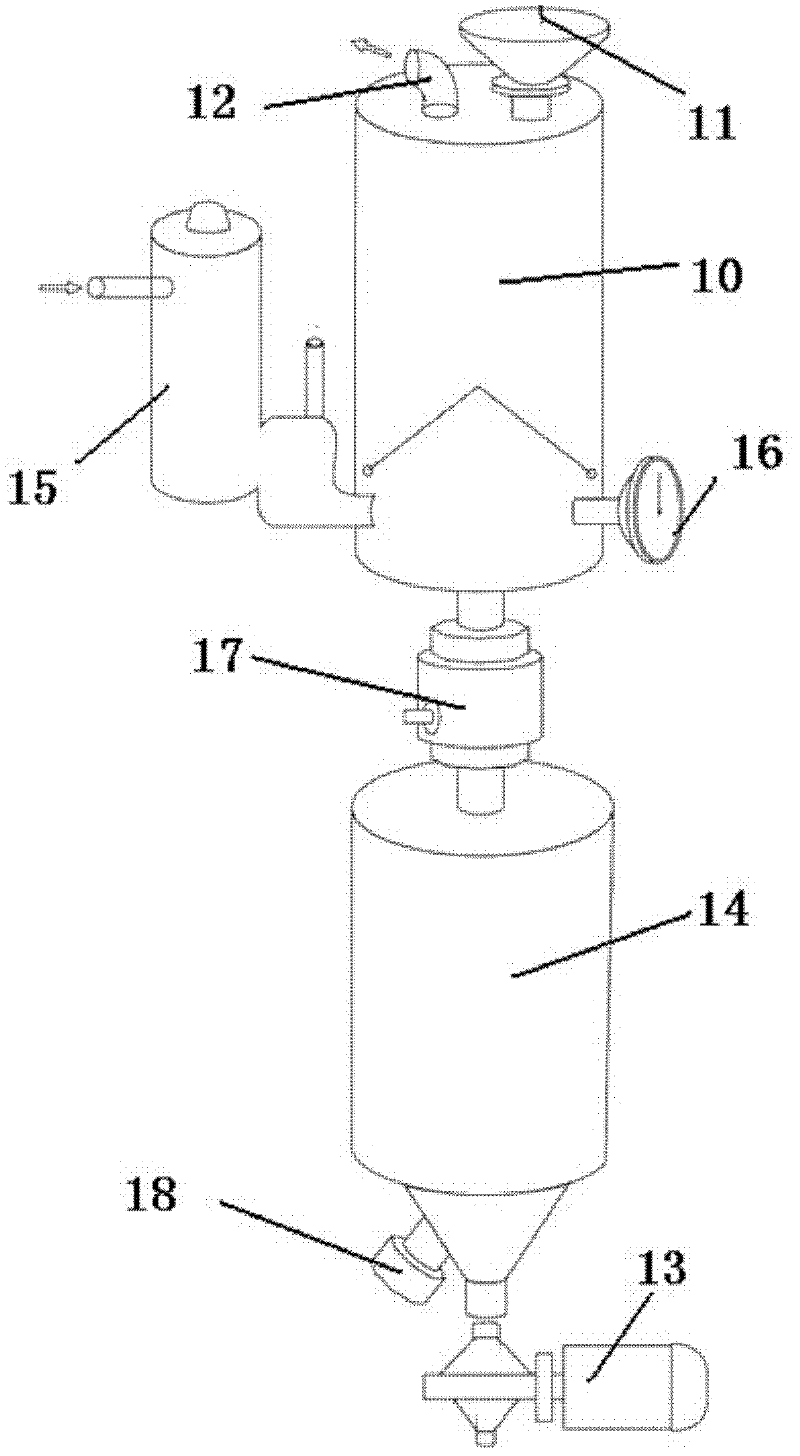

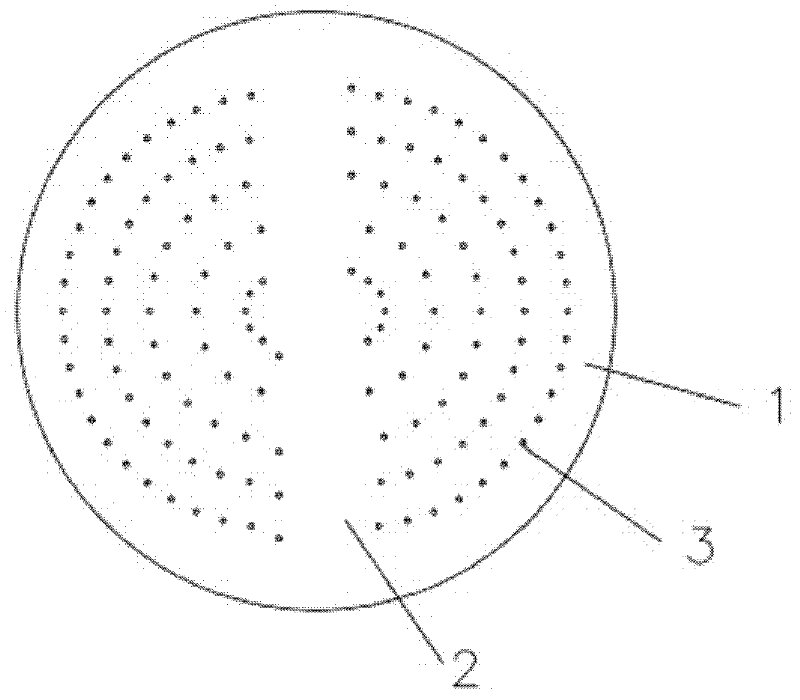

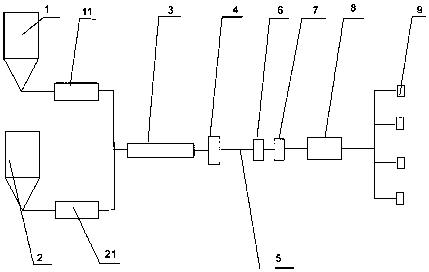

The invention discloses a production method of a fine-denier porous POY black yarn. The method comprises the following steps of: drying semi-dull slices, drying black masterbatch, adding the slices and the black masterbatch material into a screw extruder, fusing the added materials in the screw extruder, respectively processing the fused materials in a metering pump and a spinning beam, spinning on a pack, cooling the materials by lateral blowing, applying oil on strands, processing the strands in draw-off godets GR1 and GR2, winding and shaping, and inspecting products. The method is characterized in that the step of drying the black masterbatch comprises the following sub-steps of: based on a continuous drying mode, firstly, adding the black masterbatch into a crystallization and drying tank, introducing heated dry air from the lower part of the crystallization and drying tank, and blowing out the heated dry air from the top of the crystallization and drying tank so as to dry the black masterbatch, wherein the drying time is 2 hours, the dried black masterbatch falls into an intermediate material storage bin for storage under the crystallization and drying tank, and the black masterbatch is further injected by a masterbatch injector under the intermediate material storage bin. The production method of the fine-denier porous POY black yarn has high masterbatch spinnability and better cooling effect, and can improve the oil application uniformity of spinning cakes and the productivity.

Owner:桐乡市中洲化纤有限责任公司

Ceramic tile capable of releasing negative oxygen ions and preparation method thereof

The invention discloses a ceramic tile capable of releasing negative oxygen ions and a preparation method thereof. The ceramic tile is prepared from the following raw materials in parts by weight: 38-56 parts of river sand, 22-34 parts of fluorite, 18-26 parts of volcanic, 10-20 parts of dolomite, 24-36 parts of modified clay, 15-25 parts of magnesite ore, 12-18 parts of tourmaline, 10-15 parts of hexacyclic stone, 8-14 parts of medical stone, 5-10 parts of stove ash residue, 6-12 parts of talcum powder, 4-8 parts of shell powder, 3-6 parts of barium carbonate and 2-4 parts of zinc oxide. The tourmaline, the hexacyclic stone, the medical stone and the like are added into the ceramic tile, so that the ceramic tile can release negative oxygen ions beneficial to human health for a long time, can obviously enhance blood circulation, promote metabolism, improve immunity and soothe mind and body, has an effect of bacteriostat and sterilization and has an obvious deodorization function, the indoor air can be purified, and the indoor air quality is improved.

Owner:安徽省亚欧陶瓷有限责任公司

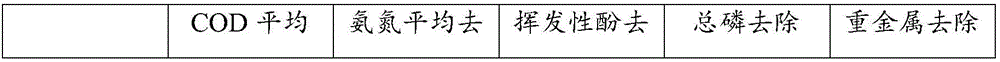

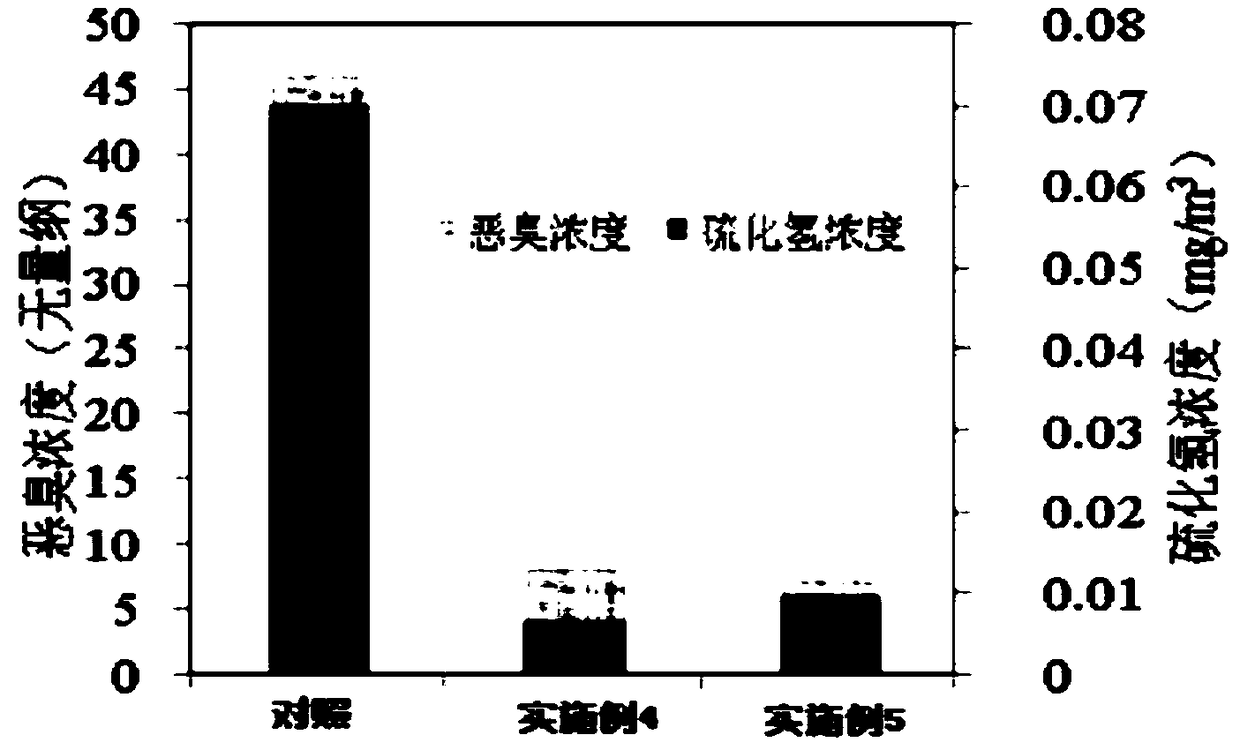

Compound bactericide for treating sewage and sewage treatment method thereof

ActiveCN106701633AGood removal effectFunction increaseFungiBacteriaOperabilityBULK ACTIVE INGREDIENT

The invention discloses compound bactericide for treating sewage and a sewage treatment method thereof, and belongs to the technical field of sewage treatment. The compound bactericide comprises the following active ingredients from following strains: rhodopseudomonas, anaerobic ammonium oxidation bacteria, candida utilis, thiobacillus denitrificans, white-rot fungi, lactobacillus plantarum, bifidobacterium, lactobacillus acidophilus, green nonsulfur bacteria, phosphorus-accumulating bacteria, aspergillus oryzae, nitrosomas, streptomyces, bacillus subtilis and propionibacterium acidipropionici. The invention also provides the method using the compound bactericide to treat the sewage. The compound bactericide and the sewage treatment method have the advantages that the effect of treating sewage is better, the technology is simple, the implementing is easy, the operability is strong, the pollution to environment is avoided, the industrial requirements are met, and the application prospect is better.

Owner:哈尔滨明慧生物技术开发有限公司

Far infrared bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556275AImprove antibacterial propertiesSignificant far infrared health functionArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceFar infrared

The invention discloses provides a far infrared bamboo charcoal viscose fiber and a preparation method thereof, in order to make up for the blank of the conventional far infrared bamboo charcoal viscose fiber and solve the problem of poor spinnability of the bamboo charcoal viscose fiber. The far infrared bamboo charcoal viscose fiber is characterized in that the fiber comprises 1-10 percent by weight of far infrared ceramic powder and 0.1-10 percent by weight of bamboo charcoal, wherein the far infrared emissivity is greater than 80 percent, the ammonia absorption rate is greater than or equal to 50 percent, the permeability is greater than or equal to 500 mm / s, and the color fastness to washing is class 4-5. The far infrared bamboo charcoal viscose fiber has a heat insulation effect; the radiated far infrared also has the health-care functions of activating cell tissues and promoting the blood circulation.

Owner:YIBIN HIEST FIBER +1

Composite photocatalitic germicide

A composite photolytic antibacterial agent for antibacterial polymer, fiber and fabrics contains proportionally the nanoparticles of TiO2, SiO2 and Ag. It features that the TiO2 and Ag nanoparticles are wrapped by SiO2 nanoparticles to form a special porous layer.

Owner:SHANGHAI JIAO TONG UNIV

Disposable sanitary product

InactiveCN102068715AInhibit the growth of bacteriaProtect the skinAbsorbent padsBandagesPerspirationNano zinc oxide

The invention relates to a disposable sanitary product with functions of resisting bacteria, removing peculiar smell and adjusting temperature. The surface layer of the sanitary product is made from phase change temperature adjusting fibers, moisture absorption and perspiration polyester fibers, composite fibers and bamboo fibers serving as raw materials. Because the surface layer of the sanitaryproduct contains the phase change temperature adjusting fibers and the moisture absorption and perspiration polyester fibers, sultry feeling is not produced in hot summer; meanwhile, because the moisture absorption and perspiration polyester fibers contain nano active carbon and the active carbon has good adsorption performance, the knitting wool has good peculiar smell removing function; the parallel composite fibers contain nano silver oxide granules and nano zinc oxide granules which have good antimicrobial and bacteriostatic performance, the knitting wool has good antimicrobial function so as to assist preventing the skin from being invaded by the bacteria, inhibit the propagation of the bacteria and achieve the antimicrobial and bacteriostatic effect and the skin protecting effect; and meanwhile, the bamboo fibers have antimicrobial and bacteriostatic characteristics.

Owner:亓传军

Method for preparing luffa deodorant and antibacterial insole

The invention provides a method for preparing a luffa deodorant and antibacterial insole, and belongs to the field of the application of health-care shoe materials for improving the microclimate of shoe cavities. The method comprises the following steps of: bleaching and softening luffa, and immersing the cleaned luffa into a matching liquid of H2O2, Na2SiO3 and MgSO3 and decolorizing and softening; cleaning, soaking in ethylene diamine tetraacetic acid (EDTA) for a moment so as to avoid yellowing, alkalifying, and soaking in a certain amount of a solution of sodium hydroxide\ethanol to perform delignification and increase the porosity of the surface of fiber; performing intermittent microwave radiation to deepen the treatment degree and strengthen the absorption performance of the luffa so as to ensure that the luffa has a good deodorization function, and adding a prepared antibacterial agent and finishing so as to ensure that the luffa which has a certain antibacterial function has a stronger antibacterial property; and finally, pressing the luffa into sheets, and compounding the transverse and longitudinal sheets according to the trend of the fiber to obtain the luffa deodorant and antibacterial insole.

Owner:SHAANXI UNIV OF SCI & TECH

Extinction bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556261ASignificant shielding rateGood deodorizing functionArtificial filaments from viscoseWet spinning methodsChemistryComposite material

The invention provides an extinction bamboo charcoal viscose fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The extinction bamboo charcoal viscose fiber is characterized by comprising the components by weight percent: 0.01-10 percent of titanium dioxide and 0.1-10 percent of bamboo charcoal, wherein the ammonia absorption rate is more than or equal to 50 percent, the air permeability is more than or equal to 500mm / s, and the color fastness to washing is of 4-5 level. The extinction bamboo charcoal viscose fiber disclosed by the invention is a novel product, has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and moisture absorption, has soft handfeel and has an extinction function.

Owner:YIBIN HIEST FIBER +1

Preparation method of high-emissivity far-infrared antimicrobial purple clay ceramsite

ActiveCN103880398APromote and improve blood circulationImprove sleep qualityClaywaresAntimicrobialBlood circulation

A preparation method of a high-emissivity far-infrared antimicrobial purple clay ceramsite mainly solves a problem that the number of present purple clay function products is small. The method comprises the processes of burdening, grinding, granulating, coloring, drying and sintering, and concretely comprises the following steps: preparing two different slurries comprising a slurry A and a slurry B according to formulas respectively, uniformly coating round purple clay granule bodies prepared by using the slurry A with the slurry B, drying, sintering, and drying the granules; and sintering the dried granules in a rapid-heating electric resistance furnace at 900-1000DEG C, and carrying out heat insulation for 30min to prepare the purple clay ceramsite. The far-infrared emission function of purple clay is utilized, proper amounts of Chinese medical stone and an antiseptic are added, so a health pillow using the prepared purple clay ceramsite has the efficacies of blood circulation promotion and improvement, sleep quality improvement, metabolism enhancement, body metabolism adjustment, immunity and antibiosis. The outer surfaces of the round purple clay bodies are coated with a slurry containing the antiseptic through a coating process, so the effect of the antiseptic is performed, and the consumption is saved, thereby the cost is reduced.

Owner:LIAONING SILICATE RES INST

Bamboo charcoal viscose fiber rich in nano-copper and preparation method of bamboo charcoal viscose fiber

ActiveCN103556272AImprove breathabilityHigh strengthArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceSpinning

The invention provides a bamboo charcoal viscose fiber rich in nano-copper and a preparation method of the bamboo charcoal viscose fiber in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The bamboo charcoal viscose fiber rich in nano-copper is characterized by being prepared by mixing a nano-copper bamboo charcoal solution with viscose throug injection before spinning, and carrying out wet spinning and post-treatment; the nano-copper bamboo charcoal solution is formed by mixing masterbatches containing the nano-copper and a bamboo charcoal solution. The fiber comprises the components by weight percent: 0.01-5 percent of nano-copper and 0.1-10 percent of bamboo charcoal; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The bamboo charcoal viscose fiber rich in the nano-copper has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the antibacterial effect of the bamboo charcoal viscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

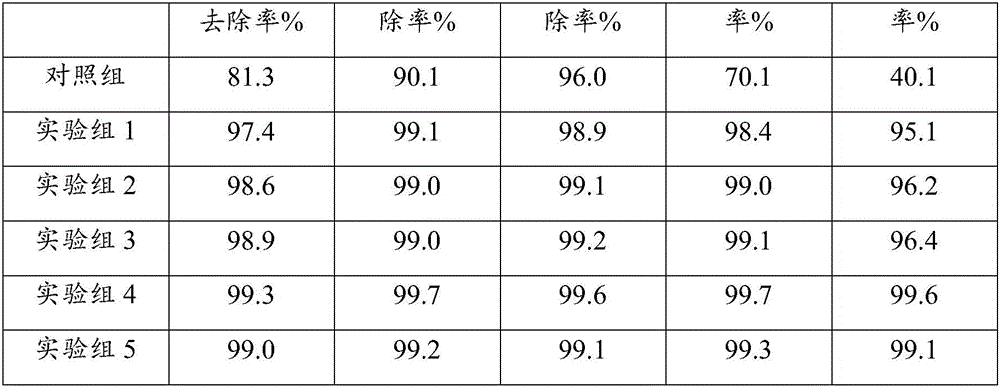

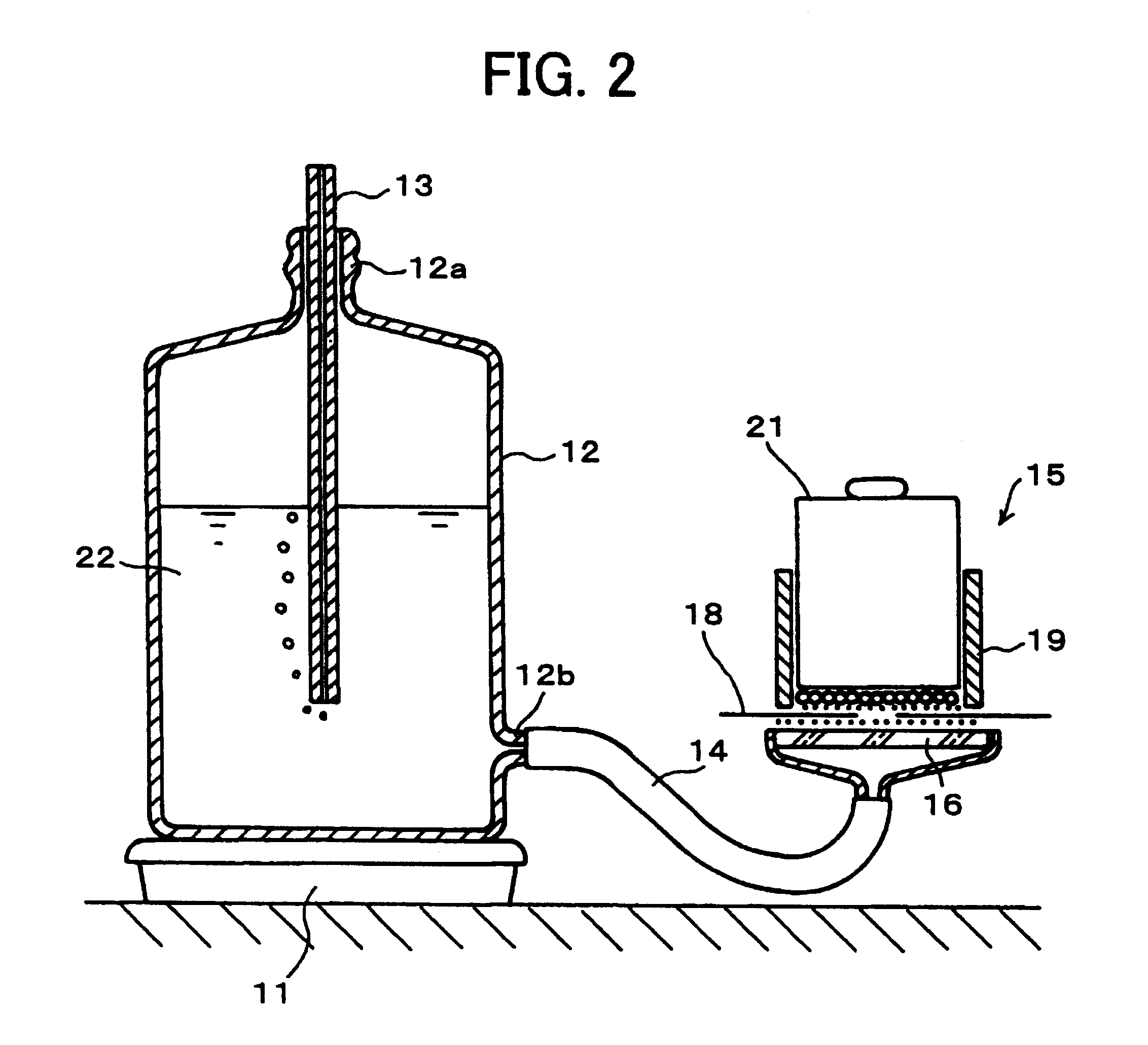

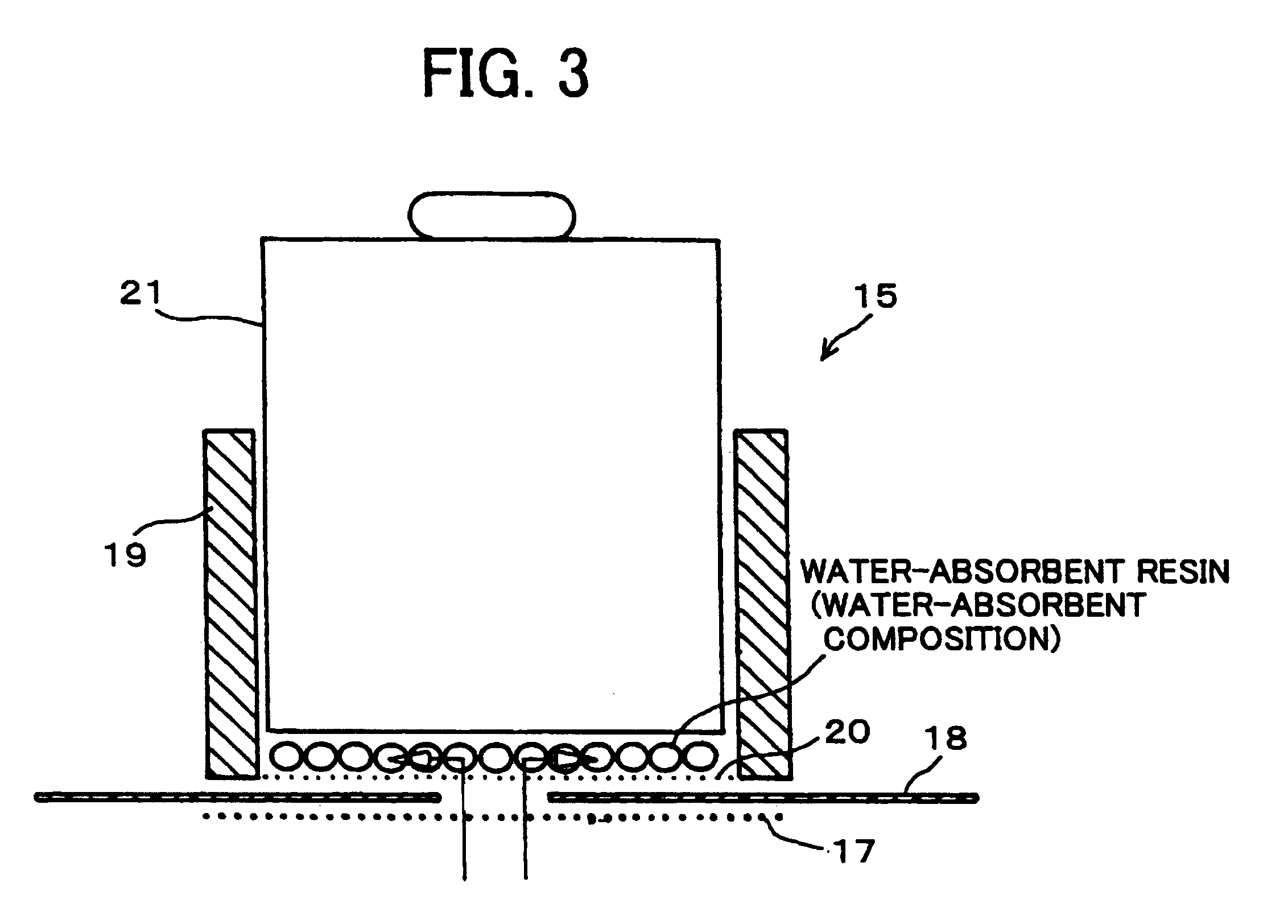

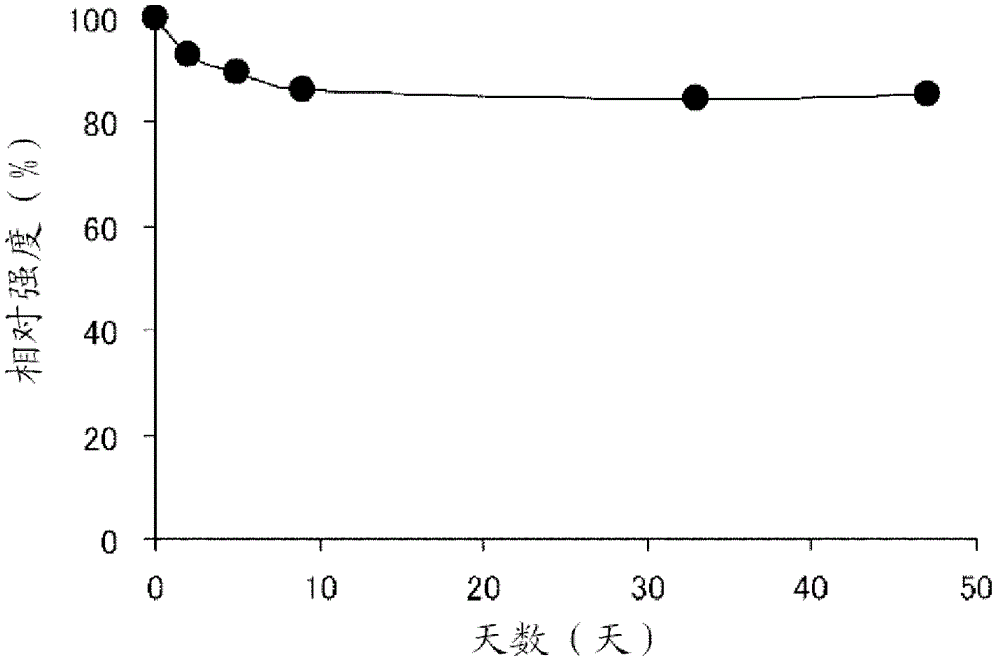

Water-absorbent composition, process for production thereof, absorbent and absorbing product

InactiveUS7825169B2Excellent characteristicsImprove deodorizing performanceGaseous substancesDeodrantsDeodorantChemistry

A water-absorbent composition includes: a specific plant extract; a water-absorbent resin whose surface portion and / or periphery thereof is treated; and / or a water-absorbent resin having a specific property. Specifically, it is preferable to use a water-absorbent resin having three characteristics: (1) a specific neutralization rate, (2) a specific particle diameter, and (3) a specific plant extract. The water-absorbent composition has a superior deodorant performance and an absorbent characteristic when the water-absorbent composition is used (provided) in an absorbing product such as a paper diaper, thereby providing a superior deodorant performance and a superior absorbent characteristic to the foregoing absorbing product.

Owner:NIPPON SHOKUBAI CO LTD

Anti-ultraviolet bamboo charcoalviscose fiber and preparation method thereof

ActiveCN103556252AGood antibacterial effectGood deodorizing functionArtificial thread manufacturing machinesArtificial filaments from viscoseBamboo charcoalViscose fiber

The invention provides an anti-ultraviolet bamboo charcoalviscose fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoalviscose fiber is poor in spinning property. The anti-ultraviolet bamboo charcoalviscose fiber is characterized by being obtained by mixing an anti-ultraviolet bamboo charcoal solution with mucilage glue through spinning before injection, and carrying out wet spinning and post-treatment, wherein the anti-ultraviolet bamboo charcoal solution is formed by mixing an anti-ultraviolet masterbatches and a bamboo charcoal solution; the anti-ultraviolet masterbatches contain an anti-ultraviolet agent. The fiber comprises the components by weight percent: 0.01-10 percent of the anti-ultraviolet agents and 0.1-10 percent of bamboo charcoal; the ultraviolet shielding rate is more than or equal to 95 percent, the ammonia absorption rate is more than or equal to 50 percent, and the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The anti-ultraviolet bamboo charcoalviscose fiber has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the anti-ultraviolet effect of the anti-ultraviolet bamboo charcoalviscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

Natural fibers containing titanium oxide and process for producing the same

InactiveUS6265064B1Improve photocatalytic performanceGood deodorizing functionSynthetic resin layered productsVacuum evaporation coatingMetallurgyNatural fiber

Owner:KYORASHA +1

Iodine- and amylase-containing fibers, process for production thereof, and use thereof

ActiveCN102803588AGood sterilization functionGood deodorizing functionCosmetic preparationsBiocideAmylaseIodine

The inventioni relates to a process for producing amylase-containing rayon fibers, which comprises a step of mixing an aqueous alkaline solution of an amylose with viscose to prepare a mixed solution, and a step of spinning the mixed solution to produce amylase-containing rayon fibers, and a step of bringing the amylase-containing rayon fibers into contact with iodine or a polyiodide ion to allow iodine or the polyiodide ion to be included in the amylase in the amylase-containing rayon fibers, wherein the amylose is an enzymatically synthesized amylase having a weight average molecular weight of 3x104 to 2x105 inclusive. Also disclosed is a method for collecting iodine from branckish water with high efficiency utilizing the amylase-containing rayon fibers.

Owner:EZAKI GLICO CO LTD +1

Fully-degradable environment-friendly paper diaper

InactiveCN103976824AHas antibacterial and deodorant functionStrong liquid absorptionAbsorbent padsBandagesPolyethylene terephthalateAdhesive

The invention discloses a fully-degradable environment-friendly paper diaper, which comprises a bottom film and an absorption body positioned at the middle position of the bottom film, wherein the absorption body is bonded with the bottom film by adopting a structural adhesive; the absorption body comprises a large cotton core, a small cotton core and a non-woven fabric which are bonded in sequence by using the structural adhesive; the large cotton core is formed by mixing crude dissolved pulp and a high-polymer water absorbent; the small cotton core is formed by mixing crude dissolved pulp and an acid high-polymer water absorbent; the bottom film is a blended film of PBAT (Poly Butylene Terephthalate) and PLA (Poly Lactic Acid). By adopting the fully-degradable environment-friendly paper diaper, various environmental pollution problems are solved, and the treatment cost is reduced greatly; moreover, with the superior anti-bacterial and deodorization functions, the type of disposable article becomes more popular, and the health of users is protected.

Owner:SUNKISS HEALTHCARE ZHEJIANG

Aromatic bamboo charcoal fiber and production process thereof

ActiveCN103541035AGood deodorizing functionGood air permeabilityArtificial filaments from viscoseWet spinning methodsAnti bacterialBamboo charcoal

The invention aims at meeting market customer demands of a product, solving the problem of poor spinnability of bamboo charcoal viscose fiber and providing aromatic bamboo charcoal fiber and a production process thereof. The aromatic bamboo charcoal fiber is characterized in that the fiber contains 0.01-10% by weight of aromatic fragrance and 0.1-10% of bamboo charcoal, the ammonia absorption rate is not less than 50%, the air permeability is not less than 500mm / s, and the color fastness to washing is level 4-5. The aromatic bamboo charcoal fiber provided by the invention has not only anti-bacterial, anti-ultraviolet and deodorizing functions, but also good air permeability and absorption, and can effectively and continuously emit aroma and realize the effects of relieving stress and refreshing people.

Owner:YIBIN HIEST FIBER +1

Antibacterial bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556278AImprove breathabilityImprove antibacterial propertiesArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceAnti bacterial

The invention provides an antibacterial bamboo charcoal viscose fiber and a preparation method thereof, which meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The antibacterial bamboo charcoal viscose fiber is characterized by being obtained by mixing an antibacterial bamboo charcoal solution with viscose through injection before spinning, and carrying out wet spinning and post-treatment, wherein the antibacterial bamboo charcoal solution is formed by mixing an antibacterial solution and a bamboo charcoal solution. The fiber comprises the components by weight percent: 0.01-10 percent of an antibacterial agent and 0.1-10 percent of bamboo charcoal; the bacteriostasis rate is more than or equal to 90 percent; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The antibacterial bamboo charcoal viscose fiber has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the antibacterial effect of the antibacterial bamboo charcoal viscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

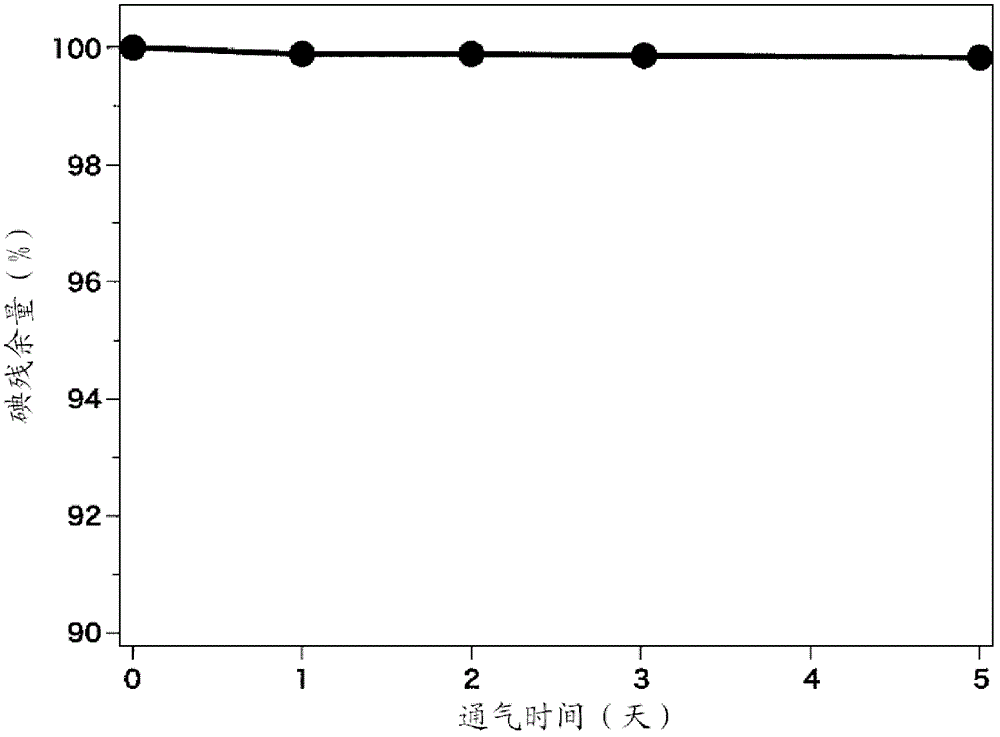

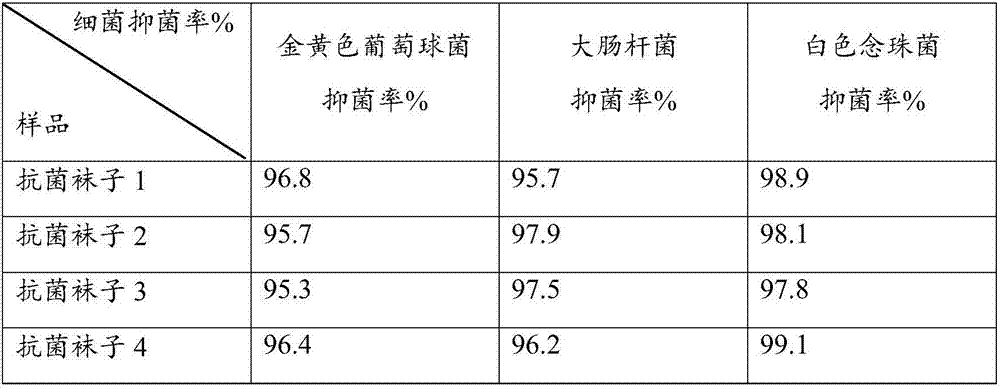

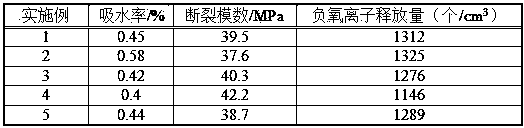

Antimicrobial milled finishing agent, preparation method and uses thereof

The invention relates to an antibiotic fulling finishing agent, a preparation method and application thereof, comprising the components of: organic-inorganic complex antibiotic finishing agents, a surfactant and distilled water based on the weight percent of 30%-50%:25%-30%:the balance: the preparation method comprises the step of: stirring the organic-inorganic complex antibiotic finishing agents, the surfactant and the distilled water for 15-20min at room temperature to be mixed uniformly for formulating the antibiotic fulling finishing agent; the method is applied to fiber products. The fiber product subjected to the treatment of the finishing agent is less in fuds and plumped in hand felling; the invention is excellently bacteriostatic against staphylococcus aureus, colon bacillus and candida albicans, prominent in deodorization function, simple in the preparation method and suitable for industrial production.

Owner:DONGHUA UNIV +1

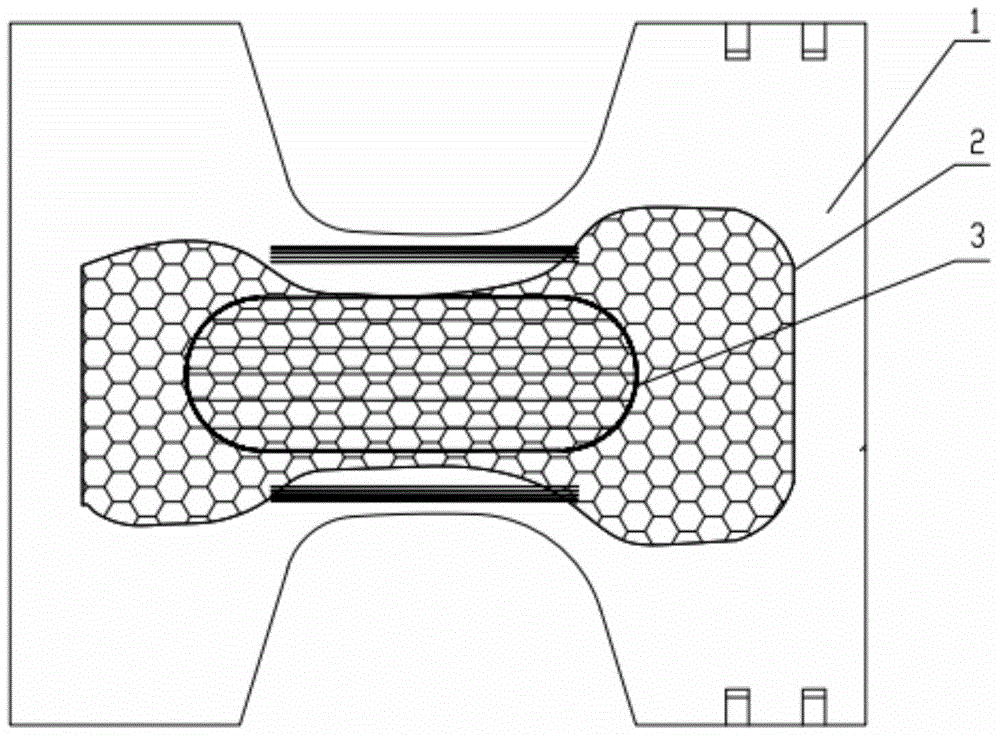

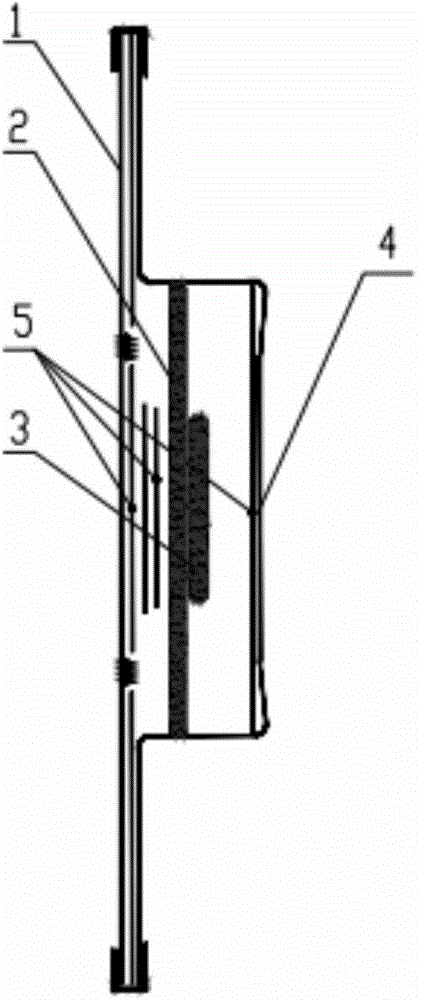

Antibacterial sock

InactiveCN107019248AAchieve fixationImprove wear resistanceBiochemical fibre treatmentHandkerchiefsYarnFiber

The invention relates to an antibacterial sock and a preparation method thereof. The antibacterial sock comprises an antibacterial master batch and fibers, wherein the antibacterial master batch is composed of diatomite and nano-silver according to a mass ratio of 9:1 to 19:1. The antibacterial sock is prepared by the following steps: attaching silver ions to diatomite so as to prepare the antibacterial master batch; blending the antibacterial master batch and the fibers so as to obtain fiber yarns; spooling, warping and weaving the fiber yarns, forming a grey fabric, and performing after-treatment, so as to obtain the antibacterial sock. The process is simple, reliable and convenient to implement. The prepared antibacterial sock is wear-resistant, breathable and excellent in health effect, has antibacterial and deodorant effects and further has excellent antibacterial effectiveness and a long-term effect.

Owner:晋大纳米科技(厦门)有限公司

Deodorizing insole and making method thereof

ActiveCN102771952AFunction increaseGrowth inhibitionLamination ancillary operationsInsolesFiberPolyester

The invention relates to a deodorizing insole and a making method thereof, belonging to the technical field of shoe linings and preparation of the shoe linings. The deodorizing insole comprises an upper layer, a core layer and a lower layer, wherein the core layer is woven by using mat grass and bonded with the lower layer, and a traditional Chinese medicine layer is arranged between the upper layer and the core layer. The making method comprises the following steps of: making the core layer, connecting and fixing each layer, dewatering and compressing, and finally cutting edges. The mat grass is creatively used as the core layer to replace the previous black-heart cotton or chemical pads in the making method. The mat grass can absorb a great amount of sweat and decompose the sweat so that the functions of the insole for curing and protecting feet are improved. Due to the addition of the traditional Chinese medicine layer, the insole has the effects of absorbing the sweat, decomposing the sweat and inhibiting bacterium growth and has the function of obvious deodorization. Besides, the upper layer is made of cotton cloth, the lower layer is made of polyester fiber, and biodegradable materials are adopted in each link of the product so that the deodorizing insole is a leading environment-friendly product in the current international insole industry and has a favorable market prospect.

Owner:苍南县龙港神箭日用品厂

Metal electric heating tube

InactiveCN101500349AGood deodorizing effectGood deodorizing functionHeating element shapesEmulsion paintsFresh airWorking environment

The invention provides an electrical metal heating tube for removing odor, which comprises a metal heating tube body, wherein the periphery surface of the metal heating tube body is provided with a deodorization coating. As the periphery surface of the metal heating tube body is provided with the deodorization coating which has excellent deodorization effect, the electrical metal heating tube which adopts the structure leads the deodorization function of the heating tubes to be more excellent, thus leading the odor of the metal heating tube self to be removed, being capable of purifying air in the heating environment, achieving fresh air in the working environment and preventing the inconvenience caused by long-term using.

Owner:ZHENJIANG TIANXIN ELECTRICAL APPLIANCE

Prechlorination synergist for source water

InactiveCN1594125AReduce deliveryReduce outputWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationAluminium chlorideWater source

The invention relates to a prechlorination synergist for source water whose components include potassium permanganate 60-75 wt%, aluminium sulphate 3-5 wt%, aluminium chloride 4-6 wt%, ferric chloride 4-6 wt%, ferrum sulphate 3-6 wt%, ferrous sulphate 4-6 wt%, manganese sulphate 6-9 wt%, organic macromolecular flocculating agent 1-2 wt%, wherein anionic polyacrylamide or non-ionic polyacrylamide can be selected as the organic macromolecular flocculating agent.

Owner:TIANJIN WATERWORKS GROUP +2

Spray covering process of solid pollution sources

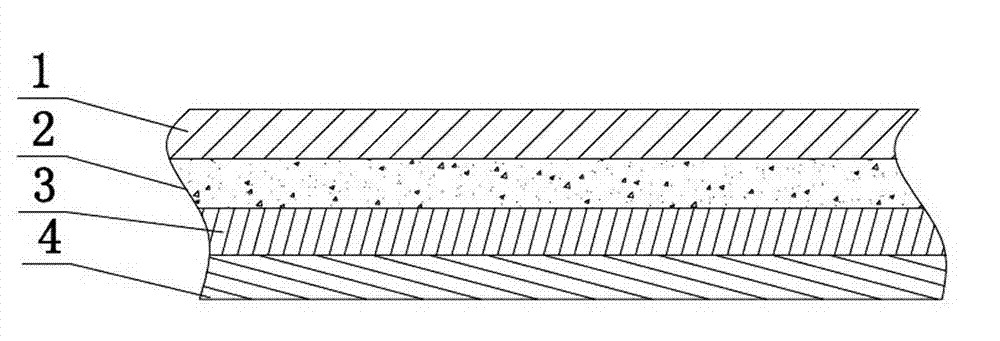

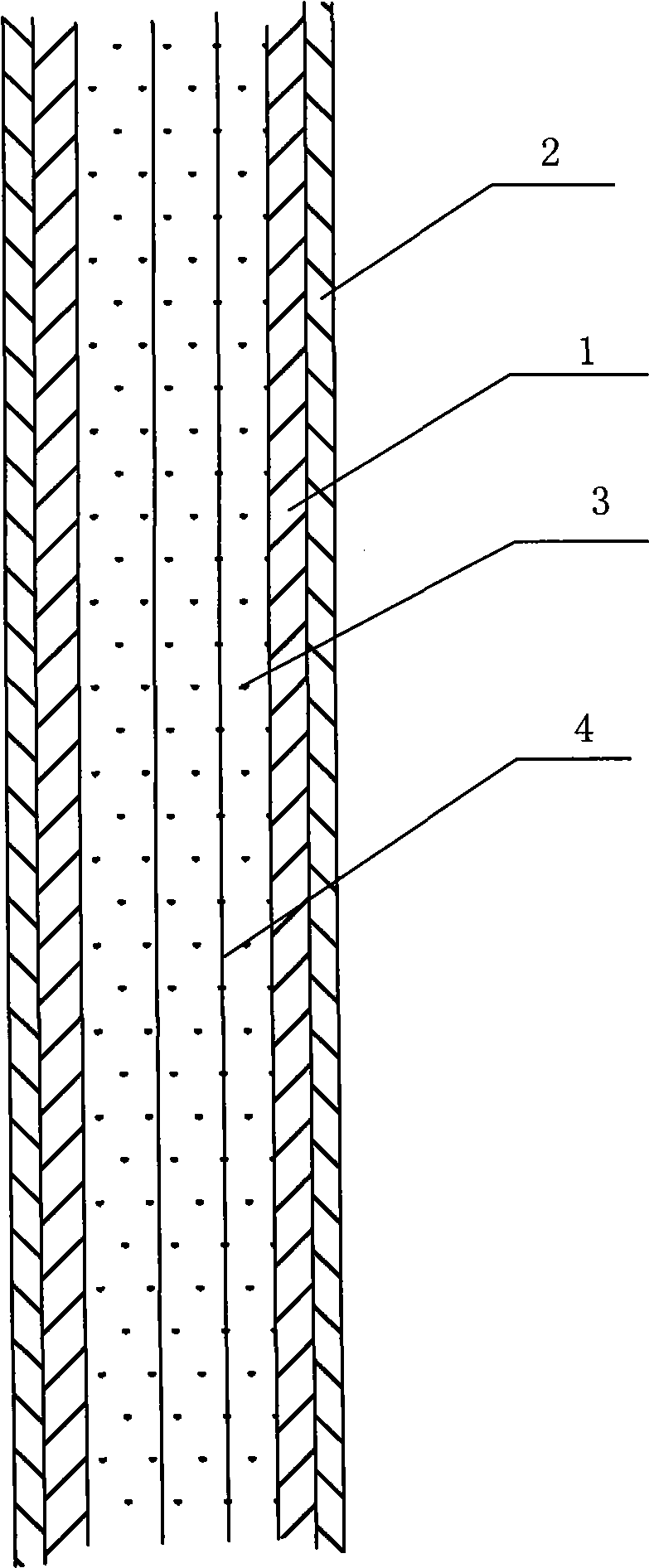

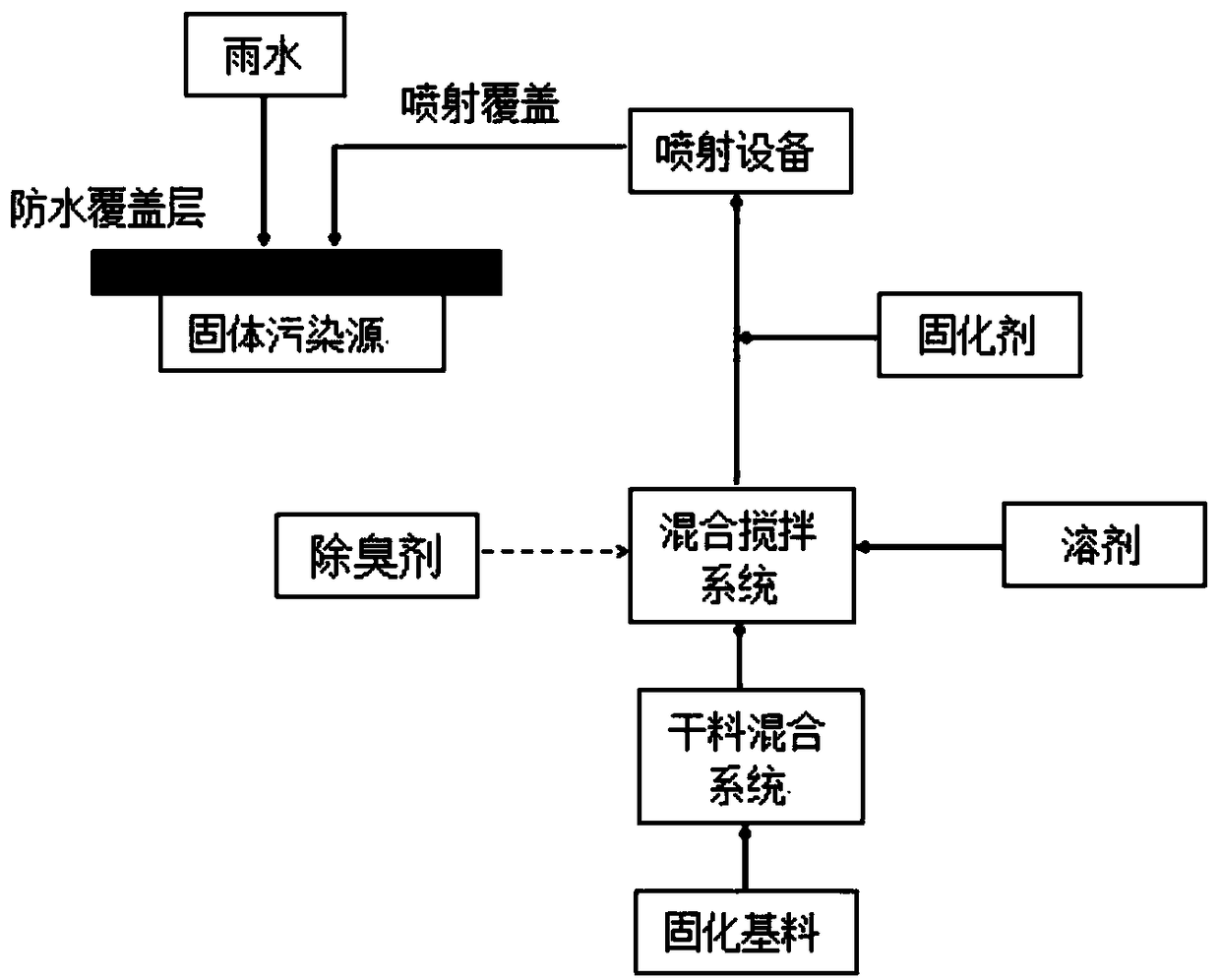

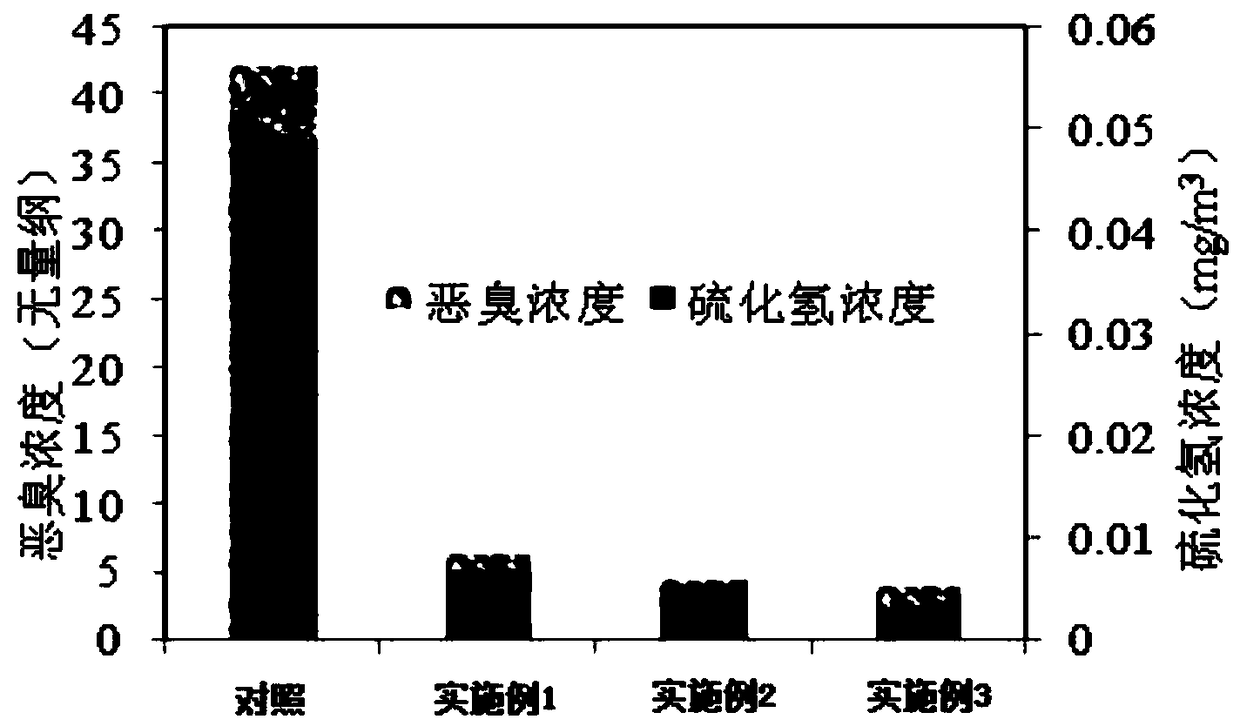

ActiveCN109332343AGood odor and deodorization functionRainproofLandfill technologiesSolid waste disposalSludgeSewage

The invention relates to a spray covering process of solid pollution sources. The solid pollution sources include refuse landfills, sludge stockpiling sites, industrial waste stacking sites, mineral tailings ponds or solid pollution sources formed by contaminated sites. The spray covering process includes the steps that a curing base material, a curing agent and a solvent are mixed to form a highviscosity paste composite material, and the surfaces of the solid pollution sources are covered by uniform spraying of spraying equipment. According to the spray covering process, diversion of rain and sewage from solid pollution source piles or sites is realized, sewage generation caused by rainwater mixing is reduced remarkably, and safety of soil and groundwater in stacking sites is ensured; meanwhile according to stink source piles, the odor isolation (deodorization) effect is good, and friendly environment is achieved; and furthermore, the functions of fire prevention, dust prevention andseepage prevention are achieved, application is wide, and practicability is high.

Owner:LIAONING HAITIANGE ENVIRONMENTAL PROTECTION TECH

Aromaticity bamboo charcoal fiber and preparation method thereof

ActiveCN103556264AImprove breathabilitySignificant shielding rateArtificial filaments from viscoseWet spinning methodsSpinningPulp and paper industry

The invention provides an aromaticity bamboo charcoal fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The aromaticity bamboo charcoal fiber is characterized in that a finished product is obtained by taking cellulose fiber pulp as a raw material, mixing an aromaticity bamboo charcoal solution and viscose through injection before spinning and performing wet spinning and post-treatment, wherein the aromaticity bamboo charcoal solution is prepared by mixing fragrant masterbatches and a bamboo charcoal solution; the fragrant masterbatches contain perfumes; the fragrant perfume content of the fiber is 0.01-10 percent; the bamboo charcoal content is 0.1-10 percent; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The aromaticity bamboo charcoal fiber disclosed by the invention has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and hygroscopicity, can effectively and continuously scatter fragrance and has the effects of relieving pressure and enabling people to be invigorating.

Owner:YIBIN HIEST FIBER +1

Functional ceramic tiles with topcoats capable of exciting release of negative oxygen ions and preparation method for functional ceramic tiles

The invention provides functional ceramic tiles with topcoats capable of exciting release of negative oxygen ions. The functional ceramic tiles comprise ceramic tile main bodies and the topcoats whichare located on surfaces of the ceramic tile main bodies and can excite release of the negative oxygen ions, wherein the topcoats capable of exciting the release of the negative oxygen ions are mainlyprepared from the following raw materials in parts by weight: 10-30 parts of potassium feldspar, 3-13 parts of wollastonite, 6-20 parts of borax, 5-18 parts of boronaluminum, 8-25 parts of tourmaline, 3-8 parts of rare-earth oxide powder, 2-10 parts of bentonite, 2-8 parts of zeolite, 8 or less parts of nano titanium dioxide, 6 or less parts of sodium tripolyphosphate and 6 or less parts of anhydrous sodium metasilicate. The invention further provides a preparation method for the functional ceramic tiles. The functional ceramic tiles can release the negative oxygen ions beneficial to human health for a long time and can be used for remarkably enhancing blood circulation, promoting metabolism and improving immunity; and meanwhile, the functional ceramic tiles further have bacteriostasis and degerming actions, have an obvious deodorizing function and can be used for purifying indoor air and improving the quality of the indoor air.

Owner:信阳市上天梯非金属矿管理区非金属矿技术开发应用研究所 +1

Anti-bacterial cool-feel yarn and fabric with the same

The invention provides anti-bacterial cool-feel yarn prepared through blowing, carding, drawing, roving and spinning of fibers. The anti-bacterial cool-feel yarn is prepared through blending of ice cool fibers, aloe fibers, cool-feel fibers and wormwood-cellulose fibers. The anti-bacterial cool-feel yarn contains, by mass, 30-60% of ice cool fibers, 20-30% of aloe fibers, 5-10% of cool-feel fibers, and 10-30% of wormwood-cellulose fibers. The anti-bacterial cool-feel yarn is made via the steps of warping, sizing, drafting and weaving. By mixing ice cool fibers, aloe fibers, cool-feel fibers and wormwood-cellulose fibers, the problem that aloe fibers are too short to be used for weaving yarn with qualified physical properties is solved, the respective advantages of ice cool fibers, aloe fibers, and wormwood-cellulose fibers are integrated and the requirements for wear characteristics of summer clothing fabric are met.

Owner:RUGAO CITY DINGYAN TEXTILE

Antistatic bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556280ASignificant far infrared health functionSignificant UV shielding rateArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceMoisture absorption

The invention provides an antistatic bamboo charcoal viscose fiber and a preparation method thereof, which fill up the blank of the conventional antistatic bamboo charcoal viscose fiber and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The antistatic bamboo charcoal viscose fiber is characterized by comprising 1-10 percent of graphite and 0.1-10 percent of bamboo charcoal, wherein the volume resistivity is lower than 1,010 ohm.cm, the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s, and the color fastness to washing is of 4-5 level. The antistatic bamboo charcoal viscose fiber disclosed by the invention has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and moisture absorption and has soft handfeel; the antistatic effect is obvious and lasting.

Owner:YIBIN HIEST FIBER +1

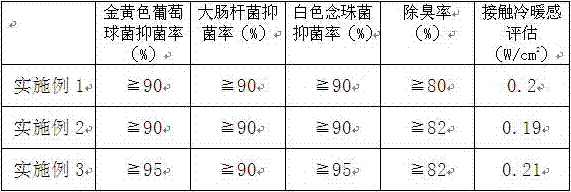

Process of making moisture-proof health wooden floor board with self-cleaning function

ActiveCN100546784CPrevent infiltrationWaterproofBelt grinding machinesWood working apparatusEpoxyLacquer

The invention discloses a method for preparing a moisture-proof self-cleaning wood floor, which includes sanding, dust removal, coating, leveling, and drying processes. Nano waterproof sealant is used for 6-side sealing and penetration, and the sealing paint is used for double-layer protection and waterproof sealing treatment; 6 primers and 3 top coats are used for painting, and the second top coat is high-efficiency negative ion powder The negative ion reaction paint layer of the mixture mixed with epoxy resin paint, the third layer of paint is the antibacterial paint surface of the mixture of TiO2 and scratch-resistant glossy UV topcoat, each paint layer passes through the roller Coating, the floor has various functions such as anti-swelling, anti-drying shrinkage, hydrophilic anti-fouling, sterilization, deodorization, air purification, negative ions, etc., which meets the needs of the modern market.

Owner:JIUSHENG WOOD

Preparation method of antibacterial polyester fiber

InactiveCN107779965AGood antibacterial functionGood deodorizing functionNew-spun product collectionSpinning head liquid feederCellulosePolyester

The invention relates to the technical field of polyester fiber preparation, in particular to a preparation method of antibacterial polyester fiber. The method specifically comprises the steps as follows: (1) preparation of antibacterial polyester melt: the antibacterial polyester melt is prepared from 70-90 parts by mass of PET polyester chips and 10-30 parts by mass of bamboo cellulose micropowder; (2) preparation of polyester fiber; (3) winding forming of polyester filament. The preparation method of the antibacterial polyester fiber comprises a simple preparation process and is convenientto operate, and the prepared polyester fiber can have excellent antibacterial, deodorization and anti-ultraviolet functions through mixing of the superfine bamboo cellulose micropowder and the polyester melt. Fabric made of the polyester fiber has good wear comfort and appearance.

Owner:新凤鸣集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com